wheel torque CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 623 of 2438

(3) Secure arm to pivot with attaching nut and

tighten 17 to 22 N Im (155 to 195 in. lbs.) torque.

(4) Close head cover and remove pin from arm pin

hole.

WIPER ARM ADJUSTMENT

FRONT ARM ADJUSTMENT

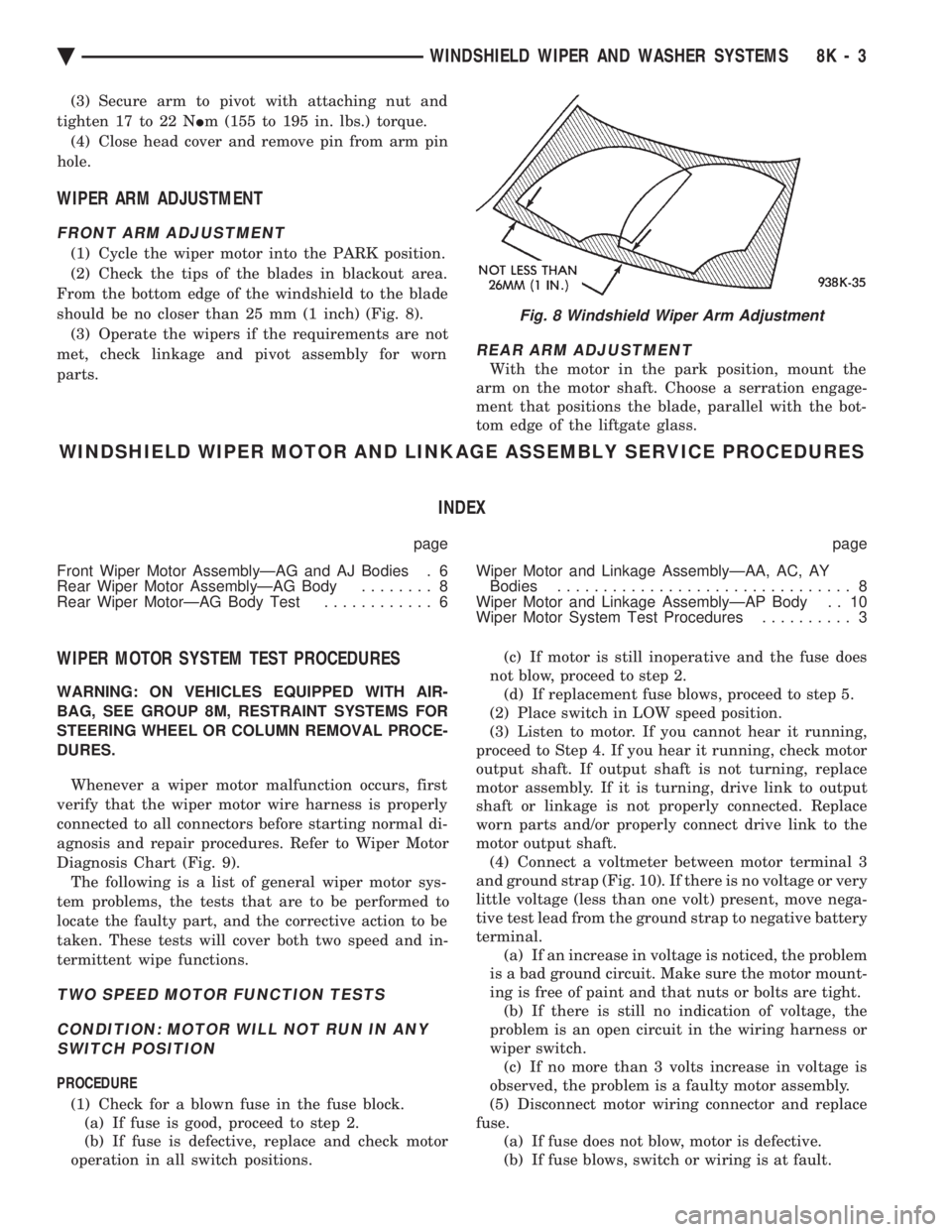

(1) Cycle the wiper motor into the PARK position.

(2) Check the tips of the blades in blackout area.

From the bottom edge of the windshield to the blade

should be no closer than 25 mm (1 inch) (Fig. 8). (3) Operate the wipers if the requirements are not

met, check linkage and pivot assembly for worn

parts.

REAR ARM ADJUSTMENT

With the motor in the park position, mount the

arm on the motor shaft. Choose a serration engage-

ment that positions the blade, parallel with the bot-

tom edge of the liftgate glass.

WINDSHIELD WIPER MOTOR AND LINKAGE ASSEMBLY SERVICE PROCEDURES

INDEX

page page

Front Wiper Motor AssemblyÐAG and AJ Bodies . 6

Rear Wiper Motor AssemblyÐAG Body ........ 8

Rear Wiper MotorÐAG Body Test ............ 6 Wiper Motor and Linkage AssemblyÐAA, AC, AY

Bodies ................................ 8

Wiper Motor and Linkage AssemblyÐAP Body . . 10

Wiper Motor System Test Procedures .......... 3

WIPER MOTOR SYSTEM TEST PROCEDURES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, first

verify that the wiper motor wire harness is properly

connected to all connectors before starting normal di-

agnosis and repair procedures. Refer to Wiper Motor

Diagnosis Chart (Fig. 9). The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken. These tests will cover both two speed and in-

termittent wipe functions.

TWO SPEED MOTOR FUNCTION TESTS

CONDITION: MOTOR WILL NOT RUN IN ANY SWITCH POSITION

PROCEDURE

(1) Check for a blown fuse in the fuse block. (a) If fuse is good, proceed to step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions. (c) If motor is still inoperative and the fuse does

not blow, proceed to step 2. (d) If replacement fuse blows, proceed to step 5.

(2) Place switch in LOW speed position.

(3) Listen to motor. If you cannot hear it running,

proceed to Step 4. If you hear it running, check motor

output shaft. If output shaft is not turning, replace

motor assembly. If it is turning, drive link to output

shaft or linkage is not properly connected. Replace

worn parts and/or properly connect drive link to the

motor output shaft. (4) Connect a voltmeter between motor terminal 3

and ground strap (Fig. 10). If there is no voltage or very

little voltage (less than one volt) present, move nega-

tive test lead from the ground strap to negative battery

terminal. (a) If an increase in voltage is noticed, the problem

is a bad ground circuit. Make sure the motor mount-

ing is free of paint and that nuts or bolts are tight. (b) If there is still no indication of voltage, the

problem is an open circuit in the wiring harness or

wiper switch. (c) If no more than 3 volts increase in voltage is

observed, the problem is a faulty motor assembly.

(5) Disconnect motor wiring connector and replace

fuse. (a) If fuse does not blow, motor is defective.

(b) If fuse blows, switch or wiring is at fault.

Fig. 8 Windshield Wiper Arm Adjustment

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 3

Page 686 of 2438

AIR BAG MODULE

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. UNDEPLOYED AIR BAG REMOVAL FROM THE

STEERING WHEEL: DISCONNECT BATTERY

GROUND CABLE AND ISOLATE. ALLOW SYS-

TEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES. BEGIN AIR BAG REMOVAL.

