air condition CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 412 of 2438

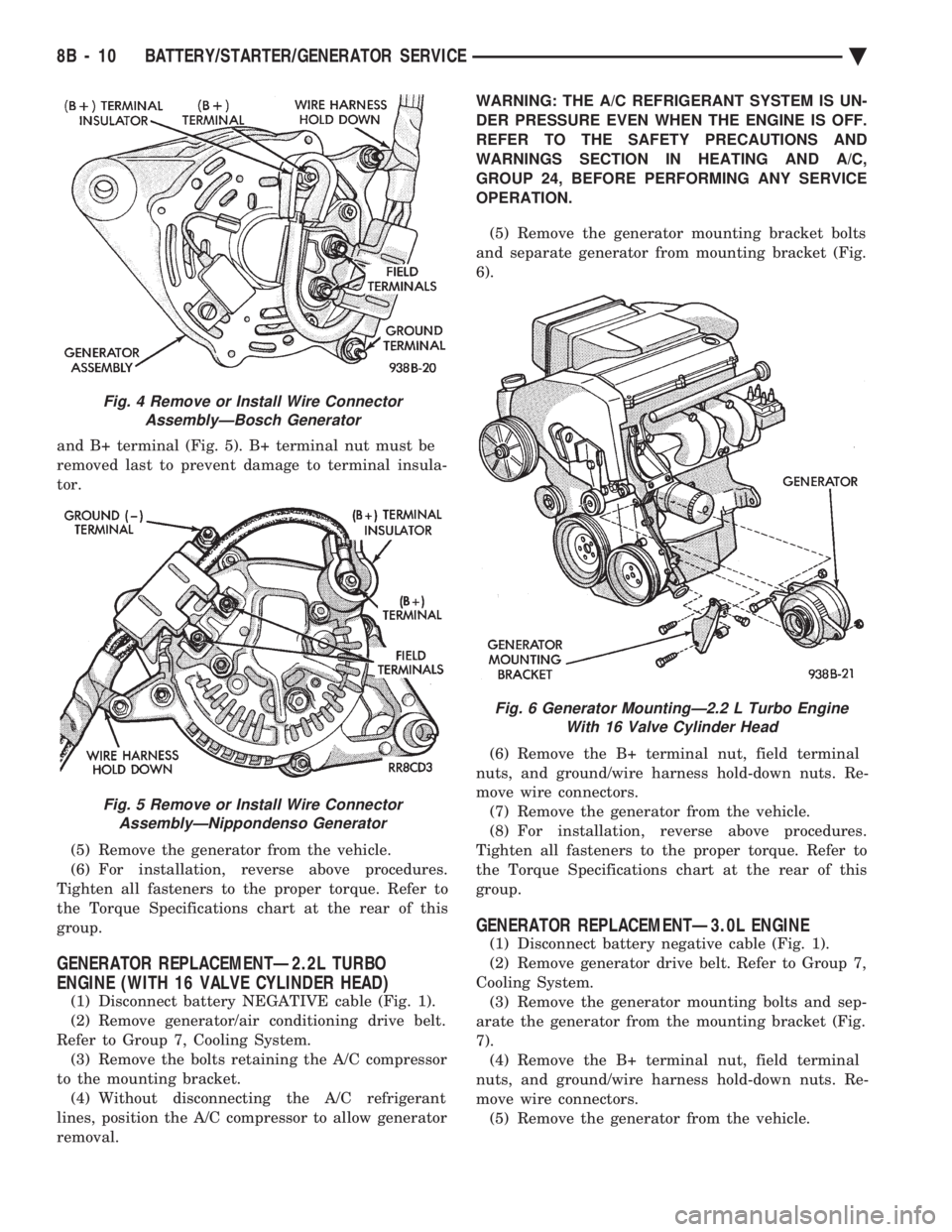

and B+ terminal (Fig. 5). B+ terminal nut must be

removed last to prevent damage to terminal insula-

tor. (5) Remove the generator from the vehicle.

(6) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ2.2L TURBO

ENGINE (WITH 16 VALVE CYLINDER HEAD)

(1) Disconnect battery NEGATIVE cable (Fig. 1).

(2) Remove generator/air conditioning drive belt.

Refer to Group 7, Cooling System. (3) Remove the bolts retaining the A/C compressor

to the mounting bracket. (4) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal. WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND

WARNINGS SECTION IN HEATING AND A/C,

GROUP 24, BEFORE PERFORMING ANY SERVICE

OPERATION.

