coolant level CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 40 of 2438

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol on the label. At the bottom NLGI symbol is the usage and qual-

ity identification letters. Wheel bearing lubricant is

identified by the letter ``G''. Chassis lubricant is iden-

tified by the letter ``L''. The letter following the us-

age letter indicates the quality of the lubricant. The

following symbols indicate the highest quality.

FLUID CAPACITIES

Fuel Tank

AP,AG and AJ ......................................53 L (14 gal.)

AA,AC and AY .....................................60 L (16 gal.)

AA-Flexible Fuel ..................................68 L (18 gal.)

Engine Oil

All.........................................................3.8 L (4.5 qts.)

Cooling System

2.2L ......................................................8.5 L (9.0 qts.)

2.5L ......................................................8.5 L (9.0 qts.)

3.0L ......................................................9.0 L (9.5 qts.)

3.3L ......................................................9.0 L (9.5 qts.)

3.8L ......................................................9.0 L (9.5 qts.)

Includes heater and coolant recovery bottle

Automatic Transaxle

Estimated Service Fill

ALL ......................................................3.8 L (4.0 qts.)

Overhaul Fill Capacity with Torque Converter

Empty

3-speed Fleet .......................................8.7 L (9.2 qts.)

3-speed .................................................8.2 L (8.8 qts.)

4-speed Electronic ................................9.4L (9.9 qts.)

Manual Transaxle

All ..........................................................9.4L (9.9 qts.)

Fill to bottom of fill hole.

Power Steering

All ...........................................................75L (1.5 pts.)

PARTS REQUIRING NO LUBRICATION

Many components on a Chrysler Corporation vehi-

cle require no periodic maintenance. Some compo-

nents are sealed and permanently lubricated. Rubber

bushings can deteriorate or limit damping ability if

lubricated. The following list of components require

no lubrication: ²

Air Pump

² Generator Bushings

² Drive Belts

² Drive Belt Idler/Tensioner Pulley

² Front Wheel Bearings

² Rubber Bushings

² Starter Bearings/Bushings

² Suspension Strut Bearings

² Throttle Control Cable

² Throttle Linkage

² Water Pump Bearings

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT JUMP START A FROZEN BATTERY, PER-

SONAL INJURY CAN RESULT. DO NOT JUMP START WHEN BATTERY INDICA-

TOR DOT IS YELLOW OR BRIGHT COLOR. DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE. DO NOT USE OPEN FLAME NEAR BATTERY.

REMOVE METALLIC JEWELRY WORN ON HANDS

OR WRISTS TO AVOID INJURY BY ACCIDENTAL

ARCHING OF BATTERY CURRENT. WHEN USING A HIGH OUTPUT BOOSTING DE-

VICE, DO NOT ALLOW BATTERY VOLTAGE TO EX-

CEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually in-

spect engine compartment for:

² Battery cable clamp condition, clean if necessary.

² Frozen battery.

² Yellow or bright color test indicator, if equipped.

² Low battery fluid level.

² Generator drive belt condition and tension.

² Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, turn off all accessories, place gear selector in

park or neutral, set park brake and operate engine

at 1200 rpm.

NLGI SYMBOL

0 - 4 LUBRICATION AND MAINTENANCE Ä

Page 46 of 2438

ENGINE COOLING SYSTEM

WARNINGS AND PRECAUTIONS

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO

NOT STORE IN OPEN OR UNMARKED CONTAIN-

ERS. WASH SKIN AND CLOTHING THOROUGHLY

AFTER COMING IN CONTACT WITH ETHYLENE

GLYCOL. KEEP OUT OF REACH OF CHILDREN. DISPOSE OF GLYCOL BASE COOLANT PROP-

ERLY, CONTACT YOUR DEALER OR GOVERNMENT

AGENCY FOR LOCATION OF COLLECTION CEN-

TER IN YOUR AREA. DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE, PER-

SONAL INJURY CAN RESULT. AVOID RADIATOR COOLING FAN WHEN ENGINE

COMPARTMENT RELATED SERVICE IS PER-

FORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Do not use straight antifreeze as engine

coolant, inadequate engine running temperatures

can result. Do not operate vehicle without proper concentra-

tion of recommended ethylene glycol coolant, high

running temperatures and cooling system corrosion

can result.

The engine cooling system will develop internal

pressure of 97 to 123 kPa (14 to 18 psi) at normal op-

erating temperature. Allow the vehicle approxi-

mately one half hour to cool off before opening the

cooling system. As an indicator of pressure, squeeze

the upper radiator hose between index finger and

thumb. If it collapses with little effort the system

would have low internal pressure and should be safe

to open to the first safety notch of the radiator cap.

Refer to Group 7, Cooling System.