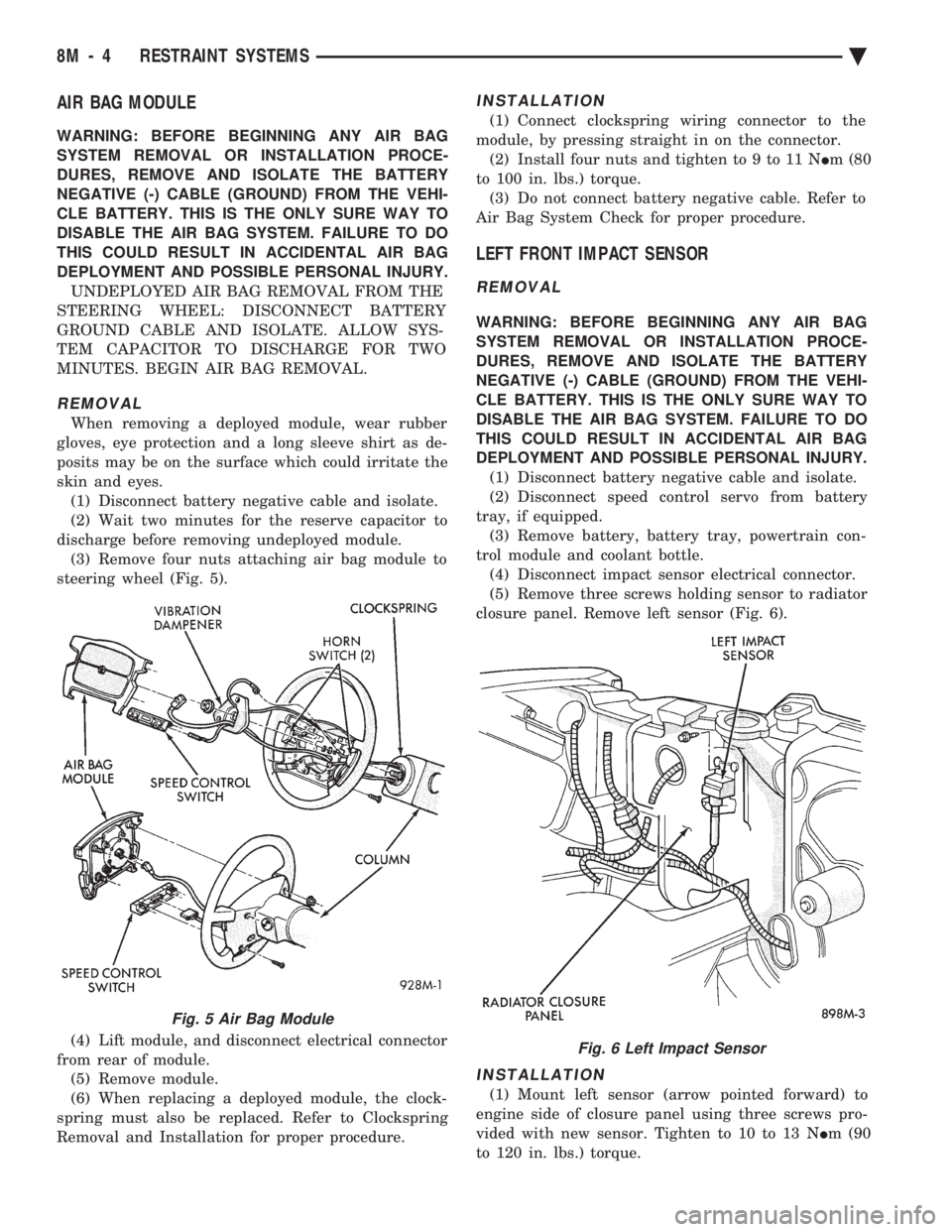

REMOVAL

When removing a deployed module, wear rubber

gloves, eye protection and a long sleeve shirt as de-

posits may be on the surface which could irritate the

skin and eyes. (1) Disconnect battery negative cable and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module to

steering wheel (Fig. 5).

(4) Lift module, and disconnect electrical connector

from rear of module. (5) Remove module.

(6) When replacing a deployed module, the clock-

spring must also be replaced. Refer to Clockspring

Removal and Installation for proper procedure.

INSTALLATION

(1) Connect clockspring wiring connector to the

module, by pressing straight in on the connector. (2) Install four nuts and tighten to 9 to 11 N Im (80

to 100 in. lbs.) torque. (3) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

LEFT FRONT IMPACT SENSOR

REMOVAL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect battery negative cable and isolate.

(2) Disconnect speed control servo from battery

tray, if equipped. (3) Remove battery, battery tray, powertrain con-

trol module and coolant bottle. (4) Disconnect impact sensor electrical connector.

(5) Remove three screws holding sensor to radiator

closure panel. Remove left sensor (Fig. 6).

INSTALLATION

(1) Mount left sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with new sensor. Tighten to 10 to 13 N Im (90

to 120 in. lbs.) torque.

Fig. 5 Air Bag Module

Fig. 6 Left Impact Sensor

8M - 4 RESTRAINT SYSTEMS Ä

Page 688 of 2438

CLOCKSPRING

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

SO COULD RESULT IN ACCIDENTAL AIR BAG DE-

PLOYMENT, AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition before starting the repair. (2) Disconnect battery negative cable and isolate.

(3) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (4) Remove the air bag module.

(5) Remove Speed Control switch and connector if

so equipped or cover. (6) Disconnect horn terminals.

(7) Remove the steering wheel.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring. (9) Disconnect the 2-way connector between the

clockspring and the instrument panel wiring harness

on top of the fuse block. (10) To remove, pull clockspring assembly from the

steering column by lifting locating fingers as neces-

sary. The clockspring cannot be repaired, and must

be replaced if faulty.

INSTALLATION

(1) Snap clockspring onto the steering column. If

the clockspring is not properly positioned, follow the

clockspring centering procedure before installing

steering wheel. (2) Connect the clockspring to the instrument

panel harness, ensure wiring locator clips are prop-

erly seated on wiring trough. Ensure harness locking

tabs are properly engaged. (3) Install steering column shrouds. Be sure air

bag wire is inside of shrouds. (4) Front wheels should still be in the straight-

ahead position. Install steering wheel, ensure the

flats on hub align with clockspring. Pull the horn

lead through the smaller upper hole. Pull the air bag

and speed control leads through the larger bottom

hole. Ensure leads are not pinched under the steer-

ing wheel. (5) Connect the horn lead wire, then the air bag

lead wire to the air bag module. (6) Install the air bag module and tighten nuts to

9to11N Im (80 to 100 in. lb.) torque.

(7) Install speed control switch and connector or

cover. (8) Do not connect battery negative cable. Refer to

Air Bag Systems Check for proper procedure.

