service CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 131 of 2438

AUTOMATIC AIR SUSPENSION INDEX

page page

Air Lines ............................... 75

Air Springs Rear ......................... 87

Compressor Performance Test .............. 77

Diagnosis .............................. 78

General Information ....................... 73

Recharge Air Spring ...................... 87 Right Shock Absorber (With Height Sensor)

.... 88

Safety Concerns ......................... 78

Service Procedures ....................... 85

Shipping Mode .......................... 78

Solenoids (Struts and Air Springs) ............ 86

System Operation ........................ 78

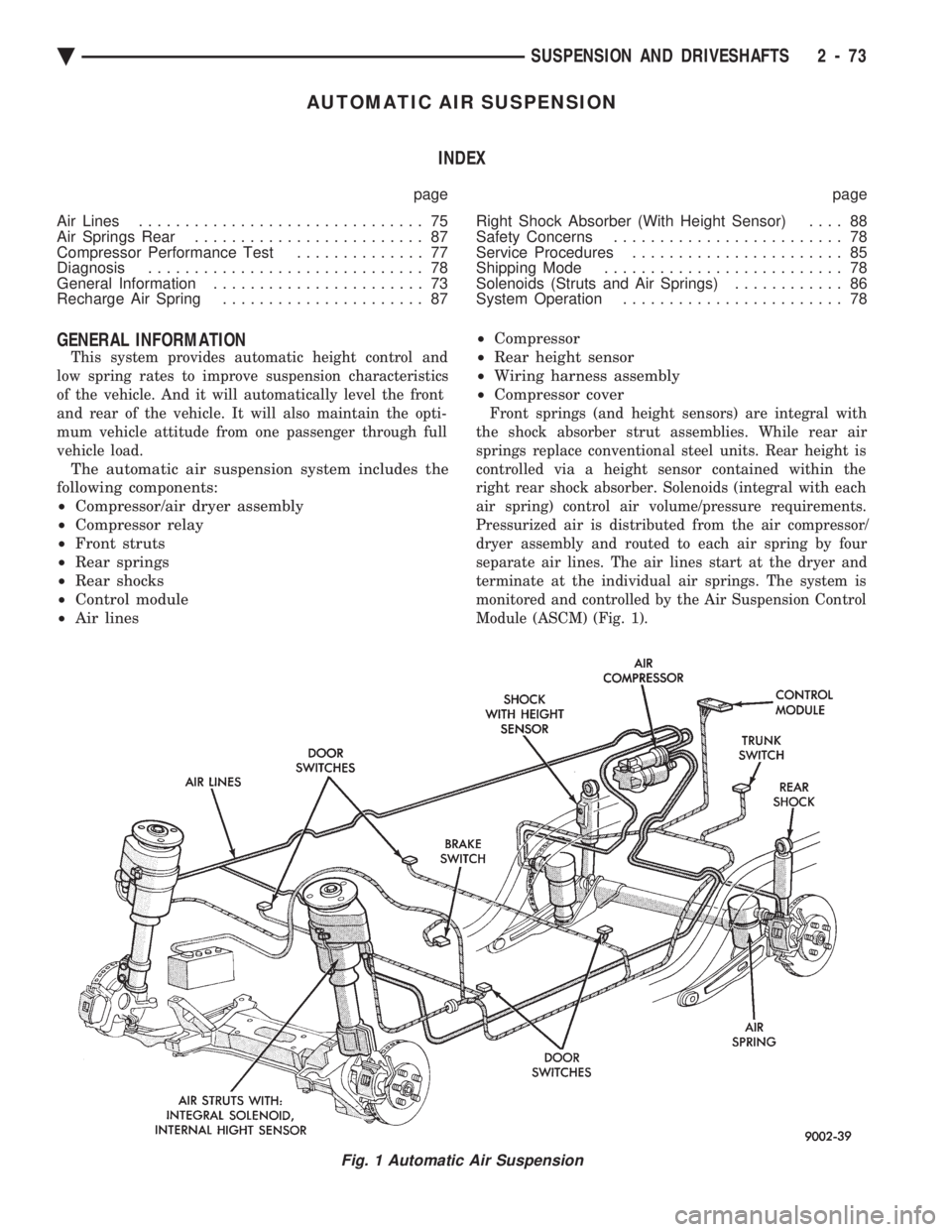

GENERAL INFORMATION

This system provides automatic height control and

low spring rates to improve suspension characteristics

of the vehicle. And it will automatically level the front

and rear of the vehicle. It will also maintain the opti-

mum vehicle attitude from one passenger through full

vehicle load.

The automatic air suspension system includes the

following components:

² Compressor/air dryer assembly

² Compressor relay

² Front struts

² Rear springs

² Rear shocks

² Control module

² Air lines ²

Compressor

² Rear height sensor

² Wiring harness assembly

² Compressor cover

Front springs (and height sensors) are integral with

the shock absorber strut assemblies. While rear air

springs replace conventional steel units. Rear height is

controlled via a height sensor contained within the

right rear shock absorber. Solenoids (integral with each

air spring) control air volume/pressure requirements.

Pressurized air is distributed from the air compressor/

dryer assembly and routed to each air spring by four

separate air lines. The air lines start at the dryer and

terminate at the individual air springs. The system is

monitored and controlled by the Air Suspension Control

Module (ASCM) (Fig. 1).

