air condition CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 353 of 2438

INSPECTION Replace water pump body assembly if it has any of

these defects: (1) Cracks or damage on the body.

(2) Water leaks from the shaft seal, evident by

coolant traces below the vent hole. (3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the hous-

ing.

ASSEMBLY

Body assembly and housing are serviced as separate

components. (1) Install new O-ring gasket in body O-ring groove.

(2) Assemble pump body to housing and tighten nine

screws to 12 N Im (105 in. lbs.) (Fig. 2).

(3) Rotate pump by hand to check for freedom of

movement. (4) Position water pump pulley to water pump.In-

stall three screws and tighten to 30 N Im (250 in. lbs.).

(5) Position new O-ring in housing to block O-ring

groove.

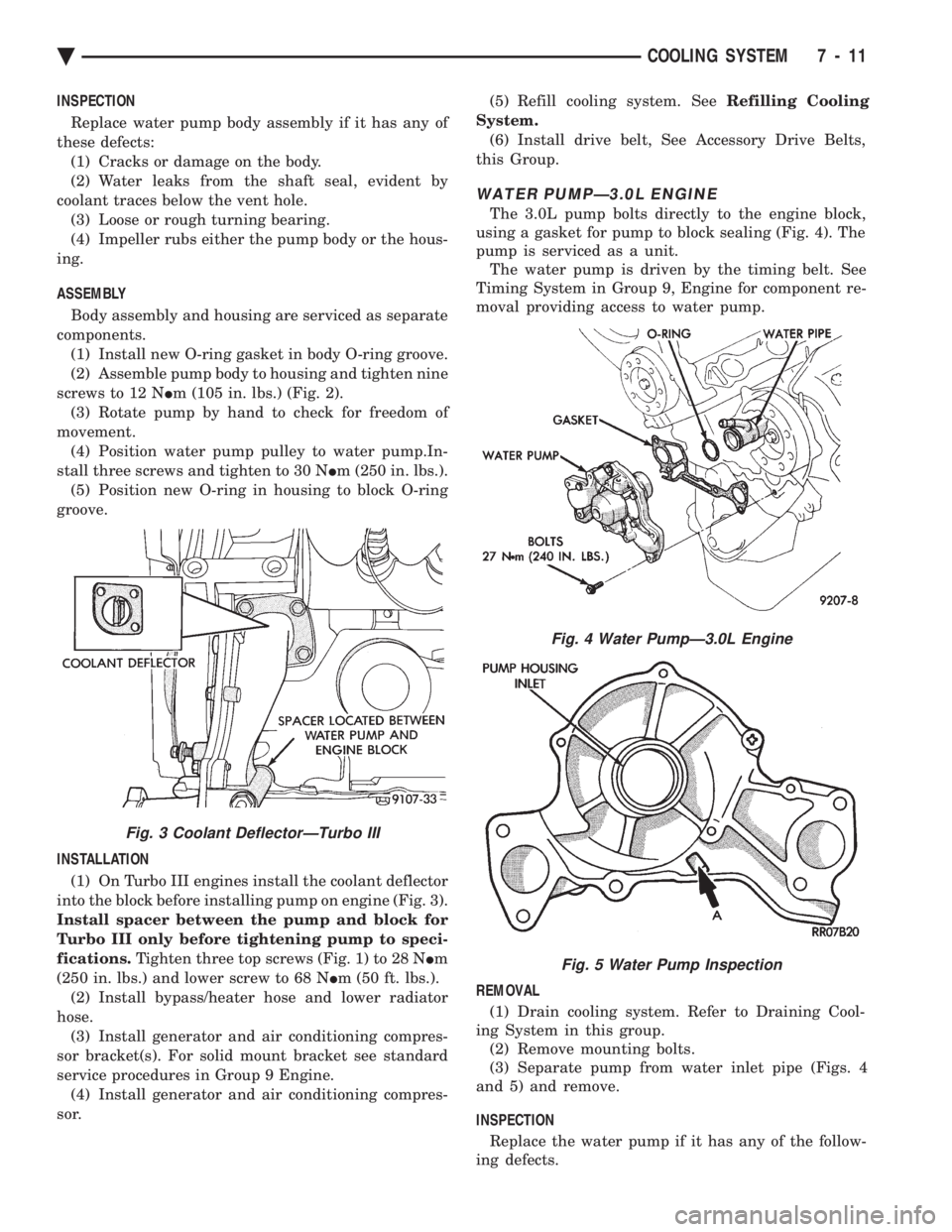

INSTALLATION (1) On Turbo III engines install the coolant deflector

into the block before installing pump on engine (Fig. 3).

Install spacer between the pump and block for

Turbo III only before tightening pump to speci-

fications. Tighten three top screws (Fig. 1) to 28 N Im

(250 in. lbs.) and lower screw to 68 N Im (50 ft. lbs.).

(2) Install bypass/heater hose and lower radiator

hose. (3) Install generator and air conditioning compres-

sor bracket(s). For solid mount bracket see standard

service procedures in Group 9 Engine. (4) Install generator and air conditioning compres-

sor. (5) Refill cooling system. See

Refilling Cooling

System. (6) Install drive belt, See Accessory Drive Belts,

this Group.

