ignition CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2 of 2438

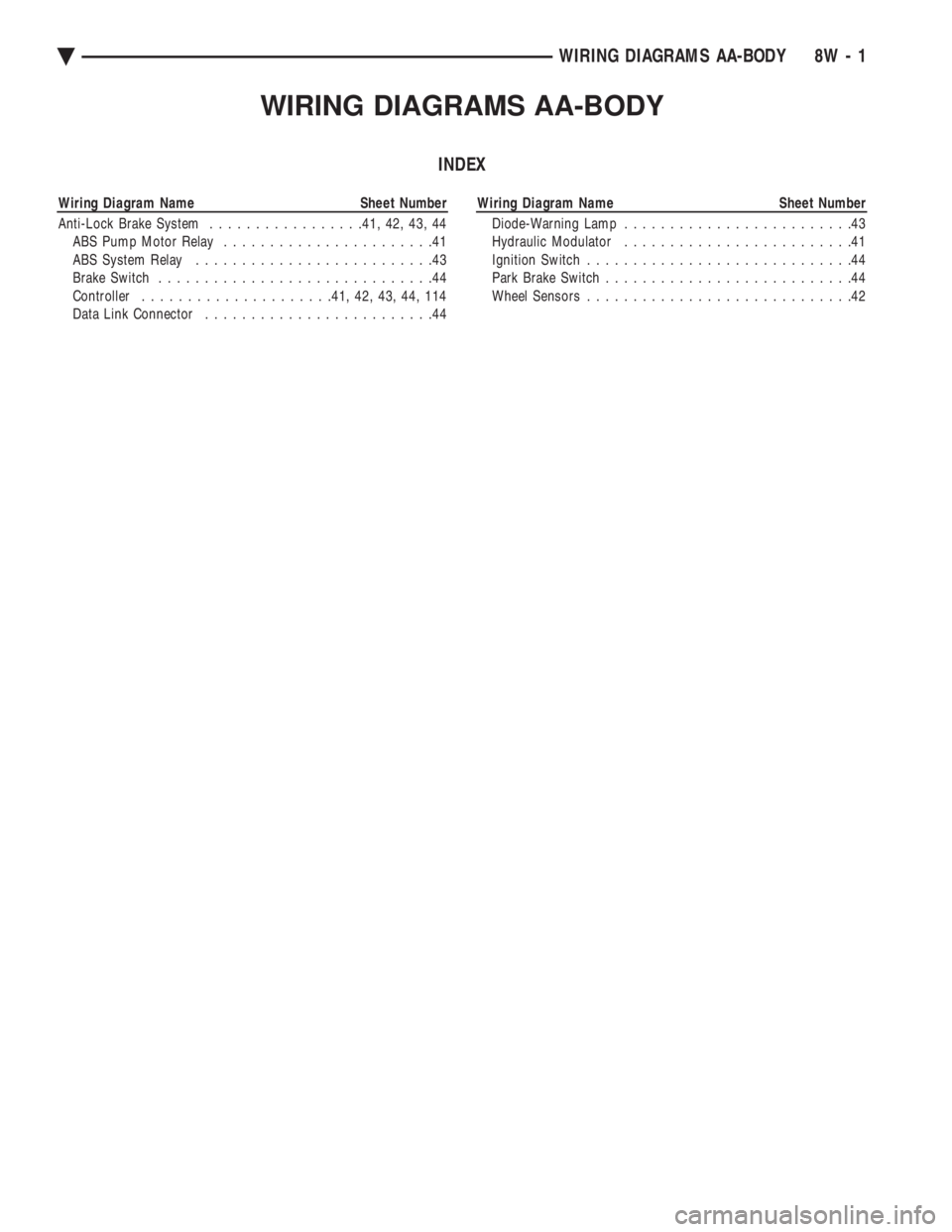

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram Name Sheet Number

Anti-Lock Brake System.................41, 42, 43, 44

ABS Pump Motor Relay.......................41

ABS System Relay..........................43

Brake Switch..............................44

Controller.....................41, 42, 43, 44, 114

Data Link Connector.........................44Wiring Diagram Name Sheet Number

Diode-Warning Lamp.........................43

Hydraulic Modulator.........................41

Ignition Switch.............................44

Park Brake Switch...........................44

Wheel Sensors.............................42

ÄWIRING DIAGRAMS AA-BODY 8W - 1

Page 22 of 2438

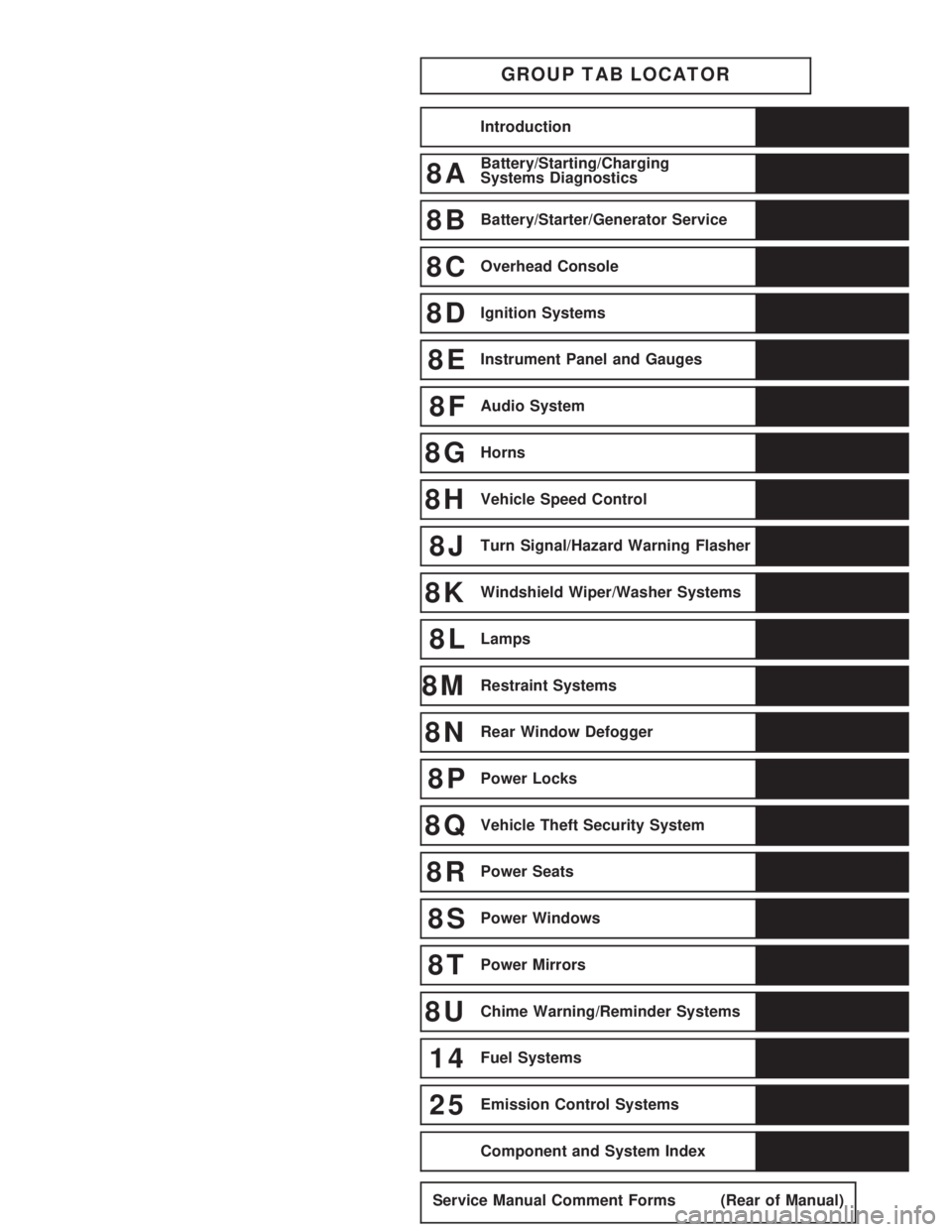

GROUP TAB LOCATOR

Introduction

8ABattery/Starting/Charging

Systems Diagnostics

8BBattery/Starter/Generator Service

8COverhead Console

8DIgnition Systems

8EInstrument Panel and Gauges

8FAudio System

8GHorns

8HVehicle Speed Control

8JTurn Signal/Hazard Warning Flasher

8KWindshield Wiper/Washer Systems

8LLamps

8MRestraint Systems

8NRear Window Defogger

8PPower Locks

8QVehicle Theft Security System

8RPower Seats

8SPower Windows

8TPower Mirrors

8UChime Warning/Reminder Systems

14Fuel Systems

25Emission Control Systems

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 31 of 2438

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

BODY ................................... 23-1

AA-VEHICLE BODY COMPONENT SERVICE .......23-11

AC-VEHICLE BODY COMPONENT SERVICE .......23-37

AG-VEHICLE BODY COMPONENT SERVICE .......23-52

AJ/27-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE ............................ 23-86

AJ-VEHICLE BODY COMPONENT SERVICE .......23-71

AP-VEHICLE BODY COMPONENT SERVICE .......23-97

AY-VEHICLE BODY COMPONENT SERVICE .......23-133

BODY DIAGNOSTIC PROCEDURES .............23-2

GENERAL SERVICE INFORMATION .............23-1

PAINT ................................. 23-4

POWER SUNROOF ........................ 23-6

WINDSHIELD ............................ 23-9

BRAKES ..................................5-1

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ......................... 5-72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY .................... 5-113

BRAKE DISC (ROTOR) ...................... 5-53

BRAKE SUPPORT ASSEMBLY .................5-25

FRONT DISC BRAKES ...................... 5-31

GENERAL INFORMATION .....................5-1

HYDRAULIC SYSTEM CONTROL VALVES .........5-26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER .....5-35

