warning light CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1284 of 2438

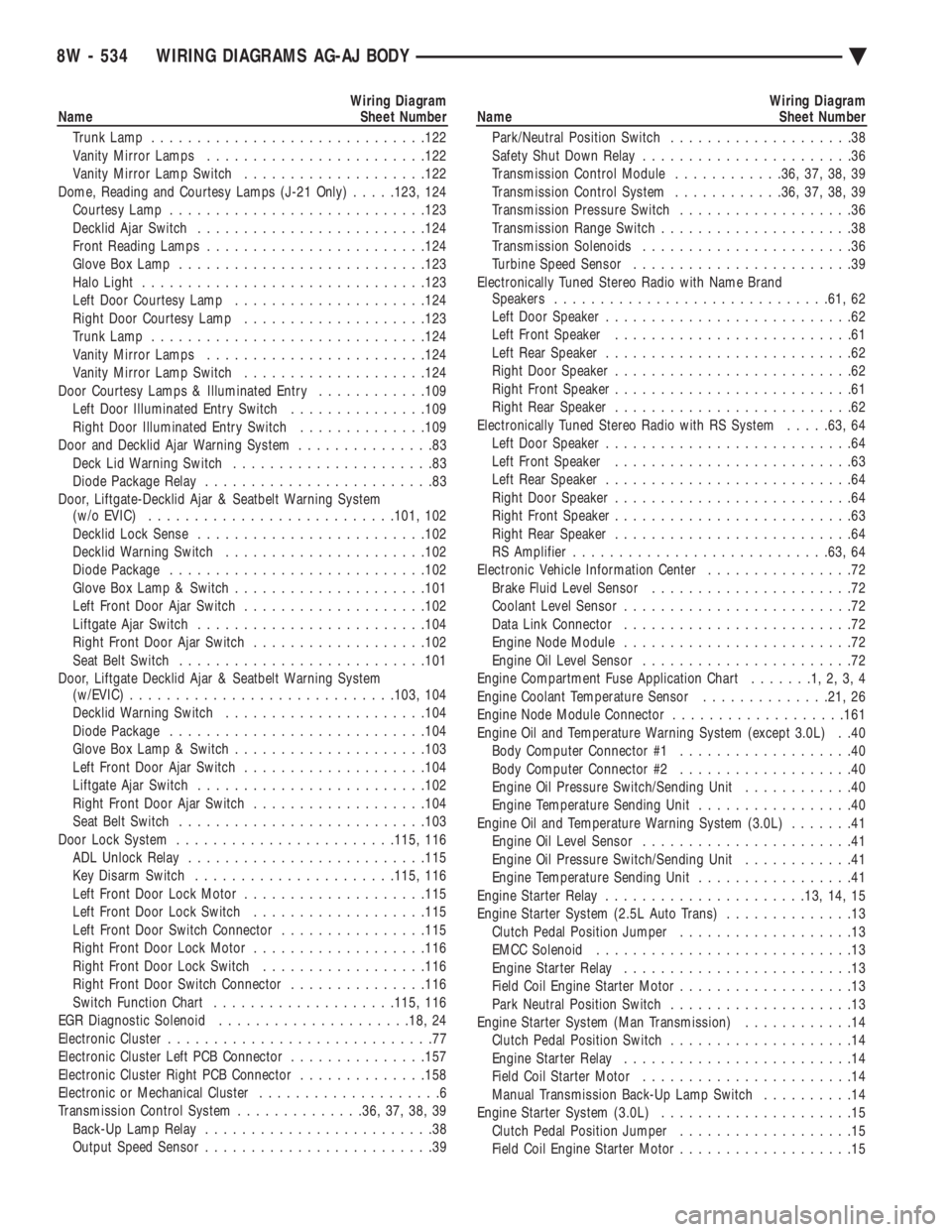

Wiring Diagram

Name Sheet Number

Trunk Lamp ............................. .122

Vanity Mirror Lamps ....................... .122

Vanity Mirror Lamp Switch ................... .122

Dome, Reading and Courtesy Lamps (J-21 Only) .....123, 124

Courtesy Lamp ........................... .123

Decklid Ajar Switch ........................ .124

Front Reading Lamps ....................... .124

Glove Box Lamp .......................... .123

Halo Light .............................. .123

Left Door Courtesy Lamp .................... .124

Right Door Courtesy Lamp ................... .123

Trunk Lamp ............................. .124

Vanity Mirror Lamps ....................... .124

Vanity Mirror Lamp Switch ................... .124

Door Courtesy Lamps & Illuminated Entry ............109

Left Door Illuminated Entry Switch ...............109

Right Door Illuminated Entry Switch ..............109

Door and Decklid Ajar Warning System ...............83

Deck Lid Warning Switch ......................83

Diode Package Relay .........................83

Door, Liftgate-Decklid Ajar & Seatbelt Warning System (w/o EVIC) .......................... .101, 102

Decklid Lock Sense ........................ .102

Decklid Warning Switch ..................... .102

Diode Package ........................... .102

Glove Box Lamp & Switch .................... .101

Left Front Door Ajar Switch ................... .102

Liftgate Ajar Switch ........................ .104

Right Front Door Ajar Switch ...................102

Seat Belt Switch .......................... .101

Door, Liftgate Decklid Ajar & Seatbelt Warning System (w/EVIC) ............................ .103, 104

Decklid Warning Switch ..................... .104

Diode Package ........................... .104

Glove Box Lamp & Switch .................... .103

Left Front Door Ajar Switch ................... .104

Liftgate Ajar Switch ........................ .102

Right Front Door Ajar Switch ...................104

Seat Belt Switch .......................... .103

Door Lock System ....................... .115, 116

ADL Unlock Relay ......................... .115

Key Disarm Switch ..................... .115, 116

Left Front Door Lock Motor ................... .115

Left Front Door Lock Switch ...................115

Left Front Door Switch Connector ................115

Right Front Door Lock Motor ...................116

Right Front Door Lock Switch ..................116

Right Front Door Switch Connector ...............116

Switch Function Chart ................... .115, 116

EGR Diagnostic Solenoid .................... .18, 24

Electronic Cluster .............................77

Electronic Cluster Left PCB Connector ...............157

Electronic Cluster Right PCB Connector ..............158

Electronic or Mechanical Cluster ....................6

Transmission Control System ..............36, 37, 38, 39

Back-Up Lamp Relay .........................38

Output Speed Sensor .........................39Wiring Diagram

Name Sheet Number

Park/Neutral Position Switch ....................38

Safety Shut Down Relay .......................36

Transmission Control Module ............36, 37, 38, 39

Transmission Control System ............36, 37, 38, 39

Transmission Pressure Switch ...................36

Transmission Range Switch .....................38

Transmission Solenoids .......................36

Turbine Speed Sensor ........................39

Electronically Tuned Stereo Radio with Name Brand Speakers ............................. .61, 62

Left Door Speaker ...........................62

Left Front Speaker ..........................61

Left Rear Speaker ...........................62

Right Door Speaker ..........................62

Right Front Speaker ..........................61

Right Rear Speaker ..........................62

Electronically Tuned Stereo Radio with RS System .....63, 64

Left Door Speaker ...........................64

Left Front Speaker ..........................63

Left Rear Speaker ...........................64

Right Door Speaker ..........................64

Right Front Speaker ..........................63

Right Rear Speaker ..........................64

RS Amplifier ........................... .63, 64

Electronic Vehicle Information Center ................72

Brake Fluid Level Sensor ......................72

Coolant Level Sensor .........................72

Data Link Connector .........................72

Engine Node Module .........................72

Engine Oil Level Sensor .......................72

Engine Compartment Fuse Application Chart .......1,2,3,4

Engine Coolant Temperature Sensor ..............21, 26

Engine Node Module Connector ...................161

Engine Oil and Temperature Warning System (except 3.0L) . .40 Body Computer Connector #1 ...................40