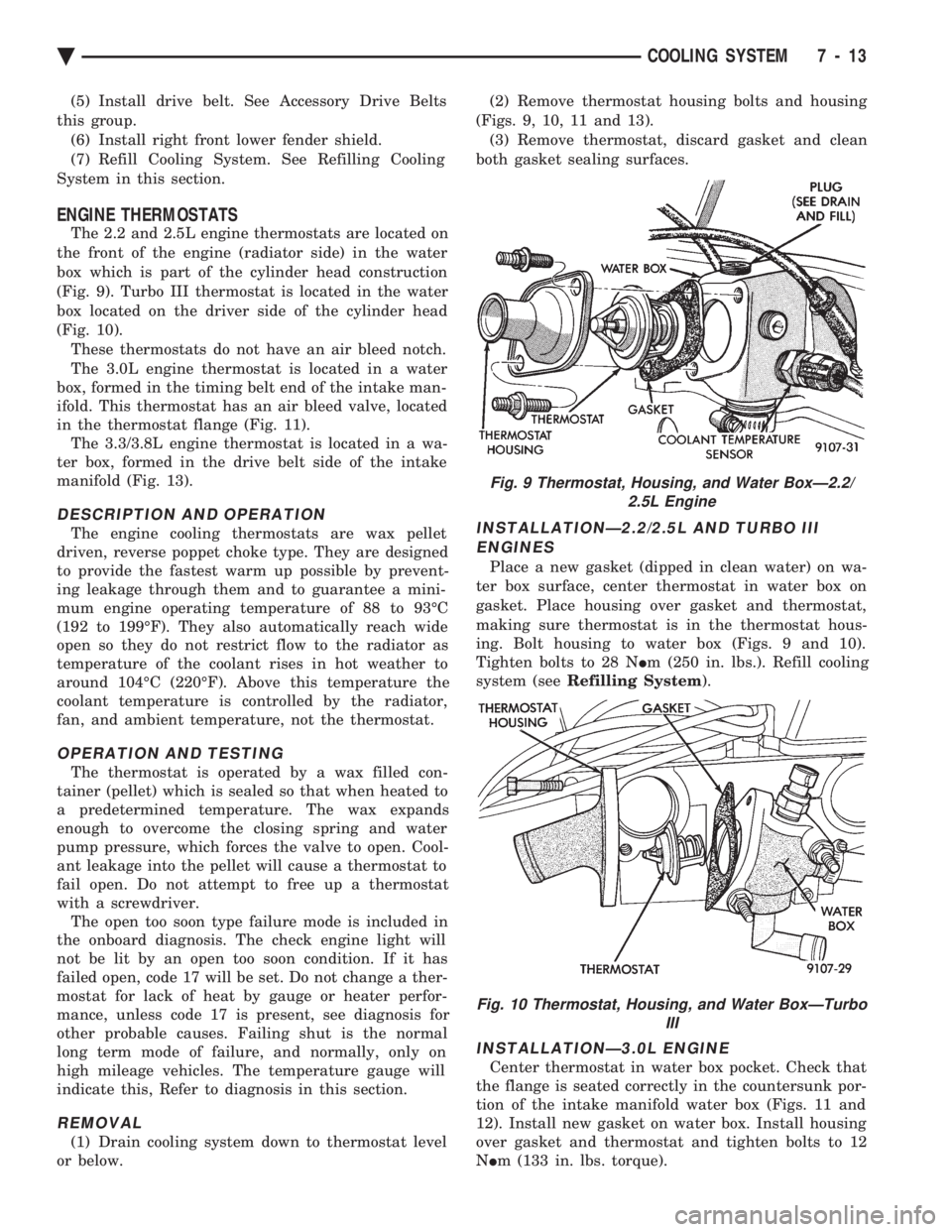

WATER PUMPÐ3.0L ENGINE

The 3.0L pump bolts directly to the engine block,

using a gasket for pump to block sealing (Fig. 4). The

pump is serviced as a unit. The water pump is driven by the timing belt. See

Timing System in Group 9, Engine for component re-

moval providing access to water pump.

REMOVAL (1) Drain cooling system. Refer to Draining Cool-

ing System in this group. (2) Remove mounting bolts.

(3) Separate pump from water inlet pipe (Figs. 4

and 5) and remove.

INSPECTION Replace the water pump if it has any of the follow-

ing defects.

Fig. 4 Water PumpÐ3.0L Engine

Fig. 5 Water Pump Inspection

Fig. 3 Coolant DeflectorÐTurbo III

Ä COOLING SYSTEM 7 - 11

Page 355 of 2438

(5) Install drive belt. See Accessory Drive Belts

this group. (6) Install right front lower fender shield.

(7) Refill Cooling System. See Refilling Cooling

System in this section.

ENGINE THERMOSTATS

The 2.2 and 2.5L engine thermostats are located on

the front of the engine (radiator side) in the water

box which is part of the cylinder head construction

(Fig. 9). Turbo III thermostat is located in the water

box located on the driver side of the cylinder head

(Fig. 10). These thermostats do not have an air bleed notch.

The 3.0L engine thermostat is located in a water

box, formed in the timing belt end of the intake man-

ifold. This thermostat has an air bleed valve, located

in the thermostat flange (Fig. 11). The 3.3/3.8L engine thermostat is located in a wa-

ter box, formed in the drive belt side of the intake

manifold (Fig. 13).

DESCRIPTION AND OPERATION

The engine cooling thermostats are wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the radiator,

fan, and ambient temperature, not the thermostat.

OPERATION AND TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed so that when heated to

a predetermined temperature. The wax expands

enough to overcome the closing spring and water

pump pressure, which forces the valve to open. Cool-

ant leakage into the pellet will cause a thermostat to

fail open. Do not attempt to free up a thermostat

with a screwdriver. The open too soon type failure mode is included in

the onboard diagnosis. The check engine light will

not be lit by an open too soon condition. If it has

failed open, code 17 will be set. Do not change a ther-

mostat for lack of heat by gauge or heater perfor-

mance, unless code 17 is present, see diagnosis for

other probable causes. Failing shut is the normal

long term mode of failure, and normally, only on

high mileage vehicles. The temperature gauge will

indicate this, Refer to diagnosis in this section.

REMOVAL

(1) Drain cooling system down to thermostat level

or below. (2) Remove thermostat housing bolts and housing

(Figs. 9, 10, 11 and 13). (3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

INSTALLATIONÐ2.2/2.5L AND TURBO III ENGINES

Place a new gasket (dipped in clean water) on wa-

ter box surface, center thermostat in water box on

gasket. Place housing over gasket and thermostat,

making sure thermostat is in the thermostat hous-

ing. Bolt housing to water box (Figs. 9 and 10).

Tighten bolts to 28 N Im (250 in. lbs.). Refill cooling

system (see Refilling System ).

INSTALLATIONÐ3.0L ENGINE

Center thermostat in water box pocket. Check that

the flange is seated correctly in the countersunk por-

tion of the intake manifold water box (Figs. 11 and

12). Install new gasket on water box. Install housing

over gasket and thermostat and tighten bolts to 12

N Im (133 in. lbs. torque).

Fig. 9 Thermostat, Housing, and Water BoxÐ2.2/

2.5L Engine

Fig. 10 Thermostat, Housing, and Water BoxÐTurbo III

Ä COOLING SYSTEM 7 - 13

Page 362 of 2438

(2) Remove radiator pressure cap when engine is

cold, Idle engine until thermostat opens, you should

observe coolant flow while looking down the filler

neck. Once flow is detected install radiator pressure

cap.

