warning light CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 376 of 2438

It is important when using the Test Indicator that

the battery be level and have a clean top to see the

correct indications. A light may be required to view

the Indicator.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERY BECAUSE OF EXPLOSIVE GASES AT FORM

ABOVE BATTERY.

STATE OF CHARGE TESTS

USING TEST INDICATOR

The built in test hydrometer (Figs. 3, 4 and 5) mea-

sures the specific gravity of the electrolyte. Specific

Gravity (SG) of the electrolyte will show state of

charge voltage. The test indicator WILL NOT show

cranking capacity of the battery. Refer to Battery

Load. Look into the sight glass (Figs. 4 and 5) and

note the color of the indicator (Fig. 5). Refer to the

following description of colors:

² GREEN = 75 to 100 degree state of charge

The battery is adequately charged for further test-

ing and may be returned to use. If the vehicle will

not crank for a maximum 15 seconds, refer to Bat-

tery Load Test in this Group for more information.

² BLACK OR DAR K=0to75degree state of

charge The battery is INADEQUATELY charged and

must be charged until green dot is visible, (12.4 volts

or greater) before the battery is tested or returned to

use. Refer to Causes of Battery Discharging.

² YELLOW OR BRIGHT COLOR = Battery must

be replace

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN YELLOW OR BRIGHT COLOR DOT IS VISI-

BLE. PERSONAL INJURY MAY OCCUR.

A yellow or bright color dot shows electrolyte level

in battery is below the test indicator (Fig. 5). Water

cannot be added to a maintenance free battery. The

battery must be replaced. A low electrolyte level may

be caused by an over charging condition. Refer to

Generator Test Procedures on Vehicle.

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 30 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF po-

sition, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The

continuous draw is due to various electronic features

or accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

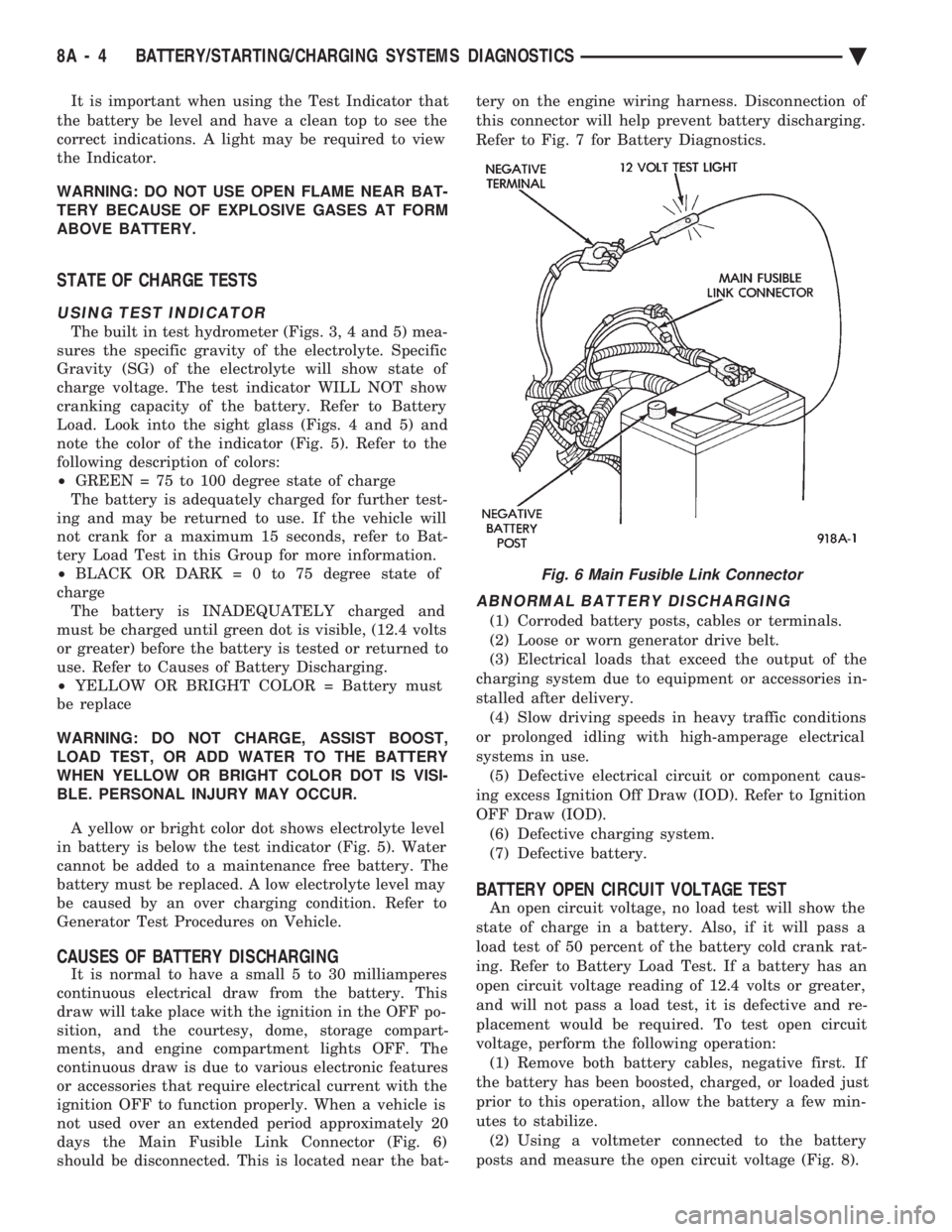

not used over an extended period approximately 20

days the Main Fusible Link Connector (Fig. 6)

should be disconnected. This is located near the bat- tery on the engine wiring harness. Disconnection of

this connector will help prevent battery discharging.

Refer to Fig. 7 for Battery Diagnostics.

ABNORMAL BATTERY DISCHARGING

(1) Corroded battery posts, cables or terminals.

(2) Loose or worn generator drive belt.

(3) Electrical loads that exceed the output of the

charging system due to equipment or accessories in-

stalled after delivery. (4) Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use. (5) Defective electrical circuit or component caus-

ing excess Ignition Off Draw (IOD). Refer to Ignition

OFF Draw (IOD). (6) Defective charging system.

(7) Defective battery.

BATTERY OPEN CIRCUIT VOLTAGE TEST

An open circuit voltage, no load test will show the

state of charge in a battery. Also, if it will pass a

load test of 50 percent of the battery cold crank rat-

ing. Refer to Battery Load Test. If a battery has an

open circuit voltage reading of 12.4 volts or greater,

and will not pass a load test, it is defective and re-

placement would be required. To test open circuit

voltage, perform the following operation: (1) Remove both battery cables, negative first. If

the battery has been boosted, charged, or loaded just

prior to this operation, allow the battery a few min-

utes to stabilize. (2) Using a voltmeter connected to the battery

posts and measure the open circuit voltage (Fig. 8).