Body Computer Connector #2 ...................40

Engine Oil Pressure Switch/Sending Unit ............40

Engine Temperature Sending Unit .................40

Engine Oil and Temperature Warning System (3.0L) .......41

Engine Oil Level Sensor .......................41

Engine Oil Pressure Switch/Sending Unit ............41

Engine Temperature Sending Unit .................41

Engine Starter Relay ..................... .13, 14, 15

Engine Starter System (2.5L Auto Trans) ..............13

Clutch Pedal Position Jumper ...................13

EMCC Solenoid ............................13

Engine Starter Relay .........................13

Field Coil Engine Starter Motor ...................13

Park Neutral Position Switch ....................13

Engine Starter System (Man Transmission) ............14

Clutch Pedal Position Switch ....................14

Engine Starter Relay .........................14

Field Coil Starter Motor .......................14

Manual Transmission Back-Up Lamp Switch ..........14

Engine Starter System (3.0L) .....................15

Clutch Pedal Position Jumper ...................15

Field Coil Engine Starter Motor ...................15

8W - 534 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1467 of 2438

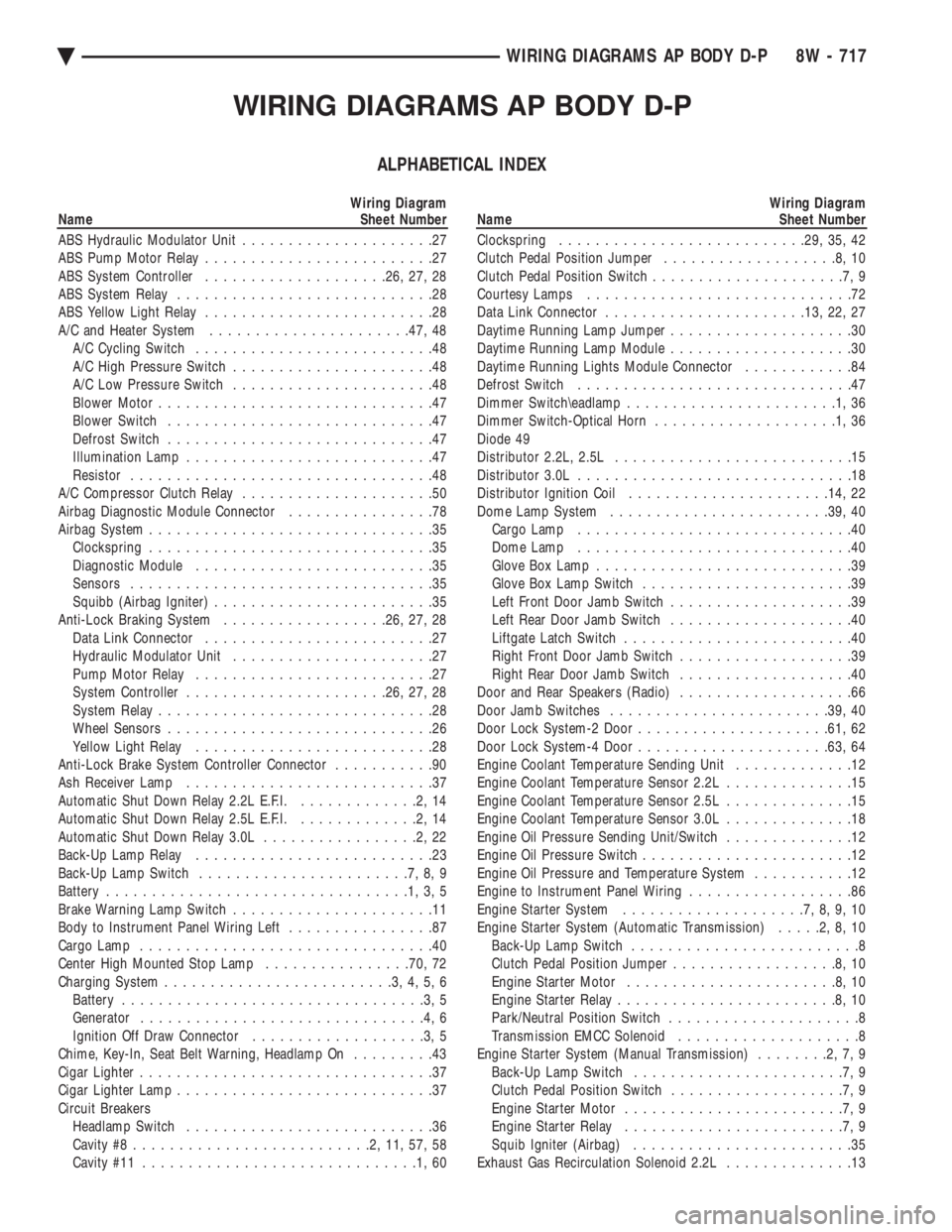

WIRING DIAGRAMS AP BODY D-P

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

ABS Hydraulic Modulator Unit .....................27

ABS Pump Motor Relay .........................27

ABS System Controller ................... .26, 27, 28

ABS System Relay ............................28

ABS Yellow Light Relay .........................28

A/C and Heater System ..................... .47, 48

A/C Cycling Switch ..........................48

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Blower Motor ..............................47