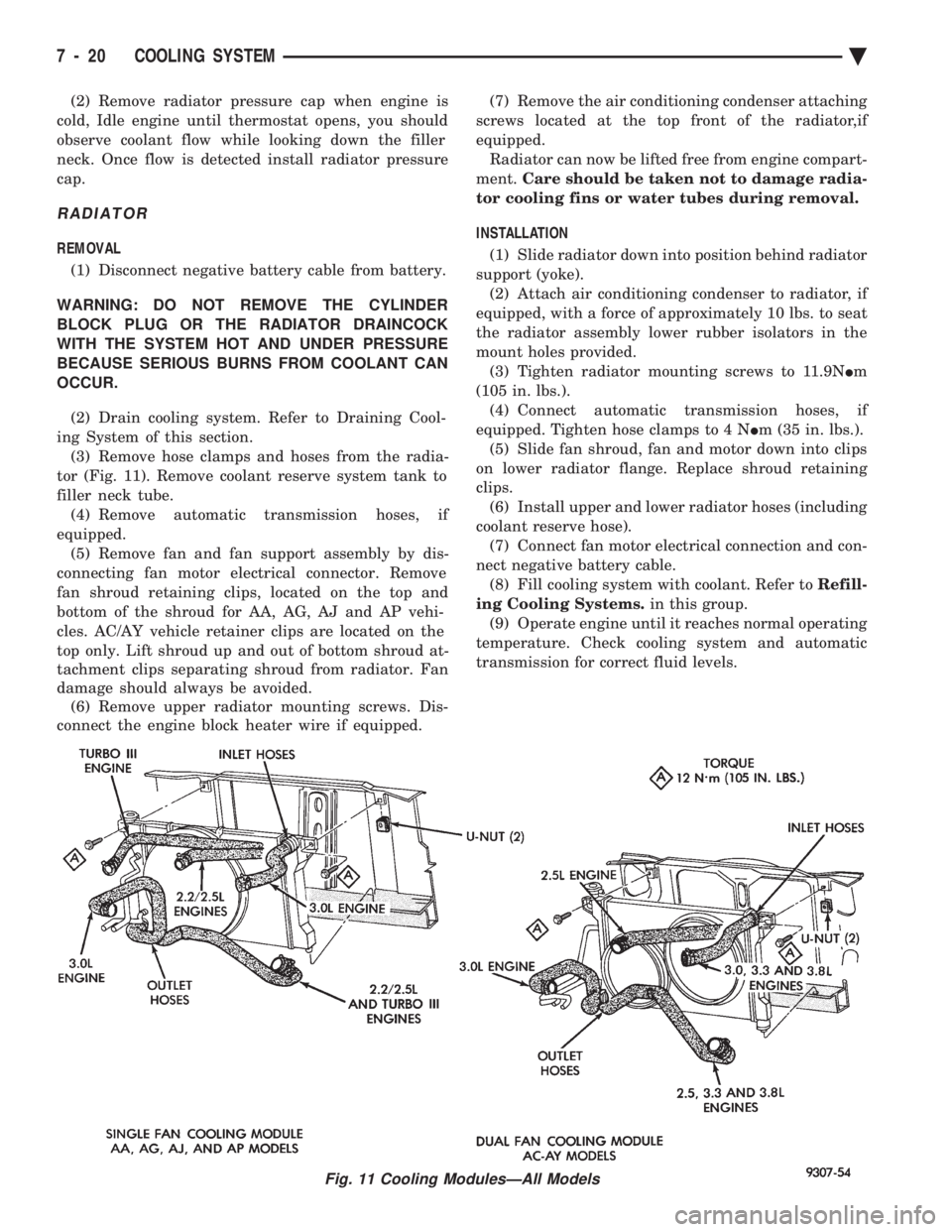

RADIATOR

REMOVAL

(1) Disconnect negative battery cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section. (3) Remove hose clamps and hoses from the radia-

tor (Fig. 11). Remove coolant reserve system tank to

filler neck tube. (4) Remove automatic transmission hoses, if

equipped. (5) Remove fan and fan support assembly by dis-

connecting fan motor electrical connector. Remove

fan shroud retaining clips, located on the top and

bottom of the shroud for AA, AG, AJ and AP vehi-

cles. AC/AY vehicle retainer clips are located on the

top only. Lift shroud up and out of bottom shroud at-

tachment clips separating shroud from radiator. Fan

damage should always be avoided. (6) Remove upper radiator mounting screws. Dis-

connect the engine block heater wire if equipped. (7) Remove the air conditioning condenser attaching

screws located at the top front of the radiator,if

equipped. Radiator can now be lifted free from engine compart-

ment. Care should be taken not to damage radia-

tor cooling fins or water tubes during removal.

INSTALLATION

(1) Slide radiator down into position behind radiator

support (yoke). (2) Attach air conditioning condenser to radiator, if

equipped, with a force of approximately 10 lbs. to seat

the radiator assembly lower rubber isolators in the

mount holes provided. (3) Tighten radiator mounting screws to 11.9N Im

(105 in. lbs.). (4) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 4 N Im (35 in. lbs.).

(5) Slide fan shroud, fan and motor down into clips

on lower radiator flange. Replace shroud retaining

clips. (6) Install upper and lower radiator hoses (including

coolant reserve hose). (7) Connect fan motor electrical connection and con-

nect negative battery cable. (8) Fill cooling system with coolant. Refer to Refill-

ing Cooling Systems. in this group.

(9) Operate engine until it reaches normal operating

temperature. Check cooling system and automatic

transmission for correct fluid levels.

Fig. 11 Cooling ModulesÐAll Models

7 - 20 COOLING SYSTEM Ä

Page 363 of 2438

RADIATOR HOSES

The hoses are removed using Constant Tension

Clamp pliers to compress hose clamp. A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses. Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended. Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original style spring type clamp.

