wheel torque CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 168 of 2438

REAR WHEEL DRUM BRAKES INDEX

page page

Brake Drum Refacing ..................... 21

Brake Shoe Assemblies ................... 19 Description

............................. 18

Service Procedures ....................... 18

DESCRIPTION

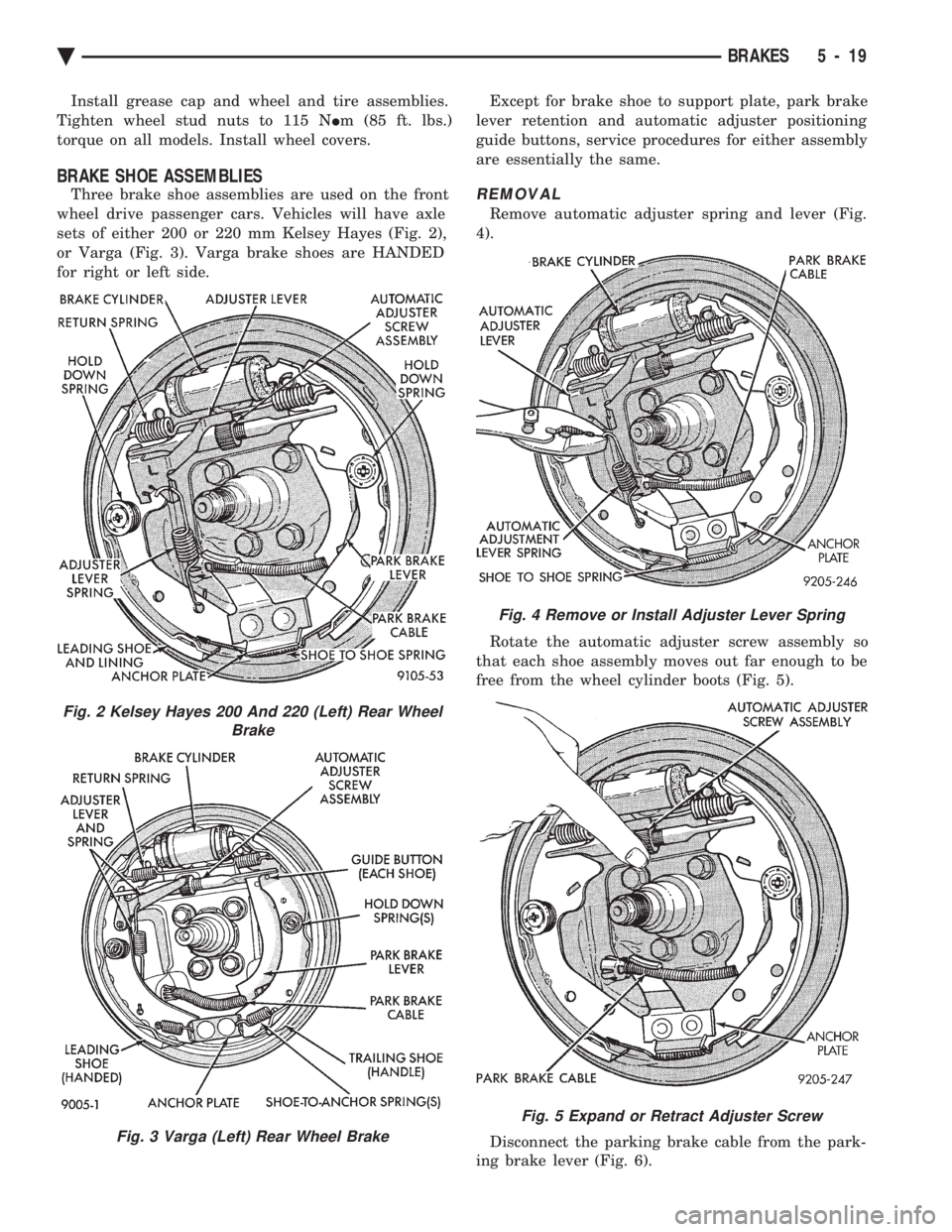

Rear wheel drum brakes (Fig .2&3)aretwoshoe,

internal expanding type with an automatic adjuster

screw assembly that is activated each time the

brakes are applied. The automatic adjuster screw is

located directly below the wheel cylinder as shown in

figure (Fig .2&3).

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS MAY

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS AND CANCER. EXTREME CARE

SHOULD BE EXERCISED WHILE SERVICING

BRAKE ASSEMBLIES OR COMPONENTS. DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH. DO NOT CREATE DUST BY SANDING, GRINDING,

AND/OR SHAVING BRAKE LININGS OR PADS UN-

LESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT. DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS. FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS. IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

SERVICE PROCEDURES

REAR BRAKE DRUM REMOVAL

If the rear brake drum is difficult to remove, fur-

ther clearance can be obtained by backing off the

brake automatic adjuster screw. Remove rubber plug

from the top of the support plate and rotate the au-

tomatic adjuster screw assembly with an upward mo-

tion, using the Brake Adjuster, Special Tool C-3784. See adjusting rear service brakes in the Service

