ignition CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1953 of 2438

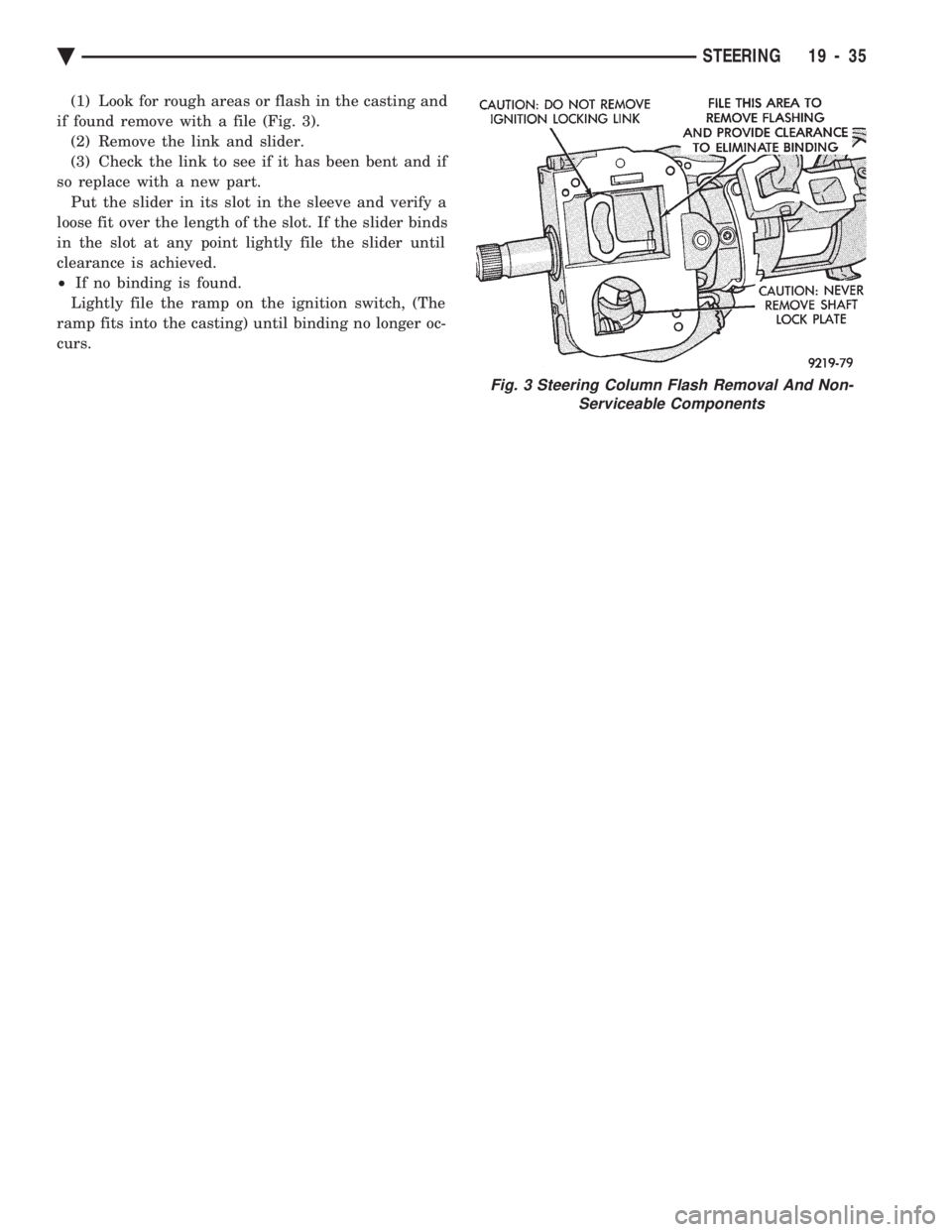

(1) Look for rough areas or flash in the casting and

if found remove with a file (Fig. 3). (2) Remove the link and slider.

(3) Check the link to see if it has been bent and if

so replace with a new part. Put the slider in its slot in the sleeve and verify a

loose fit over the length of the slot. If the slider binds

in the slot at any point lightly file the slider until

clearance is achieved.

² If no binding is found.

Lightly file the ramp on the ignition switch, (The

ramp fits into the casting) until binding no longer oc-

curs.

