engine coolant CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1468 of 2438

Wiring Diagram

Name Sheet Number

Exhaust Gas Recirculation Solenoid 2.5L ..............13

Exhaust Gas Recirculation Diagnostic Solenoid 3.0L. ......20

Fan Control System with A/C and Heater System ......49, 50

A/C Compressor Clutch .......................49

A/C Compressor Clutch Relay ...................50

Fan Control Relay ...........................50

Diode ...................................49

Radiator Fan Fuse ...........................50

Radiator Fan Motor ..........................49

Fan Control System with Heater ....................45

Fan Control Relay ...........................45

Radiator Fan Fuse ...........................45

Radiator Fan Motor ..........................45

Flasher-Hazard ..............................51

Flasher-Turn Signal ............................51

Fog Lamps ........................ .31, 32, 33, 34

Fog Lamp Switch ......................... .31, 33

Front End Lighting ........................ .31, 32

Fog Lamps ............................ .31, 32

Fog Lamp Switch ...........................31

Headlamps-Aero ........................ .31, 32

Park and Turn Signal Lamps ..................31, 32

Side Marker Lamp ....................... .31, 32

Front End Lighting w/DRL .................... .33, 34

Fog Lamps ............................ .33, 34

Fog Lamp Switch ...........................33

Headlamps-Aero ........................ .33, 34

Park and Turn Signal Lamps ..................33, 34

Side Marker Lamp ....................... .33, 34

Fuel Injection Ignition System Engine 2.2L & 2.5L ............... .13, 14, 15, 16, 17