COOLING SYSTEM INSPECTION

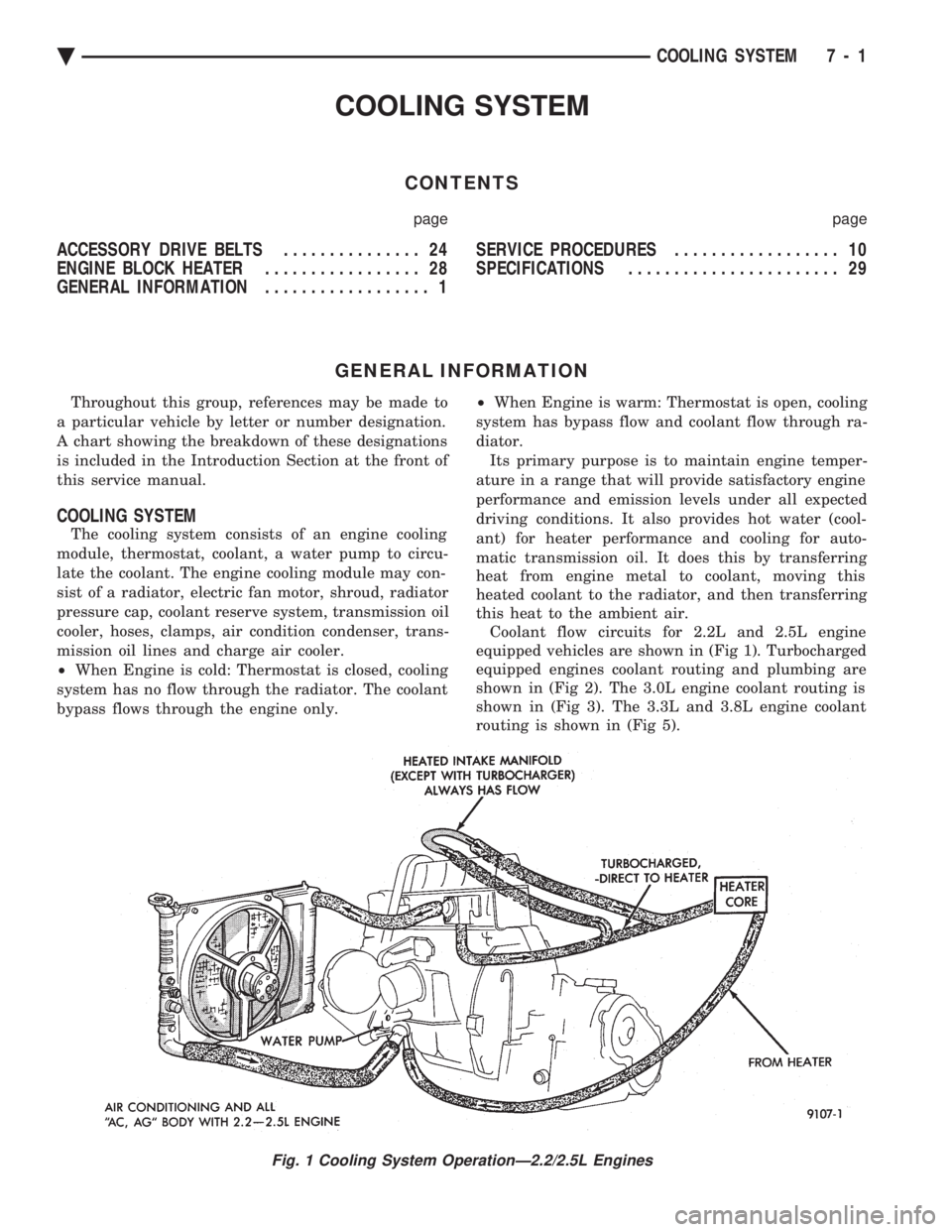

Coolant level (Fig. 5) should be inspected when

other engine compartment service is performed or

when coolant leak is suspected. Coolant recovery

tank level should read between the MIN and MAX

marks, located on the side of recovery tank, when the

engine is at normal operating temperature. Normal

coolant level maintenance does not require the re-

moval of radiator cap. Cooling system freeze protec-

tion should be tested at the onset of the winter

season or every 12 months. Service is required if

coolant is low, contaminated, rusty or freeze protec-

tion is inadequate. To properly test cooling system,

see Group 7, Cooling System.

The cooling system factory fill is a mixture of 50%

Glycol based antifreeze and 50% water. Using a suit-

able hydrometer, measure antifreeze concentration in

the radiator when the engine is cool. If the cooling

system has recently been serviced, allow coolant to

circulate for at least 20 minutes before taking hy-

drometer reading. Properly mixed coolant will pro-

tect the cooling system to -37ÉC (-35ÉF). If the freeze

protection is above -28ÉC (-20ÉF), drain enough cool-

ant from the cooling system to allow room to add an-

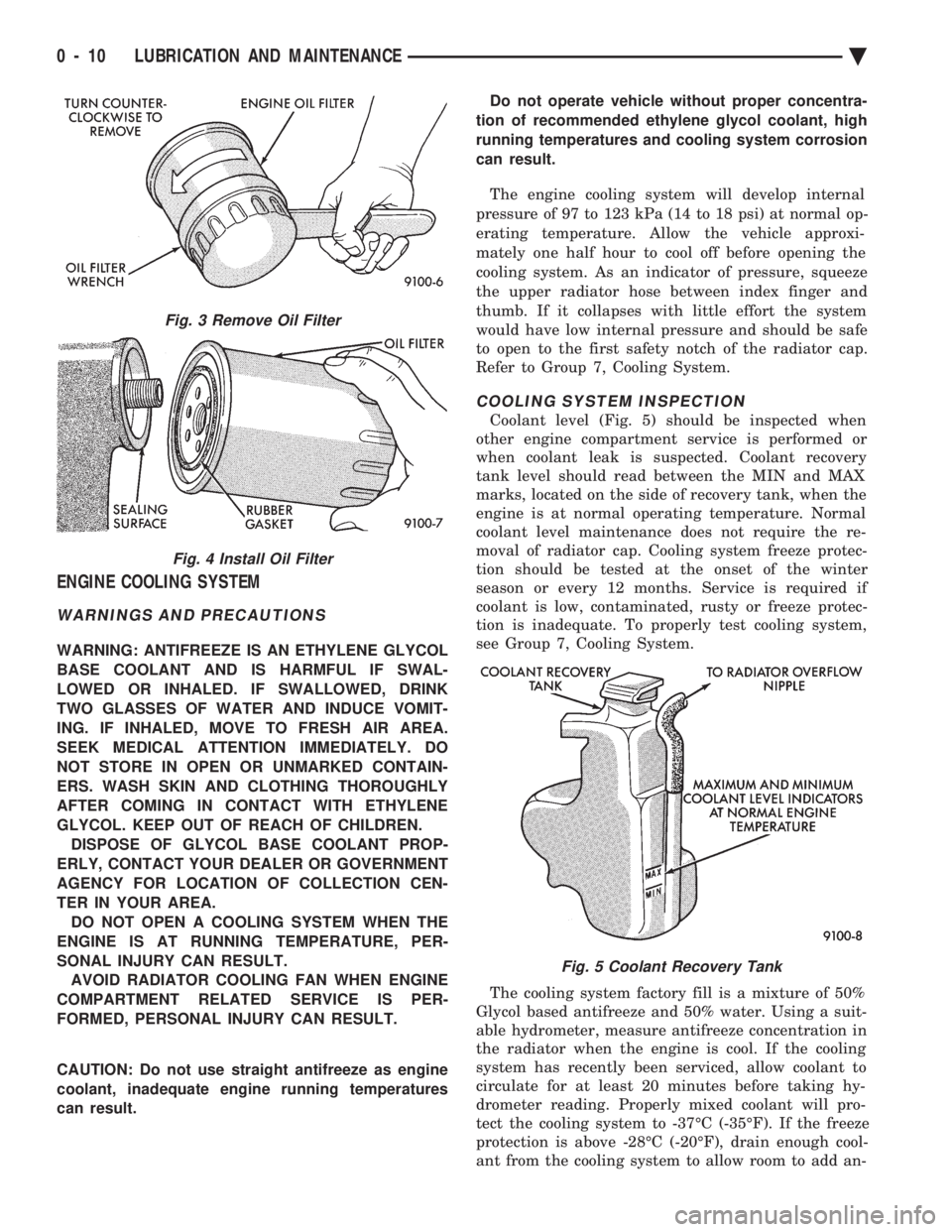

Fig. 3 Remove Oil Filter

Fig. 4 Install Oil Filter

Fig. 5 Coolant Recovery Tank

0 - 10 LUBRICATION AND MAINTENANCE Ä

Page 343 of 2438

COOLING SYSTEM

CONTENTS

page page

ACCESSORY DRIVE BELTS ............... 24

ENGINE BLOCK HEATER ................. 28

GENERAL INFORMATION .................. 1 SERVICE PROCEDURES

.................. 10

SPECIFICATIONS ....................... 29

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, a water pump to circu-

late the coolant. The engine cooling module may con-

sist of a radiator, electric fan motor, shroud, radiator

pressure cap, coolant reserve system, transmission oil

cooler, hoses, clamps, air condition condenser, trans-

mission oil lines and charge air cooler.

