key battery CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2342 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P INDEX

page page

Compressor ............................. 38

Compressor Clutch/Coil Assembly ............ 38

Compressor Shaft Seal .................... 41 Cylinder Head/Valve Plate

.................. 44

Description ............................. 38

Refrigerant System Diagnosis ............... 45

DESCRIPTION

The Sanden compressor is a 7 piston design. Sys-

tem lubrication is provided by 135 ml 615 ml (4.6 oz.

6 0.5 oz.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components:

² The pulley

² Front plate

² Field coil

The pulley and field coil are attached to the front

head of the compressor with tapered snap rings. The

hub is keyed to the compressor shaft and is retained

on the shaft with a self-locking nut. Special service

tools are required to remove and install the clutch

plate on the compressor shaft.

COMPRESSOR

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. BEFORE REMOVING A FULLY

CHARGED COMPRESSOR, REVIEW THE SAFETY

PRECAUTIONS AND WARNINGS SECTION IN THIS

GROUP. DO NOT TWIST OR KINK THE REFRIGER-

ANT LINES WHEN REMOVING A FULLY CHARGED

COMPRESSOR. SAFETY GLASSES MUST BE

WORN.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Loosen and remove drive belts (refer to group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts.

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the removal procedure.

COMPRESSOR CLUTCH/COIL ASSEMBLY

The magnetic clutch consists of a stationary elec-

tro-magnetic coil and a rotating pulley and plate as-

sembly. The electromagnetic coil is retained on the com-

pressor with a snap ring and is dimpled to maintain

its position. The pulley and plate assembly are mounted on the

compressor shaft. When the compressor is not in operation, the pul-

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

REMOVAL

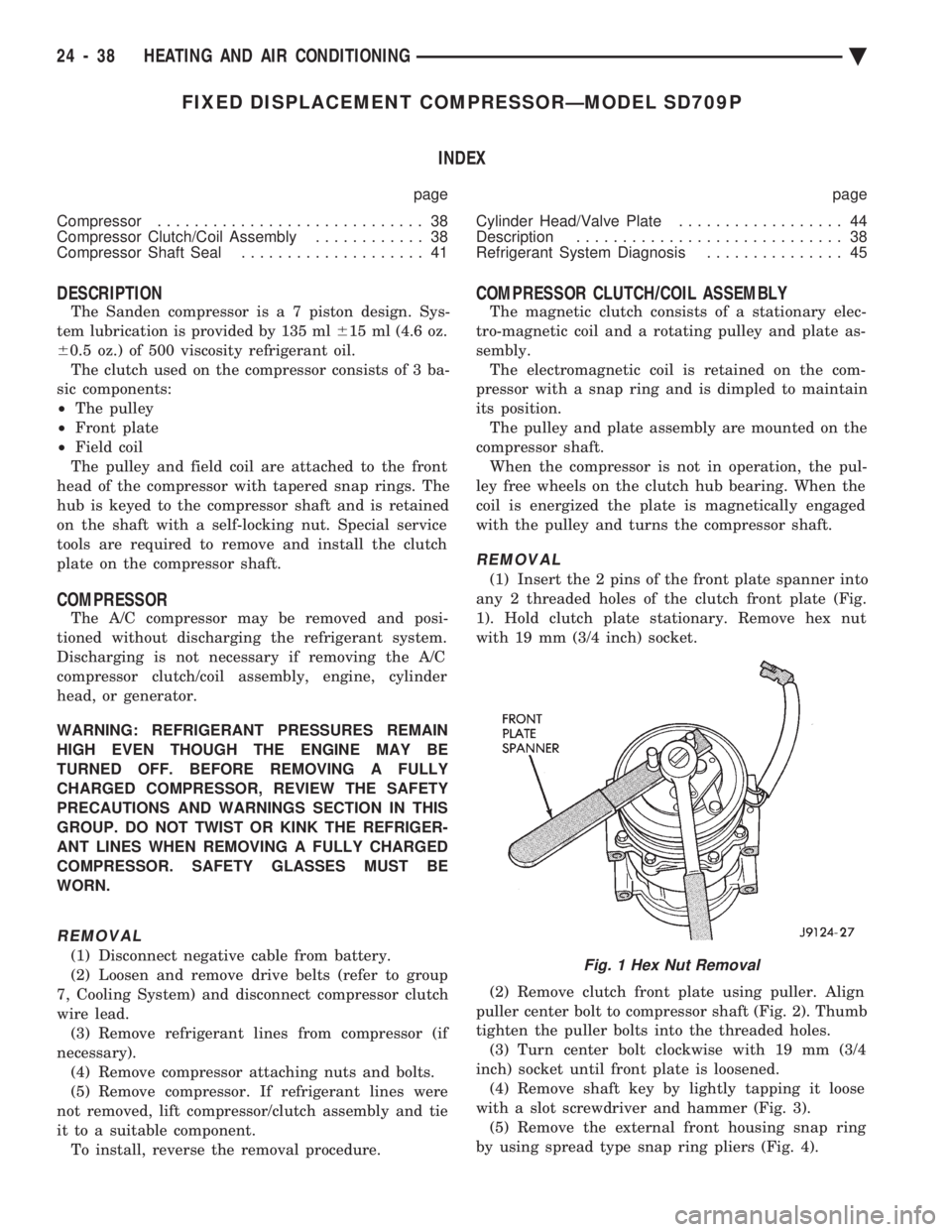

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 2). Thumb

tighten the puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened. (4) Remove shaft key by lightly tapping it loose

with a slot screwdriver and hammer (Fig. 3). (5) Remove the external front housing snap ring

by using spread type snap ring pliers (Fig. 4).

Fig. 1 Hex Nut Removal

24 - 38 HEATING AND AIR CONDITIONING Ä

Page 2378 of 2438

Involves the wiring, blend-air door actuator, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 3, 16, 17, 18, 19,

and 24 Involves the wiring, mode door actuator, or the ATC

control head.

² DIAGNOSTIC TROUBLE CODE 4

Involves the wiring, blend-air door actuator, mode

door actuator, fresh/recirc. door actuator, or the ATC

control head.

² DIAGNOSTIC TROUBLE CODE 5

Involves the wiring, fresh/recirc. door actuator, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODE 6

Involves the compressor circuit signal wiring, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODE 7

Involves the blower wiring, power module, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 8, 21, 22

Requires replacing the ATC control head.

² DIAGNOSTIC TROUBLE CODES 9, and 27

Involves the wiring, sun sensor, or the ATC control