Automatic Shut Down Relay ....................14

Data Link Connector .........................13

Distributor ...............................15

Distributor Ignition Coil .......................14

Engine Coolant Temperature Sensor ...............15

Exhaust Gas Recirculation Solenoid ................13

EVAP/Purge Solenoid .........................13

Fuel Pump Relay ...........................14

Heated Oxygen Sensor ........................17

Idle Air Control Motor ........................16

Injector .................................13

MAP Sensor ..............................15

Powertrain Control Module ...........13, 14, 15, 16, 17

Throttle Position (Sensor) ......................16

Vehicle Speed Sensor ........................15

Fuel Injection Ignition System 3.0L ........18, 19, 20, 21, 22

Automatic Shut Down Relay ....................22

Data Link Connector .........................22

Distributor ...............................18

Distributor Ignition Coil .......................22

Engine Coolant Temperature Sensor ...............18

Exhaust Gas Recirculation Solenoid ................20

EVAP/Purge Solenoid .........................19

Fuel Injectors ..............................19

Fuel Pump Relay ...........................22

Heated Oxygen Sensor ........................18Wiring Diagram

Name Sheet Number

Idle Air Control Motor ........................20

Injectors .................................19

MAP Sensor ..............................20

Power Steering Pressure Switch ..................19

Powertrain Control Module ...........18, 19, 20, 21, 22

Throttle Position (Sensor) ......................20

Vehicle Speed Sensor ........................18

Fuel Pump Motor .............................68

Fuel Tank Sending Unit .........................68

Fuel Tank System .............................68

Fuel Pump Motor ...........................58

Fuel Tank Sending Unit ........................68

Fuse Application Char t.........................1,2

Fuse Block Module ............................76

Fuses Fuse 1 ...............1,31,33,37,41,46,47,65,67

Fuse 2 ........................1,,36,39,61,64

Fuse 3 ..............................2,11,29

Fuse 4 ...........................2,11,35,43

Fuse 5 .............................1,3,5,51

Fuse 6 .........................2,11,35,41,67

Fuse 7 ...........................2,11,46,47

Fuse 9 ...........................1,35,42,65

Fuse 10 ..........................1,31,33,36

Fuse 12 ...............................1,43

Fuse 13 ....................2,3,5,39,44,55,65

Fuse 14 .............................2,11,54

Fuse 15 .............................2,11,51

Fuse 16 .............................2,11,65

Generator .................................4,6

Glove Box Lamp .............................39

Glove Box Lamp Switch .........................39

Hazard Flasher System ...................... .51, 52

Headlamp Switch ...........................1,36

Circuit Breaker .............................36

Optical Horn ..............................36

Headlamp Switch Connector ......................83

Headlamp Switch Controlled Interior Lamps .........37, 38

Headlamp Switch Controlled Interior Lighting .........37, 38

Ash Receiver Lamp ..........................37

Cigar Lighter ..............................37

Cigar Lighter Lamp ..........................37

Transmission Range Lamp .....................37

Heated Oxygen Sensor ...................... .17, 18

Heated Rear Window ..........................67

Heated Rear Window Switch ....................67

Timer ...................................67

Heater Blower Motor Resistor .....................46

Heater System ...............................46

Bi-Level Control Switch .......................46

Blower Motor ..............................46

Blower Slide Control .........................46

Illumination Lamp ...........................46

Resistor .................................46

Horn System ...............................42

Clockspring ...............................42

Horn (Hi-note) .............................42

8W - 718 WIRING DIAGRAMS AP BODY D-P Ä

Page 1470 of 2438

Wiring Diagram

Name Sheet Number

Right Rear Motor ...........................58

Right Rear Switch ...........................58

Printed Circuit Board ....................... .74, 75

Printed Circuit Board Connectors ...................73

Radiator Fan Fuse ......................... .45, 50

Radio Speakers-Door and Rear ....................66

Radio-Stereo ................................65

Name Brand Speaker Relay .....................65

Rear Lighting ....................... .69, 70, 71, 72

Back-Up Lamps .................... .69, 70, 71, 72

Center High Mounted Stop Lamps ..............70, 72

Courtesy Lamps ............................72

License Lamps ......................... .70, 72

Side Marker Lamps ................. .69, 70, 71, 72

Tail, Stop and Turn Signal Lamps .........69, 70, 71, 72

Relay Module ...............................77

Relays ABS System Relay ..........................28

A/C Compressor Clutch Relay ...................50

ABS Yellow Light Relay .......................28

ABS Pump Motor Relay .......................27

Automatic Shut Down ....................2,14,22

Back-Up Lamp Relay .........................23

Engine Starter Relay ....................7,8,9,10

Fuel Pump ............................ .14, 22

Horn ...................................42

Fan Control Relay ....................... .45, 50

Name Brand Speaker .........................65

Safety Shut Down Relay .......................25

Time Delay ...............................44

Right Front Wheel Sensor .......................26

Right Instrument Panel Interface ...................89

Right Rear Wheel Sensor ........................26

Seat Belt Warning System and Courtesy Lamps .......43, 44

Halo Lamp ...............................44

Seat Belt Warning Chime ......................43

Seat Belt Switch ............................44

Time Delay Relay ...........................44

Seat-Power System, Left ........................60

Sensors ABS Wheel Sensors ..........................26

A/C Ambient Temperature Sensor .................41

Airbag ..................................35

Engine Coolant Temperature ..................15, 18

Heated Oxygen ......................... .17, 18

MAP ................................ .15, 20

Output Speed Sensor .........................24

Throttle Position ........................ .16, 20

Turbine Speed .............................24

Vehicle Speed Sensor ..................... .15, 18

Washer Low Fluid Sensor ......................53

Solenoids EVAP/Purge Solenoid ..................... .13, 19

Exhaust Gas Recirculation .................. .13, 20

Transmission EMCC Solenoid ....................8

Transmission Solenoid ........................25

Speakers, Radio ..............................66Wiring Diagram

Name Sheet Number

Splices Splice A0-1 ...........................1,2,4,6

Splice A0-2 ............................2,4,6

Splice A1 ..............................2,4,6

Splice A2 ..............................2,4,6

Splice A3 ..............................1,36

Splice A3-1 ............................1,4,6

Splice A4 ..............................2,3,5

Splice A4-1 ............................2,4,6

Splice A11 .............................1,4,6

Splice A14 .............................2,4,6

Splice A14-1 ..............................14

Splice A14-2 ..............................22

Splice A15 .............................1,3,5

Splice A15-1 ...........................1,3,5

Splice A16 .............................2,4,6

Splice A20 ...............................28

Splice A21 ...............................11

Splice A21-1 ..........................2,13,21

Splice A21-2 ........................... .13, 21

Splice A21-3 ..............................23

Splice A142-1 .............................14

Splice A142-2 ..........................4,6,14

Splice B47 ...............................28

Splice C7 ............................. .46, 48

Splice D1 ................................24

Splice D2 ................................24

Splice E2 .............. .31, 33, 37, 41, 46, 47, 65, 67

Splice E2-1 ............ .31, 33, 37, 41, 46, 47, 65, 67

Splice F20 .......................... .35, 41, 67

Splice F20-1 .........................7,8,9,23

Splice F30 .......................... .35, 42, 65

Splice F35 ............................ .61, 63

Splice G5 ............................. .35, 43

Splice G7 .......................... .15, 18, 30

Splice K4 ................................15

Splice K4-1 ........................... .15, 18

Splice K4-2 ........................... .19, 20

Splice K6 ............................. .16, 20

Splice K7-1 ........................... .15, 18

Splice K22 ...............................20

Splice K24 ...............................18

Splice L3 ............................. .31, 33

Splice L4 ............................. .31, 33

Splice L7-1 ........................... .32, 34

Splice L7-2 ........................... .31, 33

Splice L7-3 ...............................36

Splice L7-4 ........................... .69, 71

Splice L7-5 ........................... .31, 33

Splice L20 ..............................1,36

Splice L39 ............................ .31, 33

Splice L50 ...............................52

Splice L60 ............................ .31, 33

Splice L60-1 ..............................52

Splice L61 ............................ .32, 34

Splice L61-1 ..............................52

Splice M1-1 ...................... .39, 44, 55, 65

8W - 720 WIRING DIAGRAMS AP BODY D-P Ä

Page 1575 of 2438

Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. Engine components which are required for safe op-

eration using fuel containing methanol alcohol are

identified by a standard green color and/or display

the statement methanol compatible imprinted on the

component. To ensure continued safe operation, these

components must be serviced only with genuine MO-

PAR replacement parts. Methanol compatible parts for the 2.5L FFV (Flex-

ible Fuel Vehicle) engine include, but are not limited

to; the valve stem oil seals, all piston rings, the oil

fill cap, the fuel injectors, fuel rail, fuel pressure reg-

ulator, hoses and the vacuum control harness hose. BLOCK: All four cylinder cast iron blocks have

cast-in recesses in the bottom of each cylinder bore to

provide connecting rod clearance; especially needed

for 2.5L engines. The bores are also siamese to min-

imize engine length. A coolant passage is drilled

cross-ways through the siamese section to enhance

between the bore cooling on some engine types. A

partial open deck is used for cooling and weight re-

duction with oil filter, water pump, and distributor

mounting bosses molded into the front (radiator side)

of the block. Nominal wall thickness is 4.5 mm. Five

main bearing bulkheads and a block skirt extending

3 mm below the crankshaft center line add to the

blocks high rigidity with light weight. CRANKSHAFT: A nodular cast iron crankshaft is

used in TBI engines. A forged steel crankshaft is

used in the Turbo III engine. All engines have 5 main bearings, with number 3 flanged to control

thrust. The 60 mm diameter main and 50 mm diam-

eter crank pin journals (all) have undercut radiuses

fillets that are deep rolled for added strength. To op-

timize bearing loading 4 counterweights are used.

Hydrodynamic seals (installed in diecast aluminum

retainers) provide end sealing, where the crankshaft

exits the block. Anaerobic gasket material is used for

retainer-to-block sealing. No vibration damper is

used. A sintered iron (TBI engine and steel billet

Turbo III engines) timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides mo-

tive power; via timing belt to the camshaft and inter-

mediate shaft sprockets (also sintered iron (TBI

engine and steel billet Turbo III engines) providing

timed valve, distributor, and oil pump actuation. PISTONS: Some Chrysler pistons have cast-in

steel struts at the pin bosses for autothermic control.

All 2.2L and 2.5L piston tops have cuts to provide

valve clearance. Some pistons are dished to provide

various compression ratios. Standard 2.2L and 2.5L

engines are designed for 9.5:1 and 8.9:1 compression

ratios respectively. The 2.5L piston is dished and is a

lightweight design to enhance engine smoothness.

The 2.2L turbo III uses dished pistons providing a

8.3:1 compression ratio. All standard 2.2/2.5L and

2.5L FFV engines use pressed-in piston pins to at-

tach forged steel connecting rods, 2.2L turbo III en-

gine uses a full floating piston pin and connecting

rod assembly. PISTONS RINGS: The 2.2/2.5L engines share

common piston rings throughout, including molybde-

num filled top ring for reliable compression sealing

and a tapered faced intermediate ring for additional

cylinder pressure control. The 2.5L FFV engine fea-

ture all chrome rings for enhanced long term dura-

bility under multi-fueled conditions. CYLINDER HEAD: The cylinder head is cast alu-