KELSEY HAYES DOUBLE PIN NON-FAMILY CALIPER ............................. 5-38

MASTER CYLINDER ....................... 5-66

PARKING BRAKES ........................ 5-57

POWER BRAKES ......................... 5-68

REAR DISC BRAKES ....................... 5-45

REAR WHEEL DRUM BRAKES ................5-18

SERVICE ADJUSTMENTS .....................5-4

WHEEL BEARINGS ........................ 5-70

WHEEL CYLINDERS ....................... 5-23

COOLING SYSTEM ...........................7-1

ACCESSORY DRIVE BELTS ................... 7-24

ENGINE BLOCK HEATER .................... 7-28

GENERAL INFORMATION .....................7-1

SERVICE PROCEDURES ..................... 7-10

SPECIFICATIONS ......................... 7-29

ENGINE ..................................9-1

2.2/2.5L ENGINES .........................9-8

3.0L ENGINE ............................ 9-66

3.3/3.8L ENGINE ......................... 9-98

STANDARD SERVICE PROCEDURES .............9-1

EXHAUST SYSTEM AND INTAKE MANIFOLD .........11-1

GENERAL INFORMATION .................... 11-1

SERVICE PROCEDURES ..................... 11-4

TORQUE SPECIFICATION ................... 11-25

FRAME AND BUMPERS ....................... 13-1

BUMPER AND FASCIA ...................... 13-1

FRAME ................................ 13-9

HEATING AND AIR CONDITIONING ...............24-1

AUTOMATIC TEMPERATURE CONTROL (ATC) .....24-66 COMPONENT SERVICE PROCEDURES

..........24-47

FIXED DISPLACEMENT COMPRESSORÐMODEL 10PA17............................. 24-24

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P ............................. 24-38

FIXED DISPLACEMENT COMPRESSORÐMODEL TR105 .............................. 24-32

GENERAL INFORMATION .................... 24-1

HEATER AND A/C PERFORMANCE TESTS .........24-6

REFRIGERANT SERVICE PROCEDURES ..........24-8

VACUUM CONTROL SYSTEM DIAGNOSIS .........24-4

VARIABLE DISPLACEMENT COMPRESSORÐMODEL 6C17 ............................... 24-13

INTRODUCTION .......................... Intro.-1

LUBRICATION AND MAINTENANCE ................0-1

CHASSIS AND BODY ....................... 0-19

DRIVETRAIN ............................ 0-16

ENGINE ................................0-8

GENERAL INFORMATION .....................0-1

MANUAL TRANSAXLE CLUTCH ...................6-1

STEERING ................................ 19-1

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 19-28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 19-36

GENERAL INFORMATION .................... 19-1

POWER STEERING GEAR ................... 19-25

POWER STEERING PUMPS ..................19-1

SPECIFICATIONS AND TIGHTENING REFERENCE . . . 19-42

SUSPENSION AND DRIVESHAFTS .................2-1

AUTOMATIC AIR LOAD LEVELING SYSTEM ........2-59

AUTOMATIC AIR SUSPENSION ................2-73

DRIVESHAFTS ........................... 2-25

FRONT SUSPENSION .......................2-2

FRONT SUSPENSION SERVICE PROCEDURES .......2-5

GENERAL INFORMATION .....................2-1

REAR (STUB) AXLE ALIGNMENT ALL MODELS .....2-89

REAR SUSPENSION ....................... 2-50

SPECIFICATIONS ......................... 2-91

TRANSAXLE .............................. 21-85

41TE FOUR SPEED AUTOMATIC TRANSAXLE ......21-85

41TE FOUR SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-170

41TE ON-BOARD DIAGNOSTICS .............21-145

A-523, A-543, and A-568 MANUAL TRANSAXLE ....21-1

SPECIFICATIONS ........................ 21-183

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE .......................... 21-35