² When Engine is cold: Thermostat is closed, cooling

system has no flow through the radiator. The coolant

bypass flows through the engine only. ²

When Engine is warm: Thermostat is open, cooling

system has bypass flow and coolant flow through ra-

diator. Its primary purpose is to maintain engine temper-

ature in a range that will provide satisfactory engine

performance and emission levels under all expected

driving conditions. It also provides hot water (cool-

ant) for heater performance and cooling for auto-

matic transmission oil. It does this by transferring

heat from engine metal to coolant, moving this

heated coolant to the radiator, and then transferring

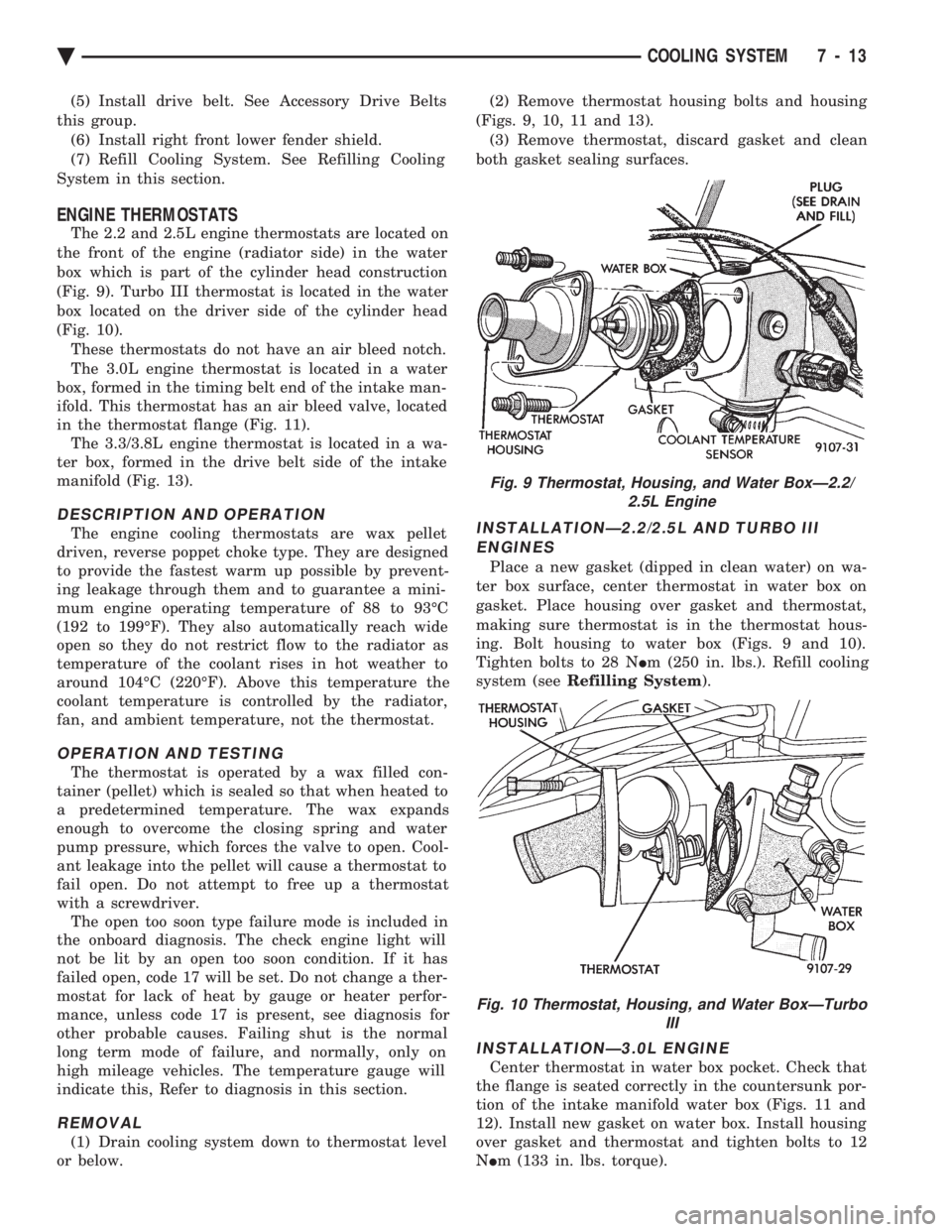

this heat to the ambient air. Coolant flow circuits for 2.2L and 2.5L engine

equipped vehicles are shown in (Fig 1). Turbocharged

equipped engines coolant routing and plumbing are

shown in (Fig 2). The 3.0L engine coolant routing is

shown in (Fig 3). The 3.3L and 3.8L engine coolant

routing is shown in (Fig 5).

Fig. 1 Cooling System OperationÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 1

Page 355 of 2438

(5) Install drive belt. See Accessory Drive Belts

this group. (6) Install right front lower fender shield.

(7) Refill Cooling System. See Refilling Cooling

System in this section.