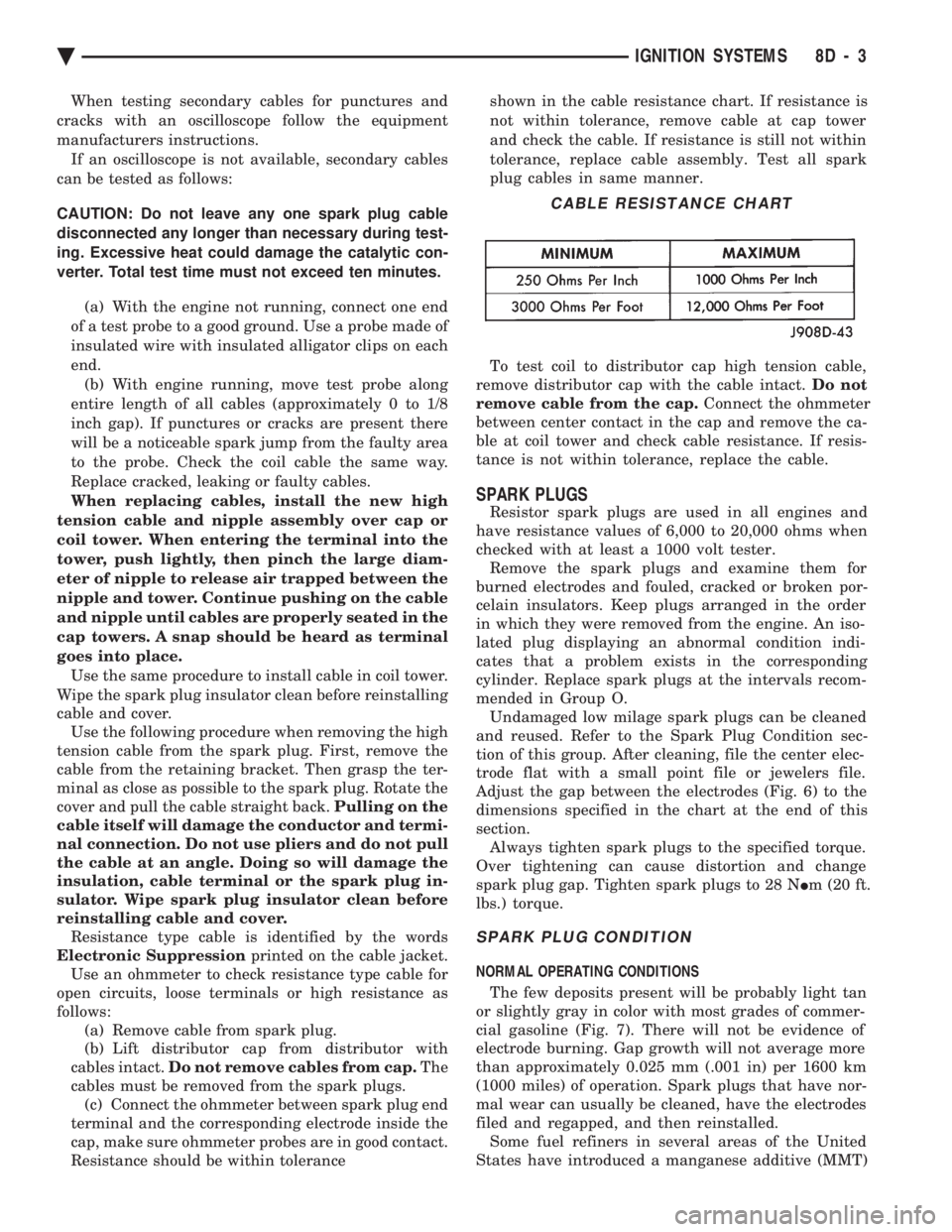

(5) Remove the generator mounting bracket bolts

and separate generator from mounting bracket (Fig.

6).

(6) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (7) Remove the generator from the vehicle.

(8) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ3.0L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Remove the generator mounting bolts and sep-

arate the generator from the mounting bracket (Fig.

7). (4) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (5) Remove the generator from the vehicle.

Fig. 4 Remove or Install Wire Connector AssemblyÐBosch Generator

Fig. 5 Remove or Install Wire ConnectorAssemblyÐNippondenso Generator

Fig. 6 Generator MountingÐ2.2 L Turbo Engine With 16 Valve Cylinder Head

8B - 10 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 445 of 2438

When testing secondary cables for punctures and

cracks with an oscilloscope follow the equipment

manufacturers instructions. If an oscilloscope is not available, secondary cables

can be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected any longer than necessary during test-

ing. Excessive heat could damage the catalytic con-

verter. Total test time must not exceed ten minutes.

(a) With the engine not running, connect one end

of a test probe to a good ground. Use a probe made of

insulated wire with insulated alligator clips on each

end. (b) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Check the coil cable the same way.

Replace cracked, leaking or faulty cables.

When replacing cables, install the new high

tension cable and nipple assembly over cap or

coil tower. When entering the terminal into the

tower, push lightly, then pinch the large diam-

eter of nipple to release air trapped between the

nipple and tower. Continue pushing on the cable

and nipple until cables are properly seated in the

cap towers. A snap should be heard as terminal

goes into place. Use the same procedure to install cable in coil tower.

Wipe the spark plug insulator clean before reinstalling

cable and cover. Use the following procedure when removing the high

tension cable from the spark plug. First, remove the

cable from the retaining bracket. Then grasp the ter-

minal as close as possible to the spark plug. Rotate the

cover and pull the cable straight back. Pulling on the

cable itself will damage the conductor and termi-

nal connection. Do not use pliers and do not pull

the cable at an angle. Doing so will damage the

insulation, cable terminal or the spark plug in-

sulator. Wipe spark plug insulator clean before

reinstalling cable and cover. Resistance type cable is identified by the words

Electronic Suppression printed on the cable jacket.

Use an ohmmeter to check resistance type cable for

open circuits, loose terminals or high resistance as

follows: (a) Remove cable from spark plug.

(b) Lift distributor cap from distributor with

cables intact. Do not remove cables from cap. The

cables must be removed from the spark plugs. (c) Connect the ohmmeter between spark plug end

terminal and the corresponding electrode inside the

cap, make sure ohmmeter probes are in good contact.

Resistance should be within tolerance shown in the cable resistance chart. If resistance is

not within tolerance, remove cable at cap tower

and check the cable. If resistance is still not within

tolerance, replace cable assembly. Test all spark

plug cables in same manner.

To test coil to distributor cap high tension cable,

remove distributor cap with the cable intact. Do not

remove cable from the cap. Connect the ohmmeter

between center contact in the cap and remove the ca-

ble at coil tower and check cable resistance. If resis-

tance is not within tolerance, replace the cable.

SPARK PLUGS

Resistor spark plugs are used in all engines and

have resistance values of 6,000 to 20,000 ohms when

checked with at least a 1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Undamaged low milage spark plugs can be cleaned

and reused. Refer to the Spark Plug Condition sec-

tion of this group. After cleaning, file the center elec-

trode flat with a small point file or jewelers file.