Fig. 6 Main Fusible Link Connector

8A - 4 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 379 of 2438

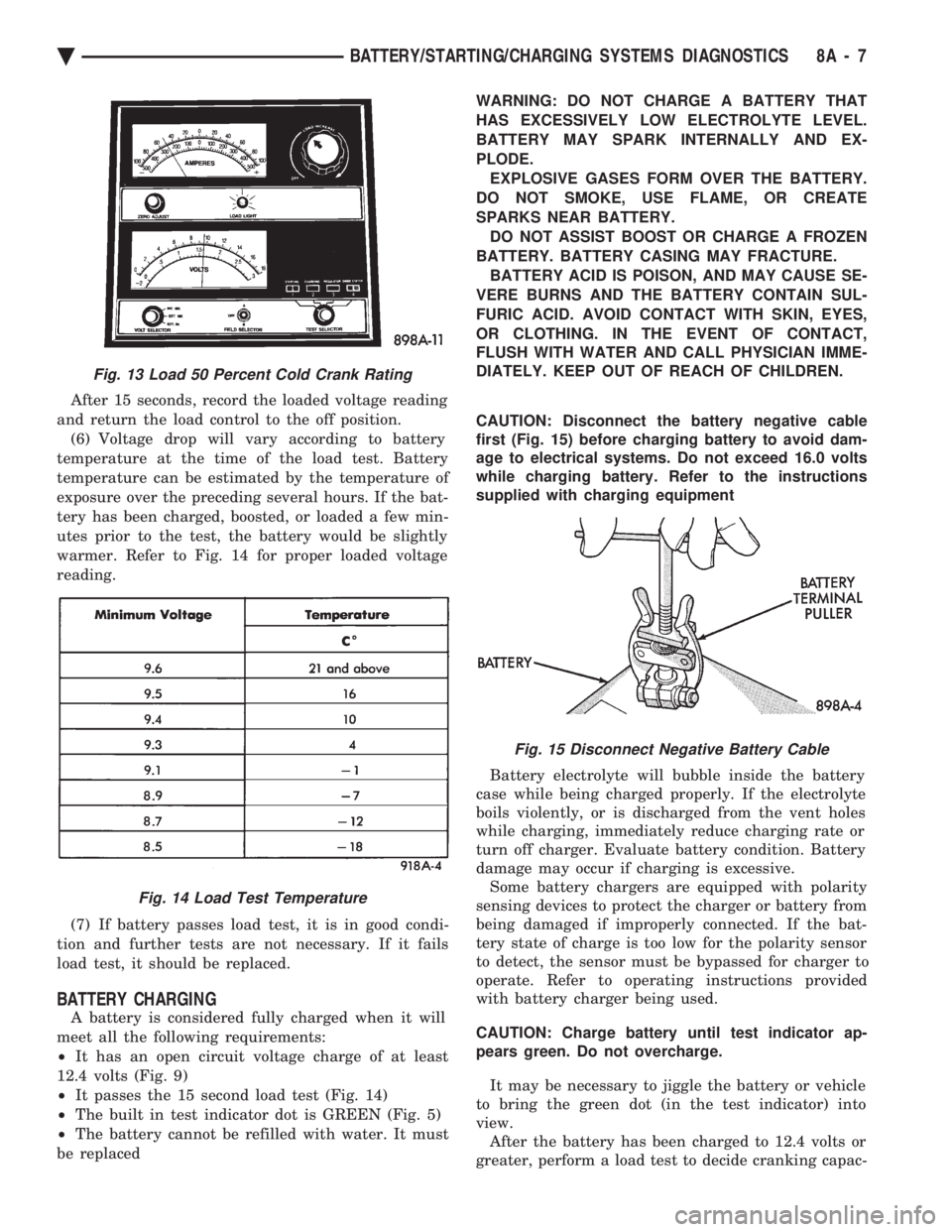

After 15 seconds, record the loaded voltage reading

and return the load control to the off position. (6) Voltage drop will vary according to battery

temperature at the time of the load test. Battery

temperature can be estimated by the temperature of

exposure over the preceding several hours. If the bat-

tery has been charged, boosted, or loaded a few min-

utes prior to the test, the battery would be slightly

warmer. Refer to Fig. 14 for proper loaded voltage

reading.

(7) If battery passes load test, it is in good condi-

tion and further tests are not necessary. If it fails

load test, it should be replaced.

BATTERY CHARGING

A battery is considered fully charged when it will

meet all the following requirements:

² It has an open circuit voltage charge of at least

12.4 volts (Fig. 9)

² It passes the 15 second load test (Fig. 14)

² The built in test indicator dot is GREEN (Fig. 5)

² The battery cannot be refilled with water. It must

be replaced WARNING: DO NOT CHARGE A BATTERY THAT

HAS EXCESSIVELY LOW ELECTROLYTE LEVEL.

BATTERY MAY SPARK INTERNALLY AND EX-

PLODE. EXPLOSIVE GASES FORM OVER THE BATTERY.

DO NOT SMOKE, USE FLAME, OR CREATE

SPARKS NEAR BATTERY. DO NOT ASSIST BOOST OR CHARGE A FROZEN

BATTERY. BATTERY CASING MAY FRACTURE. BATTERY ACID IS POISON, AND MAY CAUSE SE-

VERE BURNS AND THE BATTERY CONTAIN SUL-

FURIC ACID. AVOID CONTACT WITH SKIN, EYES,

OR CLOTHING. IN THE EVENT OF CONTACT,

FLUSH WITH WATER AND CALL PHYSICIAN IMME-

DIATELY. KEEP OUT OF REACH OF CHILDREN.

CAUTION: Disconnect the battery negative cable

first (Fig. 15) before charging battery to avoid dam-

age to electrical systems. Do not exceed 16.0 volts

while charging battery. Refer to the instructions

supplied with charging equipment

Battery electrolyte will bubble inside the battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive. Some battery chargers are equipped with polarity

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat-

tery state of charge is too low for the polarity sensor

to detect, the sensor must be bypassed for charger to

operate. Refer to operating instructions provided

with battery charger being used.

CAUTION: Charge battery until test indicator ap-

pears green. Do not overcharge.

It may be necessary to jiggle the battery or vehicle

to bring the green dot (in the test indicator) into

view. After the battery has been charged to 12.4 volts or

greater, perform a load test to decide cranking capac-

Fig. 13 Load 50 Percent Cold Crank Rating

Fig. 14 Load Test Temperature

Fig. 15 Disconnect Negative Battery Cable

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 7

Page 429 of 2438

AG AND AJ BODIES INDEX

page page

Ambient Temperature Sensor Removal ......... 20

Compass Calibration ...................... 16

Compass Diagnostics ...................... 18

Compass Module Replacement .............. 20

Demagnetizing Procedure .................. 17

Electronic Vehicle Information Center (EVIC) ..... 13

Electronic Vehicle Information Center (EVIC) Removal .............................. 20 Engine Compartment Node (ECN)