THREE SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-162

WHEELSÐTIRES ........................... 22-1

SPECIFICATIONS ......................... 22-8

TIRE SERVICE PROCEDURES .................22-1

WHEELS SERVICE PROCEDURES ..............22-6

Page 33 of 2438

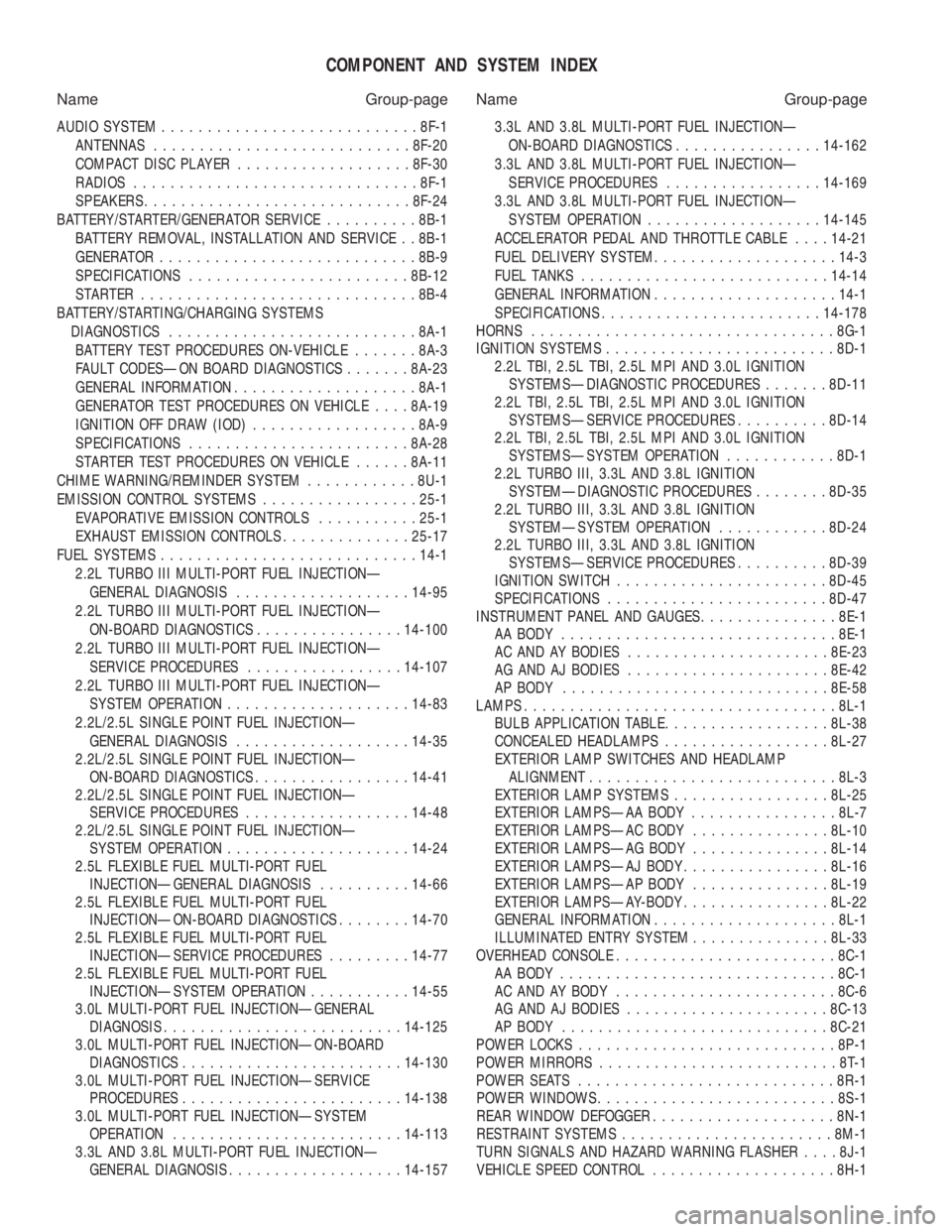

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

AUDIO SYSTEM ............................ 8F-1

ANTENNAS ............................ 8F-20

COMPACT DISC PLAYER ................... 8F-30

RADIOS ............................... 8F-1

SPEAKERS ............................. 8F-24

BATTERY/STARTER/GENERATOR SERVICE ..........8B-1

BATTERY REMOVAL, INSTALLATION AND SERVICE . . 8B-1

GENERATOR ............................ 8B-9

SPECIFICATIONS ........................ 8B-12

STARTER .............................. 8B-4

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS ........................... 8A-1

BATTERY TEST PROCEDURES ON-VEHICLE .......8A-3

FAULT CODESÐON BOARD DIAGNOSTICS .......8A-23

GENERAL INFORMATION .................... 8A-1

GENERATOR TEST PROCEDURES ON VEHICLE ....8A-19

IGNITION OFF DRAW (IOD) ..................8A-9

SPECIFICATIONS ........................ 8A-28

STARTER TEST PROCEDURES ON VEHICLE ......8A-11

CHIME WARNING/REMINDER SYSTEM ............8U-1

EMISSION CONTROL SYSTEMS .................25-1

EVAPORATIVE EMISSION CONTROLS ...........25-1

EXHAUST EMISSION CONTROLS ..............25-17

FUEL SYSTEMS ............................ 14-1

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-95

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS ................14-100

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES .................14-107

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION .................... 14-83

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-35

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS .................14-41

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SERVICE PROCEDURES .................. 14-48

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SYSTEM OPERATION .................... 14-24

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS ..........14-66

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS ........14-70

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES .........14-77

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ...........14-55

3.0L MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS .......................... 14-125

3.0L MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS ........................ 14-130

3.0L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES ........................ 14-138

3.0L MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ......................... 14-113

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-157 3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ

ON-BOARD DIAGNOSTICS ................14-162

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES .................14-169

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION ................... 14-145