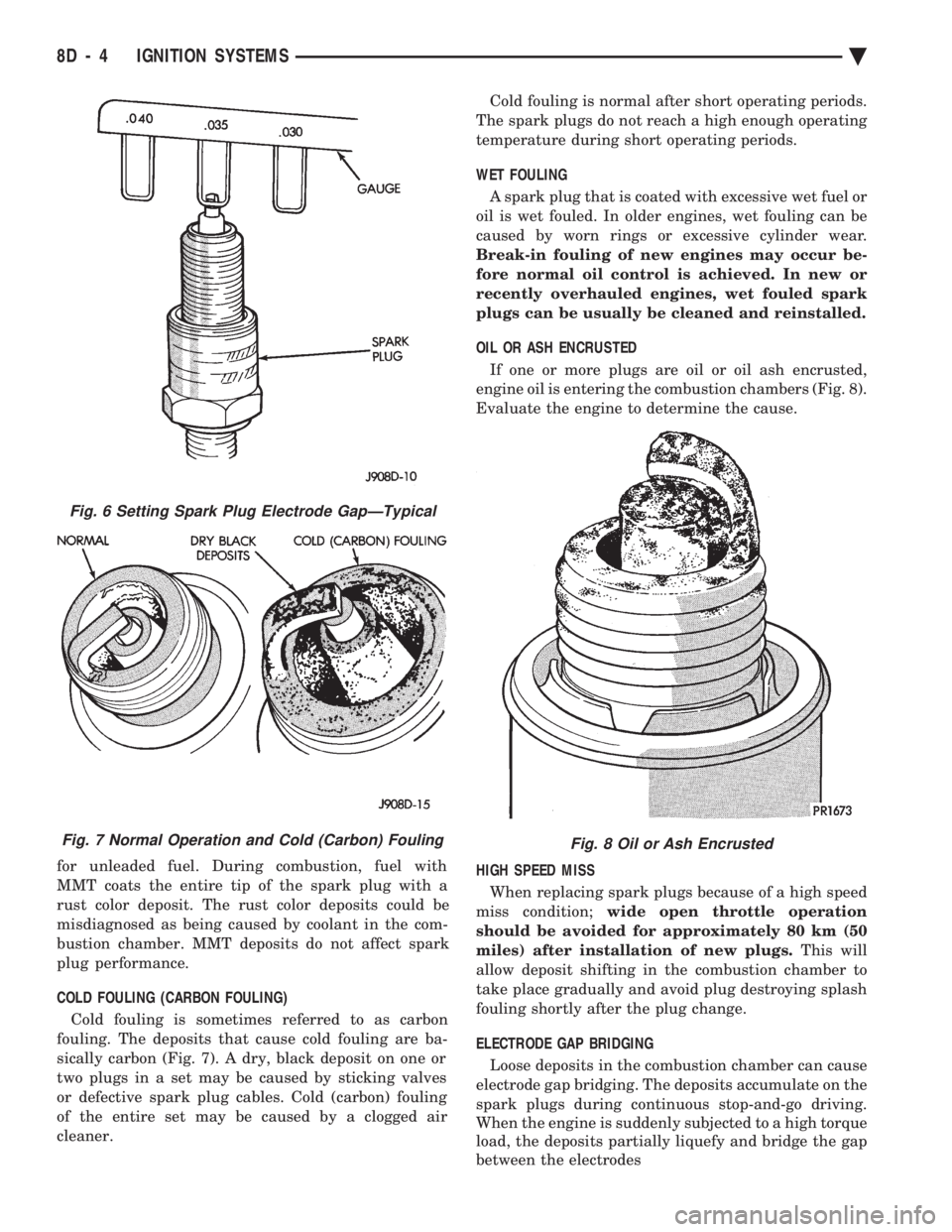

Adjust the gap between the electrodes (Fig. 6) to the

dimensions specified in the chart at the end of this

section. Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten spark plugs to 28 N Im (20 ft.

lbs.) torque.

SPARK PLUG CONDITION

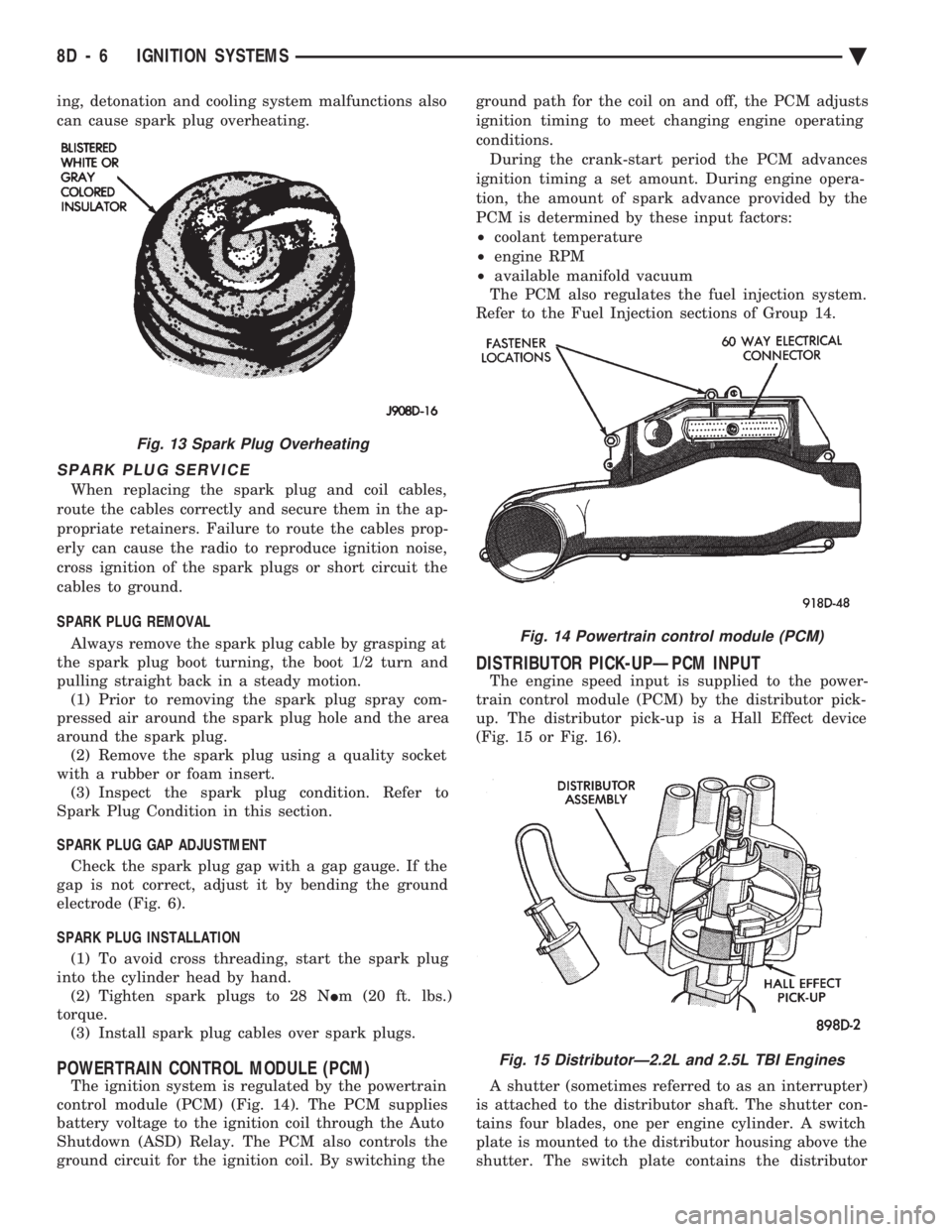

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 7). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

CABLE RESISTANCE CHART

Ä IGNITION SYSTEMS 8D - 3

Page 446 of 2438

for unleaded fuel. During combustion, fuel with

MMT coats the entire tip of the spark plug with a

rust color deposit. The rust color deposits could be

misdiagnosed as being caused by coolant in the com-

bustion chamber. MMT deposits do not affect spark

plug performance.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 7). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves

or defective spark plug cables. Cold (carbon) fouling

of the entire set may be caused by a clogged air

cleaner. Cold fouling is normal after short operating periods.

The spark plugs do not reach a high enough operating

temperature during short operating periods.

WET FOULING

A spark plug that is coated with excessive wet fuel or

oil is wet fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur be-

fore normal oil control is achieved. In new or

recently overhauled engines, wet fouled spark

plugs can be usually be cleaned and reinstalled.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or oil ash encrusted,

engine oil is entering the combustion chambers (Fig. 8).

Evaluate the engine to determine the cause.

HIGH SPEED MISS When replacing spark plugs because of a high speed

miss condition; wide open throttle operation

should be avoided for approximately 80 km (50

miles) after installation of new plugs. This will

allow deposit shifting in the combustion chamber to

take place gradually and avoid plug destroying splash

fouling shortly after the plug change.

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can cause

electrode gap bridging. The deposits accumulate on the

spark plugs during continuous stop-and-go driving.

When the engine is suddenly subjected to a high torque

load, the deposits partially liquefy and bridge the gap

between the electrodes

Fig. 6 Setting Spark Plug Electrode GapÐTypical

Fig. 7 Normal Operation and Cold (Carbon) FoulingFig. 8 Oil or Ash Encrusted

8D - 4 IGNITION SYSTEMS Ä

Page 448 of 2438

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

SPARK PLUG SERVICE

When replacing the spark plug and coil cables,

route the cables correctly and secure them in the ap-

propriate retainers. Failure to route the cables prop-

erly can cause the radio to reproduce ignition noise,

cross ignition of the spark plugs or short circuit the

cables to ground.

