service CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 156 of 2438

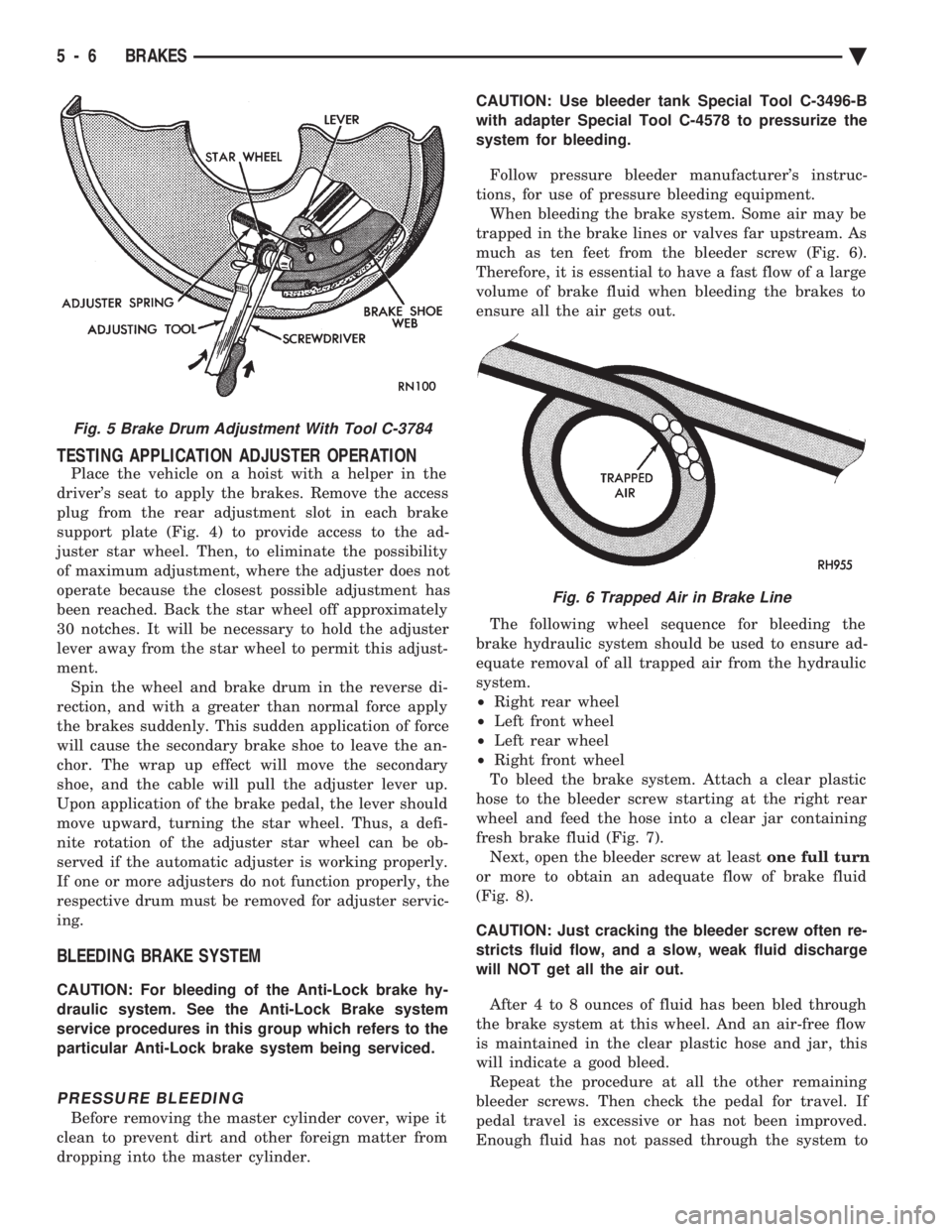

TESTING APPLICATION ADJUSTER OPERATION

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the rear adjustment slot in each brake

support plate (Fig. 4) to provide access to the ad-

juster star wheel. Then, to eliminate the possibility

of maximum adjustment, where the adjuster does not

operate because the closest possible adjustment has

been reached. Back the star wheel off approximately

30 notches. It will be necessary to hold the adjuster

lever away from the star wheel to permit this adjust-

ment. Spin the wheel and brake drum in the reverse di-

rection, and with a greater than normal force apply

the brakes suddenly. This sudden application of force

will cause the secondary brake shoe to leave the an-

chor. The wrap up effect will move the secondary

shoe, and the cable will pull the adjuster lever up.

Upon application of the brake pedal, the lever should

move upward, turning the star wheel. Thus, a defi-

nite rotation of the adjuster star wheel can be ob-

served if the automatic adjuster is working properly.

If one or more adjusters do not function properly, the

respective drum must be removed for adjuster servic-

ing.

BLEEDING BRAKE SYSTEM

CAUTION: For bleeding of the Anti-Lock brake hy-

draulic system. See the Anti-Lock Brake system

service procedures in this group which refers to the

particular Anti-Lock brake system being serviced.

PRESSURE BLEEDING

Before removing the master cylinder cover, wipe it

clean to prevent dirt and other foreign matter from

dropping into the master cylinder. CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool C-4578 to pressurize the

system for bleeding.