Blower Switch .............................47

Defrost Switch .............................47

Illumination Lamp ...........................47

Resistor .................................48

A/C Compressor Clutch Relay .....................50

Airbag Diagnostic Module Connector ................78

Airbag System ...............................35

Clockspring ...............................35

Diagnostic Module ..........................35

Sensors .................................35

Squibb (Airbag Igniter) ........................35

Anti-Lock Braking System ..................26, 27, 28

Data Link Connector .........................27

Hydraulic Modulator Unit ......................27

Pump Motor Relay ..........................27

System Controller ..................... .26, 27, 28

System Relay ..............................28

Wheel Sensors .............................26

Yellow Light Relay ..........................28

Anti-Lock Brake System Controller Connector ...........90

Ash Receiver Lamp ...........................37

Automatic Shut Down Relay 2.2L E.F.I. .............2,14

Automatic Shut Down Relay 2.5L E.F.I. .............2,14

Automatic Shut Down Relay 3.0L .................2,22

Back-Up Lamp Relay ..........................23

Back-Up Lamp Switch .......................7,8,9

Battery .................................1,3,5

Brake Warning Lamp Switch ......................11

Body to Instrument Panel Wiring Left ................87

Cargo Lamp ................................40

Center High Mounted Stop Lamp ................70, 72

Charging System .........................3,4,5,6

Battery .................................3,5

Generator ...............................4,6

Ignition Off Draw Connector ...................3,5

Chime, Key-In, Seat Belt Warning, Headlamp On .........43

Cigar Lighter ................................37

Cigar Lighter Lamp ............................37

Circuit Breakers Headlamp Switch ...........................36

Cavity #8 ..........................2,11,57,58

Cavity #11 ..............................1,60Wiring Diagram

Name Sheet Number

Clockspring .......................... .29, 35, 42

Clutch Pedal Position Jumper ...................8,10

Clutch Pedal Position Switch .....................7,9

Courtesy Lamps .............................72

Data Link Connector ..................... .13, 22, 27

Daytime Running Lamp Jumper ....................30

Daytime Running Lamp Module ....................30

Daytime Running Lights Module Connector ............84

Defrost Switch ..............................47

Dimmer Switch\eadlamp .......................1,36

Dimmer Switch-Optical Horn ....................1,36

Diode 49

Distributor 2.2L, 2.5L ..........................15

Distributor 3.0L ..............................18

Distributor Ignition Coil ..................... .14, 22

Dome Lamp System ....................... .39, 40

Cargo Lamp ..............................40

Dome Lamp ..............................40

Glove Box Lamp ............................39

Glove Box Lamp Switch .......................39

Left Front Door Jamb Switch ....................39

Left Rear Door Jamb Switch ....................40

Liftgate Latch Switch .........................40

Right Front Door Jamb Switch ...................39

Right Rear Door Jamb Switch ...................40

Door and Rear Speakers (Radio) ...................66

Door Jamb Switches ....................... .39, 40

Door Lock System-2 Door .................... .61, 62

Door Lock System-4 Door .................... .63, 64

Engine Coolant Temperature Sending Unit .............12

Engine Coolant Temperature Sensor 2.2L ..............15

Engine Coolant Temperature Sensor 2.5L ..............15

Engine Coolant Temperature Sensor 3.0L ..............18

Engine Oil Pressure Sending Unit/Switch ..............12

Engine Oil Pressure Switch .......................12

Engine Oil Pressure and Temperature System ...........12

Engine to Instrument Panel Wiring ..................86

Engine Starter System ....................7,8,9,10

Engine Starter System (Automatic Transmission) .....2,8,10

Back-Up Lamp Switch .........................8

Clutch Pedal Position Jumper ..................8,10

Engine Starter Motor .......................8,10

Engine Starter Relay ........................8,10

Park/Neutral Position Switch .....................8

Transmission EMCC Solenoid ....................8

Engine Starter System (Manual Transmission) ........2,7,9

Back-Up Lamp Switch .......................7,9

Clutch Pedal Position Switch ...................7,9

Engine Starter Motor ........................7,9

Engine Starter Relay ........................7,9

Squib Igniter (Airbag) ........................35

Exhaust Gas Recirculation Solenoid 2.2L ..............13

Ä WIRING DIAGRAMS AP BODY D-P 8W - 717

Page 1469 of 2438

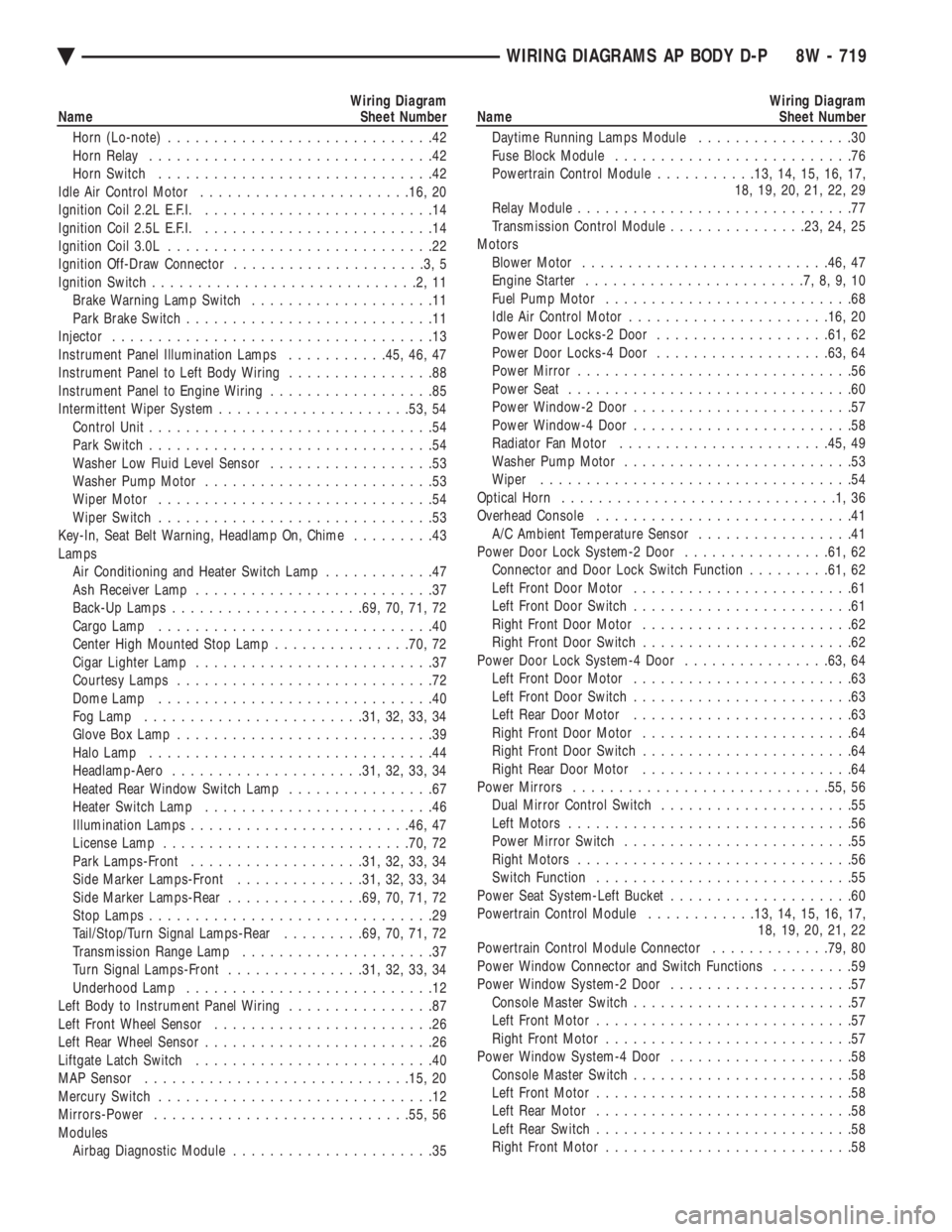

Wiring Diagram

Name Sheet Number

Horn (Lo-note) .............................42

Horn Relay ...............................42

Horn Switch ..............................42

Idle Air Control Motor ...................... .16, 20

Ignition Coil 2.2L E.F.I. .........................14

Ignition Coil 2.5L E.F.I. .........................14

Ignition Coil 3.0L .............................22

Ignition Off-Draw Connector .....................3,5

Ignition Switch .............................2,11

Brake Warning Lamp Switch ....................11

Park Brake Switch ...........................11

Injector ...................................13

Instrument Panel Illumination Lamps ...........45, 46, 47

Instrument Panel to Left Body Wiring ................88

Instrument Panel to Engine Wiring ..................85

Intermittent Wiper System .................... .53, 54

Control Unit ...............................54

Park Switch ...............................54

Washer Low Fluid Level Sensor ..................53

Washer Pump Motor .........................53

Wiper Motor ..............................54

Wiper Switch ..............................53

Key-In, Seat Belt Warning, Headlamp On, Chime .........43

Lamps Air Conditioning and Heater Switch Lamp ............47

Ash Receiver Lamp ..........................37

Back-Up Lamps .................... .69, 70, 71, 72

Cargo Lamp ..............................40

Center High Mounted Stop Lamp ...............70, 72

Cigar Lighter Lamp ..........................37

Courtesy Lamps ............................72

Dome Lamp ..............................40

Fog Lamp ....................... .31, 32, 33, 34

Glove Box Lamp ............................39

Halo Lamp ...............................44

Headlamp-Aero .................... .31, 32, 33, 34

Heated Rear Window Switch Lamp ................67

Heater Switch Lamp .........................46

Illumination Lamps ....................... .46, 47

License Lamp .......................... .70, 72

Park Lamps-Front .................. .31, 32, 33, 34

Side Marker Lamps-Front ..............31, 32, 33, 34

Side Marker Lamps-Rear ...............69, 70, 71, 72

Stop Lamps ...............................29