ENGINE THERMOSTATS

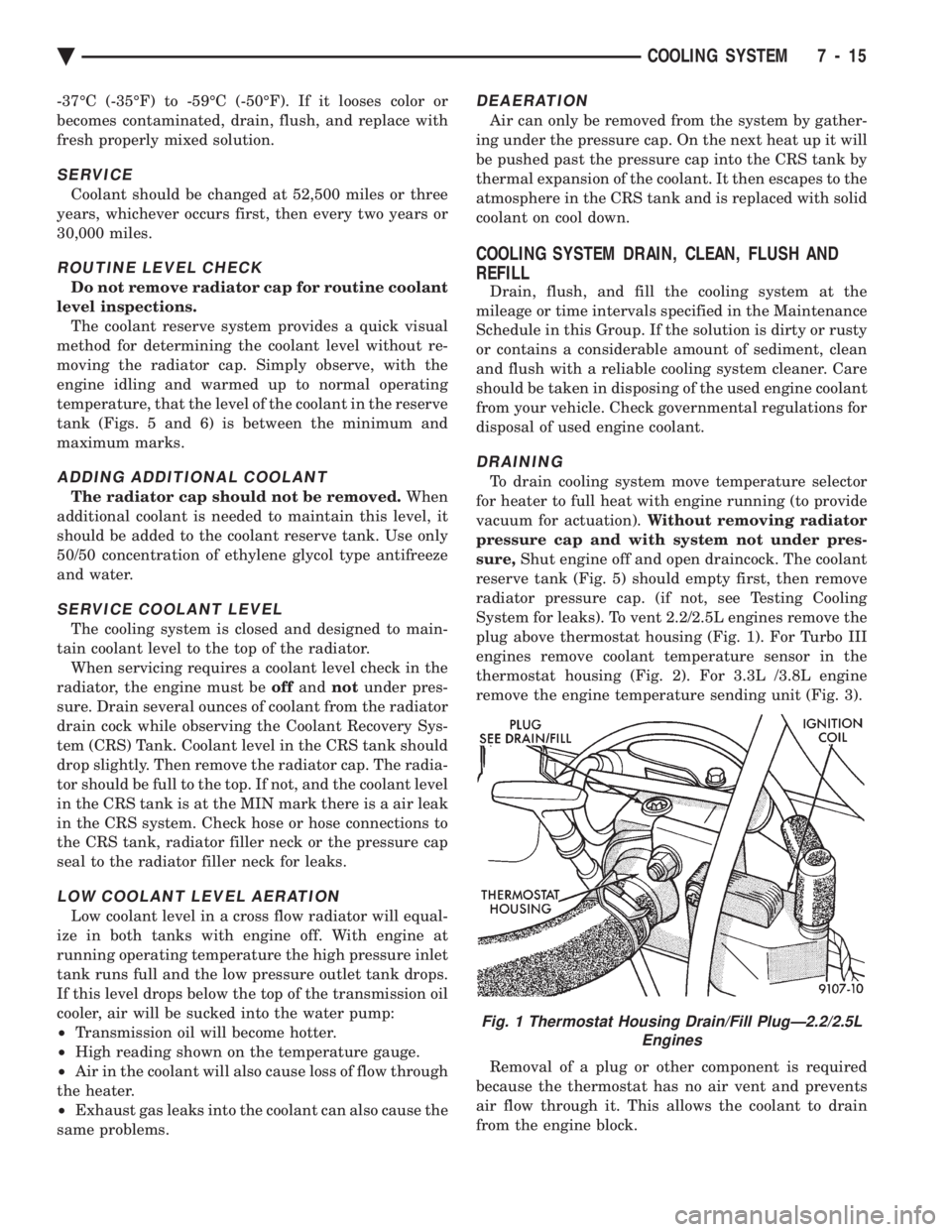

The 2.2 and 2.5L engine thermostats are located on

the front of the engine (radiator side) in the water

box which is part of the cylinder head construction

(Fig. 9). Turbo III thermostat is located in the water

box located on the driver side of the cylinder head

(Fig. 10). These thermostats do not have an air bleed notch.

The 3.0L engine thermostat is located in a water

box, formed in the timing belt end of the intake man-

ifold. This thermostat has an air bleed valve, located

in the thermostat flange (Fig. 11). The 3.3/3.8L engine thermostat is located in a wa-

ter box, formed in the drive belt side of the intake

manifold (Fig. 13).

DESCRIPTION AND OPERATION

The engine cooling thermostats are wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the radiator,

fan, and ambient temperature, not the thermostat.

OPERATION AND TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed so that when heated to

a predetermined temperature. The wax expands

enough to overcome the closing spring and water

pump pressure, which forces the valve to open. Cool-

ant leakage into the pellet will cause a thermostat to

fail open. Do not attempt to free up a thermostat

with a screwdriver. The open too soon type failure mode is included in

the onboard diagnosis. The check engine light will

not be lit by an open too soon condition. If it has

failed open, code 17 will be set. Do not change a ther-

mostat for lack of heat by gauge or heater perfor-

mance, unless code 17 is present, see diagnosis for

other probable causes. Failing shut is the normal

long term mode of failure, and normally, only on

high mileage vehicles. The temperature gauge will

indicate this, Refer to diagnosis in this section.

REMOVAL

(1) Drain cooling system down to thermostat level

or below. (2) Remove thermostat housing bolts and housing

(Figs. 9, 10, 11 and 13). (3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

INSTALLATIONÐ2.2/2.5L AND TURBO III ENGINES

Place a new gasket (dipped in clean water) on wa-

ter box surface, center thermostat in water box on

gasket. Place housing over gasket and thermostat,

making sure thermostat is in the thermostat hous-

ing. Bolt housing to water box (Figs. 9 and 10).

Tighten bolts to 28 N Im (250 in. lbs.). Refill cooling

system (see Refilling System ).

INSTALLATIONÐ3.0L ENGINE

Center thermostat in water box pocket. Check that

the flange is seated correctly in the countersunk por-

tion of the intake manifold water box (Figs. 11 and

12). Install new gasket on water box. Install housing

over gasket and thermostat and tighten bolts to 12

N Im (133 in. lbs. torque).