Fig. 1 Automatic Air Suspension

Ä SUSPENSION AND DRIVESHAFTS 2 - 73

Page 132 of 2438

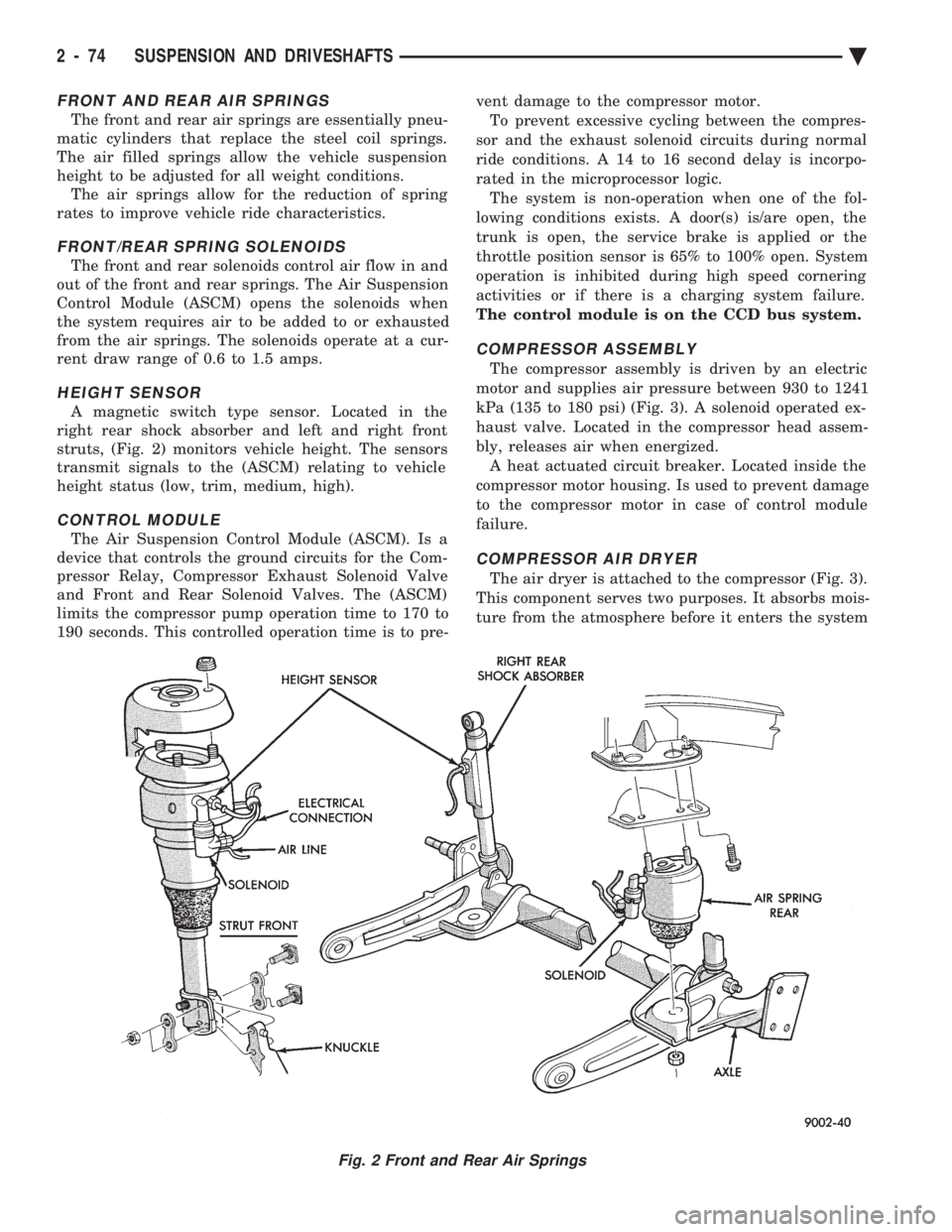

FRONT AND REAR AIR SPRINGS

The front and rear air springs are essentially pneu-

matic cylinders that replace the steel coil springs.

The air filled springs allow the vehicle suspension

height to be adjusted for all weight conditions. The air springs allow for the reduction of spring

rates to improve vehicle ride characteristics.

FRONT/REAR SPRING SOLENOIDS

The front and rear solenoids control air flow in and

out of the front and rear springs. The Air Suspension

Control Module (ASCM) opens the solenoids when

the system requires air to be added to or exhausted

from the air springs. The solenoids operate at a cur-

rent draw range of 0.6 to 1.5 amps.

HEIGHT SENSOR

A magnetic switch type sensor. Located in the

right rear shock absorber and left and right front

struts, (Fig. 2) monitors vehicle height. The sensors

transmit signals to the (ASCM) relating to vehicle

height status (low, trim, medium, high).

CONTROL MODULE

The Air Suspension Control Module (ASCM). Is a

device that controls the ground circuits for the Com-

pressor Relay, Compressor Exhaust Solenoid Valve

and Front and Rear Solenoid Valves. The (ASCM)

limits the compressor pump operation time to 170 to

190 seconds. This controlled operation time is to pre- vent damage to the compressor motor.

To prevent excessive cycling between the compres-

sor and the exhaust solenoid circuits during normal

ride conditions. A 14 to 16 second delay is incorpo-

rated in the microprocessor logic. The system is non-operation when one of the fol-

lowing conditions exists. A door(s) is/are open, the

trunk is open, the service brake is applied or the

throttle position sensor is 65% to 100% open. System

operation is inhibited during high speed cornering

activities or if there is a charging system failure.

The control module is on the CCD bus system.

COMPRESSOR ASSEMBLY

The compressor assembly is driven by an electric

motor and supplies air pressure between 930 to 1241

kPa (135 to 180 psi) (Fig. 3). A solenoid operated ex-

haust valve. Located in the compressor head assem-

bly, releases air when energized. A heat actuated circuit breaker. Located inside the

compressor motor housing. Is used to prevent damage

to the compressor motor in case of control module

failure.

COMPRESSOR AIR DRYER

The air dryer is attached to the compressor (Fig. 3).

This component serves two purposes. It absorbs mois-

ture from the atmosphere before it enters the system

Fig. 2 Front and Rear Air Springs

2 - 74 SUSPENSION AND DRIVESHAFTS Ä

Page 136 of 2438

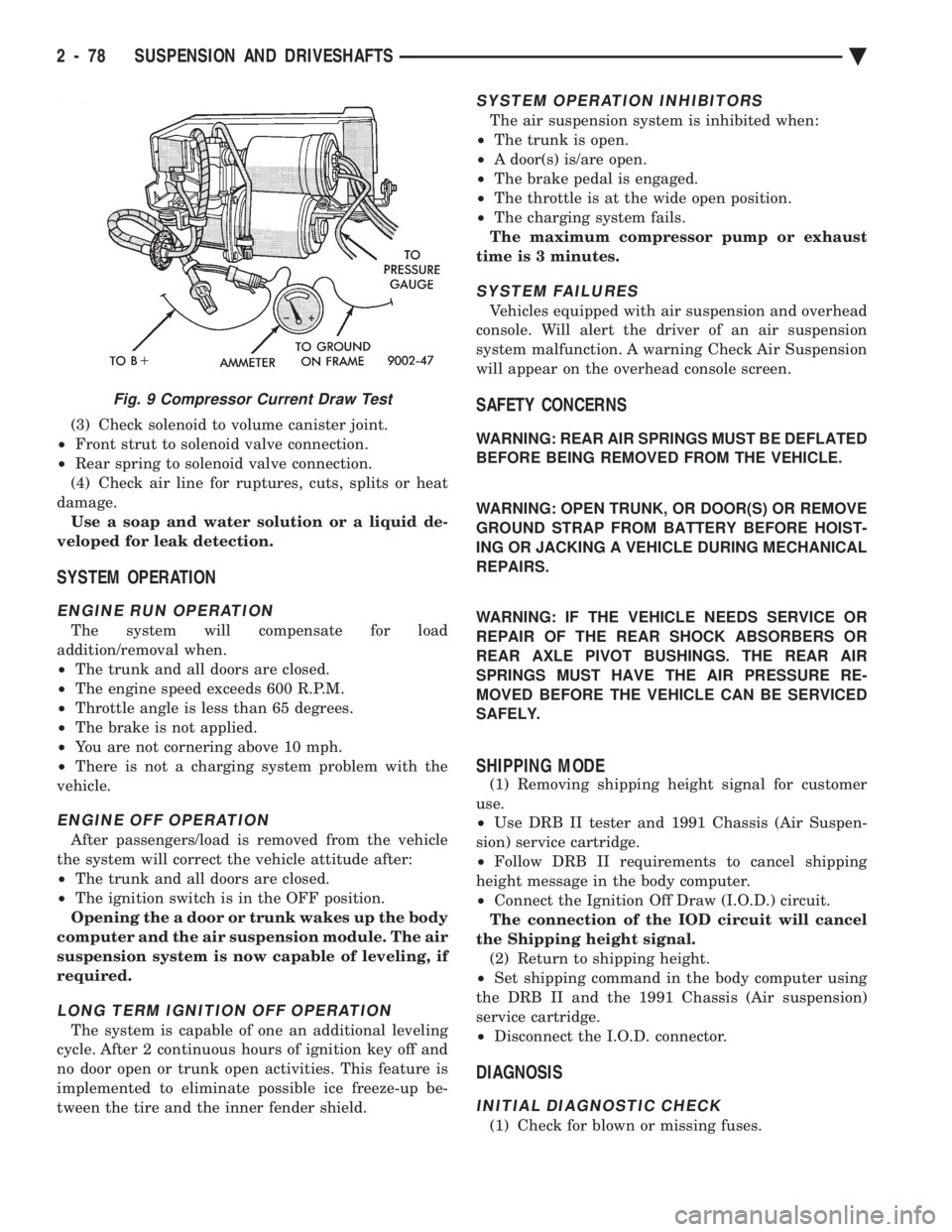

(3) Check solenoid to volume canister joint.