Tail/Stop/Turn Signal Lamps-Rear .........69, 70, 71, 72

Transmission Range Lamp .....................37

Turn Signal Lamps-Front ...............31, 32, 33, 34

Underhood Lamp ...........................12

Left Body to Instrument Panel Wiring ................87

Left Front Wheel Sensor ........................26

Left Rear Wheel Sensor .........................26

Liftgate Latch Switch ..........................40

MAP Sensor ............................ .15, 20

Mercury Switch ..............................12

Mirrors-Power ........................... .55, 56

Modules Airbag Diagnostic Module ......................35Wiring Diagram

Name Sheet Number

Daytime Running Lamps Module .................30

Fuse Block Module ..........................76

Powertrain Control Module ...........13, 14, 15, 16, 17,

18, 19, 20, 21, 22, 29

Relay Module ..............................77

Transmission Control Module ...............23, 24, 25

Motors Blower Motor .......................... .46, 47

Engine Starter ........................7,8,9,10

Fuel Pump Motor ...........................68

Idle Air Control Motor ..................... .16, 20

Power Door Locks-2 Door .................. .61, 62

Power Door Locks-4 Door .................. .63, 64

Power Mirror ..............................56

Power Seat ...............................60

Power Window-2 Door ........................57

Power Window-4 Door ........................58

Radiator Fan Motor ...................... .45, 49

Washer Pump Motor .........................53

Wiper ..................................54

Optical Horn ..............................1,36

Overhead Console ............................41

A/C Ambient Temperature Sensor .................41

Power Door Lock System-2 Door ................61, 62

Connector and Door Lock Switch Function .........61, 62

Left Front Door Motor ........................61

Left Front Door Switch ........................61

Right Front Door Motor .......................62

Right Front Door Switch .......................62

Power Door Lock System-4 Door ................63, 64

Left Front Door Motor ........................63

Left Front Door Switch ........................63

Left Rear Door Motor ........................63

Right Front Door Motor .......................64

Right Front Door Switch .......................64

Right Rear Door Motor .......................64

Power Mirrors ........................... .55, 56

Dual Mirror Control Switch .....................55

Left Motors ...............................56

Power Mirror Switch .........................55

Right Motors ..............................56

Switch Function ............................55

Power Seat System-Left Bucket ....................60

Powertrain Control Module ............13, 14, 15, 16, 17,

18, 19, 20, 21, 22

Powertrain Control Module Connector .............79, 80

Power Window Connector and Switch Functions .........59

Power Window System-2 Door ....................57

Console Master Switch ........................57

Left Front Motor ............................57

Right Front Motor ...........................57

Power Window System-4 Door ....................58

Console Master Switch ........................58

Left Front Motor ............................58

Left Rear Motor ............................58

Left Rear Switch ............................58

Right Front Motor ...........................58

Ä WIRING DIAGRAMS AP BODY D-P 8W - 719

Page 1470 of 2438

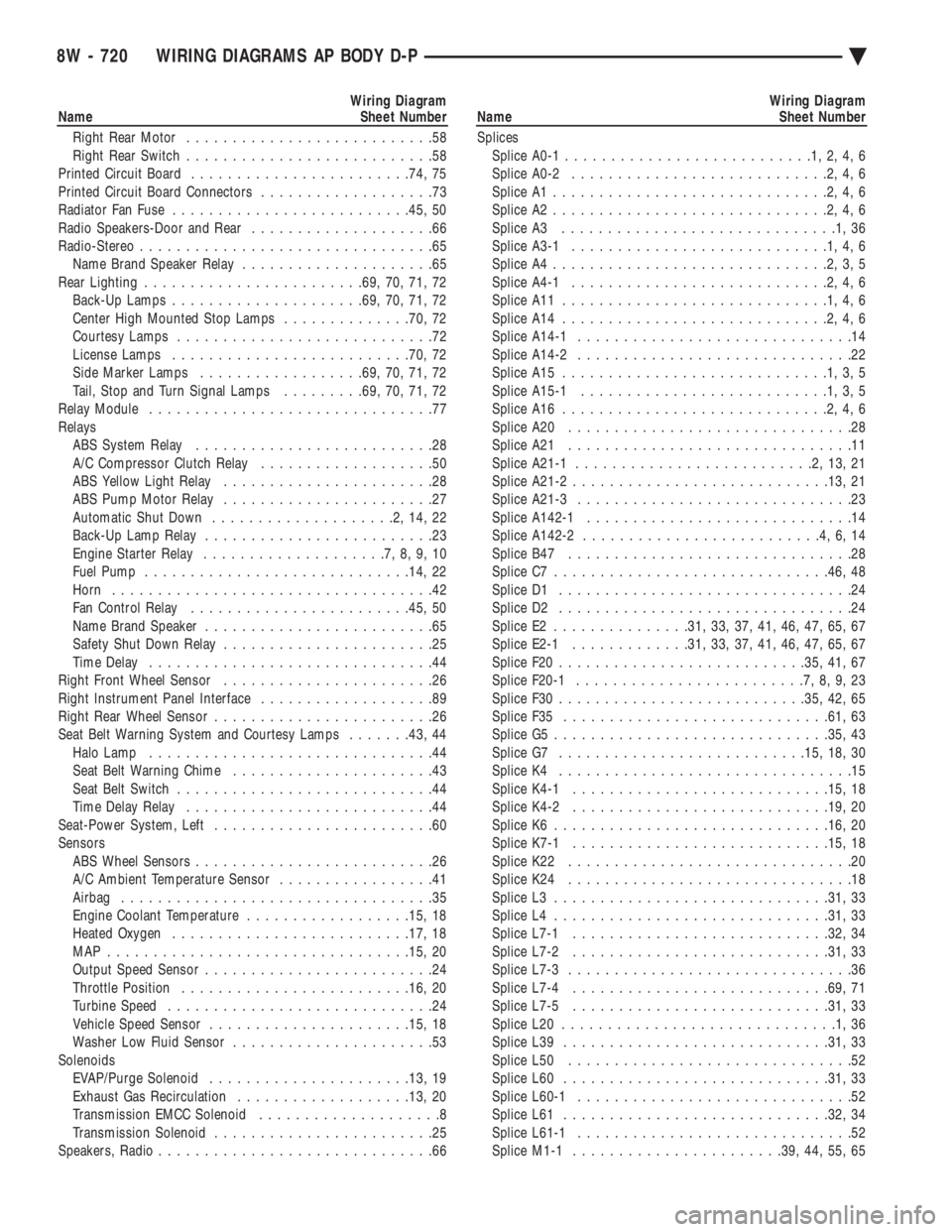

Wiring Diagram

Name Sheet Number

Right Rear Motor ...........................58

Right Rear Switch ...........................58

Printed Circuit Board ....................... .74, 75

Printed Circuit Board Connectors ...................73

Radiator Fan Fuse ......................... .45, 50

Radio Speakers-Door and Rear ....................66

Radio-Stereo ................................65

Name Brand Speaker Relay .....................65

Rear Lighting ....................... .69, 70, 71, 72

Back-Up Lamps .................... .69, 70, 71, 72

Center High Mounted Stop Lamps ..............70, 72

Courtesy Lamps ............................72

License Lamps ......................... .70, 72

Side Marker Lamps ................. .69, 70, 71, 72

Tail, Stop and Turn Signal Lamps .........69, 70, 71, 72

Relay Module ...............................77

Relays ABS System Relay ..........................28

A/C Compressor Clutch Relay ...................50

ABS Yellow Light Relay .......................28

ABS Pump Motor Relay .......................27

Automatic Shut Down ....................2,14,22

Back-Up Lamp Relay .........................23

Engine Starter Relay ....................7,8,9,10

Fuel Pump ............................ .14, 22

Horn ...................................42

Fan Control Relay ....................... .45, 50

Name Brand Speaker .........................65

Safety Shut Down Relay .......................25

Time Delay ...............................44

Right Front Wheel Sensor .......................26

Right Instrument Panel Interface ...................89

Right Rear Wheel Sensor ........................26

Seat Belt Warning System and Courtesy Lamps .......43, 44

Halo Lamp ...............................44

Seat Belt Warning Chime ......................43

Seat Belt Switch ............................44

Time Delay Relay ...........................44

Seat-Power System, Left ........................60

Sensors ABS Wheel Sensors ..........................26

A/C Ambient Temperature Sensor .................41

Airbag ..................................35

Engine Coolant Temperature ..................15, 18

Heated Oxygen ......................... .17, 18

MAP ................................ .15, 20

Output Speed Sensor .........................24

Throttle Position ........................ .16, 20

Turbine Speed .............................24

Vehicle Speed Sensor ..................... .15, 18

Washer Low Fluid Sensor ......................53

Solenoids EVAP/Purge Solenoid ..................... .13, 19

Exhaust Gas Recirculation .................. .13, 20

Transmission EMCC Solenoid ....................8

Transmission Solenoid ........................25

Speakers, Radio ..............................66Wiring Diagram

Name Sheet Number

Splices Splice A0-1 ...........................1,2,4,6

Splice A0-2 ............................2,4,6

Splice A1 ..............................2,4,6

Splice A2 ..............................2,4,6

Splice A3 ..............................1,36

Splice A3-1 ............................1,4,6

Splice A4 ..............................2,3,5

Splice A4-1 ............................2,4,6

Splice A11 .............................1,4,6

Splice A14 .............................2,4,6

Splice A14-1 ..............................14

Splice A14-2 ..............................22

Splice A15 .............................1,3,5

Splice A15-1 ...........................1,3,5

Splice A16 .............................2,4,6

Splice A20 ...............................28

Splice A21 ...............................11

