air condition CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 546 of 2438

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert dimmer shaft into dimmer knob while

aligning switch in to switch pod assembly. (3) Install switch attaching screws.

(4) Unlatch linkage and install onto push buttons.

(5) Operate all switch modes for correct operation.

(6) Install turn signal switch.

(7) Reconnect wiring for turn signal switch, mak-

ing sure wire is properly clipped into position. (8) Place together the inner and outer bezels. In-

stall five inner switch pod panel screws and three

screws from underneath the switch pod. (9) Install turn signal lever by pushing straight

into switch assembly. (10) Install switch pod assembly.

LOWER STEERING COLUMN COVER REMOVAL

(1) Remove screws along top edge of cover.

(2) Remove screw at each lower corner of cover. (3) Remove cover from underneath over column

cover. (4) For installation reverse above procedures.

GLOVEBOX MODULE REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Remove cowl side trim panel.

(3) Remove screws at right end of glovebox and

lower corners. (4) Open glovebox, remove light and disconnect

wiring. (5) Remove five screws along top of glovebox frame

and screw at each lower corner. (6) Remove glovebox assembly.

(7) For installation reverse above procedures.

CONCEALED HEADLAMP MODULE REMOVAL

(1) Remove left under panel silencer.

(2) Slide module off bayonet bracket while disen-

gaging spring retainer. (3) Disconnect wiring terminal.

(4) For installation reverse above procedures.

HOOD RELEASE REMOVE

(1) Remove lower column cover.

(2) Remove screws on fuse block and move aside.

(3) Remove screws on hood release assembly to re-

move. (4) For installation reverse above procedures.

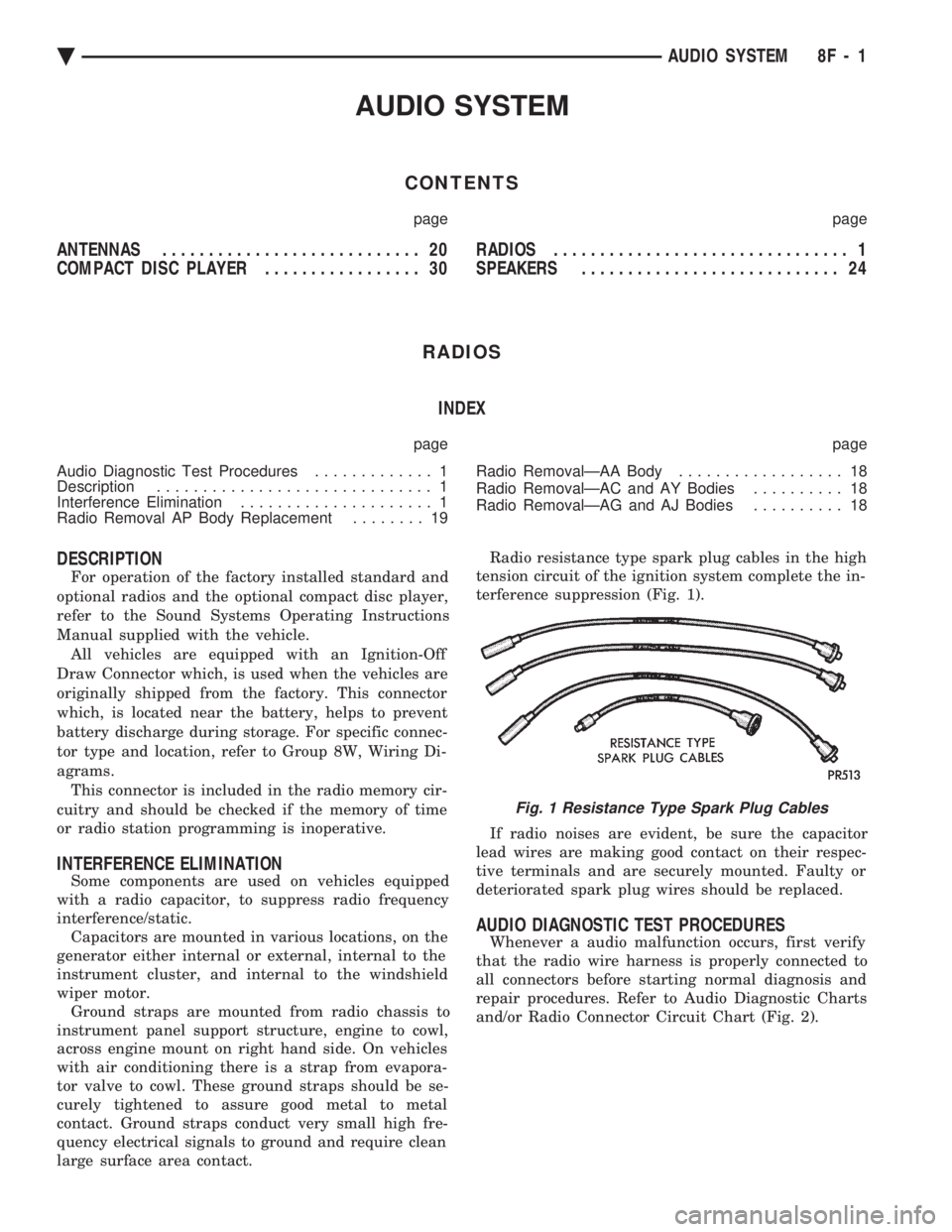

AIR CONDITIONING CONTROL REMOVE

(1) Remove center stack bezel.

(2) Remove two control mounting screws (Fig. 28

and 29).

(3) Slide control rearward, disconnect cable, vac-

uum harness, and electrical wiring. With automatic

temperature control, disconnect wiring connector; be-

ing careful not to break off locking tab. (4) For installation reverse above procedures.