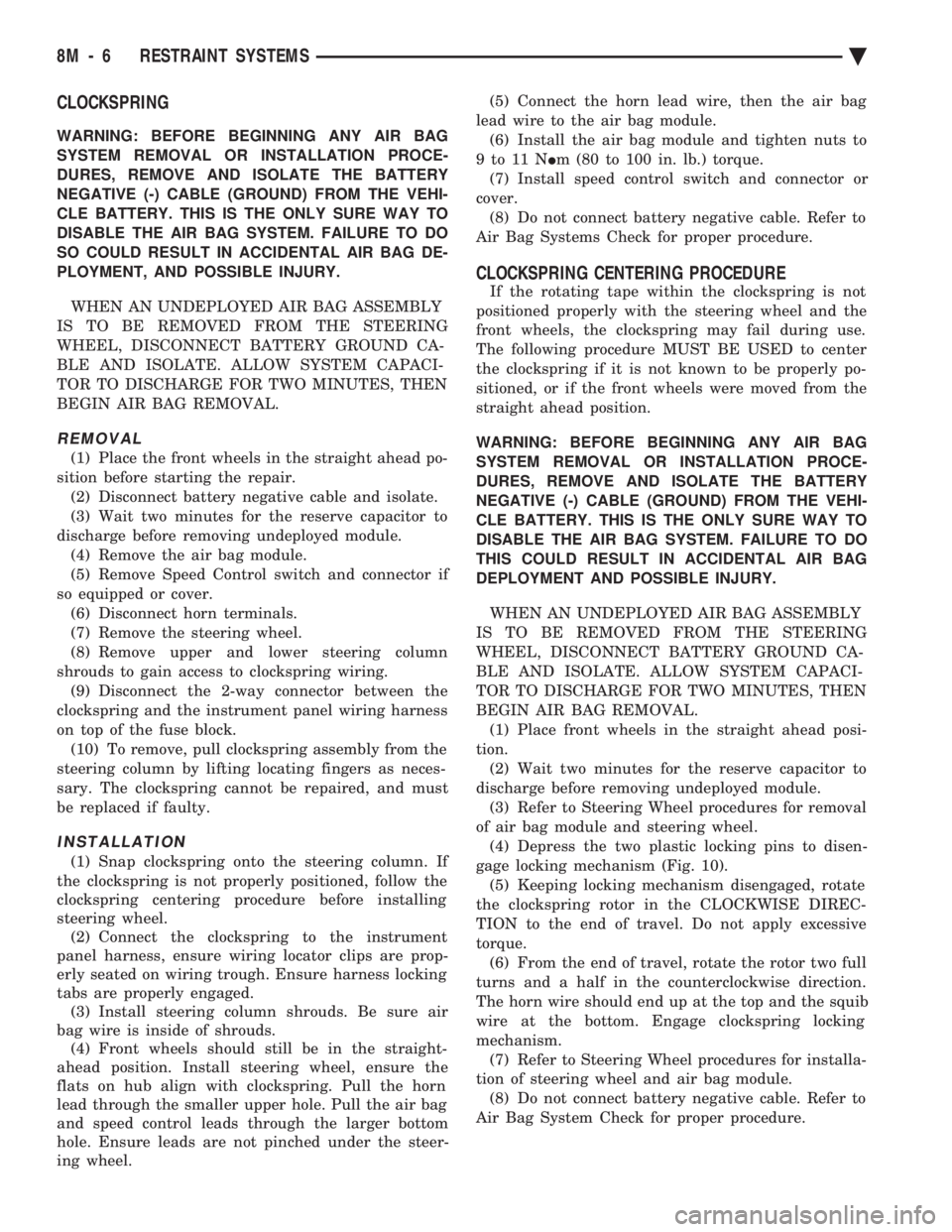

CLOCKSPRING CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedure MUST BE USED to center

the clockspring if it is not known to be properly po-

sitioned, or if the front wheels were moved from the

straight ahead position.

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL. (1) Place front wheels in the straight ahead posi-

tion. (2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Refer to Steering Wheel procedures for removal

of air bag module and steering wheel. (4) Depress the two plastic locking pins to disen-

gage locking mechanism (Fig. 10). (5) Keeping locking mechanism disengaged, rotate

the clockspring rotor in the CLOCKWISE DIREC-

TION to the end of travel. Do not apply excessive

torque. (6) From the end of travel, rotate the rotor two full

turns and a half in the counterclockwise direction.

The horn wire should end up at the top and the squib

wire at the bottom. Engage clockspring locking

mechanism. (7) Refer to Steering Wheel procedures for installa-

tion of steering wheel and air bag module. (8) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

8M - 6 RESTRAINT SYSTEMS Ä

Page 689 of 2438

STEERING WHEEL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES.

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Make sure front wheels are straight, and steer-

ing column is locked in place. (2) Disconnect battery negative cable and isolate.

(3) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (4) Remove four nuts attaching air bag module

from the back side of steering wheel. (5) Lift module, and disconnect connector from rear

of module. (6) Remove speed control switch and connector if

so equipped or cover. (7) Remove steering wheel retaining nut.

(8) Remove steering wheel with steering wheel

puller Tool C-3428B.