Adjustments section in this group of the service man-

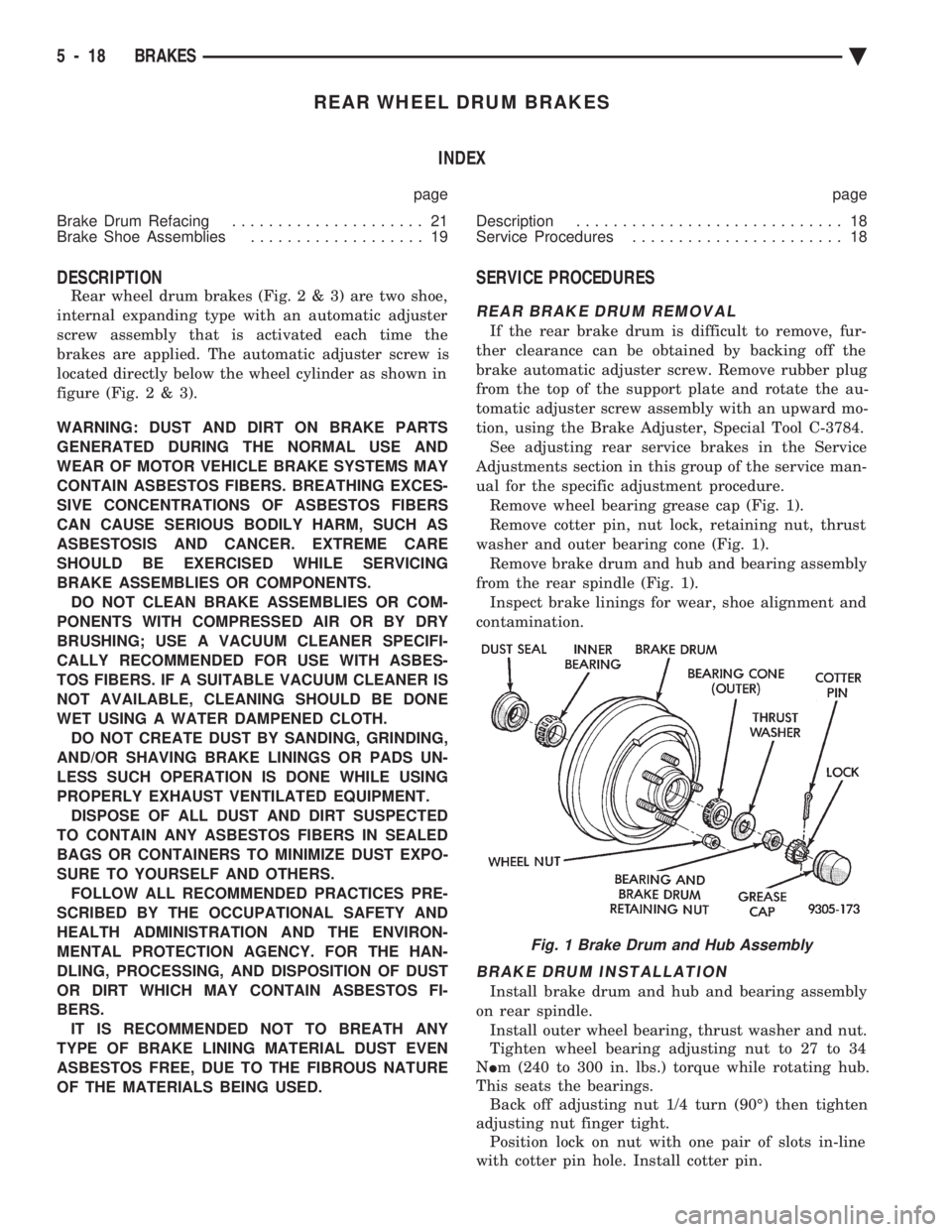

ual for the specific adjustment procedure. Remove wheel bearing grease cap (Fig. 1).

Remove cotter pin, nut lock, retaining nut, thrust

washer and outer bearing cone (Fig. 1). Remove brake drum and hub and bearing assembly

from the rear spindle (Fig. 1). Inspect brake linings for wear, shoe alignment and

contamination.

BRAKE DRUM INSTALLATION

Install brake drum and hub and bearing assembly

on rear spindle. Install outer wheel bearing, thrust washer and nut.

Tighten wheel bearing adjusting nut to 27 to 34

N Im (240 to 300 in. lbs.) torque while rotating hub.

This seats the bearings. Back off adjusting nut 1/4 turn (90É) then tighten

adjusting nut finger tight. Position lock on nut with one pair of slots in-line

with cotter pin hole. Install cotter pin.

Fig. 1 Brake Drum and Hub Assembly

5 - 18 BRAKES Ä

Page 169 of 2438

Install grease cap and wheel and tire assemblies.

Tighten wheel stud nuts to 115 N Im (85 ft. lbs.)

torque on all models. Install wheel covers.

BRAKE SHOE ASSEMBLIES

Three brake shoe assemblies are used on the front

wheel drive passenger cars. Vehicles will have axle

sets of either 200 or 220 mm Kelsey Hayes (Fig. 2),

or Varga (Fig. 3). Varga brake shoes are HANDED

for right or left side. Except for brake shoe to support plate, park brake

lever retention and automatic adjuster positioning

guide buttons, service procedures for either assembly

are essentially the same.REMOVAL

Remove automatic adjuster spring and lever (Fig.

4).

Rotate the automatic adjuster screw assembly so

that each shoe assembly moves out far enough to be

free from the wheel cylinder boots (Fig. 5).

Disconnect the parking brake cable from the park-

ing brake lever (Fig. 6).

Fig. 2 Kelsey Hayes 200 And 220 (Left) Rear Wheel Brake

Fig. 3 Varga (Left) Rear Wheel Brake

Fig. 4 Remove or Install Adjuster Lever Spring

Fig. 5 Expand or Retract Adjuster Screw

Ä BRAKES 5 - 19

Page 175 of 2438

BRAKE SUPPORT ASSEMBLY

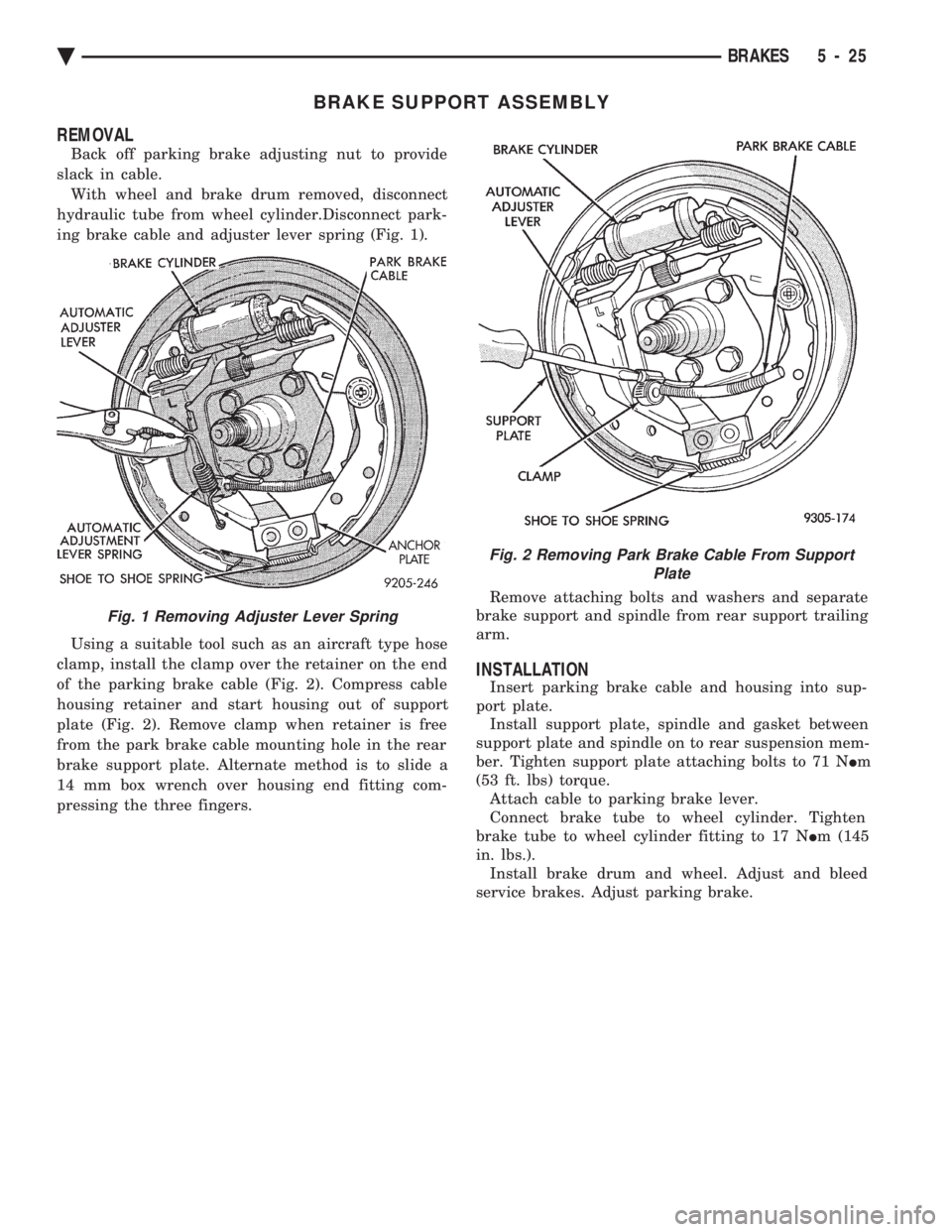

REMOVAL

Back off parking brake adjusting nut to provide

slack in cable. With wheel and brake drum removed, disconnect

hydraulic tube from wheel cylinder.Disconnect park-

ing brake cable and adjuster lever spring (Fig. 1).