............ 15

Engine Compartment Node Compass Calibration . 16

Engine Node Sensor Removal ............... 20

Map Reading Lamps ...................... 13

Overhead Console Replacement ............. 20

Thermometer and Compass ................. 16

Variance Procedure ....................... 17

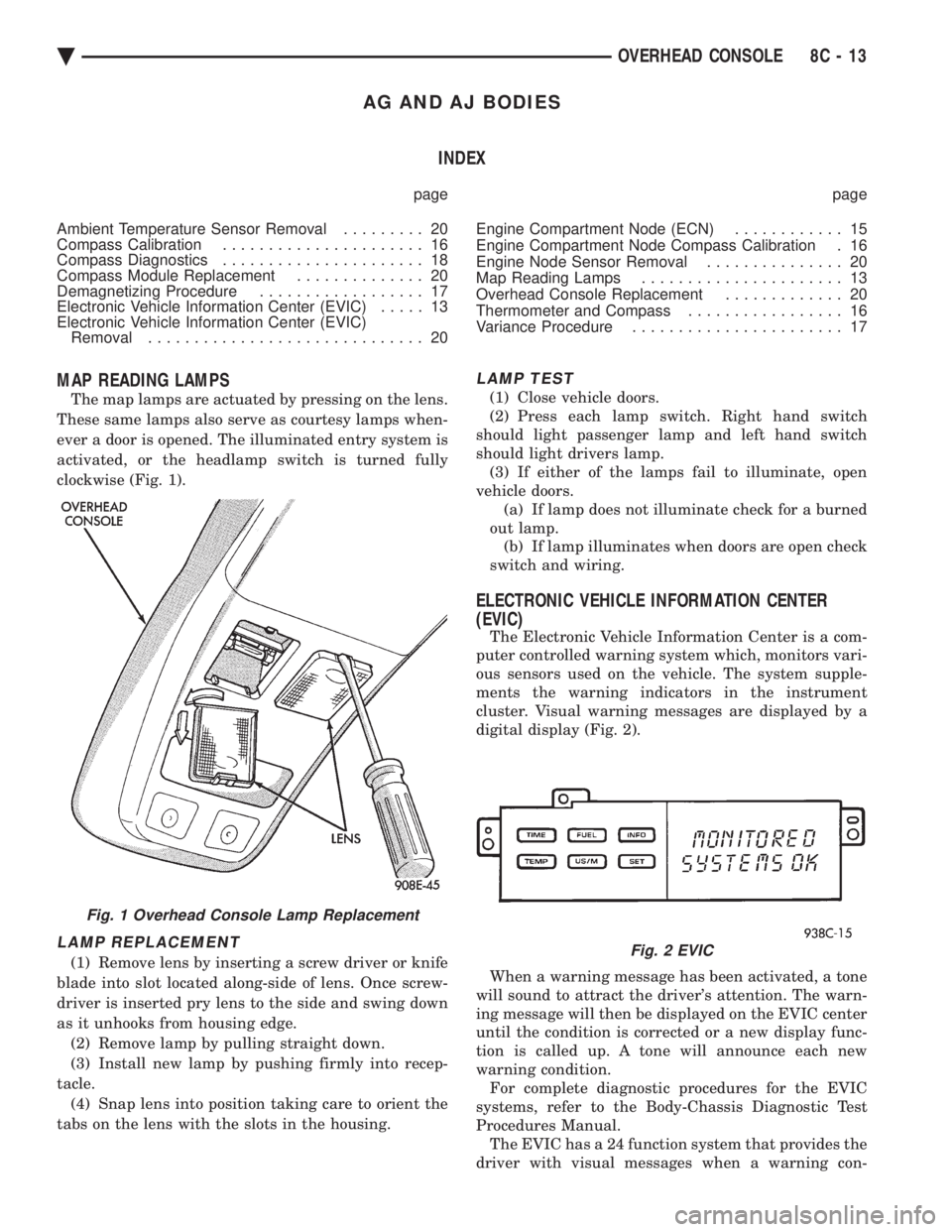

MAP READING LAMPS

The map lamps are actuated by pressing on the lens.

These same lamps also serve as courtesy lamps when-

ever a door is opened. The illuminated entry system is

activated, or the headlamp switch is turned fully

clockwise (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or knife

blade into slot located along-side of lens. Once screw-

driver is inserted pry lens to the side and swing down

as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient the

tabs on the lens with the slots in the housing.

LAMP TEST

(1) Close vehicle doors.

(2) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (3) If either of the lamps fail to illuminate, open

vehicle doors. (a) If lamp does not illuminate check for a burned

out lamp. (b) If lamp illuminates when doors are open check

switch and wiring.

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC)

The Electronic Vehicle Information Center is a com-

puter controlled warning system which, monitors vari-

ous sensors used on the vehicle. The system supple-

ments the warning indicators in the instrument

cluster. Visual warning messages are displayed by a

digital display (Fig. 2).