Fig. 9 Thermostat, Housing, and Water BoxÐ2.2/

2.5L Engine

Fig. 10 Thermostat, Housing, and Water BoxÐTurbo III

Ä COOLING SYSTEM 7 - 13

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

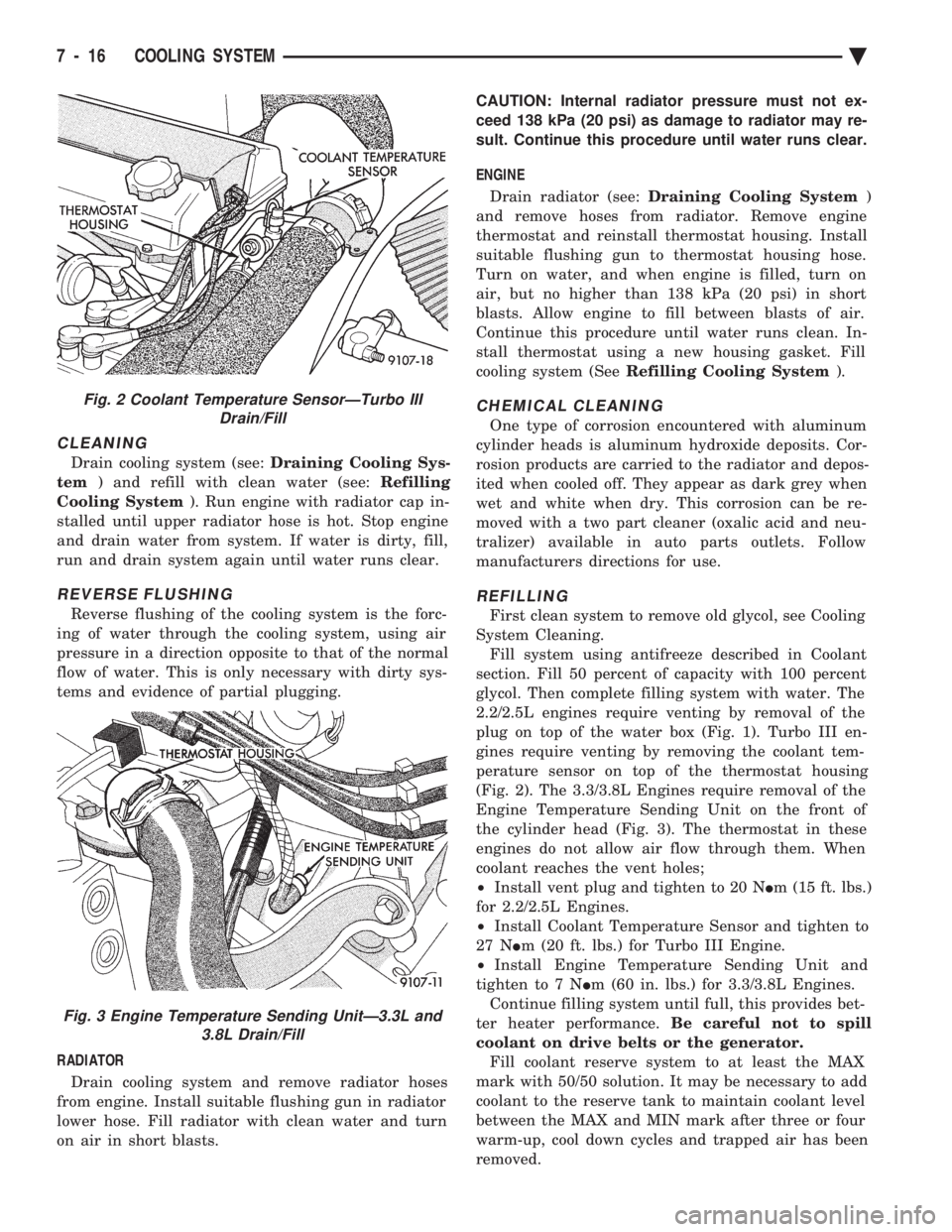

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

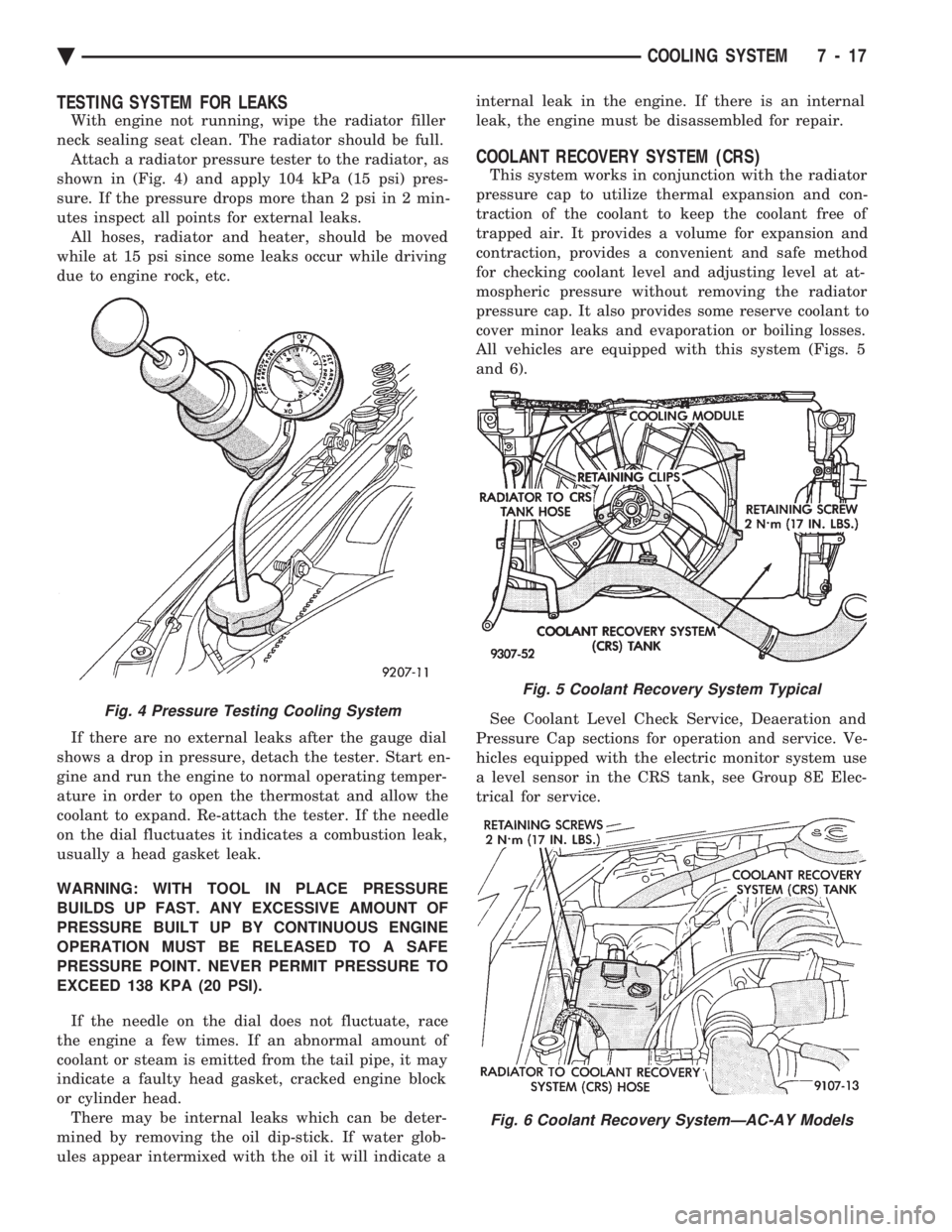

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15

Page 358 of 2438

CLEANING

Drain cooling system (see: Draining Cooling Sys-

tem ) and refill with clean water (see: Refilling

Cooling System ). Run engine with radiator cap in-

stalled until upper radiator hose is hot. Stop engine

and drain water from system. If water is dirty, fill,

run and drain system again until water runs clear.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system, using air

pressure in a direction opposite to that of the normal

flow of water. This is only necessary with dirty sys-

tems and evidence of partial plugging.