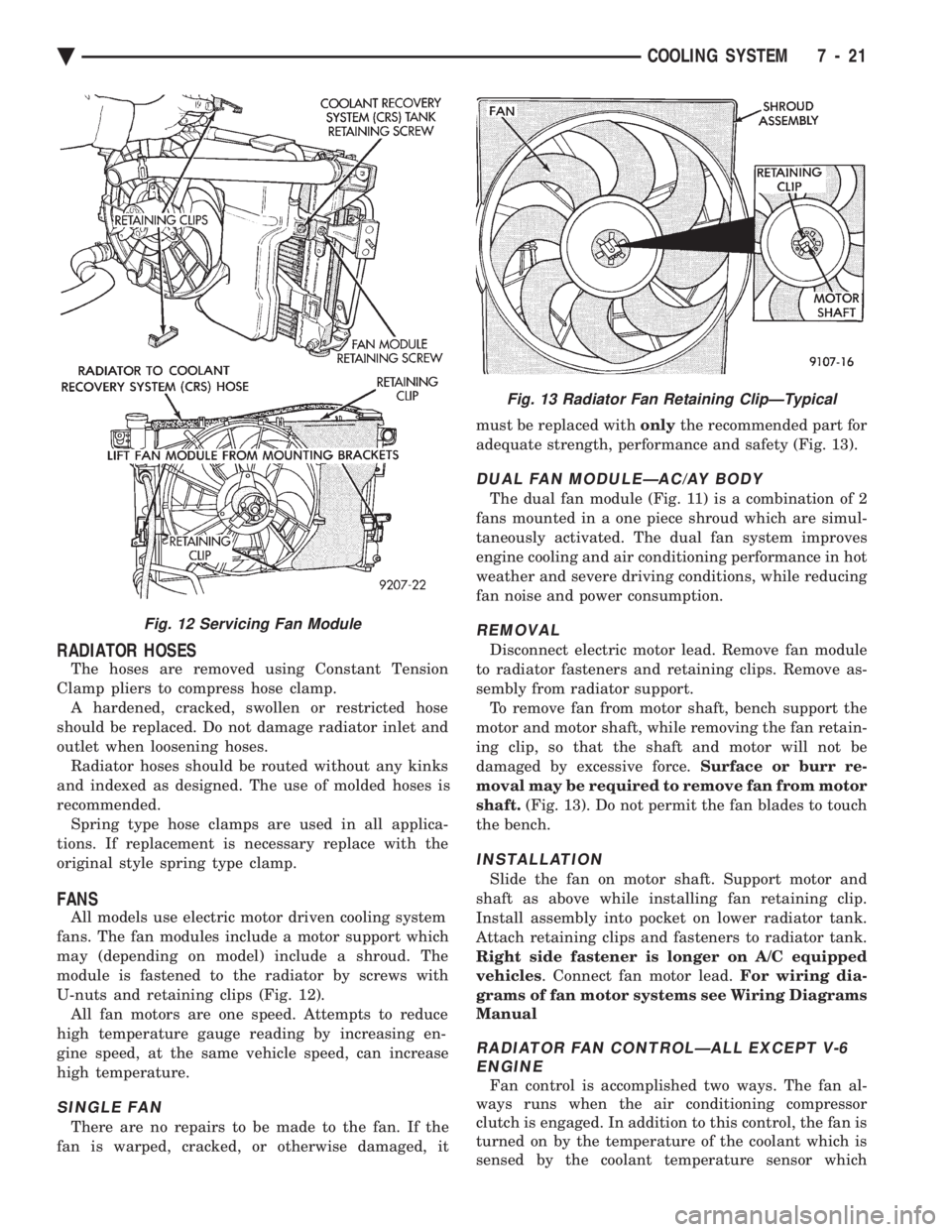

FANS

All models use electric motor driven cooling system

fans. The fan modules include a motor support which

may (depending on model) include a shroud. The

module is fastened to the radiator by screws with

U-nuts and retaining clips (Fig. 12). All fan motors are one speed. Attempts to reduce

high temperature gauge reading by increasing en-

gine speed, at the same vehicle speed, can increase

high temperature.

SINGLE FAN

There are no repairs to be made to the fan. If the

fan is warped, cracked, or otherwise damaged, it must be replaced with

onlythe recommended part for

adequate strength, performance and safety (Fig. 13).

DUAL FAN MODULEÐAC/AY BODY

The dual fan module (Fig. 11) is a combination of 2

fans mounted in a one piece shroud which are simul-

taneously activated. The dual fan system improves

engine cooling and air conditioning performance in hot

weather and severe driving conditions, while reducing

fan noise and power consumption.

REMOVAL

Disconnect electric motor lead. Remove fan module

to radiator fasteners and retaining clips. Remove as-

sembly from radiator support. To remove fan from motor shaft, bench support the

motor and motor shaft, while removing the fan retain-

ing clip, so that the shaft and motor will not be

damaged by excessive force. Surface or burr re-

moval may be required to remove fan from motor

shaft. (Fig. 13). Do not permit the fan blades to touch

the bench.

INSTALLATION

Slide the fan on motor shaft. Support motor and

shaft as above while installing fan retaining clip.

Install assembly into pocket on lower radiator tank.

Attach retaining clips and fasteners to radiator tank.

Right side fastener is longer on A/C equipped

vehicles . Connect fan motor lead. For wiring dia-

grams of fan motor systems see Wiring Diagrams

Manual

RADIATOR FAN CONTROLÐALL EXCEPT V-6 ENGINE

Fan control is accomplished two ways. The fan al-

ways runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan is

turned on by the temperature of the coolant which is

sensed by the coolant temperature sensor which

Fig. 12 Servicing Fan Module

Fig. 13 Radiator Fan Retaining ClipÐTypical

Ä COOLING SYSTEM 7 - 21

Page 364 of 2438

sends the message to the Engine Controller. The En-

gine Controller turns on the fan through the fan re-

lay. See Wiring Diagrams Manual for circuity and

diagnostics provided.Switching through the Engine Controller provides

fan control for the following conditions.

² The fan will not run during cranking until the en-

gine starts no matter what the coolant temperature

is.

² Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

² For 4 cylinder application the fan will run at ve-

hicle speeds above about 40 mph only if coolant tem-

perature reaches 110ÉC (230ÉF). It will turn off when

the temperature drops to 104ÉC (220ÉF). At speeds

below 40 mph the fan switches on at 102ÉC (215ÉF)

and off at 93ÉC (200ÉF).

² This is to help prevent steaming. The fan will run

only below 16ÉC (60ÉF) ambient. Between 38ÉC

(100ÉF) to 97ÉC (195ÉF) coolant temperature, at idle

and then only for three minutes.

RADIATOR FAN CONTROLÐAC/AY BODY V-6 ONLY

For this application, fan control is accomplished

based on coolant temperature, and on A/C head pres-

sure. These vehicles receive the variable displace-

ment compressor. The fan will go on when;

² Coolant temperature reaches 102ÉC (215ÉF) and off

at 93.4ÉC (200ÉF) regardless of vehicle speed.

² When the head pressure reaches 1516.9 kPa (220

psi) and turn off when the pressure reaches 1103 kPa

(160 psi).

TEMPERATURE GAUGE INDICATION

At idle the temperature gauge will rise slowly to

about 5/8 gauge travel. The fan will come on and the

gauge will drop to about 1/2 gauge travel, this is nor-

mal.

