service CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 85 of 2438

DRIVESHAFT IDENTIFICATION

Driveshafts are identified by the manufacturer. Vehi-

cles can be equipped with any of these driveshaft as-

semblies. Each assembly can be identified as shown in

(Fig. 2).

SERVICE PROCEDURES

Procedures for the removal and installation of the

driveshafts are essentially the same for all front

wheel drive vehicles. Each driveshaft has a spring

within the inboard Tripod C/V joint that maintains

constant engagement with the transaxle. This allows

the drive shaft to be removed without dismantling

part of the transaxle.

CAUTION: Boot sealing is vital to retain special lu-

bricants and to prevent foreign contaminants from

entering the C/V joint. Mishandling, such as allow-

ing the assemblies to dangle unsupported, pulling

or pushing the ends can cut boots or damage C/V

joints. During removal and installation procedures

always support both ends of the driveshaft to pre-

vent damage.

DRIVESHAFTS, REMOVE INSTALL

HUB NUT REMOVAL

Hub nut removal and installation is the same for

all front wheel drive vehicles. For installation see

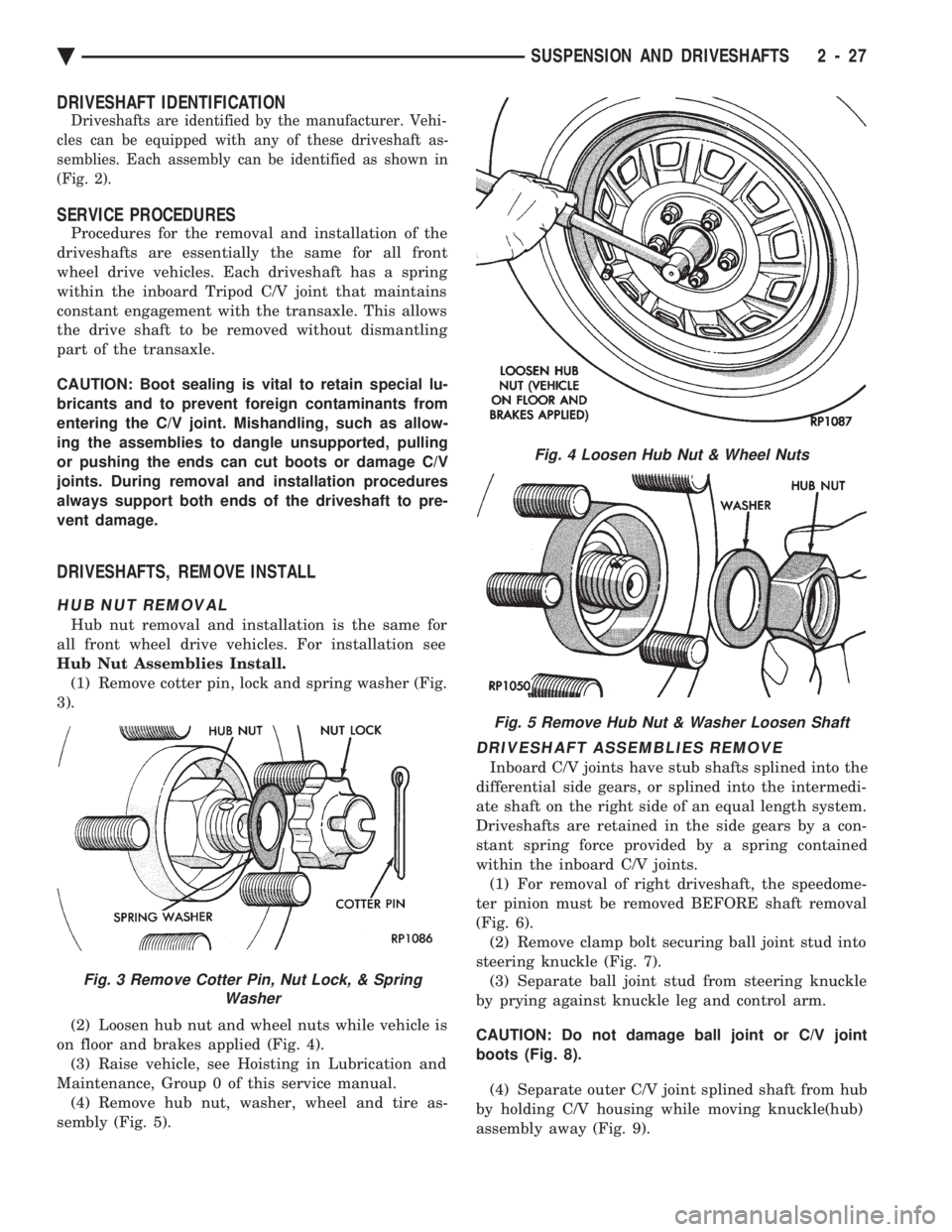

Hub Nut Assemblies Install. (1) Remove cotter pin, lock and spring washer (Fig.

3).

(2) Loosen hub nut and wheel nuts while vehicle is

on floor and brakes applied (Fig. 4). (3) Raise vehicle, see Hoisting in Lubrication and

Maintenance, Group 0 of this service manual. (4) Remove hub nut, washer, wheel and tire as-

sembly (Fig. 5).

DRIVESHAFT ASSEMBLIES REMOVE

Inboard C/V joints have stub shafts splined into the

differential side gears, or splined into the intermedi-

ate shaft on the right side of an equal length system.

Driveshafts are retained in the side gears by a con-

stant spring force provided by a spring contained

within the inboard C/V joints. (1) For removal of right driveshaft, the speedome-

ter pinion must be removed BEFORE shaft removal

(Fig. 6). (2) Remove clamp bolt securing ball joint stud into

steering knuckle (Fig. 7). (3) Separate ball joint stud from steering knuckle

by prying against knuckle leg and control arm.

CAUTION: Do not damage ball joint or C/V joint

boots (Fig. 8). (4) Separate outer C/V joint splined shaft from hub

by holding C/V housing while moving knuckle(hub)

assembly away (Fig. 9).

