charging CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 393 of 2438

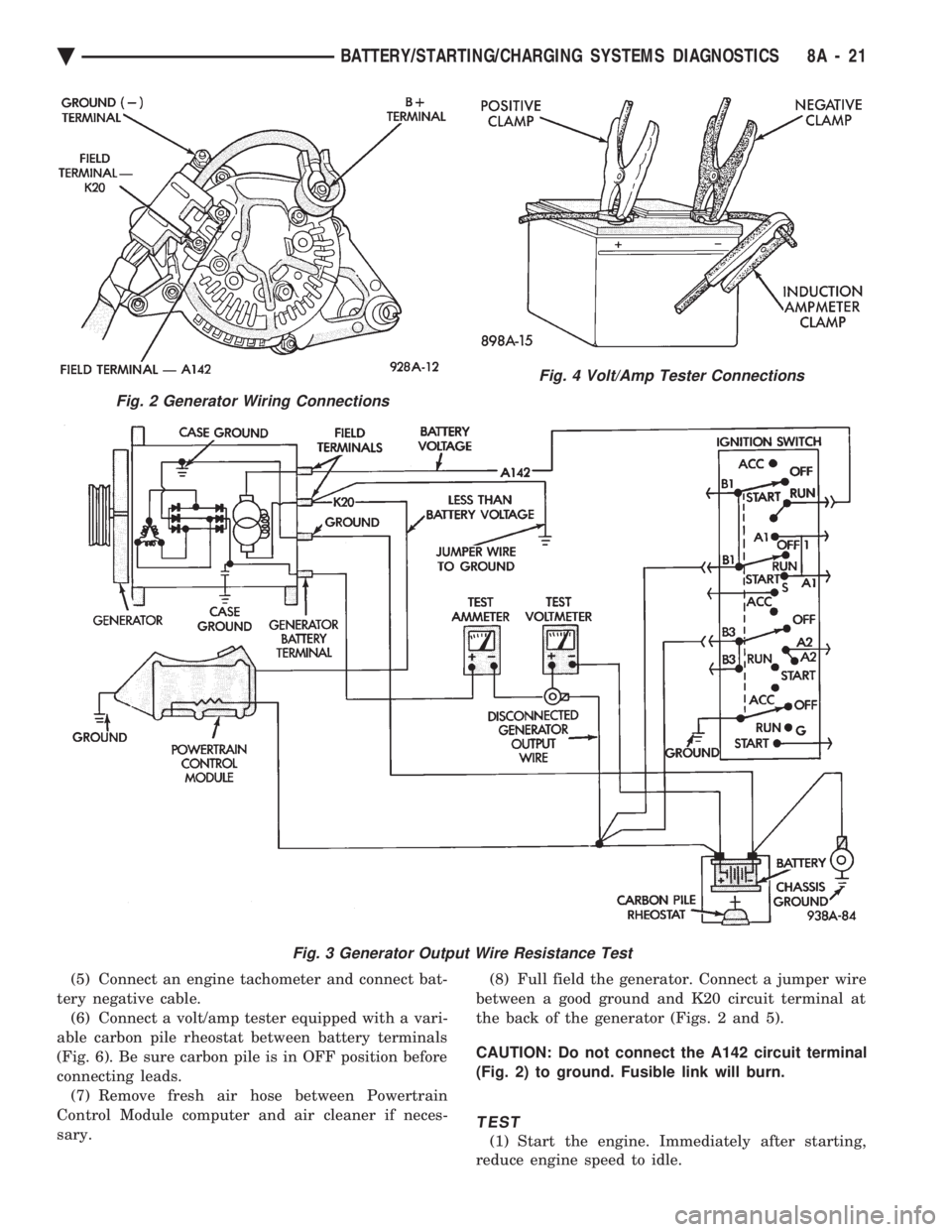

(5) Connect an engine tachometer and connect bat-

tery negative cable. (6) Connect a volt/amp tester equipped with a vari-

able carbon pile rheostat between battery terminals

(Fig. 6). Be sure carbon pile is in OFF position before

connecting leads. (7) Remove fresh air hose between Powertrain

Control Module computer and air cleaner if neces-

sary. (8) Full field the generator. Connect a jumper wire

between a good ground and K20 circuit terminal at

the back of the generator (Figs. 2 and 5).

CAUTION: Do not connect the A142 circuit terminal

(Fig. 2) to ground. Fusible link will burn.

TEST

(1) Start the engine. Immediately after starting,

reduce engine speed to idle.