Using a suitable tool such as an aircraft type hose

clamp, install the clamp over the retainer on the end

of the parking brake cable (Fig. 2). Compress cable

housing retainer and start housing out of support

plate (Fig. 2). Remove clamp when retainer is free

from the park brake cable mounting hole in the rear

brake support plate. Alternate method is to slide a

14 mm box wrench over housing end fitting com-

pressing the three fingers. Remove attaching bolts and washers and separate

brake support and spindle from rear support trailing

arm.

INSTALLATION

Insert parking brake cable and housing into sup-

port plate. Install support plate, spindle and gasket between

support plate and spindle on to rear suspension mem-

ber. Tighten support plate attaching bolts to 71 N Im

(53 ft. lbs) torque. Attach cable to parking brake lever.

Connect brake tube to wheel cylinder. Tighten

brake tube to wheel cylinder fitting to 17 N Im (145

in. lbs.). Install brake drum and wheel. Adjust and bleed

service brakes. Adjust parking brake.

Fig. 1 Removing Adjuster Lever Spring

Fig. 2 Removing Park Brake Cable From Support Plate

Ä BRAKES 5 - 25

Page 187 of 2438

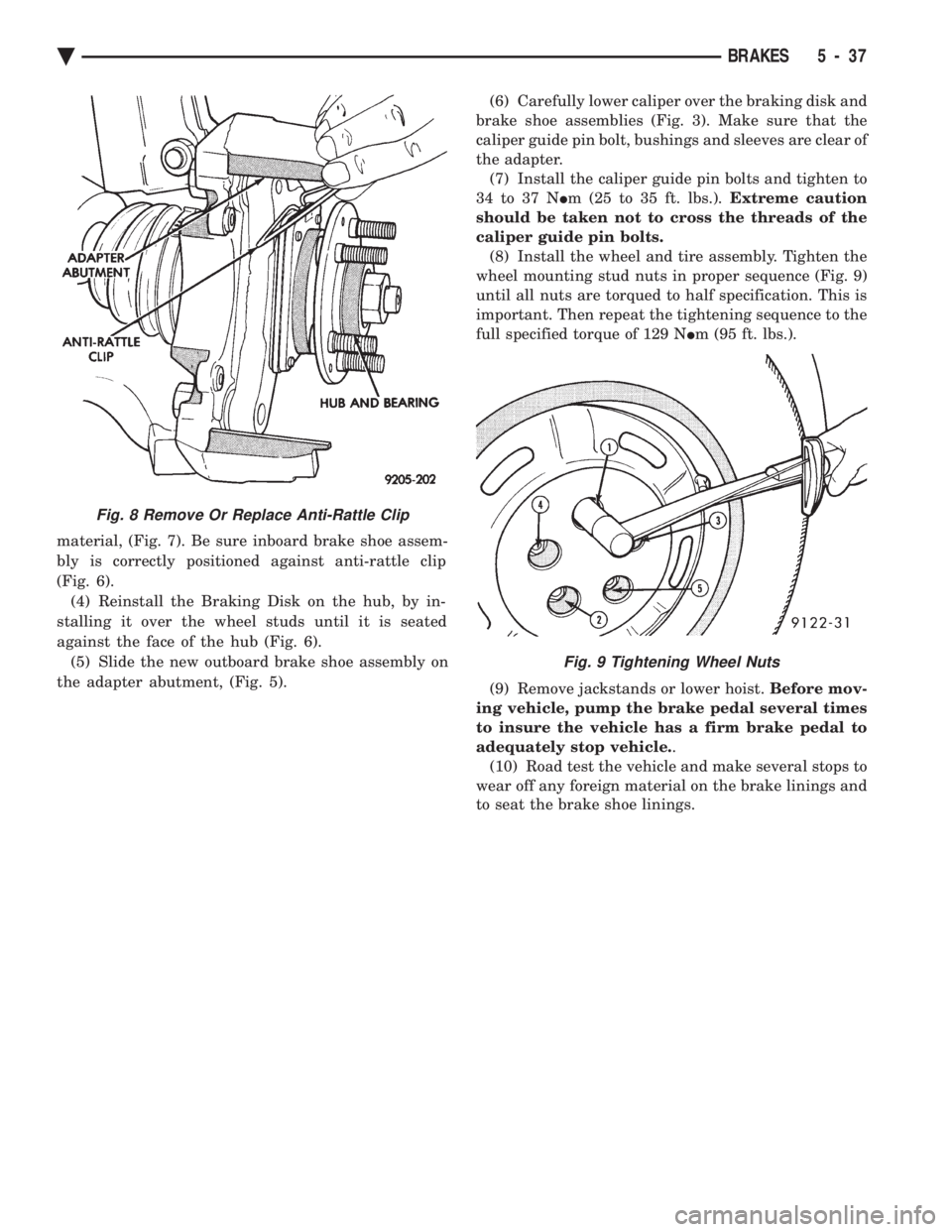

material, (Fig. 7). Be sure inboard brake shoe assem-

bly is correctly positioned against anti-rattle clip

(Fig. 6). (4) Reinstall the Braking Disk on the hub, by in-

stalling it over the wheel studs until it is seated

against the face of the hub (Fig. 6). (5) Slide the new outboard brake shoe assembly on

the adapter abutment, (Fig. 5). (6) Carefully lower caliper over the braking disk and

brake shoe assemblies (Fig. 3). Make sure that the

caliper guide pin bolt, bushings and sleeves are clear of

the adapter. (7) Install the caliper guide pin bolts and tighten to

34 to 37 N Im (25 to 35 ft. lbs.). Extreme caution

should be taken not to cross the threads of the

caliper guide pin bolts. (8) Install the wheel and tire assembly. Tighten the

wheel mounting stud nuts in proper sequence (Fig. 9)

until all nuts are torqued to half specification. This is

important. Then repeat the tightening sequence to the

full specified torque of 129 N Im (95 ft. lbs.).

(9) Remove jackstands or lower hoist. Before mov-

ing vehicle, pump the brake pedal several times

to insure the vehicle has a firm brake pedal to

adequately stop vehicle. .