minum with in-line valves. The 2.2/2.5L and 2.5L

FFV valves are arranged with alternating exhaust

and intake. The intake and exhaust ports are located

in the rearward, facing side of the head. The Turbo

III valves are arranged in two inline banks, with the

ports of the bank of two intake valves per cylinder

facing toward the radiator side of engine and ports of

the bank of two exhaust valve per cylinder facing to-

ward the dash panel. The intake ports feed fast-burn

design combustion chambers (2.2/2.5L and 2.5L FFV

only) with the spark plug located close to the center

line of the combustion chamber for optimum effi-

ciency. An integral oil gallery within the cylinder

head supplies oil to the hydraulic lash adjusters,

camshaft, and valve mechanisms. CAMSHAFT: The nodular iron camshaft has five

bearing journals (2.2/2.5L and 2.5L FFV). The Turbo

III employs dual camshafts that have nine bearing

journals. Flanges at the rear journal control cam-

Fig. 1 Engine Identification

Ä 2.2/2.5L ENGINE 9 - 9

Page 1635 of 2438

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

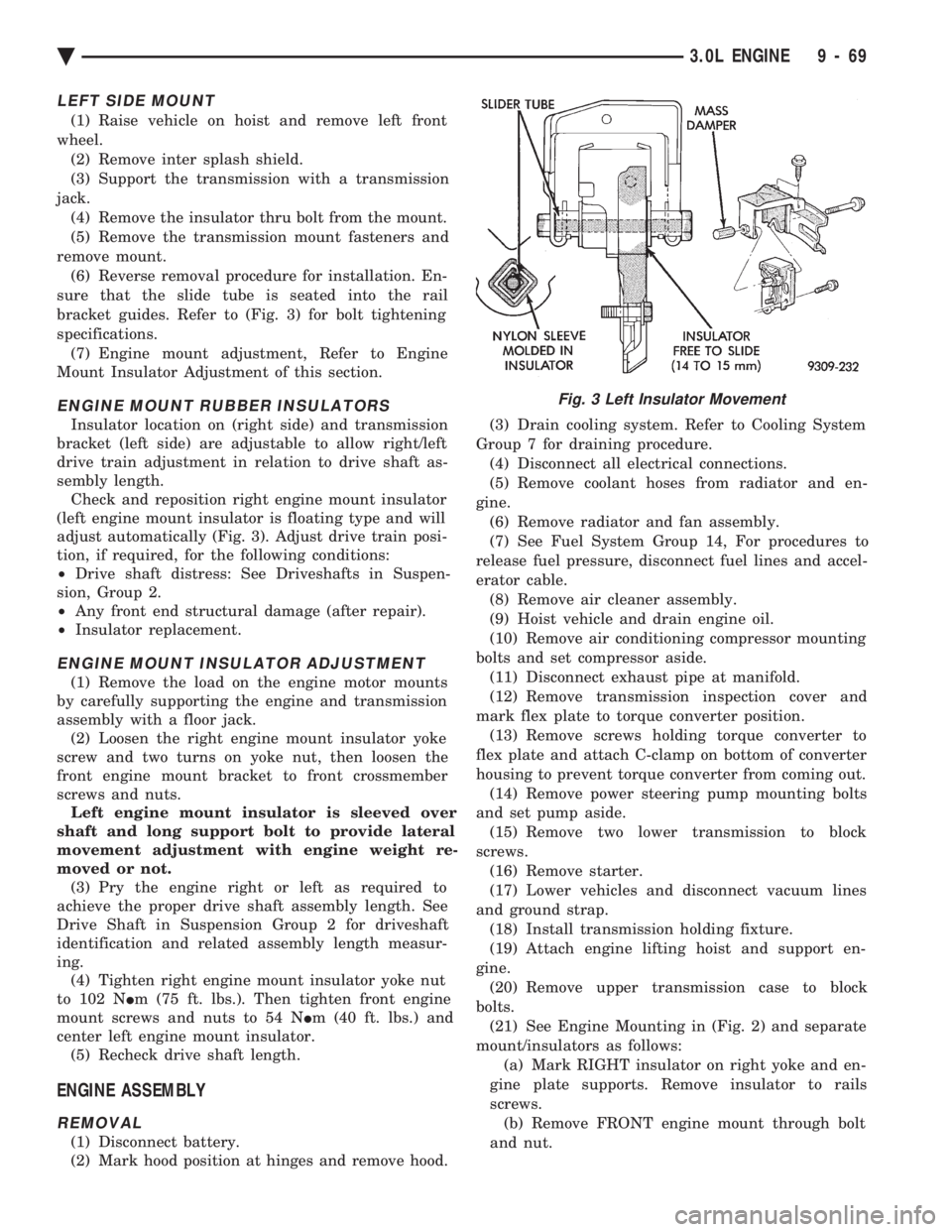

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) and transmission

bracket (left side) are adjustable to allow right/left

drive train adjustment in relation to drive shaft as-

sembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 3). Adjust drive train posi-

tion, if required, for the following conditions:

² Drive shaft distress: See Driveshafts in Suspen-

sion, Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (2) Loosen the right engine mount insulator yoke

screw and two turns on yoke nut, then loosen the

front engine mount bracket to front crossmember

screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. See

Drive Shaft in Suspension Group 2 for driveshaft

identification and related assembly length measur-

ing. (4) Tighten right engine mount insulator yoke nut

to 102 N Im (75 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood. (3) Drain cooling system. Refer to Cooling System

Group 7 for draining procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and en-

gine. (6) Remove radiator and fan assembly.

(7) See Fuel System Group 14, For procedures to

release fuel pressure, disconnect fuel lines and accel-

erator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from coming out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 2) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right yoke and en-

gine plate supports. Remove insulator to rails

screws. (b) Remove FRONT engine mount through bolt

and nut.