Fig. 2 Generator Wiring Connections

Fig. 3 Generator Output Wire Resistance Test

Fig. 4 Volt/Amp Tester Connections

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 21

Page 394 of 2438

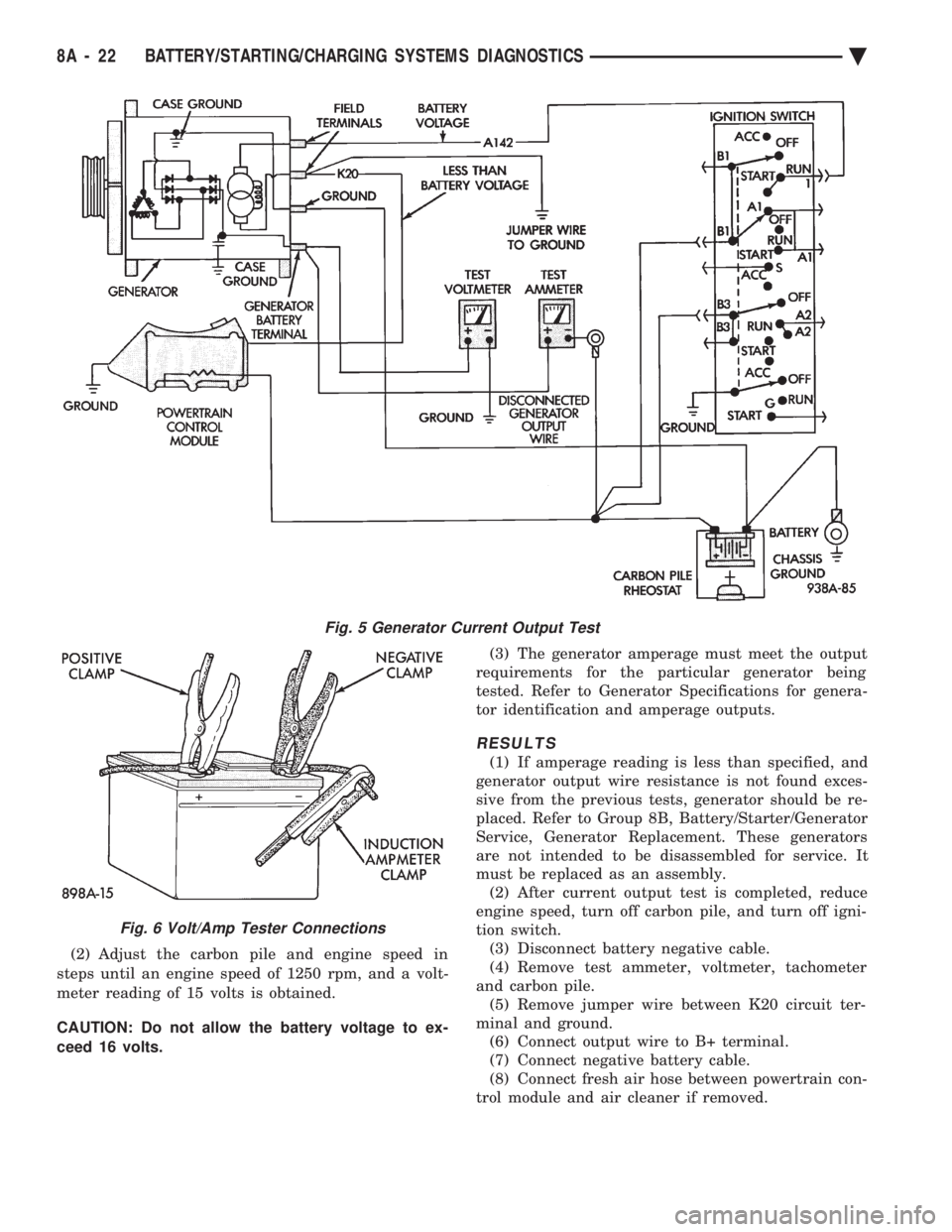

(2) Adjust the carbon pile and engine speed in

steps until an engine speed of 1250 rpm, and a volt-

meter reading of 15 volts is obtained.

CAUTION: Do not allow the battery voltage to ex-

ceed 16 volts. (3) The generator amperage must meet the output

requirements for the particular generator being

tested. Refer to Generator Specifications for genera-

tor identification and amperage outputs.

RESULTS

(1) If amperage reading is less than specified, and

generator output wire resistance is not found exces-

sive from the previous tests, generator should be re-

placed. Refer to Group 8B, Battery/Starter/Generator

Service, Generator Replacement. These generators

are not intended to be disassembled for service. It

must be replaced as an assembly. (2) After current output test is completed, reduce

engine speed, turn off carbon pile, and turn off igni-

tion switch. (3) Disconnect battery negative cable.

(4) Remove test ammeter, voltmeter, tachometer

and carbon pile. (5) Remove jumper wire between K20 circuit ter-

minal and ground. (6) Connect output wire to B+ terminal.

(7) Connect negative battery cable.

(8) Connect fresh air hose between powertrain con-

trol module and air cleaner if removed.

Fig. 5 Generator Current Output Test

Fig. 6 Volt/Amp Tester Connections

8A - 22 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 395 of 2438

FAULT CODESÐON BOARD DIAGNOSTICS INDEX

page page

Diagnostic Testing Using Fault Codes ......... 24

Drb II Diagnostic Tester ................... 24 General Description/Information

.............. 23

GENERAL DESCRIPTION/INFORMATION

Another way of diagnosing charging system prob-

lems can be accomplished using the On Board Diag-

nostic System Fault Codes. A Fault Code shows a potential problem in a mon-

itored circuit, or a condition caused by a faulty component. A

Fault Code can be retrieved by turning the ignition

switch ON-OFF-ON-OFF-ON without starting the

engine, and counting the number of flashes of the

Malfunction Indicator (CHECK ENGINE) Lamp in

the instrument cluster.

EXAMPLES:

² If the Malfunction Indicator (Check Engine) Lamp

flashes four times, pauses, and flashes one more

time, a Code 41 is shown. The first set of four flashes

indicates number four. The second set of one flash in-

dicates one.

² If the Malfunction Indicator (Check Engine) Lamp

flashes four times, pauses, and flashes six more

times, a Code 46 is shown. The first set of four

flashes indicates number four. The second set of six

flashes indicates six.