ACCELERATOR PEDAL AND THROTTLE CABLE ....14-21

FUEL DELIVERY SYSTEM .................... 14-3

FUEL TANKS ........................... 14-14

GENERAL INFORMATION .................... 14-1

SPECIFICATIONS ........................ 14-178

HORNS ................................. 8G-1

IGNITION SYSTEMS ......................... 8D-1

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES .......8D-11

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSERVICE PROCEDURES ..........8D-14

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSYSTEM OPERATION ............8D-1

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES ........8D-35

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION ............8D-24

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMSÐSERVICE PROCEDURES ..........8D-39

IGNITION SWITCH ....................... 8D-45

SPECIFICATIONS ........................ 8D-47

INSTRUMENT PANEL AND GAUGES ...............8E-1

AA BODY .............................. 8E-1

AC AND AY BODIES ...................... 8E-23

AG AND AJ BODIES ...................... 8E-42

AP BODY ............................. 8E-58

LAMPS .................................. 8L-1

BULB APPLICATION TABLE ..................8L-38

CONCEALED HEADLAMPS ..................8L-27

EXTERIOR LAMP SWITCHES AND HEADLAMP ALIGNMENT ........................... 8L-3

EXTERIOR LAMP SYSTEMS .................8L-25

EXTERIOR LAMPSÐAA BODY ................8L-7

EXTERIOR LAMPSÐAC BODY ...............8L-10

EXTERIOR LAMPSÐAG BODY ...............8L-14

EXTERIOR LAMPSÐAJ BODY ................8L-16

EXTERIOR LAMPSÐAP BODY ...............8L-19

EXTERIOR LAMPSÐAY-BODY ................8L-22

GENERAL INFORMATION .................... 8L-1

ILLUMINATED ENTRY SYSTEM ...............8L-33

OVERHEAD CONSOLE ........................ 8C-1

AA BODY .............................. 8C-1

AC AND AY BODY ........................ 8C-6

AG AND AJ BODIES ...................... 8C-13

AP BODY ............................. 8C-21

POWER LOCKS ............................ 8P-1

POWER MIRRORS ..........................8T-1

POWER SEATS ............................ 8R-1

POWER WINDOWS .......................... 8S-1

REAR WINDOW DEFOGGER .................... 8N-1

RESTRAINT SYSTEMS ....................... 8M-1

TURN SIGNALS AND HAZARD WARNING FLASHER ....8J-1

VEHICLE SPEED CONTROL .................... 8H-1

Page 44 of 2438

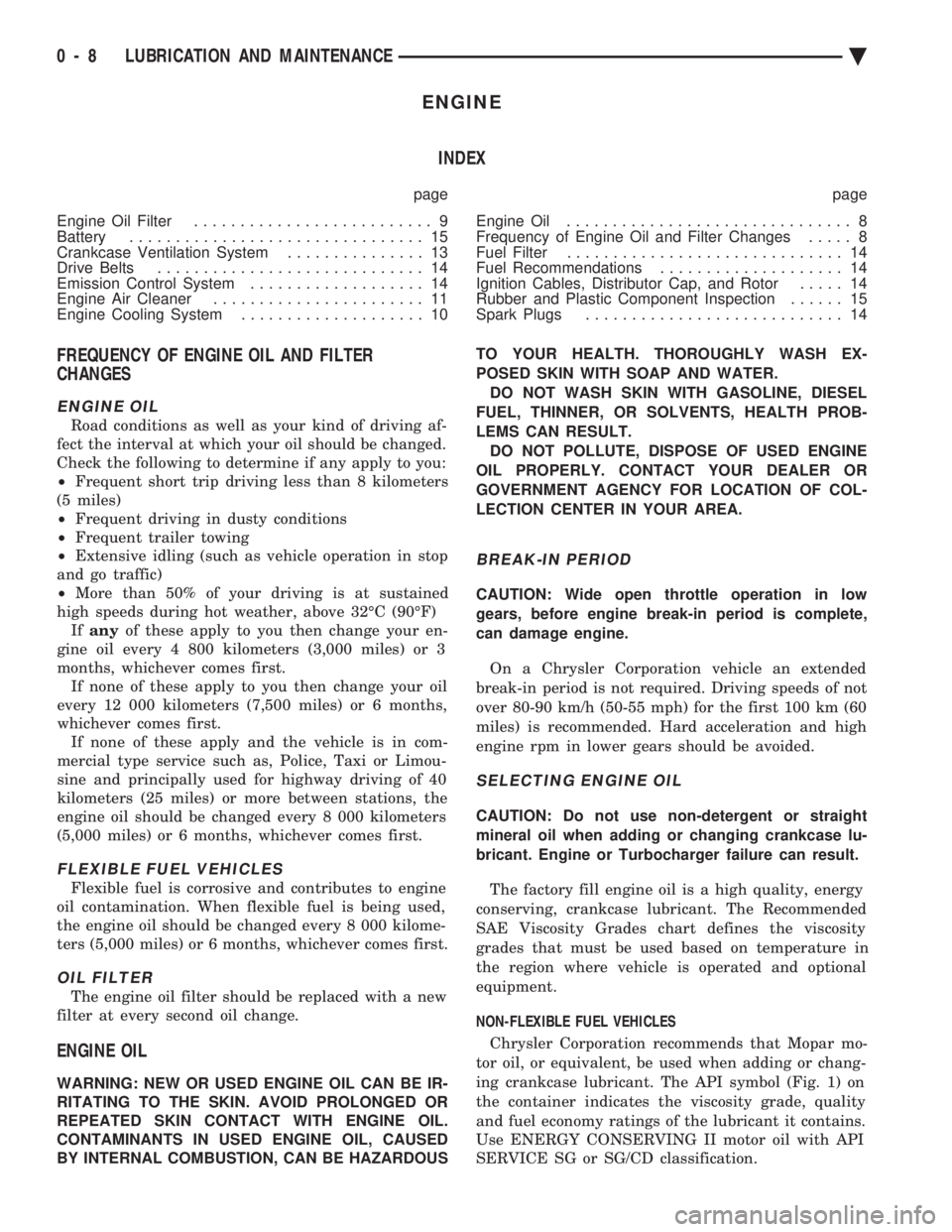

ENGINE INDEX

page page

Engine Oil Filter .......................... 9

Battery ................................ 15

Crankcase Ventilation System ............... 13

Drive Belts ............................. 14

Emission Control System ................... 14

Engine Air Cleaner ....................... 11

Engine Cooling System .................... 10 Engine Oil

............................... 8

Frequency of Engine Oil and Filter Changes ..... 8

Fuel Filter .............................. 14

Fuel Recommendations .................... 14

Ignition Cables, Distributor Cap, and Rotor ..... 14