Fig. 3 Left Insulator Movement

Ä 3.0L ENGINE 9 - 69

Page 1667 of 2438

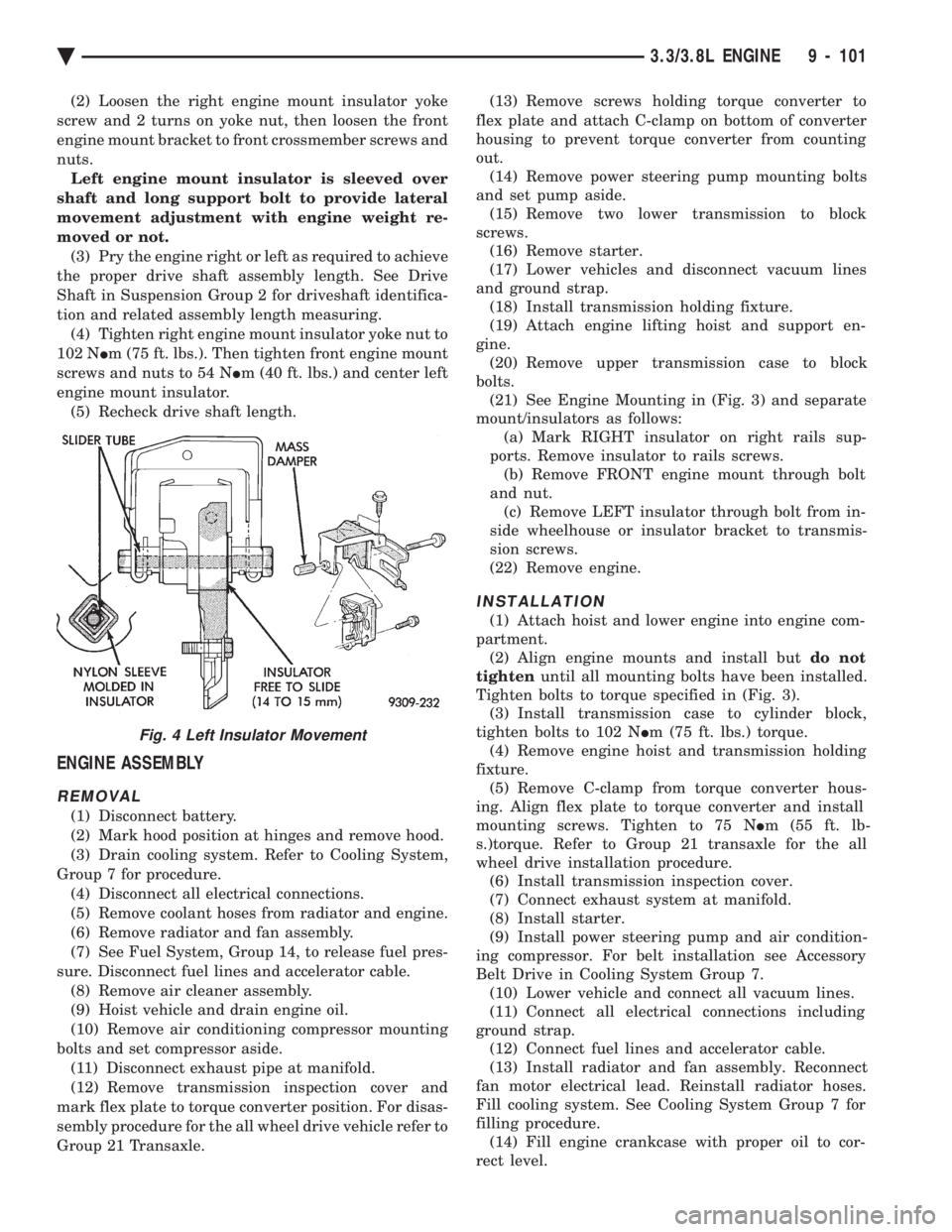

(2) Loosen the right engine mount insulator yoke

screw and 2 turns on yoke nut, then loosen the front

engine mount bracket to front crossmember screws and

nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to achieve

the proper drive shaft assembly length. See Drive

Shaft in Suspension Group 2 for driveshaft identifica-

tion and related assembly length measuring. (4) Tighten right engine mount insulator yoke nut to

102 N Im (75 ft. lbs.). Then tighten front engine mount

screws and nuts to 54 N Im (40 ft. lbs.) and center left

engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood.

(3) Drain cooling system. Refer to Cooling System,

Group 7 for procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and engine.

(6) Remove radiator and fan assembly.

(7) See Fuel System, Group 14, to release fuel pres-

sure. Disconnect fuel lines and accelerator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. For disas-

sembly procedure for the all wheel drive vehicle refer to

Group 21 Transaxle. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from counting

out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 3) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right rails sup-

ports. Remove insulator to rails screws. (b) Remove FRONT engine mount through bolt

and nut. (c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 3). (3) Install transmission case to cylinder block,

tighten bolts to 102 N Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture. (5) Remove C-clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N Im (55 ft. lb-

s.)torque. Refer to Group 21 transaxle for the all

wheel drive installation procedure. (6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation see Accessory

Belt Drive in Cooling System Group 7. (10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap. (12) Connect fuel lines and accelerator cable.

(13) Install radiator and fan assembly. Reconnect

fan motor electrical lead. Reinstall radiator hoses.

Fill cooling system. See Cooling System Group 7 for

filling procedure. (14) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 4 Left Insulator Movement

Ä 3.3/3.8L ENGINE 9 - 101

Page 1708 of 2438

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is se-

lected.

TURBOCHARGER

REMOVAL

The turbocharger is removed from below the vehi-

cle. Cylinder head removal for component accessibil-

ity is not required. (1) Disconnect negative battery cable. Remove Air

Cleaner assembly (Fig. 1). (2) From Above: Remove front engine mount

through bolt and rotate engine (Top) forward away

from cowl. Refer to Engine Removal in Engine,

Group 9. (3) Remove Air Cleaner Support (Fig. 1).

(4) Disconnect Heated Oxygen sensor lead wire

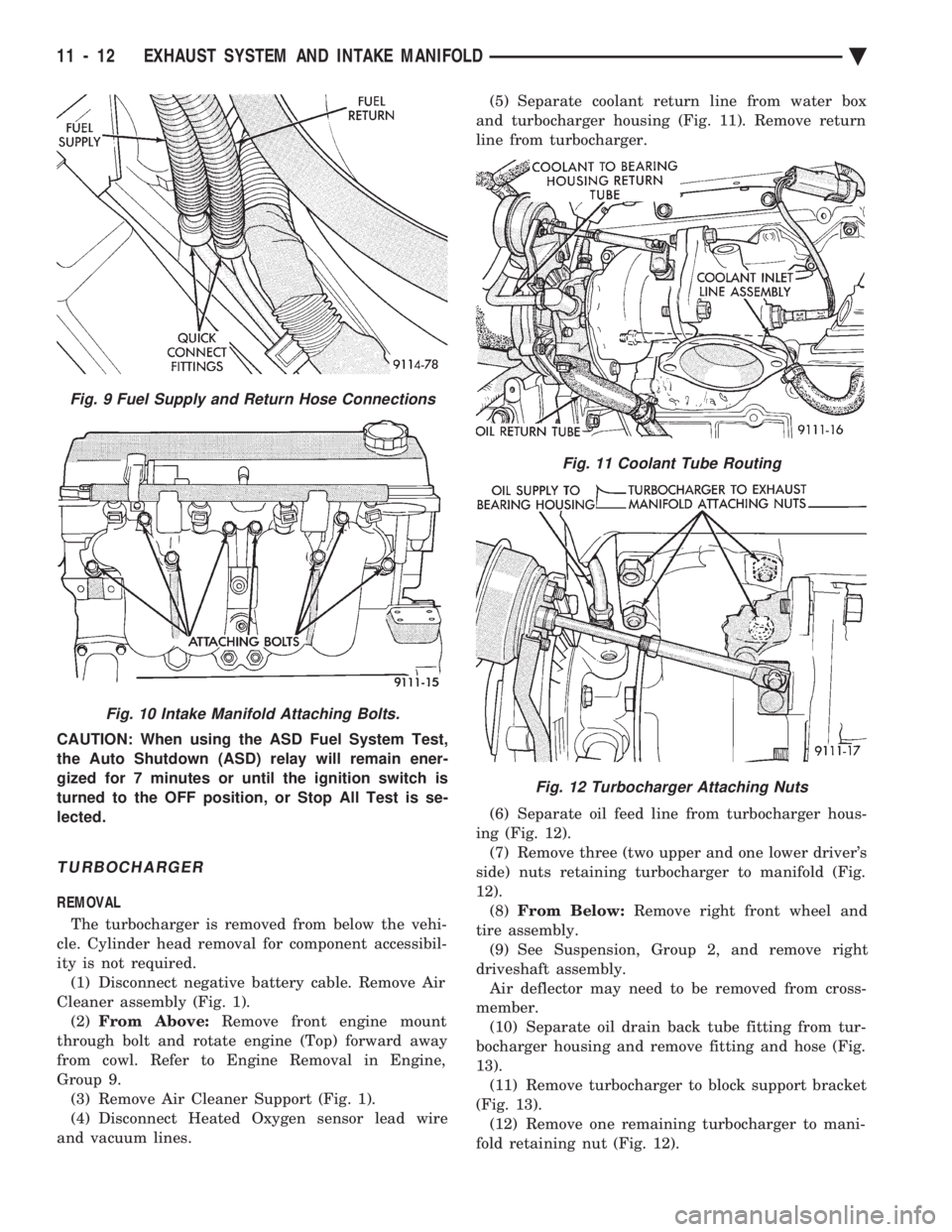

and vacuum lines. (5) Separate coolant return line from water box

and turbocharger housing (Fig. 11). Remove return

line from turbocharger.

