differential CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2351 of 2438

COMPONENT SERVICE PROCEDURES INDEX

page page

Air Distribution Duct ...................... 50

Air Distribution Duct ...................... 52

Ambient Switch .......................... 47

Blend-Air Door .......................... 64

Blower Motor ............................ 58

Blower Motor Wheel Assembly .............. 58

Blower Resistor Block ..................... 49

Condensate Drain Tube ................... 64

Condenser Assembly ...................... 57

Condenser Fan Control Switch .............. 47

Defroster Duct ........................... 51

Defroster Duct Adapter .................... 51

Defroster Ducts/Demister Ducts and Hoses ..... 52

Differential Pressure Cut-Out Switch Diagnosis . . 48

Evaporator Coil .......................... 64 Expansion Valve

......................... 55

Filter-Drier Assembly ...................... 57

Fin-Sensing Cycling Clutch Switch ............ 53

Heater Core ............................ 64

Heater Hoses ........................... 51

Heater-A/C Unit AssemblyÐRemoval and Installation ............................ 61

Heater-A/C Unit Recondition ................ 63

Low or Differential Pressure Cut-Off Switch ..... 54

Temperature Control CableÐAA,AP,AG and AJ Models ............................ 49

Temperature Control CableÐAC/AY Models .... 48

Vacuum ActuatorÐFresh/Recirc Door ......... 50

Vacuum ActuatorsÐMode Doors ............. 52

AMBIENT SWITCH

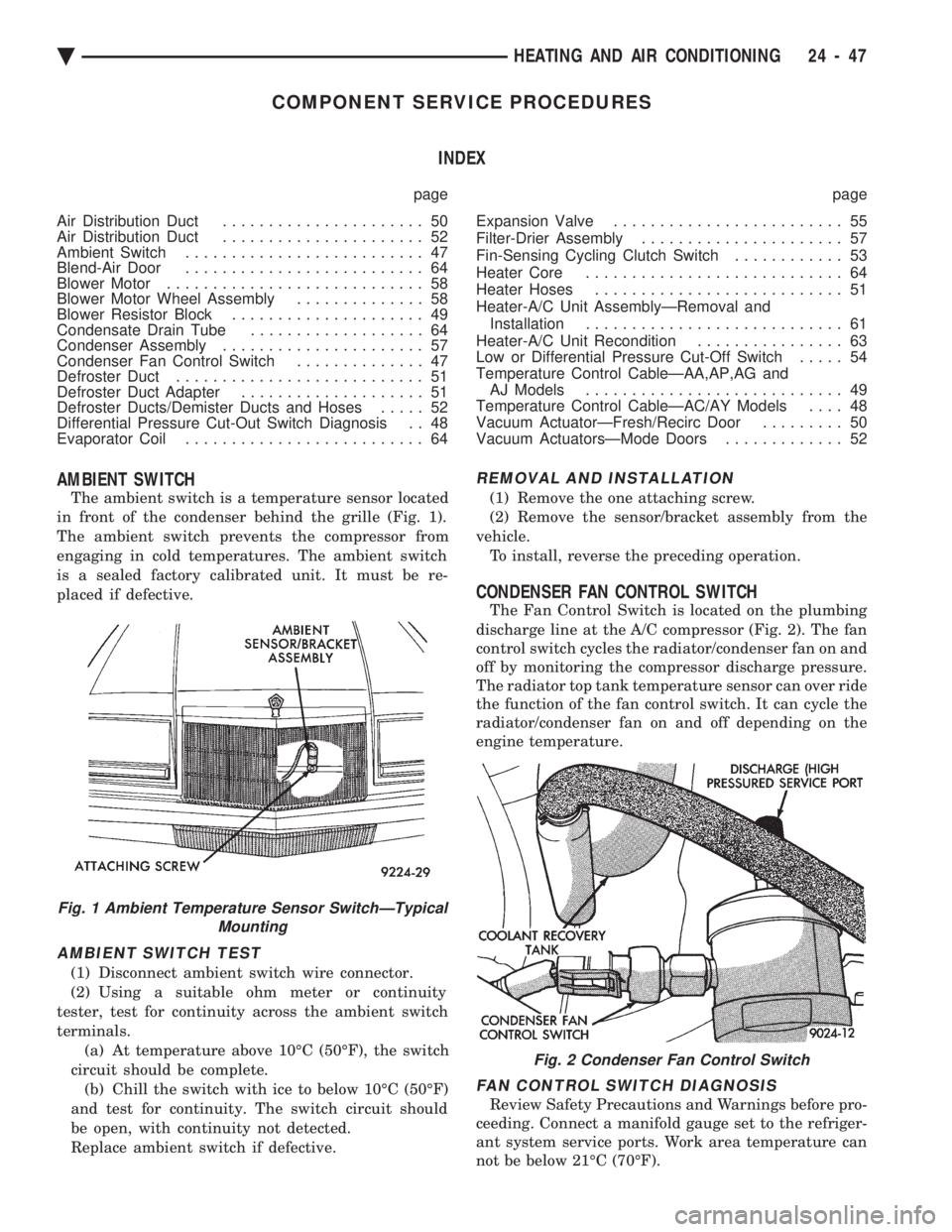

The ambient switch is a temperature sensor located

in front of the condenser behind the grille (Fig. 1).

The ambient switch prevents the compressor from

engaging in cold temperatures. The ambient switch

is a sealed factory calibrated unit. It must be re-

placed if defective.

AMBIENT SWITCH TEST

(1) Disconnect ambient switch wire connector.

(2) Using a suitable ohm meter or continuity

tester, test for continuity across the ambient switch

terminals. (a) At temperature above 10ÉC (50ÉF), the switch

circuit should be complete. (b) Chill the switch with ice to below 10ÉC (50ÉF)

and test for continuity. The switch circuit should

be open, with continuity not detected.

Replace ambient switch if defective.

REMOVAL AND INSTALLATION

(1) Remove the one attaching screw.

(2) Remove the sensor/bracket assembly from the

vehicle. To install, reverse the preceding operation.