² Front strut to solenoid valve connection.

² Rear spring to solenoid valve connection.

(4) Check air line for ruptures, cuts, splits or heat

damage. Use a soap and water solution or a liquid de-

veloped for leak detection.

SYSTEM OPERATION

ENGINE RUN OPERATION

The system will compensate for load

addition/removal when.

² The trunk and all doors are closed.

² The engine speed exceeds 600 R.P.M.

² Throttle angle is less than 65 degrees.

² The brake is not applied.

² You are not cornering above 10 mph.

² There is not a charging system problem with the

vehicle.

ENGINE OFF OPERATION

After passengers/load is removed from the vehicle

the system will correct the vehicle attitude after:

² The trunk and all doors are closed.

² The ignition switch is in the OFF position.

Opening the a door or trunk wakes up the body

computer and the air suspension module. The air

suspension system is now capable of leveling, if

required.

LONG TERM IGNITION OFF OPERATION

The system is capable of one an additional leveling

cycle. After 2 continuous hours of ignition key off and

no door open or trunk open activities. This feature is

implemented to eliminate possible ice freeze-up be-

tween the tire and the inner fender shield.

SYSTEM OPERATION INHIBITORS

The air suspension system is inhibited when:

² The trunk is open.

² A door(s) is/are open.

² The brake pedal is engaged.

² The throttle is at the wide open position.

² The charging system fails.

The maximum compressor pump or exhaust

time is 3 minutes.

SYSTEM FAILURES

Vehicles equipped with air suspension and overhead

console. Will alert the driver of an air suspension

system malfunction. A warning Check Air Suspension

will appear on the overhead console screen.

SAFETY CONCERNS

WARNING: REAR AIR SPRINGS MUST BE DEFLATED

BEFORE BEING REMOVED FROM THE VEHICLE.

WARNING: OPEN TRUNK, OR DOOR(S) OR REMOVE

GROUND STRAP FROM BATTERY BEFORE HOIST-

ING OR JACKING A VEHICLE DURING MECHANICAL

REPAIRS.

WARNING: IF THE VEHICLE NEEDS SERVICE OR

REPAIR OF THE REAR SHOCK ABSORBERS OR

REAR AXLE PIVOT BUSHINGS. THE REAR AIR

SPRINGS MUST HAVE THE AIR PRESSURE RE-

MOVED BEFORE THE VEHICLE CAN BE SERVICED

SAFELY.

SHIPPING MODE

(1) Removing shipping height signal for customer

use.

² Use DRB II tester and 1991 Chassis (Air Suspen-

sion) service cartridge.

² Follow DRB II requirements to cancel shipping

height message in the body computer.

² Connect the Ignition Off Draw (I.O.D.) circuit.

The connection of the IOD circuit will cancel

the Shipping height signal. (2) Return to shipping height.

² Set shipping command in the body computer using

the DRB II and the 1991 Chassis (Air suspension)

service cartridge.

² Disconnect the I.O.D. connector.

DIAGNOSIS

INITIAL DIAGNOSTIC CHECK

(1) Check for blown or missing fuses.

Fig. 9 Compressor Current Draw Test

2 - 78 SUSPENSION AND DRIVESHAFTS Ä

Page 137 of 2438

(2) Check all connectors for correct assembly. Check

all connectors for incorrectly installed termi-

nals. (3) Check pin #21 for minimum of 9.5 volts.

(4) Check pin #20 for minimum of 9.5 volts (with

ignition key on). (5) Check voltage at pins #5 and #16. The measure-

ment should exceed 0 volts. (6) Check pin #19 for continuity.

(7) The engine speed should exceed 680 rpm during

idle. All doors and trunk must be closed for the

system to function.

DIAGNOSTICS PROCEDURES

(1) Use the D.R.B. II tester and the 1991 air suspen-

sion diagnostic service cartridge to begin the trouble-

shooting process. (2) Use the D.R.B. mating connector under the dash

(drivers side) to plug-in the D.R.B. II test connector

(Fig. 10). (3) The tester will conduct a complete check of the

suspension system status. (4) The tester will list the steps to follow to access

and diagnose the failure. (5) A Volt/Ohm meter can be used for some diagnos-

tic testing.