(10) Road test the vehicle and make several stops to

wear off any foreign material on the brake linings and

to seat the brake shoe linings.

Fig. 8 Remove Or Replace Anti-Rattle Clip

Fig. 9 Tightening Wheel Nuts

Ä BRAKES 5 - 37

Page 190 of 2438

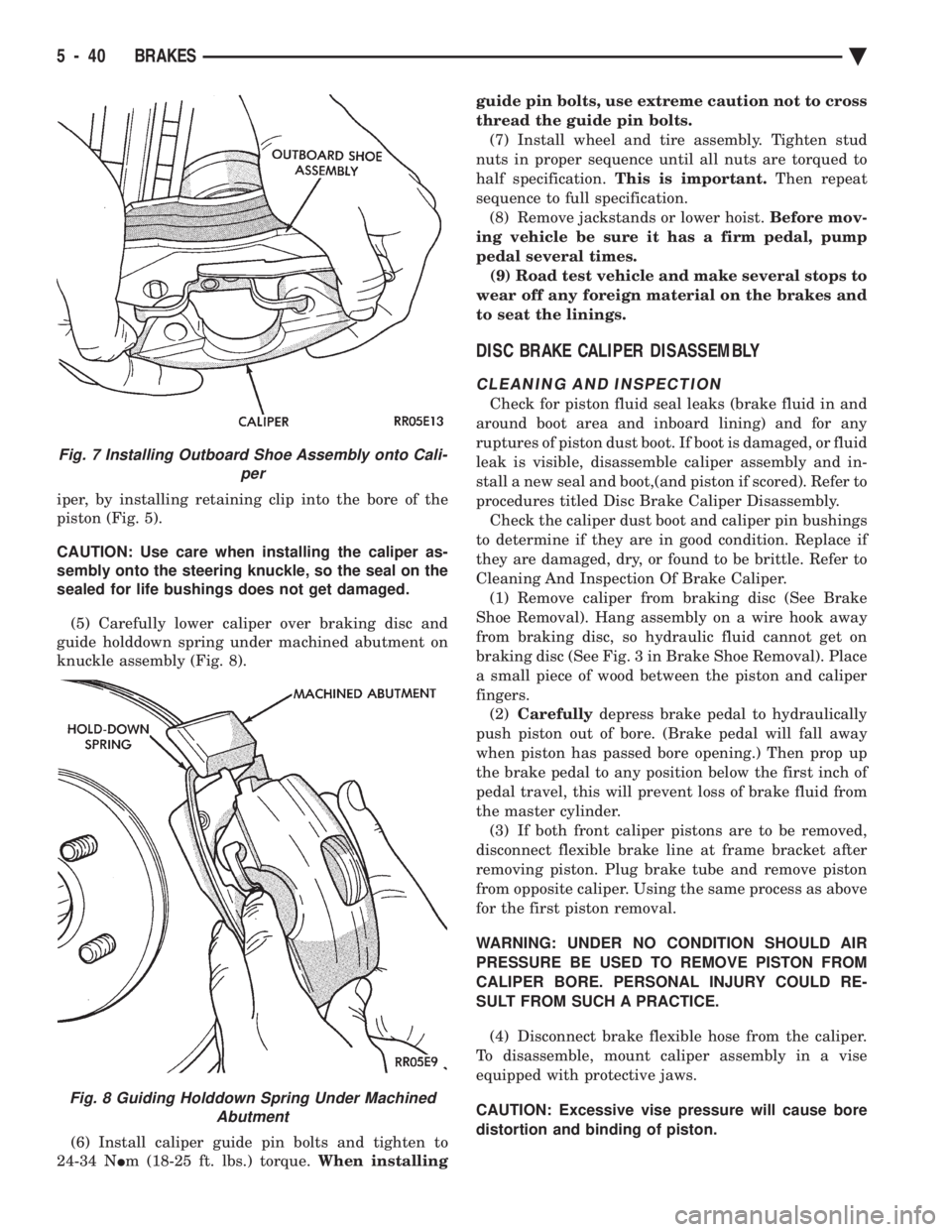

iper, by installing retaining clip into the bore of the

piston (Fig. 5).

CAUTION: Use care when installing the caliper as-

sembly onto the steering knuckle, so the seal on the

sealed for life bushings does not get damaged.

(5) Carefully lower caliper over braking disc and

guide holddown spring under machined abutment on

knuckle assembly (Fig. 8).

(6) Install caliper guide pin bolts and tighten to

24-34 N Im (18-25 ft. lbs.) torque. When installing guide pin bolts, use extreme caution not to cross

thread the guide pin bolts.

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal, pump

pedal several times. (9) Road test vehicle and make several stops to

wear off any foreign material on the brakes and

to seat the linings.

DISC BRAKE CALIPER DISASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or fluid

leak is visible, disassemble caliper assembly and in-

stall a new seal and boot,(and piston if scored). Refer to

procedures titled Disc Brake Caliper Disassembly. Check the caliper dust boot and caliper pin bushings

to determine if they are in good condition. Replace if

they are damaged, dry, or found to be brittle. Refer to

Cleaning And Inspection Of Brake Caliper. (1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 3 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers. (2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder. (3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