Follow pressure bleeder manufacturer's instruc-

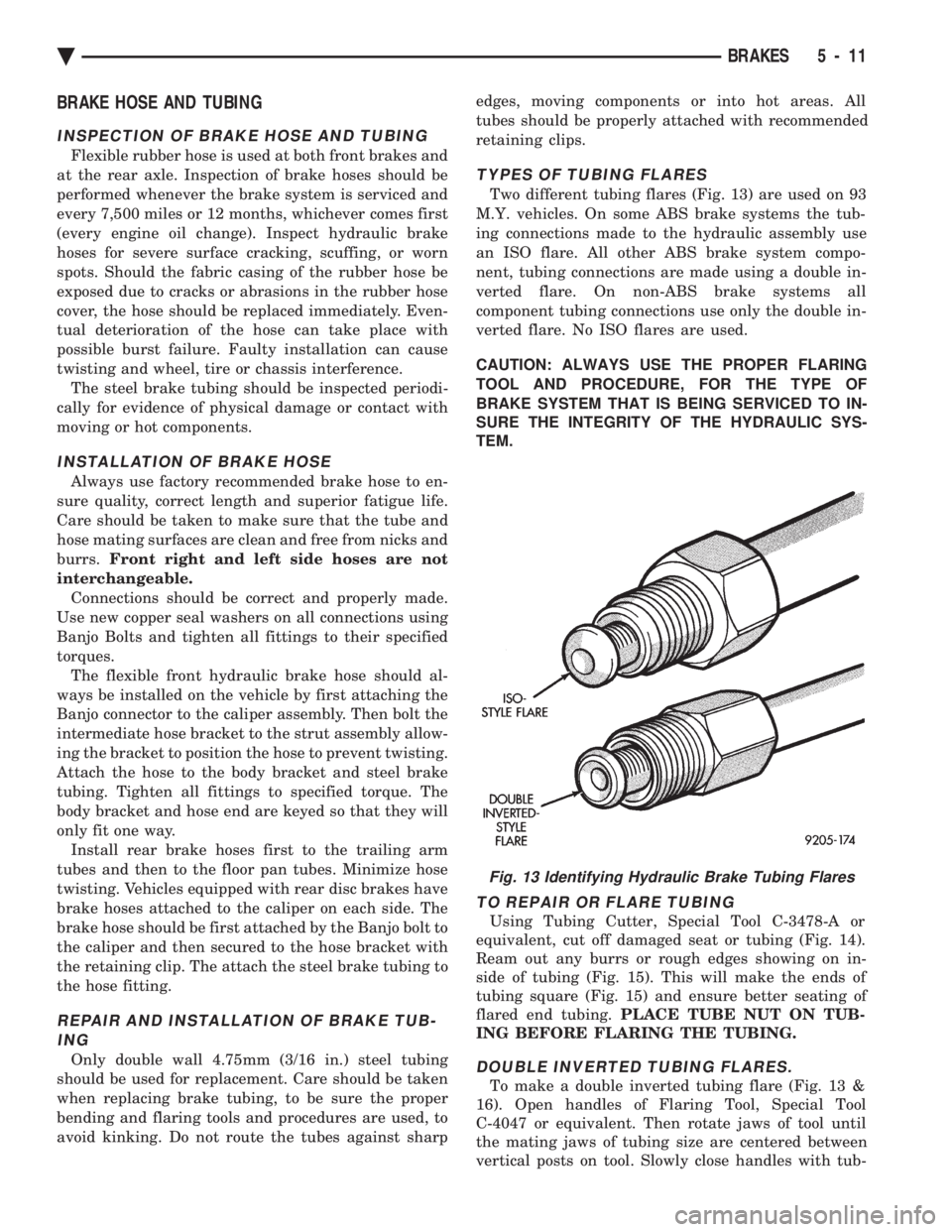

tions, for use of pressure bleeding equipment. When bleeding the brake system. Some air may be

trapped in the brake lines or valves far upstream. As

much as ten feet from the bleeder screw (Fig. 6).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure ad-

equate removal of all trapped air from the hydraulic

system.

² Right rear wheel

² Left front wheel

² Left rear wheel

² Right front wheel

To bleed the brake system. Attach a clear plastic

hose to the bleeder screw starting at the right rear

wheel and feed the hose into a clear jar containing

fresh brake fluid (Fig. 7). Next, open the bleeder screw at least one full turn

or more to obtain an adequate flow of brake fluid

(Fig. 8).

CAUTION: Just cracking the bleeder screw often re-

stricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

After 4 to 8 ounces of fluid has been bled through

the brake system at this wheel. And an air-free flow

is maintained in the clear plastic hose and jar, this

will indicate a good bleed. Repeat the procedure at all the other remaining

bleeder screws. Then check the pedal for travel. If

pedal travel is excessive or has not been improved.

Enough fluid has not passed through the system to

Fig. 5 Brake Drum Adjustment With Tool C-3784

Fig. 6 Trapped Air in Brake Line

5 - 6 BRAKES Ä

Page 161 of 2438

BRAKE HOSE AND TUBING

INSPECTION OF BRAKE HOSE AND TUBING

Flexible rubber hose is used at both front brakes and

at the rear axle. Inspection of brake hoses should be

performed whenever the brake system is serviced and

every 7,500 miles or 12 months, whichever comes first

(every engine oil change). Inspect hydraulic brake

hoses for severe surface cracking, scuffing, or worn

spots. Should the fabric casing of the rubber hose be

exposed due to cracks or abrasions in the rubber hose

cover, the hose should be replaced immediately. Even-

tual deterioration of the hose can take place with

possible burst failure. Faulty installation can cause

twisting and wheel, tire or chassis interference. The steel brake tubing should be inspected periodi-

cally for evidence of physical damage or contact with

moving or hot components.

INSTALLATION OF BRAKE HOSE

Always use factory recommended brake hose to en-

sure quality, correct length and superior fatigue life.

Care should be taken to make sure that the tube and

hose mating surfaces are clean and free from nicks and

burrs. Front right and left side hoses are not

interchangeable. Connections should be correct and properly made.

Use new copper seal washers on all connections using

Banjo Bolts and tighten all fittings to their specified

torques. The flexible front hydraulic brake hose should al-

ways be installed on the vehicle by first attaching the

Banjo connector to the caliper assembly. Then bolt the

intermediate hose bracket to the strut assembly allow-

ing the bracket to position the hose to prevent twisting.

Attach the hose to the body bracket and steel brake

tubing. Tighten all fittings to specified torque. The

body bracket and hose end are keyed so that they will

only fit one way. Install rear brake hoses first to the trailing arm

tubes and then to the floor pan tubes. Minimize hose

twisting. Vehicles equipped with rear disc brakes have

brake hoses attached to the caliper on each side. The

brake hose should be first attached by the Banjo bolt to

the caliper and then secured to the hose bracket with

the retaining clip. The attach the steel brake tubing to

the hose fitting.

REPAIR AND INSTALLATION OF BRAKE TUB- ING

Only double wall 4.75mm (3/16 in.) steel tubing

should be used for replacement. Care should be taken

when replacing brake tubing, to be sure the proper

bending and flaring tools and procedures are used, to

avoid kinking. Do not route the tubes against sharp edges, moving components or into hot areas. All

tubes should be properly attached with recommended

retaining clips.