Fig. 3 Remove Cotter Pin, Nut Lock, & Spring Washer

Fig. 4 Loosen Hub Nut & Wheel Nuts

Fig. 5 Remove Hub Nut & Washer Loosen Shaft

Ä SUSPENSION AND DRIVESHAFTS 2 - 27

Page 87 of 2438

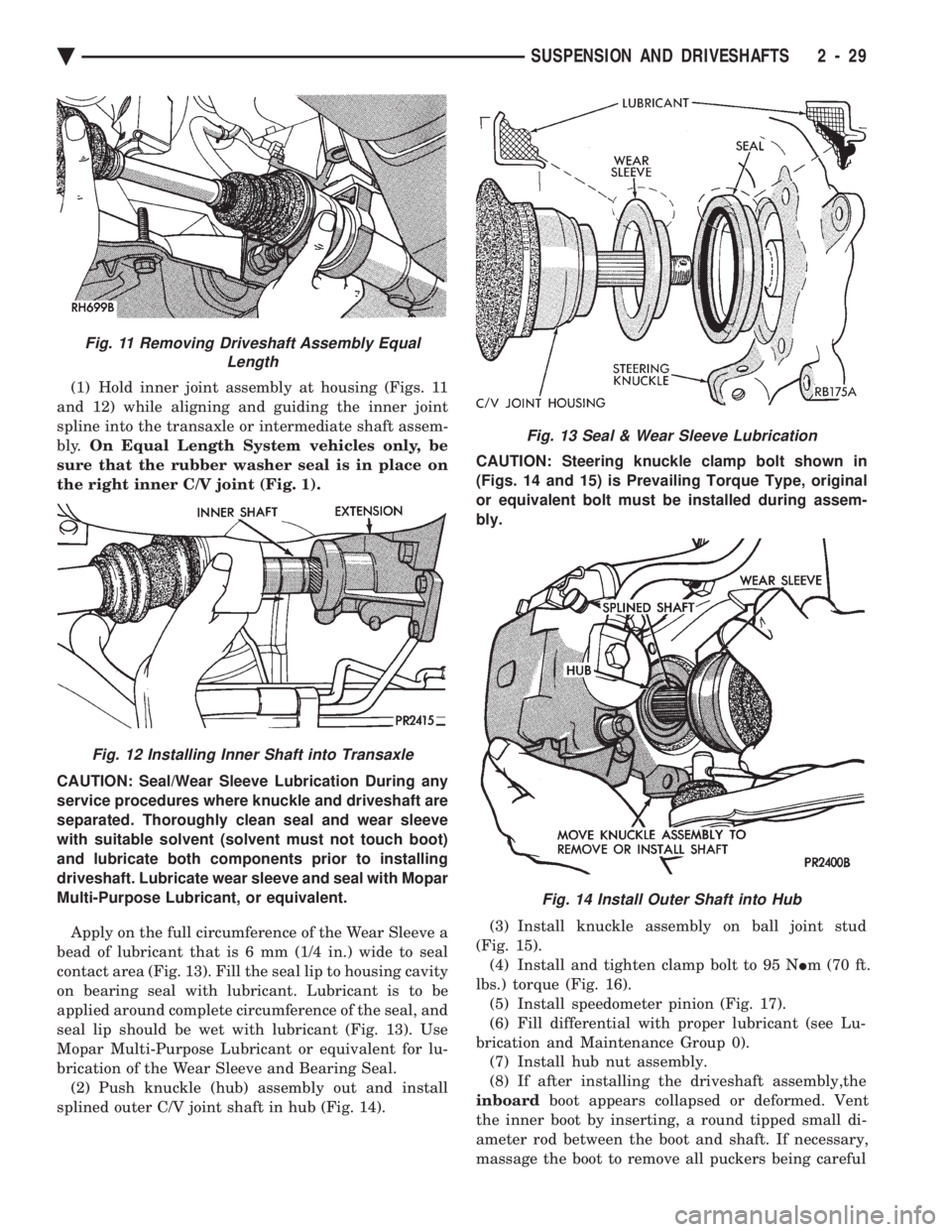

(1) Hold inner joint assembly at housing (Figs. 11

and 12) while aligning and guiding the inner joint

spline into the transaxle or intermediate shaft assem-

bly. On Equal Length System vehicles only, be

sure that the rubber washer seal is in place on

the right inner C/V joint (Fig. 1).

CAUTION: Seal/Wear Sleeve Lubrication During any

service procedures where knuckle and driveshaft are

separated. Thoroughly clean seal and wear sleeve

with suitable solvent (solvent must not touch boot)

and lubricate both components prior to installing

driveshaft. Lubricate wear sleeve and seal with Mopar

Multi-Purpose Lubricant, or equivalent.

Apply on the full circumference of the Wear Sleeve a

bead of lubricant that is 6 mm (1/4 in.) wide to seal

contact area (Fig. 13). Fill the seal lip to housing cavity

on bearing seal with lubricant. Lubricant is to be

applied around complete circumference of the seal, and

seal lip should be wet with lubricant (Fig. 13). Use

Mopar Multi-Purpose Lubricant or equivalent for lu-

brication of the Wear Sleeve and Bearing Seal. (2) Push knuckle (hub) assembly out and install

splined outer C/V joint shaft in hub (Fig. 14). CAUTION: Steering knuckle clamp bolt shown in

(Figs. 14 and 15) is Prevailing Torque Type, original

or equivalent bolt must be installed during assem-

bly.

(3) Install knuckle assembly on ball joint stud

(Fig. 15). (4) Install and tighten clamp bolt to 95 N Im (70 ft.

lbs.) torque (Fig. 16). (5) Install speedometer pinion (Fig. 17).

(6) Fill differential with proper lubricant (see Lu-

brication and Maintenance Group 0). (7) Install hub nut assembly.

(8) If after installing the driveshaft assembly,the

inboard boot appears collapsed or deformed. Vent

the inner boot by inserting, a round tipped small di-

ameter rod between the boot and shaft. If necessary,

massage the boot to remove all puckers being careful

Fig. 13 Seal & Wear Sleeve Lubrication

Fig. 14 Install Outer Shaft into Hub

Fig. 11 Removing Driveshaft Assembly Equal Length

Fig. 12 Installing Inner Shaft into Transaxle

Ä SUSPENSION AND DRIVESHAFTS 2 - 29

Page 88 of 2438

not to allow dirt to enter or grease to leave the boot

cavity. The clamp must be removed and discarded be-

fore the rod can be inserted. After venting, install a

new Service Clamp. (See Boots Install section at the

end of this group for details).