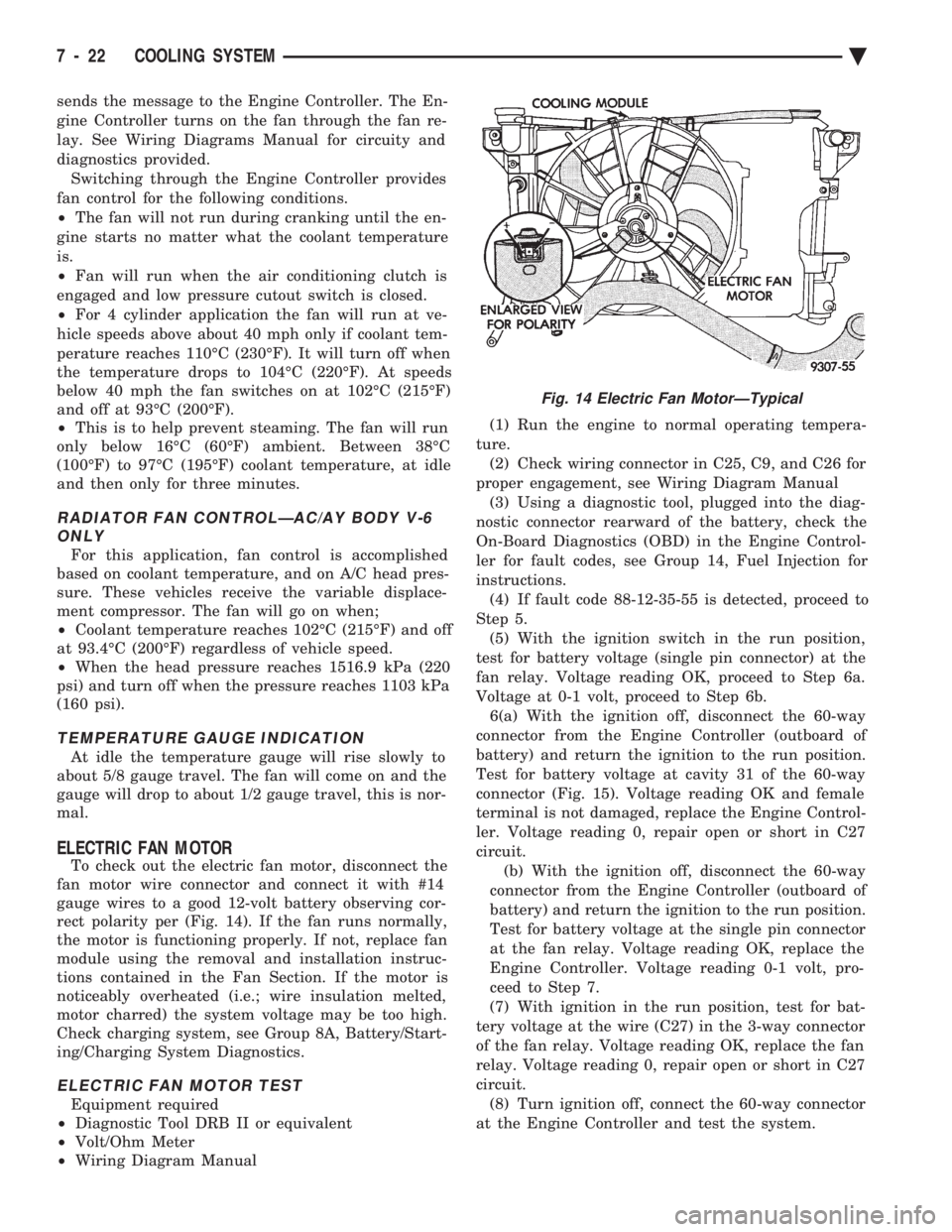

ELECTRIC FAN MOTOR

To check out the electric fan motor, disconnect the

fan motor wire connector and connect it with #14

gauge wires to a good 12-volt battery observing cor-

rect polarity per (Fig. 14). If the fan runs normally,

the motor is functioning properly. If not, replace fan

module using the removal and installation instruc-

tions contained in the Fan Section. If the motor is

noticeably overheated (i.e.; wire insulation melted,

motor charred) the system voltage may be too high.

Check charging system, see Group 8A, Battery/Start-

ing/Charging System Diagnostics.

ELECTRIC FAN MOTOR TEST

Equipment required

² Diagnostic Tool DRB II or equivalent

² Volt/Ohm Meter

² Wiring Diagram Manual (1) Run the engine to normal operating tempera-

ture. (2) Check wiring connector in C25, C9, and C26 for

proper engagement, see Wiring Diagram Manual (3) Using a diagnostic tool, plugged into the diag-

nostic connector rearward of the battery, check the

On-Board Diagnostics (OBD) in the Engine Control-

ler for fault codes, see Group 14, Fuel Injection for

instructions. (4) If fault code 88-12-35-55 is detected, proceed to

Step 5. (5) With the ignition switch in the run position,

test for battery voltage (single pin connector) at the

fan relay. Voltage reading OK, proceed to Step 6a.

Voltage at 0-1 volt, proceed to Step 6b. 6(a) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at cavity 31 of the 60-way

connector (Fig. 15). Voltage reading OK and female

terminal is not damaged, replace the Engine Control-

ler. Voltage reading 0, repair open or short in C27

circuit. (b) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at the single pin connector

at the fan relay. Voltage reading OK, replace the

Engine Controller. Voltage reading 0-1 volt, pro-

ceed to Step 7.

(7) With ignition in the run position, test for bat-

tery voltage at the wire (C27) in the 3-way connector

of the fan relay. Voltage reading OK, replace the fan

relay. Voltage reading 0, repair open or short in C27

circuit. (8) Turn ignition off, connect the 60-way connector

at the Engine Controller and test the system.