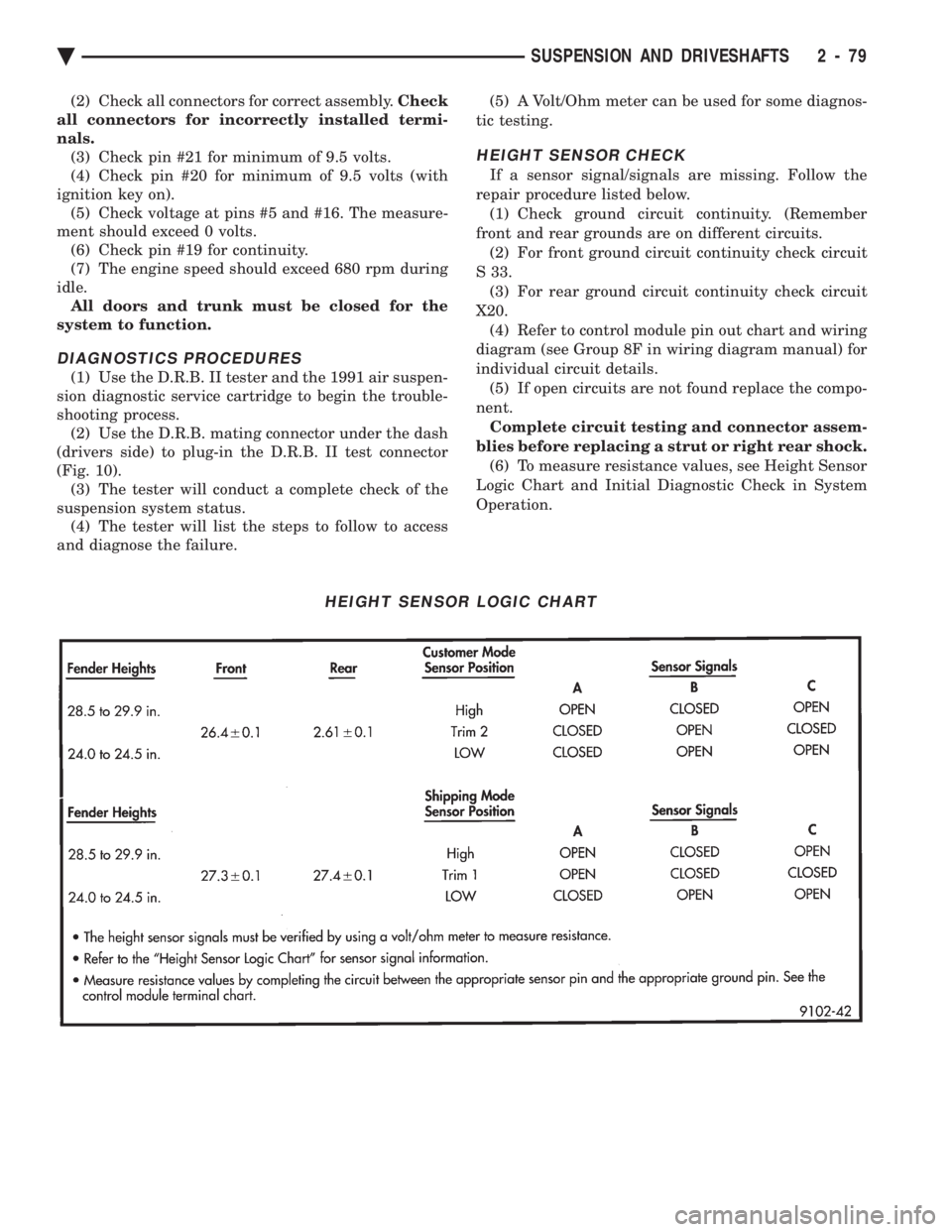

HEIGHT SENSOR CHECK

If a sensor signal/signals are missing. Follow the

repair procedure listed below. (1) Check ground circuit continuity. (Remember

front and rear grounds are on different circuits. (2) For front ground circuit continuity check circuit

S 33. (3) For rear ground circuit continuity check circuit

X20. (4) Refer to control module pin out chart and wiring

diagram (see Group 8F in wiring diagram manual) for

individual circuit details. (5) If open circuits are not found replace the compo-

nent. Complete circuit testing and connector assem-

blies before replacing a strut or right rear shock. (6) To measure resistance values, see Height Sensor

Logic Chart and Initial Diagnostic Check in System

Operation.

HEIGHT SENSOR LOGIC CHART

Ä SUSPENSION AND DRIVESHAFTS 2 - 79

Page 143 of 2438

SERVICE PROCEDURES

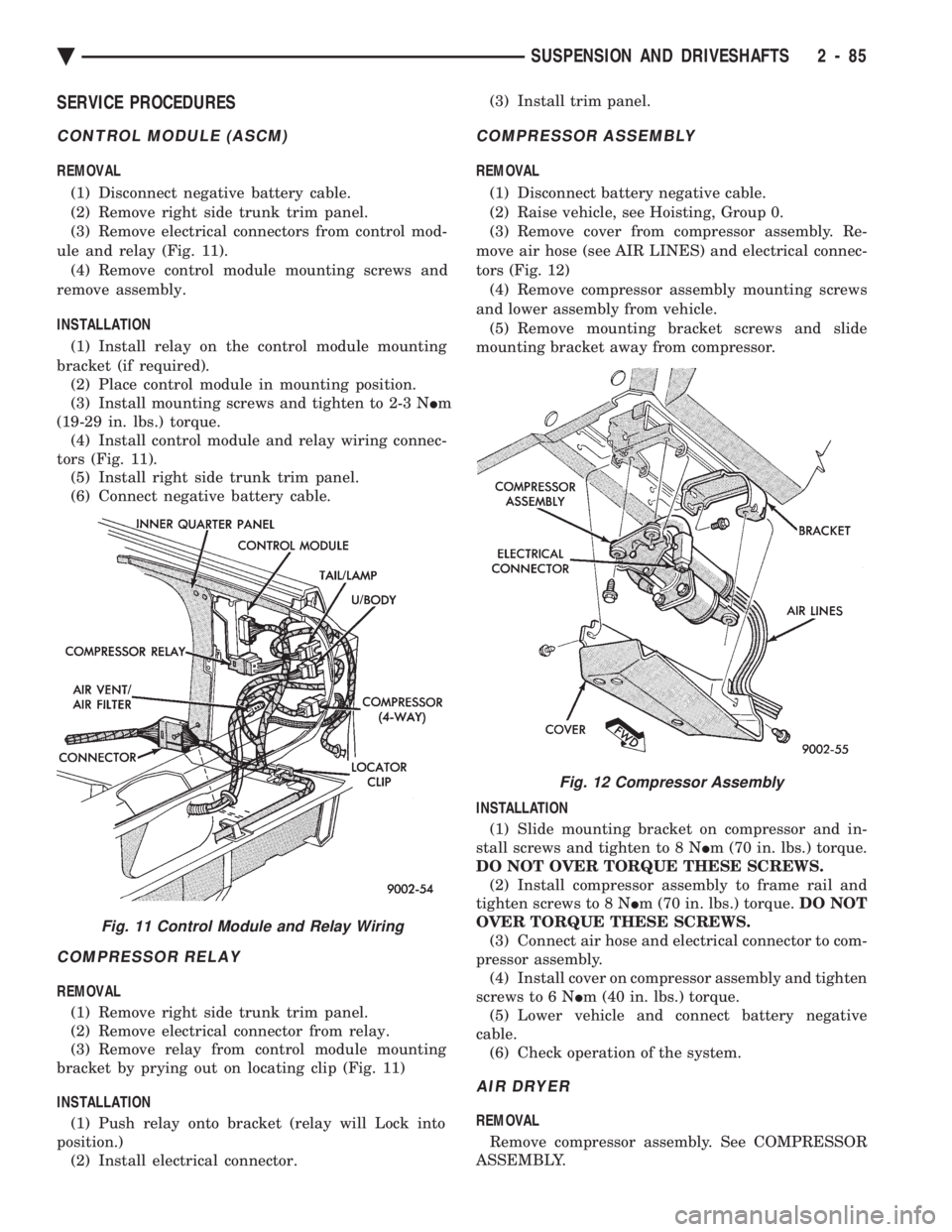

CONTROL MODULE (ASCM)

REMOVAL (1) Disconnect negative battery cable.

(2) Remove right side trunk trim panel.

(3) Remove electrical connectors from control mod-

ule and relay (Fig. 11). (4) Remove control module mounting screws and

remove assembly.

INSTALLATION

(1) Install relay on the control module mounting

bracket (if required). (2) Place control module in mounting position.

(3) Install mounting screws and tighten to 2-3 N Im

(19-29 in. lbs.) torque. (4) Install control module and relay wiring connec-

tors (Fig. 11). (5) Install right side trunk trim panel.

(6) Connect negative battery cable.

COMPRESSOR RELAY

REMOVAL

(1) Remove right side trunk trim panel.

(2) Remove electrical connector from relay.

(3) Remove relay from control module mounting

bracket by prying out on locating clip (Fig. 11)

INSTALLATION (1) Push relay onto bracket (relay will Lock into

position.) (2) Install electrical connector. (3) Install trim panel.

COMPRESSOR ASSEMBLY

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle, see Hoisting, Group 0.

(3) Remove cover from compressor assembly. Re-

move air hose (see AIR LINES) and electrical connec-

tors (Fig. 12) (4) Remove compressor assembly mounting screws

and lower assembly from vehicle. (5) Remove mounting bracket screws and slide

mounting bracket away from compressor.

INSTALLATION (1) Slide mounting bracket on compressor and in-

stall screws and tighten to 8 N Im (70 in. lbs.) torque.