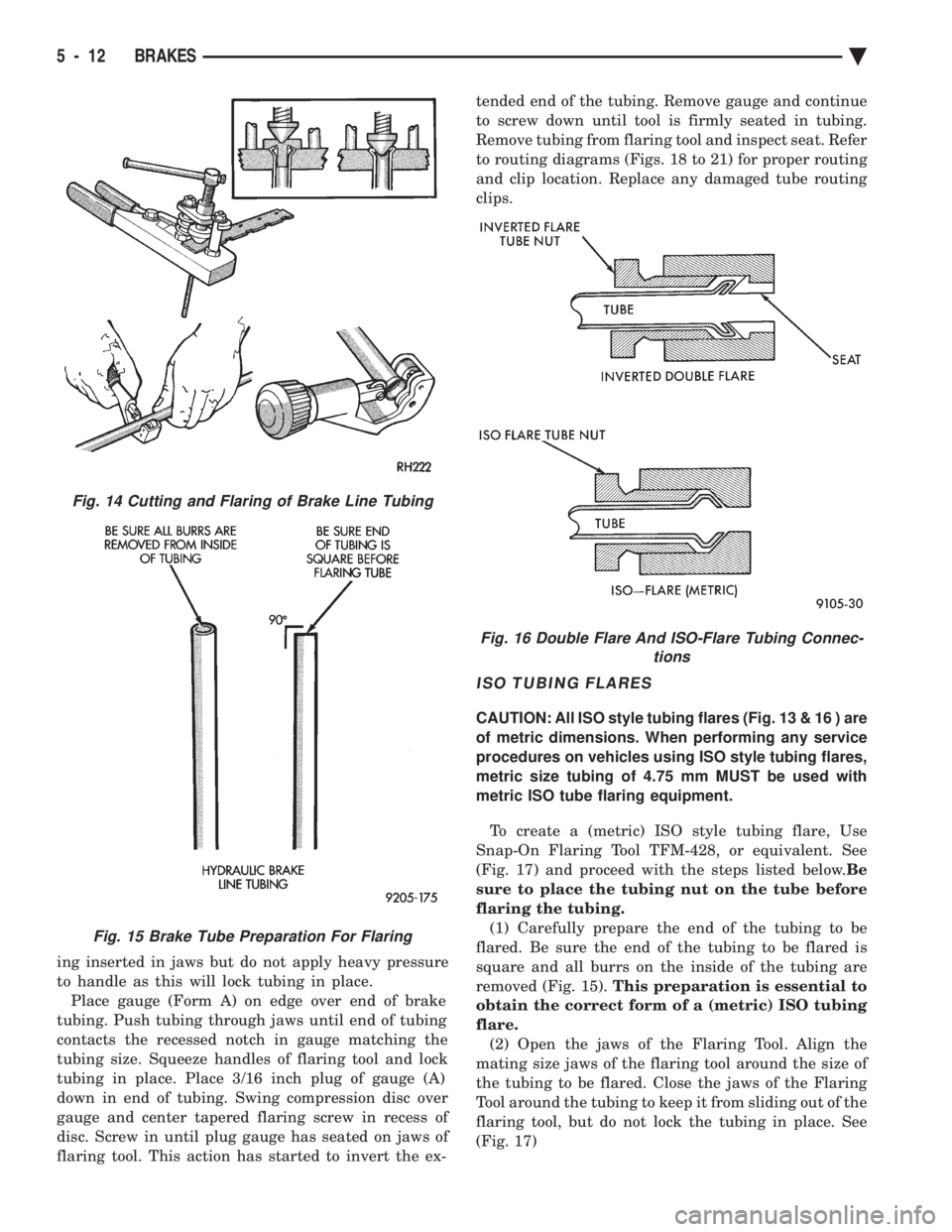

TYPES OF TUBING FLARES

Two different tubing flares (Fig. 13) are used on 93

M.Y. vehicles. On some ABS brake systems the tub-

ing connections made to the hydraulic assembly use

an ISO flare. All other ABS brake system compo-

nent, tubing connections are made using a double in-

verted flare. On non-ABS brake systems all

component tubing connections use only the double in-

verted flare. No ISO flares are used.

CAUTION: ALWAYS USE THE PROPER FLARING

TOOL AND PROCEDURE, FOR THE TYPE OF

BRAKE SYSTEM THAT IS BEING SERVICED TO IN-

SURE THE INTEGRITY OF THE HYDRAULIC SYS-

TEM.

TO REPAIR OR FLARE TUBING

Using Tubing Cutter, Special Tool C-3478-A or

equivalent, cut off damaged seat or tubing (Fig. 14).

Ream out any burrs or rough edges showing on in-

side of tubing (Fig. 15). This will make the ends of

tubing square (Fig. 15) and ensure better seating of

flared end tubing. PLACE TUBE NUT ON TUB-

ING BEFORE FLARING THE TUBING.

DOUBLE INVERTED TUBING FLARES.

To make a double inverted tubing flare (Fig. 13 &

16). Open handles of Flaring Tool, Special Tool

C-4047 or equivalent. Then rotate jaws of tool until

the mating jaws of tubing size are centered between

vertical posts on tool. Slowly close handles with tub-

Fig. 13 Identifying Hydraulic Brake Tubing Flares

Ä BRAKES 5 - 11

Page 162 of 2438

ing inserted in jaws but do not apply heavy pressure

to handle as this will lock tubing in place.Place gauge (Form A) on edge over end of brake

tubing. Push tubing through jaws until end of tubing

contacts the recessed notch in gauge matching the

tubing size. Squeeze handles of flaring tool and lock

tubing in place. Place 3/16 inch plug of gauge (A)

down in end of tubing. Swing compression disc over

gauge and center tapered flaring screw in recess of

disc. Screw in until plug gauge has seated on jaws of

flaring tool. This action has started to invert the ex- tended end of the tubing. Remove gauge and continue

to screw down until tool is firmly seated in tubing.

Remove tubing from flaring tool and inspect seat. Refer

to routing diagrams (Figs. 18 to 21) for proper routing

and clip location. Replace any damaged tube routing

clips.

ISO TUBING FLARES

CAUTION: All ISO style tubing flares (Fig. 13 & 16 ) are

of metric dimensions. When performing any service

procedures on vehicles using ISO style tubing flares,

metric size tubing of 4.75 mm MUST be used with

metric ISO tube flaring equipment.

To create a (metric) ISO style tubing flare, Use

Snap-On Flaring Tool TFM-428, or equivalent. See

(Fig. 17) and proceed with the steps listed below. Be

sure to place the tubing nut on the tube before

flaring the tubing. (1) Carefully prepare the end of the tubing to be

flared. Be sure the end of the tubing to be flared is

square and all burrs on the inside of the tubing are

removed (Fig. 15). This preparation is essential to

obtain the correct form of a (metric) ISO tubing

flare. (2) Open the jaws of the Flaring Tool. Align the

mating size jaws of the flaring tool around the size of

the tubing to be flared. Close the jaws of the Flaring

Tool around the tubing to keep it from sliding out of the

flaring tool, but do not lock the tubing in place. See

(Fig. 17)