SPARK PLUG REMOVAL

Always remove the spark plug cable by grasping at

the spark plug boot turning, the boot 1/2 turn and

pulling straight back in a steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

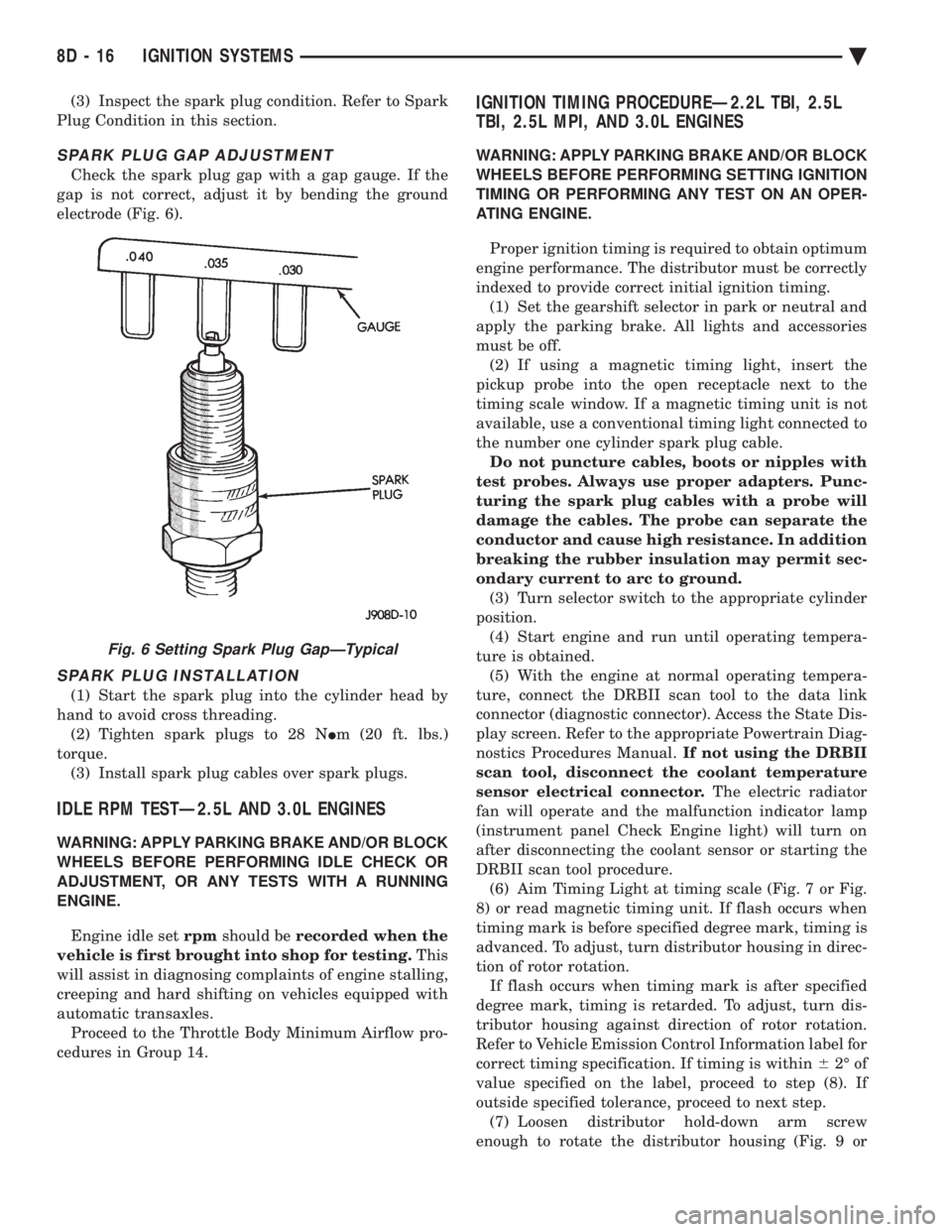

SPARK PLUG GAP ADJUSTMENT Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION (1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

POWERTRAIN CONTROL MODULE (PCM)

The ignition system is regulated by the powertrain

control module (PCM) (Fig. 14). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls the

ground circuit for the ignition coil. By switching the ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

During the crank-start period the PCM advances

ignition timing a set amount. During engine opera-

tion, the amount of spark advance provided by the

PCM is determined by these input factors:

² coolant temperature

² engine RPM

² available manifold vacuum

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

DISTRIBUTOR PICK-UPÐPCM INPUT

The engine speed input is supplied to the power-

train control module (PCM) by the distributor pick-

up. The distributor pick-up is a Hall Effect device

(Fig. 15 or Fig. 16).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

shutter. The switch plate contains the distributor

Fig. 14 Powertrain control module (PCM)

Fig. 15 DistributorÐ2.2L and 2.5L TBI Engines

Fig. 13 Spark Plug Overheating

8D - 6 IGNITION SYSTEMS Ä

Page 458 of 2438

(3) Inspect the spark plug condition. Refer to Spark

Plug Condition in this section.

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TESTÐ2.5L AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING IDLE CHECK OR

ADJUSTMENT, OR ANY TESTS WITH A RUNNING

ENGINE.

Engine idle set rpmshould be recorded when the

vehicle is first brought into shop for testing. This

will assist in diagnosing complaints of engine stalling,

creeping and hard shifting on vehicles equipped with

automatic transaxles. Proceed to the Throttle Body Minimum Airflow pro-

cedures in Group 14.

IGNITION TIMING PROCEDUREÐ2.2L TBI, 2.5L

TBI, 2.5L MPI, AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING SETTING IGNITION

TIMING OR PERFORMING ANY TEST ON AN OPER-

ATING ENGINE.

Proper ignition timing is required to obtain optimum

engine performance. The distributor must be correctly

indexed to provide correct initial ignition timing. (1) Set the gearshift selector in park or neutral and

apply the parking brake. All lights and accessories

must be off. (2) If using a magnetic timing light, insert the

pickup probe into the open receptacle next to the

timing scale window. If a magnetic timing unit is not

available, use a conventional timing light connected to

the number one cylinder spark plug cable. Do not puncture cables, boots or nipples with

test probes. Always use proper adapters. Punc-

turing the spark plug cables with a probe will

damage the cables. The probe can separate the

conductor and cause high resistance. In addition

breaking the rubber insulation may permit sec-

ondary current to arc to ground. (3) Turn selector switch to the appropriate cylinder

position. (4) Start engine and run until operating tempera-

ture is obtained. (5) With the engine at normal operating tempera-

ture, connect the DRBII scan tool to the data link

connector (diagnostic connector). Access the State Dis-

play screen. Refer to the appropriate Powertrain Diag-

nostics Procedures Manual. If not using the DRBII

scan tool, disconnect the coolant temperature

sensor electrical connector. The electric radiator

fan will operate and the malfunction indicator lamp

(instrument panel Check Engine light) will turn on

after disconnecting the coolant sensor or starting the

DRBII scan tool procedure. (6) Aim Timing Light at timing scale (Fig. 7 or Fig.

8) or read magnetic timing unit. If flash occurs when

timing mark is before specified degree mark, timing is

advanced. To adjust, turn distributor housing in direc-

tion of rotor rotation. If flash occurs when timing mark is after specified

degree mark, timing is retarded. To adjust, turn dis-

tributor housing against direction of rotor rotation.