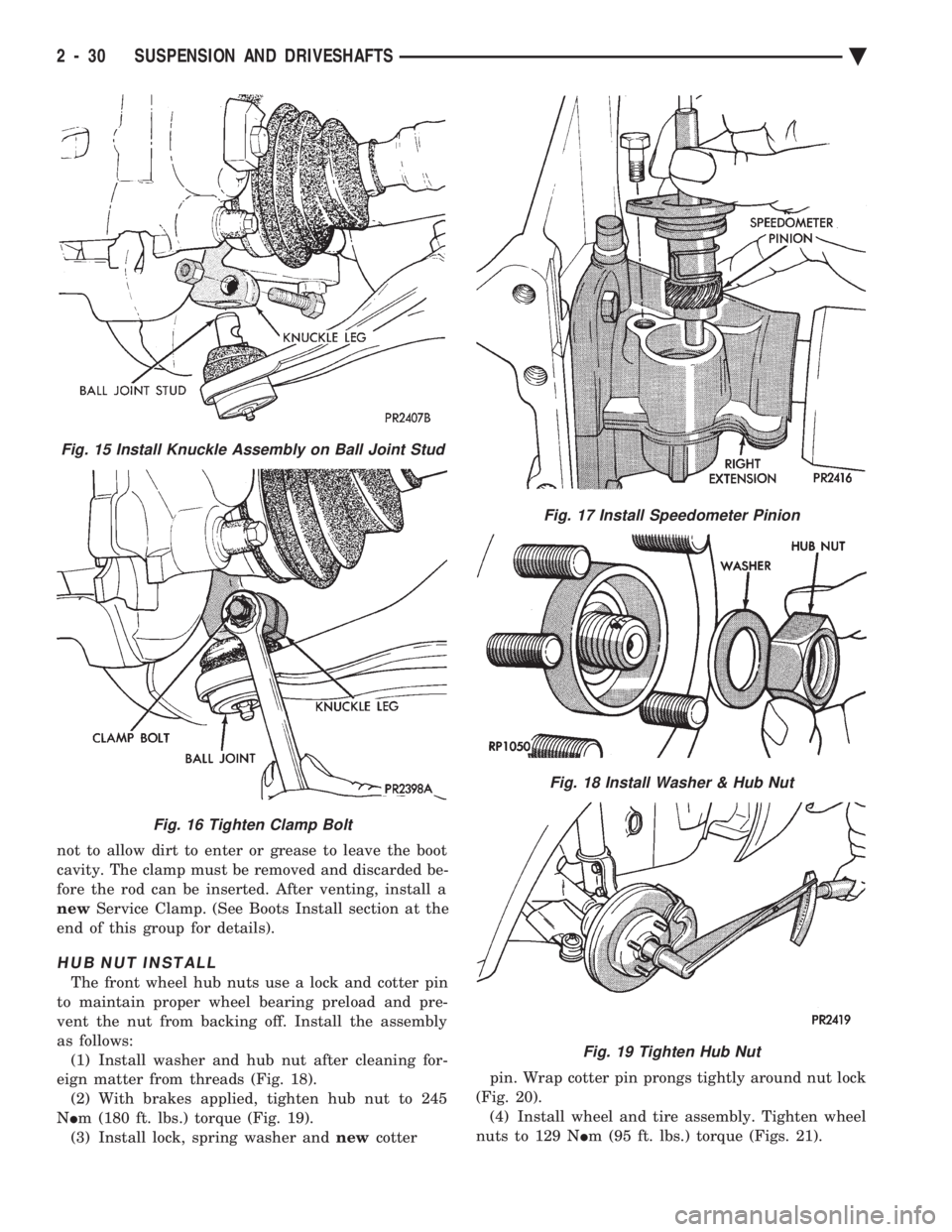

HUB NUT INSTALL

The front wheel hub nuts use a lock and cotter pin

to maintain proper wheel bearing preload and pre-

vent the nut from backing off. Install the assembly

as follows: (1) Install washer and hub nut after cleaning for-

eign matter from threads (Fig. 18). (2) With brakes applied, tighten hub nut to 245

N Im (180 ft. lbs.) torque (Fig. 19).

(3) Install lock, spring washer and newcotter pin. Wrap cotter pin prongs tightly around nut lock

(Fig. 20). (4) Install wheel and tire assembly. Tighten wheel

nuts to 129 N Im (95 ft. lbs.) torque (Figs. 21).

Fig. 15 Install Knuckle Assembly on Ball Joint Stud

Fig. 16 Tighten Clamp Bolt

Fig. 17 Install Speedometer Pinion

Fig. 18 Install Washer & Hub Nut

Fig. 19 Tighten Hub Nut

2 - 30 SUSPENSION AND DRIVESHAFTS Ä

Page 89 of 2438

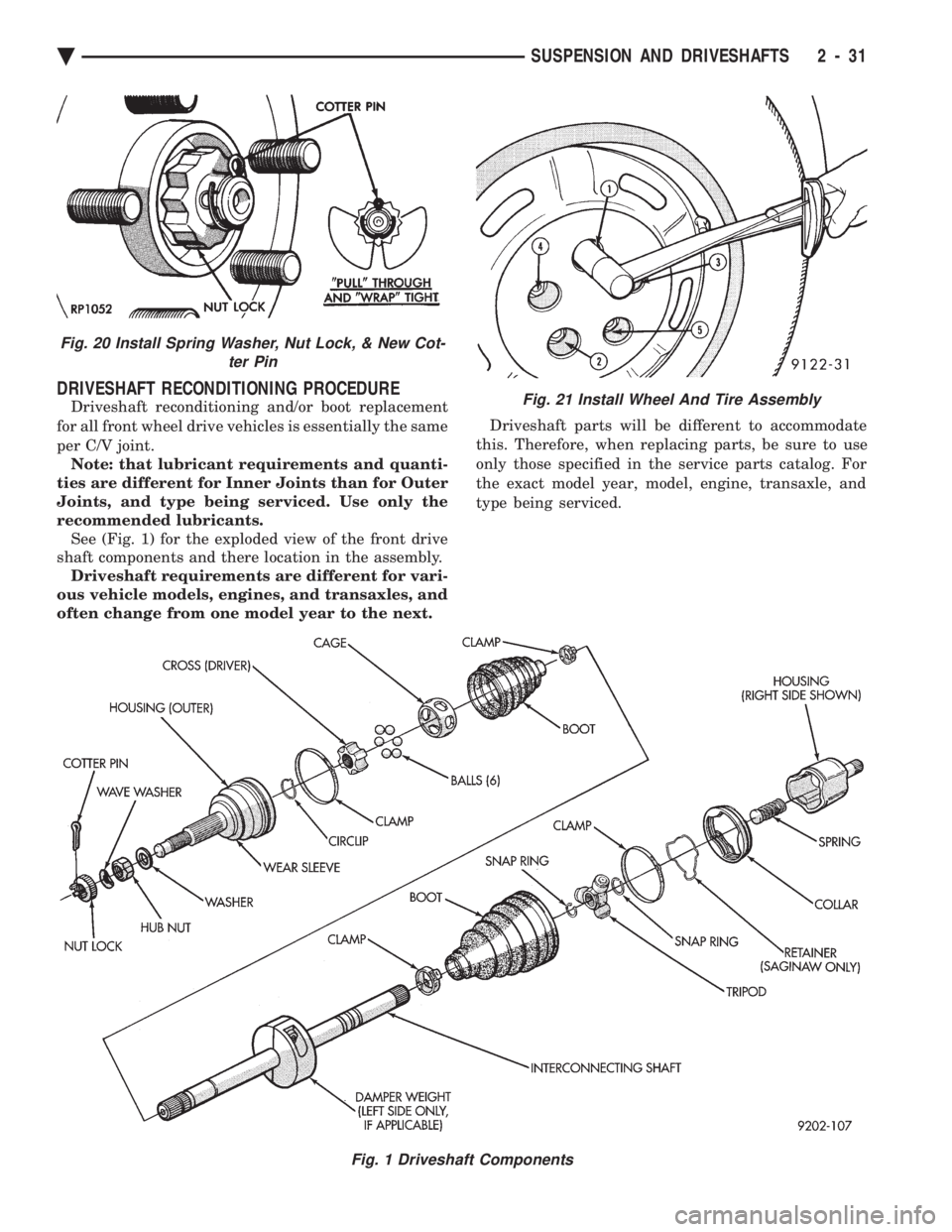

DRIVESHAFT RECONDITIONING PROCEDURE

Driveshaft reconditioning and/or boot replacement

for all front wheel drive vehicles is essentially the same

per C/V joint. Note: that lubricant requirements and quanti-

ties are different for Inner Joints than for Outer

Joints, and type being serviced. Use only the

recommended lubricants. See (Fig. 1) for the exploded view of the front drive

shaft components and there location in the assembly. Driveshaft requirements are different for vari-