When a warning message has been activated, a tone

will sound to attract the driver's attention. The warn-

ing message will then be displayed on the EVIC center

until the condition is corrected or a new display func-

tion is called up. A tone will announce each new

warning condition. For complete diagnostic procedures for the EVIC

systems, refer to the Body-Chassis Diagnostic Test

Procedures Manual. The EVIC has a 24 function system that provides the

driver with visual messages when a warning con-

Fig. 1 Overhead Console Lamp Replacement

Fig. 2 EVIC

Ä OVERHEAD CONSOLE 8C - 13

Page 458 of 2438

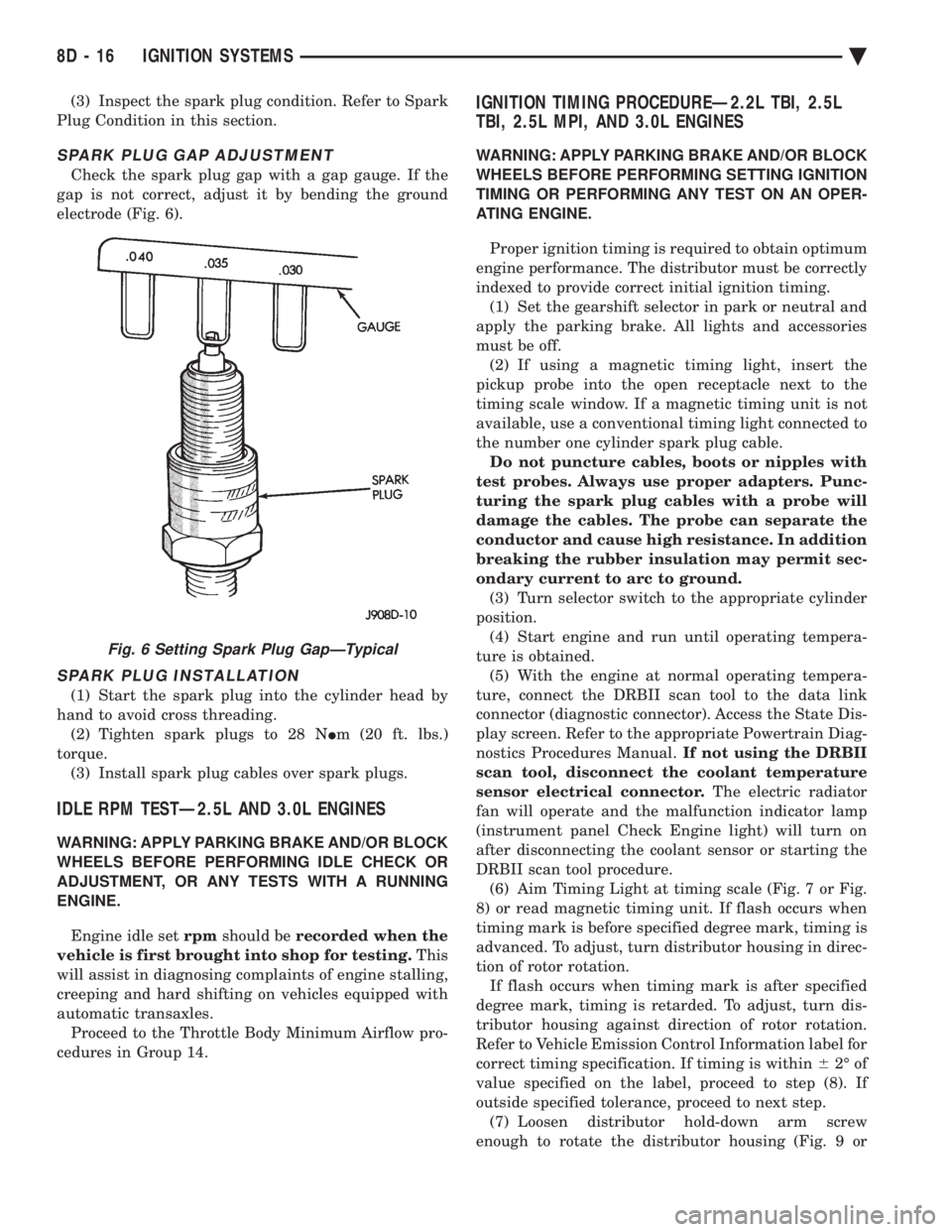

(3) Inspect the spark plug condition. Refer to Spark

Plug Condition in this section.

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TESTÐ2.5L AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING IDLE CHECK OR

ADJUSTMENT, OR ANY TESTS WITH A RUNNING

ENGINE.

Engine idle set rpmshould be recorded when the

vehicle is first brought into shop for testing. This

will assist in diagnosing complaints of engine stalling,

creeping and hard shifting on vehicles equipped with

automatic transaxles. Proceed to the Throttle Body Minimum Airflow pro-

cedures in Group 14.

IGNITION TIMING PROCEDUREÐ2.2L TBI, 2.5L

TBI, 2.5L MPI, AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING SETTING IGNITION

TIMING OR PERFORMING ANY TEST ON AN OPER-

ATING ENGINE.

Proper ignition timing is required to obtain optimum

engine performance. The distributor must be correctly

indexed to provide correct initial ignition timing. (1) Set the gearshift selector in park or neutral and

apply the parking brake. All lights and accessories

must be off. (2) If using a magnetic timing light, insert the

pickup probe into the open receptacle next to the

timing scale window. If a magnetic timing unit is not

available, use a conventional timing light connected to

the number one cylinder spark plug cable. Do not puncture cables, boots or nipples with

test probes. Always use proper adapters. Punc-

turing the spark plug cables with a probe will

damage the cables. The probe can separate the

conductor and cause high resistance. In addition

breaking the rubber insulation may permit sec-

ondary current to arc to ground. (3) Turn selector switch to the appropriate cylinder

position. (4) Start engine and run until operating tempera-

ture is obtained. (5) With the engine at normal operating tempera-

ture, connect the DRBII scan tool to the data link

connector (diagnostic connector). Access the State Dis-

play screen. Refer to the appropriate Powertrain Diag-

nostics Procedures Manual. If not using the DRBII

scan tool, disconnect the coolant temperature

sensor electrical connector. The electric radiator

fan will operate and the malfunction indicator lamp

(instrument panel Check Engine light) will turn on

after disconnecting the coolant sensor or starting the

DRBII scan tool procedure. (6) Aim Timing Light at timing scale (Fig. 7 or Fig.

8) or read magnetic timing unit. If flash occurs when

timing mark is before specified degree mark, timing is

advanced. To adjust, turn distributor housing in direc-

tion of rotor rotation. If flash occurs when timing mark is after specified

degree mark, timing is retarded. To adjust, turn dis-

tributor housing against direction of rotor rotation.

Refer to Vehicle Emission Control Information label for

correct timing specification. If timing is within 62É of

value specified on the label, proceed to step (8). If

outside specified tolerance, proceed to next step. (7) Loosen distributor hold-down arm screw

enough to rotate the distributor housing (Fig. 9 or

Fig. 6 Setting Spark Plug GapÐTypical

8D - 16 IGNITION SYSTEMS Ä

Page 483 of 2438

(2) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Cracked, leaking or faulty cables should

be replaced. Use the following procedure when removing the

high tension cable from the spark plug. First, remove

the cable from the retaining bracket. Then grasp the

terminal as close as possible to the spark plug. Ro-

tate the cover (boot) slightly and pull straight back.

Do not use pliers and do not pull the cable at an

angle. Doing so will damage the insulation, cable

terminal or the spark plug insulator. Wipe spark

plug insulator clean before reinstalling cable

and cover. Resistance cables are identified by the words Elec-

tronic Suppression .

Use an ohmmeter to check cables for opens, loose

terminals or high resistance. (a) Remove cable from spark plug.

(b) Remove cable from the coil tower.

(c) Connect the ohmmeter between spark plug

end terminal and the coil end terminal. Resistance

should be within tolerance shown in the cable re-

sistance chart. If resistance is not within tolerance,

replace cable assembly. Test all spark plug cables

in same manner.