² If the Malfunction Indication (Check Engine)

Lamp flashes four times, pauses, and flashes seven

more times, a Code 47 is shown. The first set of four

flashes indicates number four. The second set of

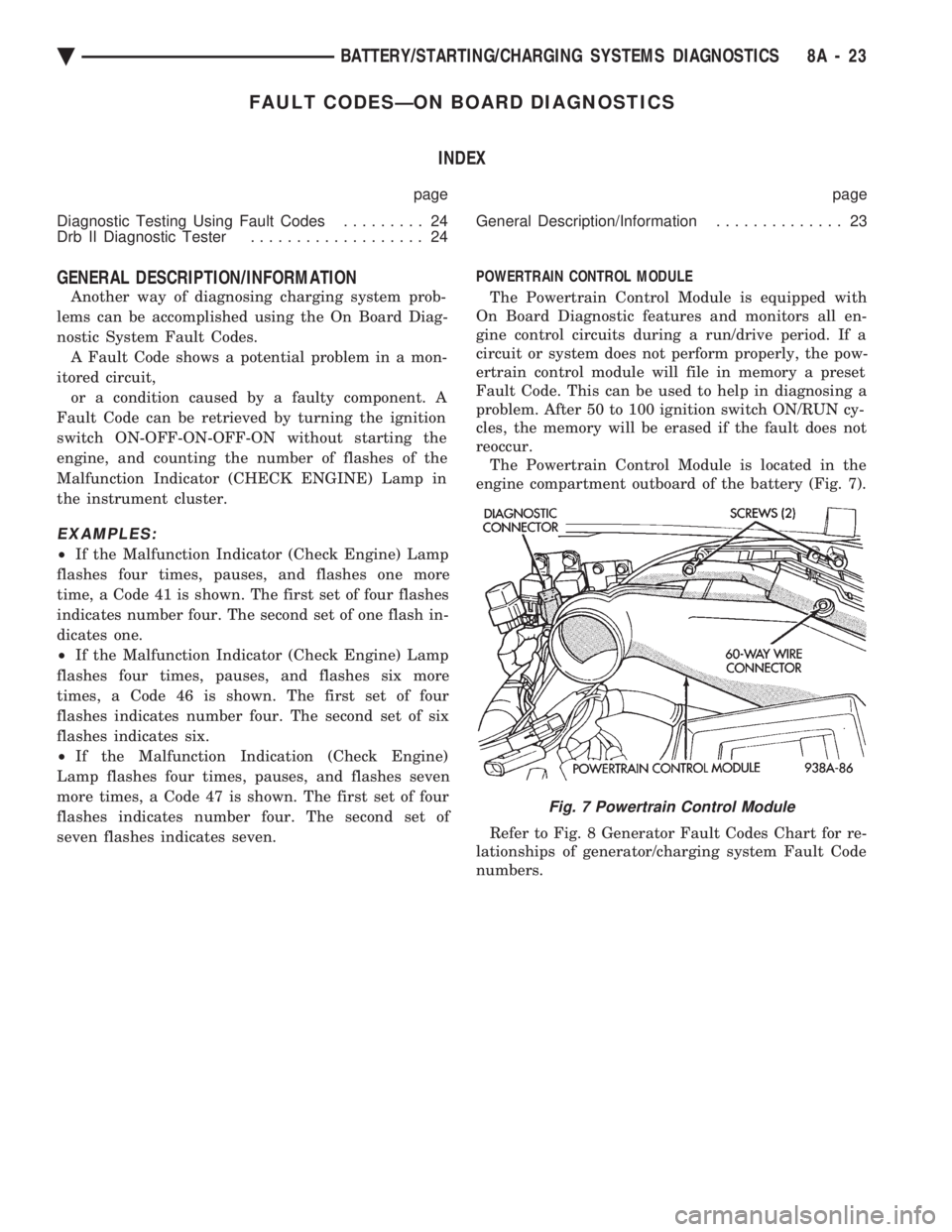

seven flashes indicates seven. POWERTRAIN CONTROL MODULE

The Powertrain Control Module is equipped with

On Board Diagnostic features and monitors all en-

gine control circuits during a run/drive period. If a

circuit or system does not perform properly, the pow-

ertrain control module will file in memory a preset

Fault Code. This can be used to help in diagnosing a

problem. After 50 to 100 ignition switch ON/RUN cy-

cles, the memory will be erased if the fault does not

reoccur. The Powertrain Control Module is located in the

engine compartment outboard of the battery (Fig. 7).