ous vehicle models, engines, and transaxles, and

often change from one model year to the next. Driveshaft parts will be different to accommodate

this. Therefore, when replacing parts, be sure to use

only those specified in the service parts catalog. For

the exact model year, model, engine, transaxle, and

type being serviced.

Fig. 1 Driveshaft Components

Fig. 21 Install Wheel And Tire Assembly

Fig. 20 Install Spring Washer, Nut Lock, & New Cot- ter Pin

Ä SUSPENSION AND DRIVESHAFTS 2 - 31

Page 100 of 2438

(4) Repeat process for stub shaft yoke after align-

ing marks on yoke and shaft.

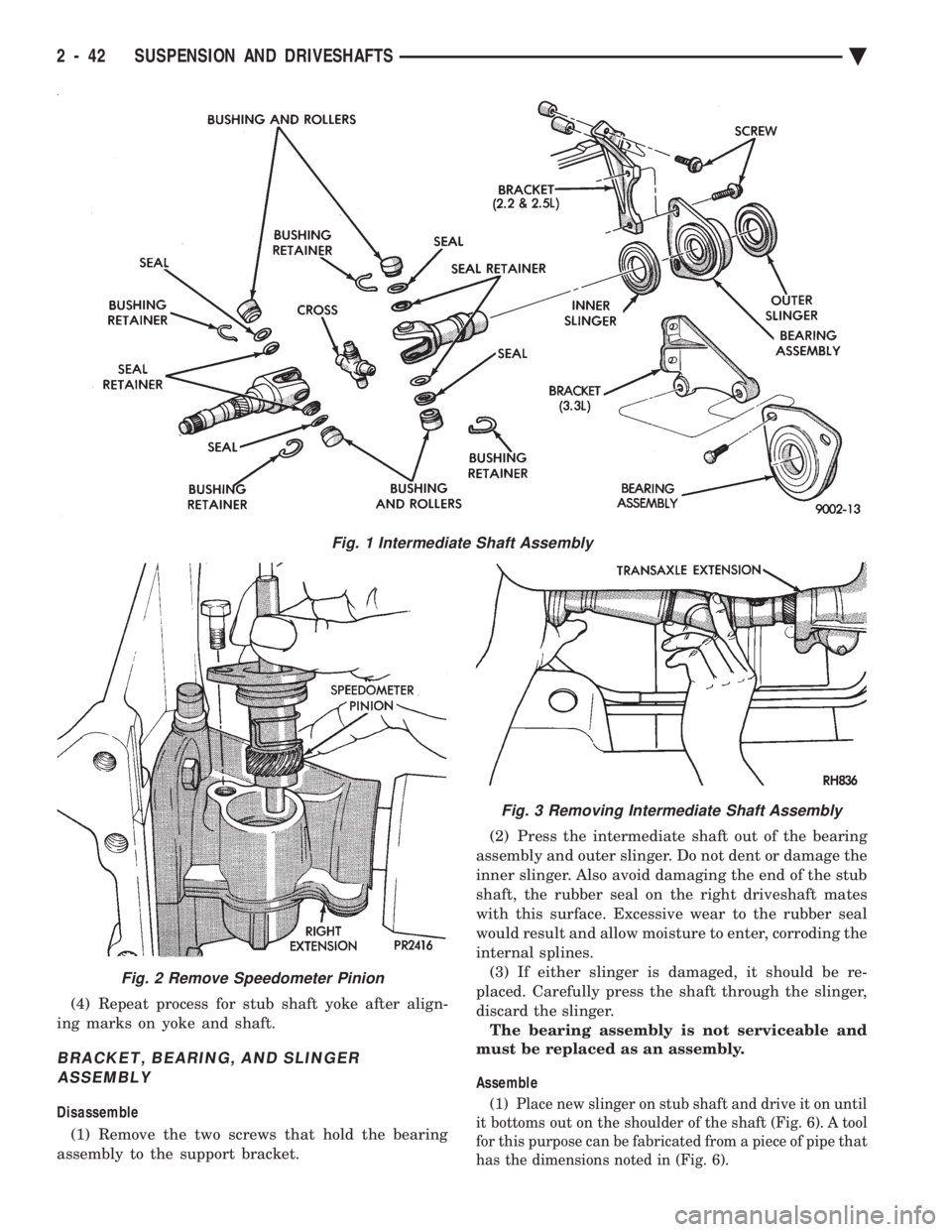

BRACKET, BEARING, AND SLINGER ASSEMBLY

Disassemble

(1) Remove the two screws that hold the bearing

assembly to the support bracket. (2) Press the intermediate shaft out of the bearing

assembly and outer slinger. Do not dent or damage the

inner slinger. Also avoid damaging the end of the stub

shaft, the rubber seal on the right driveshaft mates

with this surface. Excessive wear to the rubber seal

would result and allow moisture to enter, corroding the

internal splines. (3) If either slinger is damaged, it should be re-

placed. Carefully press the shaft through the slinger,

discard the slinger. The bearing assembly is not serviceable and

must be replaced as an assembly.

Assemble(1) Place new slinger on stub shaft and drive it on until

it bottoms out on the shoulder of the shaft (Fig. 6). A tool

for this purpose can be fabricated from a piece of pipe that

has the dimensions noted in (Fig. 6).