Fig. 7 Installing Outboard Shoe Assembly onto Cali- per

Fig. 8 Guiding Holddown Spring Under MachinedAbutment

5 - 40 BRAKES Ä

Page 197 of 2438

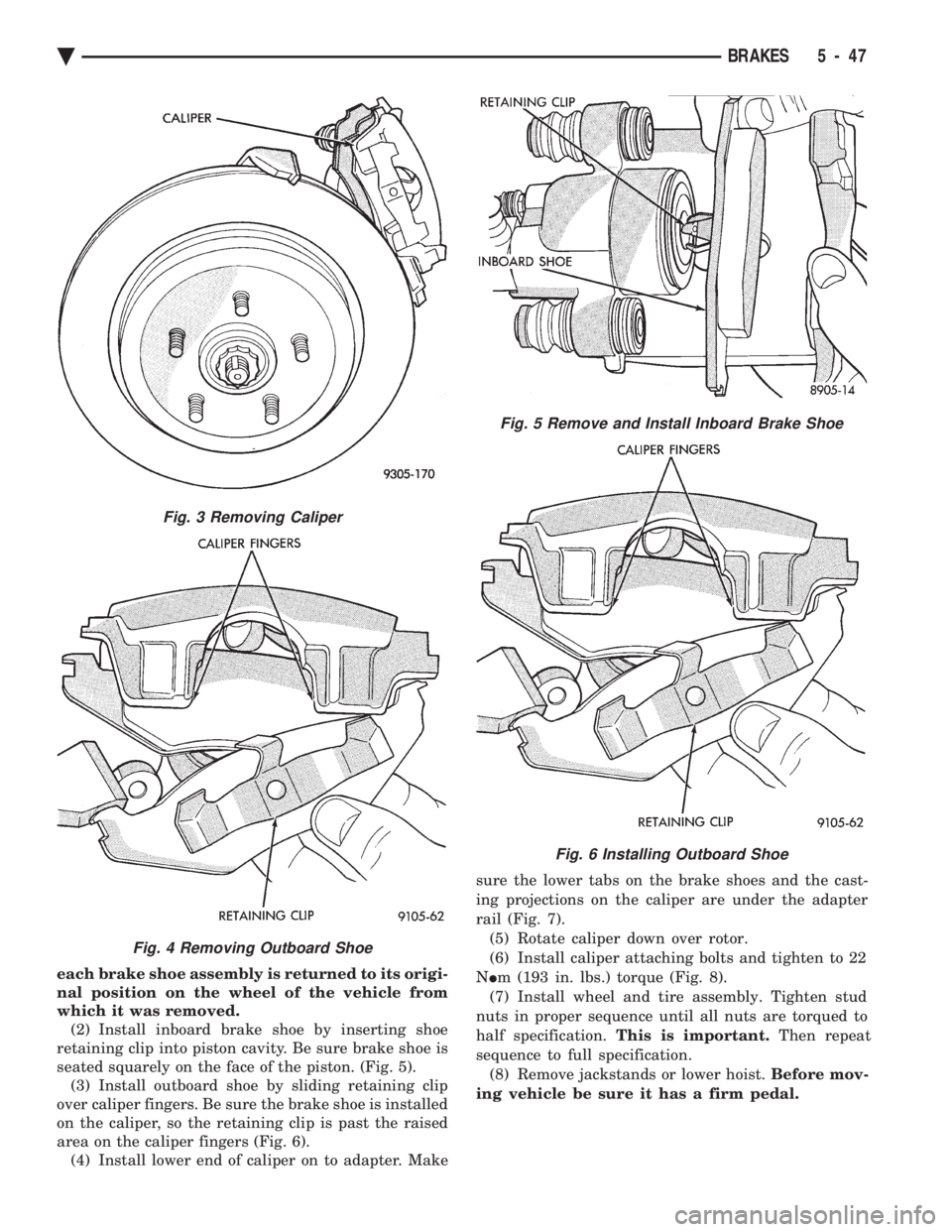

each brake shoe assembly is returned to its origi-

nal position on the wheel of the vehicle from

which it was removed. (2) Install inboard brake shoe by inserting shoe

retaining clip into piston cavity. Be sure brake shoe is

seated squarely on the face of the piston. (Fig. 5). (3) Install outboard shoe by sliding retaining clip

over caliper fingers. Be sure the brake shoe is installed

on the caliper, so the retaining clip is past the raised

area on the caliper fingers (Fig. 6). (4) Install lower end of caliper on to adapter. Make sure the lower tabs on the brake shoes and the cast-

ing projections on the caliper are under the adapter

rail (Fig. 7). (5) Rotate caliper down over rotor.

(6) Install caliper attaching bolts and tighten to 22

N Im (193 in. lbs.) torque (Fig. 8).

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal.

Fig. 5 Remove and Install Inboard Brake Shoe

Fig. 6 Installing Outboard Shoe

Fig. 3 Removing Caliper

Fig. 4 Removing Outboard Shoe

Ä BRAKES 5 - 47

Page 204 of 2438

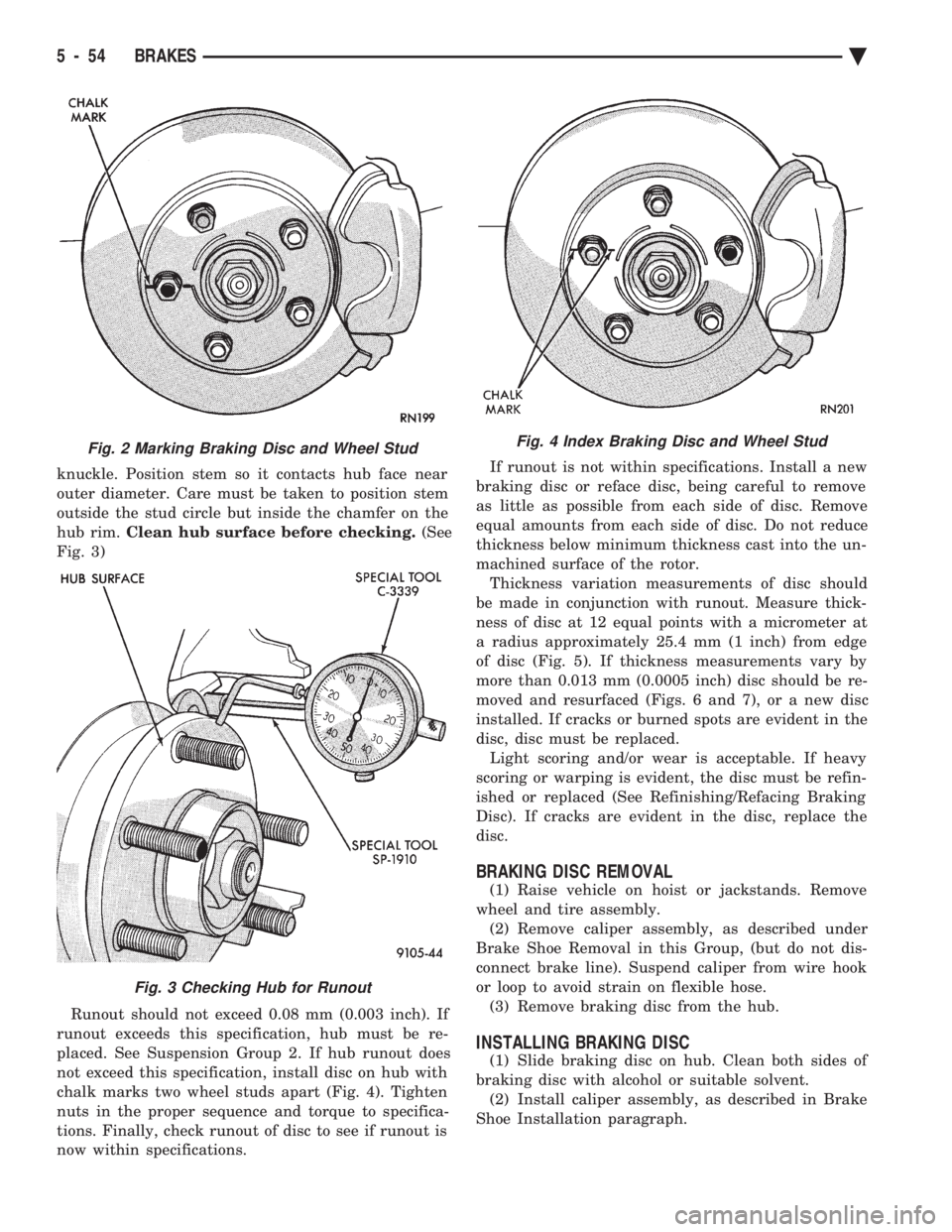

knuckle. Position stem so it contacts hub face near

outer diameter. Care must be taken to position stem

outside the stud circle but inside the chamfer on the

hub rim. Clean hub surface before checking. (See

Fig. 3)