RADIATOR Drain cooling system and remove radiator hoses

from engine. Install suitable flushing gun in radiator

lower hose. Fill radiator with clean water and turn

on air in short blasts. CAUTION: Internal radiator pressure must not ex-

ceed 138 kPa (20 psi) as damage to radiator may re-

sult. Continue this procedure until water runs clear.

ENGINE

Drain radiator (see: Draining Cooling System )

and remove hoses from radiator. Remove engine

thermostat and reinstall thermostat housing. Install

suitable flushing gun to thermostat housing hose.

Turn on water, and when engine is filled, turn on

air, but no higher than 138 kPa (20 psi) in short

blasts. Allow engine to fill between blasts of air.

Continue this procedure until water runs clean. In-

stall thermostat using a new housing gasket. Fill

cooling system (See Refilling Cooling System ).

CHEMICAL CLEANING

One type of corrosion encountered with aluminum

cylinder heads is aluminum hydroxide deposits. Cor-

rosion products are carried to the radiator and depos-

ited when cooled off. They appear as dark grey when

wet and white when dry. This corrosion can be re-

moved with a two part cleaner (oxalic acid and neu-

tralizer) available in auto parts outlets. Follow

manufacturers directions for use.

REFILLING

First clean system to remove old glycol, see Cooling

System Cleaning. Fill system using antifreeze described in Coolant

section. Fill 50 percent of capacity with 100 percent

glycol. Then complete filling system with water. The

2.2/2.5L engines require venting by removal of the

plug on top of the water box (Fig. 1). Turbo III en-

gines require venting by removing the coolant tem-

perature sensor on top of the thermostat housing

(Fig. 2). The 3.3/3.8L Engines require removal of the

Engine Temperature Sending Unit on the front of

the cylinder head (Fig. 3). The thermostat in these

engines do not allow air flow through them. When

coolant reaches the vent holes;

² Install vent plug and tighten to 20 N Im (15 ft. lbs.)

for 2.2/2.5L Engines.

² Install Coolant Temperature Sensor and tighten to

27 N Im (20 ft. lbs.) for Turbo III Engine.

² Install Engine Temperature Sending Unit and

tighten to 7 N Im (60 in. lbs.) for 3.3/3.8L Engines.

Continue filling system until full, this provides bet-

ter heater performance. Be careful not to spill

coolant on drive belts or the generator. Fill coolant reserve system to at least the MAX

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank to maintain coolant level

between the MAX and MIN mark after three or four

warm-up, cool down cycles and trapped air has been

removed.

Fig. 2 Coolant Temperature SensorÐTurbo III Drain/Fill

Fig. 3 Engine Temperature Sending UnitÐ3.3L and 3.8L Drain/Fill

7 - 16 COOLING SYSTEM Ä

Page 359 of 2438

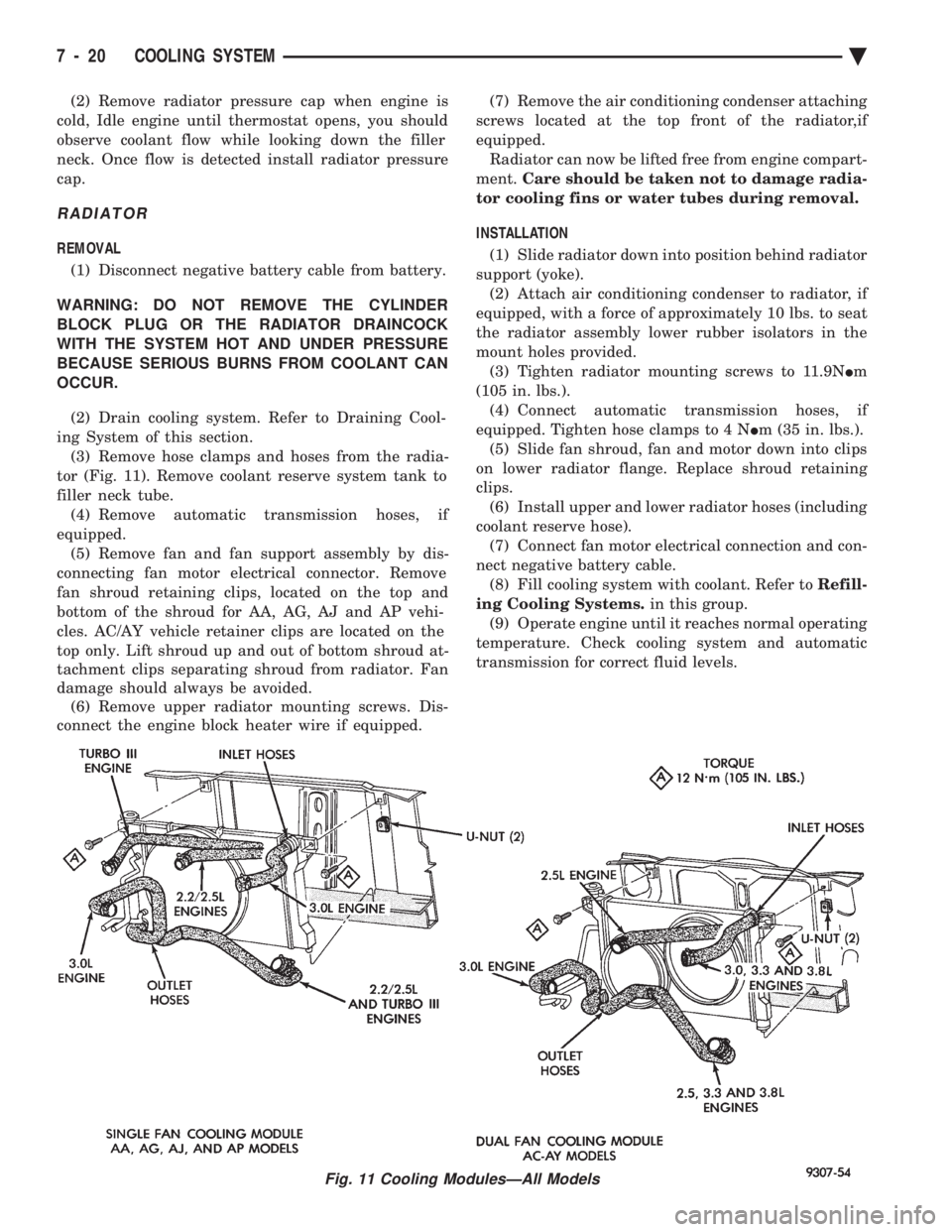

TESTING SYSTEM FOR LEAKS

With engine not running, wipe the radiator filler

neck sealing seat clean. The radiator should be full. Attach a radiator pressure tester to the radiator, as

shown in (Fig. 4) and apply 104 kPa (15 psi) pres-

sure. If the pressure drops more than 2 psi in 2 min-

utes inspect all points for external leaks. All hoses, radiator and heater, should be moved

while at 15 psi since some leaks occur while driving

due to engine rock, etc.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start en-

gine and run the engine to normal operating temper-

ature in order to open the thermostat and allow the

coolant to expand. Re-attach the tester. If the needle

on the dial fluctuates it indicates a combustion leak,

usually a head gasket leak.