DO NOT OVER TORQUE THESE SCREWS. (2) Install compressor assembly to frame rail and

tighten screws to 8 N Im (70 in. lbs.) torque. DO NOT

OVER TORQUE THESE SCREWS. (3) Connect air hose and electrical connector to com-

pressor assembly. (4) Install cover on compressor assembly and tighten

screws to 6 N Im (40 in. lbs.) torque.

(5) Lower vehicle and connect battery negative

cable. (6) Check operation of the system.

AIR DRYER

REMOVAL

Remove compressor assembly. See COMPRESSOR

ASSEMBLY.

Fig. 11 Control Module and Relay Wiring

Fig. 12 Compressor Assembly

Ä SUSPENSION AND DRIVESHAFTS 2 - 85

Page 145 of 2438

INSTALL

(1) Inspect O-Ring condition and position on sole-

noid stem. (O-Ring can become dislodged during re-

moval (Fig. 16). (2) Install solenoid with tangs to top ledge of hous-

ing and install retaining clip. (3) Reconnect air line and electrical connection.

STRUT (AIR SUSPENSION) DAMPERASSEMBLY

Service procedures for removal and installation for

(air or steel spring) assemblies are essentially the

same. Except for air venting/recharging and discon-

necting/connecting air lines and electrical connection.

REMOVAL (1) Disconnect battery negative cable.

(2) Hoist vehicle and remove wheel and tire assem-

bly. (3) See AIR LINES AND FITTINGS and discon-

nect air line. (4) Disconnect electrical leads, solenoid and height

sensors. (5) See SOLENOIDS (STRUT AND AIR SPRING)

and vent air spring and remove solenoids. (6) See STRUT DAMPER ASSEMBLY in FRONT

SUSPENSION and remove strut.

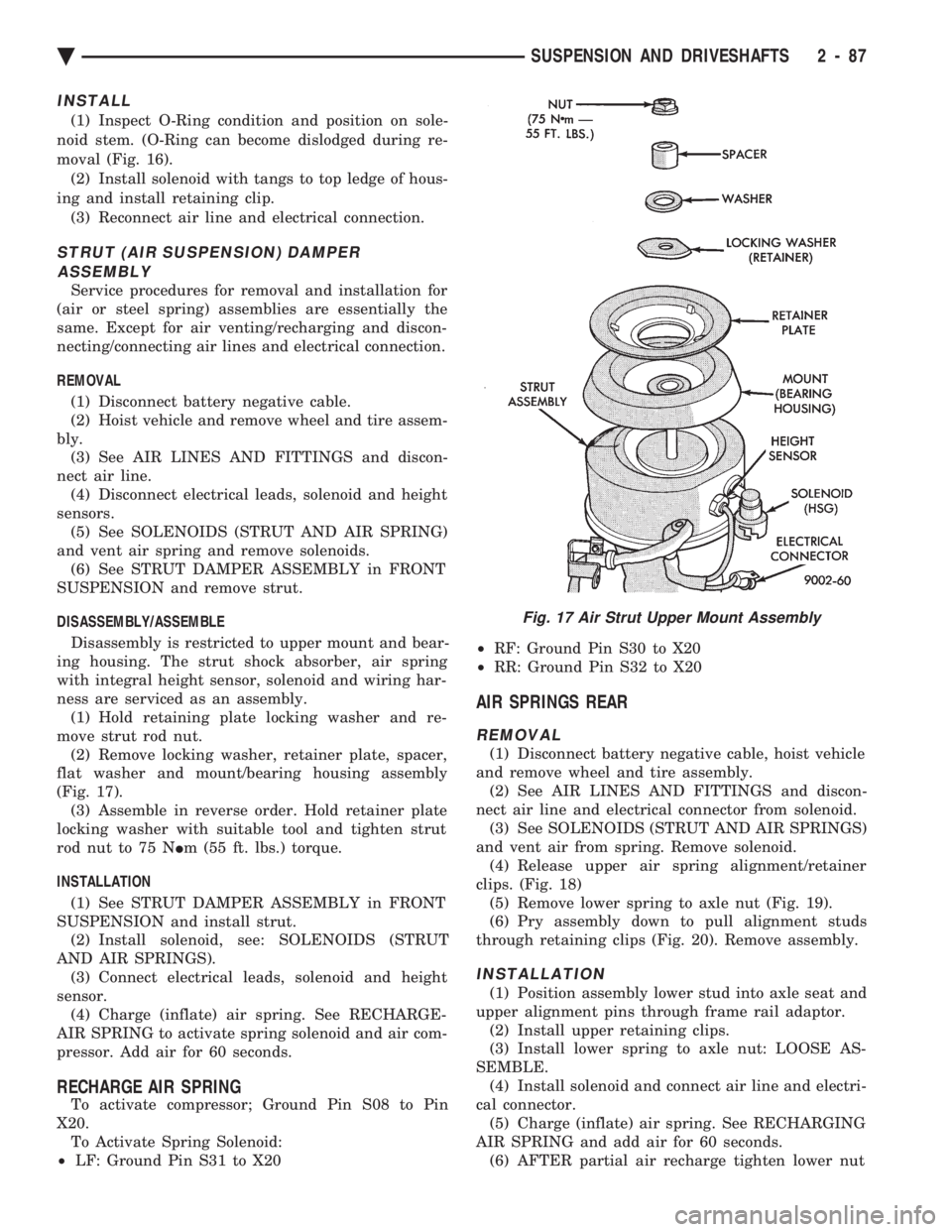

DISASSEMBLY/ASSEMBLE Disassembly is restricted to upper mount and bear-

ing housing. The strut shock absorber, air spring

with integral height sensor, solenoid and wiring har-

ness are serviced as an assembly. (1) Hold retaining plate locking washer and re-

move strut rod nut. (2) Remove locking washer, retainer plate, spacer,

flat washer and mount/bearing housing assembly

(Fig. 17). (3) Assemble in reverse order. Hold retainer plate

locking washer with suitable tool and tighten strut

rod nut to 75 N Im (55 ft. lbs.) torque.

INSTALLATION (1) See STRUT DAMPER ASSEMBLY in FRONT

SUSPENSION and install strut. (2) Install solenoid, see: SOLENOIDS (STRUT

AND AIR SPRINGS). (3) Connect electrical leads, solenoid and height

sensor. (4) Charge (inflate) air spring. See RECHARGE-

AIR SPRING to activate spring solenoid and air com-

pressor. Add air for 60 seconds.

RECHARGE AIR SPRING

To activate compressor; Ground Pin S08 to Pin

X20. To Activate Spring Solenoid:

² LF: Ground Pin S31 to X20 ²

RF: Ground Pin S30 to X20

² RR: Ground Pin S32 to X20

AIR SPRINGS REAR

REMOVAL

(1) Disconnect battery negative cable, hoist vehicle

and remove wheel and tire assembly. (2) See AIR LINES AND FITTINGS and discon-

nect air line and electrical connector from solenoid. (3) See SOLENOIDS (STRUT AND AIR SPRINGS)

and vent air from spring. Remove solenoid. (4) Release upper air spring alignment/retainer

clips. (Fig. 18) (5) Remove lower spring to axle nut (Fig. 19).

(6) Pry assembly down to pull alignment studs

through retaining clips (Fig. 20). Remove assembly.

INSTALLATION

(1) Position assembly lower stud into axle seat and

upper alignment pins through frame rail adaptor. (2) Install upper retaining clips.