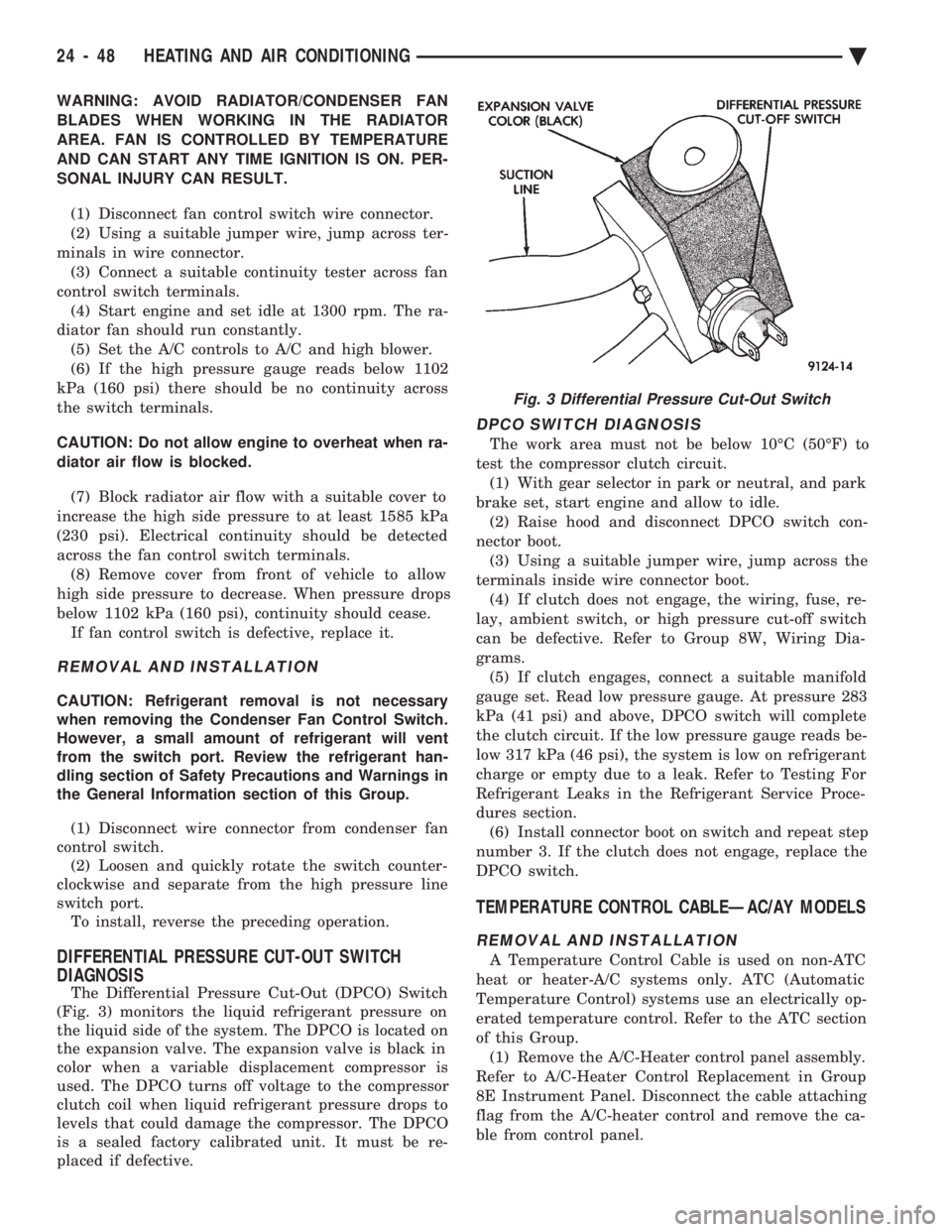

CONDENSER FAN CONTROL SWITCH

The Fan Control Switch is located on the plumbing

discharge line at the A/C compressor (Fig. 2). The fan

control switch cycles the radiator/condenser fan on and

off by monitoring the compressor discharge pressure.

The radiator top tank temperature sensor can over ride

the function of the fan control switch. It can cycle the

radiator/condenser fan on and off depending on the

engine temperature.

FAN CONTROL SWITCH DIAGNOSIS

Review Safety Precautions and Warnings before pro-

ceeding. Connect a manifold gauge set to the refriger-

ant system service ports. Work area temperature can

not be below 21ÉC (70ÉF).

Fig. 1 Ambient Temperature Sensor SwitchÐTypical Mounting

Fig. 2 Condenser Fan Control Switch

Ä HEATING AND AIR CONDITIONING 24 - 47

Page 2352 of 2438

WARNING: AVOID RADIATOR/CONDENSER FAN

BLADES WHEN WORKING IN THE RADIATOR

AREA. FAN IS CONTROLLED BY TEMPERATURE

AND CAN START ANY TIME IGNITION IS ON. PER-

SONAL INJURY CAN RESULT.

(1) Disconnect fan control switch wire connector.

(2) Using a suitable jumper wire, jump across ter-

minals in wire connector. (3) Connect a suitable continuity tester across fan

control switch terminals. (4) Start engine and set idle at 1300 rpm. The ra-

diator fan should run constantly. (5) Set the A/C controls to A/C and high blower.

(6) If the high pressure gauge reads below 1102

kPa (160 psi) there should be no continuity across

the switch terminals.

CAUTION: Do not allow engine to overheat when ra-

diator air flow is blocked.

(7) Block radiator air flow with a suitable cover to

increase the high side pressure to at least 1585 kPa

(230 psi). Electrical continuity should be detected

across the fan control switch terminals. (8) Remove cover from front of vehicle to allow

high side pressure to decrease. When pressure drops

below 1102 kPa (160 psi), continuity should cease. If fan control switch is defective, replace it.

REMOVAL AND INSTALLATION

CAUTION: Refrigerant removal is not necessary

when removing the Condenser Fan Control Switch.

However, a small amount of refrigerant will vent

from the switch port. Review the refrigerant han-

dling section of Safety Precautions and Warnings in

the General Information section of this Group.

(1) Disconnect wire connector from condenser fan

control switch. (2) Loosen and quickly rotate the switch counter-

clockwise and separate from the high pressure line

switch port. To install, reverse the preceding operation.