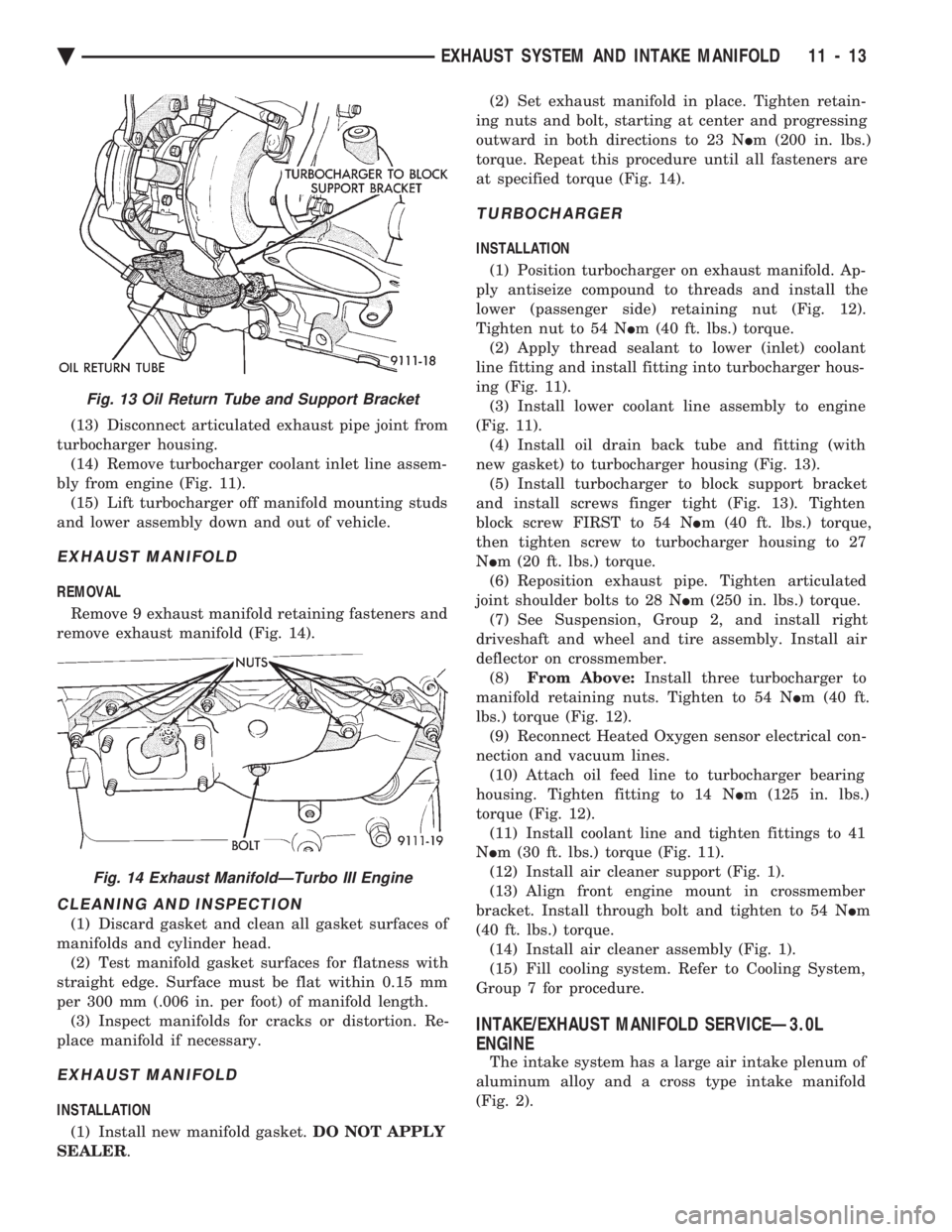

(6) Separate oil feed line from turbocharger hous-

ing (Fig. 12). (7) Remove three (two upper and one lower driver's

side) nuts retaining turbocharger to manifold (Fig.