SPARK PLUG SERVICE

When replacing the spark plug cables, route the ca-

bles correctly and secure them in the appropriate re-

tainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross ig-

nition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a

steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

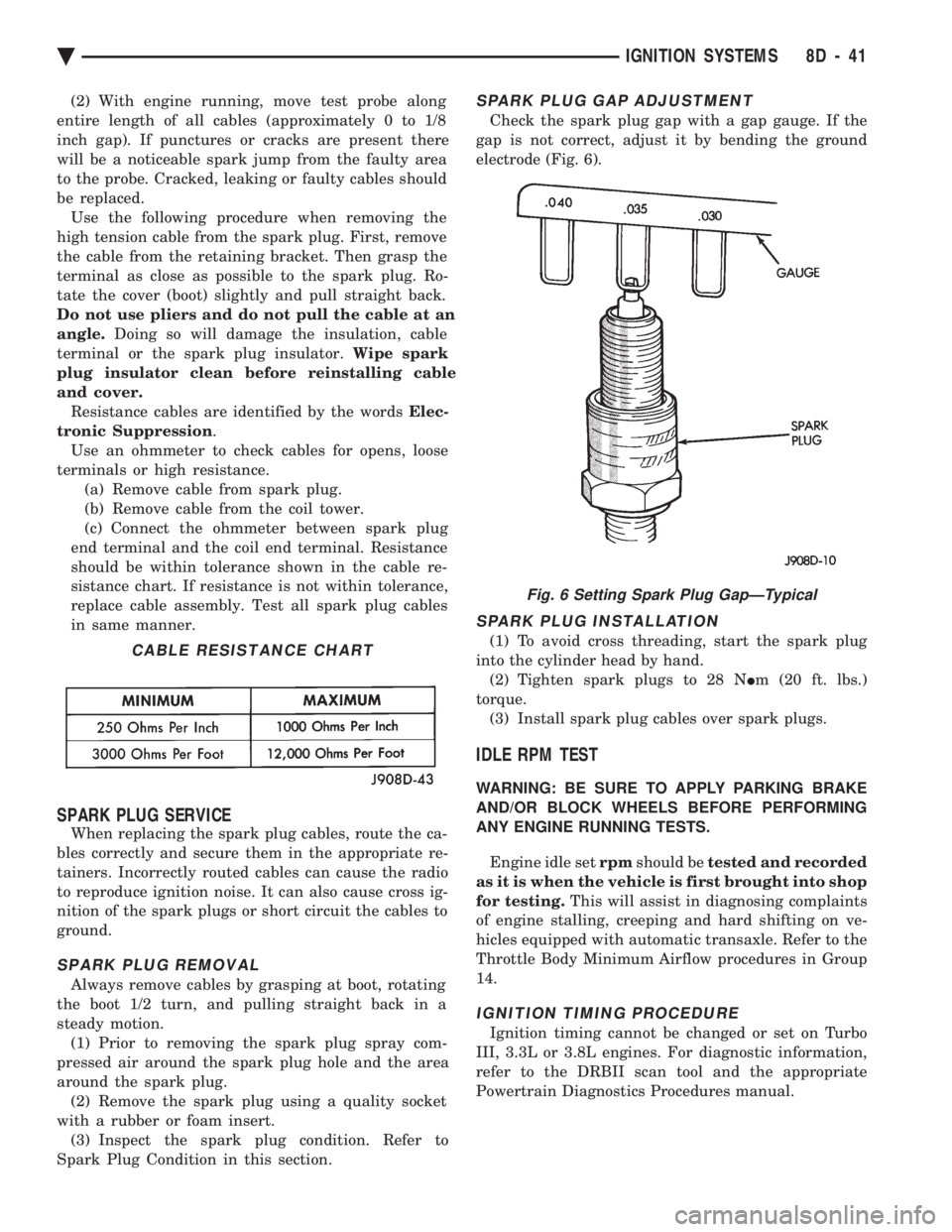

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TEST

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY ENGINE RUNNING TESTS.

Engine idle set rpmshould be tested and recorded

as it is when the vehicle is first brought into shop

for testing. This will assist in diagnosing complaints

of engine stalling, creeping and hard shifting on ve-

hicles equipped with automatic transaxle. Refer to the

Throttle Body Minimum Airflow procedures in Group

14.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on Turbo

III, 3.3L or 3.8L engines. For diagnostic information,

refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

CABLE RESISTANCE CHART

Fig. 6 Setting Spark Plug GapÐTypical

Ä IGNITION SYSTEMS 8D - 41

Page 494 of 2438

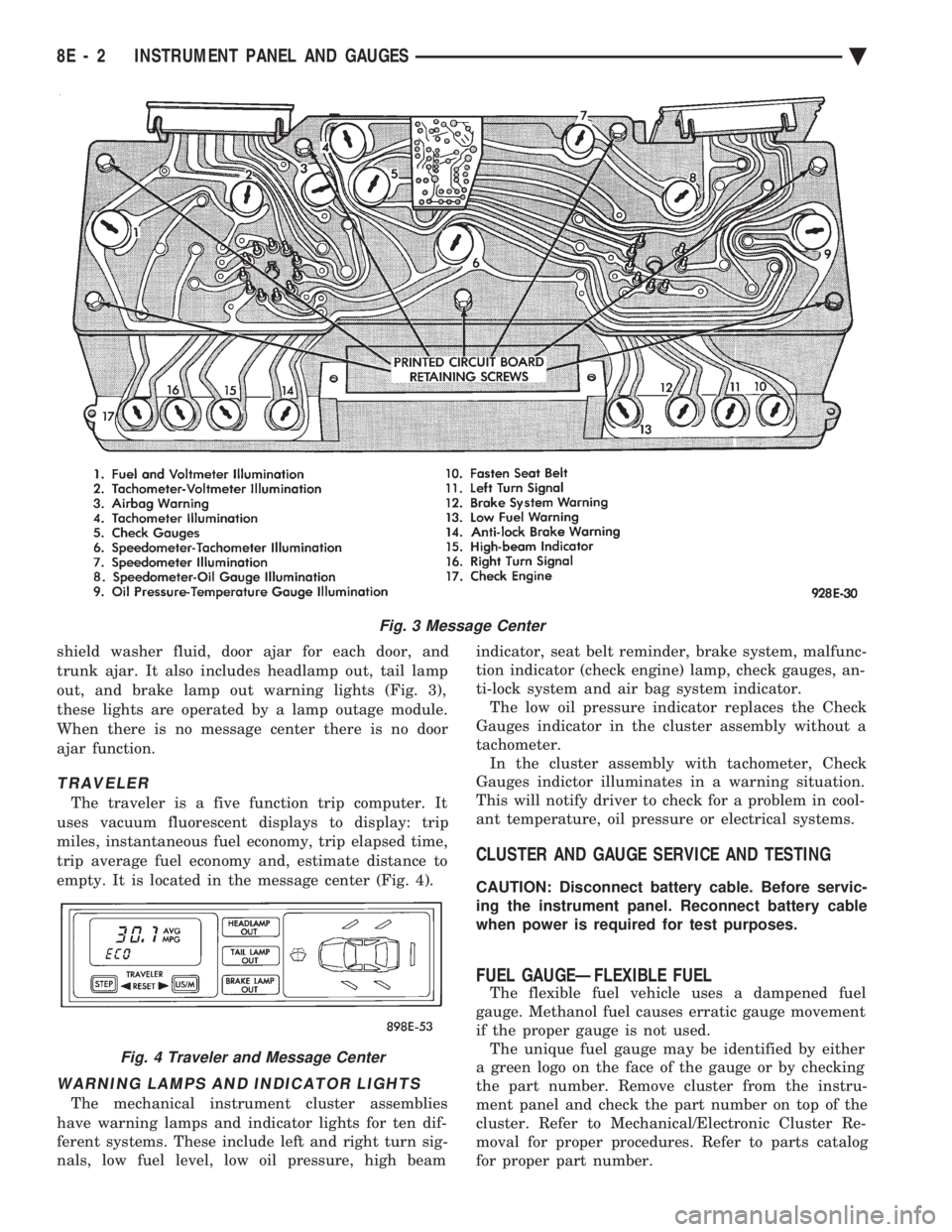

shield washer fluid, door ajar for each door, and

trunk ajar. It also includes headlamp out, tail lamp

out, and brake lamp out warning lights (Fig. 3),

these lights are operated by a lamp outage module.

When there is no message center there is no door

ajar function.