DIFFERENTIAL PRESSURE CUT-OUT SWITCH

DIAGNOSIS

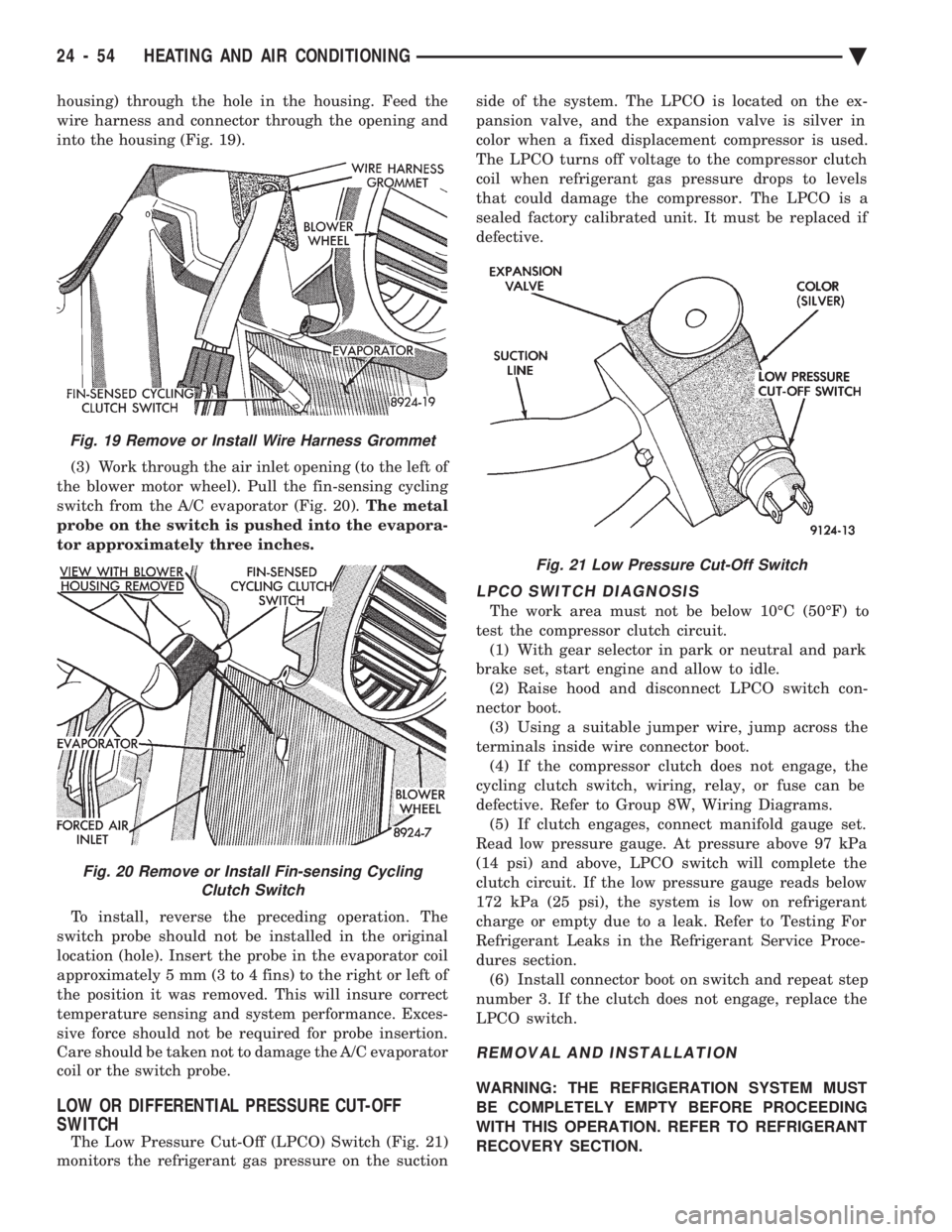

The Differential Pressure Cut-Out (DPCO) Switch

(Fig. 3) monitors the liquid refrigerant pressure on

the liquid side of the system. The DPCO is located on

the expansion valve. The expansion valve is black in

color when a variable displacement compressor is

used. The DPCO turns off voltage to the compressor

clutch coil when liquid refrigerant pressure drops to

levels that could damage the compressor. The DPCO

is a sealed factory calibrated unit. It must be re-

placed if defective.

DPCO SWITCH DIAGNOSIS

The work area must not be below 10ÉC (50ÉF) to

test the compressor clutch circuit. (1) With gear selector in park or neutral, and park

brake set, start engine and allow to idle. (2) Raise hood and disconnect DPCO switch con-

nector boot. (3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot. (4) If clutch does not engage, the wiring, fuse, re-

lay, ambient switch, or high pressure cut-off switch

can be defective. Refer to Group 8W, Wiring Dia-

grams. (5) If clutch engages, connect a suitable manifold

gauge set. Read low pressure gauge. At pressure 283

kPa (41 psi) and above, DPCO switch will complete

the clutch circuit. If the low pressure gauge reads be-

low 317 kPa (46 psi), the system is low on refrigerant

charge or empty due to a leak. Refer to Testing For

Refrigerant Leaks in the Refrigerant Service Proce-

dures section. (6) Install connector boot on switch and repeat step

number 3. If the clutch does not engage, replace the

DPCO switch.

TEMPERATURE CONTROL CABLEÐAC/AY MODELS

REMOVAL AND INSTALLATION

A Temperature Control Cable is used on non-ATC

heat or heater-A/C systems only. ATC (Automatic

Temperature Control) systems use an electrically op-

erated temperature control. Refer to the ATC section

of this Group. (1) Remove the A/C-Heater control panel assembly.