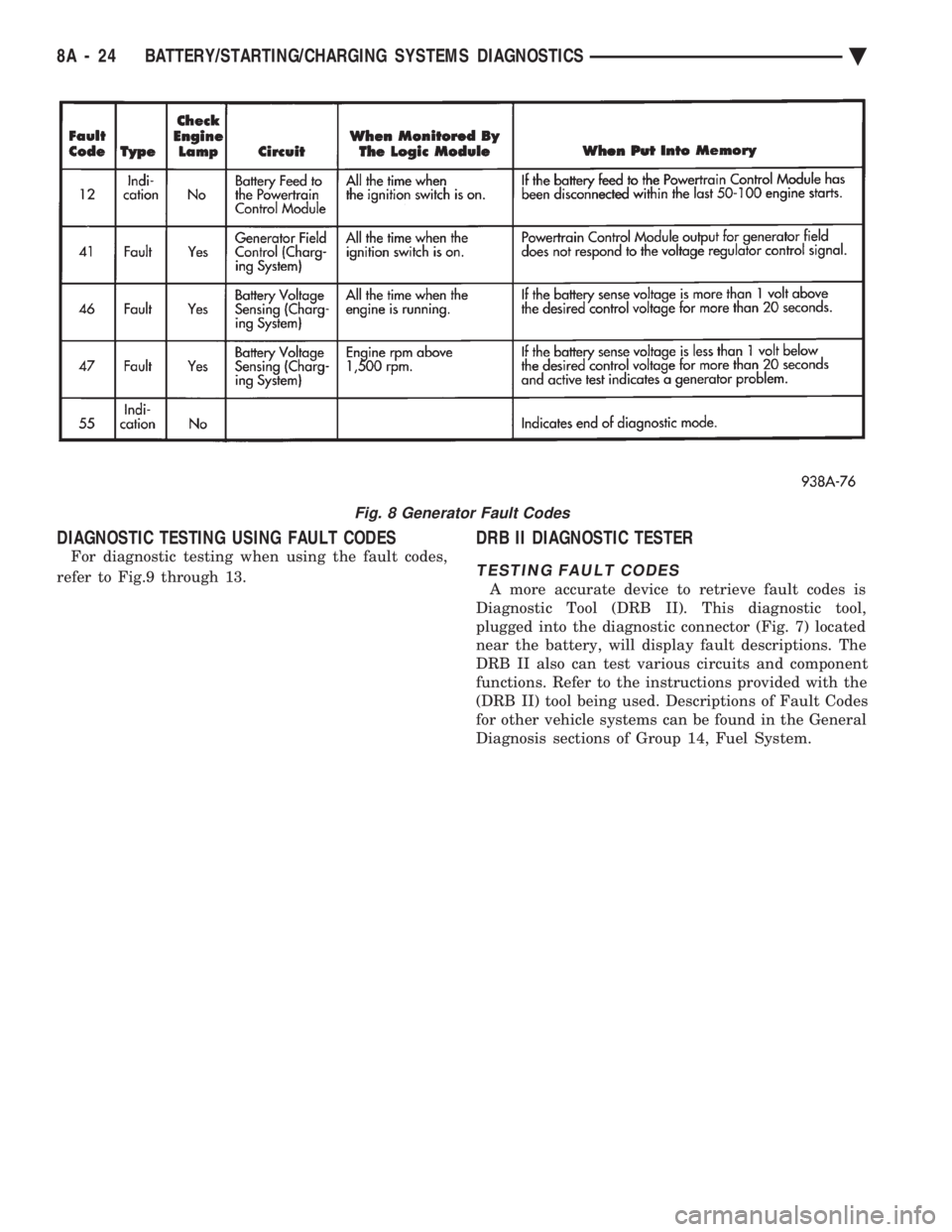

Refer to Fig. 8 Generator Fault Codes Chart for re-

lationships of generator/charging system Fault Code

numbers.