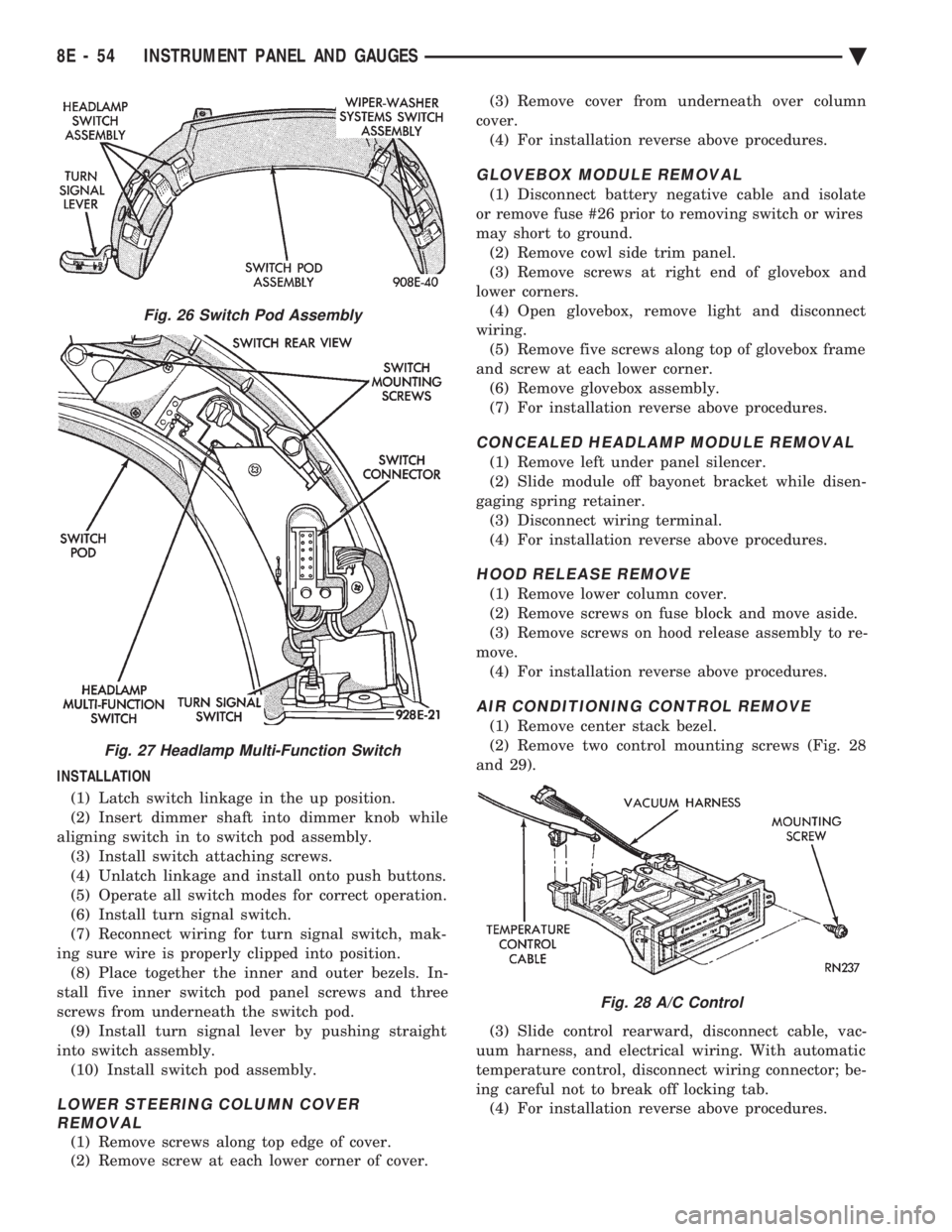

Fig. 26 Switch Pod Assembly

Fig. 27 Headlamp Multi-Function Switch

Fig. 28 A/C Control

8E - 54 INSTRUMENT PANEL AND GAUGES Ä

Page 567 of 2438

AUDIO SYSTEM

CONTENTS

page page

ANTENNAS ............................ 20

COMPACT DISC PLAYER ................. 30 RADIOS

................................ 1

SPEAKERS ............................ 24

RADIOS INDEX

page page

Audio Diagnostic Test Procedures ............. 1

Description .............................. 1

Interference Elimination ..................... 1

Radio Removal AP Body Replacement ........ 19 Radio RemovalÐAA Body

.................. 18

Radio RemovalÐAC and AY Bodies .......... 18

Radio RemovalÐAG and AJ Bodies .......... 18

DESCRIPTION

For operation of the factory installed standard and

optional radios and the optional compact disc player,

refer to the Sound Systems Operating Instructions

Manual supplied with the vehicle. All vehicles are equipped with an Ignition-Off

Draw Connector which, is used when the vehicles are

originally shipped from the factory. This connector

which, is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer to Group 8W, Wiring Di-

agrams. This connector is included in the radio memory cir-

cuitry and should be checked if the memory of time

or radio station programming is inoperative.

INTERFERENCE ELIMINATION

Some components are used on vehicles equipped

with a radio capacitor, to suppress radio frequency

interference/static. Capacitors are mounted in various locations, on the

generator either internal or external, internal to the

instrument cluster, and internal to the windshield

wiper motor. Ground straps are mounted from radio chassis to

instrument panel support structure, engine to cowl,

across engine mount on right hand side. On vehicles

with air conditioning there is a strap from evapora-

tor valve to cowl. These ground straps should be se-

curely tightened to assure good metal to metal

contact. Ground straps conduct very small high fre-

quency electrical signals to ground and require clean

large surface area contact. Radio resistance type spark plug cables in the high

tension circuit of the ignition system complete the in-

terference suppression (Fig. 1).

If radio noises are evident, be sure the capacitor

lead wires are making good contact on their respec-

tive terminals and are securely mounted. Faulty or

deteriorated spark plug wires should be replaced.

AUDIO DIAGNOSTIC TEST PROCEDURES

Whenever a audio malfunction occurs, first verify

that the radio wire harness is properly connected to

all connectors before starting normal diagnosis and

repair procedures. Refer to Audio Diagnostic Charts

and/or Radio Connector Circuit Chart (Fig. 2).

Fig. 1 Resistance Type Spark Plug Cables

Ä AUDIO SYSTEM 8F - 1

Page 594 of 2438

(3) Remove shelf trim panel (Fig. 33).

(4) Remove four speaker retaining screws.

(5) Pull speaker away from shelf panel and discon-

nect wiring. (6) For installation reverse above procedures.