Fig. 3 Steering Column Flash Removal And Non- Serviceable Components

Ä STEERING 19 - 35

Page 1954 of 2438

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK INDEX

page page

General Information ....................... 36

Interlock System Adjustment ................ 37 Interlock System Operation Check

............ 36

Shifter/Ignition Interlock Cable ............... 38

GENERAL INFORMATION

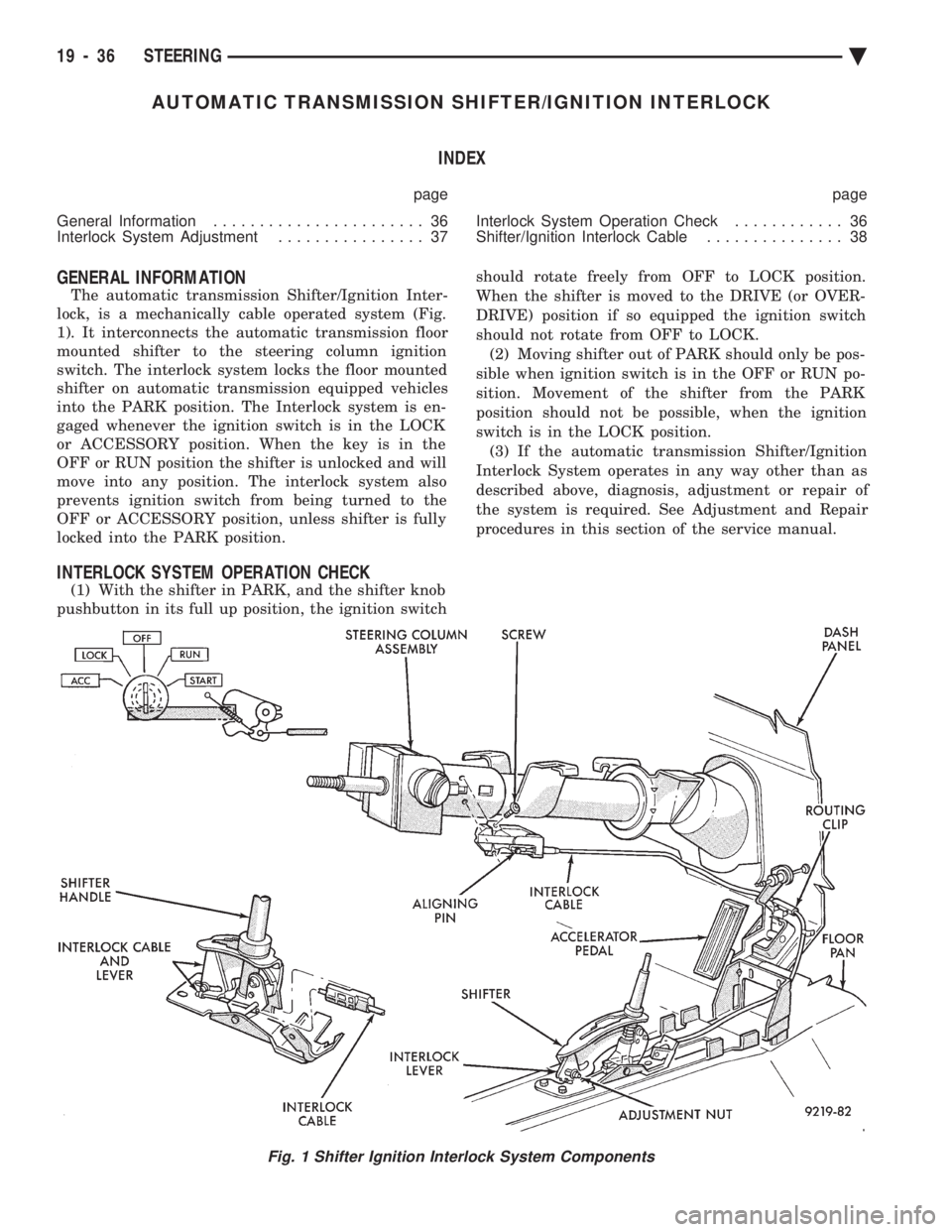

The automatic transmission Shifter/Ignition Inter-

lock, is a mechanically cable operated system (Fig.

1). It interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The interlock system locks the floor mounted

shifter on automatic transmission equipped vehicles

into the PARK position. The Interlock system is en-

gaged whenever the ignition switch is in the LOCK

or ACCESSORY position. When the key is in the

OFF or RUN position the shifter is unlocked and will

move into any position. The interlock system also

prevents ignition switch from being turned to the

OFF or ACCESSORY position, unless shifter is fully

locked into the PARK position.

INTERLOCK SYSTEM OPERATION CHECK

(1) With the shifter in PARK, and the shifter knob

pushbutton in its full up position, the ignition switch should rotate freely from OFF to LOCK position.

When the shifter is moved to the DRIVE (or OVER-

DRIVE) position if so equipped the ignition switch

should not rotate from OFF to LOCK. (2) Moving shifter out of PARK should only be pos-

sible when ignition switch is in the OFF or RUN po-

sition. Movement of the shifter from the PARK

position should not be possible, when the ignition

switch is in the LOCK position. (3) If the automatic transmission Shifter/Ignition

Interlock System operates in any way other than as

described above, diagnosis, adjustment or repair of

the system is required. See Adjustment and Repair

procedures in this section of the service manual.

Fig. 1 Shifter Ignition Interlock System Components

19 - 36 STEERING Ä

Page 1955 of 2438

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch is binding, operating effort high or

can not be turned to the LOCK position, with shifter locked

in PARK, adjustment of Interlock System may be

required. To adjust Interlock System, follow procedure

listed below. (1) Remove the shift knob to shifter retaining screw

and shift knob from shifter (Fig. 2). Leave the shifter

release button in shifter handle.

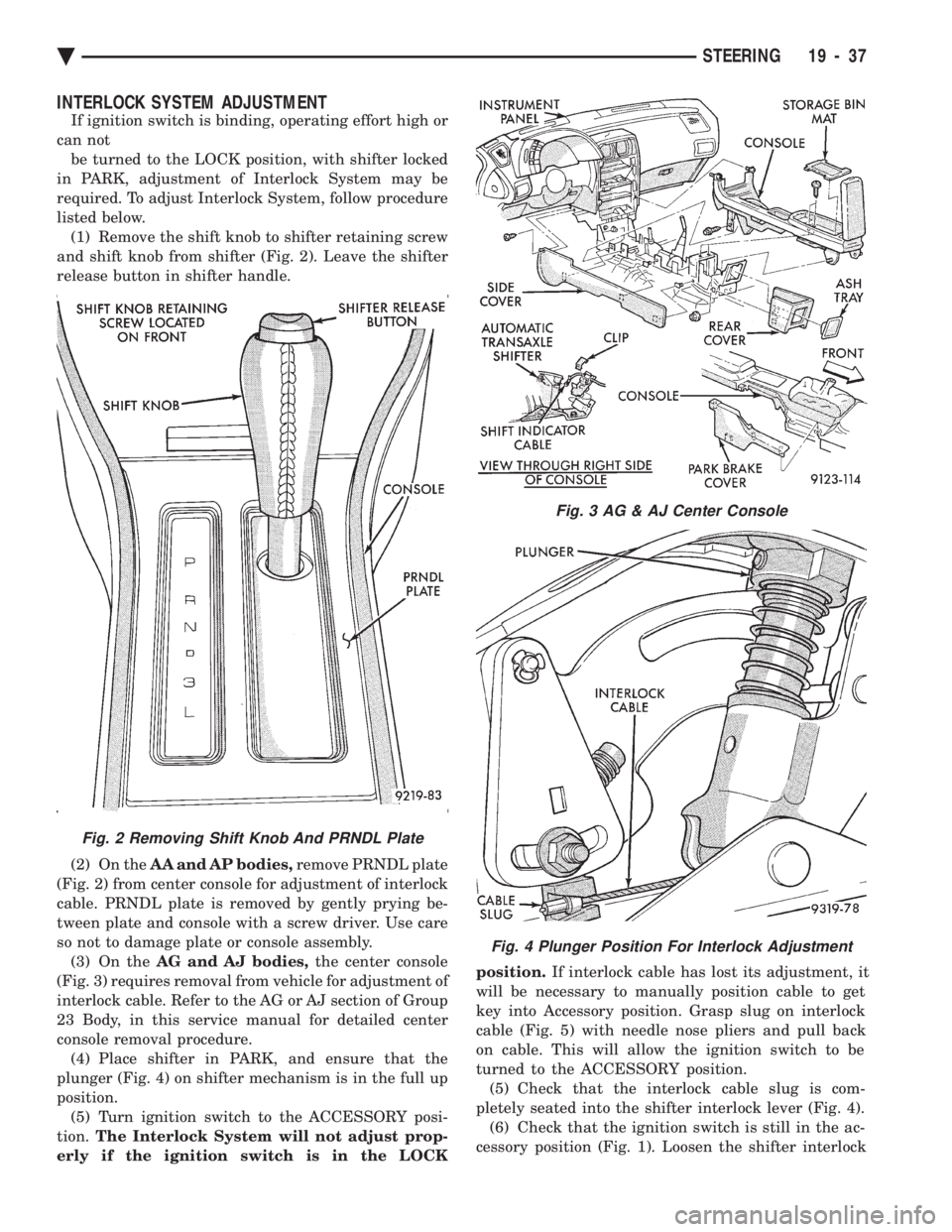

(2) On the AA and AP bodies, remove PRNDL plate

(Fig. 2) from center console for adjustment of interlock

cable. PRNDL plate is removed by gently prying be-

tween plate and console with a screw driver. Use care

so not to damage plate or console assembly. (3) On the AG and AJ bodies, the center console