Refer to Vehicle Emission Control Information label for

correct timing specification. If timing is within 62É of

value specified on the label, proceed to step (8). If

outside specified tolerance, proceed to next step. (7) Loosen distributor hold-down arm screw

enough to rotate the distributor housing (Fig. 9 or

Fig. 6 Setting Spark Plug GapÐTypical

8D - 16 IGNITION SYSTEMS Ä

Page 462 of 2438

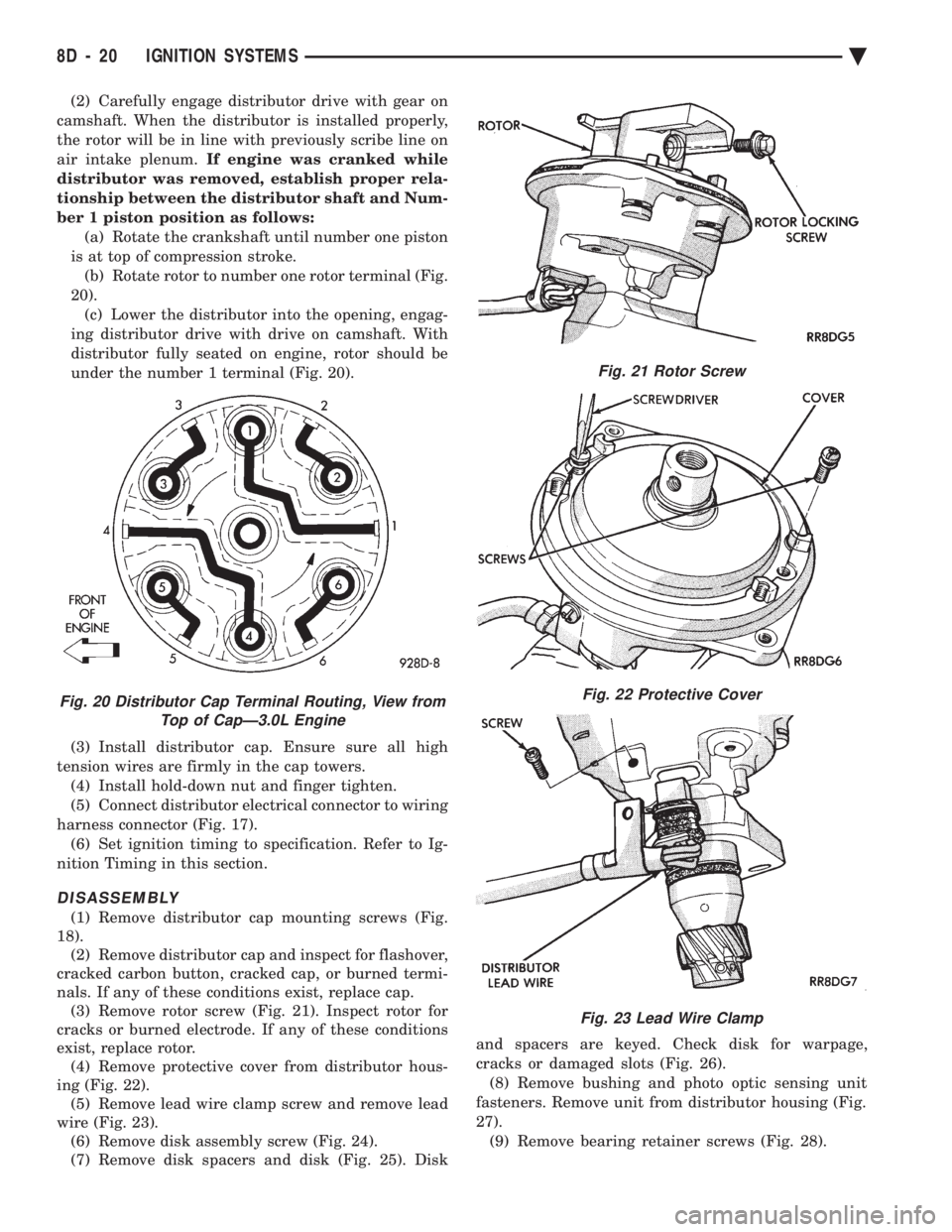

(2) Carefully engage distributor drive with gear on

camshaft. When the distributor is installed properly,

the rotor will be in line with previously scribe line on

air intake plenum. If engine was cranked while

distributor was removed, establish proper rela-

tionship between the distributor shaft and Num-

ber 1 piston position as follows: (a) Rotate the crankshaft until number one piston

is at top of compression stroke. (b) Rotate rotor to number one rotor terminal (Fig.

20). (c) Lower the distributor into the opening, engag-

ing distributor drive with drive on camshaft. With

distributor fully seated on engine, rotor should be

under the number 1 terminal (Fig. 20).

(3) Install distributor cap. Ensure sure all high

tension wires are firmly in the cap towers. (4) Install hold-down nut and finger tighten.

(5) Connect distributor electrical connector to wiring

harness connector (Fig. 17). (6) Set ignition timing to specification. Refer to Ig-

nition Timing in this section.

DISASSEMBLY

(1) Remove distributor cap mounting screws (Fig.

18). (2) Remove distributor cap and inspect for flashover,

cracked carbon button, cracked cap, or burned termi-

nals. If any of these conditions exist, replace cap. (3) Remove rotor screw (Fig. 21). Inspect rotor for

cracks or burned electrode. If any of these conditions

exist, replace rotor. (4) Remove protective cover from distributor hous-

ing (Fig. 22). (5) Remove lead wire clamp screw and remove lead

wire (Fig. 23). (6) Remove disk assembly screw (Fig. 24).

(7) Remove disk spacers and disk (Fig. 25). Disk and spacers are keyed. Check disk for warpage,

cracks or damaged slots (Fig. 26). (8) Remove bushing and photo optic sensing unit

fasteners. Remove unit from distributor housing (Fig.

27). (9) Remove bearing retainer screws (Fig. 28).