Fig. 1 Intermediate Shaft Assembly

Fig. 2 Remove Speedometer Pinion

Fig. 3 Removing Intermediate Shaft Assembly

2 - 42 SUSPENSION AND DRIVESHAFTS Ä

Page 102 of 2438

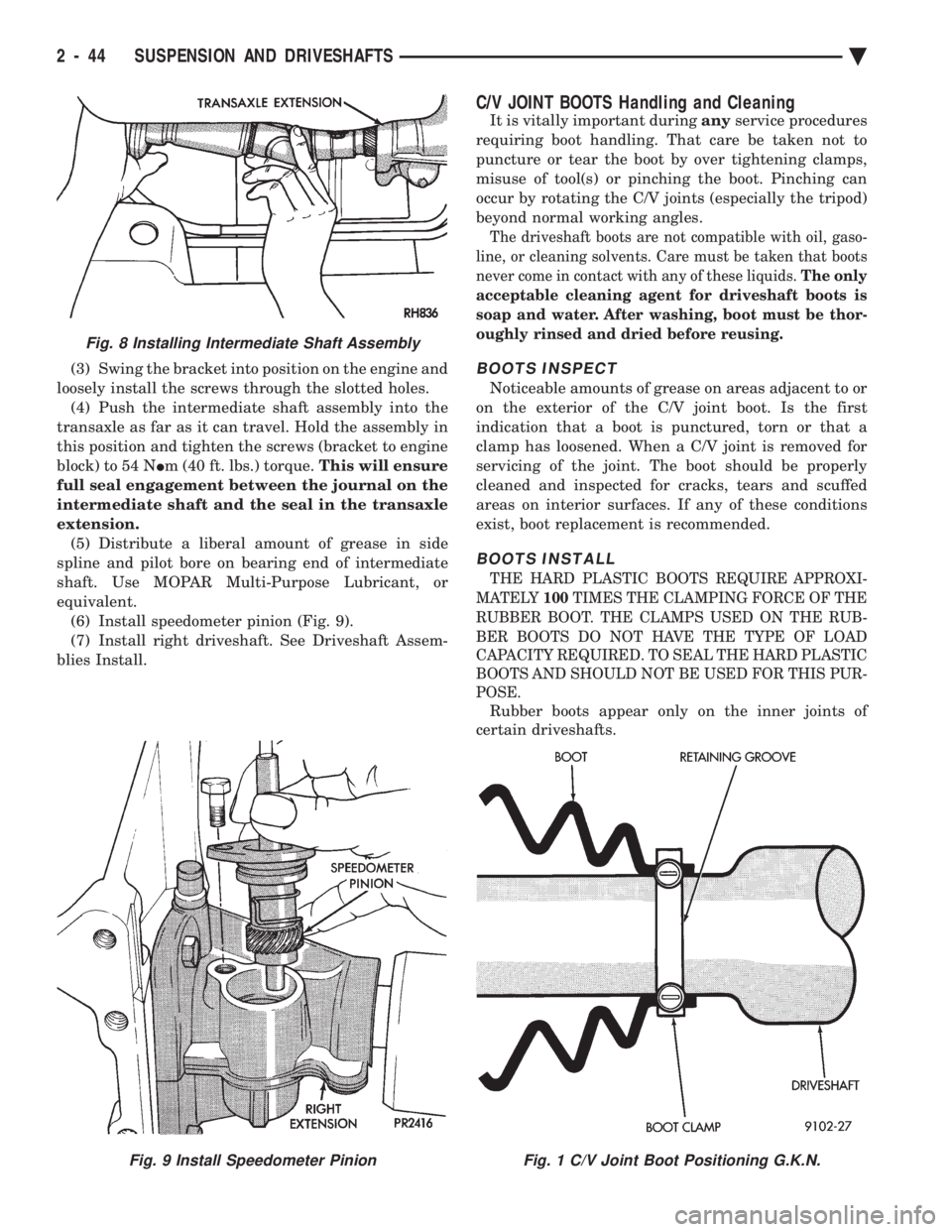

(3) Swing the bracket into position on the engine and

loosely install the screws through the slotted holes. (4) Push the intermediate shaft assembly into the

transaxle as far as it can travel. Hold the assembly in

this position and tighten the screws (bracket to engine

block) to 54 N Im (40 ft. lbs.) torque. This will ensure

full seal engagement between the journal on the

intermediate shaft and the seal in the transaxle

extension. (5) Distribute a liberal amount of grease in side

spline and pilot bore on bearing end of intermediate

shaft. Use MOPAR Multi-Purpose Lubricant, or

equivalent. (6) Install speedometer pinion (Fig. 9).

(7) Install right driveshaft. See Driveshaft Assem-

blies Install.

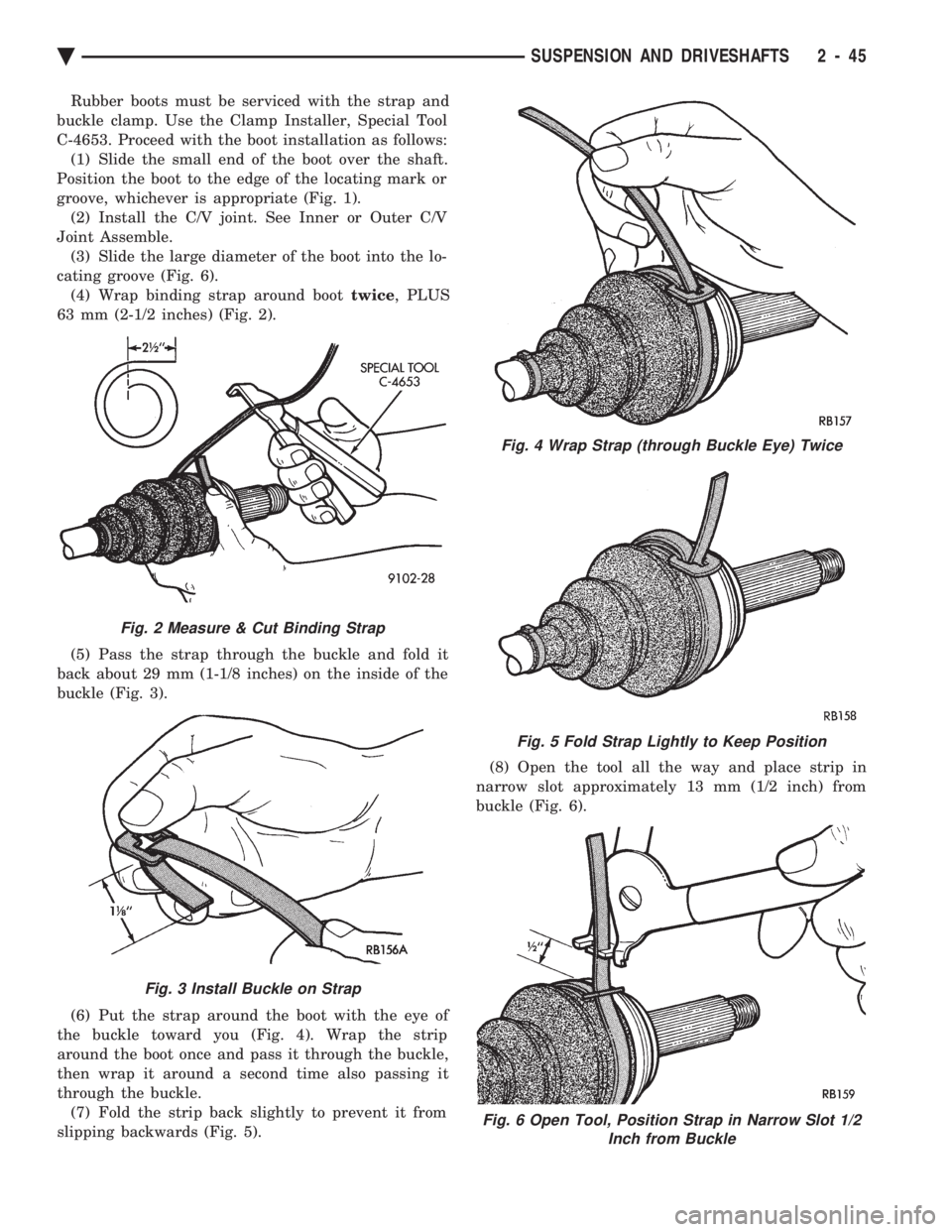

C/V JOINT BOOTS Handling and Cleaning

It is vitally important during anyservice procedures

requiring boot handling. That care be taken not to

puncture or tear the boot by over tightening clamps,

misuse of tool(s) or pinching the boot. Pinching can

occur by rotating the C/V joints (especially the tripod)

beyond normal working angles.