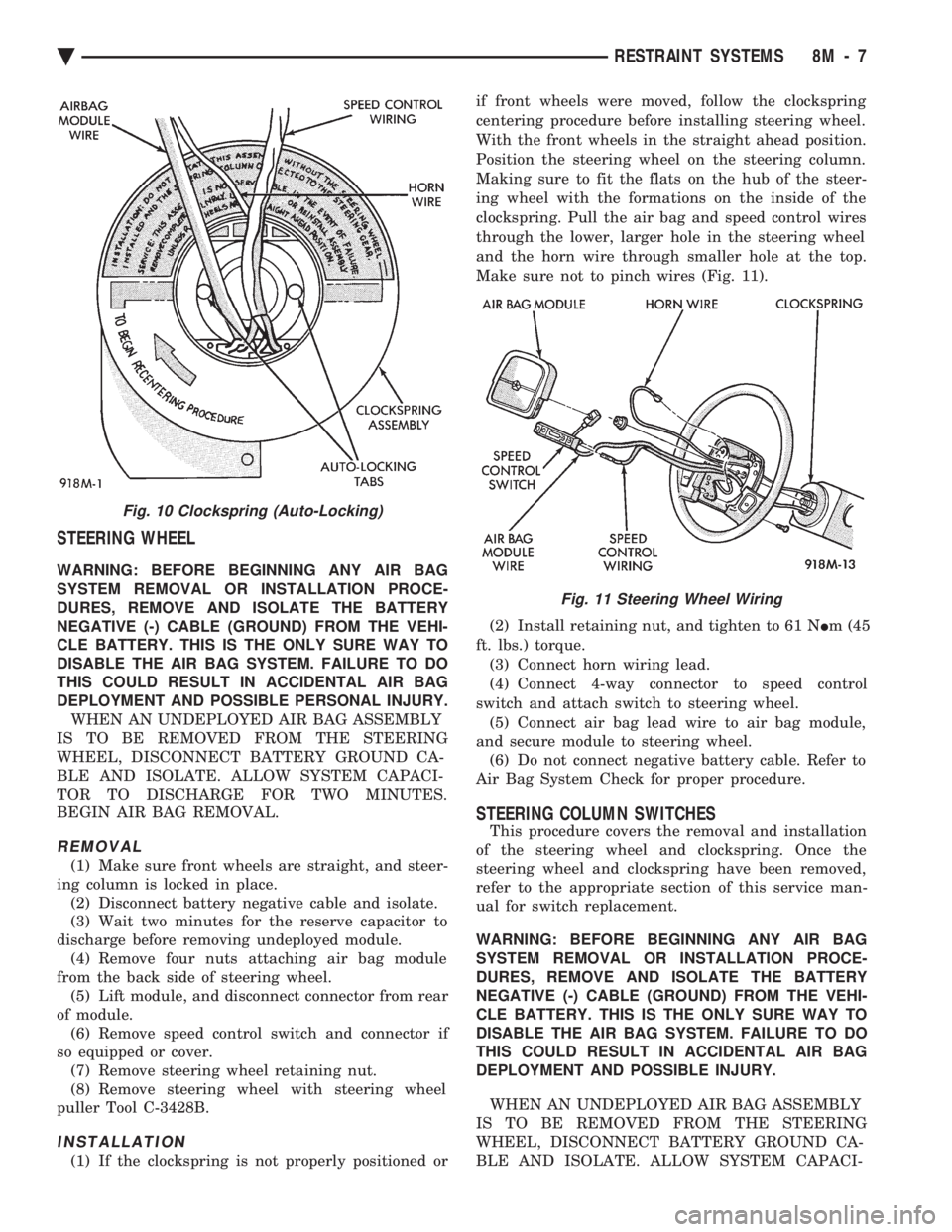

INSTALLATION

(1) If the clockspring is not properly positioned or if front wheels were moved, follow the clockspring

centering procedure before installing steering wheel.

With the front wheels in the straight ahead position.

Position the steering wheel on the steering column.

Making sure to fit the flats on the hub of the steer-

ing wheel with the formations on the inside of the

clockspring. Pull the air bag and speed control wires

through the lower, larger hole in the steering wheel

and the horn wire through smaller hole at the top.

Make sure not to pinch wires (Fig. 11).

(2) Install retaining nut, and tighten to 61 N Im (45

ft. lbs.) torque. (3) Connect horn wiring lead.

(4) Connect 4-way connector to speed control

switch and attach switch to steering wheel. (5) Connect air bag lead wire to air bag module,

and secure module to steering wheel. (6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

STEERING COLUMN SWITCHES

This procedure covers the removal and installation

of the steering wheel and clockspring. Once the

steering wheel and clockspring have been removed,

refer to the appropriate section of this service man-

ual for switch replacement.

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

Fig. 10 Clockspring (Auto-Locking)

Fig. 11 Steering Wheel Wiring

Ä RESTRAINT SYSTEMS 8M - 7

Page 690 of 2438

TOR TO DISCHARGE FOR TWO MINUTES.

BEGIN AIR BAG REMOVAL.

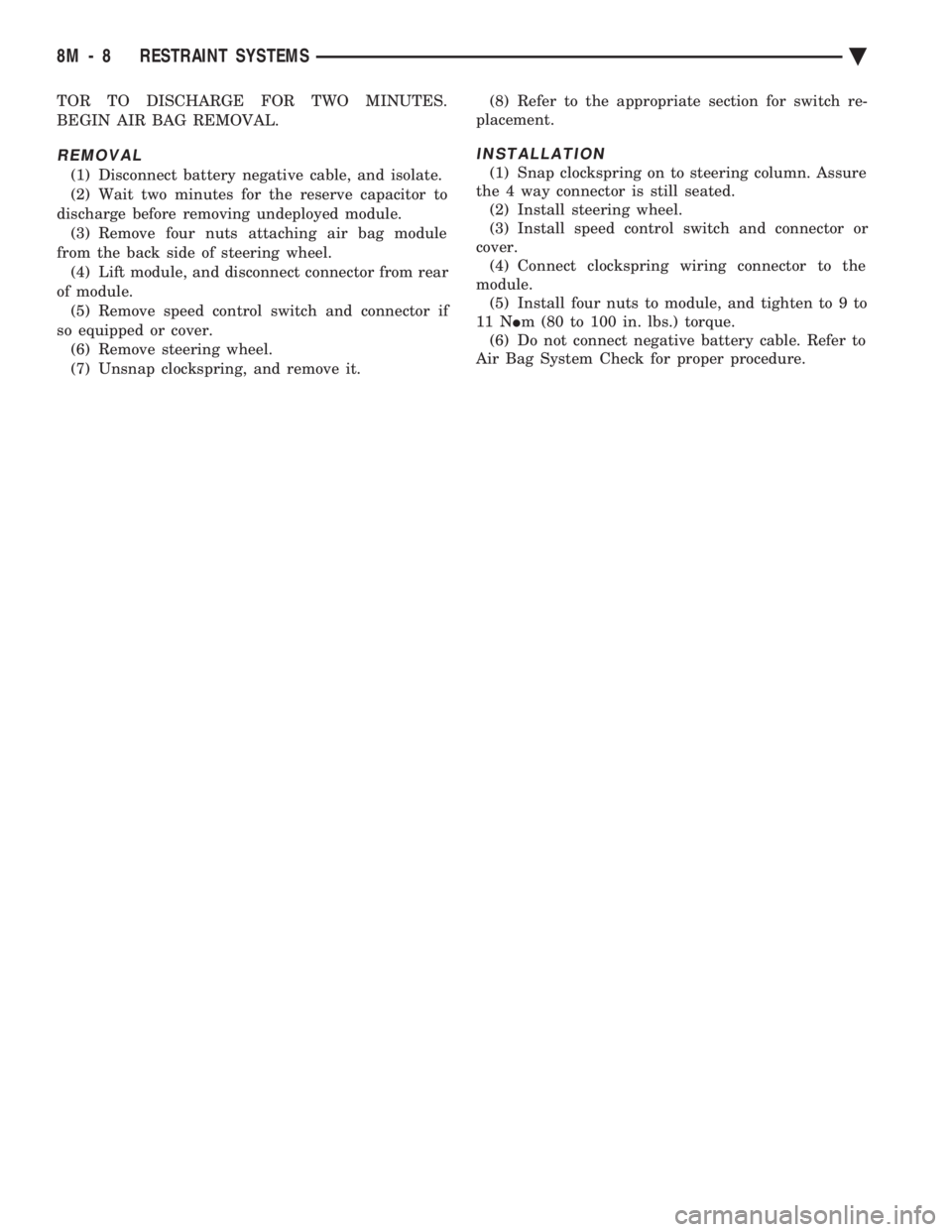

REMOVAL

(1) Disconnect battery negative cable, and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module

from the back side of steering wheel. (4) Lift module, and disconnect connector from rear

of module. (5) Remove speed control switch and connector if

so equipped or cover. (6) Remove steering wheel.

(7) Unsnap clockspring, and remove it. (8) Refer to the appropriate section for switch re-

placement.

INSTALLATION

(1) Snap clockspring on to steering column. Assure

the 4 way connector is still seated. (2) Install steering wheel.

(3) Install speed control switch and connector or

cover. (4) Connect clockspring wiring connector to the

module. (5) Install four nuts to module, and tighten to 9 to

11 N Im (80 to 100 in. lbs.) torque.

(6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

8M - 8 RESTRAINT SYSTEMS Ä

Page 1580 of 2438

CAUTION: Make sure clutch cable has been discon-

nected. (20) Remove front engine mount screw and nut.