Runout should not exceed 0.08 mm (0.003 inch). If

runout exceeds this specification, hub must be re-

placed. See Suspension Group 2. If hub runout does

not exceed this specification, install disc on hub with

chalk marks two wheel studs apart (Fig. 4). Tighten

nuts in the proper sequence and torque to specifica-

tions. Finally, check runout of disc to see if runout is

now within specifications. If runout is not within specifications. Install a new

braking disc or reface disc, being careful to remove

as little as possible from each side of disc. Remove

equal amounts from each side of disc. Do not reduce

thickness below minimum thickness cast into the un-

machined surface of the rotor. Thickness variation measurements of disc should

be made in conjunction with runout. Measure thick-

ness of disc at 12 equal points with a micrometer at

a radius approximately 25.4 mm (1 inch) from edge

of disc (Fig. 5). If thickness measurements vary by

more than 0.013 mm (0.0005 inch) disc should be re-

moved and resurfaced (Figs. 6 and 7), or a new disc

installed. If cracks or burned spots are evident in the

disc, disc must be replaced. Light scoring and/or wear is acceptable. If heavy

scoring or warping is evident, the disc must be refin-

ished or replaced (See Refinishing/Refacing Braking

Disc). If cracks are evident in the disc, replace the

disc.

BRAKING DISC REMOVAL

(1) Raise vehicle on hoist or jackstands. Remove

wheel and tire assembly. (2) Remove caliper assembly, as described under

Brake Shoe Removal in this Group, (but do not dis-

connect brake line). Suspend caliper from wire hook

or loop to avoid strain on flexible hose. (3) Remove braking disc from the hub.

INSTALLING BRAKING DISC

(1) Slide braking disc on hub. Clean both sides of

braking disc with alcohol or suitable solvent. (2) Install caliper assembly, as described in Brake

Shoe Installation paragraph.

Fig. 2 Marking Braking Disc and Wheel Stud

Fig. 3 Checking Hub for Runout

Fig. 4 Index Braking Disc and Wheel Stud

5 - 54 BRAKES Ä

Page 214 of 2438

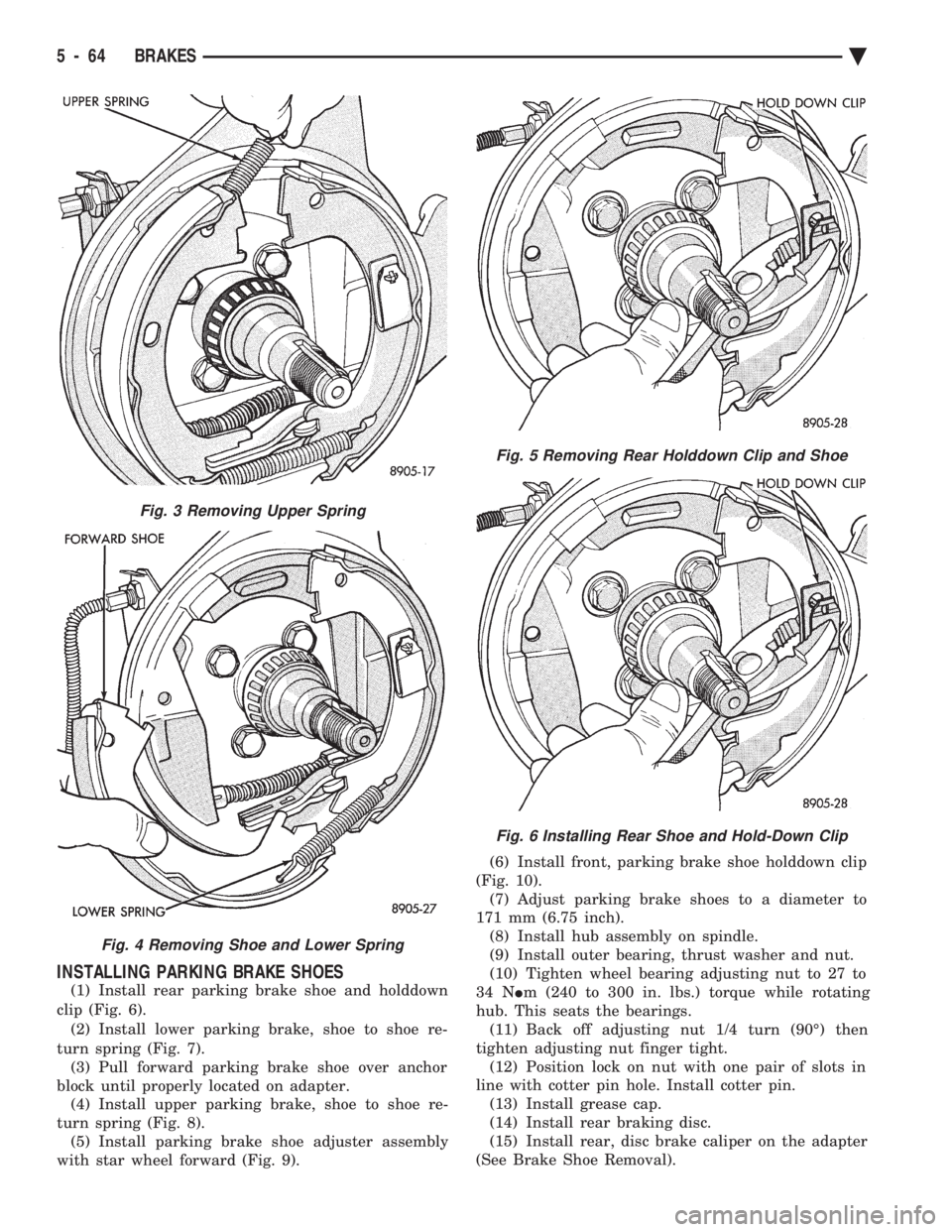

INSTALLING PARKING BRAKE SHOES

(1) Install rear parking brake shoe and holddown

clip (Fig. 6). (2) Install lower parking brake, shoe to shoe re-

turn spring (Fig. 7). (3) Pull forward parking brake shoe over anchor

block until properly located on adapter. (4) Install upper parking brake, shoe to shoe re-

turn spring (Fig. 8). (5) Install parking brake shoe adjuster assembly

with star wheel forward (Fig. 9). (6) Install front, parking brake shoe holddown clip

(Fig. 10). (7) Adjust parking brake shoes to a diameter to

171 mm (6.75 inch). (8) Install hub assembly on spindle.

(9) Install outer bearing, thrust washer and nut.

(10) Tighten wheel bearing adjusting nut to 27 to

34 N Im (240 to 300 in. lbs.) torque while rotating

hub. This seats the bearings. (11) Back off adjusting nut 1/4 turn (90É) then

tighten adjusting nut finger tight. (12) Position lock on nut with one pair of slots in

line with cotter pin hole. Install cotter pin. (13) Install grease cap.

(14) Install rear braking disc.

(15) Install rear, disc brake caliper on the adapter

(See Brake Shoe Removal).