12). (8) From Below: Remove right front wheel and

tire assembly. (9) See Suspension, Group 2, and remove right

driveshaft assembly. Air deflector may need to be removed from cross-

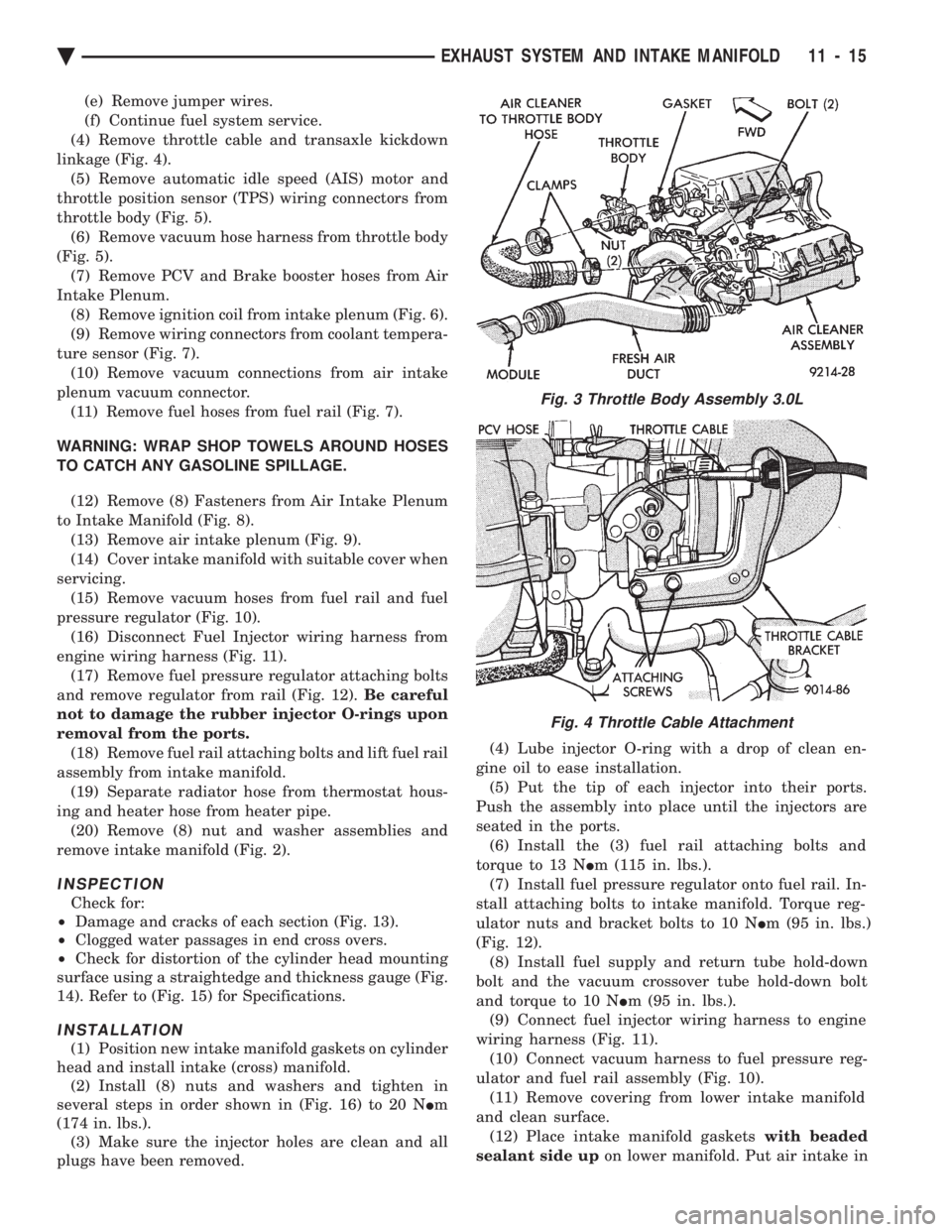

member. (10) Separate oil drain back tube fitting from tur-

bocharger housing and remove fitting and hose (Fig.

13). (11) Remove turbocharger to block support bracket

(Fig. 13). (12) Remove one remaining turbocharger to mani-

fold retaining nut (Fig. 12).

Fig. 11 Coolant Tube Routing

Fig. 12 Turbocharger Attaching Nuts

Fig. 9 Fuel Supply and Return Hose Connections

Fig. 10 Intake Manifold Attaching Bolts.

11 - 12 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1709 of 2438

(13) Disconnect articulated exhaust pipe joint from

turbocharger housing. (14) Remove turbocharger coolant inlet line assem-

bly from engine (Fig. 11). (15) Lift turbocharger off manifold mounting studs

and lower assembly down and out of vehicle.

EXHAUST MANIFOLD

REMOVAL

Remove 9 exhaust manifold retaining fasteners and

remove exhaust manifold (Fig. 14).

CLEANING AND INSPECTION

(1) Discard gasket and clean all gasket surfaces of

manifolds and cylinder head. (2) Test manifold gasket surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (.006 in. per foot) of manifold length. (3) Inspect manifolds for cracks or distortion. Re-

place manifold if necessary.

EXHAUST MANIFOLD

INSTALLATION

(1) Install new manifold gasket. DO NOT APPLY

SEALER . (2) Set exhaust manifold in place. Tighten retain-

ing nuts and bolt, starting at center and progressing

outward in both directions to 23 N Im (200 in. lbs.)

torque. Repeat this procedure until all fasteners are

at specified torque (Fig. 14).

TURBOCHARGER

INSTALLATION

(1) Position turbocharger on exhaust manifold. Ap-

ply antiseize compound to threads and install the

lower (passenger side) retaining nut (Fig. 12).

Tighten nut to 54 N Im (40 ft. lbs.) torque.

(2) Apply thread sealant to lower (inlet) coolant

line fitting and install fitting into turbocharger hous-

ing (Fig. 11). (3) Install lower coolant line assembly to engine

(Fig. 11). (4) Install oil drain back tube and fitting (with

new gasket) to turbocharger housing (Fig. 13). (5) Install turbocharger to block support bracket

and install screws finger tight (Fig. 13). Tighten

block screw FIRST to 54 N Im (40 ft. lbs.) torque,

then tighten screw to turbocharger housing to 27

N Im (20 ft. lbs.) torque.

(6) Reposition exhaust pipe. Tighten articulated

joint shoulder bolts to 28 N Im (250 in. lbs.) torque.

(7) See Suspension, Group 2, and install right

driveshaft and wheel and tire assembly. Install air

deflector on crossmember. (8) From Above: Install three turbocharger to

manifold retaining nuts. Tighten to 54 N Im (40 ft.

lbs.) torque (Fig. 12). (9) Reconnect Heated Oxygen sensor electrical con-

nection and vacuum lines. (10) Attach oil feed line to turbocharger bearing

housing. Tighten fitting to 14 N Im (125 in. lbs.)

torque (Fig. 12). (11) Install coolant line and tighten fittings to 41

N Im (30 ft. lbs.) torque (Fig. 11).

(12) Install air cleaner support (Fig. 1).

(13) Align front engine mount in crossmember

bracket. Install through bolt and tighten to 54 N Im

(40 ft. lbs.) torque. (14) Install air cleaner assembly (Fig. 1).

(15) Fill cooling system. Refer to Cooling System,

Group 7 for procedure.

INTAKE/EXHAUST MANIFOLD SERVICEÐ3.0L

ENGINE

The intake system has a large air intake plenum of

aluminum alloy and a cross type intake manifold

(Fig. 2).

Fig. 13 Oil Return Tube and Support Bracket

Fig. 14 Exhaust ManifoldÐTurbo III Engine

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 13

Page 1711 of 2438

(e) Remove jumper wires.

(f) Continue fuel system service.

(4) Remove throttle cable and transaxle kickdown

linkage (Fig. 4). (5) Remove automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors from

throttle body (Fig. 5). (6) Remove vacuum hose harness from throttle body

(Fig. 5). (7) Remove PCV and Brake booster hoses from Air

Intake Plenum. (8) Remove ignition coil from intake plenum (Fig. 6).

(9) Remove wiring connectors from coolant tempera-

ture sensor (Fig. 7). (10) Remove vacuum connections from air intake

plenum vacuum connector. (11) Remove fuel hoses from fuel rail (Fig. 7).

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE. (12) Remove (8) Fasteners from Air Intake Plenum

to Intake Manifold (Fig. 8). (13) Remove air intake plenum (Fig. 9).

(14) Cover intake manifold with suitable cover when

servicing. (15) Remove vacuum hoses from fuel rail and fuel

pressure regulator (Fig. 10). (16) Disconnect Fuel Injector wiring harness from

engine wiring harness (Fig. 11). (17) Remove fuel pressure regulator attaching bolts

and remove regulator from rail (Fig. 12). Be careful

not to damage the rubber injector O-rings upon

removal from the ports. (18) Remove fuel rail attaching bolts and lift fuel rail

assembly from intake manifold. (19) Separate radiator hose from thermostat hous-

ing and heater hose from heater pipe. (20) Remove (8) nut and washer assemblies and

remove intake manifold (Fig. 2).