The driveshaft boots are not compatible with oil, gaso-

line, or cleaning solvents. Care must be taken that boots

never come in contact with any of these liquids. The only

acceptable cleaning agent for driveshaft boots is

soap and water. After washing, boot must be thor-

oughly rinsed and dried before reusing.

BOOTS INSPECT

Noticeable amounts of grease on areas adjacent to or

on the exterior of the C/V joint boot. Is the first

indication that a boot is punctured, torn or that a

clamp has loosened. When a C/V joint is removed for

servicing of the joint. The boot should be properly

cleaned and inspected for cracks, tears and scuffed

areas on interior surfaces. If any of these conditions

exist, boot replacement is recommended.

BOOTS INSTALL

THE HARD PLASTIC BOOTS REQUIRE APPROXI-

MATELY 100TIMES THE CLAMPING FORCE OF THE

RUBBER BOOT. THE CLAMPS USED ON THE RUB-

BER BOOTS DO NOT HAVE THE TYPE OF LOAD

CAPACITY REQUIRED. TO SEAL THE HARD PLASTIC

BOOTS AND SHOULD NOT BE USED FOR THIS PUR-

POSE.

Rubber boots appear only on the inner joints of

certain driveshafts.

Fig. 9 Install Speedometer PinionFig. 1 C/V Joint Boot Positioning G.K.N.

Fig. 8 Installing Intermediate Shaft Assembly

2 - 44 SUSPENSION AND DRIVESHAFTS Ä

Page 103 of 2438

Rubber boots must be serviced with the strap and

buckle clamp. Use the Clamp Installer, Special Tool

C-4653. Proceed with the boot installation as follows: (1) Slide the small end of the boot over the shaft.

Position the boot to the edge of the locating mark or

groove, whichever is appropriate (Fig. 1). (2) Install the C/V joint. See Inner or Outer C/V

Joint Assemble. (3) Slide the large diameter of the boot into the lo-

cating groove (Fig. 6). (4) Wrap binding strap around boot twice, PLUS

63 mm (2-1/2 inches) (Fig. 2).

(5) Pass the strap through the buckle and fold it

back about 29 mm (1-1/8 inches) on the inside of the

buckle (Fig. 3).

(6) Put the strap around the boot with the eye of

the buckle toward you (Fig. 4). Wrap the strip

around the boot once and pass it through the buckle,

then wrap it around a second time also passing it

through the buckle. (7) Fold the strip back slightly to prevent it from

slipping backwards (Fig. 5). (8) Open the tool all the way and place strip in

narrow slot approximately 13 mm (1/2 inch) from

buckle (Fig. 6).

Fig. 2 Measure & Cut Binding Strap

Fig. 3 Install Buckle on Strap

Fig. 4 Wrap Strap (through Buckle Eye) Twice

Fig. 5 Fold Strap Lightly to Keep Position

Fig. 6 Open Tool, Position Strap in Narrow Slot 1/2 Inch from Buckle

Ä SUSPENSION AND DRIVESHAFTS 2 - 45

Page 106 of 2438

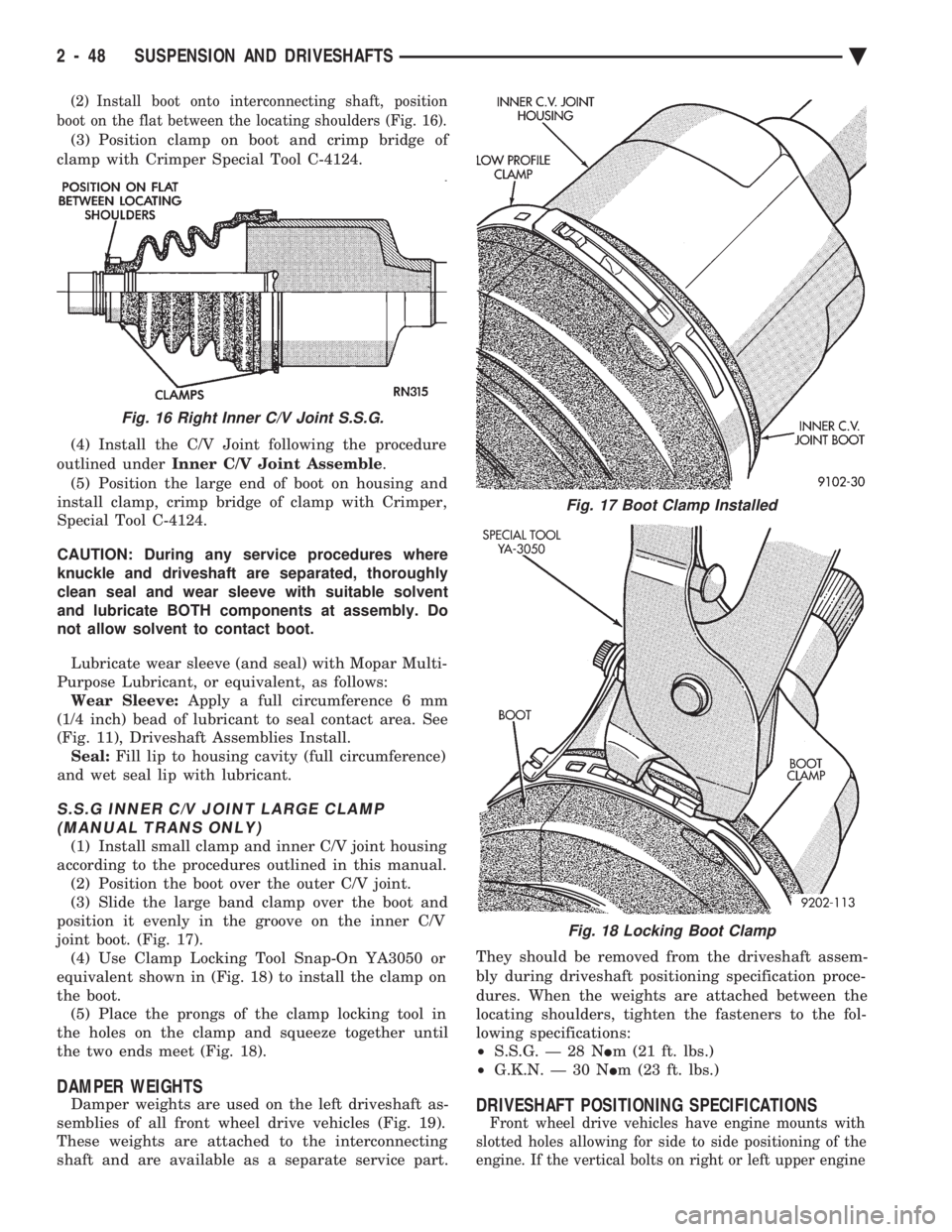

(2) Install boot onto interconnecting shaft, position

boot on the flat between the locating shoulders (Fig. 16).