Fig. 7 Powertrain Control Module

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 23

Page 396 of 2438

DIAGNOSTIC TESTING USING FAULT CODES

For diagnostic testing when using the fault codes,

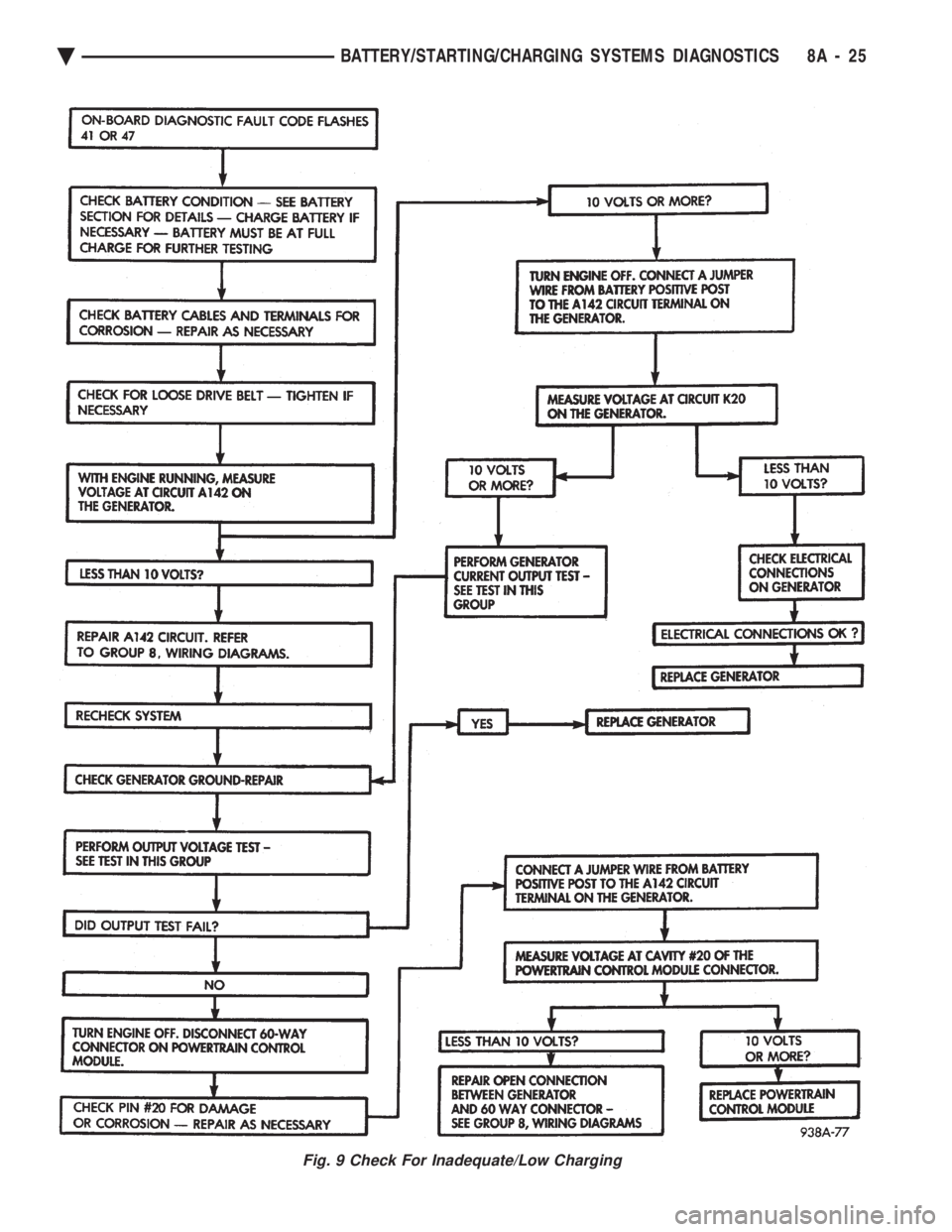

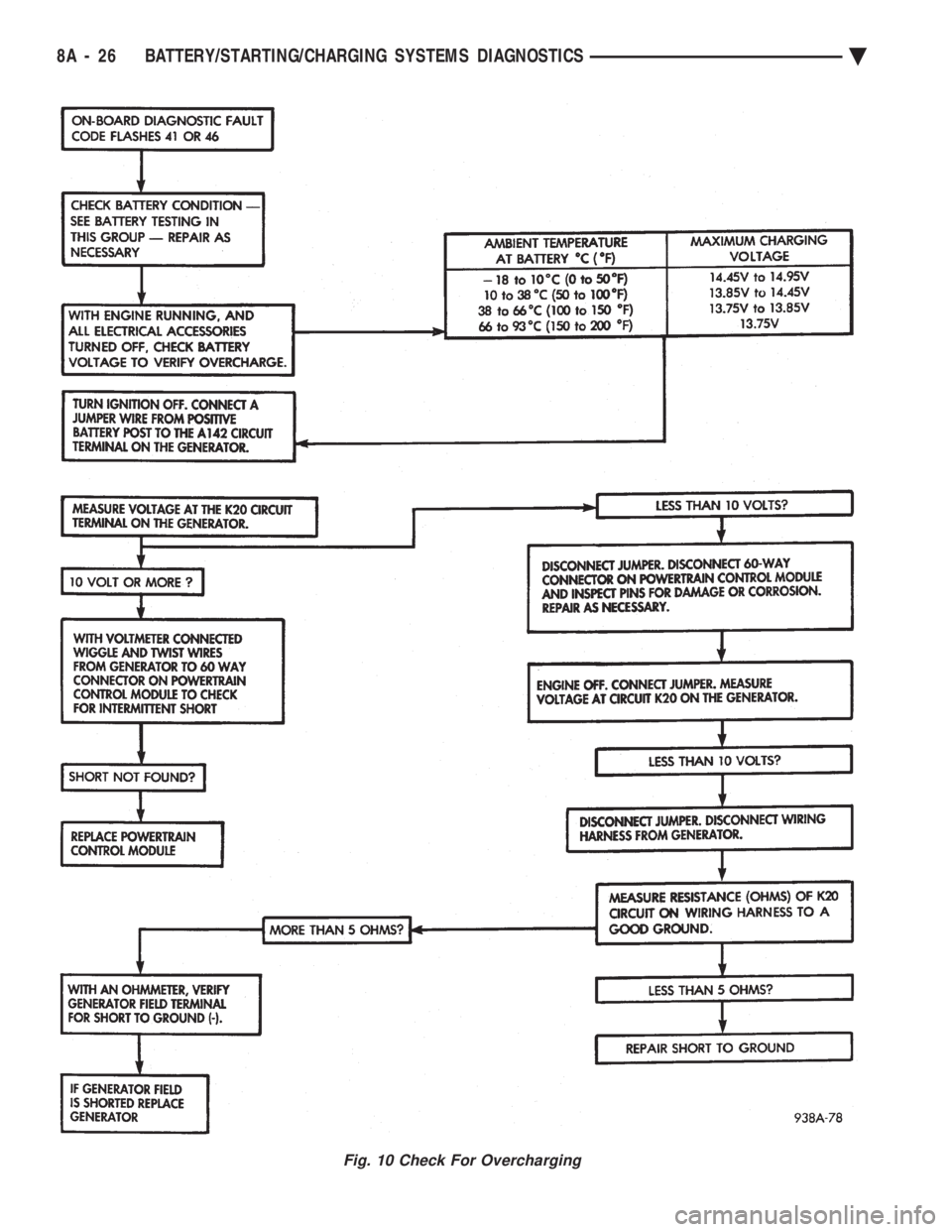

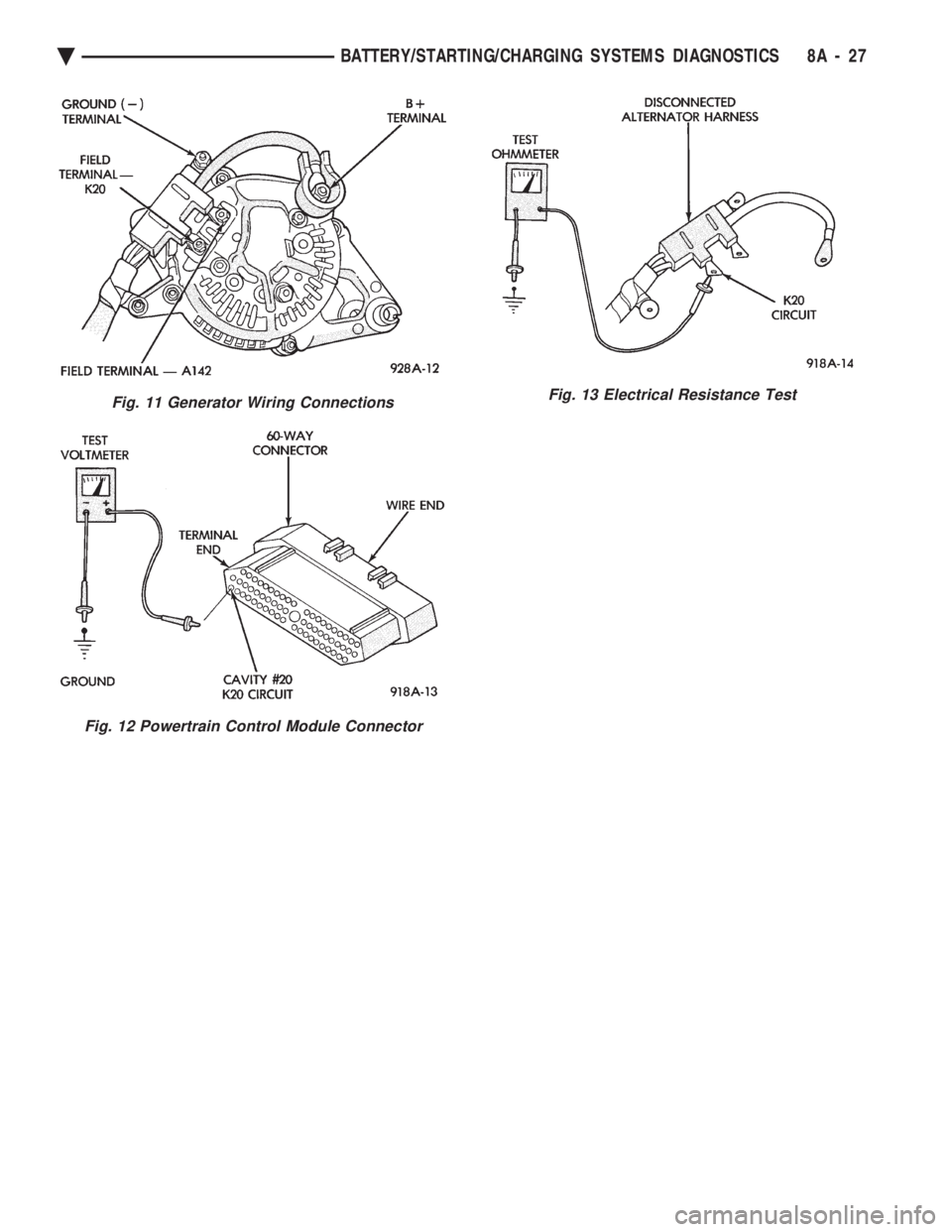

refer to Fig.9 through 13.

DRB II DIAGNOSTIC TESTER

TESTING FAULT CODES

A more accurate device to retrieve fault codes is

Diagnostic Tool (DRB II). This diagnostic tool,

plugged into the diagnostic connector (Fig. 7) located

near the battery, will display fault descriptions. The

DRB II also can test various circuits and component

functions. Refer to the instructions provided with the

(DRB II) tool being used. Descriptions of Fault Codes

for other vehicle systems can be found in the General

Diagnosis sections of Group 14, Fuel System.