(Fig. 3) requires removal from vehicle for adjustment of

interlock cable. Refer to the AG or AJ section of Group

23 Body, in this service manual for detailed center

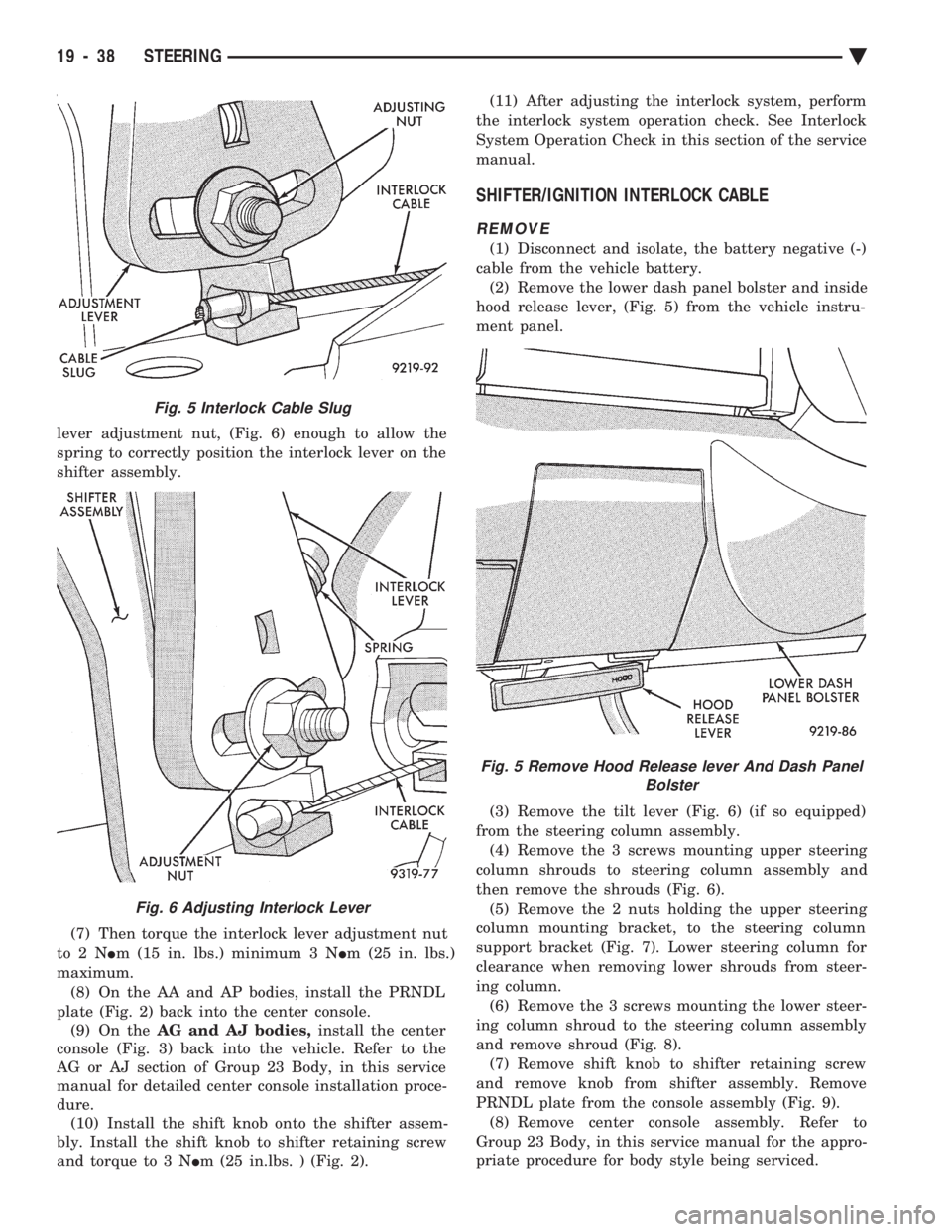

console removal procedure. (4) Place shifter in PARK, and ensure that the

plunger (Fig. 4) on shifter mechanism is in the full up

position. (5) Turn ignition switch to the ACCESSORY posi-

tion. The Interlock System will not adjust prop-

erly if the ignition switch is in the LOCK position.

If interlock cable has lost its adjustment, it

will be necessary to manually position cable to get

key into Accessory position. Grasp slug on interlock

cable (Fig. 5) with needle nose pliers and pull back

on cable. This will allow the ignition switch to be

turned to the ACCESSORY position. (5) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever (Fig. 4). (6) Check that the ignition switch is still in the ac-

cessory position (Fig. 1). Loosen the shifter interlock

Fig. 3 AG & AJ Center Console

Fig. 4 Plunger Position For Interlock Adjustment

Fig. 2 Removing Shift Knob And PRNDL Plate

Ä STEERING 19 - 37

Page 1956 of 2438

lever adjustment nut, (Fig. 6) enough to allow the

spring to correctly position the interlock lever on the

shifter assembly.

(7) Then torque the interlock lever adjustment nut

to2N Im (15 in. lbs.) minimum 3 N Im (25 in. lbs.)

maximum. (8) On the AA and AP bodies, install the PRNDL

plate (Fig. 2) back into the center console. (9) On the AG and AJ bodies, install the center

console (Fig. 3) back into the vehicle. Refer to the

AG or AJ section of Group 23 Body, in this service

manual for detailed center console installation proce-

dure. (10) Install the shift knob onto the shifter assem-

bly. Install the shift knob to shifter retaining screw

and torque to 3 N Im (25 in.lbs. ) (Fig. 2). (11) After adjusting the interlock system, perform

the interlock system operation check. See Interlock

System Operation Check in this section of the service

manual.

SHIFTER/IGNITION INTERLOCK CABLE

REMOVE

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery. (2) Remove the lower dash panel bolster and inside

hood release lever, (Fig. 5) from the vehicle instru-

ment panel.

(3) Remove the tilt lever (Fig. 6) (if so equipped)

from the steering column assembly. (4) Remove the 3 screws mounting upper steering

column shrouds to steering column assembly and

then remove the shrouds (Fig. 6). (5) Remove the 2 nuts holding the upper steering

column mounting bracket, to the steering column

support bracket (Fig. 7). Lower steering column for

clearance when removing lower shrouds from steer-

ing column. (6) Remove the 3 screws mounting the lower steer-

ing column shroud to the steering column assembly

and remove shroud (Fig. 8). (7) Remove shift knob to shifter retaining screw

and remove knob from shifter assembly. Remove

PRNDL plate from the console assembly (Fig. 9). (8) Remove center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for body style being serviced.