(21) Remove manual transmission damper.

(22) Remove left insulator through bolt from inside

wheelhouse or insulator bracket to transmission

screws. (23) Remove engine from vehicle.

INSTALLATION

(1) Install hoist to the engine and lower engine

into the engine compartment. SEE: ENGINE MOUNT RUBBER INSULATORS,

THIS GROUP. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

(3) Install transmission case to cylinder block

mounting screws. Tighten to 95 N Im (70 ft. lbs.)

torque. (4) Remove engine hoist and transmission holding

fixture. (5) Install ground strap.

(6) Install right inner splash shield.

(7) Connect starter. See Electrical Group 8 for in-

stallation. (8) Connect exhaust system. See Exhaust Systems

Group 11 for installation. (9) Manual Transmission: Install transmission

case lower cover. Automatic Transmission: Remove C clamp from

torque converter housing. Align flexplate to torque

converter and install mounting screws. Tighten to 75

N Im (55 ft. lbs.) torque.

(10) Manual Transmission: Connect clutch cable.

See Clutch Group 6. (11) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt

tension adjustment. (12) Connect fuel line, heater hose, and accelerator

cable. (13) Connect all electrical connections and har-

nesses at throttle body and engine. (14) Install oil filter. Fill engine crankcase with

proper oil to correct level. (15) Install air conditioning compressor (if

equipped). See Heater and Air Conditioning, Group

24 for installation. (16) Install air cleaner and hoses.

(17) Install radiator and shroud assembly . Install

radiator hoses. Fill cooling system. See Cooling Sys-

tem Group 7 for filling procedure. (18) Install hood.

(19) Connect battery.

(20) Start engine and run until operating temper-

ature is reached. (21) Adjust transmission linkage, if necessary.

SOLID MOUNT COMPRESSOR BRACKET SERVICE

When service procedures require solid mount

bracket removal and installation for example: cylin-

der head removal, etc., it is important that bracket

fasteners numbered 1 through 7 (Fig. 4) be removed

and installed in sequence, as instructed in Remove

and Install.

ACCESSORIES REMOVAL

(1) Remove (and install/adjust) belts,see Accessory

Drive Belts in Cooling System,Group 7. (2) Remove air conditioning compressor (in vehicle

with lines and set aside) (Fig. 6). (3) Remove generator pivot bolt and remove gener-

ator (in vehicle: turn wiring side up and disconnect,

then rotate generator, pulley end towards engine and

remove). (4) Remove air conditioner compressor belt idler.

SOLID MOUNT BRACKETÐREMOVAL (FIG. 4)

(1) Remove right engine mount yoke screw (see

Engine Remove Fig. 3) securing engine mount sup-

port strut to engine mount bracket. (2) Remove five side mounting bolts #1, #4 , #5,

#6, and #7 (Fig. 4). (3) Remove front mounting nut, #2, and remove

front bolt #3*. (4) Remove front mounting bolt and strut, rotate

solid mount bracket away from engine and slide

bracket on stud until #2 nut mounting stud until

free. Remove spacer from stud.

SOLID MOUNT BRACKETÐINSTALLATION

(1) Put spacer onto stud, then install bracket on

front (#2 nut) mounting stud and slide bracket over

timing belt cover into position. (2) Loosen assembly bracket to engine fasteners

(numbered #1 through #7 in Fig. 6). (3)

CAUTION: Fasteners MUST BE TIGHTENED IN SE-

QUENCE and to specified torque as follows :

² First Bolt #1 to 3.3 N Im (30 in. lbs.)

² Second Nut #2 and Bolt #3 to 54 N Im (40 ft. lbs.).

² Third Bolts #1 (second tightening) #4 and #5 to

54 N Im (40 ft. lbs.).

² Fourth Bolts #6 and #7 to 54 N Im (40 ft. lbs.).

(4) Install generator and compressor. Tighten com-

pressor mounting bracket bolts to 54 N Im (40 ft.

lbs.).

SOLID MOUNT COMPRESSOR BRACKET SERVICEÐTURBO III ENGINE

REMOVAL

(1) Disconnect negative battery cable

9 - 14 2.2/2.5L ENGINE Ä

Page 1598 of 2438

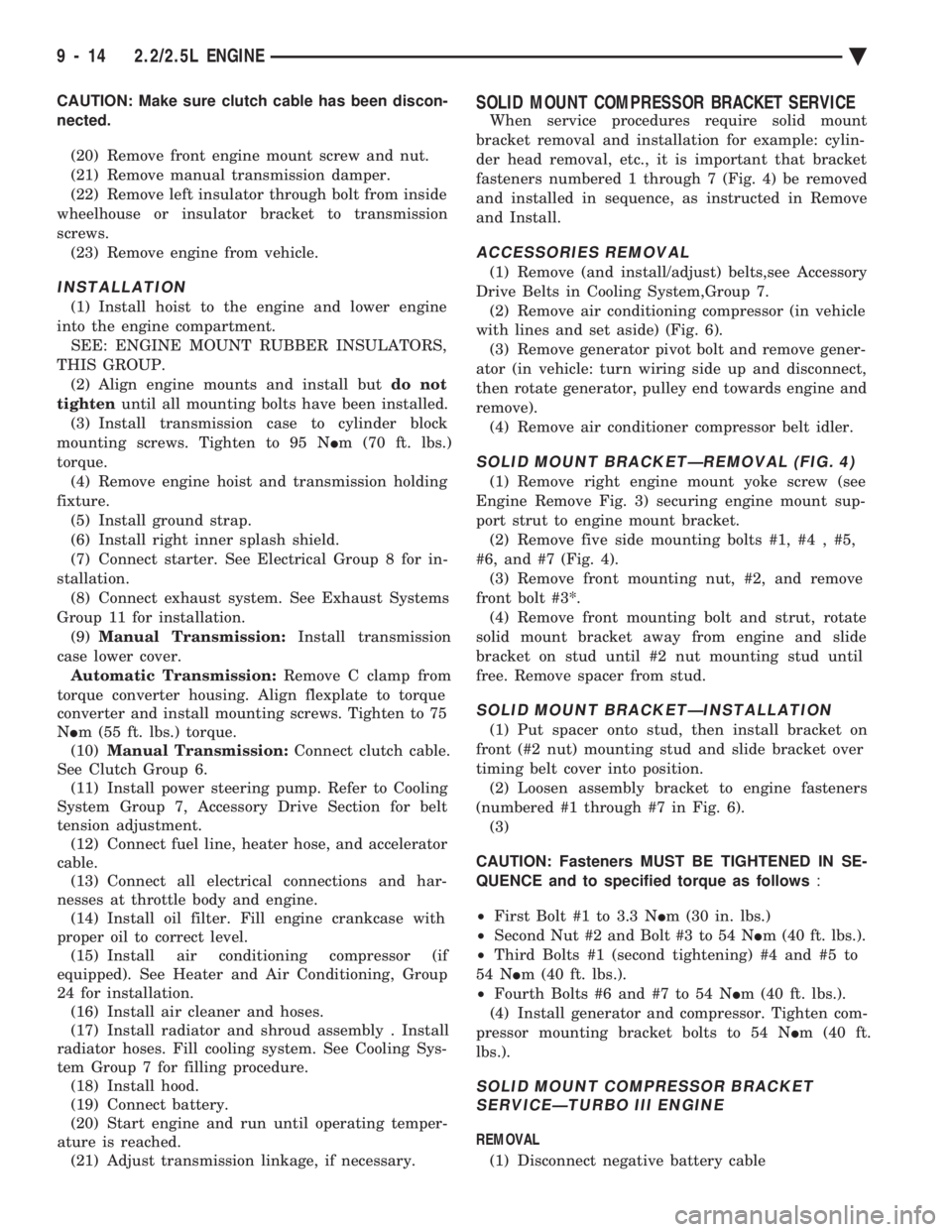

Before installing the bolts, the threads should be

cleaned and oiled. Tighten the cylinder head bolts in the sequence

shown in (Fig. 5 ). Using the 4 step torque turn

method, tighten according to the following values:

² First All to 61 N Im (45 ft. lbs.)