Refer to A/C-Heater Control Replacement in Group

8E Instrument Panel. Disconnect the cable attaching

flag from the A/C-heater control and remove the ca-

ble from control panel.

Fig. 3 Differential Pressure Cut-Out Switch

24 - 48 HEATING AND AIR CONDITIONING Ä

Page 2358 of 2438

housing) through the hole in the housing. Feed the

wire harness and connector through the opening and

into the housing (Fig. 19). (3) Work through the air inlet opening (to the left of

the blower motor wheel). Pull the fin-sensing cycling

switch from the A/C evaporator (Fig. 20). The metal

probe on the switch is pushed into the evapora-

tor approximately three inches.

To install, reverse the preceding operation. The

switch probe should not be installed in the original

location (hole). Insert the probe in the evaporator coil

approximately 5 mm (3 to 4 fins) to the right or left of

the position it was removed. This will insure correct

temperature sensing and system performance. Exces-

sive force should not be required for probe insertion.

Care should be taken not to damage the A/C evaporator

coil or the switch probe.

LOW OR DIFFERENTIAL PRESSURE CUT-OFF

SWITCH

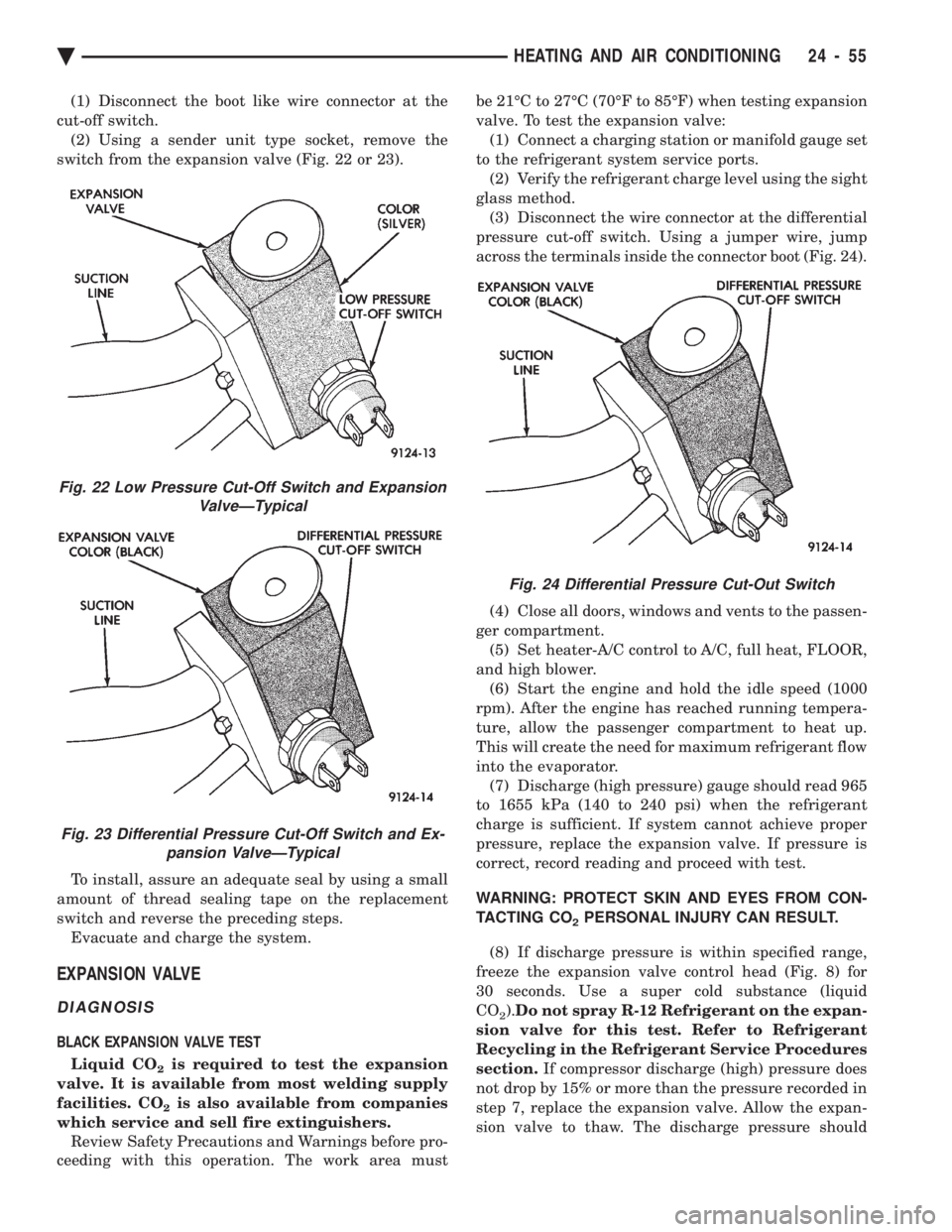

The Low Pressure Cut-Off (LPCO) Switch (Fig. 21)