Fig. 5 Interlock Cable Slug

Fig. 6 Adjusting Interlock Lever

Fig. 5 Remove Hood Release lever And Dash Panel Bolster

19 - 38 STEERING Ä

Page 1958 of 2438

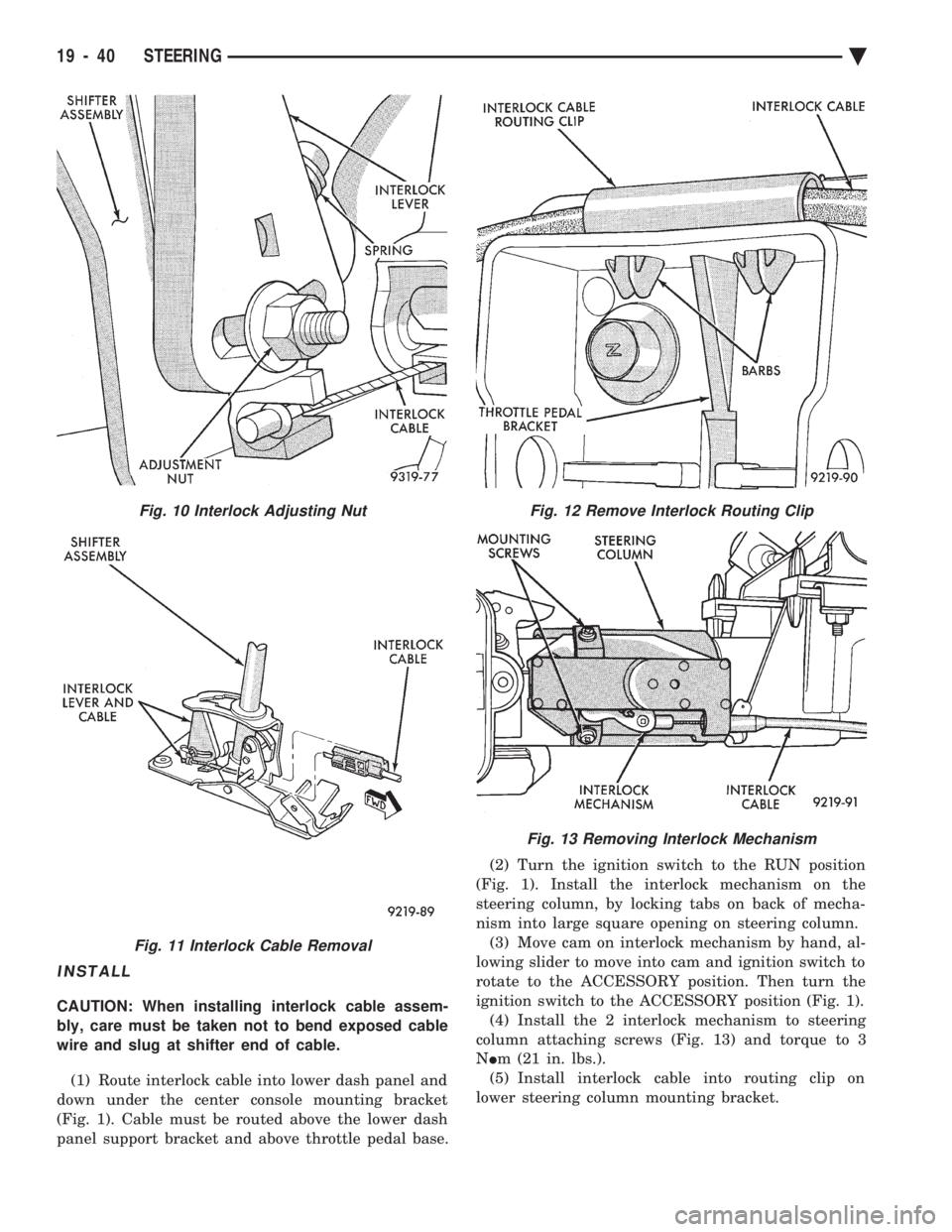

INSTALL

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.

(1) Route interlock cable into lower dash panel and

down under the center console mounting bracket

(Fig. 1). Cable must be routed above the lower dash

panel support bracket and above throttle pedal base. (2) Turn the ignition switch to the RUN position

(Fig. 1). Install the interlock mechanism on the

steering column, by locking tabs on back of mecha-

nism into large square opening on steering column. (3) Move cam on interlock mechanism by hand, al-

lowing slider to move into cam and ignition switch to

rotate to the ACCESSORY position. Then turn the

ignition switch to the ACCESSORY position (Fig. 1). (4) Install the 2 interlock mechanism to steering

column attaching screws (Fig. 13) and torque to 3

N Im (21 in. lbs.).

(5) Install interlock cable into routing clip on

lower steering column mounting bracket.

Fig. 10 Interlock Adjusting Nut

Fig. 11 Interlock Cable Removal

Fig. 12 Remove Interlock Routing Clip

Fig. 13 Removing Interlock Mechanism

19 - 40 STEERING Ä

Page 1959 of 2438

CAUTION: Interlock cable must by completely

clipped to the throttle pedal bracket with both barbs

of clip fully installed through mounting holes. This

is to prevent interference with throttle pedal.

(6) Snap the interlock cable routing clip into the 2

holes on the throttle pedal mounting bracket (Fig.