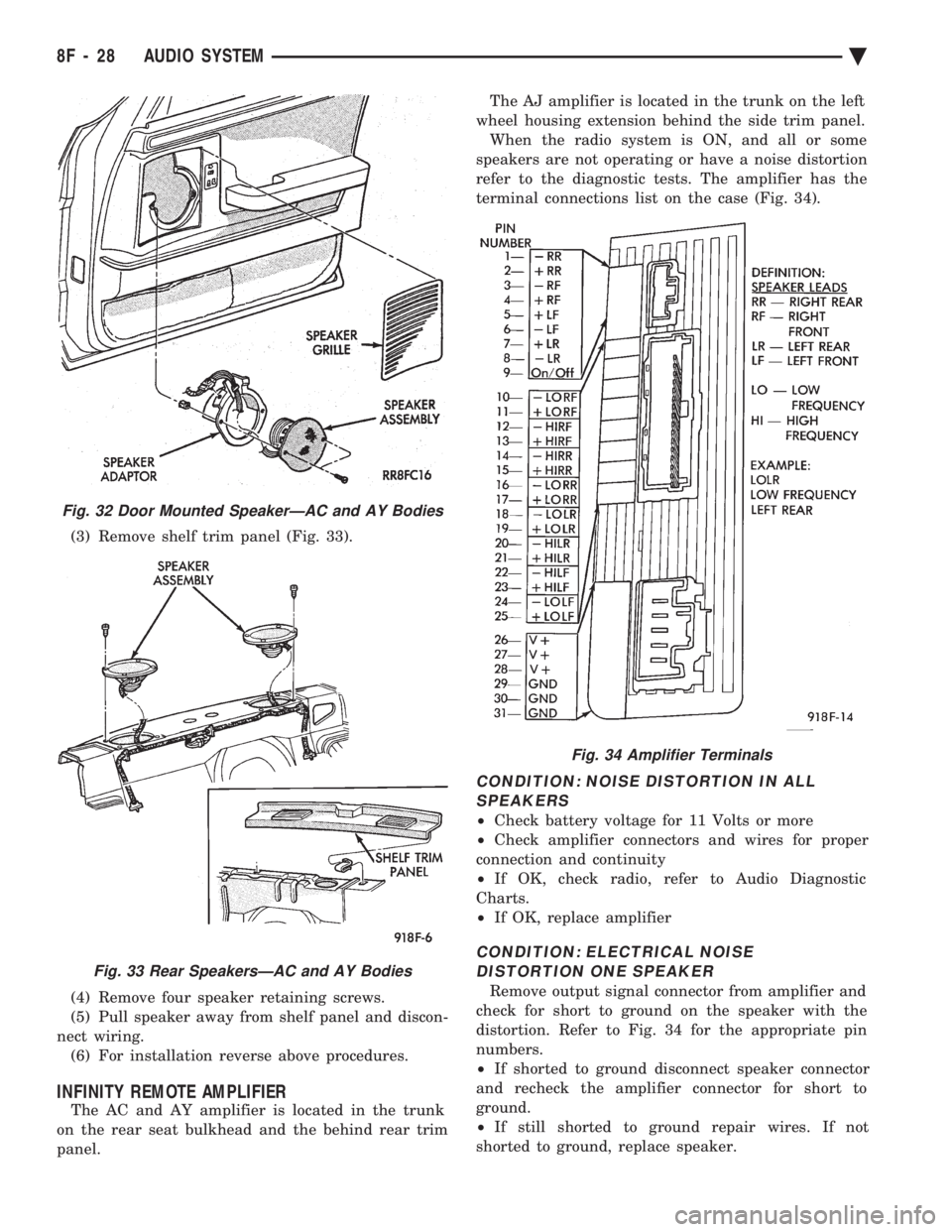

INFINITY REMOTE AMPLIFIER

The AC and AY amplifier is located in the trunk

on the rear seat bulkhead and the behind rear trim

panel. The AJ amplifier is located in the trunk on the left

wheel housing extension behind the side trim panel. When the radio system is ON, and all or some

speakers are not operating or have a noise distortion

refer to the diagnostic tests. The amplifier has the

terminal connections list on the case (Fig. 34).

CONDITION: NOISE DISTORTION IN ALL SPEAKERS

² Check battery voltage for 11 Volts or more

² Check amplifier connectors and wires for proper

connection and continuity

² If OK, check radio, refer to Audio Diagnostic

Charts.

² If OK, replace amplifier

CONDITION: ELECTRICAL NOISE

DISTORTION ONE SPEAKER

Remove output signal connector from amplifier and

check for short to ground on the speaker with the

distortion. Refer to Fig. 34 for the appropriate pin

numbers.

² If shorted to ground disconnect speaker connector

and recheck the amplifier connector for short to

ground.

² If still shorted to ground repair wires. If not

shorted to ground, replace speaker.

Fig. 32 Door Mounted SpeakerÐAC and AY Bodies

Fig. 33 Rear SpeakersÐAC and AY Bodies

Fig. 34 Amplifier Terminals

8F - 28 AUDIO SYSTEM Ä

Page 595 of 2438

² If no short to ground at connector, check speaker

resistance at amplifier connector for an reading of

three to five ohms.

² If resistance is OK, refer to Radio Diagnosis. If ra-

dio checks OK, replace amplifier.

² If resistance is less than three ohms check

speaker. Check across the speaker connector if less

than three ohms replace speaker. If resistance is OK

repair wires

CONDITION: MECHANICAL NOISE DISTORTION

² Check trim for loose parts and speaker attach-

ments for buzzes

² Remove speaker still connected and listen for dis-

tortion. Distortion replace speaker.

CONDITION: ONE SPEAKER NON-OPERATIVE

² Remove output signal connector from amplifier

and check for three to five ohms resistance to the

non-operative speaker. Refer to Fig. 34 for the appro-

priate pin numbers.

² If resistance is less than three ohms, test speaker

for resistance.

² If OK repair wire. If not replace speaker.

CONDITION: ALL SPEAKERS NON-OPERATIVE

²Check radio for being ON, are the display lights

on

² Radio not ON, refer to Radio Diagnosis

² Check Amplifier Connectors and wires for proper

connection

² Check pin 9 and pin 27 for battery voltage

² If voltage OK replace amplifier ²

If pin 27 has battery voltage and pin 9 has 0 volt-

age. Refer to Power Antenna Diagnosis and test volt-

age at antenna relay.

² If pin 9 has battery voltage and pin 27 has 0 volt-

age. Check pin 27 for short to ground.

² If shorted to ground repair wire

² If no short to ground check fuse cavity number 16

for blown fuse.

² If fuse blows again replace amplifier

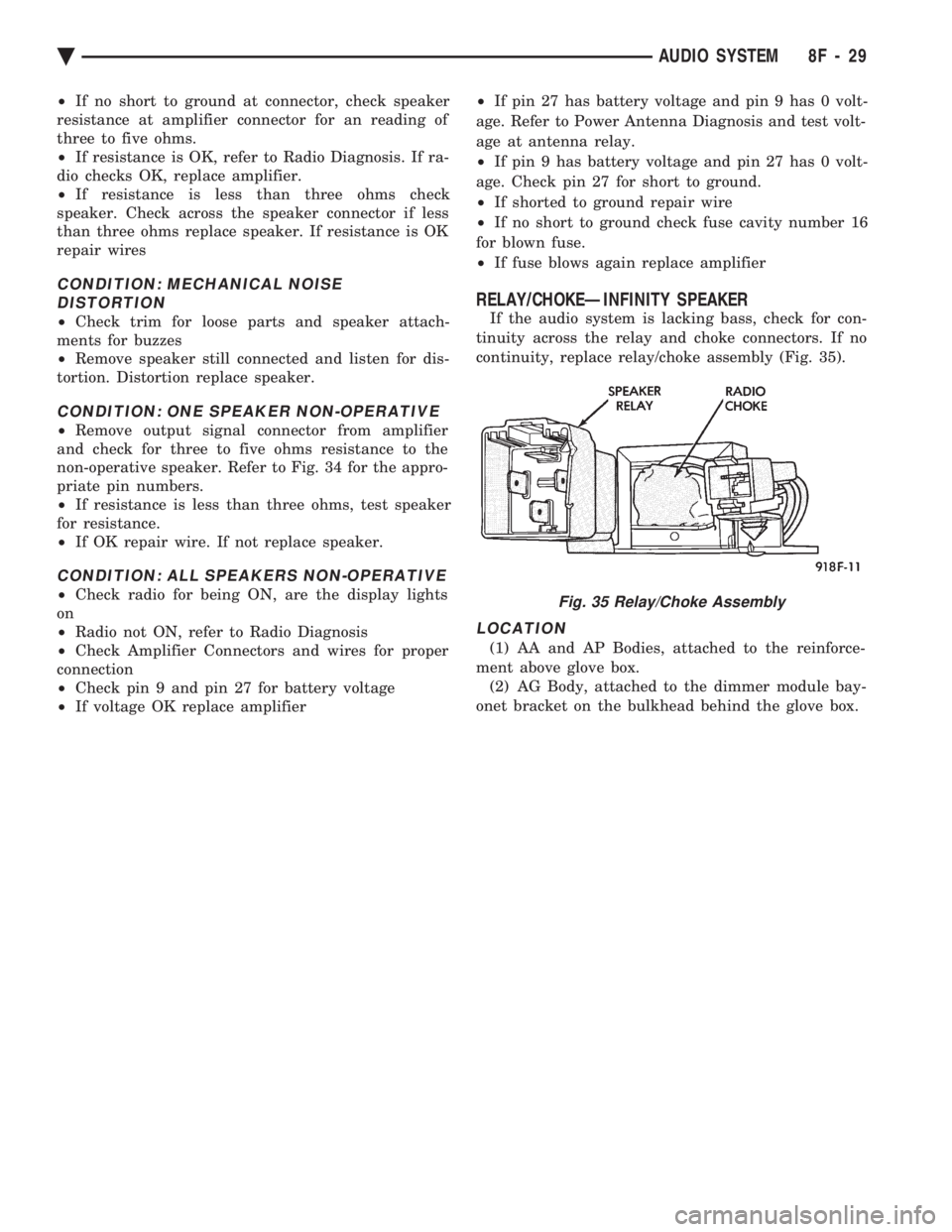

RELAY/CHOKEÐINFINITY SPEAKER

If the audio system is lacking bass, check for con-

tinuity across the relay and choke connectors. If no

continuity, replace relay/choke assembly (Fig. 35).