Fig. 21 Rotor Screw

Fig. 22 Protective Cover

Fig. 23 Lead Wire Clamp

Fig. 20 Distributor Cap Terminal Routing, View from Top of CapÐ3.0L Engine

8D - 20 IGNITION SYSTEMS Ä

Page 469 of 2438

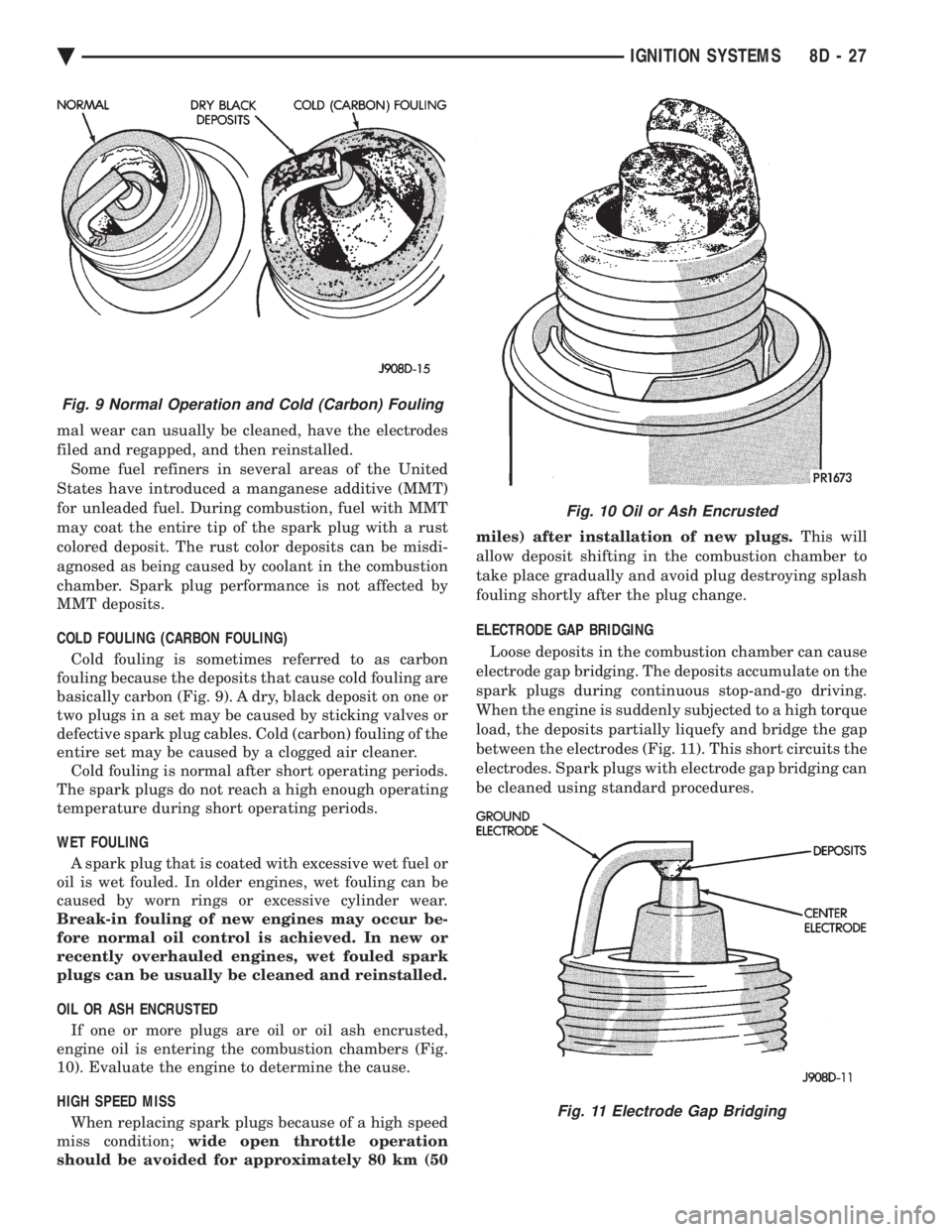

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING) Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling are

basically carbon (Fig. 9). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves or

defective spark plug cables. Cold (carbon) fouling of the

entire set may be caused by a clogged air cleaner. Cold fouling is normal after short operating periods.

The spark plugs do not reach a high enough operating

temperature during short operating periods.

WET FOULING A spark plug that is coated with excessive wet fuel or

oil is wet fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur be-

fore normal oil control is achieved. In new or

recently overhauled engines, wet fouled spark

plugs can be usually be cleaned and reinstalled.

OIL OR ASH ENCRUSTED If one or more plugs are oil or oil ash encrusted,

engine oil is entering the combustion chambers (Fig.

10). Evaluate the engine to determine the cause.

HIGH SPEED MISS When replacing spark plugs because of a high speed

miss condition; wide open throttle operation

should be avoided for approximately 80 km (50 miles) after installation of new plugs.

This will

allow deposit shifting in the combustion chamber to

take place gradually and avoid plug destroying splash

fouling shortly after the plug change.

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can cause

electrode gap bridging. The deposits accumulate on the

spark plugs during continuous stop-and-go driving.

When the engine is suddenly subjected to a high torque

load, the deposits partially liquefy and bridge the gap

between the electrodes (Fig. 11). This short circuits the

electrodes. Spark plugs with electrode gap bridging can

be cleaned using standard procedures.

Fig. 9 Normal Operation and Cold (Carbon) Fouling

Fig. 10 Oil or Ash Encrusted

Fig. 11 Electrode Gap Bridging

Ä IGNITION SYSTEMS 8D - 27

Page 483 of 2438

(2) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Cracked, leaking or faulty cables should

be replaced. Use the following procedure when removing the

high tension cable from the spark plug. First, remove

the cable from the retaining bracket. Then grasp the

terminal as close as possible to the spark plug. Ro-

tate the cover (boot) slightly and pull straight back.

Do not use pliers and do not pull the cable at an

angle. Doing so will damage the insulation, cable

terminal or the spark plug insulator. Wipe spark

plug insulator clean before reinstalling cable

and cover. Resistance cables are identified by the words Elec-

tronic Suppression .

Use an ohmmeter to check cables for opens, loose

terminals or high resistance. (a) Remove cable from spark plug.

(b) Remove cable from the coil tower.

(c) Connect the ohmmeter between spark plug

end terminal and the coil end terminal. Resistance

should be within tolerance shown in the cable re-

sistance chart. If resistance is not within tolerance,

replace cable assembly. Test all spark plug cables

in same manner.