INSPECTION

Check for:

² Damage and cracks of each section (Fig. 13).

² Clogged water passages in end cross overs.

² Check for distortion of the cylinder head mounting

surface using a straightedge and thickness gauge (Fig.

14). Refer to (Fig. 15) for Specifications.

INSTALLATION

(1) Position new intake manifold gaskets on cylinder

head and install intake (cross) manifold. (2) Install (8) nuts and washers and tighten in

several steps in order shown in (Fig. 16) to 20 N Im

(174 in. lbs.). (3) Make sure the injector holes are clean and all

plugs have been removed. (4) Lube injector O-ring with a drop of clean en-

gine oil to ease installation. (5) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports. (6) Install the (3) fuel rail attaching bolts and

torque to 13 N Im (115 in. lbs.).

(7) Install fuel pressure regulator onto fuel rail. In-

stall attaching bolts to intake manifold. Torque reg-

ulator nuts and bracket bolts to 10 N Im (95 in. lbs.)

(Fig. 12). (8) Install fuel supply and return tube hold-down

bolt and the vacuum crossover tube hold-down bolt

and torque to 10 N Im (95 in. lbs.).

(9) Connect fuel injector wiring harness to engine

wiring harness (Fig. 11). (10) Connect vacuum harness to fuel pressure reg-

ulator and fuel rail assembly (Fig. 10). (11) Remove covering from lower intake manifold

and clean surface. (12) Place intake manifold gaskets with beaded

sealant side up on lower manifold. Put air intake in

Fig. 3 Throttle Body Assembly 3.0L

Fig. 4 Throttle Cable Attachment

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 15

Page 1717 of 2438

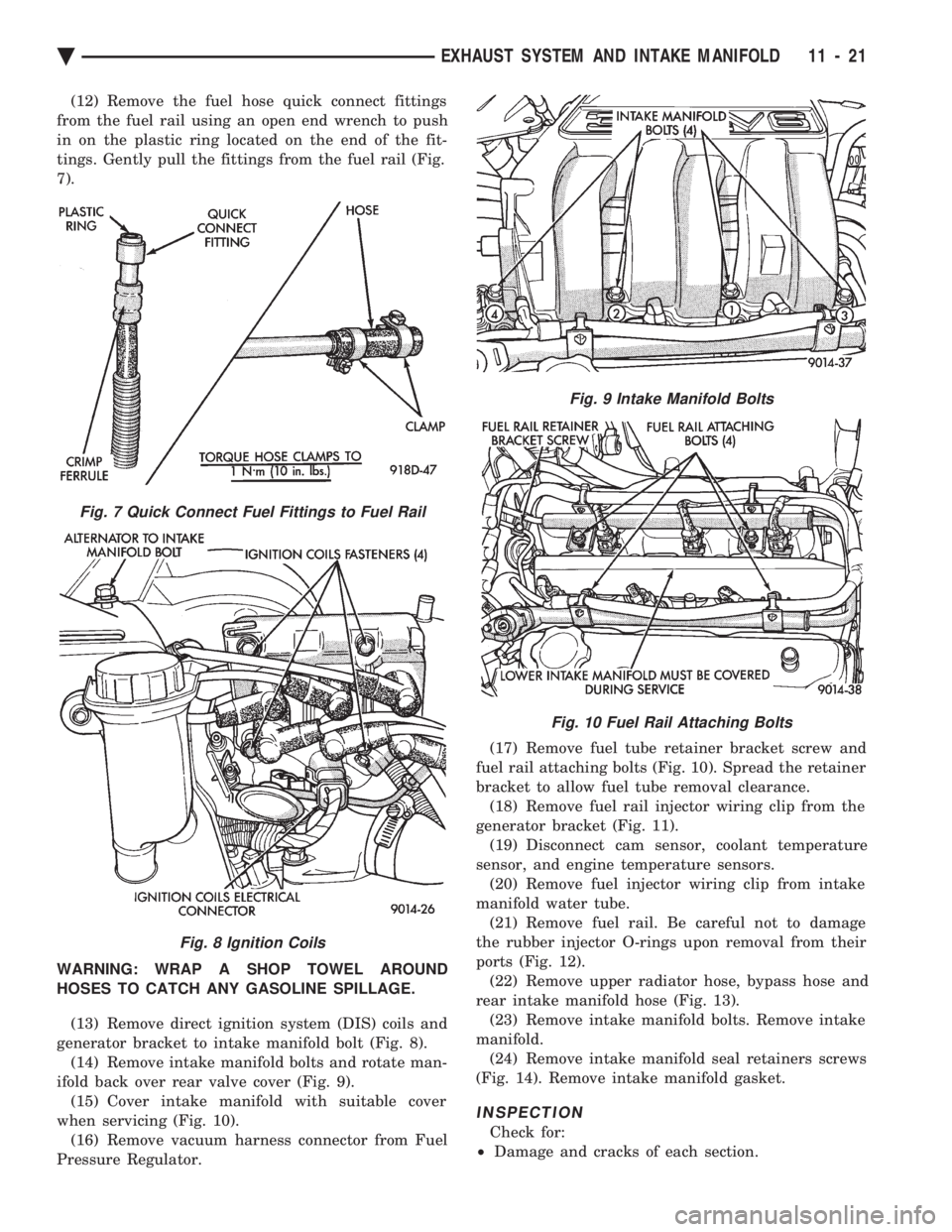

(12) Remove the fuel hose quick connect fittings

from the fuel rail using an open end wrench to push

in on the plastic ring located on the end of the fit-

tings. Gently pull the fittings from the fuel rail (Fig.

7).

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

(13) Remove direct ignition system (DIS) coils and

generator bracket to intake manifold bolt (Fig. 8). (14) Remove intake manifold bolts and rotate man-

ifold back over rear valve cover (Fig. 9). (15) Cover intake manifold with suitable cover

when servicing (Fig. 10). (16) Remove vacuum harness connector from Fuel

Pressure Regulator. (17) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 10). Spread the retainer

bracket to allow fuel tube removal clearance. (18) Remove fuel rail injector wiring clip from the

generator bracket (Fig. 11). (19) Disconnect cam sensor, coolant temperature

sensor, and engine temperature sensors. (20) Remove fuel injector wiring clip from intake

manifold water tube. (21) Remove fuel rail. Be careful not to damage

the rubber injector O-rings upon removal from their

ports (Fig. 12). (22) Remove upper radiator hose, bypass hose and

rear intake manifold hose (Fig. 13). (23) Remove intake manifold bolts. Remove intake

manifold. (24) Remove intake manifold seal retainers screws

(Fig. 14). Remove intake manifold gasket.

INSPECTION

Check for:

² Damage and cracks of each section.