LOCATION

(1) AA and AP Bodies, attached to the reinforce-

ment above glove box. (2) AG Body, attached to the dimmer module bay-

onet bracket on the bulkhead behind the glove box.

Fig. 35 Relay/Choke Assembly

Ä AUDIO SYSTEM 8F - 29

Page 596 of 2438

COMPACT DISC PLAYER

WARNING: USE OF THE CONTROLS, ADJUST-

MENTS, OR SERVICE PROCEDURES NOT SPECI-

FIED HERE OR IN THE OWNER MANUAL MAY

RESULT IN HAZARDOUS RADIATION EXPOSURE.

REPAIR PROCEDURES SHOULD ONLY BE PER-

FORMED BY A TRAINED TECHNICIAN.

DIAGNOSIS TEST

Power to the compact disc player is supplied by the

radio through the CD interface cable. The compact

disc player will only work with the radio system

turned ON. When a compact disc is inserted with the

label side facing up, the disc is automatically loaded

and will begin to play. The CD player may eject the disc with a display of

E under the following conditions:

² The surface of the disc is dirty or wet

² The disc was inserted with the label side facing

down

² The disc is defective

² The CD player may skip or mute while playing a

disc under severe vibration conditions example pot

holes, railroad tracks, etc.

² If the CD player becomes too hot at temperatures

above 60ÉC (140 ÉF) the CD player will shut down

with a display of HOT until it cools down. Refer to

the Audio Diagnostic Charts.

COMPACT DISC PLAYER REPLACEMENT

With intergral compact disc player refer to Radio

Removal.

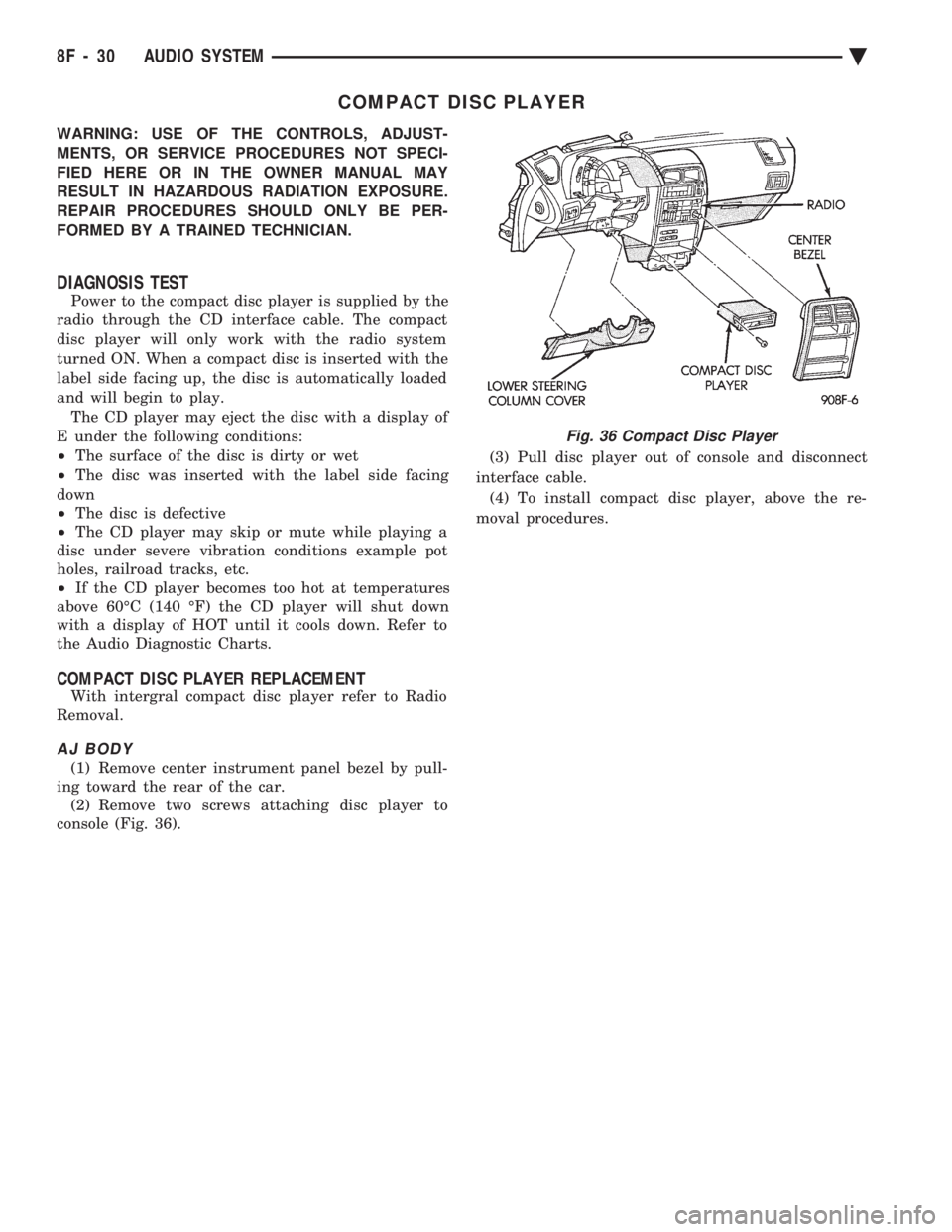

AJ BODY

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car. (2) Remove two screws attaching disc player to

console (Fig. 36). (3) Pull disc player out of console and disconnect

interface cable. (4) To install compact disc player, above the re-

moval procedures.

Fig. 36 Compact Disc Player

8F - 30 AUDIO SYSTEM Ä

Page 623 of 2438

(3) Secure arm to pivot with attaching nut and

tighten 17 to 22 N Im (155 to 195 in. lbs.) torque.

(4) Close head cover and remove pin from arm pin

hole.