WARNING: WITH TOOL IN PLACE PRESSURE

BUILDS UP FAST. ANY EXCESSIVE AMOUNT OF

PRESSURE BUILT UP BY CONTINUOUS ENGINE

OPERATION MUST BE RELEASED TO A SAFE

PRESSURE POINT. NEVER PERMIT PRESSURE TO

EXCEED 138 KPA (20 PSI).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block

or cylinder head. There may be internal leaks which can be deter-

mined by removing the oil dip-stick. If water glob-

ules appear intermixed with the oil it will indicate a internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

COOLANT RECOVERY SYSTEM (CRS)

This system works in conjunction with the radiator

pressure cap to utilize thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. It provides a volume for expansion and

contraction, provides a convenient and safe method

for checking coolant level and adjusting level at at-

mospheric pressure without removing the radiator

pressure cap. It also provides some reserve coolant to

cover minor leaks and evaporation or boiling losses.

All vehicles are equipped with this system (Figs. 5

and 6).

See Coolant Level Check Service, Deaeration and

Pressure Cap sections for operation and service. Ve-

hicles equipped with the electric monitor system use

a level sensor in the CRS tank, see Group 8E Elec-

trical for service.

Fig. 4 Pressure Testing Cooling System

Fig. 5 Coolant Recovery System Typical

Fig. 6 Coolant Recovery SystemÐAC-AY Models

Ä COOLING SYSTEM 7 - 17

Page 362 of 2438

(2) Remove radiator pressure cap when engine is

cold, Idle engine until thermostat opens, you should

observe coolant flow while looking down the filler

neck. Once flow is detected install radiator pressure

cap.

RADIATOR

REMOVAL

(1) Disconnect negative battery cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section. (3) Remove hose clamps and hoses from the radia-

tor (Fig. 11). Remove coolant reserve system tank to

filler neck tube. (4) Remove automatic transmission hoses, if

equipped. (5) Remove fan and fan support assembly by dis-

connecting fan motor electrical connector. Remove

fan shroud retaining clips, located on the top and

bottom of the shroud for AA, AG, AJ and AP vehi-

cles. AC/AY vehicle retainer clips are located on the

top only. Lift shroud up and out of bottom shroud at-

tachment clips separating shroud from radiator. Fan

damage should always be avoided. (6) Remove upper radiator mounting screws. Dis-

connect the engine block heater wire if equipped. (7) Remove the air conditioning condenser attaching

screws located at the top front of the radiator,if

equipped. Radiator can now be lifted free from engine compart-

ment. Care should be taken not to damage radia-

tor cooling fins or water tubes during removal.

INSTALLATION

(1) Slide radiator down into position behind radiator

support (yoke). (2) Attach air conditioning condenser to radiator, if

equipped, with a force of approximately 10 lbs. to seat

the radiator assembly lower rubber isolators in the

mount holes provided. (3) Tighten radiator mounting screws to 11.9N Im

(105 in. lbs.). (4) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 4 N Im (35 in. lbs.).

(5) Slide fan shroud, fan and motor down into clips

on lower radiator flange. Replace shroud retaining

clips. (6) Install upper and lower radiator hoses (including

coolant reserve hose). (7) Connect fan motor electrical connection and con-

nect negative battery cable. (8) Fill cooling system with coolant. Refer to Refill-

ing Cooling Systems. in this group.

(9) Operate engine until it reaches normal operating

temperature. Check cooling system and automatic

transmission for correct fluid levels.