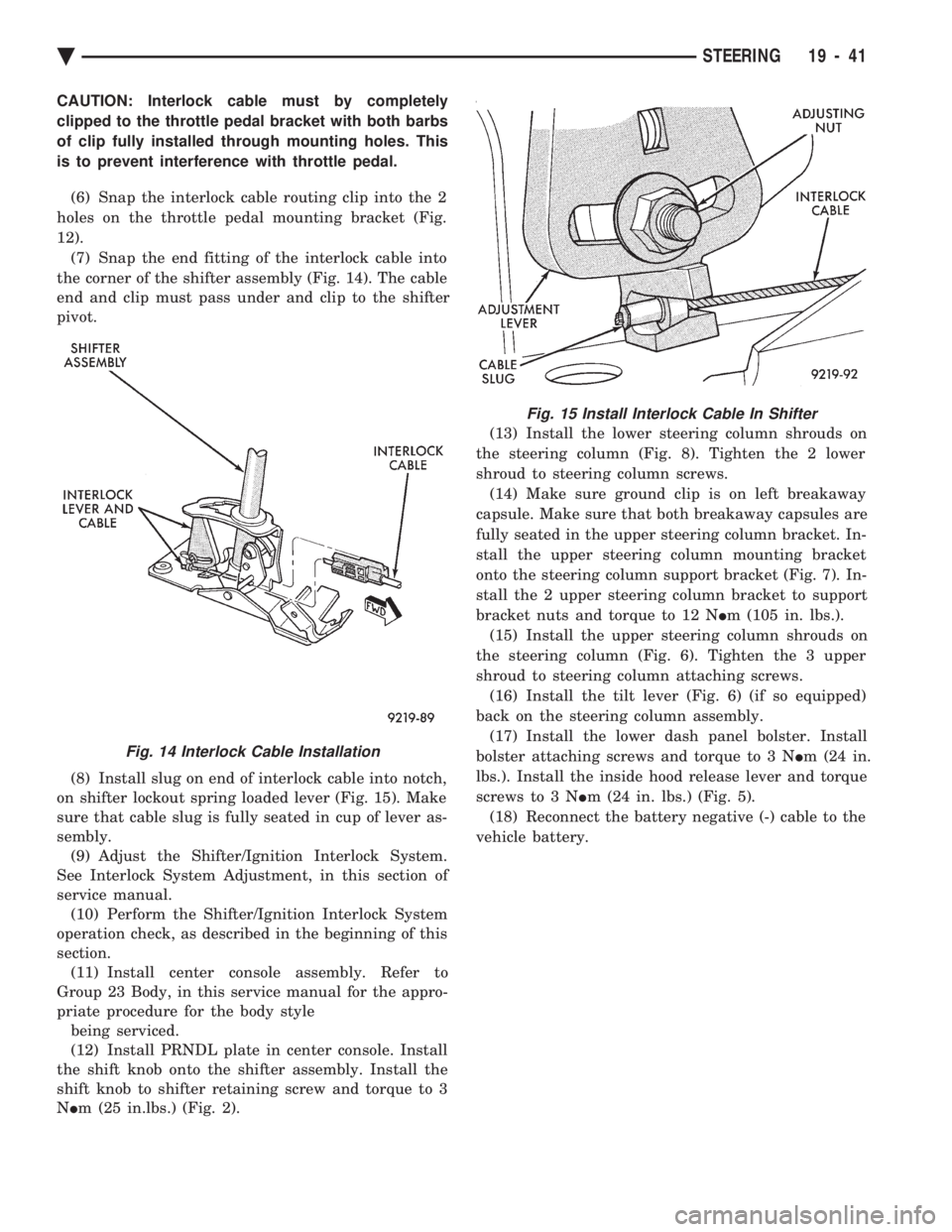

12). (7) Snap the end fitting of the interlock cable into

the corner of the shifter assembly (Fig. 14). The cable

end and clip must pass under and clip to the shifter

pivot.

(8) Install slug on end of interlock cable into notch,

on shifter lockout spring loaded lever (Fig. 15). Make

sure that cable slug is fully seated in cup of lever as-

sembly. (9) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section of

service manual. (10) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section. (11) Install center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for the body style being serviced.

(12) Install PRNDL plate in center console. Install

the shift knob onto the shifter assembly. Install the

shift knob to shifter retaining screw and torque to 3

N Im (25 in.lbs.) (Fig. 2). (13) Install the lower steering column shrouds on

the steering column (Fig. 8). Tighten the 2 lower

shroud to steering column screws. (14) Make sure ground clip is on left breakaway

capsule. Make sure that both breakaway capsules are

fully seated in the upper steering column bracket. In-

stall the upper steering column mounting bracket

onto the steering column support bracket (Fig. 7). In-

stall the 2 upper steering column bracket to support

bracket nuts and torque to 12 N Im (105 in. lbs.).

(15) Install the upper steering column shrouds on

the steering column (Fig. 6). Tighten the 3 upper

shroud to steering column attaching screws. (16) Install the tilt lever (Fig. 6) (if so equipped)

back on the steering column assembly. (17) Install the lower dash panel bolster. Install

bolster attaching screws and torque to 3 N Im (24 in.

lbs.). Install the inside hood release lever and torque

screws to 3 N Im (24 in. lbs.) (Fig. 5).

(18) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 14 Interlock Cable Installation

Fig. 15 Install Interlock Cable In Shifter

Ä STEERING 19 - 41

Page 2060 of 2438

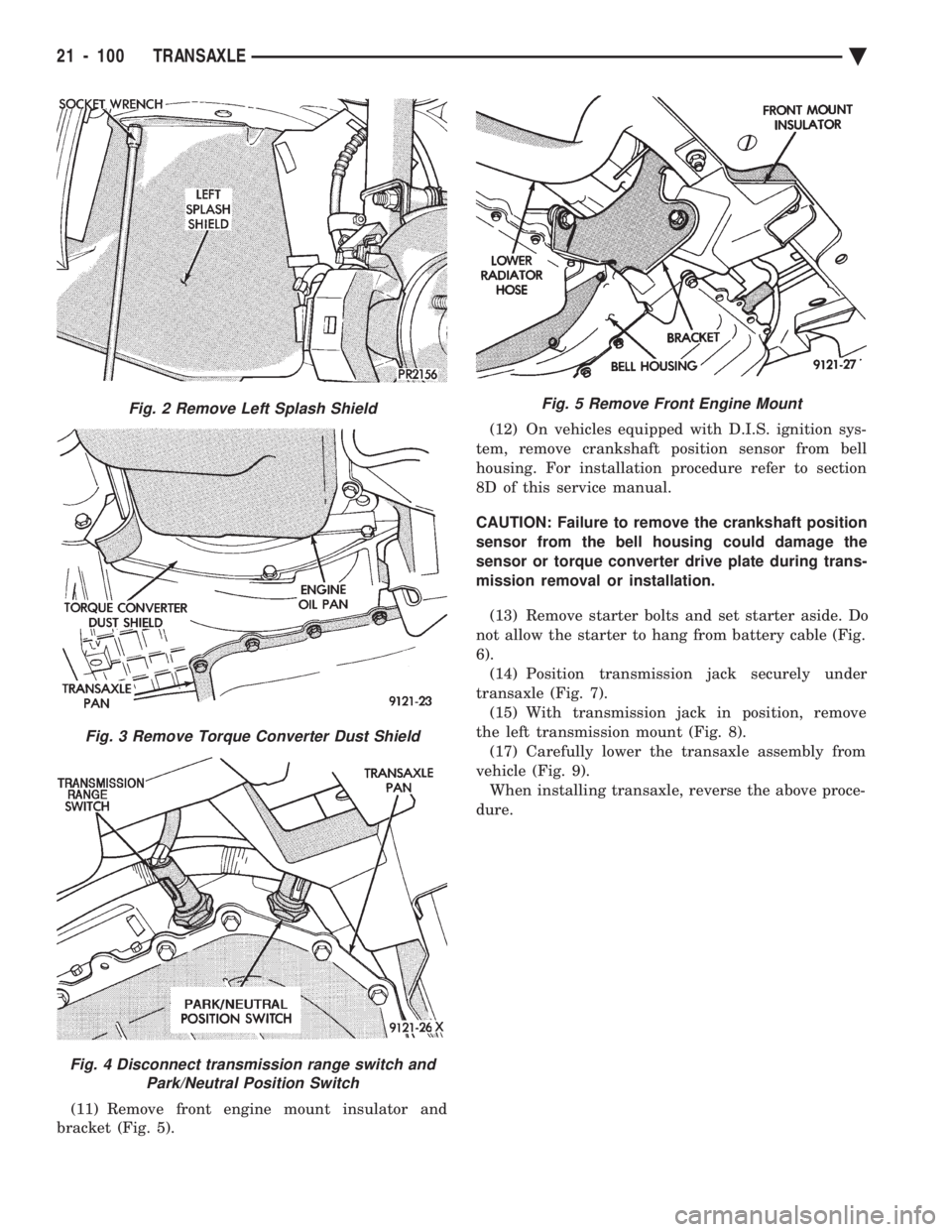

(11) Remove front engine mount insulator and

bracket (Fig. 5). (12) On vehicles equipped with D.I.S. ignition sys-

tem, remove crankshaft position sensor from bell

housing. For installation procedure refer to section

8D of this service manual.