Fig. 3 Removing Upper Spring

Fig. 4 Removing Shoe and Lower Spring

Fig. 5 Removing Rear Holddown Clip and Shoe

Fig. 6 Installing Rear Shoe and Hold-Down Clip

5 - 64 BRAKES Ä

Page 220 of 2438

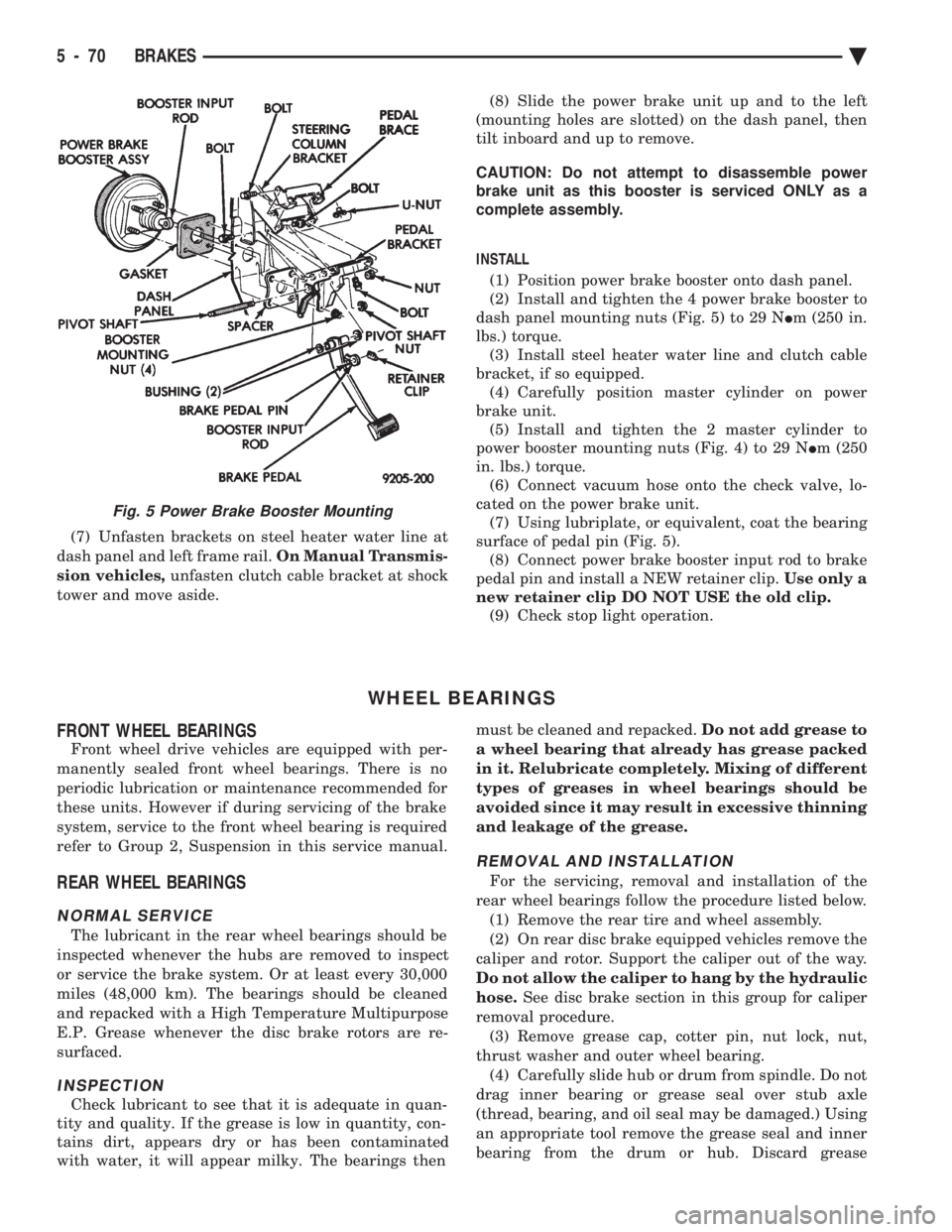

(7) Unfasten brackets on steel heater water line at

dash panel and left frame rail. On Manual Transmis-

sion vehicles, unfasten clutch cable bracket at shock

tower and move aside. (8) Slide the power brake unit up and to the left

(mounting holes are slotted) on the dash panel, then

tilt inboard and up to remove.

CAUTION: Do not attempt to disassemble power

brake unit as this booster is serviced ONLY as a

complete assembly.

INSTALL (1) Position power brake booster onto dash panel.

(2) Install and tighten the 4 power brake booster to

dash panel mounting nuts (Fig. 5) to 29 N Im (250 in.

lbs.) torque. (3) Install steel heater water line and clutch cable

bracket, if so equipped. (4) Carefully position master cylinder on power

brake unit. (5) Install and tighten the 2 master cylinder to

power booster mounting nuts (Fig. 4) to 29 N Im (250

in. lbs.) torque. (6) Connect vacuum hose onto the check valve, lo-

cated on the power brake unit. (7) Using lubriplate, or equivalent, coat the bearing

surface of pedal pin (Fig. 5). (8) Connect power brake booster input rod to brake

pedal pin and install a NEW retainer clip. Use only a

new retainer clip DO NOT USE the old clip. (9) Check stop light operation.

WHEEL BEARINGS

FRONT WHEEL BEARINGS

Front wheel drive vehicles are equipped with per-

manently sealed front wheel bearings. There is no

periodic lubrication or maintenance recommended for

these units. However if during servicing of the brake

system, service to the front wheel bearing is required

refer to Group 2, Suspension in this service manual.

REAR WHEEL BEARINGS

NORMAL SERVICE

The lubricant in the rear wheel bearings should be

inspected whenever the hubs are removed to inspect

or service the brake system. Or at least every 30,000

miles (48,000 km). The bearings should be cleaned

and repacked with a High Temperature Multipurpose

E.P. Grease whenever the disc brake rotors are re-

surfaced.

INSPECTION

Check lubricant to see that it is adequate in quan-

tity and quality. If the grease is low in quantity, con-

tains dirt, appears dry or has been contaminated

with water, it will appear milky. The bearings then must be cleaned and repacked.

Do not add grease to

a wheel bearing that already has grease packed

in it. Relubricate completely. Mixing of different

types of greases in wheel bearings should be

avoided since it may result in excessive thinning

and leakage of the grease.

REMOVAL AND INSTALLATION

For the servicing, removal and installation of the

rear wheel bearings follow the procedure listed below. (1) Remove the rear tire and wheel assembly.

(2) On rear disc brake equipped vehicles remove the

caliper and rotor. Support the caliper out of the way.