WIPER ARM ADJUSTMENT

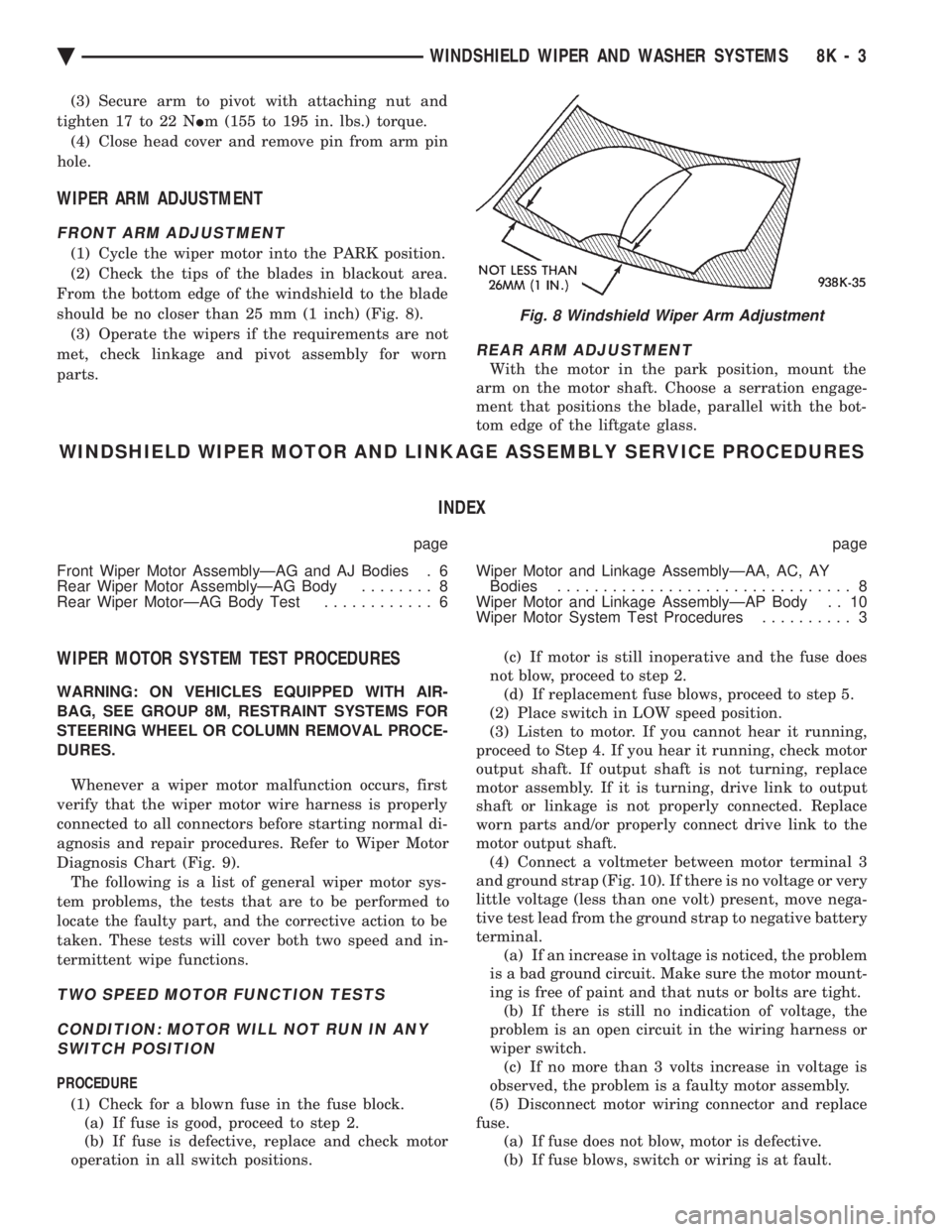

FRONT ARM ADJUSTMENT

(1) Cycle the wiper motor into the PARK position.

(2) Check the tips of the blades in blackout area.

From the bottom edge of the windshield to the blade

should be no closer than 25 mm (1 inch) (Fig. 8). (3) Operate the wipers if the requirements are not

met, check linkage and pivot assembly for worn

parts.

REAR ARM ADJUSTMENT

With the motor in the park position, mount the

arm on the motor shaft. Choose a serration engage-

ment that positions the blade, parallel with the bot-

tom edge of the liftgate glass.

WINDSHIELD WIPER MOTOR AND LINKAGE ASSEMBLY SERVICE PROCEDURES

INDEX

page page

Front Wiper Motor AssemblyÐAG and AJ Bodies . 6

Rear Wiper Motor AssemblyÐAG Body ........ 8

Rear Wiper MotorÐAG Body Test ............ 6 Wiper Motor and Linkage AssemblyÐAA, AC, AY

Bodies ................................ 8

Wiper Motor and Linkage AssemblyÐAP Body . . 10

Wiper Motor System Test Procedures .......... 3

WIPER MOTOR SYSTEM TEST PROCEDURES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, first

verify that the wiper motor wire harness is properly

connected to all connectors before starting normal di-

agnosis and repair procedures. Refer to Wiper Motor

Diagnosis Chart (Fig. 9). The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken. These tests will cover both two speed and in-

termittent wipe functions.

TWO SPEED MOTOR FUNCTION TESTS

CONDITION: MOTOR WILL NOT RUN IN ANY SWITCH POSITION

PROCEDURE

(1) Check for a blown fuse in the fuse block. (a) If fuse is good, proceed to step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions. (c) If motor is still inoperative and the fuse does

not blow, proceed to step 2. (d) If replacement fuse blows, proceed to step 5.

(2) Place switch in LOW speed position.

(3) Listen to motor. If you cannot hear it running,

proceed to Step 4. If you hear it running, check motor

output shaft. If output shaft is not turning, replace

motor assembly. If it is turning, drive link to output

shaft or linkage is not properly connected. Replace

worn parts and/or properly connect drive link to the

motor output shaft. (4) Connect a voltmeter between motor terminal 3

and ground strap (Fig. 10). If there is no voltage or very

little voltage (less than one volt) present, move nega-

tive test lead from the ground strap to negative battery

terminal. (a) If an increase in voltage is noticed, the problem

is a bad ground circuit. Make sure the motor mount-

ing is free of paint and that nuts or bolts are tight. (b) If there is still no indication of voltage, the

problem is an open circuit in the wiring harness or

wiper switch. (c) If no more than 3 volts increase in voltage is

observed, the problem is a faulty motor assembly.

(5) Disconnect motor wiring connector and replace

fuse. (a) If fuse does not blow, motor is defective.

(b) If fuse blows, switch or wiring is at fault.