CAUTION: Failure to remove the crankshaft position

sensor from the bell housing could damage the

sensor or torque converter drive plate during trans-

mission removal or installation.

(13) Remove starter bolts and set starter aside. Do

not allow the starter to hang from battery cable (Fig.

6). (14) Position transmission jack securely under

transaxle (Fig. 7). (15) With transmission jack in position, remove

the left transmission mount (Fig. 8). (17) Carefully lower the transaxle assembly from

vehicle (Fig. 9). When installing transaxle, reverse the above proce-

dure.

Fig. 2 Remove Left Splash Shield

Fig. 3 Remove Torque Converter Dust Shield

Fig. 4 Disconnect transmission range switch and Park/Neutral Position Switch

Fig. 5 Remove Front Engine Mount

21 - 100 TRANSAXLE Ä

Page 2352 of 2438

WARNING: AVOID RADIATOR/CONDENSER FAN

BLADES WHEN WORKING IN THE RADIATOR

AREA. FAN IS CONTROLLED BY TEMPERATURE

AND CAN START ANY TIME IGNITION IS ON. PER-

SONAL INJURY CAN RESULT.

(1) Disconnect fan control switch wire connector.

(2) Using a suitable jumper wire, jump across ter-

minals in wire connector. (3) Connect a suitable continuity tester across fan

control switch terminals. (4) Start engine and set idle at 1300 rpm. The ra-

diator fan should run constantly. (5) Set the A/C controls to A/C and high blower.

(6) If the high pressure gauge reads below 1102

kPa (160 psi) there should be no continuity across

the switch terminals.

CAUTION: Do not allow engine to overheat when ra-

diator air flow is blocked.

(7) Block radiator air flow with a suitable cover to

increase the high side pressure to at least 1585 kPa

(230 psi). Electrical continuity should be detected

across the fan control switch terminals. (8) Remove cover from front of vehicle to allow

high side pressure to decrease. When pressure drops

below 1102 kPa (160 psi), continuity should cease. If fan control switch is defective, replace it.

REMOVAL AND INSTALLATION

CAUTION: Refrigerant removal is not necessary

when removing the Condenser Fan Control Switch.

However, a small amount of refrigerant will vent

from the switch port. Review the refrigerant han-

dling section of Safety Precautions and Warnings in

the General Information section of this Group.

(1) Disconnect wire connector from condenser fan

control switch. (2) Loosen and quickly rotate the switch counter-

clockwise and separate from the high pressure line

switch port. To install, reverse the preceding operation.

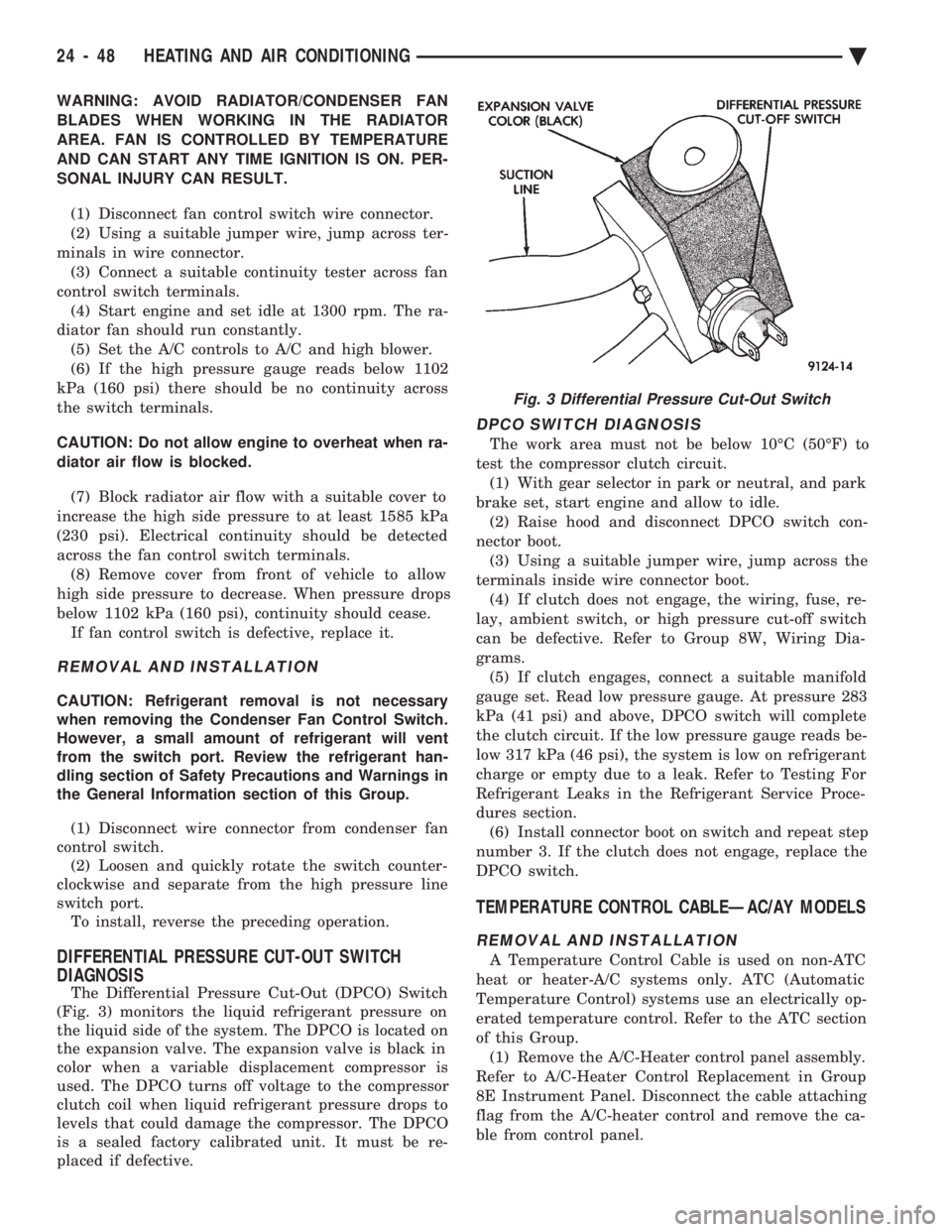

DIFFERENTIAL PRESSURE CUT-OUT SWITCH

DIAGNOSIS

The Differential Pressure Cut-Out (DPCO) Switch

(Fig. 3) monitors the liquid refrigerant pressure on

the liquid side of the system. The DPCO is located on

the expansion valve. The expansion valve is black in

color when a variable displacement compressor is

used. The DPCO turns off voltage to the compressor

clutch coil when liquid refrigerant pressure drops to

levels that could damage the compressor. The DPCO

is a sealed factory calibrated unit. It must be re-

placed if defective.