Fig. 8 Generator Fault Codes

8A - 24 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 397 of 2438

Fig. 9 Check For Inadequate/Low Charging

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 25

Page 398 of 2438

Fig. 10 Check For Overcharging

8A - 26 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 399 of 2438

Fig. 11 Generator Wiring Connections

Fig. 12 Powertrain Control Module Connector

Fig. 13 Electrical Resistance Test

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 27

Page 400 of 2438

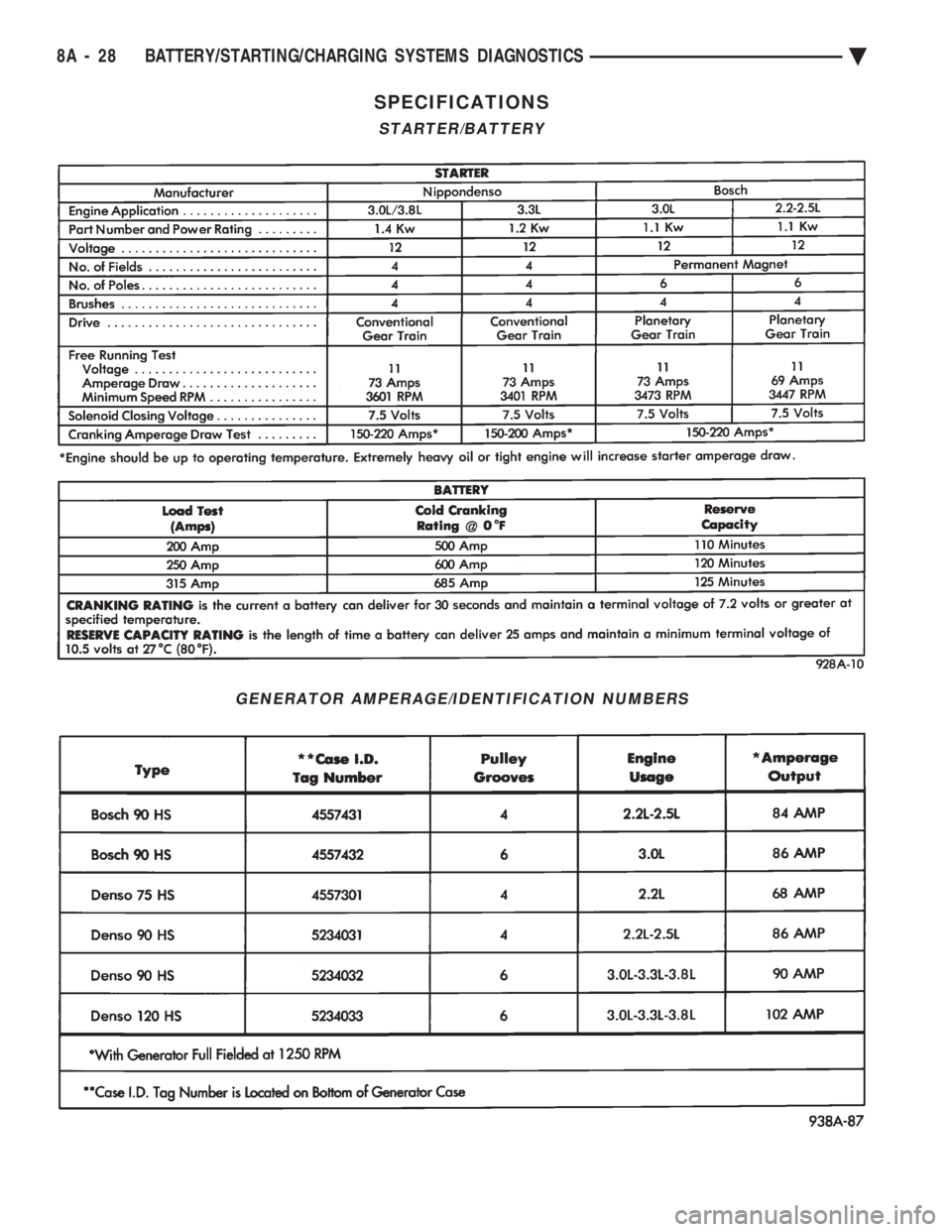

SPECIFICATIONS

STARTER/BATTERY

GENERATOR AMPERAGE/IDENTIFICATION NUMBERS

8A - 28 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 401 of 2438

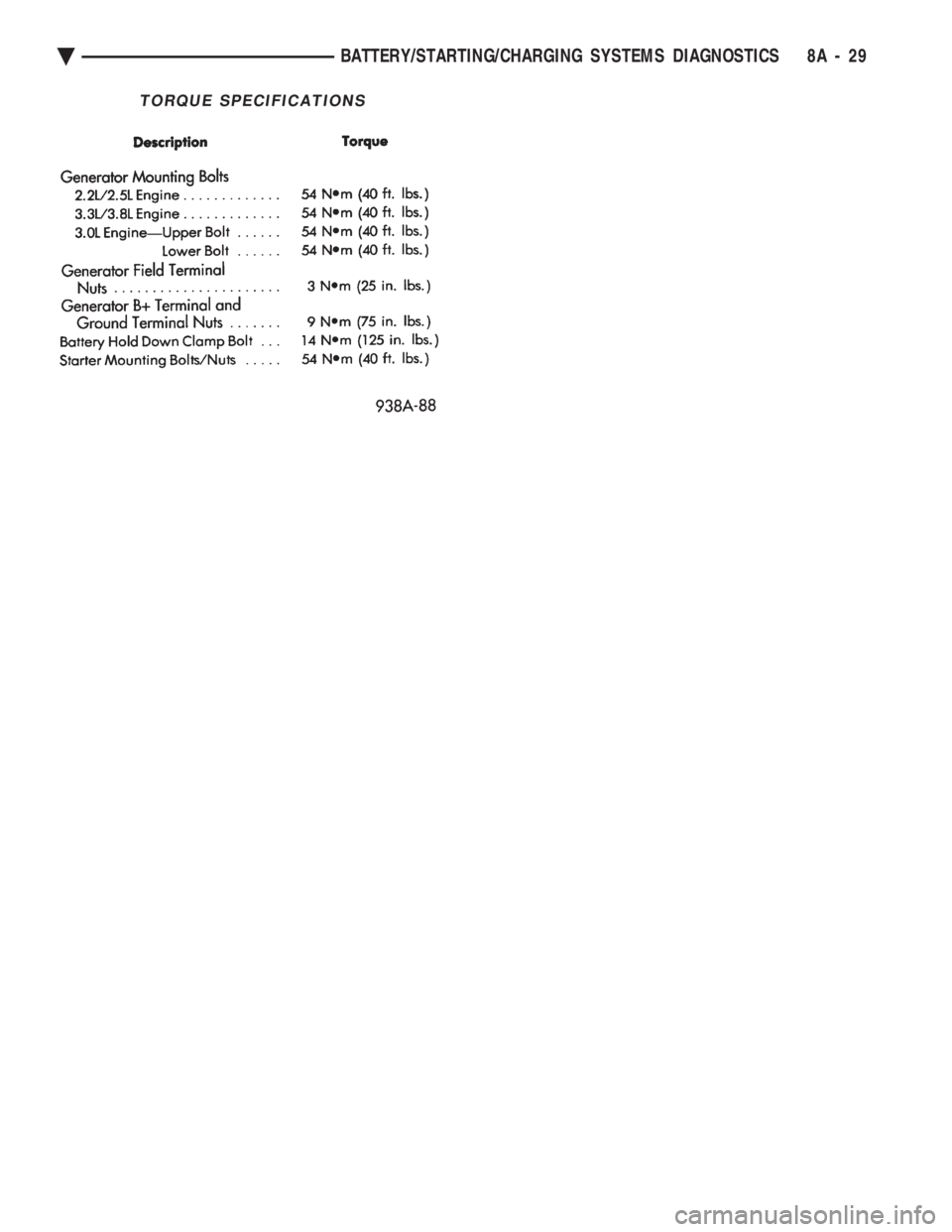

TORQUE SPECIFICATIONS

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 29

Page 403 of 2438

BATTERY/STARTER/GENERATOR SERVICE

CONTENTS

page page

BATTERY REMOVAL, INSTALLATION AND SERVICE ............................. 1

GENERATOR ............................ 9 SPECIFICATIONS

....................... 12

STARTER ............................... 4

BATTERY REMOVAL, INSTALLATION AND SERVICE

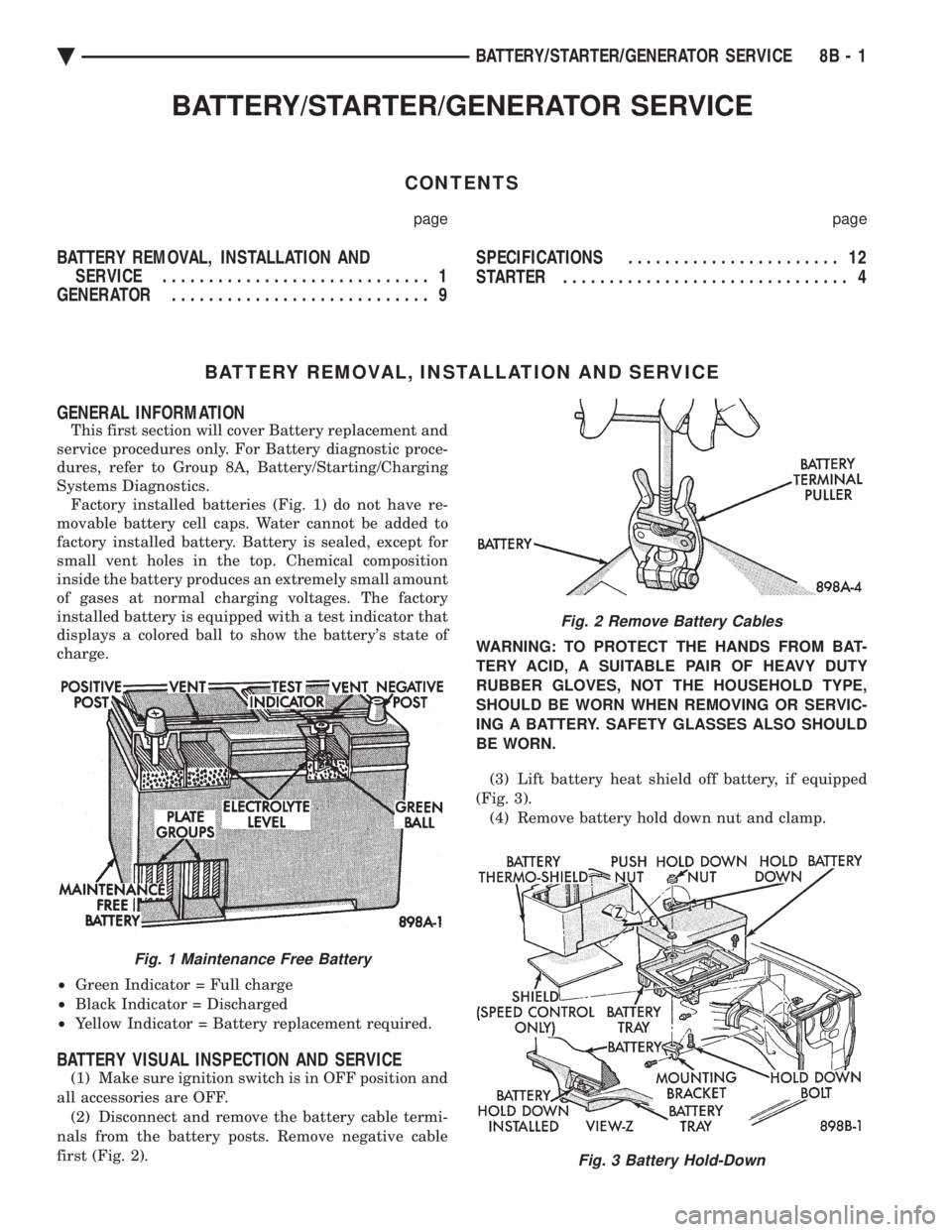

GENERAL INFORMATION

This first section will cover Battery replacement and

service procedures only. For Battery diagnostic proce-