Fig. 14 Electric Fan MotorÐTypical

7 - 22 COOLING SYSTEM Ä

Page 366 of 2438

ACCESSORY DRIVE BELTS INDEX

page page

2.2/2.5L Engine Belts Remove/Install-Adjust .... 24

3.0L Engine Belts Remove/Install and Adjust .... 25

3.3/3.8L and Turbo III Engine Accessory Drive Belt Remove and Install

..................... 26

General Information ....................... 24

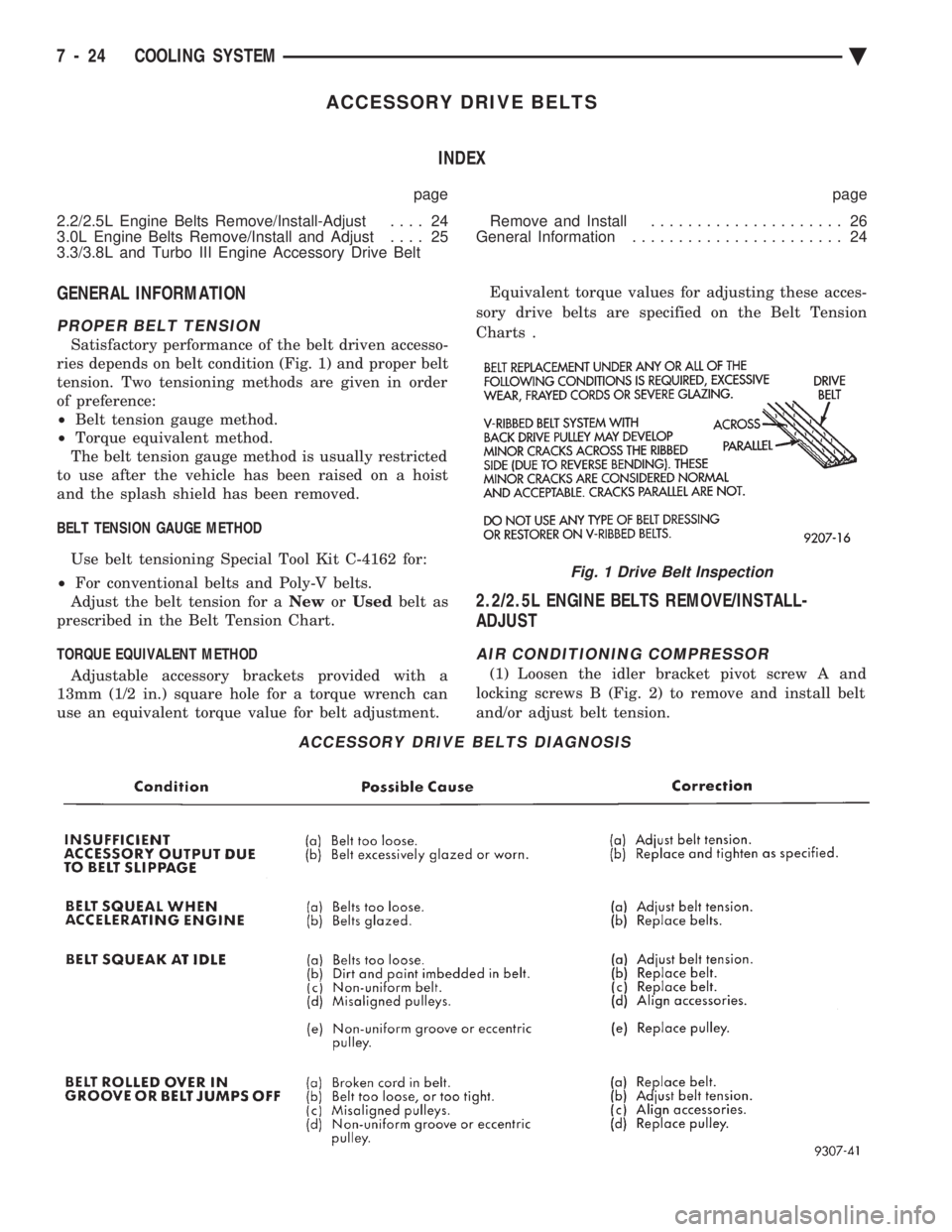

GENERAL INFORMATION

PROPER BELT TENSION

Satisfactory performance of the belt driven accesso-

ries depends on belt condition (Fig. 1) and proper belt

tension. Two tensioning methods are given in order

of preference:

² Belt tension gauge method.

² Torque equivalent method.

The belt tension gauge method is usually restricted

to use after the vehicle has been raised on a hoist

and the splash shield has been removed.

BELT TENSION GAUGE METHOD Use belt tensioning Special Tool Kit C-4162 for:

² For conventional belts and Poly-V belts.

Adjust the belt tension for a NeworUsed belt as

prescribed in the Belt Tension Chart.

TORQUE EQUIVALENT METHOD Adjustable accessory brackets provided with a

13mm (1/2 in.) square hole for a torque wrench can

use an equivalent torque value for belt adjustment. Equivalent torque values for adjusting these acces-

sory drive belts are specified on the Belt Tension

Charts .

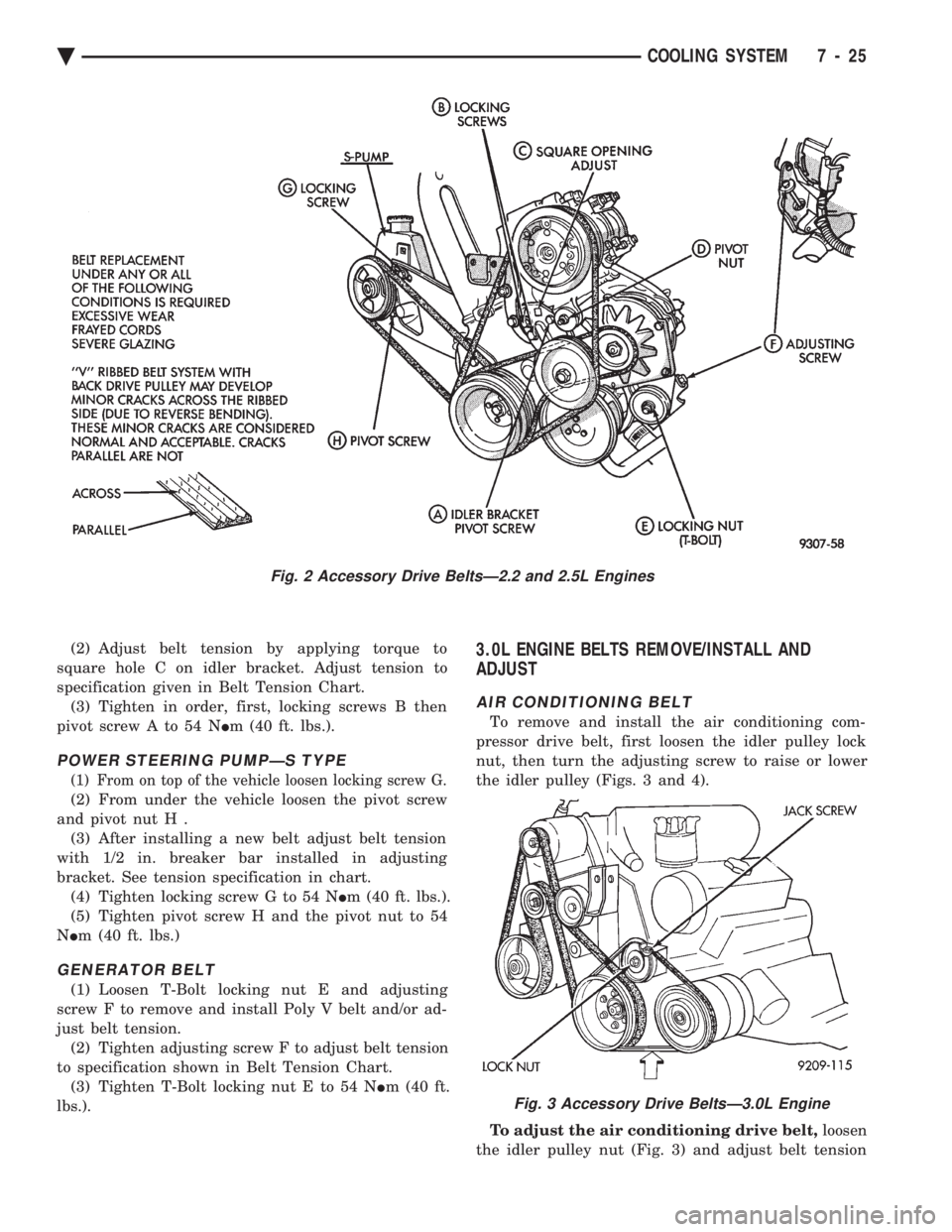

2.2/2.5L ENGINE BELTS REMOVE/INSTALL-

ADJUST

AIR CONDITIONING COMPRESSOR

(1) Loosen the idler bracket pivot screw A and

locking screws B (Fig. 2) to remove and install belt

and/or adjust belt tension.

ACCESSORY DRIVE BELTS DIAGNOSIS

Fig. 1 Drive Belt Inspection

7 - 24 COOLING SYSTEM Ä

Page 367 of 2438

(2) Adjust belt tension by applying torque to

square hole C on idler bracket. Adjust tension to

specification given in Belt Tension Chart. (3) Tighten in order, first, locking screws B then

pivot screw A to 54 N Im (40 ft. lbs.).

POWER STEERING PUMPÐS TYPE

(1) From on top of the vehicle loosen locking screw G.

(2) From under the vehicle loosen the pivot screw

and pivot nut H . (3) After installing a new belt adjust belt tension

with 1/2 in. breaker bar installed in adjusting

bracket. See tension specification in chart. (4) Tighten locking screw G to 54 N Im (40 ft. lbs.).