head.

² DIAGNOSTIC TROUBLE CODES 10, and 28

Involves the wiring, water temperature sensor, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 11, and 25

Involves the wiring, ambient temperature sensor, or

the ATC control head.

² DIAGNOSTIC TROUBLE CODES 12, and 26

Involves the wiring, in-car temperature

sensor/aspirator, or the ATC control head.

DIAGNOSTIC TROUBLE CODE SERVICE PROCE-

DURES

The control keyboard will not function if pins

7, 9, 17, 19, or 20 of the 21-way wiring connector

are shorted to battery voltage. For electrical pin numbers, refer to the wiring Pin

out charts (Figs. 1, 2, 3, 4, 5, or 6).

DIAGNOSTIC TROUBLE CODE 1ÐOUTPUT FAILURE WITH ALL OUTPUTS LOW

(1) Remove pin #2 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Disconnect 21-way connector from control. With an

ohmmeter, measure the resistance between pin #2 and

pin #12 of 21-way. This should be between 2,600 and

2,800 ohms. If yes, the power module is good. Source of voltage on pin #2 is in the wiring. Repair

and retest system. (2) Remove pin #13 from 21-way connector on con-

trol and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #13.

Repair and retest system. (3) Remove pin #5 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #5.

Repair and retest system. (4) Remove pin #6 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #6.

Repair and retest system. (5) Remove pin #15 from 21-way connector on con-

trol and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #15.

Repair and retest system.

DIAGNOSTIC TROUBLE CODE 2ÐBLEND AC- TUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 2 and 3 occur

simultaneously, do both procedures. There is

typically only 1 failure. (1) Disconnect terminal #6 on the ATC control 21-

way connector and retest the system. Note that remov-

ing this terminal may generate additional Diagnostic

Trouble Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 2 reappears, replace

control. (3) If code 2 does not reappear, the problem is a

shorted blend door actuator motor or a short to ground

in circuit 33 (pin #6). (4) Remove 21-way connector and check for continu-

ity from pin #6 to chassis ground. There should not be

any continuity. If continuity is there, repair wiring and

retest. (5) Check resistance across pins #6 and #4 of the

21-way for a shorted actuator motor. Resistance should

be between 20 and 50 ohms. If not correct, replace

actuator.

DIAGNOSTIC TROUBLE CODE 3ÐMODE AC- TUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 2 and 3 occur

simultaneously, do both procedures. There is

typically only 1 failure. (1) Disconnect terminal #5 on the ATC control 21-

way connector and retest the system. Removing this

terminal may generate additional Diagnostic Trouble

Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 3 reappears, replace

control. (3) If code 3 does not reappear, the problem is a

shorted mode door actuator motor, or a short to ground

in circuit #35 (pin #5). (4) Remove 21-way and check for continuity from pin

#5 to chassis ground. There should not be any continu-

ity. If continuity is there, repair wiring and retest.

24 - 74 HEATING AND AIR CONDITIONING Ä