Splice A21-1 ..........................2,13,21

Splice A21-2 ........................... .13, 21

Splice A21-3 ..............................23

Splice A142-1 .............................14

Splice A142-2 ..........................4,6,14

Splice B47 ...............................28

Splice C7 ............................. .46, 48

Splice D1 ................................24

Splice D2 ................................24

Splice E2 .............. .31, 33, 37, 41, 46, 47, 65, 67

Splice E2-1 ............ .31, 33, 37, 41, 46, 47, 65, 67

Splice F20 .......................... .35, 41, 67

Splice F20-1 .........................7,8,9,23

Splice F30 .......................... .35, 42, 65

Splice F35 ............................ .61, 63

Splice G5 ............................. .35, 43

Splice G7 .......................... .15, 18, 30

Splice K4 ................................15

Splice K4-1 ........................... .15, 18

Splice K4-2 ........................... .19, 20

Splice K6 ............................. .16, 20

Splice K7-1 ........................... .15, 18

Splice K22 ...............................20

Splice K24 ...............................18

Splice L3 ............................. .31, 33

Splice L4 ............................. .31, 33

Splice L7-1 ........................... .32, 34

Splice L7-2 ........................... .31, 33

Splice L7-3 ...............................36

Splice L7-4 ........................... .69, 71

Splice L7-5 ........................... .31, 33

Splice L20 ..............................1,36

Splice L39 ............................ .31, 33

Splice L50 ...............................52

Splice L60 ............................ .31, 33

Splice L60-1 ..............................52

Splice L61 ............................ .32, 34

Splice L61-1 ..............................52

Splice M1-1 ...................... .39, 44, 55, 65

8W - 720 WIRING DIAGRAMS AP BODY D-P Ä

Page 1618 of 2438

PISTON PINS

DISASSEMBLY Turbo III engine piston-pin-connecting rod assem-

blies should not be disassembled unless a malfunc-

tion is present or a damaged assembly component is

to be replaced. WARNING: APPROVED SAFETY GLASSES

MUST BE WORN DURING PISTON LOCK

RING REMOVAL OR INSTALLATION TO PRE-

VENT POSSIBLE INJURY FROM FLYING

PARTS.

(1) Carefully, remove piston pin lock rings from

piston, using a small screwdriver in removal notch

(Fig. 10). (2) Discard used lock ring.

(3) Following lock ring removal, attempt to slide

pin out of piston. If pin does not slide out freely by

hand;

² Check for burr on outer edge of lock ring groove. If

one is present, carefully scrape burr away with a

knife or other hand tool, being careful not to damage

lock ring retaining groove. (4) Slide out piston pin to complete disassembly.

(5) Inspect components, discard damaged or exces-

sively worn parts refer to specifications (Fig. 12). If a

piston is replaced, a new pin should be used.

PISTON PINS

REASSEMBLY

(1) Different lock rings are used for turbocharged

engine applications. Consult the Service Note, pro- vided with the lock ring service package, to select

the correct lock rings from the package for your ap-

plication.

(2) Carefully, install one NEWlock ring with gap

towards piston top in lock ring groove. Do not rein-

stall used lock rings. (3) Position connecting rod and slide in lightly oil

piston pinch (4) Install second NEWlock ring with gap towards

piston top in lock ring groove, use small screwdriver

if needed.

CAUTION: BOTH lock rings must be FULLY

SEATED in lock ring grooves or engine failure will

occur.

(5) Check piston pin end play pin movement be-

tween lock rings in assembly.

PISTON RINGÐREMOVAL

(1) ID mark on face of upper and intermediate pis-

ton rings must point toward piston crown. (2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 13). (3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston. (4) Clean ring grooves of any carbon deposits.

Fig. 11 Engine Piston PinsÐTurbo III, Naturally Aspirated and Flexible Fuel Vehicles

Fig. 12 Piston Pin Specifications

Fig. 13 Piston RingsÐRemoving and Installing

9 - 52 2.2/2.5L ENGINE Ä

Page 1703 of 2438

CLEANING AND INSPECTION

(1) Discard gaskets and clean all gasket surfaces

on both manifolds and on cylinder head. (2) Test gasket surfaces of manifolds for flatness

with a straight edge. Surfaces must be flat within

0.15mm per 300mm (.006 in. per foot) of manifold

length. (3) Inspect manifolds for cracks and distortion.

INSTALLATION

(1) Install a new intake and exhaust manifold gas-

ket. Coat steel gasket lightly with Gasket Sealer on

manifold side. Do notcoat composition gasket with

(any) sealer. (2) Set exhaust manifold in place. Tighten retain-

ing nuts starting at center and progressing outward

in both directions to 23 N Im (200 in. lbs.) torque. Re-

peat this procedure until all nuts are at specified

torque. (3) Set intake manifold in place.

(4) Raise vehicle and tighten retaining screws

starting at center and progressing outward in both

directions to 23 N Im (200 in. lbs.) torque (Fig. 3). Re-

peat this procedure until all screws are at specified

torque. (5) Reverse removal procedures 1-9 for installation.

(6) With the DRBII Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is se-

lected.

INTAKE AND EXHAUST MANIFOLDSÐFLEXIBLE

FUEL ENGINE

INTAKE MANIFOLD

The manifold is die-cast aluminum with upper ple-

num and 4 tubes lower runners. These attach to the

cylinder head, with each runner leading directly to a

cylinder. The manifold is also machined for fuel rail attach-

ment and injector installation. The throttle body is

installed on the upper plenum of the manifold.

EXHAUST MANIFOLD

All high strength iron casting that intermesh with

the intake manifold. For standard engines a four

branch design collects and directs exhaust gases to

the conical (articulated joint connection) outlet.

INTAKE/EXHAUST MANIFOLDS

SERVICEÐFLEXIBLE FUEL ENGINES

Intake and exhaust manifolds use a one piece gas-

ket. Service procedures requiring removal and instal-

lation of either must include both manifolds.

SERVICE PRECAUTIONS

Methanol is more toxic than gasoline. Always re-

lease fuel system pressure before servicing fuel sys-

tem components and wear methanol resistant gloves

and eye protection. Avoid breathing methanol vapors or ingesting

methanol. Headaches, dizziness and even uncon-

sciousness could result from breathing these vapors.

Serious injury, blindness and even death could result

from ingesting methanol. Methanol vapors are extremely flammable and can

travel along the ground. Service vehicles in well ven-

tilated areas and avoid ignition sources. Never

smoke while servicing the vehicle. Do not allow methanol to contact skin. Prolonged

contact with methanol can cause dry skin or an al-

lergic skin reaction. Also, prolonged contact could re-

sult in absorption through the skin.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION WHILE SERVICING THE FUEL SYS-

TEM.

(a) Disconnect negative cable from battery.

(b) Remove fuel filler cap.