TRAVELER

The traveler is a five function trip computer. It

uses vacuum fluorescent displays to display: trip

miles, instantaneous fuel economy, trip elapsed time,

trip average fuel economy and, estimate distance to

empty. It is located in the message center (Fig. 4).

WARNING LAMPS AND INDICATOR LIGHTS

The mechanical instrument cluster assemblies

have warning lamps and indicator lights for ten dif-

ferent systems. These include left and right turn sig-

nals, low fuel level, low oil pressure, high beam indicator, seat belt reminder, brake system, malfunc-

tion indicator (check engine) lamp, check gauges, an-

ti-lock system and air bag system indicator. The low oil pressure indicator replaces the Check

Gauges indicator in the cluster assembly without a

tachometer. In the cluster assembly with tachometer, Check

Gauges indictor illuminates in a warning situation.

This will notify driver to check for a problem in cool-

ant temperature, oil pressure or electrical systems.

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect battery cable. Before servic-

ing the instrument panel. Reconnect battery cable

when power is required for test purposes.

FUEL GAUGEÐFLEXIBLE FUEL

The flexible fuel vehicle uses a dampened fuel

gauge. Methanol fuel causes erratic gauge movement

if the proper gauge is not used. The unique fuel gauge may be identified by either

a green logo on the face of the gauge or by checking

the part number. Remove cluster from the instru-

ment panel and check the part number on top of the

cluster. Refer to Mechanical/Electronic Cluster Re-

moval for proper procedures. Refer to parts catalog

for proper part number.

Fig. 3 Message Center

Fig. 4 Traveler and Message Center

8E - 2 INSTRUMENT PANEL AND GAUGES Ä

Page 495 of 2438

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

LOW OIL PRESSURE/CHECK GAUGES WARNING LAMP TEST

The low oil pressure/check gauges warning lamp

will illuminate when the ignition key is turned to

the ON position without starting the vehicle. In the cluster assembly without tachometer, the

low oil pressure lamp will illuminate if the engine oil

pressure drops below a safe oil pressure level. In the cluster assembly with tachometer, the Check

Gauges warning lamp illuminates when there is a

problem in oil pressure level, high engine tempera-

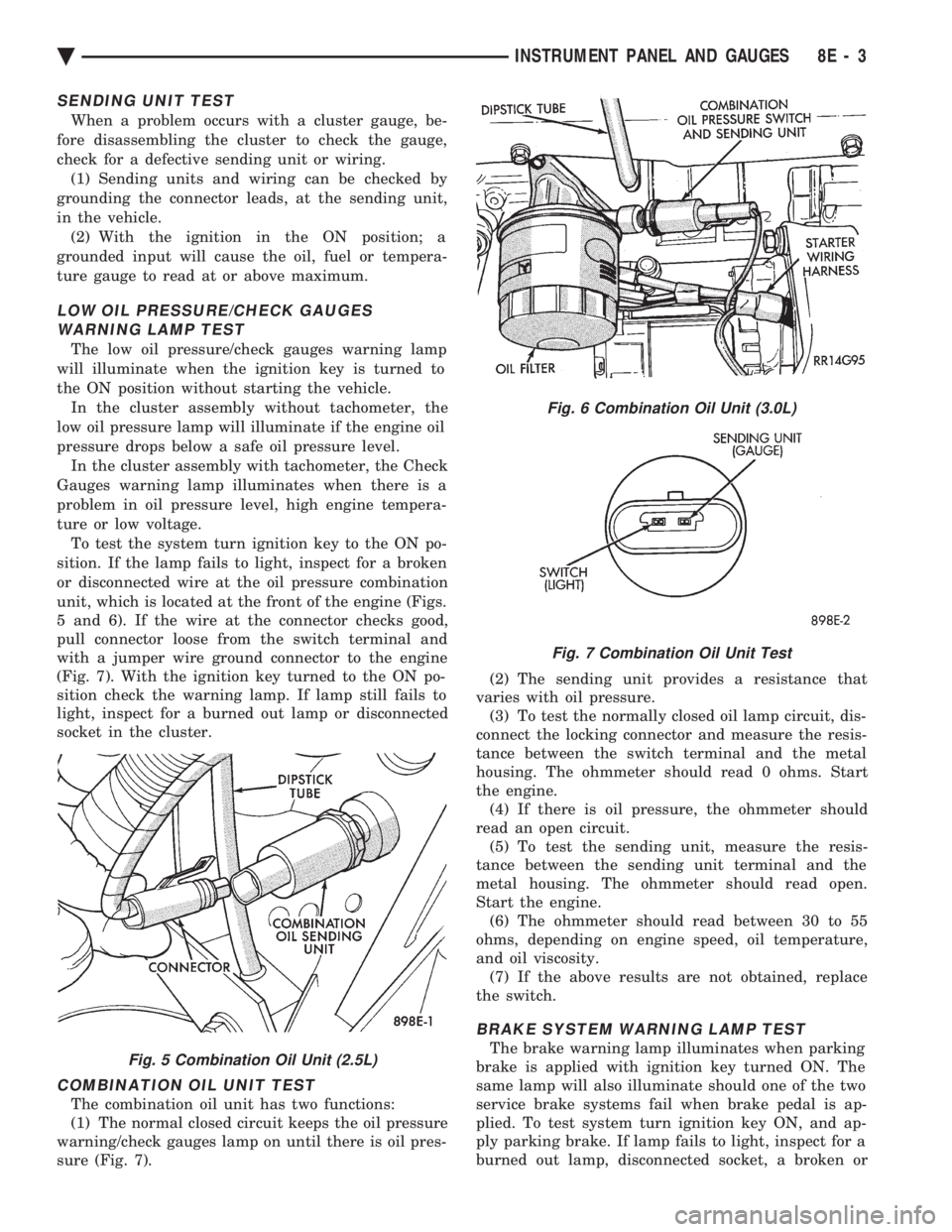

ture or low voltage. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

unit, which is located at the front of the engine (Figs.

5 and 6). If the wire at the connector checks good,

pull connector loose from the switch terminal and

with a jumper wire ground connector to the engine

(Fig. 7). With the ignition key turned to the ON po-

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out lamp or disconnected

socket in the cluster.

COMBINATION OIL UNIT TEST

The combination oil unit has two functions:

(1) The normal closed circuit keeps the oil pressure

warning/check gauges lamp on until there is oil pres-

sure (Fig. 7). (2) The sending unit provides a resistance that

varies with oil pressure. (3) To test the normally closed oil lamp circuit, dis-

connect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine. (4) If there is oil pressure, the ohmmeter should

read an open circuit. (5) To test the sending unit, measure the resis-

tance between the sending unit terminal and the

metal housing. The ohmmeter should read open.

Start the engine. (6) The ohmmeter should read between 30 to 55

ohms, depending on engine speed, oil temperature,

and oil viscosity. (7) If the above results are not obtained, replace

the switch.