monitors the refrigerant gas pressure on the suction side of the system. The LPCO is located on the ex-

pansion valve, and the expansion valve is silver in

color when a fixed displacement compressor is used.

The LPCO turns off voltage to the compressor clutch

coil when refrigerant gas pressure drops to levels

that could damage the compressor. The LPCO is a

sealed factory calibrated unit. It must be replaced if

defective.

LPCO SWITCH DIAGNOSIS

The work area must not be below 10ÉC (50ÉF) to

test the compressor clutch circuit. (1) With gear selector in park or neutral and park

brake set, start engine and allow to idle. (2) Raise hood and disconnect LPCO switch con-

nector boot. (3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot. (4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams. (5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, LPCO switch will complete the

clutch circuit. If the low pressure gauge reads below

172 kPa (25 psi), the system is low on refrigerant

charge or empty due to a leak. Refer to Testing For

Refrigerant Leaks in the Refrigerant Service Proce-

dures section. (6) Install connector boot on switch and repeat step

number 3. If the clutch does not engage, replace the

LPCO switch.

REMOVAL AND INSTALLATION

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION. REFER TO REFRIGERANT

RECOVERY SECTION.

Fig. 21 Low Pressure Cut-Off Switch

Fig. 19 Remove or Install Wire Harness Grommet

Fig. 20 Remove or Install Fin-sensing Cycling Clutch Switch

24 - 54 HEATING AND AIR CONDITIONING Ä

Page 2359 of 2438

(1) Disconnect the boot like wire connector at the

cut-off switch. (2) Using a sender unit type socket, remove the

switch from the expansion valve (Fig. 22 or 23).

To install, assure an adequate seal by using a small

amount of thread sealing tape on the replacement

switch and reverse the preceding steps. Evacuate and charge the system.

EXPANSION VALVE

DIAGNOSIS

BLACK EXPANSION VALVE TEST

Liquid CO

2is required to test the expansion

valve. It is available from most welding supply

facilities. CO

2is also available from companies

which service and sell fire extinguishers. Review Safety Precautions and Warnings before pro-

ceeding with this operation. The work area must be 21ÉC to 27ÉC (70ÉF to 85ÉF) when testing expansion

valve. To test the expansion valve: (1) Connect a charging station or manifold gauge set

to the refrigerant system service ports. (2) Verify the refrigerant charge level using the sight

glass method. (3) Disconnect the wire connector at the differential

pressure cut-off switch. Using a jumper wire, jump

across the terminals inside the connector boot (Fig. 24).

(4) Close all doors, windows and vents to the passen-

ger compartment. (5) Set heater-A/C control to A/C, full heat, FLOOR,

and high blower. (6) Start the engine and hold the idle speed (1000

rpm). After the engine has reached running tempera-

ture, allow the passenger compartment to heat up.

This will create the need for maximum refrigerant flow

into the evaporator. (7) Discharge (high pressure) gauge should read 965

to 1655 kPa (140 to 240 psi) when the refrigerant

charge is sufficient. If system cannot achieve proper

pressure, replace the expansion valve. If pressure is

correct, record reading and proceed with test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO

2PERSONAL INJURY CAN RESULT.

(8) If discharge pressure is within specified range,

freeze the expansion valve control head (Fig. 8) for

30 seconds. Use a super cold substance (liquid

CO

2). Do not spray R-12 Refrigerant on the expan-

sion valve for this test. Refer to Refrigerant

Recycling in the Refrigerant Service Procedures

section. If compressor discharge (high) pressure does

not drop by 15% or more than the pressure recorded in

step 7, replace the expansion valve. Allow the expan-

sion valve to thaw. The discharge pressure should

Fig. 22 Low Pressure Cut-Off Switch and Expansion ValveÐTypical

Fig. 23 Differential Pressure Cut-Off Switch and Ex-pansion ValveÐTypical

Fig. 24 Differential Pressure Cut-Out Switch

Ä HEATING AND AIR CONDITIONING 24 - 55