dures, refer to Group 8A, Battery/Starting/Charging

Systems Diagnostics. Factory installed batteries (Fig. 1) do not have re-

movable battery cell caps. Water cannot be added to

factory installed battery. Battery is sealed, except for

small vent holes in the top. Chemical composition

inside the battery produces an extremely small amount

of gases at normal charging voltages. The factory

installed battery is equipped with a test indicator that

displays a colored ball to show the battery's state of

charge.

² Green Indicator = Full charge

² Black Indicator = Discharged

² Yellow Indicator = Battery replacement required.

BATTERY VISUAL INSPECTION AND SERVICE

(1) Make sure ignition switch is in OFF position and

all accessories are OFF. (2) Disconnect and remove the battery cable termi-

nals from the battery posts. Remove negative cable

first (Fig. 2). WARNING: TO PROTECT THE HANDS FROM BAT-

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES, NOT THE HOUSEHOLD TYPE,

SHOULD BE WORN WHEN REMOVING OR SERVIC-

ING A BATTERY. SAFETY GLASSES ALSO SHOULD

BE WORN.

(3) Lift battery heat shield off battery, if equipped

(Fig. 3). (4) Remove battery hold down nut and clamp.

Fig. 1 Maintenance Free Battery

Fig. 2 Remove Battery Cables

Fig. 3 Battery Hold-Down

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 1