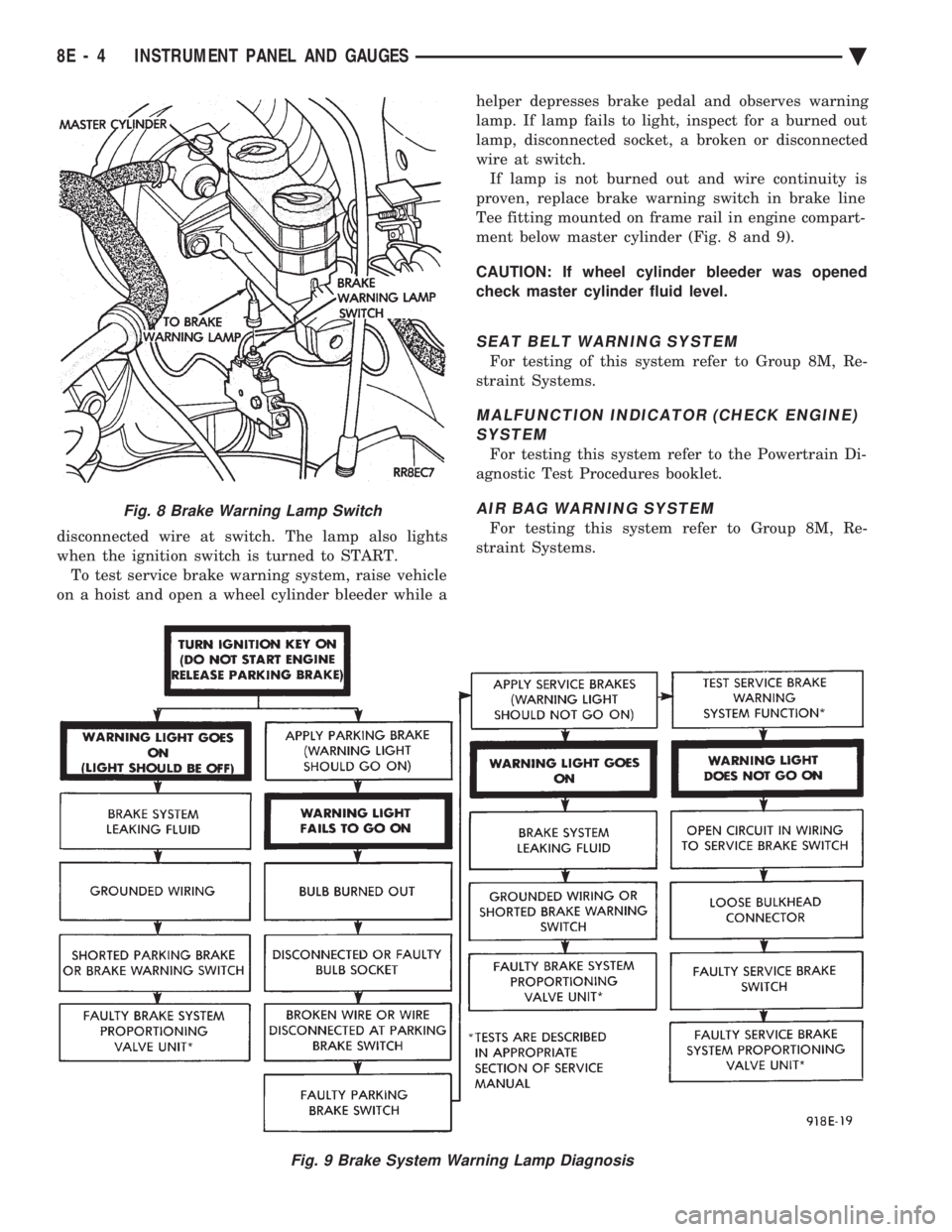

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken orFig. 5 Combination Oil Unit (2.5L)

Fig. 6 Combination Oil Unit (3.0L)

Fig. 7 Combination Oil Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 3

Page 496 of 2438

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START.To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 8 and 9).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing this system refer to the Powertrain Di-

agnostic Test Procedures booklet.

AIR BAG WARNING SYSTEM

For testing this system refer to Group 8M, Re-

straint Systems.

Fig. 8 Brake Warning Lamp Switch

Fig. 9 Brake System Warning Lamp Diagnosis

8E - 4 INSTRUMENT PANEL AND GAUGES Ä

Page 516 of 2438

MESSAGE CENTER

The message center is a car graphic warning lamp

module. This conventional warning system and lo-

cated above the headlamp switch.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's Manual supplied with the

vehicle.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MECHANICAL CLUSTER AND GAUGE SERVICE

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for the test only.

Disconnect negative battery cable after test and be-

fore continuing service procedures.