(3) Install lower spring to axle nut: LOOSE AS-

SEMBLE. (4) Install solenoid and connect air line and electri-

cal connector. (5) Charge (inflate) air spring. See RECHARGING

AIR SPRING and add air for 60 seconds. (6) AFTER partial air recharge tighten lower nut

Fig. 17 Air Strut Upper Mount Assembly

Ä SUSPENSION AND DRIVESHAFTS 2 - 87

Page 147 of 2438

REAR (STUB) AXLE ALIGNMENT ALL MODELS INDEX

page page

General Information ....................... 89 Rear Wheel Alignment..................... 89

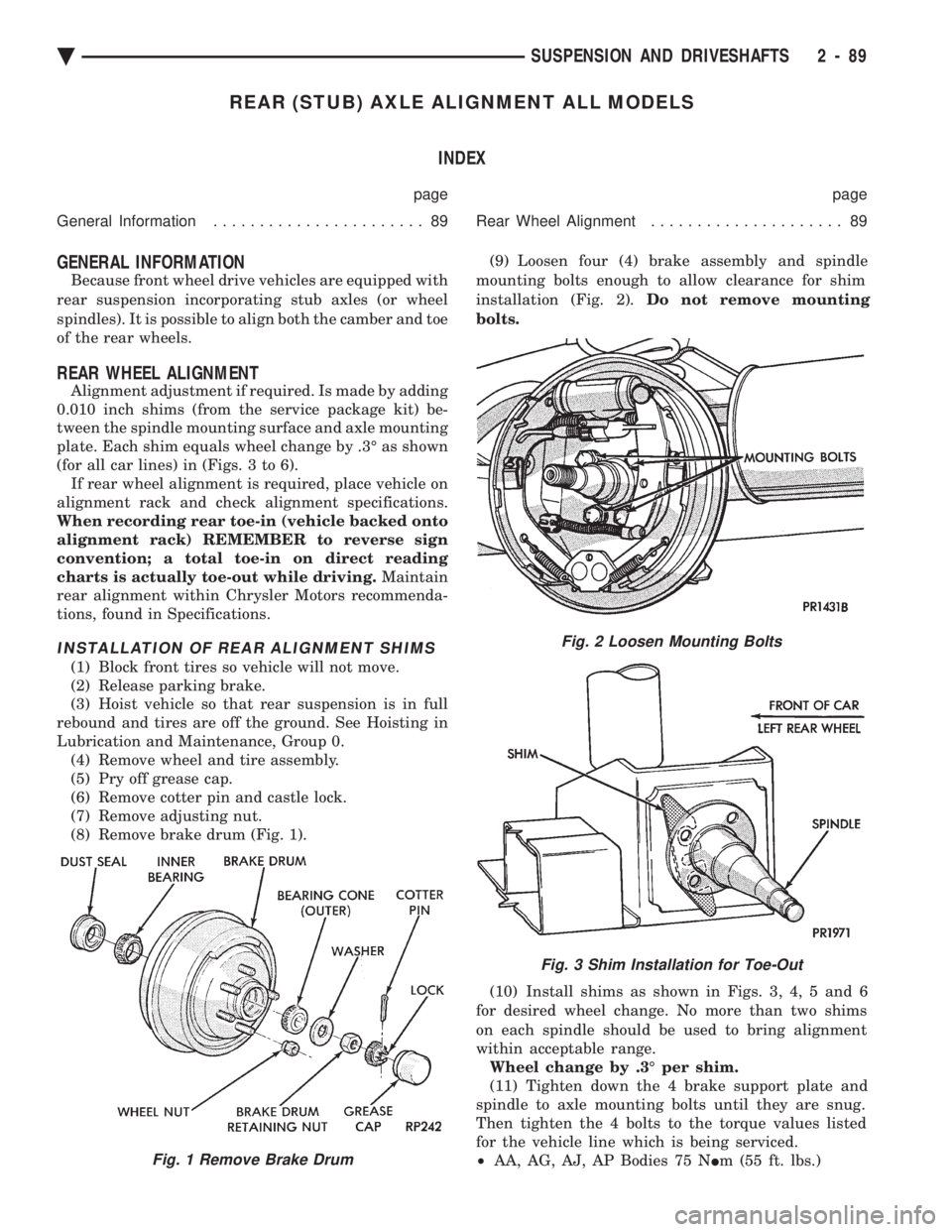

GENERAL INFORMATION

Because front wheel drive vehicles are equipped with

rear suspension incorporating stub axles (or wheel

spindles). It is possible to align both the camber and toe

of the rear wheels.

REAR WHEEL ALIGNMENT

Alignment adjustment if required. Is made by adding

0.010 inch shims (from the service package kit) be-

tween the spindle mounting surface and axle mounting

plate. Each shim equals wheel change by .3É as shown

(for all car lines) in (Figs. 3 to 6). If rear wheel alignment is required, place vehicle on

alignment rack and check alignment specifications.

When recording rear toe-in (vehicle backed onto

alignment rack) REMEMBER to reverse sign

convention; a total toe-in on direct reading

charts is actually toe-out while driving. Maintain

rear alignment within Chrysler Motors recommenda-

tions, found in Specifications.

INSTALLATION OF REAR ALIGNMENT SHIMS

(1) Block front tires so vehicle will not move.

(2) Release parking brake.

(3) Hoist vehicle so that rear suspension is in full

rebound and tires are off the ground. See Hoisting in

Lubrication and Maintenance, Group 0. (4) Remove wheel and tire assembly.

(5) Pry off grease cap.

(6) Remove cotter pin and castle lock.

(7) Remove adjusting nut.

(8) Remove brake drum (Fig. 1). (9) Loosen four (4) brake assembly and spindle

mounting bolts enough to allow clearance for shim

installation (Fig. 2). Do not remove mounting

bolts.

(10) Install shims as shown in Figs. 3, 4, 5 and 6

for desired wheel change. No more than two shims

on each spindle should be used to bring alignment

within acceptable range. Wheel change by .3É per shim.

(11) Tighten down the 4 brake support plate and

spindle to axle mounting bolts until they are snug.

Then tighten the 4 bolts to the torque values listed

for the vehicle line which is being serviced.

² AA, AG, AJ, AP Bodies 75 N Im (55 ft. lbs.)

Fig. 2 Loosen Mounting Bolts

Fig. 3 Shim Installation for Toe-Out

Fig. 1 Remove Brake Drum

Ä SUSPENSION AND DRIVESHAFTS 2 - 89

Page 151 of 2438

BRAKES

CONTENTS

page page

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ............. 72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY ....... 113

BRAKE DISC (ROTOR) ................... 53

BRAKE SUPPORT ASSEMBLY ............. 25

FRONT DISC BRAKES ................... 31

GENERAL INFORMATION .................. 1

HYDRAULIC SYSTEM CONTROL VALVES . . . 26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER ............................ 35 KELSEY HAYES DOUBLE PIN NON-FAMILY

CALIPER ............................ 38

MASTER CYLINDER ..................... 66

PARKING BRAKES ...................... 57

POWER BRAKES ....................... 68

REAR DISC BRAKES .................... 45

REAR WHEEL DRUM BRAKES ............ 18

SERVICE ADJUSTMENTS .................. 4

WHEEL BEARINGS ...................... 70

WHEEL CYLINDERS ..................... 23

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the break down of these designa-

tions is included in the Introduction Section at the

front of this service manual. Standard brake equipment consists of:

² Double pin floating caliper disc front brakes.