Fig. 8 Windshield Wiper Arm Adjustment

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 3

Page 625 of 2438

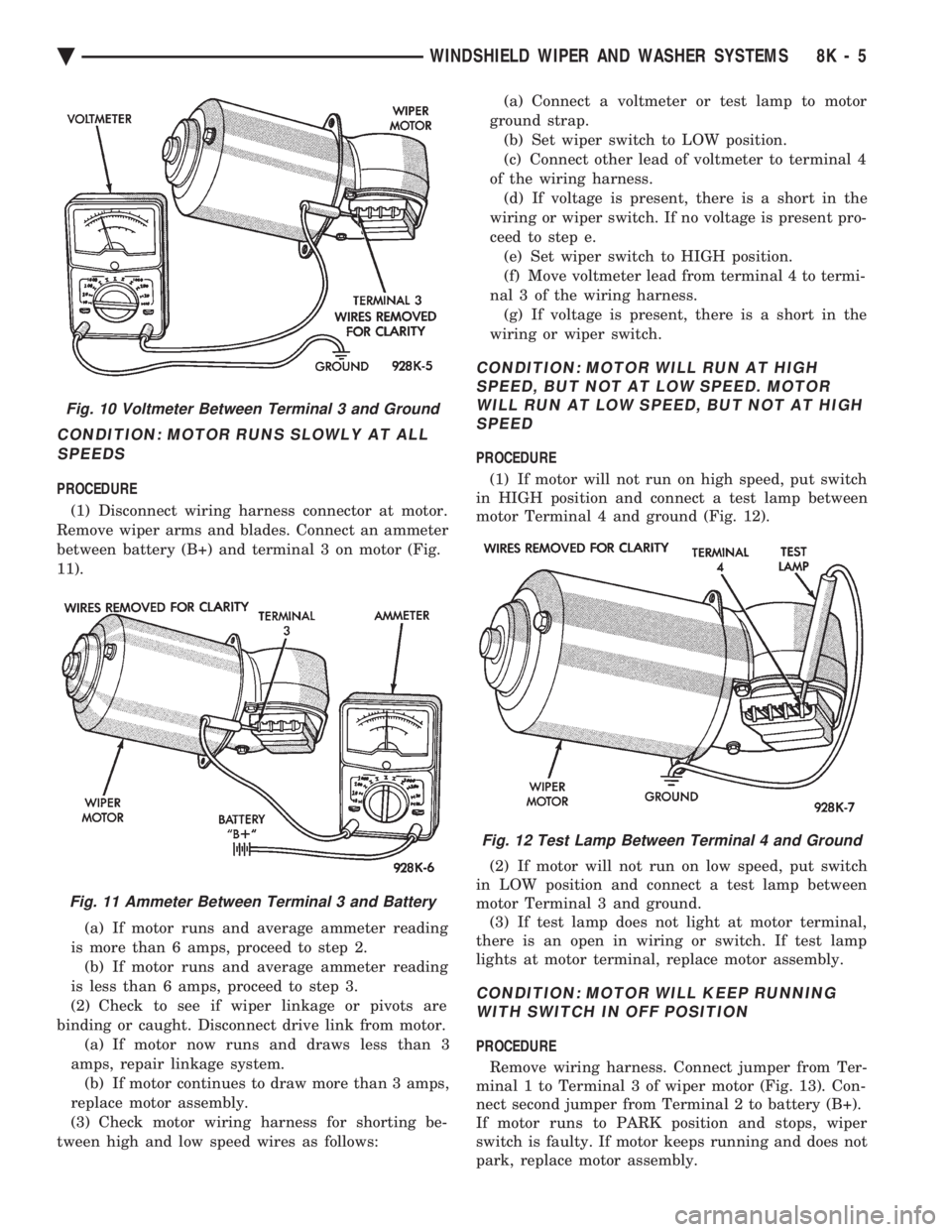

CONDITION: MOTOR RUNS SLOWLY AT ALL SPEEDS

PROCEDURE

(1) Disconnect wiring harness connector at motor.

Remove wiper arms and blades. Connect an ammeter

between battery (B+) and terminal 3 on motor (Fig.

11).

(a) If motor runs and average ammeter reading

is more than 6 amps, proceed to step 2. (b) If motor runs and average ammeter reading

is less than 6 amps, proceed to step 3.

(2) Check to see if wiper linkage or pivots are

binding or caught. Disconnect drive link from motor. (a) If motor now runs and draws less than 3

amps, repair linkage system. (b) If motor continues to draw more than 3 amps,

replace motor assembly.

(3) Check motor wiring harness for shorting be-

tween high and low speed wires as follows: (a) Connect a voltmeter or test lamp to motor

ground strap. (b) Set wiper switch to LOW position.

(c) Connect other lead of voltmeter to terminal 4

of the wiring harness. (d) If voltage is present, there is a short in the

wiring or wiper switch. If no voltage is present pro-

ceed to step e. (e) Set wiper switch to HIGH position.

(f) Move voltmeter lead from terminal 4 to termi-

nal 3 of the wiring harness. (g) If voltage is present, there is a short in the

wiring or wiper switch.

CONDITION: MOTOR WILL RUN AT HIGH SPEED, BUT NOT AT LOW SPEED. MOTORWILL RUN AT LOW SPEED, BUT NOT AT HIGHSPEED

PROCEDURE

(1) If motor will not run on high speed, put switch

in HIGH position and connect a test lamp between

motor Terminal 4 and ground (Fig. 12).

(2) If motor will not run on low speed, put switch

in LOW position and connect a test lamp between

motor Terminal 3 and ground. (3) If test lamp does not light at motor terminal,

there is an open in wiring or switch. If test lamp

lights at motor terminal, replace motor assembly.

CONDITION: MOTOR WILL KEEP RUNNING WITH SWITCH IN OFF POSITION

PROCEDURE

Remove wiring harness. Connect jumper from Ter-

minal 1 to Terminal 3 of wiper motor (Fig. 13). Con-

nect second jumper from Terminal 2 to battery (B+).

If motor runs to PARK position and stops, wiper

switch is faulty. If motor keeps running and does not

park, replace motor assembly.

Fig. 10 Voltmeter Between Terminal 3 and Ground

Fig. 11 Ammeter Between Terminal 3 and Battery

Fig. 12 Test Lamp Between Terminal 4 and Ground

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 5

Page 626 of 2438

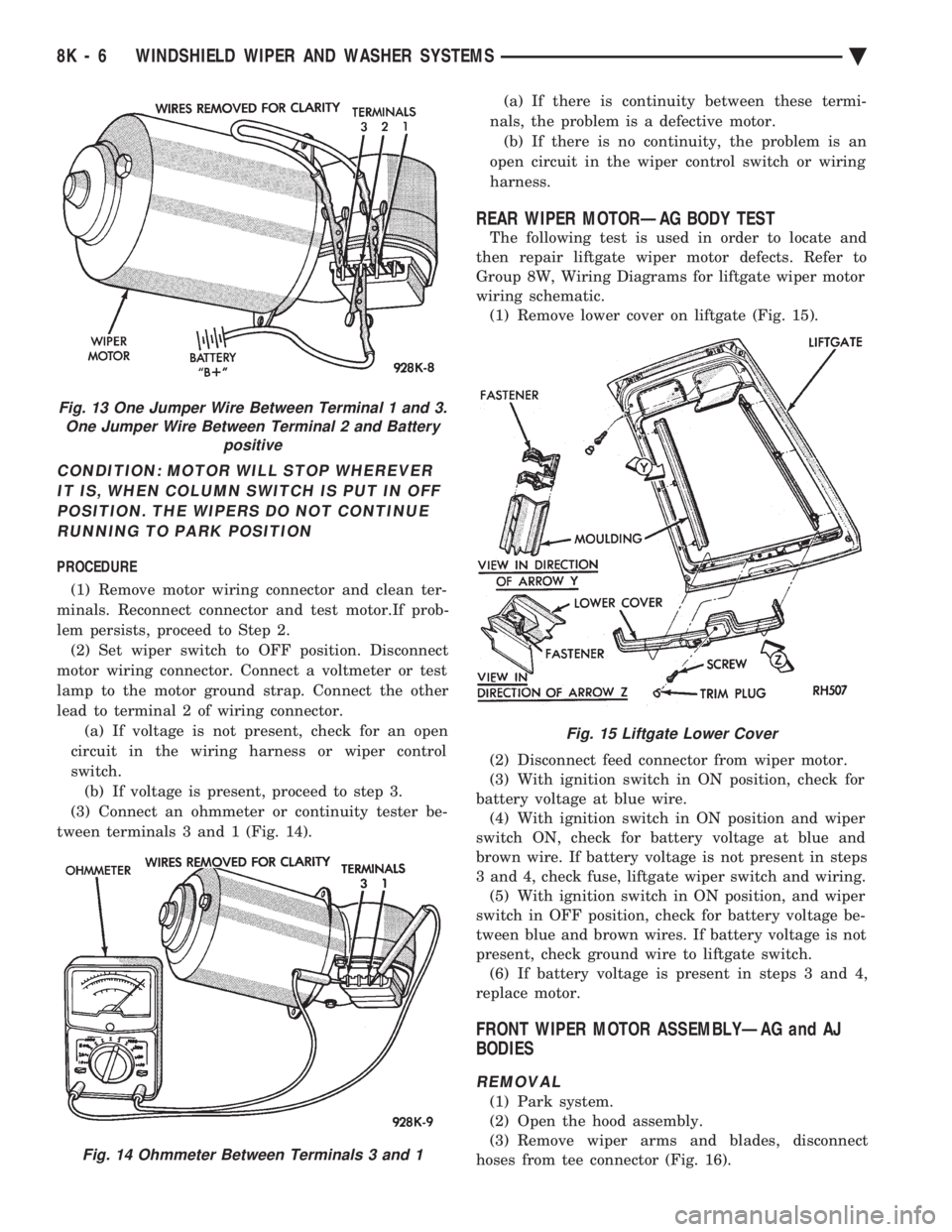

CONDITION: MOTOR WILL STOP WHEREVER IT IS, WHEN COLUMN SWITCH IS PUT IN OFFPOSITION. THE WIPERS DO NOT CONTINUERUNNING TO PARK POSITION