Rubber and Plastic Component Inspection ...... 15

Spark Plugs ............................ 14

FREQUENCY OF ENGINE OIL AND FILTER

CHANGES

ENGINE OIL

Road conditions as well as your kind of driving af-

fect the interval at which your oil should be changed.

Check the following to determine if any apply to you:

² Frequent short trip driving less than 8 kilometers

(5 miles)

² Frequent driving in dusty conditions

² Frequent trailer towing

² Extensive idling (such as vehicle operation in stop

and go traffic)

² More than 50% of your driving is at sustained

high speeds during hot weather, above 32ÉC (90ÉF) If any of these apply to you then change your en-

gine oil every 4 800 kilometers (3,000 miles) or 3

months, whichever comes first. If none of these apply to you then change your oil

every 12 000 kilometers (7,500 miles) or 6 months,

whichever comes first. If none of these apply and the vehicle is in com-

mercial type service such as, Police, Taxi or Limou-

sine and principally used for highway driving of 40

kilometers (25 miles) or more between stations, the

engine oil should be changed every 8 000 kilometers

(5,000 miles) or 6 months, whichever comes first.

FLEXIBLE FUEL VEHICLES

Flexible fuel is corrosive and contributes to engine

oil contamination. When flexible fuel is being used,

the engine oil should be changed every 8 000 kilome-

ters (5,000 miles) or 6 months, whichever comes first.

OIL FILTER

The engine oil filter should be replaced with a new

filter at every second oil change.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE IR-

RITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED

BY INTERNAL COMBUSTION, CAN BE HAZARDOUS TO YOUR HEALTH. THOROUGHLY WASH EX-

POSED SKIN WITH SOAP AND WATER. DO NOT WASH SKIN WITH GASOLINE, DIESEL

FUEL, THINNER, OR SOLVENTS, HEALTH PROB-

LEMS CAN RESULT. DO NOT POLLUTE, DISPOSE OF USED ENGINE

OIL PROPERLY. CONTACT YOUR DEALER OR

GOVERNMENT AGENCY FOR LOCATION OF COL-

LECTION CENTER IN YOUR AREA.

BREAK-IN PERIOD

CAUTION: Wide open throttle operation in low

gears, before engine break-in period is complete,

can damage engine.

On a Chrysler Corporation vehicle an extended

break-in period is not required. Driving speeds of not

over 80-90 km/h (50-55 mph) for the first 100 km (60

miles) is recommended. Hard acceleration and high

engine rpm in lower gears should be avoided.

SELECTING ENGINE OIL

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase lu-

bricant. Engine or Turbocharger failure can result.

The factory fill engine oil is a high quality, energy

conserving, crankcase lubricant. The Recommended

SAE Viscosity Grades chart defines the viscosity

grades that must be used based on temperature in

the region where vehicle is operated and optional

equipment.

NON-FLEXIBLE FUEL VEHICLES Chrysler Corporation recommends that Mopar mo-

tor oil, or equivalent, be used when adding or chang-

ing crankcase lubricant. The API symbol (Fig. 1) on

the container indicates the viscosity grade, quality

and fuel economy ratings of the lubricant it contains.