Fig. 11 Cooling ModulesÐAll Models

7 - 20 COOLING SYSTEM Ä

Page 370 of 2438

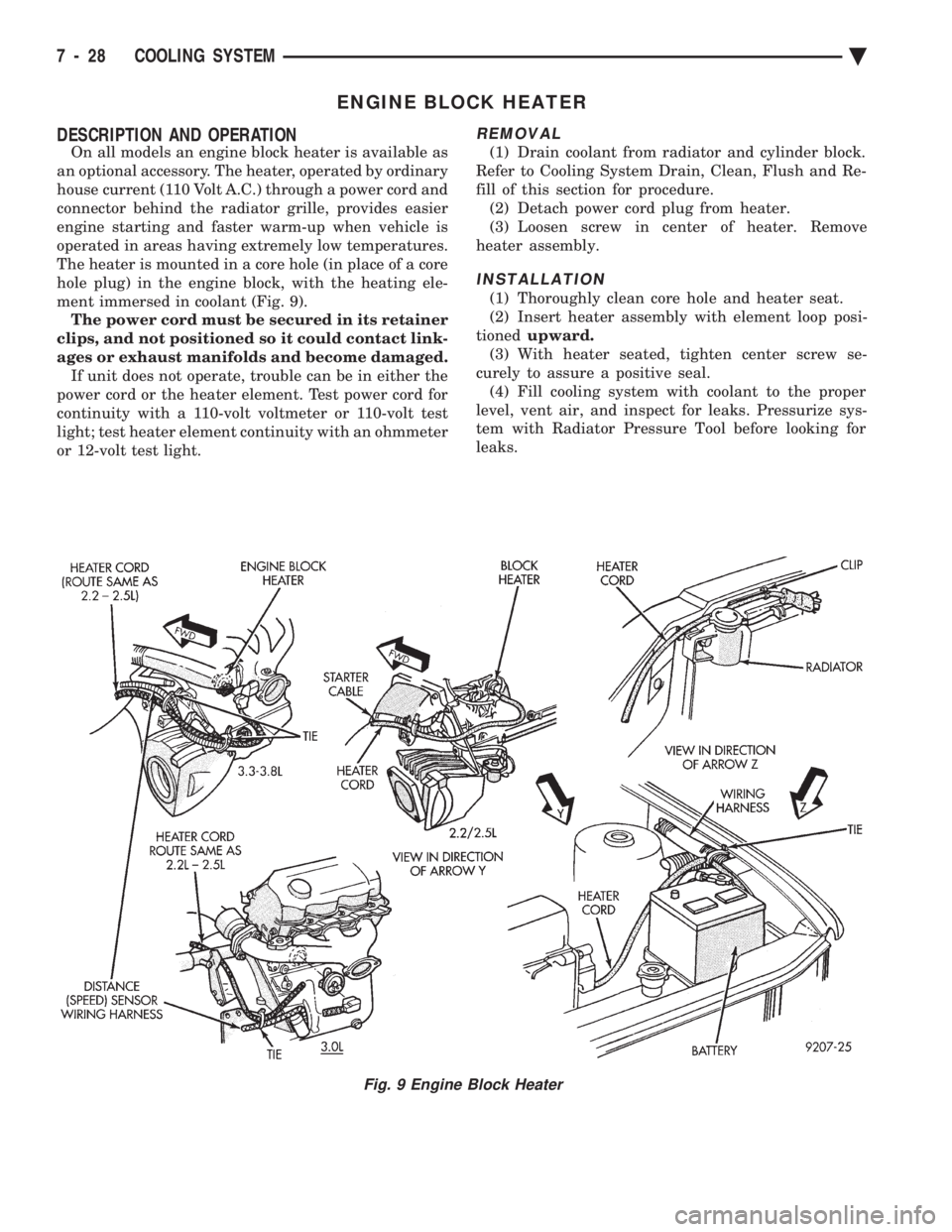

ENGINE BLOCK HEATER

DESCRIPTION AND OPERATION

On all models an engine block heater is available as

an optional accessory. The heater, operated by ordinary

house current (110 Volt A.C.) through a power cord and

connector behind the radiator grille, provides easier

engine starting and faster warm-up when vehicle is

operated in areas having extremely low temperatures.

The heater is mounted in a core hole (in place of a core

hole plug) in the engine block, with the heating ele-

ment immersed in coolant (Fig. 9). The power cord must be secured in its retainer

clips, and not positioned so it could contact link-

ages or exhaust manifolds and become damaged. If unit does not operate, trouble can be in either the

power cord or the heater element. Test power cord for

continuity with a 110-volt voltmeter or 110-volt test

light; test heater element continuity with an ohmmeter

or 12-volt test light.

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Drain, Clean, Flush and Re-

fill of this section for procedure. (2) Detach power cord plug from heater.

(3) Loosen screw in center of heater. Remove

heater assembly.

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tioned upward.

(3) With heater seated, tighten center screw se-

curely to assure a positive seal. (4) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks. Pressurize sys-

tem with Radiator Pressure Tool before looking for

leaks.

Fig. 9 Engine Block Heater

7 - 28 COOLING SYSTEM Ä

Page 423 of 2438

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

²

Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since last

reset. The display will be updated every 16 seconds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds.

² To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message.

The EVIC display may be turned off by pressing the

TIME and SET buttons at the same time. Pressing the

buttons a second time will restore the display.

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC overhead console via the

CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

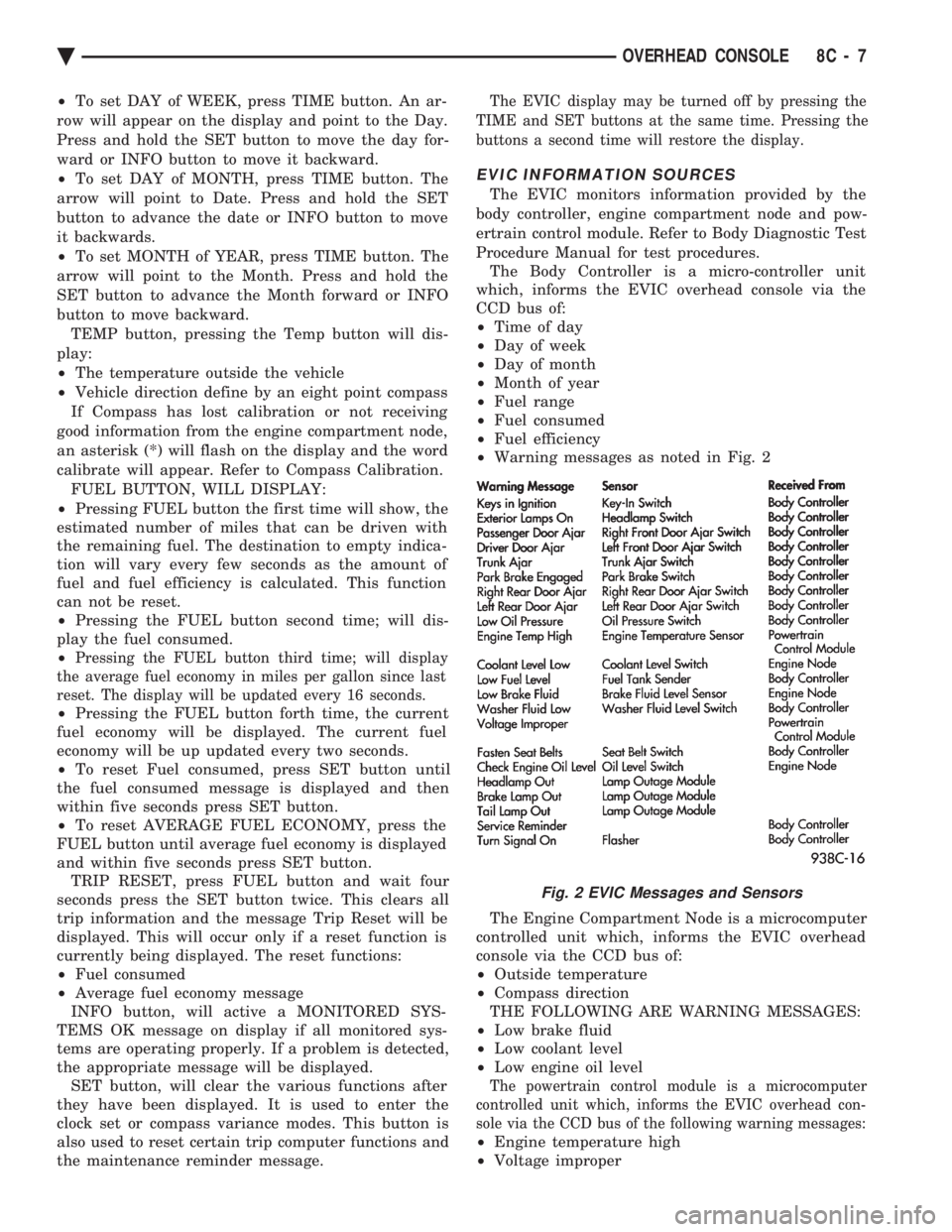

² Warning messages as noted in Fig. 2

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC overhead

console via the CCD bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC overhead con-

sole via the CCD bus of the following warning messages:

² Engine temperature high

² Voltage improper

Fig. 2 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 7