PROCEDURE

(1) Remove motor wiring connector and clean ter-

minals. Reconnect connector and test motor.If prob-

lem persists, proceed to Step 2. (2) Set wiper switch to OFF position. Disconnect

motor wiring connector. Connect a voltmeter or test

lamp to the motor ground strap. Connect the other

lead to terminal 2 of wiring connector. (a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch. (b) If voltage is present, proceed to step 3.

(3) Connect an ohmmeter or continuity tester be-

tween terminals 3 and 1 (Fig. 14). (a) If there is continuity between these termi-

nals, the problem is a defective motor. (b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

REAR WIPER MOTORÐAG BODY TEST

The following test is used in order to locate and

then repair liftgate wiper motor defects. Refer to

Group 8W, Wiring Diagrams for liftgate wiper motor

wiring schematic. (1) Remove lower cover on liftgate (Fig. 15).

(2) Disconnect feed connector from wiper motor.

(3) With ignition switch in ON position, check for

battery voltage at blue wire. (4) With ignition switch in ON position and wiper

switch ON, check for battery voltage at blue and

brown wire. If battery voltage is not present in steps

3 and 4, check fuse, liftgate wiper switch and wiring. (5) With ignition switch in ON position, and wiper

switch in OFF position, check for battery voltage be-

tween blue and brown wires. If battery voltage is not

present, check ground wire to liftgate switch. (6) If battery voltage is present in steps 3 and 4,

replace motor.

FRONT WIPER MOTOR ASSEMBLYÐAG and AJ

BODIES

REMOVAL

(1) Park system.

(2) Open the hood assembly.

(3) Remove wiper arms and blades, disconnect

hoses from tee connector (Fig. 16).

Fig. 13 One Jumper Wire Between Terminal 1 and 3. One Jumper Wire Between Terminal 2 and Battery positive

Fig. 14 Ohmmeter Between Terminals 3 and 1

Fig. 15 Liftgate Lower Cover

8K - 6 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 632 of 2438

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES

INDEX

page page

Intermittent Windshield Wiper Switch Tests ..... 12

Intermittent Wipe Switch Test ............... 14

Intermittent Wiper Function Tests ............ 14

Intermittent Wiper Motor System Test ......... 12 Pulse Intermittent Windshield Wiper Controller

(PIWWC) .............................. 15

Standard Wiper Switch Test ................ 14

Wiper Switch Service Procedure ............. 15

INTERMITTENT WIPER MOTOR SYSTEM TEST

Intermittent Wiper Motor Service Procedures for

diagnosis of problems which do not involve the delay

function, refer to the Two-Speed Motor Function

Tests. The two-speed functions of all wiper motors

are identical. If a problem occurs, only in the DELAY mode, the

following tests are to be performed.

INTERMITTENT WINDSHIELD WIPER SWITCH

TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

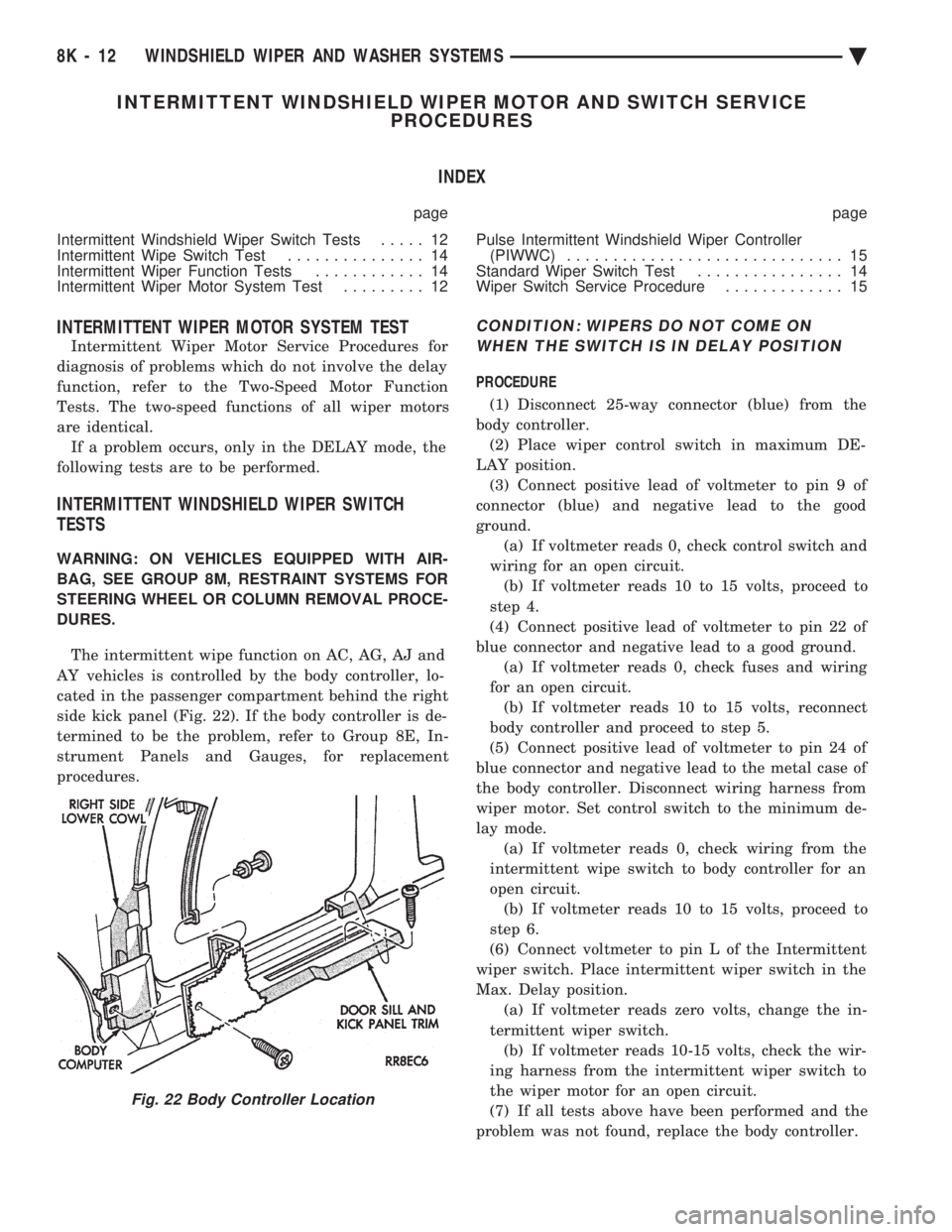

The intermittent wipe function on AC, AG, AJ and

AY vehicles is controlled by the body controller, lo-

cated in the passenger compartment behind the right

side kick panel (Fig. 22). If the body controller is de-

termined to be the problem, refer to Group 8E, In-

strument Panels and Gauges, for replacement

procedures.