Use ENERGY CONSERVING II motor oil with API

SERVICE SG or SG/CD classification.

0 - 8 LUBRICATION AND MAINTENANCE Ä

Page 50 of 2438

PCV SYSTEM TEST

Refer to group 25, Emission Control System for

proper procedures to test PCV system.

FUEL RECOMMENDATIONS

Chrysler Corporation recommends that only fuel pur-

chased from a reputable retailer be used. Use high qual-

ity, unleaded gasoline to provide satisfactory

driveability and highest fuel economy. Gasoline contain-

ing detergent and corrosion control additives are desire-

able. If the engine develops spark knock (audible ping),

poor performance, hard starting or stalling, purchase

fuel from another source. Engine performance can vary

when using different brands of gasoline with the same

octane rating. Occasional light engine spark knock un-

der heavy acceleration, at low speed or when vehicle is

heavily loaded is not harmful. Extended periods of

spark knock under moderate acceleration or at cruising

speed can damage the engine. The cause of excessive

spark knock condition must be diagnosed and corrected.

For diagnostic procedures refer to Group 14, Fuel Sys-

tem and Powertrain Diagnostic Procedures manual.

SELECTING GASOLINE

CAUTION:Do not use fuel containing METHANOL

(methyl or wood alcohol), damage to fuel system

will result. Do not use leaded gasoline, damage to catalytic

converter will result and vehicle will not conform to

emission control standards.

ETHANOL, MTBE OR ETBE BLENDS

All Chrysler Corporation vehicles are designed to

use unleaded gasoline ONLY. Gasohol blends, con-

taining 10% Ethanol (ethyl or grain alcohol) 90% un-

leaded gasoline can be used provided it has adequate

octane rating. Fuel blends containing up to 15% MTBE (Methyl

Tertiary Butyl Ether) and 85% unleaded gasoline can

be used. Fuel blends containing up to 17% ETBE

(Ethyl Tertiary Butyl Ether) and 83% unleaded gas-

oline can also be used. Fuel blended with ethanol, MTBE or ETBE are

also referred to as reformulated or clean air gasoline.

These fuels contribute less emissions to the atmo-

sphere. Chrysler Corporation recommends that

blended fuels be used when available

METHANOL BLENDS Using gasoline blended with methanol can result

in starting and driveability problems. Deterioration

of fuel system components will result. Methanol in-

duced problems are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty. NON-TURBOCHARGED ENGINES

Use regular unleaded gasoline having a minimum

octane rating of 87 (R+M)/2. Higher octane premium

unleaded gasoline can be used if desired.

2.2L 16 VALVE TURBOCHARGED ENGINE

Use premium unleaded gasoline having a mini-

mum octane rating of 91 (R+M)/2. Gasoline with oc-

tane rating less than 91 (R+M)/2 can be used if

recommended gasoline is not available. Low octane

gasoline will reduce engine performance.

FLEXIBLE FUEL VEHICLES

CAUTION: Do not use 100% methanol, damage to

fuel system can result. Use unleaded regular gasoline having a minimum

octane rating of 87 (R=M)/2 and M85 fuel that is

85% methanol and 15% unleaded gasoline, or a mix-

ture of these two.

FUEL FILTER

The fuel filter requires service only when a fuel

contamination problem is suspected. For proper diag-

nostic and service procedures refer to Group 14, Fuel

System,

IGNITION CABLES, DISTRIBUTOR CAP, AND

ROTOR

Inspect and test ignition cables, distributor cap and

rotor when the spark plugs are replaced. Oil and

grime should be cleaned from the ignition cables and

distributor cap to avoid possible spark plug fouling.

Mopar, Foamy Engine Degreaser, or equivalent is

recommended for cleaning the engine compartment.

For proper service and diagnostic procedures refer to

Group 8D, Ignition System.

SPARK PLUGS

Ignition spark plugs should be replaced at the

mileage interval described in the Lubrication and

Maintenance Schedules. Refer to the General Infor-

mation section of this group. For proper service pro-

cedures refer to Group 8D, Ignition Systems.

DRIVE BELTS

Inspect and adjust drive belts at the interval de-

scribed in the Lubrication and Maintenance Sched-

ules. Refer to General Information section of this

group. For proper inspection and adjustment proce-

dures, see Group 7, Cooling System.