Fig. 14 Cutting and Flaring of Brake Line Tubing

Fig. 15 Brake Tube Preparation For Flaring

Fig. 16 Double Flare And ISO-Flare Tubing Connec- tions

5 - 12 BRAKES Ä

Page 168 of 2438

REAR WHEEL DRUM BRAKES INDEX

page page

Brake Drum Refacing ..................... 21

Brake Shoe Assemblies ................... 19 Description

............................. 18

Service Procedures ....................... 18

DESCRIPTION

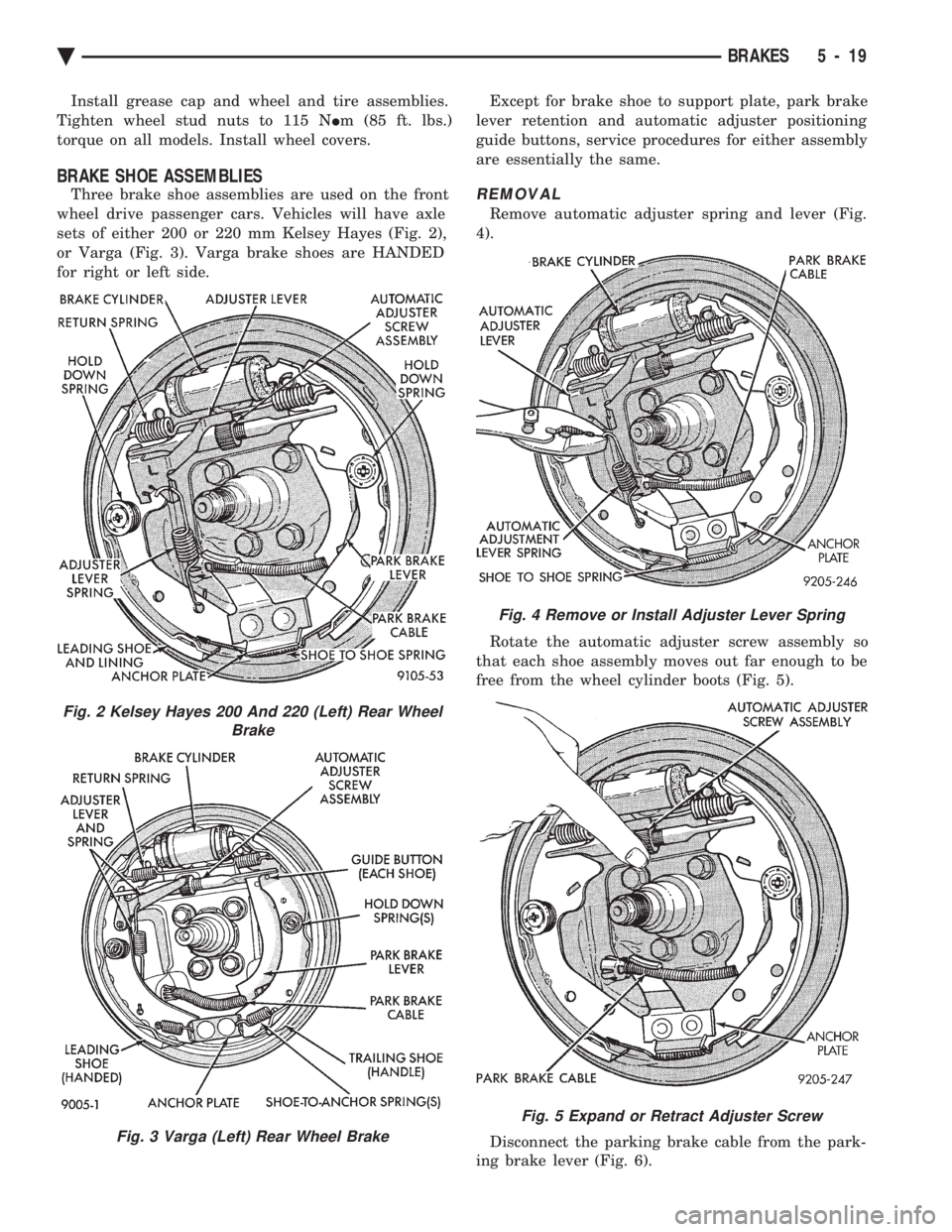

Rear wheel drum brakes (Fig .2&3)aretwoshoe,

internal expanding type with an automatic adjuster

screw assembly that is activated each time the

brakes are applied. The automatic adjuster screw is

located directly below the wheel cylinder as shown in

figure (Fig .2&3).

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS MAY

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS AND CANCER. EXTREME CARE

SHOULD BE EXERCISED WHILE SERVICING

BRAKE ASSEMBLIES OR COMPONENTS. DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH. DO NOT CREATE DUST BY SANDING, GRINDING,

AND/OR SHAVING BRAKE LININGS OR PADS UN-

LESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT. DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS. FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS. IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

SERVICE PROCEDURES

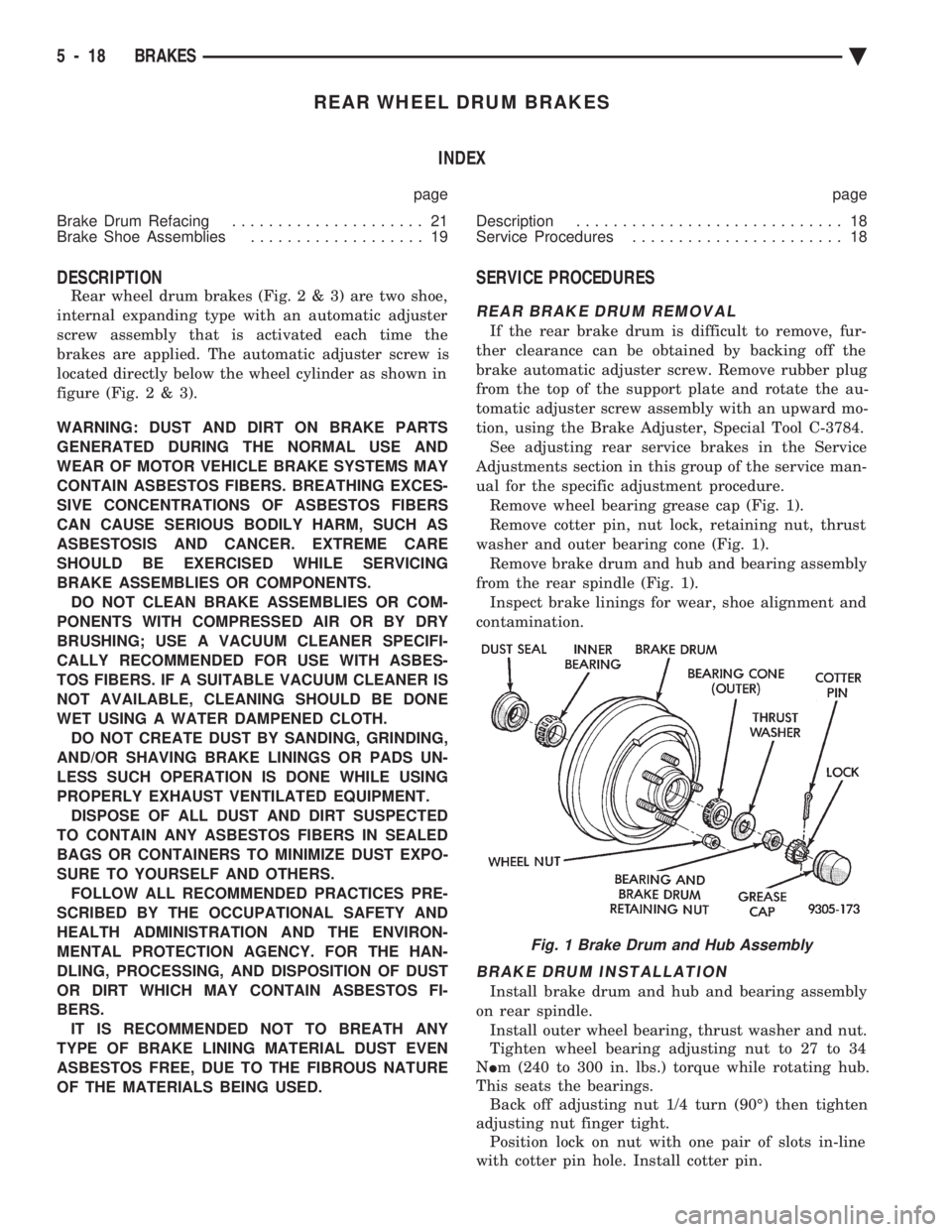

REAR BRAKE DRUM REMOVAL

If the rear brake drum is difficult to remove, fur-

ther clearance can be obtained by backing off the

brake automatic adjuster screw. Remove rubber plug

from the top of the support plate and rotate the au-

tomatic adjuster screw assembly with an upward mo-

tion, using the Brake Adjuster, Special Tool C-3784. See adjusting rear service brakes in the Service

Adjustments section in this group of the service man-

ual for the specific adjustment procedure. Remove wheel bearing grease cap (Fig. 1).

Remove cotter pin, nut lock, retaining nut, thrust

washer and outer bearing cone (Fig. 1). Remove brake drum and hub and bearing assembly

from the rear spindle (Fig. 1). Inspect brake linings for wear, shoe alignment and

contamination.