CONDITION: WIPERS DO NOT COME ON WHEN THE SWITCH IS IN DELAY POSITION

PROCEDURE

(1) Disconnect 25-way connector (blue) from the

body controller. (2) Place wiper control switch in maximum DE-

LAY position. (3) Connect positive lead of voltmeter to pin 9 of

connector (blue) and negative lead to the good

ground. (a) If voltmeter reads 0, check control switch and

wiring for an open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Connect positive lead of voltmeter to pin 22 of

blue connector and negative lead to a good ground. (a) If voltmeter reads 0, check fuses and wiring

for an open circuit. (b) If voltmeter reads 10 to 15 volts, reconnect

body controller and proceed to step 5.

(5) Connect positive lead of voltmeter to pin 24 of

blue connector and negative lead to the metal case of

the body controller. Disconnect wiring harness from

wiper motor. Set control switch to the minimum de-

lay mode. (a) If voltmeter reads 0, check wiring from the

intermittent wipe switch to body controller for an

open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 6.

(6) Connect voltmeter to pin L of the Intermittent

wiper switch. Place intermittent wiper switch in the

Max. Delay position. (a) If voltmeter reads zero volts, change the in-

termittent wiper switch. (b) If voltmeter reads 10-15 volts, check the wir-

ing harness from the intermittent wiper switch to

the wiper motor for an open circuit.

(7) If all tests above have been performed and the

problem was not found, replace the body controller.

Fig. 22 Body Controller Location

8K - 12 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 696 of 2438

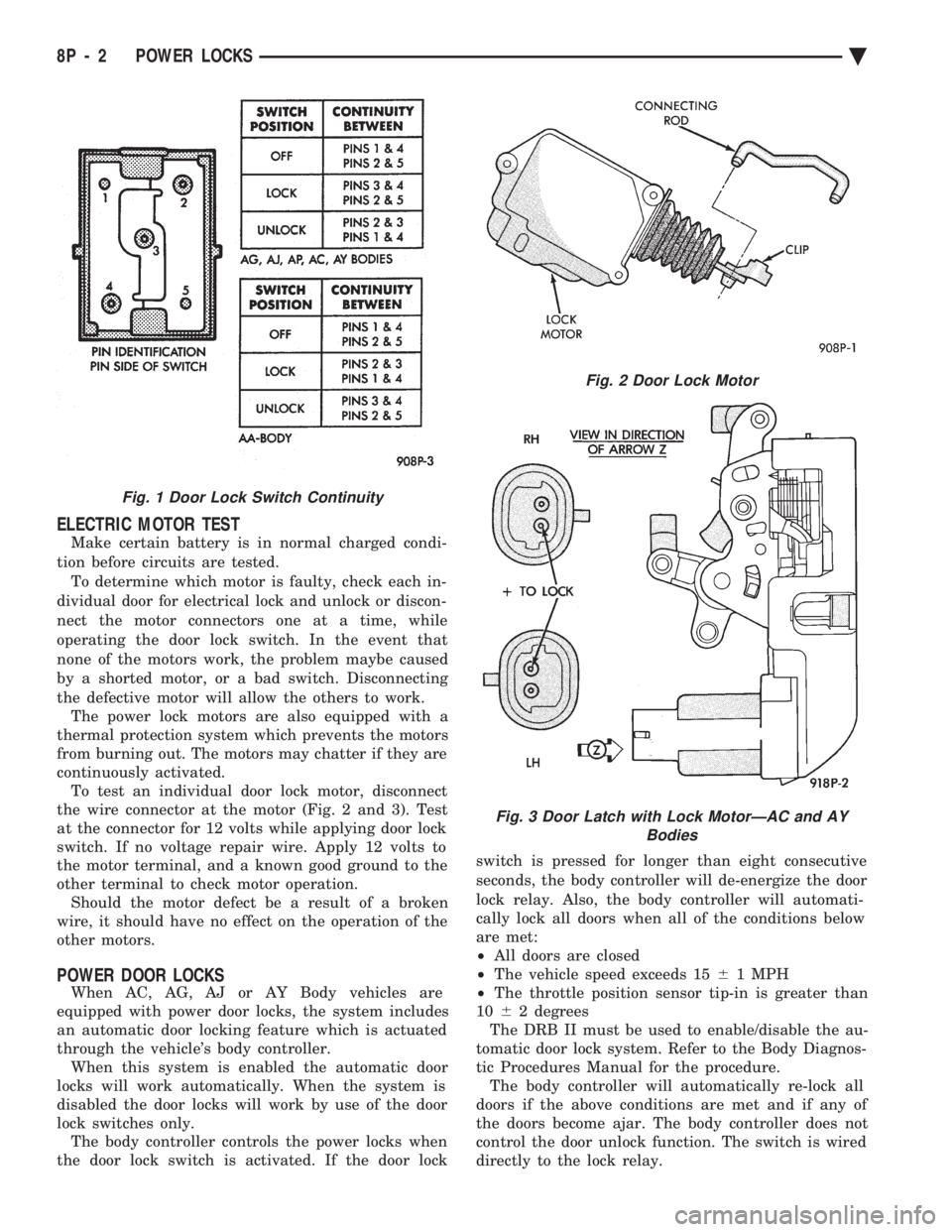

ELECTRIC MOTOR TEST

Make certain battery is in normal charged condi-

tion before circuits are tested. To determine which motor is faulty, check each in-

dividual door for electrical lock and unlock or discon-

nect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem maybe caused

by a shorted motor, or a bad switch. Disconnecting

the defective motor will allow the others to work. The power lock motors are also equipped with a

thermal protection system which prevents the motors

from burning out. The motors may chatter if they are

continuously activated. To test an individual door lock motor, disconnect

the wire connector at the motor (Fig. 2 and 3). Test

at the connector for 12 volts while applying door lock

switch. If no voltage repair wire. Apply 12 volts to

the motor terminal, and a known good ground to the

other terminal to check motor operation. Should the motor defect be a result of a broken

wire, it should have no effect on the operation of the

other motors.

POWER DOOR LOCKS

When AC, AG, AJ or AY Body vehicles are

equipped with power door locks, the system includes

an automatic door locking feature which is actuated

through the vehicle's body controller. When this system is enabled the automatic door

locks will work automatically. When the system is

disabled the door locks will work by use of the door

lock switches only. The body controller controls the power locks when

the door lock switch is activated. If the door lock switch is pressed for longer than eight consecutive

seconds, the body controller will de-energize the door

lock relay. Also, the body controller will automati-

cally lock all doors when all of the conditions below

are met:

² All doors are closed

² The vehicle speed exceeds 15 61 MPH

² The throttle position sensor tip-in is greater than

10 62 degrees

The DRB II must be used to enable/disable the au-

tomatic door lock system. Refer to the Body Diagnos-

tic Procedures Manual for the procedure. The body controller will automatically re-lock all

doors if the above conditions are met and if any of

the doors become ajar. The body controller does not

control the door unlock function. The switch is wired

directly to the lock relay.

Fig. 1 Door Lock Switch Continuity

Fig. 2 Door Lock Motor

Fig. 3 Door Latch with Lock MotorÐAC and AY Bodies

8P - 2 POWER LOCKS Ä