DPCO SWITCH DIAGNOSIS

The work area must not be below 10ÉC (50ÉF) to

test the compressor clutch circuit. (1) With gear selector in park or neutral, and park

brake set, start engine and allow to idle. (2) Raise hood and disconnect DPCO switch con-

nector boot. (3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot. (4) If clutch does not engage, the wiring, fuse, re-

lay, ambient switch, or high pressure cut-off switch

can be defective. Refer to Group 8W, Wiring Dia-

grams. (5) If clutch engages, connect a suitable manifold

gauge set. Read low pressure gauge. At pressure 283

kPa (41 psi) and above, DPCO switch will complete

the clutch circuit. If the low pressure gauge reads be-

low 317 kPa (46 psi), the system is low on refrigerant

charge or empty due to a leak. Refer to Testing For

Refrigerant Leaks in the Refrigerant Service Proce-

dures section. (6) Install connector boot on switch and repeat step

number 3. If the clutch does not engage, replace the

DPCO switch.

TEMPERATURE CONTROL CABLEÐAC/AY MODELS

REMOVAL AND INSTALLATION

A Temperature Control Cable is used on non-ATC

heat or heater-A/C systems only. ATC (Automatic

Temperature Control) systems use an electrically op-

erated temperature control. Refer to the ATC section

of this Group. (1) Remove the A/C-Heater control panel assembly.

Refer to A/C-Heater Control Replacement in Group

8E Instrument Panel. Disconnect the cable attaching

flag from the A/C-heater control and remove the ca-

ble from control panel.

Fig. 3 Differential Pressure Cut-Out Switch

24 - 48 HEATING AND AIR CONDITIONING Ä

Page 2372 of 2438

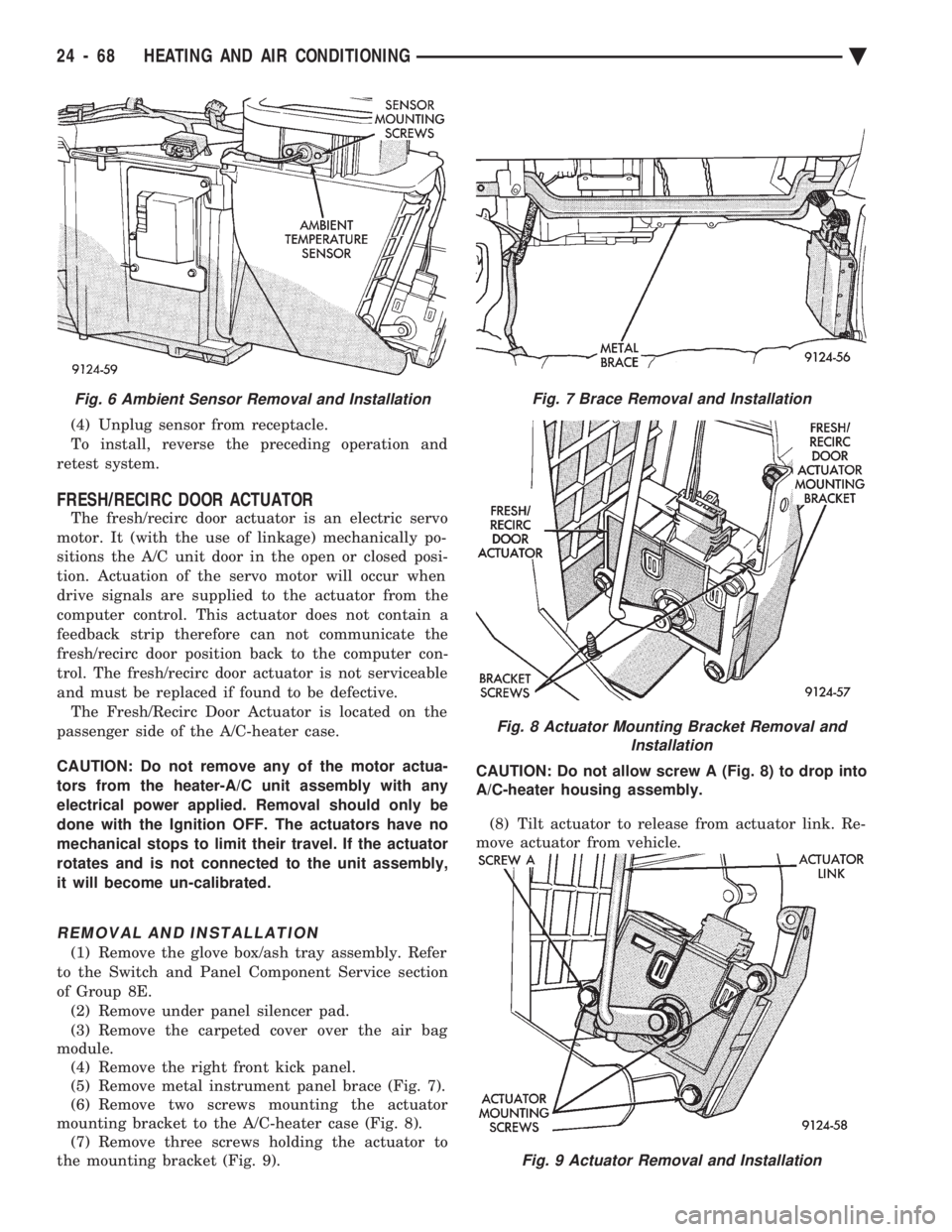

(4) Unplug sensor from receptacle.

To install, reverse the preceding operation and

retest system.

FRESH/RECIRC DOOR ACTUATOR

The fresh/recirc door actuator is an electric servo

motor. It (with the use of linkage) mechanically po-

sitions the A/C unit door in the open or closed posi-

tion. Actuation of the servo motor will occur when

drive signals are supplied to the actuator from the

computer control. This actuator does not contain a

feedback strip therefore can not communicate the

fresh/recirc door position back to the computer con-

trol. The fresh/recirc door actuator is not serviceable

and must be replaced if found to be defective. The Fresh/Recirc Door Actuator is located on the

passenger side of the A/C-heater case.

CAUTION: Do not remove any of the motor actua-

tors from the heater-A/C unit assembly with any

electrical power applied. Removal should only be

done with the Ignition OFF. The actuators have no

mechanical stops to limit their travel. If the actuator

rotates and is not connected to the unit assembly,

it will become un-calibrated.

REMOVAL AND INSTALLATION

(1) Remove the glove box/ash tray assembly. Refer

to the Switch and Panel Component Service section

of Group 8E. (2) Remove under panel silencer pad.

(3) Remove the carpeted cover over the air bag

module. (4) Remove the right front kick panel.

(5) Remove metal instrument panel brace (Fig. 7).

(6) Remove two screws mounting the actuator

mounting bracket to the A/C-heater case (Fig. 8). (7) Remove three screws holding the actuator to

the mounting bracket (Fig. 9). CAUTION: Do not allow screw A (Fig. 8) to drop into

A/C-heater housing assembly.