² Second All to 88 N Im (65 ft. lbs.)

² Third All (again) to 88 N Im (65 ft., lbs.)

² Fourth + 1/4 Turn Do not use torque wrench

for this step.

² Bolt torque after 1/4 turn should be over 90 ft. lbs.

If not, replace the bolt. Refer to Intake and Exhaust Manifold Service in

Exhaust Systems and Intake Manifold Group 11 for

installation procedure. Refer to the Timing Belt and Solid Mount Com-

pressor Mount Bracket service procedures in this

group for installations procedures.

TIMING BELT COVER SERVICEÐTURBO III

ENGINE

REMOVAL

(1) Remove PCV tube and upper timing belt cover

screws (Fig. 1). Remove upper cover. (2) Remove accessory drive belt. Refer to Cooling

System Group 7 for procedure. (3) Raise vehicle on a hoist and remove right

wheel and inner splash shield (Fig. 2).

(4) Remove water pump pulley and crankshaft pul-

ley retaining bolts (Fig. 3), remove pulleys. (5) Remove lower accessory drive belt idler and

tensioner pulley (Fig. 4).

Fig. 1 Timing Belt Cover Screws

Fig. 5 Cylinder Head Tightening Sequence

Fig. 2 Right Inner Splash Shield

Fig. 3 Crankshaft and Water Pump Pulleys

9 - 32 2.2/2.5L ENGINE Ä

Page 1599 of 2438

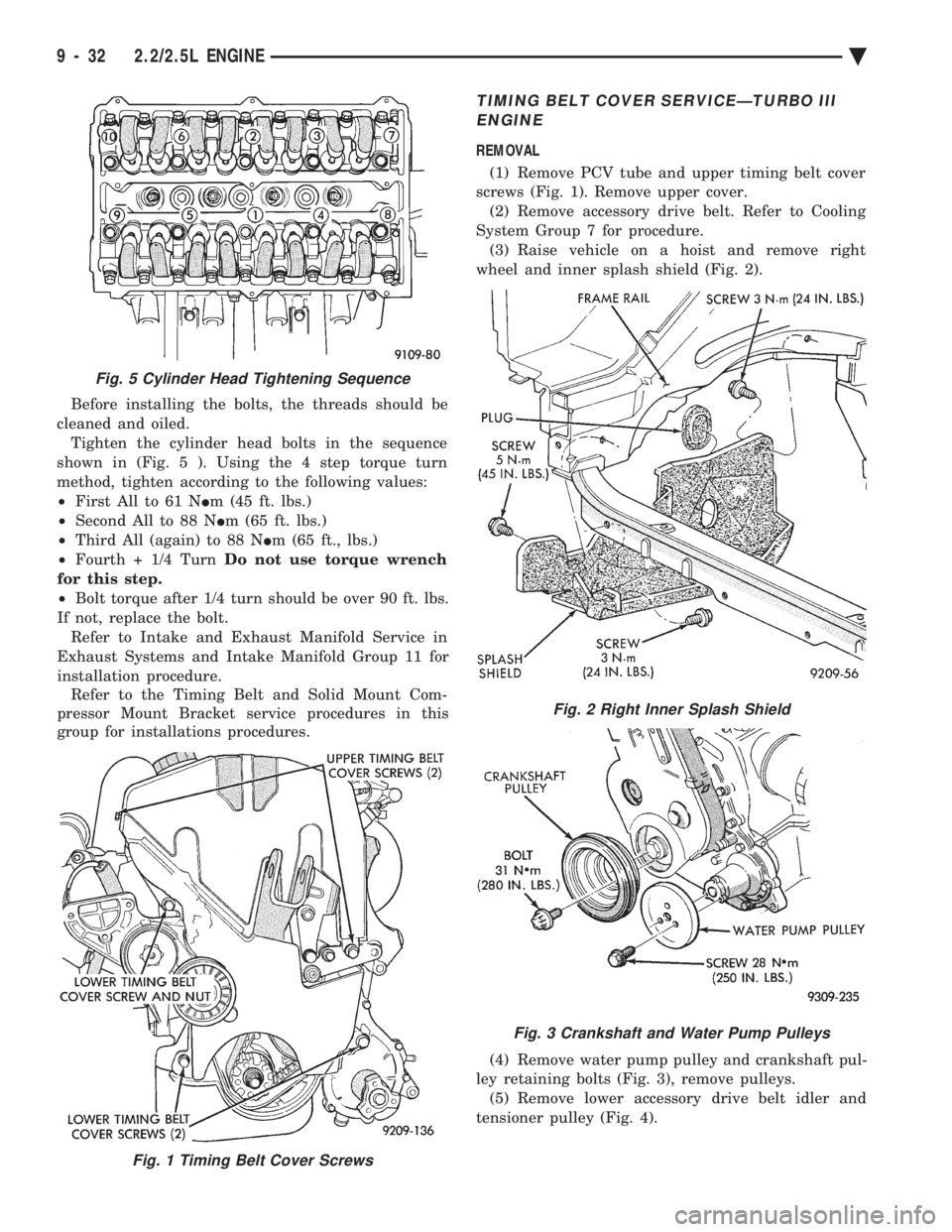

CAUTION: Do not use a impact wrench to remove

pulley bolts. (6) Remove lower timing belt cover fasteners (Fig.

1). Remove cover.

INSTALLATION (1) Raise vehicle on hoist. Install lower timing belt

cover and tighten fasteners to 12 N Im (105 in. lbs.)

torque (Fig. 4).

CAUTION: Do not use impact wrench on accessory

drive belt tensioner bolt. It may cause damage to

tensioner arm. Accessory drive belt tensioner pul-

ley bolt must be installed finger tight. (2) Install accessory drive belt tensioner pulley

bolt finger tight. Then tighten bolt to 54 N Im (40 ft.

lbs.) torque (Fig. 4). (3) Install crankshaft and water pump pulleys

(Fig. 3). (4) Install inner splash shield and wheel (Fig. 2).

(5) Install accessory drive belt. Refer to Cooling

System Group 7 for procedure. (6) Install upper timing belt cover and tighten

screws to 4 N Im (36 in. lbs.) torque. Install PCV tube

(Fig. 1).