(3) Position clamp on boot and crimp bridge of

clamp with Crimper Special Tool C-4124.

(4) Install the C/V Joint following the procedure

outlined under Inner C/V Joint Assemble .

(5) Position the large end of boot on housing and

install clamp, crimp bridge of clamp with Crimper,

Special Tool C-4124.

CAUTION: During any service procedures where

knuckle and driveshaft are separated, thoroughly

clean seal and wear sleeve with suitable solvent

and lubricate BOTH components at assembly. Do

not allow solvent to contact boot.

Lubricate wear sleeve (and seal) with Mopar Multi-

Purpose Lubricant, or equivalent, as follows: Wear Sleeve: Apply a full circumference 6 mm

(1/4 inch) bead of lubricant to seal contact area. See

(Fig. 11), Driveshaft Assemblies Install. Seal: Fill lip to housing cavity (full circumference)

and wet seal lip with lubricant.

S.S.G INNER C/V JOINT LARGE CLAMP (MANUAL TRANS ONLY)

(1) Install small clamp and inner C/V joint housing

according to the procedures outlined in this manual. (2) Position the boot over the outer C/V joint.

(3) Slide the large band clamp over the boot and

position it evenly in the groove on the inner C/V

joint boot. (Fig. 17). (4) Use Clamp Locking Tool Snap-On YA3050 or

equivalent shown in (Fig. 18) to install the clamp on

the boot. (5) Place the prongs of the clamp locking tool in

the holes on the clamp and squeeze together until

the two ends meet (Fig. 18).

DAMPER WEIGHTS

Damper weights are used on the left driveshaft as-

semblies of all front wheel drive vehicles (Fig. 19).

These weights are attached to the interconnecting

shaft and are available as a separate service part. They should be removed from the driveshaft assem-

bly during driveshaft positioning specification proce-

dures. When the weights are attached between the

locating shoulders, tighten the fasteners to the fol-

lowing specifications:

² S.S.G. Ð 28 N Im (21 ft. lbs.)

² G.K.N. Ð 30 N Im (23 ft. lbs.)DRIVESHAFT POSITIONING SPECIFICATIONS

Front wheel drive vehicles have engine mounts with

slotted holes allowing for side to side positioning of the

engine. If the vertical bolts on right or left upper engine

Fig. 16 Right Inner C/V Joint S.S.G.

Fig. 17 Boot Clamp Installed

Fig. 18 Locking Boot Clamp

2 - 48 SUSPENSION AND DRIVESHAFTS Ä

Page 117 of 2438

AUTOMATIC AIR LOAD LEVELING SYSTEM INDEX

page page

Compressor Performance Test .............. 61

Compressor Relay ........................ 72

Control Module .......................... 72

General Information ....................... 59

Major Components ....................... 59 Rear Leveling Diagnostic Procedures

......... 65

Right Shock Absorber (With Height Sensor) .... 72

Service Procedures ....................... 62

System Operation ........................ 61

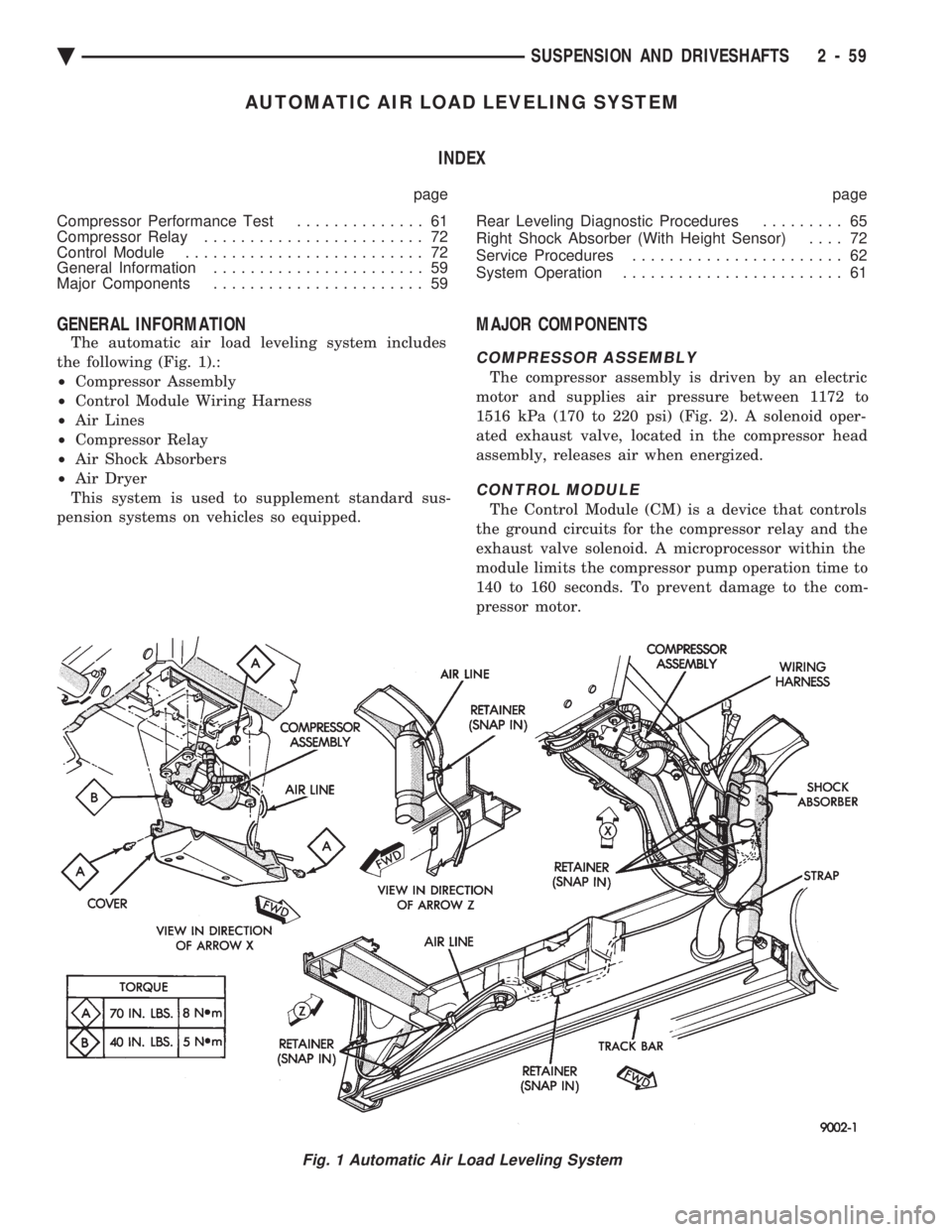

GENERAL INFORMATION

The automatic air load leveling system includes

the following (Fig. 1).:

² Compressor Assembly

² Control Module Wiring Harness

² Air Lines

² Compressor Relay

² Air Shock Absorbers

² Air Dryer

This system is used to supplement standard sus-

pension systems on vehicles so equipped.