(5) Tighten pivot screw H and the pivot nut to 54

N Im (40 ft. lbs.)

GENERATOR BELT

(1) Loosen T-Bolt locking nut E and adjusting

screw F to remove and install Poly V belt and/or ad-

just belt tension. (2) Tighten adjusting screw F to adjust belt tension

to specification shown in Belt Tension Chart. (3) Tighten T-Bolt locking nut E to 54 N Im (40 ft.

lbs.).

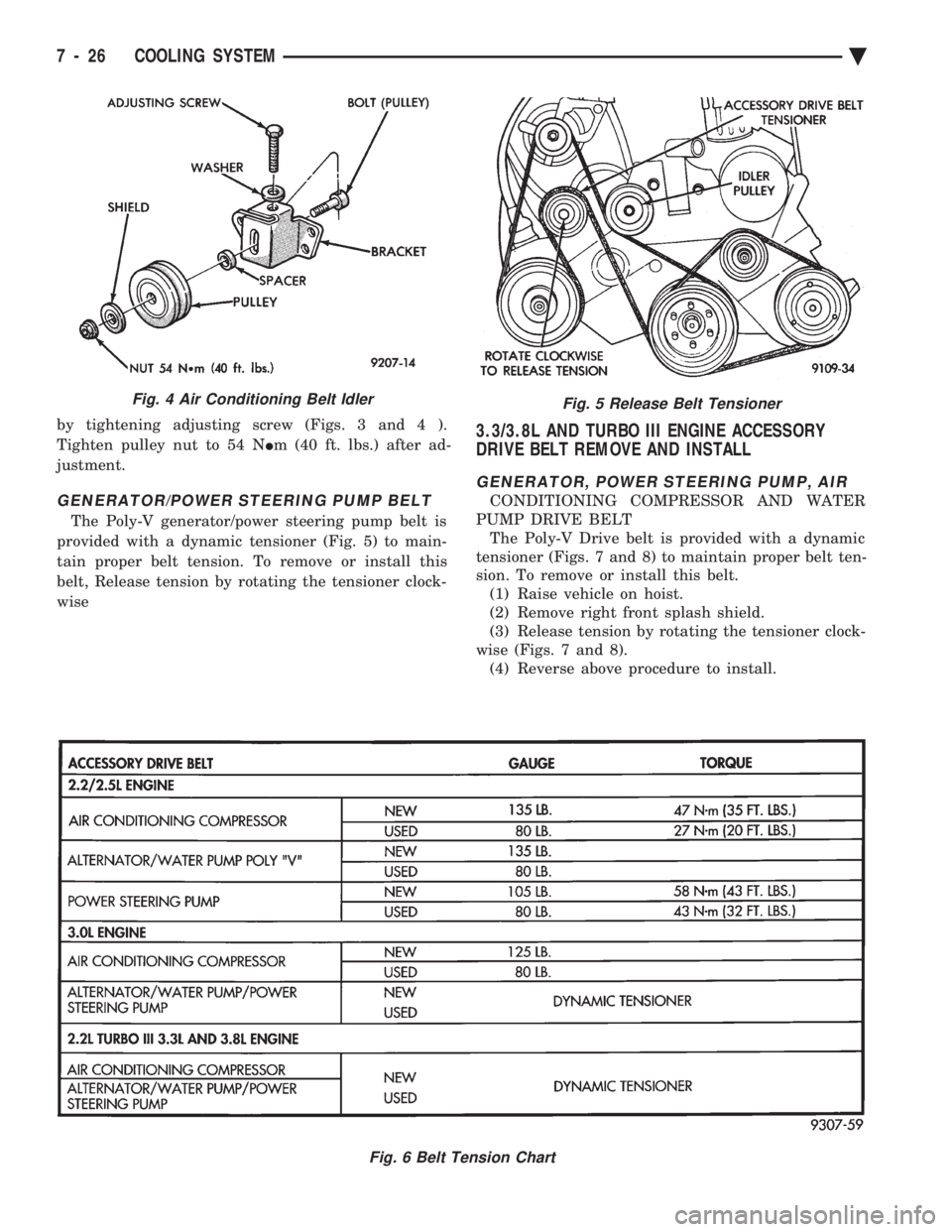

3.0L ENGINE BELTS REMOVE/INSTALL AND

ADJUST

AIR CONDITIONING BELT

To remove and install the air conditioning com-

pressor drive belt, first loosen the idler pulley lock

nut, then turn the adjusting screw to raise or lower

the idler pulley (Figs. 3 and 4).

To adjust the air conditioning drive belt, loosen

the idler pulley nut (Fig. 3) and adjust belt tension

Fig. 2 Accessory Drive BeltsÐ2.2 and 2.5L Engines

Fig. 3 Accessory Drive BeltsÐ3.0L Engine

Ä COOLING SYSTEM 7 - 25

Page 368 of 2438

by tightening adjusting screw (Figs. 3 and 4 ).

Tighten pulley nut to 54 N Im (40 ft. lbs.) after ad-

justment.

GENERATOR/POWER STEERING PUMP BELT

The Poly-V generator/power steering pump belt is

provided with a dynamic tensioner (Fig. 5) to main-

tain proper belt tension. To remove or install this

belt, Release tension by rotating the tensioner clock-

wise

3.3/3.8L AND TURBO III ENGINE ACCESSORY

DRIVE BELT REMOVE AND INSTALL

GENERATOR, POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR AND WATER

PUMP DRIVE BELT The Poly-V Drive belt is provided with a dynamic

tensioner (Figs. 7 and 8) to maintain proper belt ten-

sion. To remove or install this belt. (1) Raise vehicle on hoist.

(2) Remove right front splash shield.

(3) Release tension by rotating the tensioner clock-

wise (Figs. 7 and 8). (4) Reverse above procedure to install.

Fig. 5 Release Belt Tensioner

Fig. 6 Belt Tension Chart

Fig. 4 Air Conditioning Belt Idler

7 - 26 COOLING SYSTEM Ä

Page 388 of 2438

relay to starter solenoid for loose or corroded connec-

tions. Particularly at starter terminals.

² Repeat test. If engine still fails to crank properly,

trouble is within starter or starter mounted solenoid,

and it must be removed for repairs. Refer to Group

8B, Battery/Starter/Generator Service, Starter re-

placement.

STARTER RELAY TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform the preceding starter solenoid tests

BEFORE performing starter relay tests. Refer to

Starter Solenoid Test. (3) Locate and remove the starter relay. For

starter relay locations, refer to Starter Solenoid Test

(Fig. 13 or 14). (4) After the starter relay has been located and re-

moved, refer to Starter Relay Tests (Fig. 15).

NEUTRAL STARTING AND BACK-UP SWITCH

AUTOMATIC TRANSMISSION ONLY

For electrical diagnostics, when checking starter

circuits, refer to Starter Relay Tests (Fig. 15). For replacement of switch, refer to Group 21, Tran-

saxle, Neutral Starting and Switch Replacement.