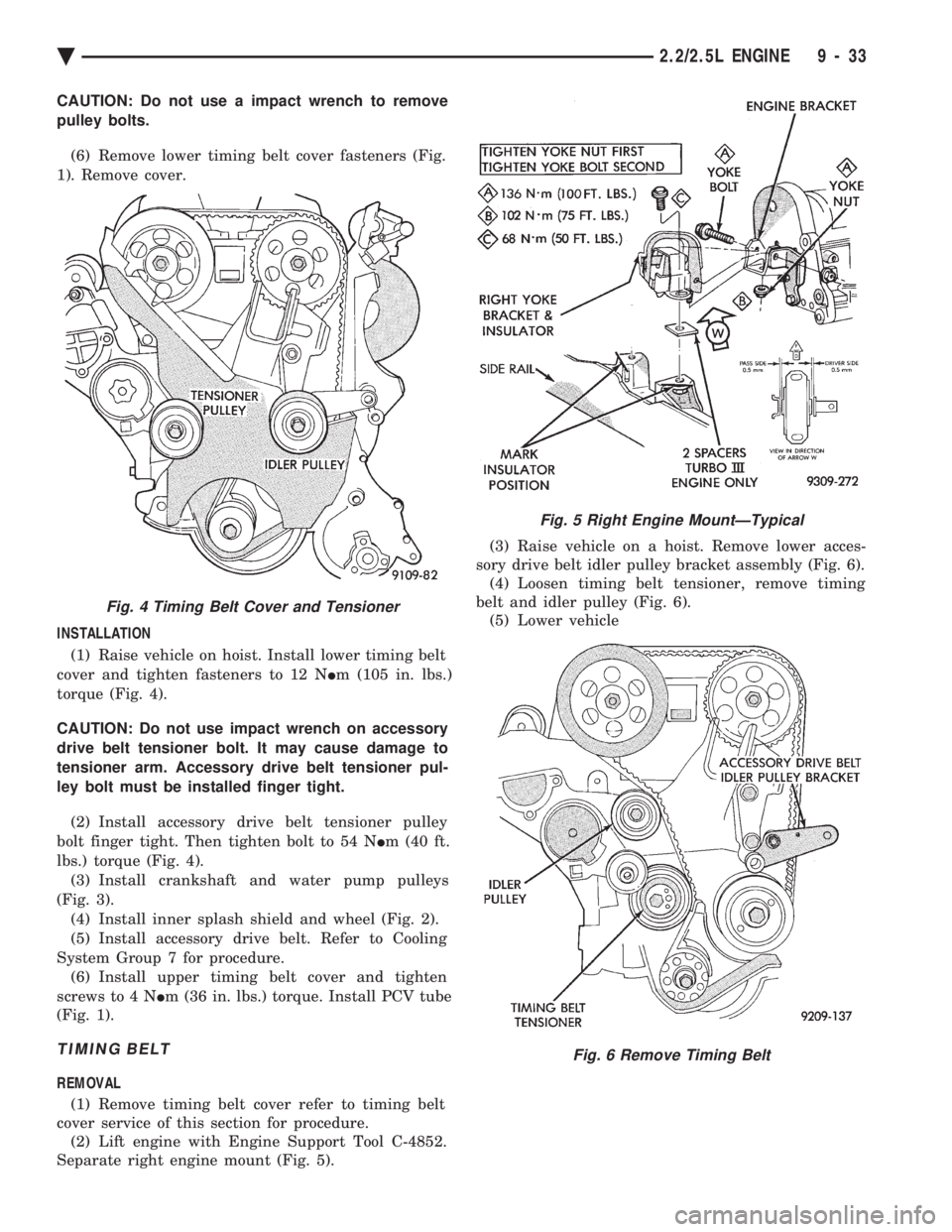

TIMING BELT

REMOVAL

(1) Remove timing belt cover refer to timing belt

cover service of this section for procedure. (2) Lift engine with Engine Support Tool C-4852.

Separate right engine mount (Fig. 5). (3) Raise vehicle on a hoist. Remove lower acces-

sory drive belt idler pulley bracket assembly (Fig. 6). (4) Loosen timing belt tensioner, remove timing