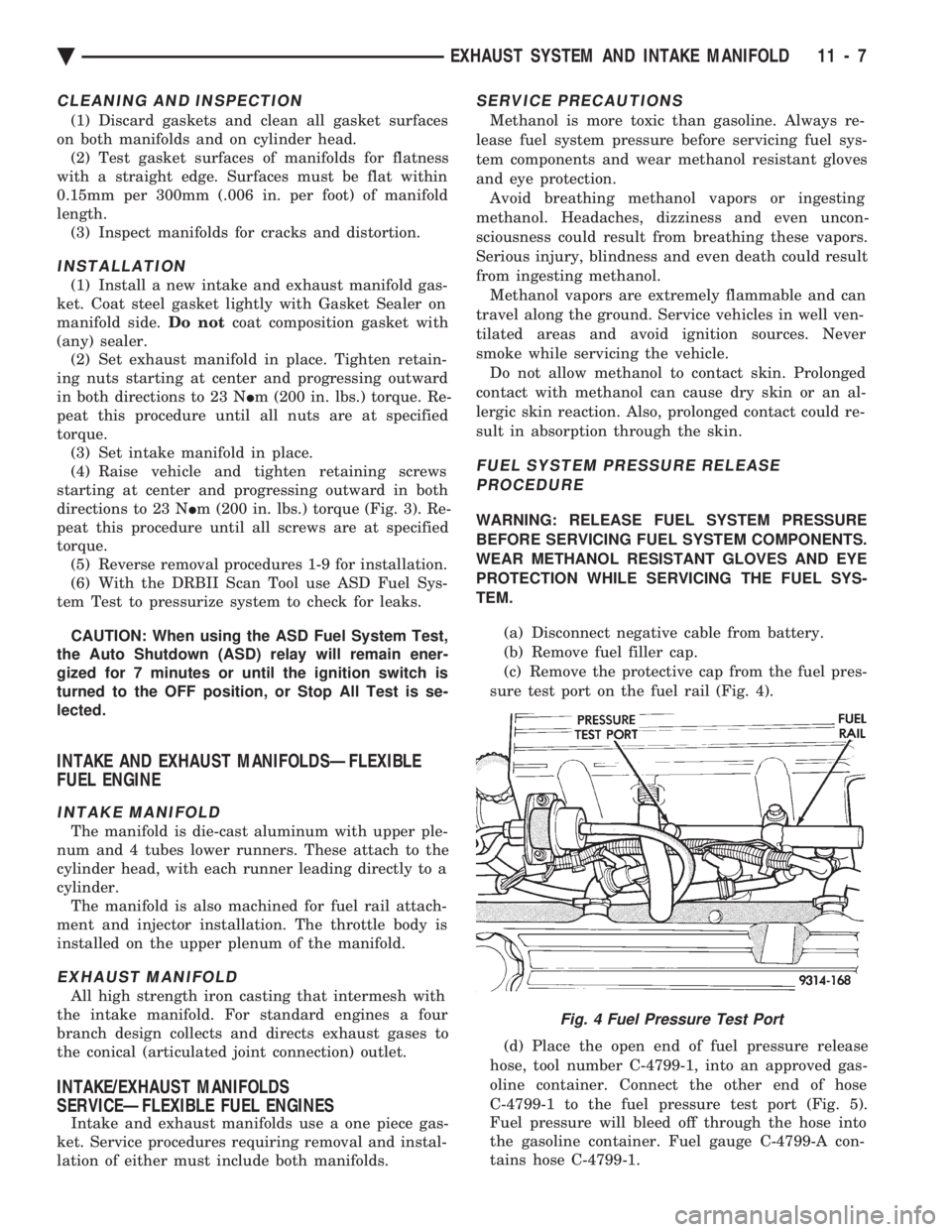

(c) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 4).

(d) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gas-

oline container. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 5).

Fuel pressure will bleed off through the hose into

the gasoline container. Fuel gauge C-4799-A con-

tains hose C-4799-1.

Fig. 4 Fuel Pressure Test Port

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 7

Page 1751 of 2438

fuel tube enters the fitting, the retainer locks the shoul-

der of the nipple in place and the O-rings seal the tube.

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

When installing fuel tubes, route them in the holders

along the frame rail, fuel tank and the rear of the en-

gine.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section. (3) Remove any loose dirt from quick connect fit-

tings.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE.

(4) Push the quick connect fitting toward the fuel

tube while depressing the built-in release tool. Then

slightly twist the fitting and pull it off the fuel tube

(Fig. 14). (5) Cover the fitting to prevent contamination.

TUBE/FITTING SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

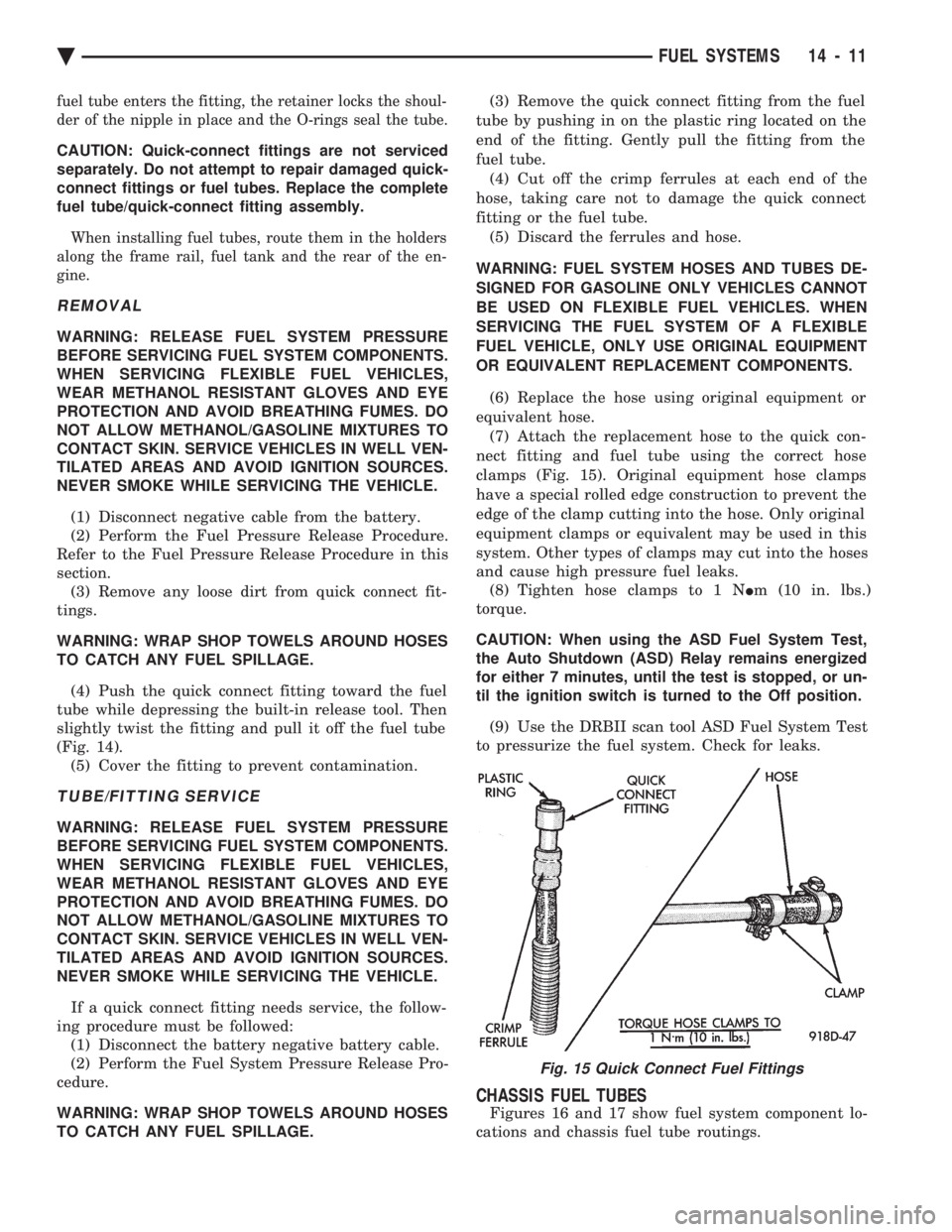

If a quick connect fitting needs service, the follow-

ing procedure must be followed: (1) Disconnect the battery negative battery cable.

(2) Perform the Fuel System Pressure Release Pro-

cedure.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE. (3) Remove the quick connect fitting from the fuel

tube by pushing in on the plastic ring located on the

end of the fitting. Gently pull the fitting from the

fuel tube. (4) Cut off the crimp ferrules at each end of the

hose, taking care not to damage the quick connect

fitting or the fuel tube. (5) Discard the ferrules and hose.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

(6) Replace the hose using original equipment or

equivalent hose. (7) Attach the replacement hose to the quick con-

nect fitting and fuel tube using the correct hose

clamps (Fig. 15). Original equipment hose clamps

have a special rolled edge construction to prevent the

edge of the clamp cutting into the hose. Only original

equipment clamps or equivalent may be used in this

system. Other types of clamps may cut into the hoses

and cause high pressure fuel leaks. (8) Tighten hose clamps to 1 N Im (10 in. lbs.)

torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

CHASSIS FUEL TUBES

Figures 16 and 17 show fuel system component lo-

cations and chassis fuel tube routings.

Fig. 15 Quick Connect Fuel Fittings

Ä FUEL SYSTEMS 14 - 11

Page 1756 of 2438

jector terminal in the harness connector. Repeat pro-

cedure for 2 to 3 injectors.

FUEL TANK

DRAINING FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure. (3) Remove ground cable from battery.

(4) Raise vehicle on hoist.