STARTER INTERLOCK SWITCHÐCLUTCH PEDAL MOUNTED

MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to the Starter Relay

Tests. For replacement and/or adjustment of the switch,

refer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

IGNITION SWITCH TEST

After testing the starter solenoid and relay, test ig-

nition switch and wiring. Refer to Group 8D, Ignition

Systems, or the Front Wheel Drive Car Wiring Dia-

grams Service Manual. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

BENCH TESTING STARTER SOLENOID

(1) Disconnect field coil wire from field coil termi-

nal (Fig. 16 or 17). (2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester. Con-

tinuity should be detected (Fig. 18 or 19). (3) Check for continuity between solenoid terminal

and solenoid housing (Fig. 20 or 21). Continuity

should be detected. If continuity is detected, solenoid

is good. (4) If continuity is not detected in either test, sole-

noid has an open circuit and is defective. If equipped

with:

² BOSCH STARTER: Replace the solenoid.

² NIPPONDENSO STARTER: Replace the starter

assembly.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 411 of 2438

GENERATOR INDEX

page page

General Information ........................ 9

Generator ReplacementÐ2.2L Turbo Engine (With 16 Valve Cylinder Head) ............. 10 Generator ReplacementÐ2.2L/2.5L Engine

...... 9

Generator ReplacementÐ3.0L Engine ......... 10

Generator ReplacementÐ3.3L/3.8L Engine ..... 11

GENERAL INFORMATION

This section will cover generator removal and instal-

lation only. Information covering generator on-vehicle

testing and diagnosis can be found in Group 8A,

Battery/Starting/Charging Systems Diagnostics. To

identify the generator, refer to the Generator Specifi-

cation chart at the rear of this section. These generators are not intended to be disas-

sembled for service. It must be replaced as an

assembly.

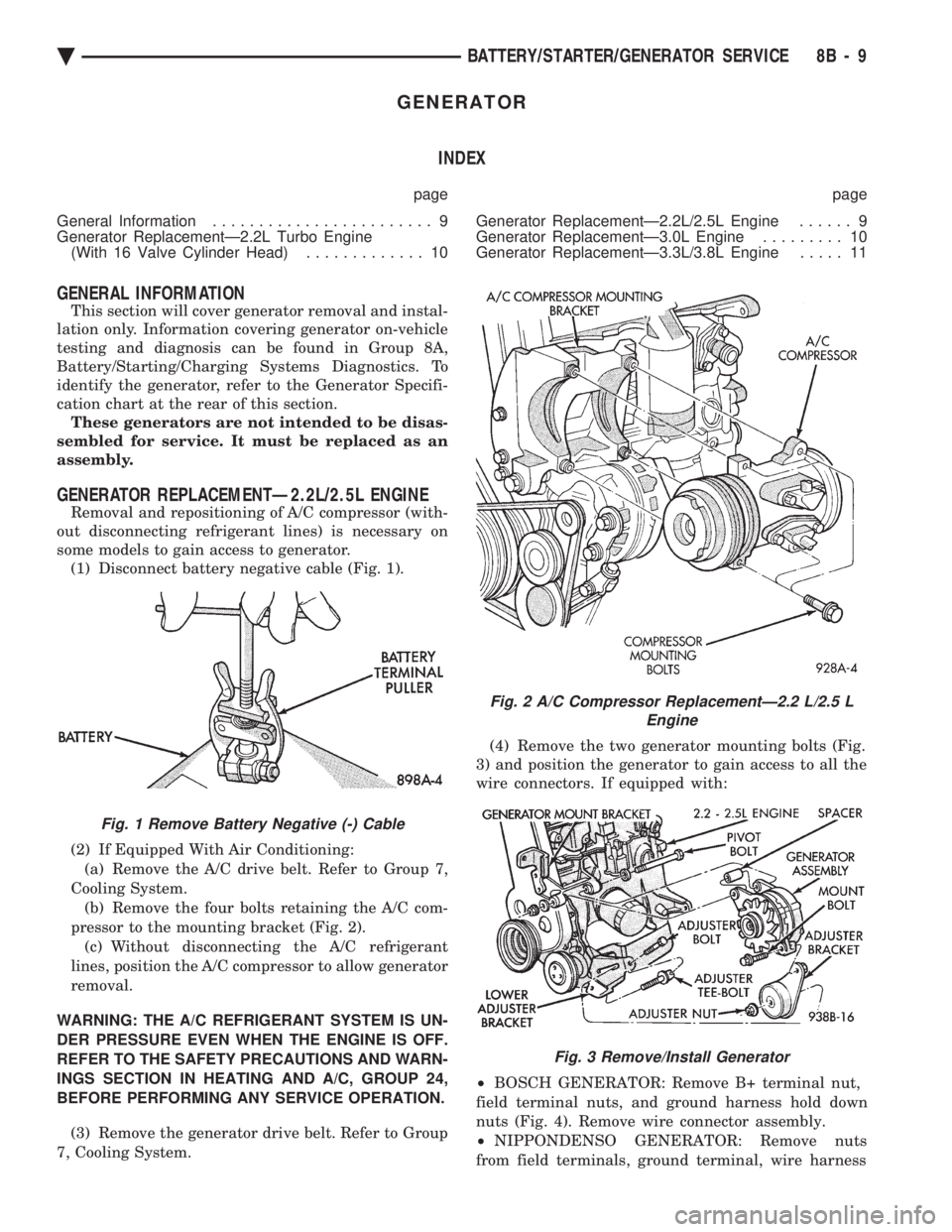

GENERATOR REPLACEMENTÐ2.2L/2.5L ENGINE

Removal and repositioning of A/C compressor (with-

out disconnecting refrigerant lines) is necessary on

some models to gain access to generator. (1) Disconnect battery negative cable (Fig. 1).

(2) If Equipped With Air Conditioning:

(a) Remove the A/C drive belt. Refer to Group 7,

Cooling System. (b) Remove the four bolts retaining the A/C com-

pressor to the mounting bracket (Fig. 2). (c) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal.

WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND WARN-

INGS SECTION IN HEATING AND A/C, GROUP 24,

BEFORE PERFORMING ANY SERVICE OPERATION. (3) Remove the generator drive belt. Refer to Group

7, Cooling System. (4) Remove the two generator mounting bolts (Fig.

3) and position the generator to gain access to all the

wire connectors. If equipped with:

² BOSCH GENERATOR: Remove B+ terminal nut,

field terminal nuts, and ground harness hold down

nuts (Fig. 4). Remove wire connector assembly.

² NIPPONDENSO GENERATOR: Remove nuts

from field terminals, ground terminal, wire harness

Fig. 1 Remove Battery Negative (-) Cable

Fig. 2 A/C Compressor ReplacementÐ2.2 L/2.5 L Engine

Fig. 3 Remove/Install Generator

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 9