SPARK PLUG SERVICE

When replacing the spark plug cables, route the ca-

bles correctly and secure them in the appropriate re-

tainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross ig-

nition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a

steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

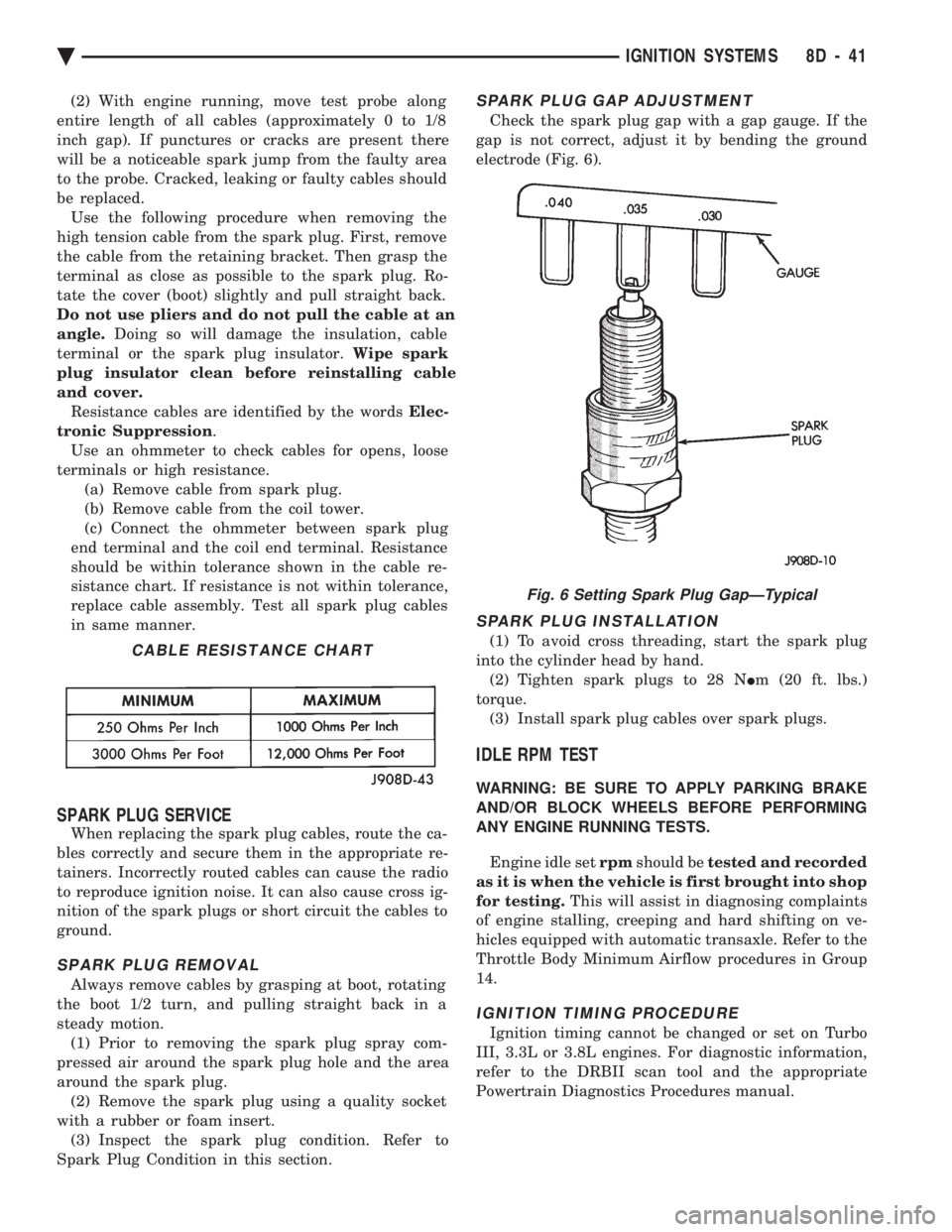

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TEST

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY ENGINE RUNNING TESTS.

Engine idle set rpmshould be tested and recorded

as it is when the vehicle is first brought into shop

for testing. This will assist in diagnosing complaints

of engine stalling, creeping and hard shifting on ve-

hicles equipped with automatic transaxle. Refer to the

Throttle Body Minimum Airflow procedures in Group

14.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on Turbo

III, 3.3L or 3.8L engines. For diagnostic information,

refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

CABLE RESISTANCE CHART

Fig. 6 Setting Spark Plug GapÐTypical

Ä IGNITION SYSTEMS 8D - 41

Page 513 of 2438

(3) Remove four screws from ash receiver/cup

holder housing. (4) For installation reverse above procedures.

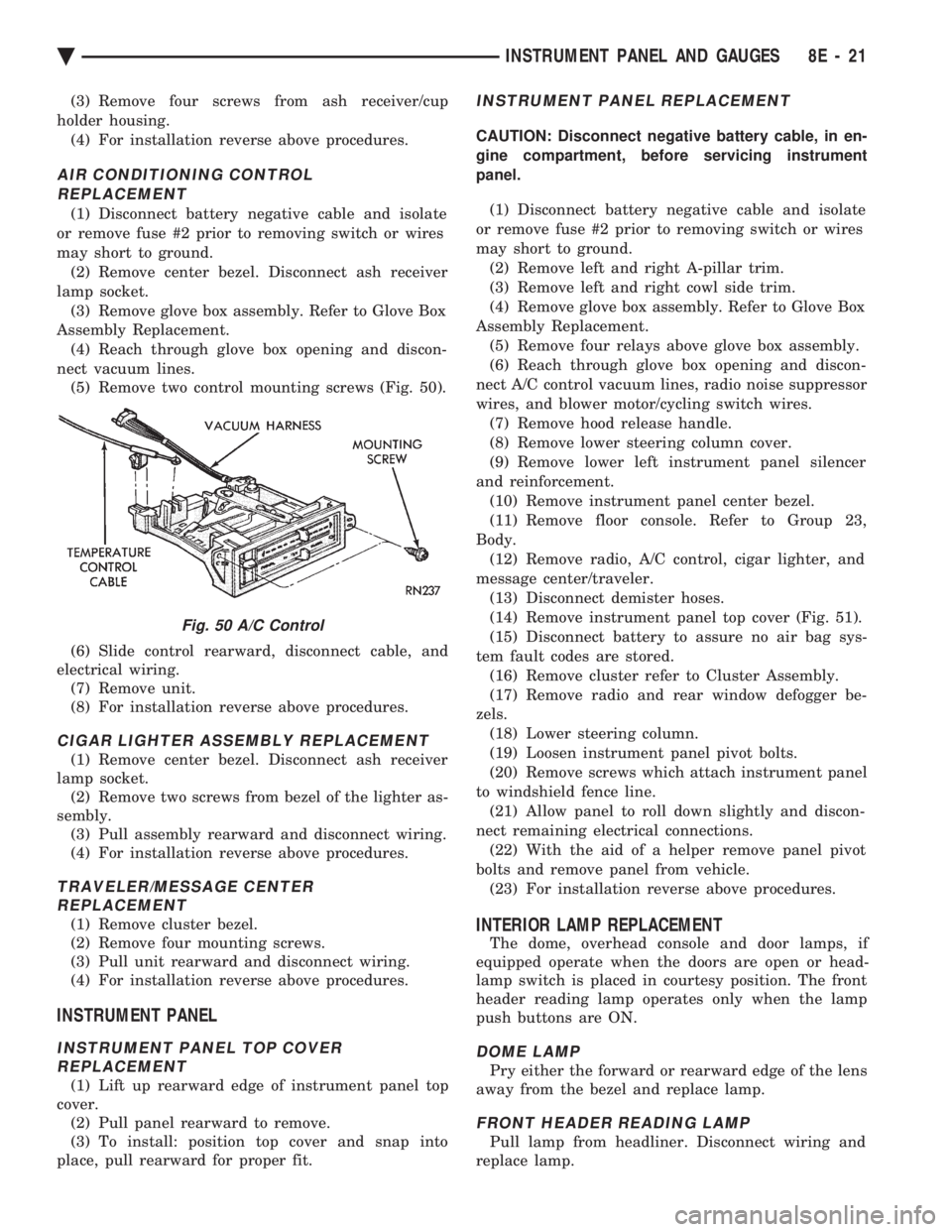

AIR CONDITIONING CONTROLREPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove center bezel. Disconnect ash receiver

lamp socket. (3) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (4) Reach through glove box opening and discon-

nect vacuum lines. (5) Remove two control mounting screws (Fig. 50).

(6) Slide control rearward, disconnect cable, and

electrical wiring. (7) Remove unit.

(8) For installation reverse above procedures.

CIGAR LIGHTER ASSEMBLY REPLACEMENT

(1) Remove center bezel. Disconnect ash receiver

lamp socket. (2) Remove two screws from bezel of the lighter as-

sembly. (3) Pull assembly rearward and disconnect wiring.