BRAKE DRUM INSTALLATION

Install brake drum and hub and bearing assembly

on rear spindle. Install outer wheel bearing, thrust washer and nut.

Tighten wheel bearing adjusting nut to 27 to 34

N Im (240 to 300 in. lbs.) torque while rotating hub.

This seats the bearings. Back off adjusting nut 1/4 turn (90É) then tighten

adjusting nut finger tight. Position lock on nut with one pair of slots in-line

with cotter pin hole. Install cotter pin.

Fig. 1 Brake Drum and Hub Assembly

5 - 18 BRAKES Ä

Page 169 of 2438

Install grease cap and wheel and tire assemblies.

Tighten wheel stud nuts to 115 N Im (85 ft. lbs.)

torque on all models. Install wheel covers.

BRAKE SHOE ASSEMBLIES

Three brake shoe assemblies are used on the front

wheel drive passenger cars. Vehicles will have axle

sets of either 200 or 220 mm Kelsey Hayes (Fig. 2),

or Varga (Fig. 3). Varga brake shoes are HANDED

for right or left side. Except for brake shoe to support plate, park brake

lever retention and automatic adjuster positioning

guide buttons, service procedures for either assembly

are essentially the same.REMOVAL

Remove automatic adjuster spring and lever (Fig.

4).

Rotate the automatic adjuster screw assembly so

that each shoe assembly moves out far enough to be

free from the wheel cylinder boots (Fig. 5).

Disconnect the parking brake cable from the park-

ing brake lever (Fig. 6).

Fig. 2 Kelsey Hayes 200 And 220 (Left) Rear Wheel Brake

Fig. 3 Varga (Left) Rear Wheel Brake

Fig. 4 Remove or Install Adjuster Lever Spring

Fig. 5 Expand or Retract Adjuster Screw

Ä BRAKES 5 - 19

Page 172 of 2438

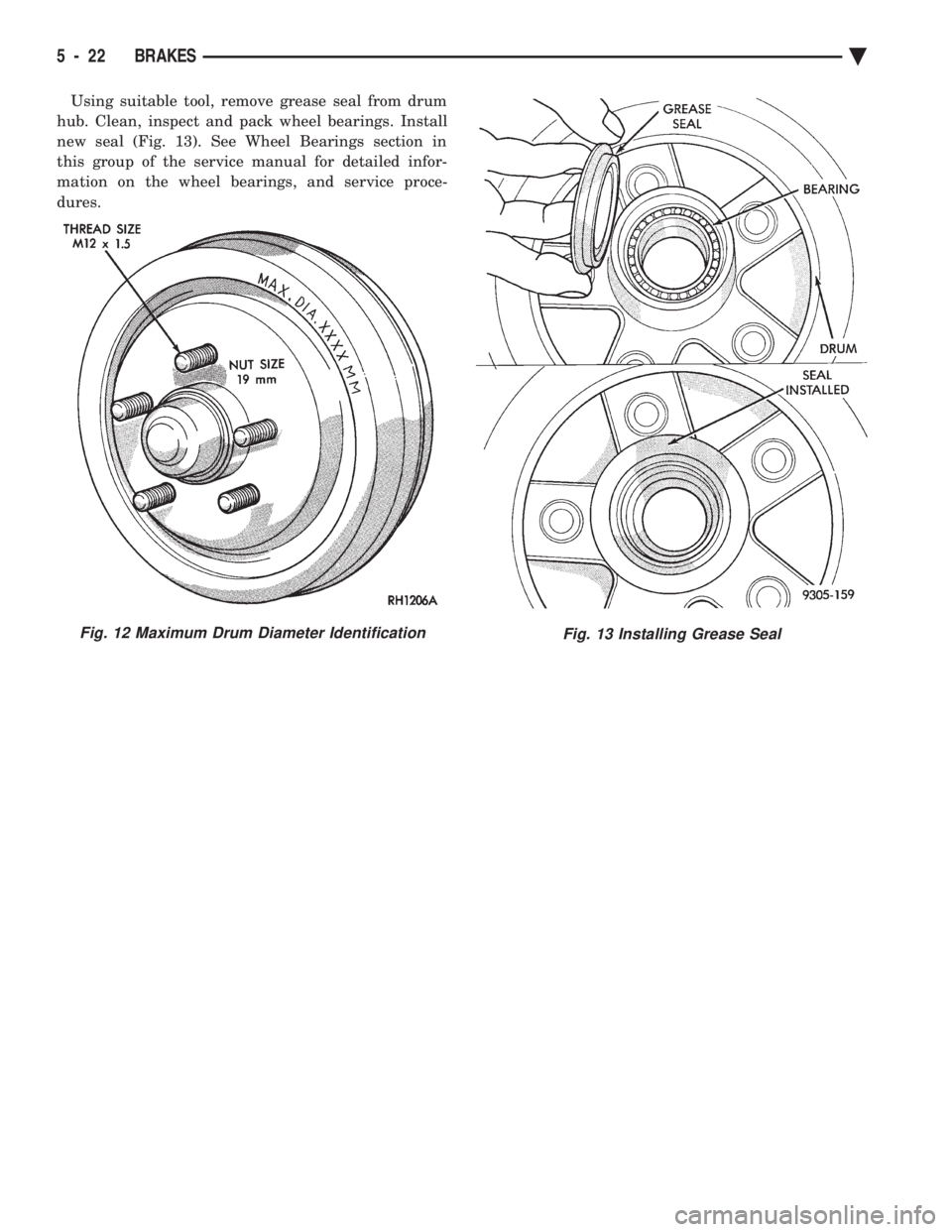

Using suitable tool, remove grease seal from drum

hub. Clean, inspect and pack wheel bearings. Install

new seal (Fig. 13). See Wheel Bearings section in

this group of the service manual for detailed infor-

mation on the wheel bearings, and service proce-

dures.