Do not allow the caliper to hang by the hydraulic

hose. See disc brake section in this group for caliper

removal procedure. (3) Remove grease cap, cotter pin, nut lock, nut,

thrust washer and outer wheel bearing. (4) Carefully slide hub or drum from spindle. Do not

drag inner bearing or grease seal over stub axle

(thread, bearing, and oil seal may be damaged.) Using

an appropriate tool remove the grease seal and inner

bearing from the drum or hub. Discard grease

Fig. 5 Power Brake Booster Mounting

5 - 70 BRAKES Ä

Page 245 of 2438

(7) With the pressure bleeder turned on, open the

caliper bleed screw 3/4 to one full turn allowing brake

fluid to flow into the container. Leave bleed screw open

until a clear, bubble-free flow of brake fluid is coming

from the hose in the container. If the reservoir has been

drained or the hydraulic assembly removed from the

car before the bleeding operation. Slowly pump the

brake pedal one or two times while the bleed screw is

open and fluid is flowing. This will help purge any

trapped air from the hydraulic assembly. Tighten

bleeder screw to 10 N Im (7.5 ft. lbs.) torque.

(8) Step 7 above should be done at all wheel brakes,

following the order wheel by wheel as listed below. a) Left rear.

b) Right rear.

c) Left front.

d) Right front.

(9) After bleeding is completed at all four wheel

brakes. Remove pressure bleeding equipment and

adapter by closing pressure bleeder valve and slowly

unscrewing bleeder adapter from hydraulic assembly

reservoir. Failure to release pressure in the reser-

voir will cause spillage of brake fluid, and could

result in personal injury or damage to painted

surfaces. (10) Using a syringe or equivalent method, remove

excess fluid from the reservoir to bring the brake fluid

to the required fill level (Fig. 1). If brake fluid is below

the proper level add Mopar tbrake fluid or equivalent

conforming to DOT 3, requirements. (11) Install the reservoir caps and turn on the igni-

tion to allow the (ABS) pump to charge the accumula-

tor.

MANUAL BLEEDING

Brake lines can be bled, using the manual bleeding

method. Manual bleeding is a two person operation,

one to pump the brake pedal and the other to bleed

each wheel brake. The following procedure should be

used: De-pressurizing the hydraulic accumulator is done

by following the steps described below. (1) Verify that the ignition switch is in the off posi-

tion. (2) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use the

procedure as described in De-Pressurizing Hydraulic

Accumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, PRIOR TO PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

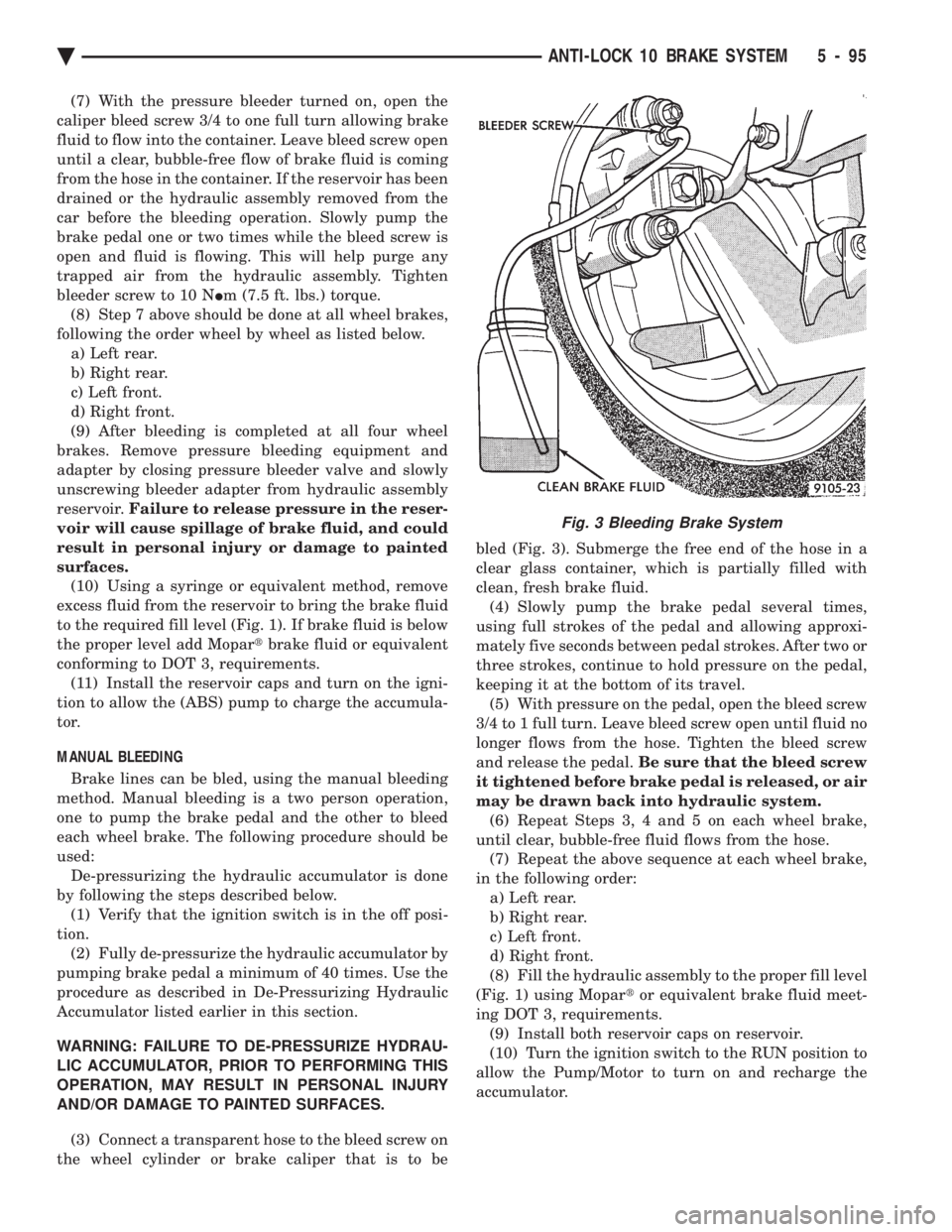

(3) Connect a transparent hose to the bleed screw on

the wheel cylinder or brake caliper that is to be bled (Fig. 3). Submerge the free end of the hose in a

clear glass container, which is partially filled with

clean, fresh brake fluid.

(4) Slowly pump the brake pedal several times,

using full strokes of the pedal and allowing approxi-

mately five seconds between pedal strokes. After two or

three strokes, continue to hold pressure on the pedal,

keeping it at the bottom of its travel. (5) With pressure on the pedal, open the bleed screw

3/4 to 1 full turn. Leave bleed screw open until fluid no

longer flows from the hose. Tighten the bleed screw

and release the pedal. Be sure that the bleed screw

it tightened before brake pedal is released, or air

may be drawn back into hydraulic system. (6) Repeat Steps 3, 4 and 5 on each wheel brake,

until clear, bubble-free fluid flows from the hose. (7) Repeat the above sequence at each wheel brake,

in the following order: a) Left rear.

b) Right rear.

c) Left front.

d) Right front.

(8) Fill the hydraulic assembly to the proper fill level

(Fig. 1) using Mopar tor equivalent brake fluid meet-

ing DOT 3, requirements. (9) Install both reservoir caps on reservoir.

(10) Turn the ignition switch to the RUN position to

allow the Pump/Motor to turn on and recharge the

accumulator.

Fig. 3 Bleeding Brake System

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 95