MAJOR COMPONENTS

COMPRESSOR ASSEMBLY

The compressor assembly is driven by an electric

motor and supplies air pressure between 1172 to

1516 kPa (170 to 220 psi) (Fig. 2). A solenoid oper-

ated exhaust valve, located in the compressor head

assembly, releases air when energized.

CONTROL MODULE

The Control Module (CM) is a device that controls

the ground circuits for the compressor relay and the

exhaust valve solenoid. A microprocessor within the

module limits the compressor pump operation time to

140 to 160 seconds. To prevent damage to the com-

pressor motor.

Fig. 1 Automatic Air Load Leveling System

Ä SUSPENSION AND DRIVESHAFTS 2 - 59

Page 120 of 2438

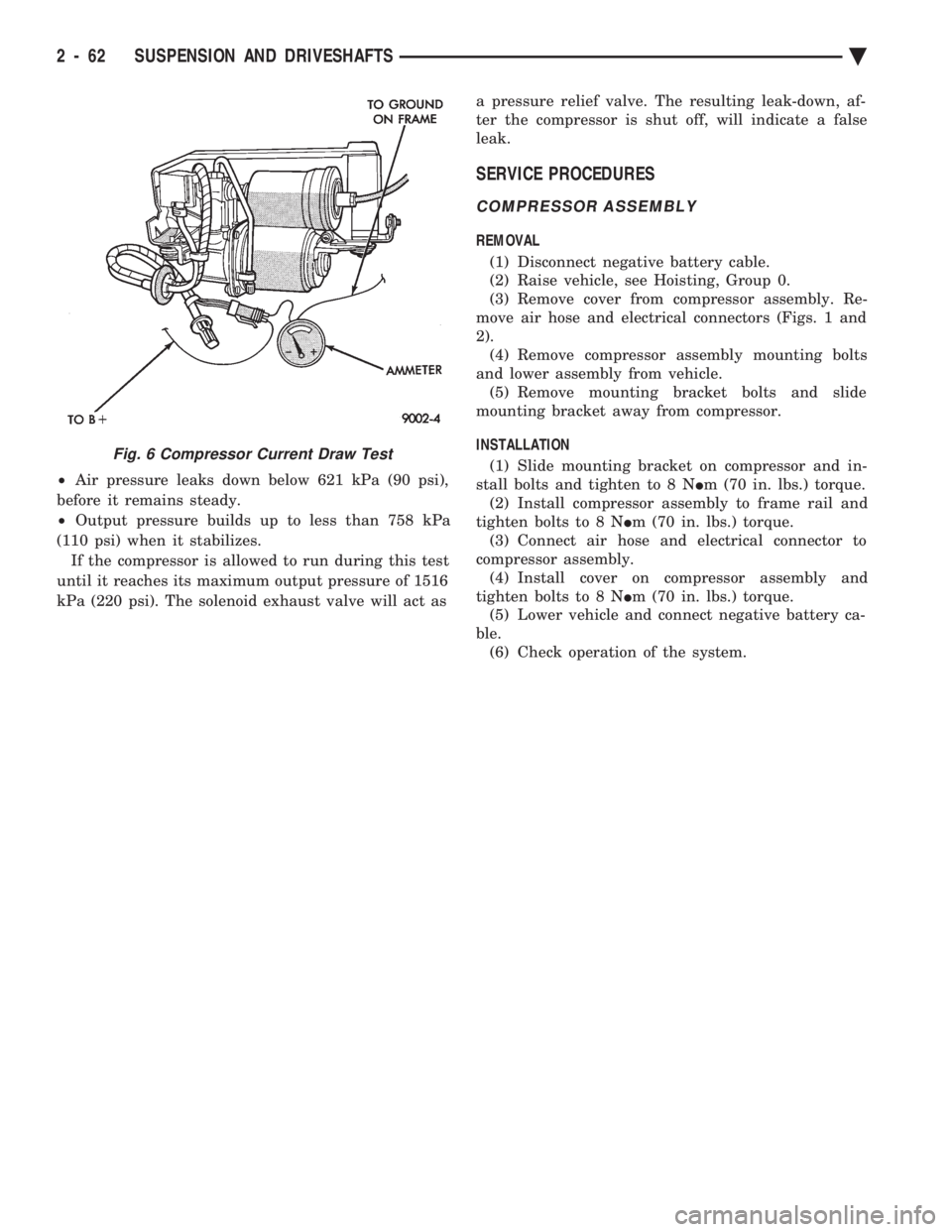

² Air pressure leaks down below 621 kPa (90 psi),

before it remains steady.

² Output pressure builds up to less than 758 kPa

(110 psi) when it stabilizes. If the compressor is allowed to run during this test

until it reaches its maximum output pressure of 1516

kPa (220 psi). The solenoid exhaust valve will act as a pressure relief valve. The resulting leak-down, af-

ter the compressor is shut off, will indicate a false

leak.

SERVICE PROCEDURES

COMPRESSOR ASSEMBLY

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle, see Hoisting, Group 0.

(3) Remove cover from compressor assembly. Re-

move air hose and electrical connectors (Figs. 1 and

2). (4) Remove compressor assembly mounting bolts

and lower assembly from vehicle. (5) Remove mounting bracket bolts and slide

mounting bracket away from compressor.

INSTALLATION (1) Slide mounting bracket on compressor and in-

stall bolts and tighten to 8 N Im (70 in. lbs.) torque.

(2) Install compressor assembly to frame rail and

tighten bolts to 8 N Im (70 in. lbs.) torque.

(3) Connect air hose and electrical connector to

compressor assembly. (4) Install cover on compressor assembly and

tighten bolts to 8 N Im (70 in. lbs.) torque.

(5) Lower vehicle and connect negative battery ca-

ble. (6) Check operation of the system.

Fig. 6 Compressor Current Draw Test

2 - 62 SUSPENSION AND DRIVESHAFTS Ä