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

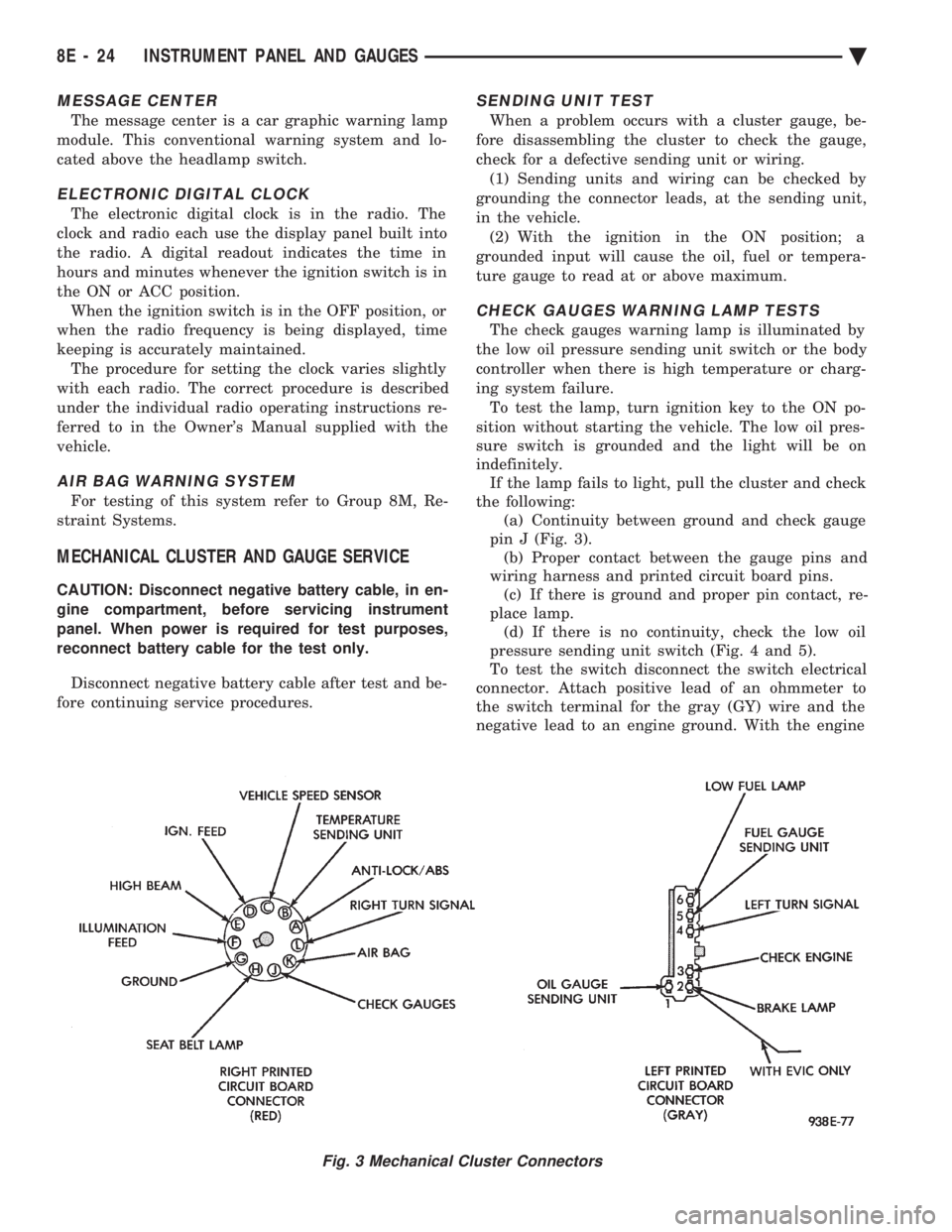

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp is illuminated by

the low oil pressure sending unit switch or the body

controller when there is high temperature or charg-

ing system failure. To test the lamp, turn ignition key to the ON po-

sition without starting the vehicle. The low oil pres-

sure switch is grounded and the light will be on

indefinitely. If the lamp fails to light, pull the cluster and check

the following: (a) Continuity between ground and check gauge

pin J (Fig. 3). (b) Proper contact between the gauge pins and

wiring harness and printed circuit board pins. (c) If there is ground and proper pin contact, re-

place lamp. (d) If there is no continuity, check the low oil

pressure sending unit switch (Fig. 4 and 5).

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

Fig. 3 Mechanical Cluster Connectors

8E - 24 INSTRUMENT PANEL AND GAUGES Ä

Page 517 of 2438

off, there should be continuity in the system. Start

the engine. With the engine running, the ohmmeter

should show no continuity. If the above results are

not obtained, replace the switch.

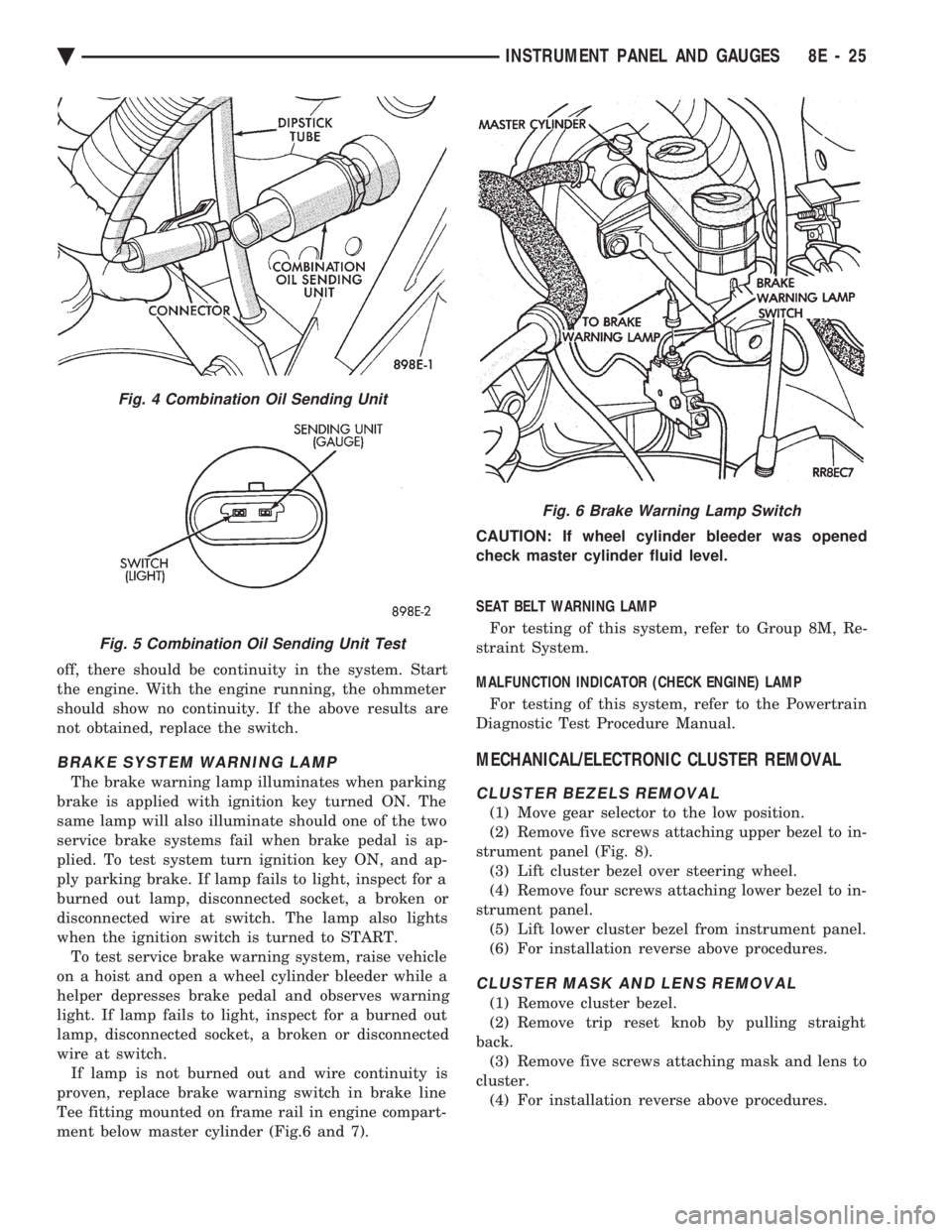

BRAKE SYSTEM WARNING LAMP

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

light. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig.6 and 7). CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SEAT BELT WARNING LAMP

For testing of this system, refer to Group 8M, Re-

straint System.

MALFUNCTION INDICATOR (CHECK ENGINE) LAMP

For testing of this system, refer to the Powertrain

Diagnostic Test Procedure Manual.

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

CLUSTER BEZELS REMOVAL

(1) Move gear selector to the low position.

(2) Remove five screws attaching upper bezel to in-

strument panel (Fig. 8). (3) Lift cluster bezel over steering wheel.

(4) Remove four screws attaching lower bezel to in-

strument panel. (5) Lift lower cluster bezel from instrument panel.

(6) For installation reverse above procedures.

CLUSTER MASK AND LENS REMOVAL

(1) Remove cluster bezel.

(2) Remove trip reset knob by pulling straight

back. (3) Remove five screws attaching mask and lens to

cluster. (4) For installation reverse above procedures.

Fig. 4 Combination Oil Sending Unit

Fig. 5 Combination Oil Sending Unit Test

Fig. 6 Brake Warning Lamp Switch

Ä INSTRUMENT PANEL AND GAUGES 8E - 25