(8) Tilt actuator to release from actuator link. Re-

move actuator from vehicle.

Fig. 9 Actuator Removal and Installation

Fig. 6 Ambient Sensor Removal and InstallationFig. 7 Brace Removal and Installation

Fig. 8 Actuator Mounting Bracket Removal and Installation

24 - 68 HEATING AND AIR CONDITIONING Ä

Page 2373 of 2438

To install, reverse the preceding operation.

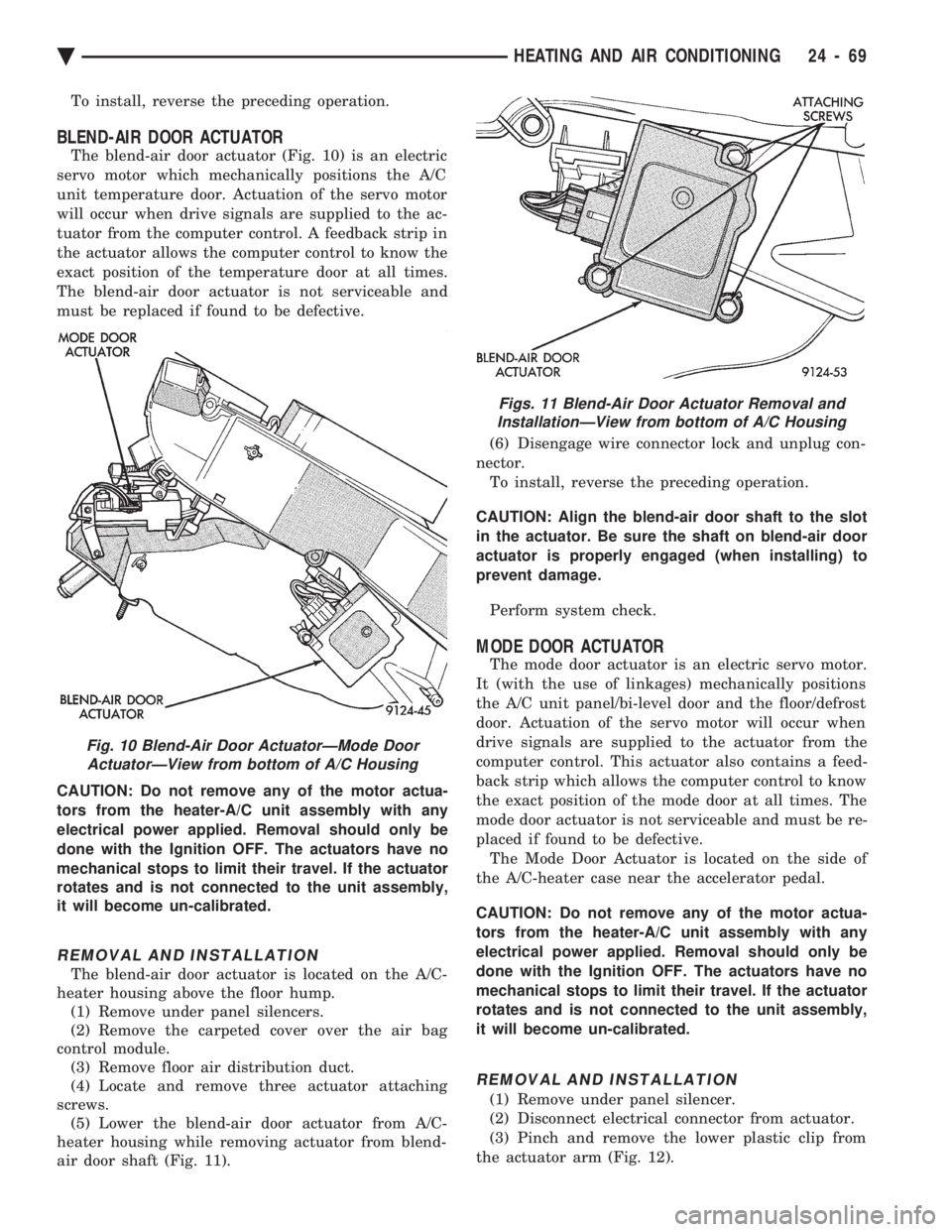

BLEND-AIR DOOR ACTUATOR

The blend-air door actuator (Fig. 10) is an electric

servo motor which mechanically positions the A/C

unit temperature door. Actuation of the servo motor

will occur when drive signals are supplied to the ac-

tuator from the computer control. A feedback strip in

the actuator allows the computer control to know the

exact position of the temperature door at all times.

The blend-air door actuator is not serviceable and

must be replaced if found to be defective.

CAUTION: Do not remove any of the motor actua-

tors from the heater-A/C unit assembly with any

electrical power applied. Removal should only be

done with the Ignition OFF. The actuators have no

mechanical stops to limit their travel. If the actuator

rotates and is not connected to the unit assembly,

it will become un-calibrated.

REMOVAL AND INSTALLATION

The blend-air door actuator is located on the A/C-

heater housing above the floor hump. (1) Remove under panel silencers.

(2) Remove the carpeted cover over the air bag

control module. (3) Remove floor air distribution duct.

(4) Locate and remove three actuator attaching

screws. (5) Lower the blend-air door actuator from A/C-

heater housing while removing actuator from blend-

air door shaft (Fig. 11). (6) Disengage wire connector lock and unplug con-

nector. To install, reverse the preceding operation.

CAUTION: Align the blend-air door shaft to the slot

in the actuator. Be sure the shaft on blend-air door

actuator is properly engaged (when installing) to

prevent damage.

Perform system check.

MODE DOOR ACTUATOR

The mode door actuator is an electric servo motor.

It (with the use of linkages) mechanically positions

the A/C unit panel/bi-level door and the floor/defrost

door. Actuation of the servo motor will occur when

drive signals are supplied to the actuator from the

computer control. This actuator also contains a feed-

back strip which allows the computer control to know

the exact position of the mode door at all times. The

mode door actuator is not serviceable and must be re-

placed if found to be defective. The Mode Door Actuator is located on the side of

the A/C-heater case near the accelerator pedal.

CAUTION: Do not remove any of the motor actua-

tors from the heater-A/C unit assembly with any

electrical power applied. Removal should only be

done with the Ignition OFF. The actuators have no

mechanical stops to limit their travel. If the actuator

rotates and is not connected to the unit assembly,

it will become un-calibrated.

REMOVAL AND INSTALLATION

(1) Remove under panel silencer.

(2) Disconnect electrical connector from actuator.

(3) Pinch and remove the lower plastic clip from

the actuator arm (Fig. 12).

Fig. 10 Blend-Air Door ActuatorÐMode Door ActuatorÐView from bottom of A/C Housing

Figs. 11 Blend-Air Door Actuator Removal andInstallationÐView from bottom of A/C Housing

Ä HEATING AND AIR CONDITIONING 24 - 69