(4) For installation reverse above procedures.

TRAVELER/MESSAGE CENTER REPLACEMENT

(1) Remove cluster bezel.

(2) Remove four mounting screws.

(3) Pull unit rearward and disconnect wiring.

(4) For installation reverse above procedures.

INSTRUMENT PANEL

INSTRUMENT PANEL TOP COVER REPLACEMENT

(1) Lift up rearward edge of instrument panel top

cover. (2) Pull panel rearward to remove.

(3) To install: position top cover and snap into

place, pull rearward for proper fit.

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove left and right A-pillar trim.

(3) Remove left and right cowl side trim.

(4) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (5) Remove four relays above glove box assembly.

(6) Reach through glove box opening and discon-

nect A/C control vacuum lines, radio noise suppressor

wires, and blower motor/cycling switch wires. (7) Remove hood release handle.

(8) Remove lower steering column cover.

(9) Remove lower left instrument panel silencer

and reinforcement. (10) Remove instrument panel center bezel.

(11) Remove floor console. Refer to Group 23,

Body. (12) Remove radio, A/C control, cigar lighter, and

message center/traveler. (13) Disconnect demister hoses.

(14) Remove instrument panel top cover (Fig. 51).

(15) Disconnect battery to assure no air bag sys-

tem fault codes are stored. (16) Remove cluster refer to Cluster Assembly.

(17) Remove radio and rear window defogger be-

zels. (18) Lower steering column.

(19) Loosen instrument panel pivot bolts.

(20) Remove screws which attach instrument panel

to windshield fence line. (21) Allow panel to roll down slightly and discon-

nect remaining electrical connections. (22) With the aid of a helper remove panel pivot

bolts and remove panel from vehicle. (23) For installation reverse above procedures.

INTERIOR LAMP REPLACEMENT

The dome, overhead console and door lamps, if

equipped operate when the doors are open or head-

lamp switch is placed in courtesy position. The front

header reading lamp operates only when the lamp

push buttons are ON.

DOME LAMP

Pry either the forward or rearward edge of the lens

away from the bezel and replace lamp.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

Fig. 50 A/C Control

Ä INSTRUMENT PANEL AND GAUGES 8E - 21

Page 529 of 2438

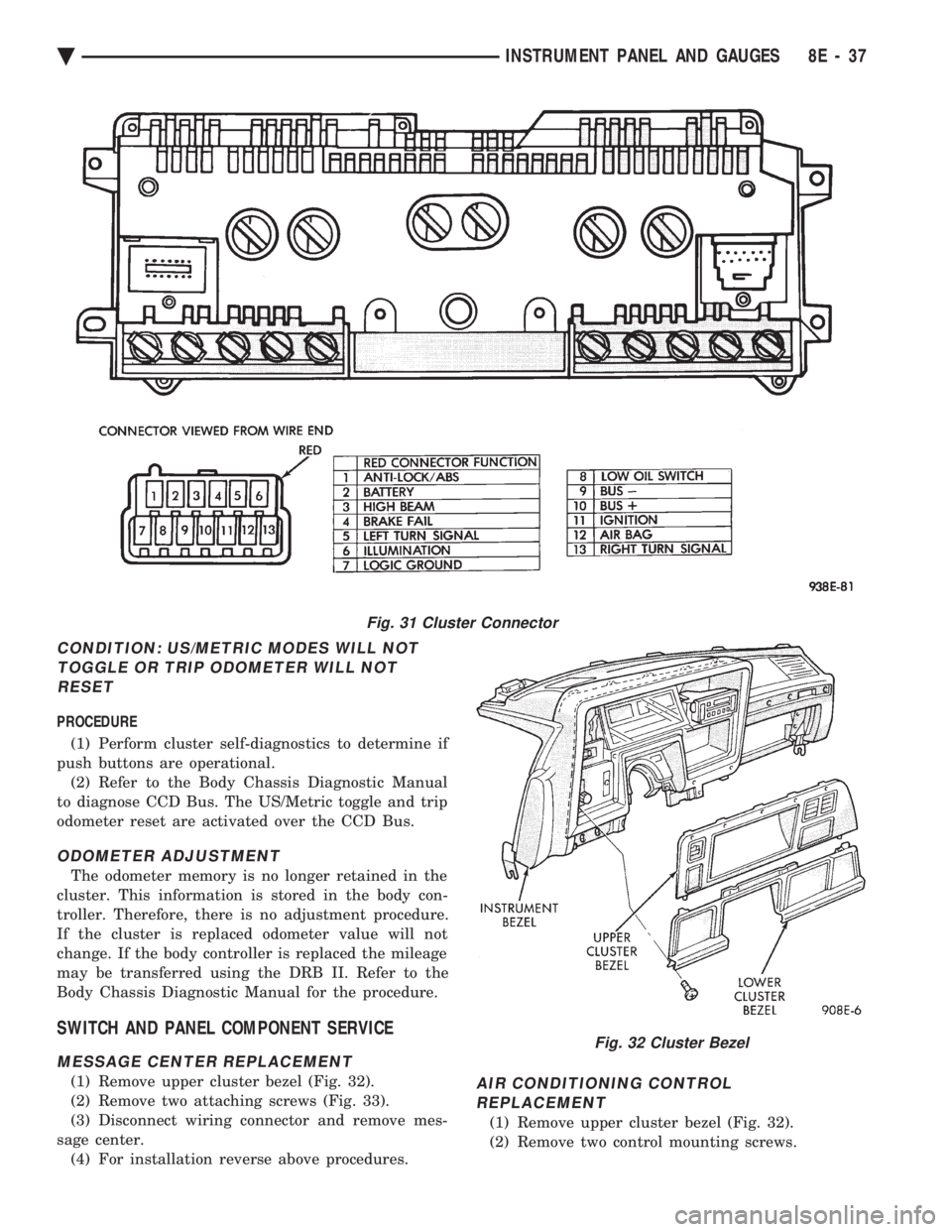

CONDITION: US/METRIC MODES WILL NOT TOGGLE OR TRIP ODOMETER WILL NOTRESET

PROCEDURE

(1) Perform cluster self-diagnostics to determine if

push buttons are operational. (2) Refer to the Body Chassis Diagnostic Manual

to diagnose CCD Bus. The US/Metric toggle and trip

odometer reset are activated over the CCD Bus.

ODOMETER ADJUSTMENT

The odometer memory is no longer retained in the

cluster. This information is stored in the body con-

troller. Therefore, there is no adjustment procedure.

If the cluster is replaced odometer value will not

change. If the body controller is replaced the mileage

may be transferred using the DRB II. Refer to the

Body Chassis Diagnostic Manual for the procedure.

SWITCH AND PANEL COMPONENT SERVICE

MESSAGE CENTER REPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two attaching screws (Fig. 33).

(3) Disconnect wiring connector and remove mes-

sage center. (4) For installation reverse above procedures.AIR CONDITIONING CONTROLREPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two control mounting screws.

Fig. 31 Cluster Connector

Fig. 32 Cluster Bezel

Ä INSTRUMENT PANEL AND GAUGES 8E - 37