Fig. 12 Maximum Drum Diameter IdentificationFig. 13 Installing Grease Seal

5 - 22 BRAKES Ä

Page 173 of 2438

WHEEL CYLINDERS INDEX

page page

General Information ....................... 23

Installing Wheel Cylinders .................. 24 Service Procedures

....................... 23

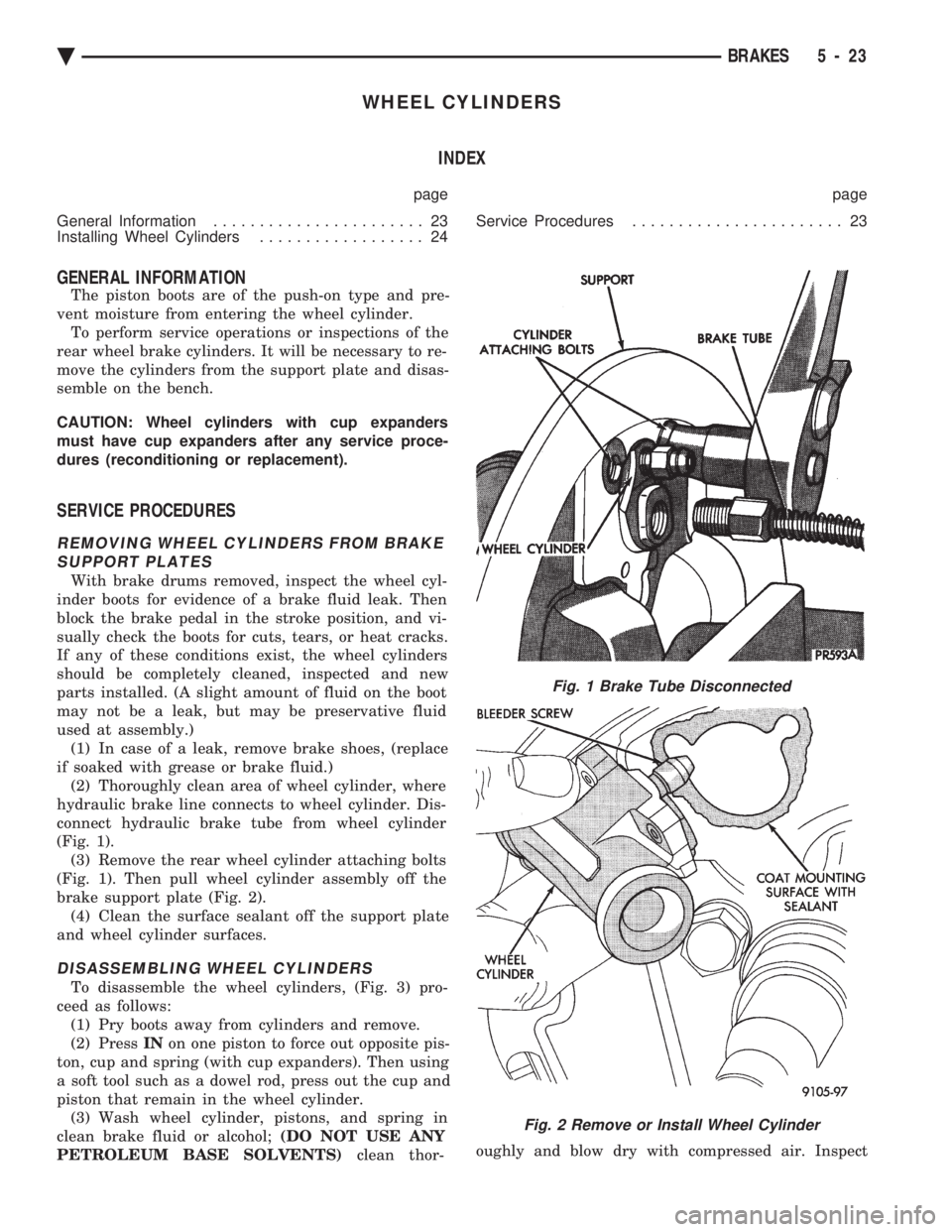

GENERAL INFORMATION

The piston boots are of the push-on type and pre-

vent moisture from entering the wheel cylinder. To perform service operations or inspections of the

rear wheel brake cylinders. It will be necessary to re-

move the cylinders from the support plate and disas-

semble on the bench.

CAUTION: Wheel cylinders with cup expanders

must have cup expanders after any service proce-

dures (reconditioning or replacement).

SERVICE PROCEDURES

REMOVING WHEEL CYLINDERS FROM BRAKE SUPPORT PLATES

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Then

block the brake pedal in the stroke position, and vi-

sually check the boots for cuts, tears, or heat cracks.

If any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed. (A slight amount of fluid on the boot

may not be a leak, but may be preservative fluid

used at assembly.) (1) In case of a leak, remove brake shoes, (replace

if soaked with grease or brake fluid.) (2) Thoroughly clean area of wheel cylinder, where

hydraulic brake line connects to wheel cylinder. Dis-

connect hydraulic brake tube from wheel cylinder

(Fig. 1). (3) Remove the rear wheel cylinder attaching bolts

(Fig. 1). Then pull wheel cylinder assembly off the

brake support plate (Fig. 2). (4) Clean the surface sealant off the support plate

and wheel cylinder surfaces.

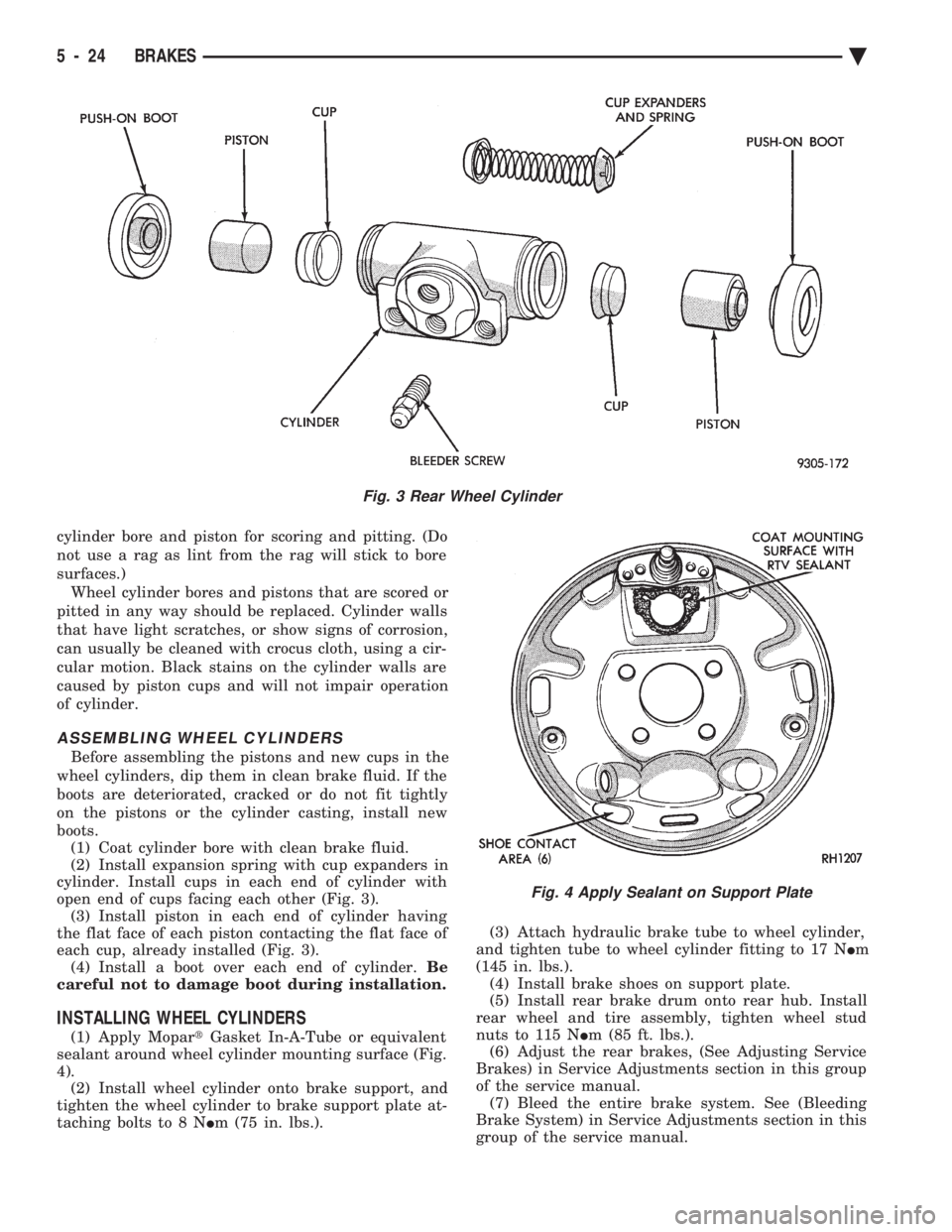

DISASSEMBLING WHEEL CYLINDERS

To disassemble the wheel cylinders, (Fig. 3) pro-

ceed as follows: (1) Pry boots away from cylinders and remove.