² Rear automatic adjusting drum brakes.

² Differential valve with a brake warning switch.

² Master cylinder.

² Vacuum power booster.

² Double pin floating caliper rear disc brakes are

available on some models. The Bendix Anti-Lock 10 braking system, uses the

standard power brake system caliper assemblies,

braking discs, pedal assembly, brake lines and hoses.

The unique parts of the Bendix Anti-Lock 10 braking

system consists of the following components. Propor-

tioning valves, wheel speed sensors, tone wheels,

electronic control unit, modulator assembly and hy-

draulic assembly. These components replace the con-

ventional master cylinder and power booster. The

components will be described in detail in the Bendix

Anti-Lock 10 brake section in this group of the ser-

vice manual. The Bendix Anti-Lock 6 braking system, uses the

following standard brake system components. Master

cylinder, power booster, caliper assemblies, braking

discs, pedal assembly, brake lines and hoses. The

unique parts of the Bendix Anti-Lock 6 braking sys-

tem consists of the following components. Modulator

assembly, unique proportioning valves, wheel speed

sensors, tone wheels, and electronic control unit.

These components will be described in detail in the

Bendix Anti-Lock 6 brake section in this group of the

service manual. The front disc brake shoes have semi-metallic lin-

ings. The hydraulic brake system (Fig .123and4)is

diagonally split on both the Non-ABS and ABS brak-

ing system. With the left front and right rear brakes

on one hydraulic system and the right front and left

rear on the other. The Non-ABS and ABS brake system may use dif-

ferent types of brake line fittings and tubing flares.

The Non-ABS brake system uses double wall tubing

flares and fittings at all tubing joint locations. Some

ABS brake systems use both ISO style tubing flares

and double wall tubing flares and corresponding fit-

tings at different joint locations. See (Figs . 2 3 and 4)

for specific joint locations and type of tubing flare. The front disc brakes consist of two different types

of caliper assemblies. A double pin Kelsey-Hayes cal-

iper (family caliper) with a bolt-on adapter attached

to the steering knuckle. Or a double pin Kelsey-

Hayes caliper (non-family caliper) which mounts di-

rectly to rails on the steering knuckle. The non-

family caliper is only used on the AY Body

(Imperials).

CAUTION: Caliper pistons, boots and seals for the

different caliper assemblies used on the front and

rear disc brake assemblies are not interchangeable.

Misusage could result in a complete brake system

failure. Be sure that the parts are replaced with the

correct replacement parts, refer to the parts book

for the type and model year of the vehicle being

worked on.

The master cylinder is anodized, lightweight alu-

minum, with a bore size of 24.0mm, 21.0mm or 7/8

inch.

Ä BRAKES 5 - 1

Page 154 of 2438

SERVICE ADJUSTMENTS INDEX

page page

Adjusting Rear Service Brakes ............... 4

Bleeding Brake System ..................... 6

Brake Hose and Tubing ................... 11

Master Cylinder Fluid Level .................. 4 Stop Lamp Switch Adjustment (All Vehicles)

.... 13

Test for Fluid Contamination ................. 7

Testing Application Adjuster Operation ......... 6

Wheel Stud Nut Tightening .................. 7

MASTER CYLINDER FLUID LEVEL

ALL EXCEPT AC/AY BODY WITH ABS

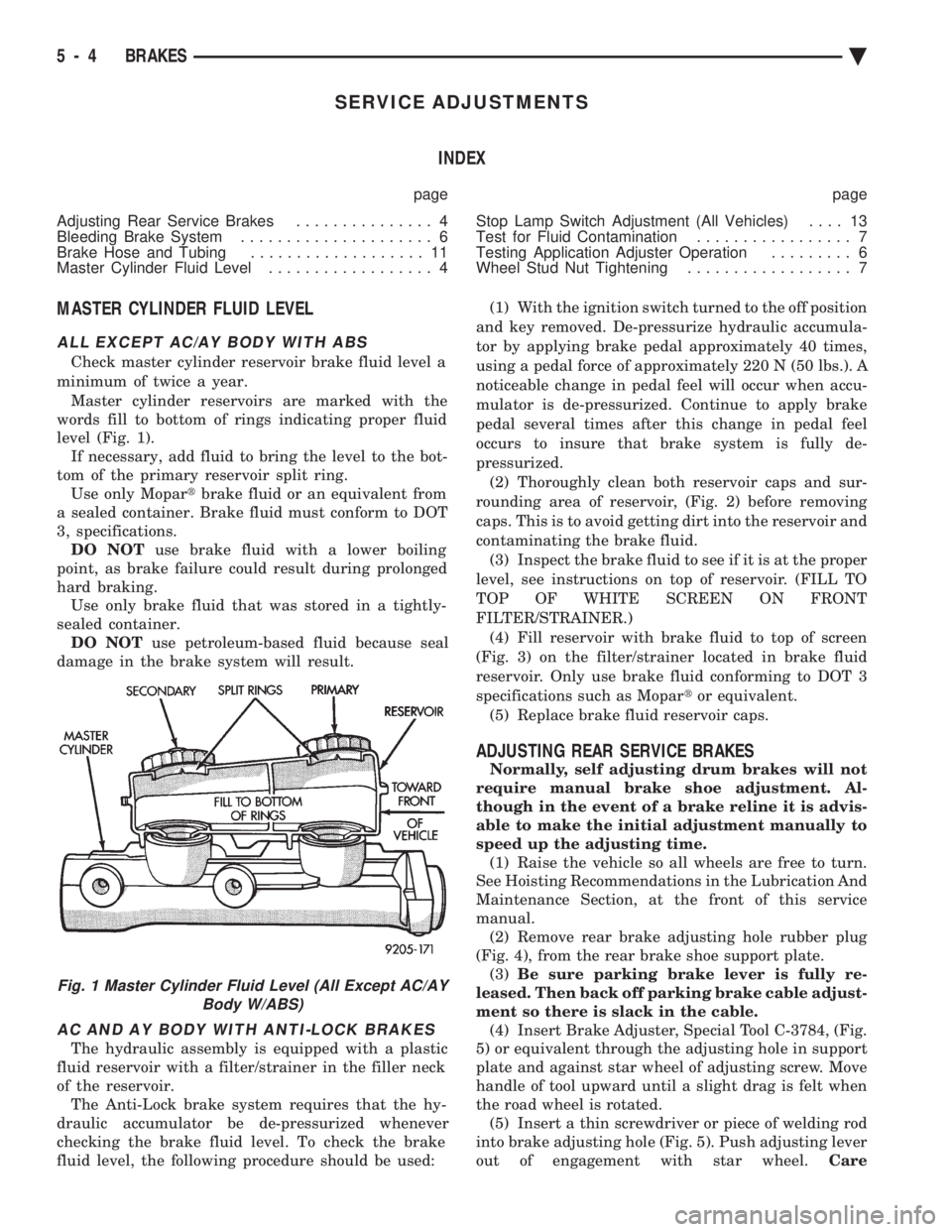

Check master cylinder reservoir brake fluid level a

minimum of twice a year. Master cylinder reservoirs are marked with the

words fill to bottom of rings indicating proper fluid

level (Fig. 1). If necessary, add fluid to bring the level to the bot-

tom of the primary reservoir split ring. Use only Mopar tbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications. DO NOT use brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking. Use only brake fluid that was stored in a tightly-

sealed container. DO NOT use petroleum-based fluid because seal

damage in the brake system will result.