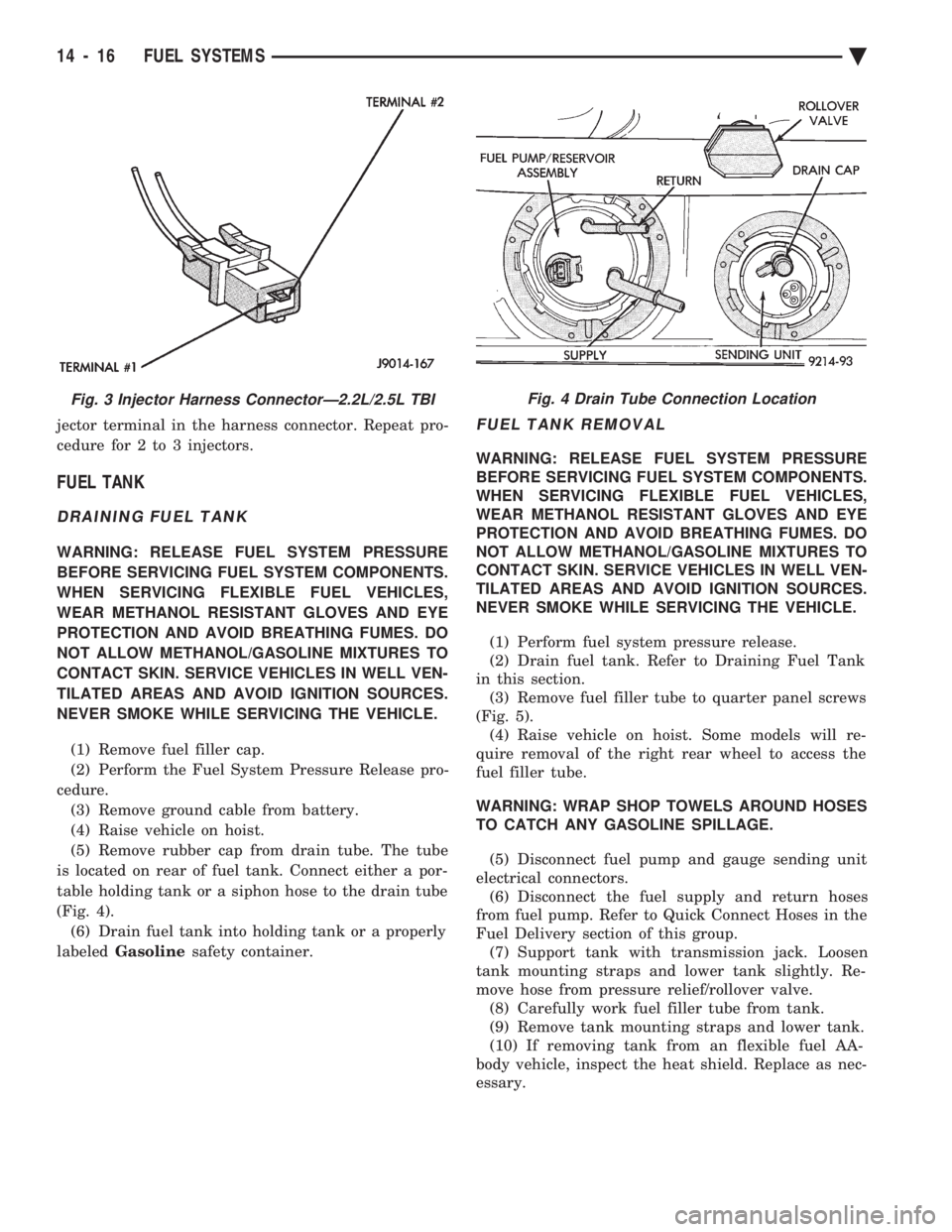

(5) Remove rubber cap from drain tube. The tube

is located on rear of fuel tank. Connect either a por-

table holding tank or a siphon hose to the drain tube

(Fig. 4). (6) Drain fuel tank into holding tank or a properly

labeled Gasoline safety container.

FUEL TANK REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Perform fuel system pressure release.

(2) Drain fuel tank. Refer to Draining Fuel Tank

in this section. (3) Remove fuel filler tube to quarter panel screws

(Fig. 5). (4) Raise vehicle on hoist. Some models will re-

quire removal of the right rear wheel to access the

fuel filler tube.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

(5) Disconnect fuel pump and gauge sending unit

electrical connectors. (6) Disconnect the fuel supply and return hoses

from fuel pump. Refer to Quick Connect Hoses in the

Fuel Delivery section of this group. (7) Support tank with transmission jack. Loosen

tank mounting straps and lower tank slightly. Re-

move hose from pressure relief/rollover valve. (8) Carefully work fuel filler tube from tank.

(9) Remove tank mounting straps and lower tank.

(10) If removing tank from an flexible fuel AA-

body vehicle, inspect the heat shield. Replace as nec-

essary.

Fig. 3 Injector Harness ConnectorÐ2.2L/2.5L TBIFig. 4 Drain Tube Connection Location

14 - 16 FUEL SYSTEMS Ä

Page 1758 of 2438

INSTALLATION

WARNING: FUEL TANKS DESIGNED FOR GASO-

LINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS. (1) Position fuel tank on transmission jack. Con-

nect vapor separator/rollover valve hose and position

insulator pad on fuel tank. Position vapor vent so

that it is not pinched between tank and floor pan

during installation. (2) Raise tank and fuel filler tube carefully into

position. Use a light coating of power steering fluid

to ease fuel filler tube installation. Ensure filler tube

grommet is not damaged. Verify that the tube is in-

stalled correctly. (3) Tighten fuel tank strap nuts to 23 N Im (250 in.

lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent. (4) Lubricate the metal tubes on the fuel pump

with clean 30 weight engine oil. Install the quick

connect fuel fittings. Refer to Quick Connect Fittings

in the Fuel Delivery section of this Group. (5) Attach electrical connector to fuel pump mod-

ule and level sensor unit. (6) Lower the vehicle.

(7) Attach filler tube to filler neck opening in

quarter panel. Tighten quarter panel screws to 2

N Im (17 in. lbs.) torque.

(8) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL PUMP MODULE

Refer to the Fuel Delivery section of this group.

METHANOL CONCENTRATION SENSOR

Refer to the Fuel Delivery section of this group.