Fig. 7 Quick Connect Fuel Fittings to Fuel Rail

Fig. 8 Ignition Coils

Fig. 9 Intake Manifold Bolts

Fig. 10 Fuel Rail Attaching Bolts

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 21

Page 1719 of 2438

(7) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 12). (8) Install the (4) fuel rail attaching bolts and

tighten to 22 N Im (200 in. lbs.) torque (Fig. 10).

(9) Install fuel tube retaining bracket screw and

tighten to 4 N Im (35 in. lbs.) torque (Fig. 10).

(10) Reconnect cam sensor, coolant temperature

sensor and engine temperature sensors (Fig. 11). (11) Install fuel injector harness wiring clips on

the generator bracket and intake manifold water

tube (Fig. 11). (12) Connect fuel pressure regulator vacuum line.

(13) Remove covering on lower intake manifold

and clean surface. (14) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight. (15) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. Do not torque.

(16) Tighten intake manifold bolts to 28 N Im (250

in. lbs.) torque in the sequence shown in (Fig. 9). (17) Tighten generator bracket to intake manifold

bolt to 54 N Im (40 ft. lbs.) torque (Fig. 8).

(18) Tighten the cylinder head to intake manifold

strut bolts to 54 N Im (40 ft. lbs.) torque (Fig. 5).

(19) Connect ground strap, MAP and heated oxy-

gen sensor electrical connectors (Fig. 6). (20) Connect charge temperature sensor electrical

connector (Fig. 5). (21) Connect vacuum harness to intake plenum

(Fig. 5). (22) Using a new gasket, connect the EGR tube

flange to the intake manifold and tighten to 22 N Im

(200 in. lbs.) torque. (23) Clip wiring harness into the hole in the throt-

tle cable bracket. (24) Connect the wiring connectors to the throttle

position sensor TPS and automatic idle speed AIS

motor (Fig. 4). (25) Connect vacuum harness to throttle body (Fig.

4). (26) Install the direct ignition system DIS coils.

Tighten fasteners to 12 N Im (105 in. lbs.) torque

(Fig. 8). (27) Lubricate the ends of the chassis fuel tubes

with 30 wt oil. Connect fuel supply and return hoses

to chassis fuel tube assembly. pull back on the quick

connect fitting to ensure complete insertion (Fig. 7).

(Refer to Fuel Hoses, Clamps and Quick Connect Fit-

tings in Group 14 Fuel Systems). (28) Install throttle cable (Fig. 3).

(29) Connect fuel injector wiring harness.

(30) Install air cleaner and hose assembly (Fig. 2).

(31) Connect negative battery cable. Fill Cooling

System. See Cooling System, Group 7. (32) With the DRBII Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is se-

lected.

EXHAUST MANIFOLDS

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe from

rear cowl side exhaust manifold at articulated joint. (2) Separate EGR tube from rear manifold and dis-

connect Heated Oxygen Sensor lead wire (Fig. 16). (3) Remove Generator/Power Steering Support

Strut (Fig. 16). (4) Remove bolts attaching cross-over pipe to man-

ifold (Fig. 16).

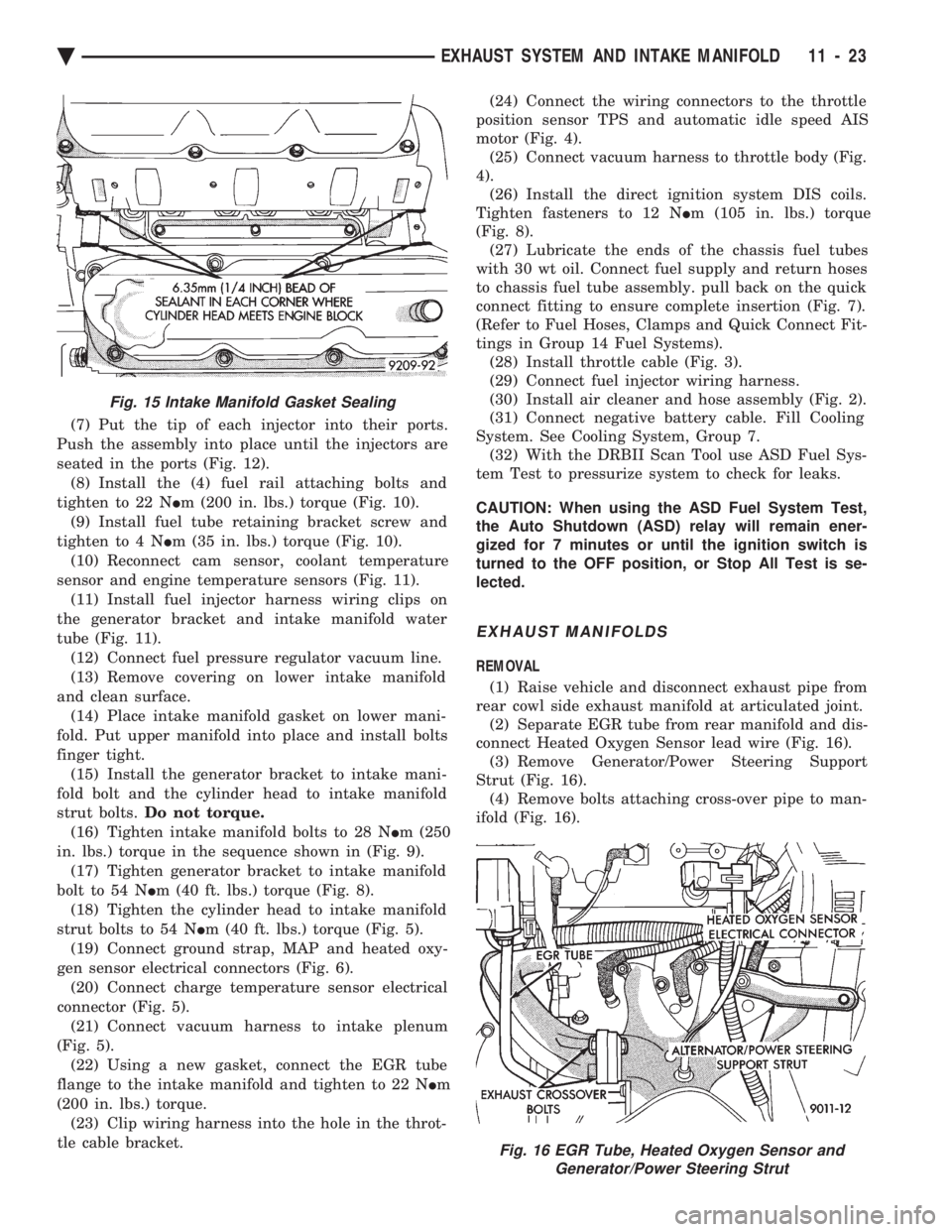

Fig. 15 Intake Manifold Gasket Sealing

Fig. 16 EGR Tube, Heated Oxygen Sensor and Generator/Power Steering Strut

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 23