belt and idler pulley (Fig. 6). (5) Lower vehicle

Fig. 4 Timing Belt Cover and Tensioner

Fig. 5 Right Engine MountÐTypical

Fig. 6 Remove Timing Belt

Ä 2.2/2.5L ENGINE 9 - 33

Page 1635 of 2438

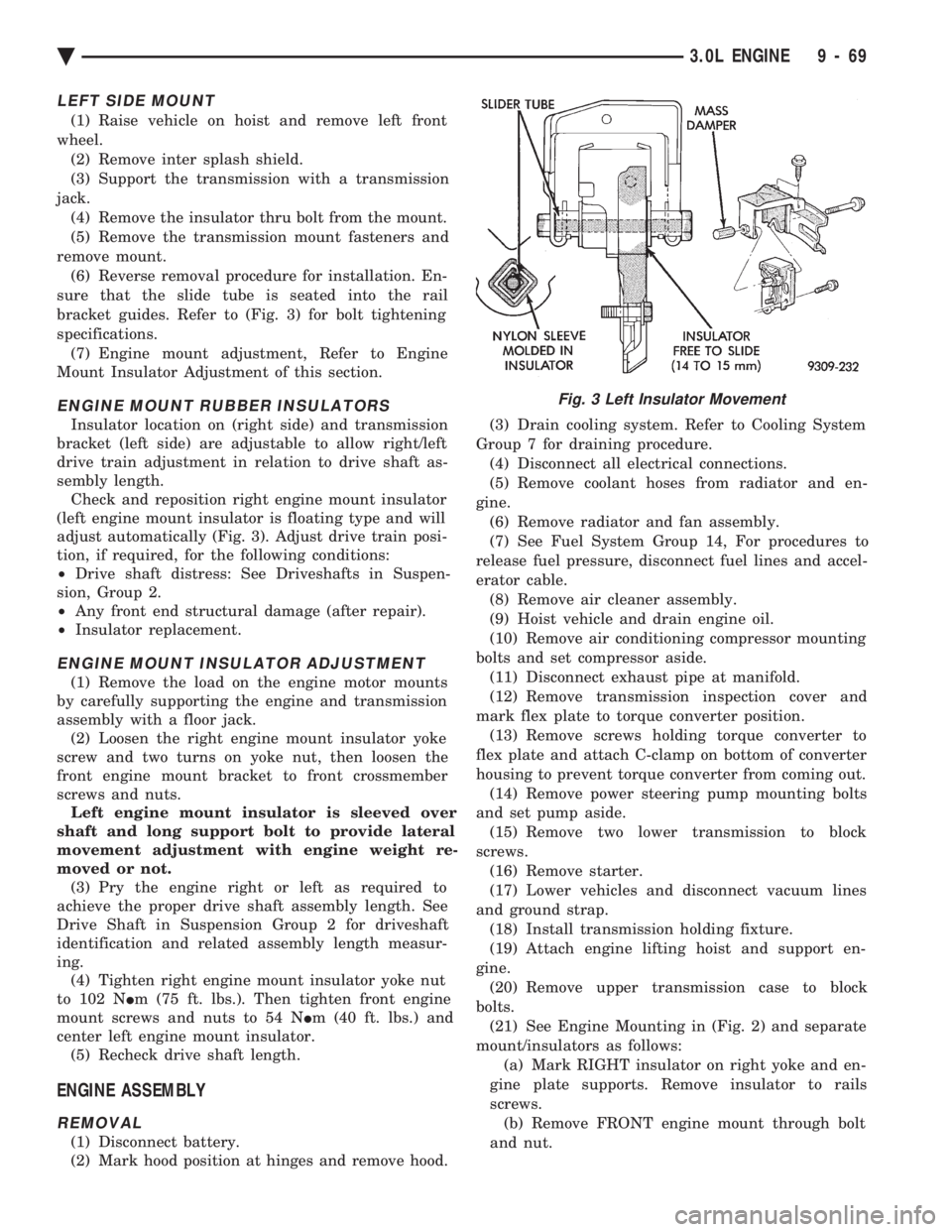

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) and transmission

bracket (left side) are adjustable to allow right/left

drive train adjustment in relation to drive shaft as-

sembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 3). Adjust drive train posi-

tion, if required, for the following conditions:

² Drive shaft distress: See Driveshafts in Suspen-

sion, Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (2) Loosen the right engine mount insulator yoke

screw and two turns on yoke nut, then loosen the

front engine mount bracket to front crossmember

screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. See

Drive Shaft in Suspension Group 2 for driveshaft

identification and related assembly length measur-

ing. (4) Tighten right engine mount insulator yoke nut

to 102 N Im (75 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood. (3) Drain cooling system. Refer to Cooling System

Group 7 for draining procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and en-

gine. (6) Remove radiator and fan assembly.

(7) See Fuel System Group 14, For procedures to

release fuel pressure, disconnect fuel lines and accel-

erator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from coming out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 2) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right yoke and en-

gine plate supports. Remove insulator to rails

screws. (b) Remove FRONT engine mount through bolt

and nut.

Fig. 3 Left Insulator Movement

Ä 3.0L ENGINE 9 - 69

Page 1636 of 2438

(c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

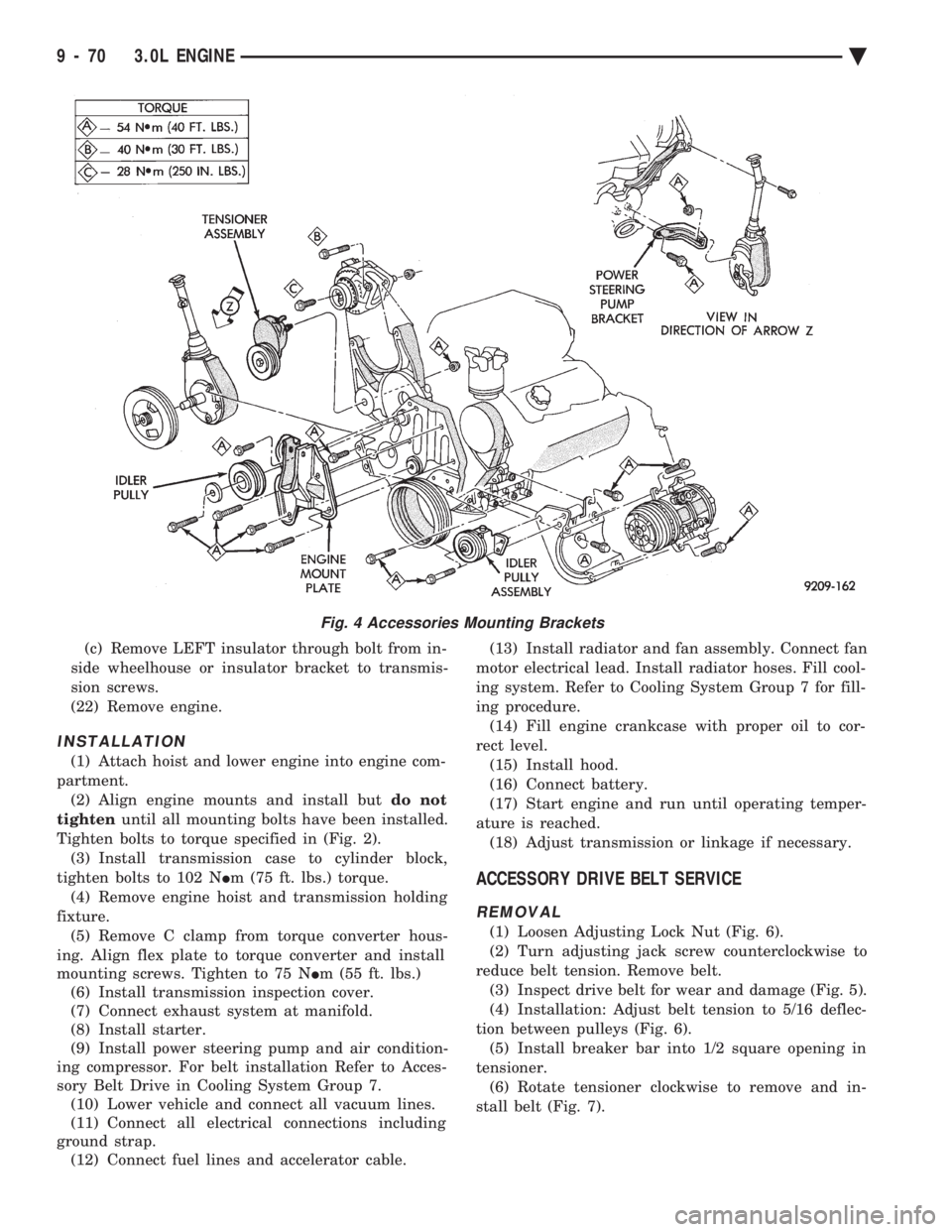

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 2). (3) Install transmission case to cylinder block,

tighten bolts to 102 N Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture. (5) Remove C clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N Im (55 ft. lbs.)

(6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation Refer to Acces-

sory Belt Drive in Cooling System Group 7. (10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap. (12) Connect fuel lines and accelerator cable. (13) Install radiator and fan assembly. Connect fan

motor electrical lead. Install radiator hoses. Fill cool-

ing system. Refer to Cooling System Group 7 for fill-

ing procedure. (14) Fill engine crankcase with proper oil to cor-

rect level. (15) Install hood.

(16) Connect battery.

(17) Start engine and run until operating temper-

ature is reached. (18) Adjust transmission or linkage if necessary.

ACCESSORY DRIVE BELT SERVICE

REMOVAL

(1) Loosen Adjusting Lock Nut (Fig. 6).

(2) Turn adjusting jack screw counterclockwise to

reduce belt tension. Remove belt. (3) Inspect drive belt for wear and damage (Fig. 5).

(4) Installation: Adjust belt tension to 5/16 deflec-

tion between pulleys (Fig. 6). (5) Install breaker bar into 1/2 square opening in

tensioner. (6) Rotate tensioner clockwise to remove and in-

stall belt (Fig. 7).

Fig. 4 Accessories Mounting Brackets

9 - 70 3.0L ENGINE Ä