(2) Press INon one piston to force out opposite pis-

ton, cup and spring (with cup expanders). Then using

a soft tool such as a dowel rod, press out the cup and

piston that remain in the wheel cylinder. (3) Wash wheel cylinder, pistons, and spring in

clean brake fluid or alcohol; (DO NOT USE ANY

PETROLEUM BASE SOLVENTS) clean thor- oughly and blow dry with compressed air. Inspect

Fig. 1 Brake Tube Disconnected

Fig. 2 Remove or Install Wheel Cylinder

Ä

BRAKES 5 - 23

Page 174 of 2438

cylinder bore and piston for scoring and pitting. (Do

not use a rag as lint from the rag will stick to bore

surfaces.) Wheel cylinder bores and pistons that are scored or

pitted in any way should be replaced. Cylinder walls

that have light scratches, or show signs of corrosion,

can usually be cleaned with crocus cloth, using a cir-

cular motion. Black stains on the cylinder walls are

caused by piston cups and will not impair operation

of cylinder.

ASSEMBLING WHEEL CYLINDERS

Before assembling the pistons and new cups in the

wheel cylinders, dip them in clean brake fluid. If the

boots are deteriorated, cracked or do not fit tightly

on the pistons or the cylinder casting, install new

boots. (1) Coat cylinder bore with clean brake fluid.

(2) Install expansion spring with cup expanders in

cylinder. Install cups in each end of cylinder with

open end of cups facing each other (Fig. 3). (3) Install piston in each end of cylinder having

the flat face of each piston contacting the flat face of

each cup, already installed (Fig. 3). (4) Install a boot over each end of cylinder. Be

careful not to damage boot during installation.

INSTALLING WHEEL CYLINDERS

(1) Apply Mopar tGasket In-A-Tube or equivalent

sealant around wheel cylinder mounting surface (Fig.

4). (2) Install wheel cylinder onto brake support, and

tighten the wheel cylinder to brake support plate at-

taching bolts to 8 N Im (75 in. lbs.). (3) Attach hydraulic brake tube to wheel cylinder,

and tighten tube to wheel cylinder fitting to 17 N Im

(145 in. lbs.). (4) Install brake shoes on support plate.

(5) Install rear brake drum onto rear hub. Install

rear wheel and tire assembly, tighten wheel stud

nuts to 115 N Im (85 ft. lbs.).

(6) Adjust the rear brakes, (See Adjusting Service

Brakes) in Service Adjustments section in this group

of the service manual. (7) Bleed the entire brake system. See (Bleeding

Brake System) in Service Adjustments section in this

group of the service manual.

Fig. 3 Rear Wheel Cylinder

Fig. 4 Apply Sealant on Support Plate

5 - 24 BRAKES Ä

Page 175 of 2438

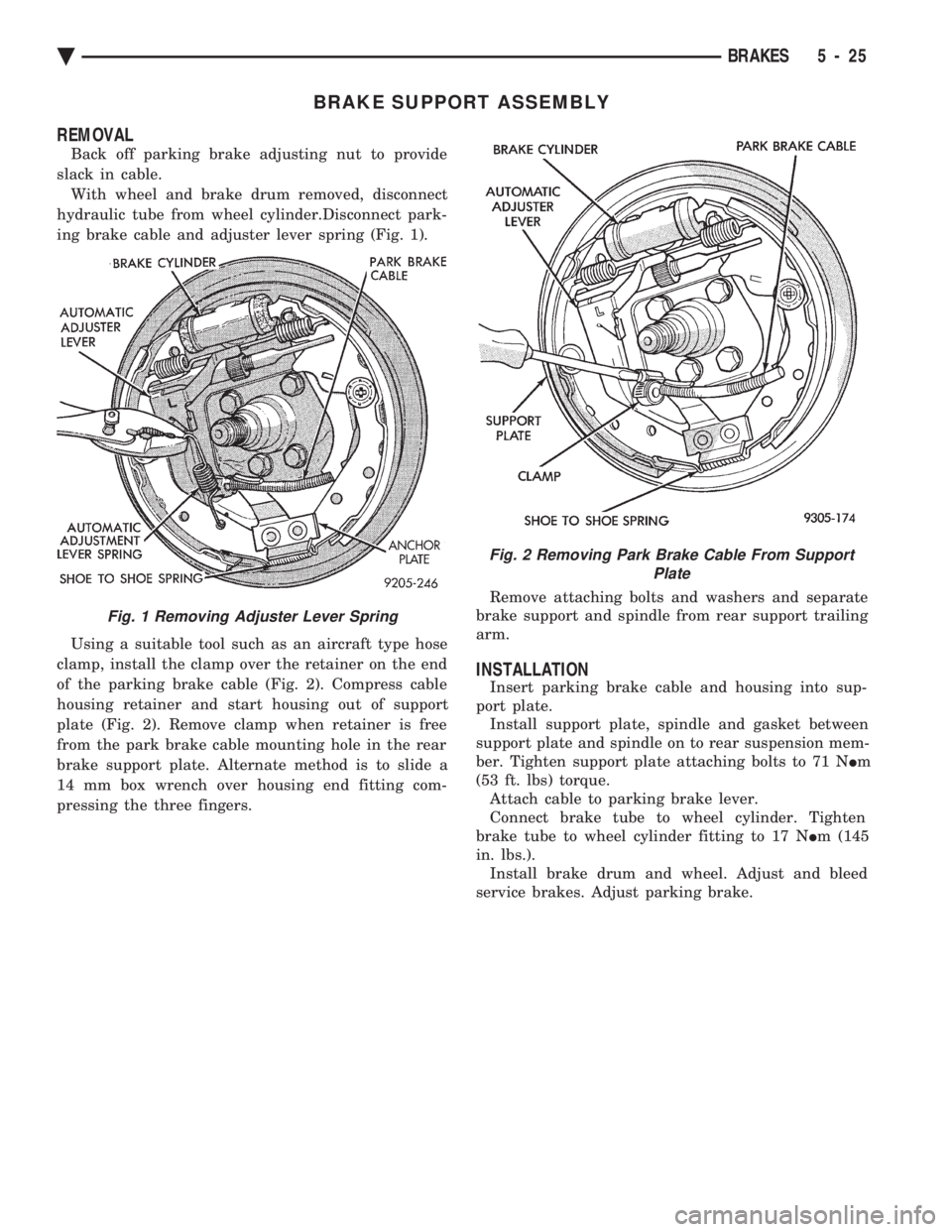

BRAKE SUPPORT ASSEMBLY

REMOVAL

Back off parking brake adjusting nut to provide

slack in cable. With wheel and brake drum removed, disconnect

hydraulic tube from wheel cylinder.Disconnect park-

ing brake cable and adjuster lever spring (Fig. 1).