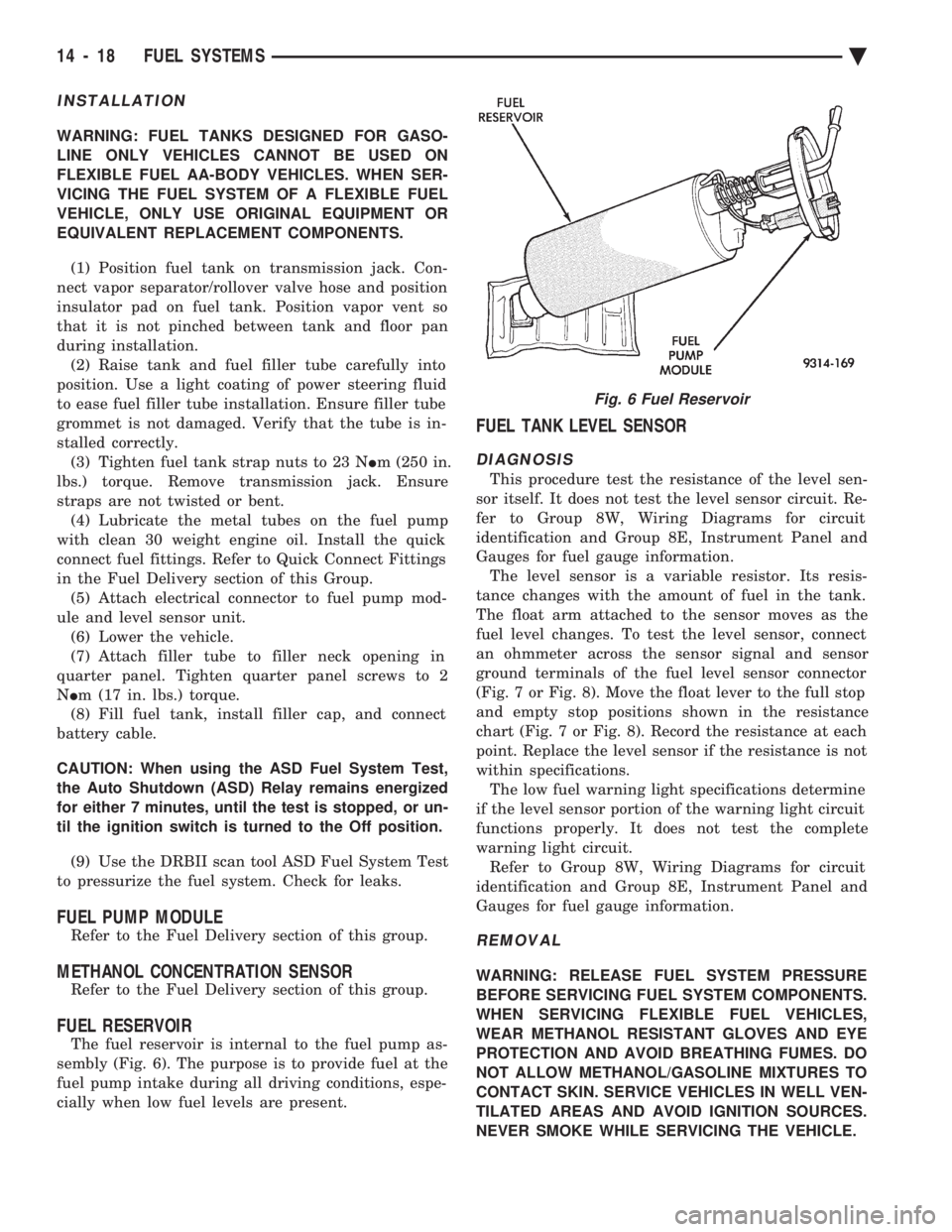

FUEL RESERVOIR

The fuel reservoir is internal to the fuel pump as-

sembly (Fig. 6). The purpose is to provide fuel at the

fuel pump intake during all driving conditions, espe-

cially when low fuel levels are present.

FUEL TANK LEVEL SENSOR

DIAGNOSIS

This procedure test the resistance of the level sen-

sor itself. It does not test the level sensor circuit. Re-

fer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information. The level sensor is a variable resistor. Its resis-

tance changes with the amount of fuel in the tank.

The float arm attached to the sensor moves as the

fuel level changes. To test the level sensor, connect

an ohmmeter across the sensor signal and sensor

ground terminals of the fuel level sensor connector

(Fig. 7 or Fig. 8). Move the float lever to the full stop

and empty stop positions shown in the resistance

chart (Fig. 7 or Fig. 8). Record the resistance at each

point. Replace the level sensor if the resistance is not

within specifications. The low fuel warning light specifications determine

if the level sensor portion of the warning light circuit

functions properly. It does not test the complete

warning light circuit. Refer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Fig. 6 Fuel Reservoir

14 - 18 FUEL SYSTEMS Ä

Page 1761 of 2438

INSTALLATION

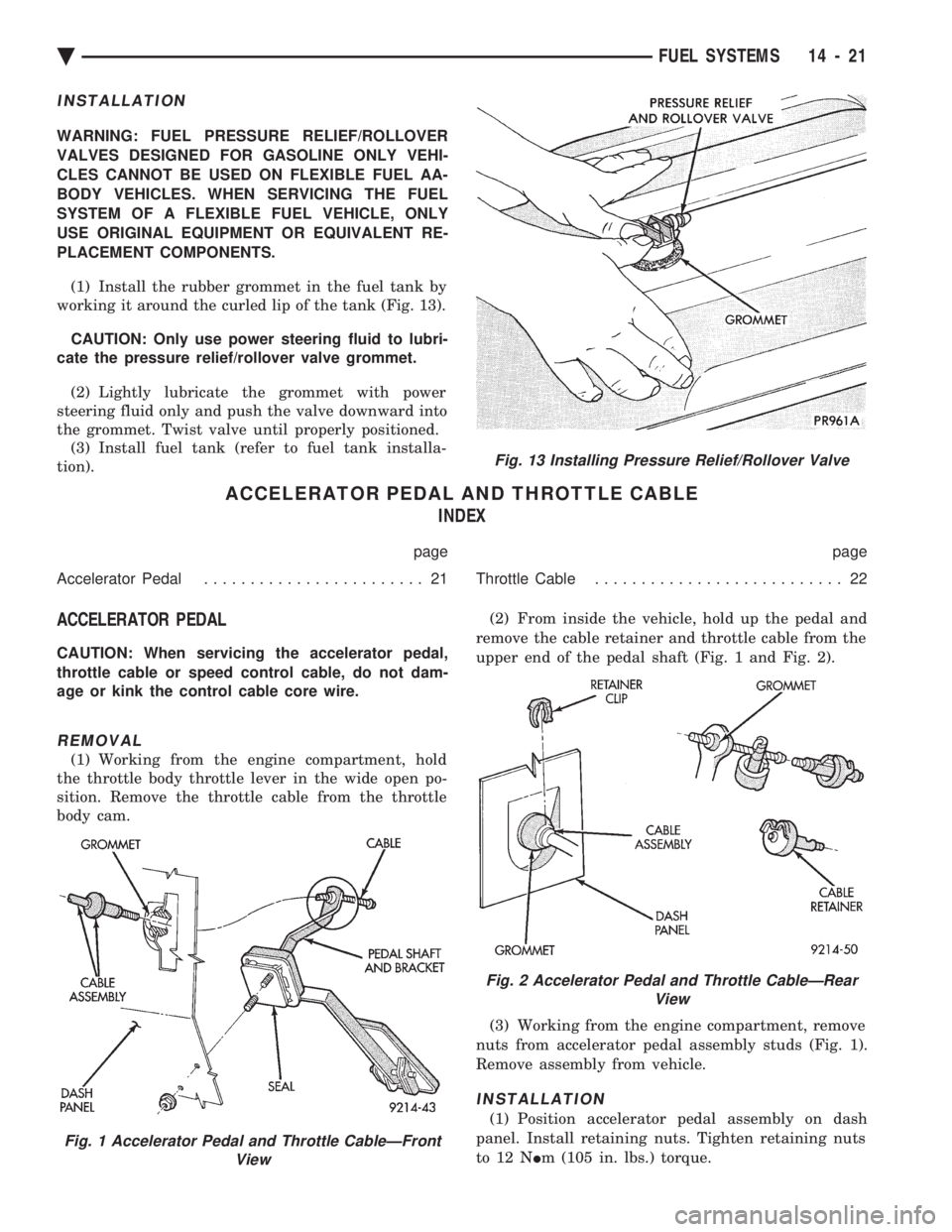

WARNING: FUEL PRESSURE RELIEF/ROLLOVER

VALVES DESIGNED FOR GASOLINE ONLY VEHI-

CLES CANNOT BE USED ON FLEXIBLE FUEL AA-

BODY VEHICLES. WHEN SERVICING THE FUEL

SYSTEM OF A FLEXIBLE FUEL VEHICLE, ONLY

USE ORIGINAL EQUIPMENT OR EQUIVALENT RE-

PLACEMENT COMPONENTS. (1) Install the rubber grommet in the fuel tank by

working it around the curled lip of the tank (Fig. 13).

CAUTION: Only use power steering fluid to lubri-

cate the pressure relief/rollover valve grommet.

(2) Lightly lubricate the grommet with power

steering fluid only and push the valve downward into

the grommet. Twist valve until properly positioned. (3) Install fuel tank (refer to fuel tank installa-

tion).

ACCELERATOR PEDAL AND THROTTLE CABLE INDEX

page page

Accelerator Pedal ........................ 21 Throttle Cable........................... 22

ACCELERATOR PEDAL

CAUTION: When servicing the accelerator pedal,

throttle cable or speed control cable, do not dam-

age or kink the control cable core wire.

REMOVAL

(1) Working from the engine compartment, hold

the throttle body throttle lever in the wide open po-

sition. Remove the throttle cable from the throttle

body cam. (2) From inside the vehicle, hold up the pedal and

remove the cable retainer and throttle cable from the

upper end of the pedal shaft (Fig. 1 and Fig. 2).

(3) Working from the engine compartment, remove

nuts from accelerator pedal assembly studs (Fig. 1).

Remove assembly from vehicle.

INSTALLATION

(1) Position accelerator pedal assembly on dash

panel. Install retaining nuts. Tighten retaining nuts

to 12 N Im (105 in. lbs.) torque.

Fig. 1 Accelerator Pedal and Throttle CableÐFront

View

Fig. 13 Installing Pressure Relief/Rollover Valve

Fig. 2 Accelerator Pedal and Throttle CableÐRearView

Ä FUEL SYSTEMS 14 - 21