AC AND AY BODY WITH ANTI-LOCK BRAKES

The hydraulic assembly is equipped with a plastic

fluid reservoir with a filter/strainer in the filler neck

of the reservoir. The Anti-Lock brake system requires that the hy-

draulic accumulator be de-pressurized whenever

checking the brake fluid level. To check the brake

fluid level, the following procedure should be used: (1) With the ignition switch turned to the off position

and key removed. De-pressurize hydraulic accumula-

tor by applying brake pedal approximately 40 times,

using a pedal force of approximately 220 N (50 lbs.). A

noticeable change in pedal feel will occur when accu-

mulator is de-pressurized. Continue to apply brake

pedal several times after this change in pedal feel

occurs to insure that brake system is fully de-

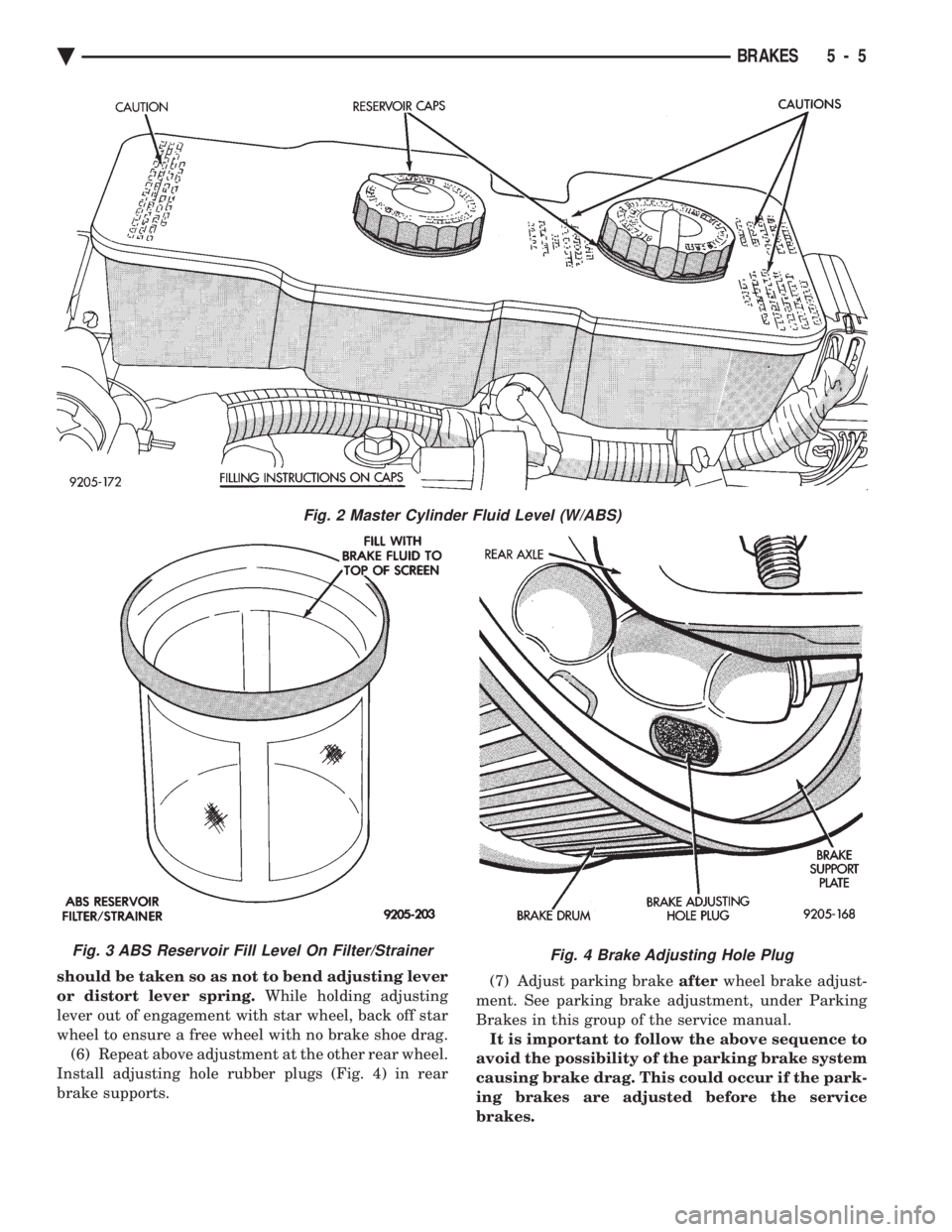

pressurized. (2) Thoroughly clean both reservoir caps and sur-

rounding area of reservoir, (Fig. 2) before removing

caps. This is to avoid getting dirt into the reservoir and

contaminating the brake fluid. (3) Inspect the brake fluid to see if it is at the proper

level, see instructions on top of reservoir. (FILL TO

TOP OF WHITE SCREEN ON FRONT

FILTER/STRAINER.) (4) Fill reservoir with brake fluid to top of screen

(Fig. 3) on the filter/strainer located in brake fluid

reservoir. Only use brake fluid conforming to DOT 3

specifications such as Mopar tor equivalent.

(5) Replace brake fluid reservoir caps.

ADJUSTING REAR SERVICE BRAKES

Normally, self adjusting drum brakes will not

require manual brake shoe adjustment. Al-

though in the event of a brake reline it is advis-

able to make the initial adjustment manually to

speed up the adjusting time. (1) Raise the vehicle so all wheels are free to turn.

See Hoisting Recommendations in the Lubrication And

Maintenance Section, at the front of this service

manual. (2) Remove rear brake adjusting hole rubber plug

(Fig. 4), from the rear brake shoe support plate. (3) Be sure parking brake lever is fully re-

leased. Then back off parking brake cable adjust-

ment so there is slack in the cable. (4) Insert Brake Adjuster, Special Tool C-3784, (Fig.

5) or equivalent through the adjusting hole in support

plate and against star wheel of adjusting screw. Move

handle of tool upward until a slight drag is felt when

the road wheel is rotated. (5) Insert a thin screwdriver or piece of welding rod

into brake adjusting hole (Fig. 5). Push adjusting lever

out of engagement with star wheel. Care

Fig. 1 Master Cylinder Fluid Level (All Except AC/AY

Body W/ABS)

5 - 4 BRAKES Ä

Page 155 of 2438

should be taken so as not to bend adjusting lever

or distort lever spring. While holding adjusting

lever out of engagement with star wheel, back off star

wheel to ensure a free wheel with no brake shoe drag. (6) Repeat above adjustment at the other rear wheel.

Install adjusting hole rubber plugs (Fig. 4) in rear

brake supports. (7) Adjust parking brake

afterwheel brake adjust-

ment. See parking brake adjustment, under Parking

Brakes in this group of the service manual. It is important to follow the above sequence to

avoid the possibility of the parking brake system

causing brake drag. This could occur if the park-

ing brakes are adjusted before the service

brakes.

Fig. 4 Brake Adjusting Hole Plug

Fig. 2 Master Cylinder Fluid Level (W/ABS)

Fig. 3 ABS Reservoir Fill Level On Filter/Strainer

Ä BRAKES 5 - 5