Using a suitable tool such as an aircraft type hose

clamp, install the clamp over the retainer on the end

of the parking brake cable (Fig. 2). Compress cable

housing retainer and start housing out of support

plate (Fig. 2). Remove clamp when retainer is free

from the park brake cable mounting hole in the rear

brake support plate. Alternate method is to slide a

14 mm box wrench over housing end fitting com-

pressing the three fingers. Remove attaching bolts and washers and separate

brake support and spindle from rear support trailing

arm.

INSTALLATION

Insert parking brake cable and housing into sup-

port plate. Install support plate, spindle and gasket between

support plate and spindle on to rear suspension mem-

ber. Tighten support plate attaching bolts to 71 N Im

(53 ft. lbs) torque. Attach cable to parking brake lever.

Connect brake tube to wheel cylinder. Tighten

brake tube to wheel cylinder fitting to 17 N Im (145

in. lbs.). Install brake drum and wheel. Adjust and bleed

service brakes. Adjust parking brake.

Fig. 1 Removing Adjuster Lever Spring

Fig. 2 Removing Park Brake Cable From Support Plate

Ä BRAKES 5 - 25

Page 176 of 2438

HYDRAULIC SYSTEM CONTROL VALVES INDEX

page page

ABS Brake Proportioning Valve Operation ...... 27

General Information ....................... 26

Hydraulic System Service Procedures ......... 27 Non-ABS Proportioning Unit Operation

........ 26

Pressure Differential Warning Light Switch ...... 26

Testing ABS Proportioning Valves ............ 29

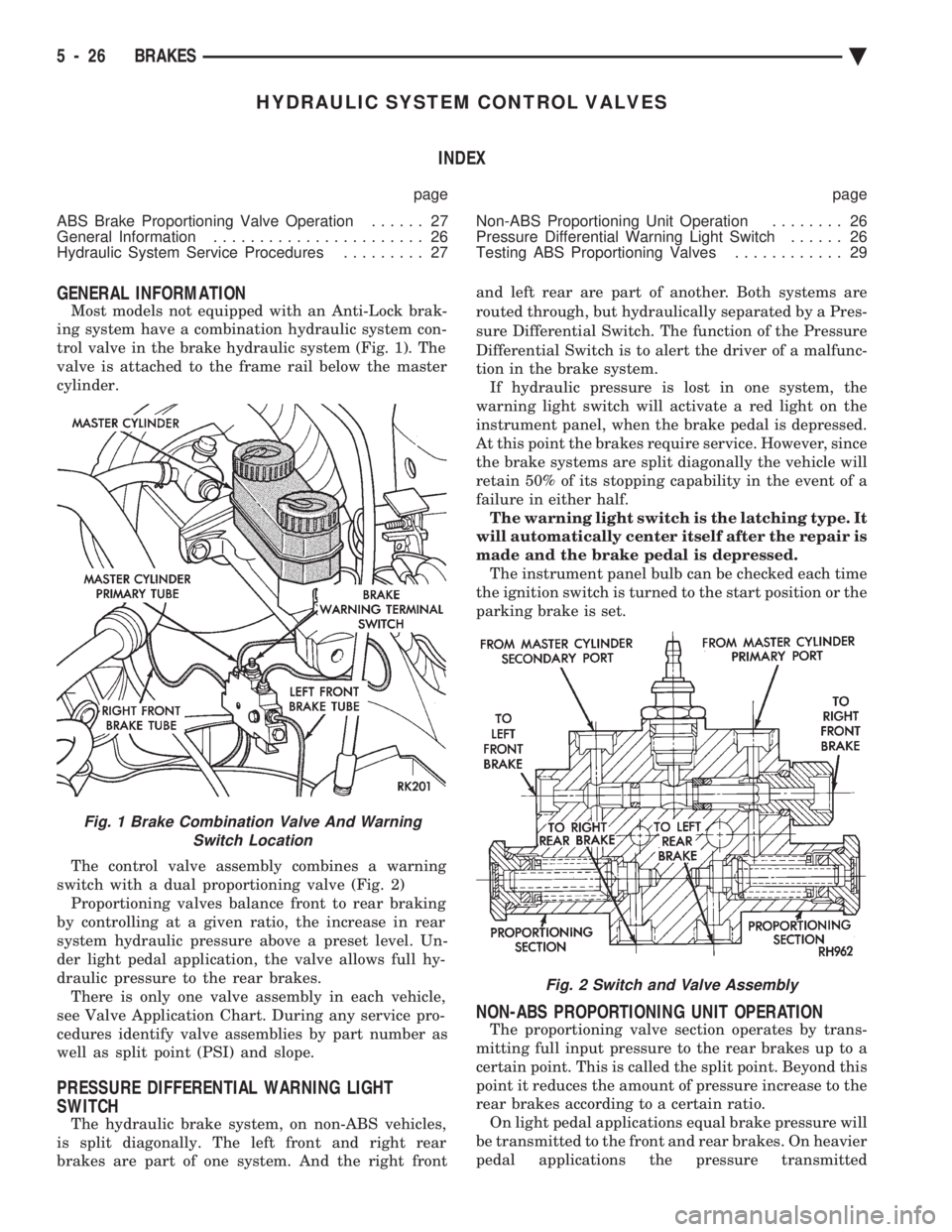

GENERAL INFORMATION

Most models not equipped with an Anti-Lock brak-

ing system have a combination hydraulic system con-

trol valve in the brake hydraulic system (Fig. 1). The

valve is attached to the frame rail below the master

cylinder.

The control valve assembly combines a warning

switch with a dual proportioning valve (Fig. 2) Proportioning valves balance front to rear braking

by controlling at a given ratio, the increase in rear

system hydraulic pressure above a preset level. Un-

der light pedal application, the valve allows full hy-

draulic pressure to the rear brakes. There is only one valve assembly in each vehicle,

see Valve Application Chart. During any service pro-

cedures identify valve assemblies by part number as

well as split point (PSI) and slope.

PRESSURE DIFFERENTIAL WARNING LIGHT

SWITCH

The hydraulic brake system, on non-ABS vehicles,

is split diagonally. The left front and right rear

brakes are part of one system. And the right front and left rear are part of another. Both systems are

routed through, but hydraulically separated by a Pres-

sure Differential Switch. The function of the Pressure

Differential Switch is to alert the driver of a malfunc-

tion in the brake system. If hydraulic pressure is lost in one system, the

warning light switch will activate a red light on the

instrument panel, when the brake pedal is depressed.

At this point the brakes require service. However, since

the brake systems are split diagonally the vehicle will

retain 50% of its stopping capability in the event of a

failure in either half. The warning light switch is the latching type. It

will automatically center itself after the repair is

made and the brake pedal is depressed. The instrument panel bulb can be checked each time

the ignition switch is turned to the start position or the

parking brake is set.

NON-ABS PROPORTIONING UNIT OPERATION

The proportioning valve section operates by trans-

mitting full input pressure to the rear brakes up to a

certain point. This is called the split point. Beyond this

point it reduces the amount of pressure increase to the

rear brakes according to a certain ratio. On light pedal applications equal brake pressure will

be transmitted to the front and rear brakes. On heavier

pedal applications the pressure transmitted

Fig. 1 Brake Combination Valve And Warning Switch Location

Fig. 2 Switch and Valve Assembly

5 - 26 BRAKES Ä