EMISSION CONTROL SYSTEM

Inspect all emission control components and hoses

when other under hood service is performed. Refer to

emission system Vacuum Hose Label located on the

0 - 14 LUBRICATION AND MAINTENANCE Ä

Page 56 of 2438

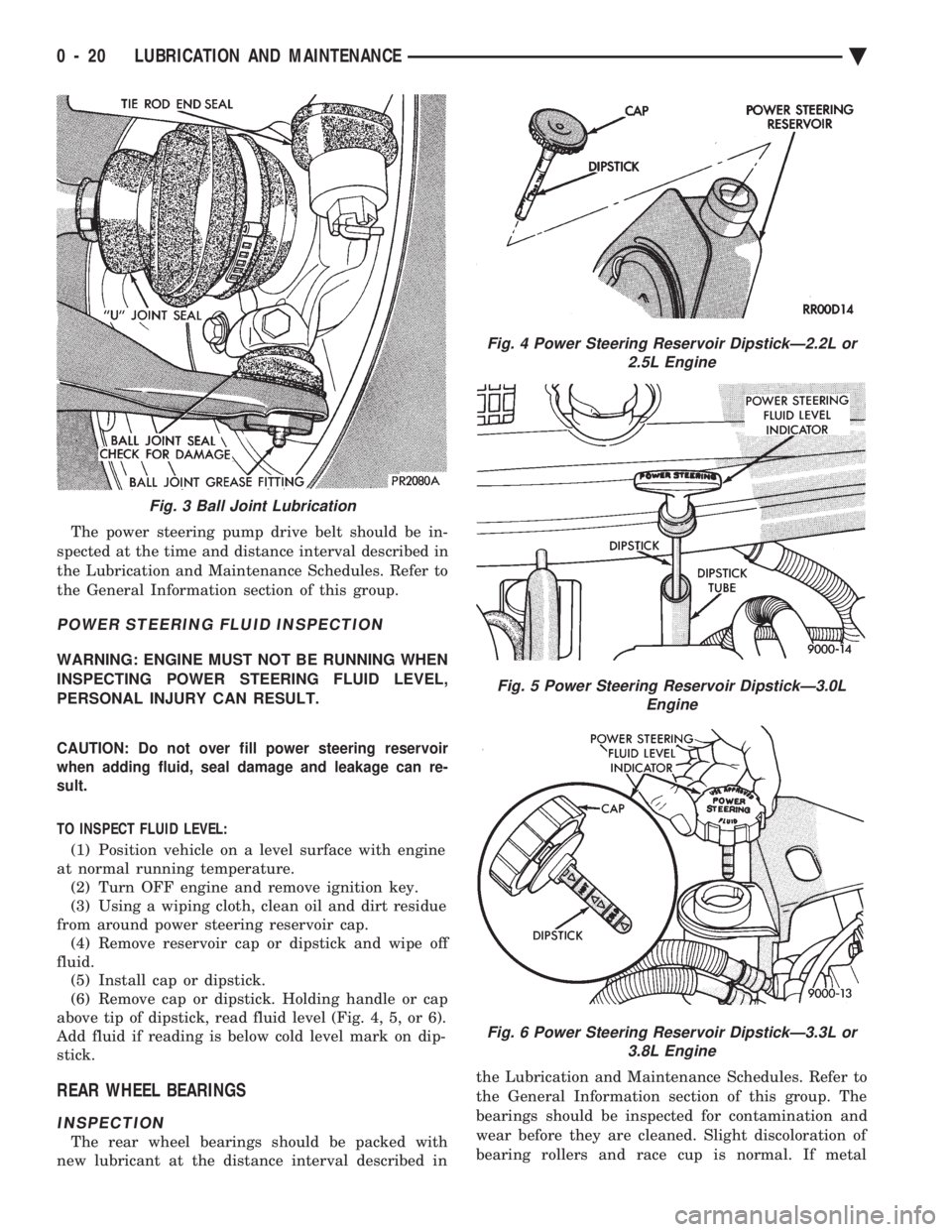

The power steering pump drive belt should be in-

spected at the time and distance interval described in

the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group.

POWER STEERING FLUID INSPECTION

WARNING: ENGINE MUST NOT BE RUNNING WHEN

INSPECTING POWER STEERING FLUID LEVEL,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not over fill power steering reservoir

when adding fluid, seal damage and leakage can re-

sult.

TO INSPECT FLUID LEVEL:

(1) Position vehicle on a level surface with engine

at normal running temperature. (2) Turn OFF engine and remove ignition key.

(3) Using a wiping cloth, clean oil and dirt residue

from around power steering reservoir cap. (4) Remove reservoir cap or dipstick and wipe off

fluid. (5) Install cap or dipstick.

(6) Remove cap or dipstick. Holding handle or cap

above tip of dipstick, read fluid level (Fig. 4, 5, or 6).

Add fluid if reading is below cold level mark on dip-

stick.

REAR WHEEL BEARINGS

INSPECTION

The rear wheel bearings should be packed with

new lubricant at the distance interval described in the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group. The

bearings should be inspected for contamination and

wear before they are cleaned. Slight discoloration of

bearing rollers and race cup is normal. If metal

Fig. 3 Ball Joint Lubrication

Fig. 4 Power Steering Reservoir DipstickÐ2.2L or 2.5L Engine

Fig. 5 Power Steering Reservoir DipstickÐ3.0L Engine

Fig. 6 Power Steering Reservoir DipstickÐ3.3L or3.8L Engine

0 - 20 LUBRICATION AND MAINTENANCE Ä

Page 58 of 2438

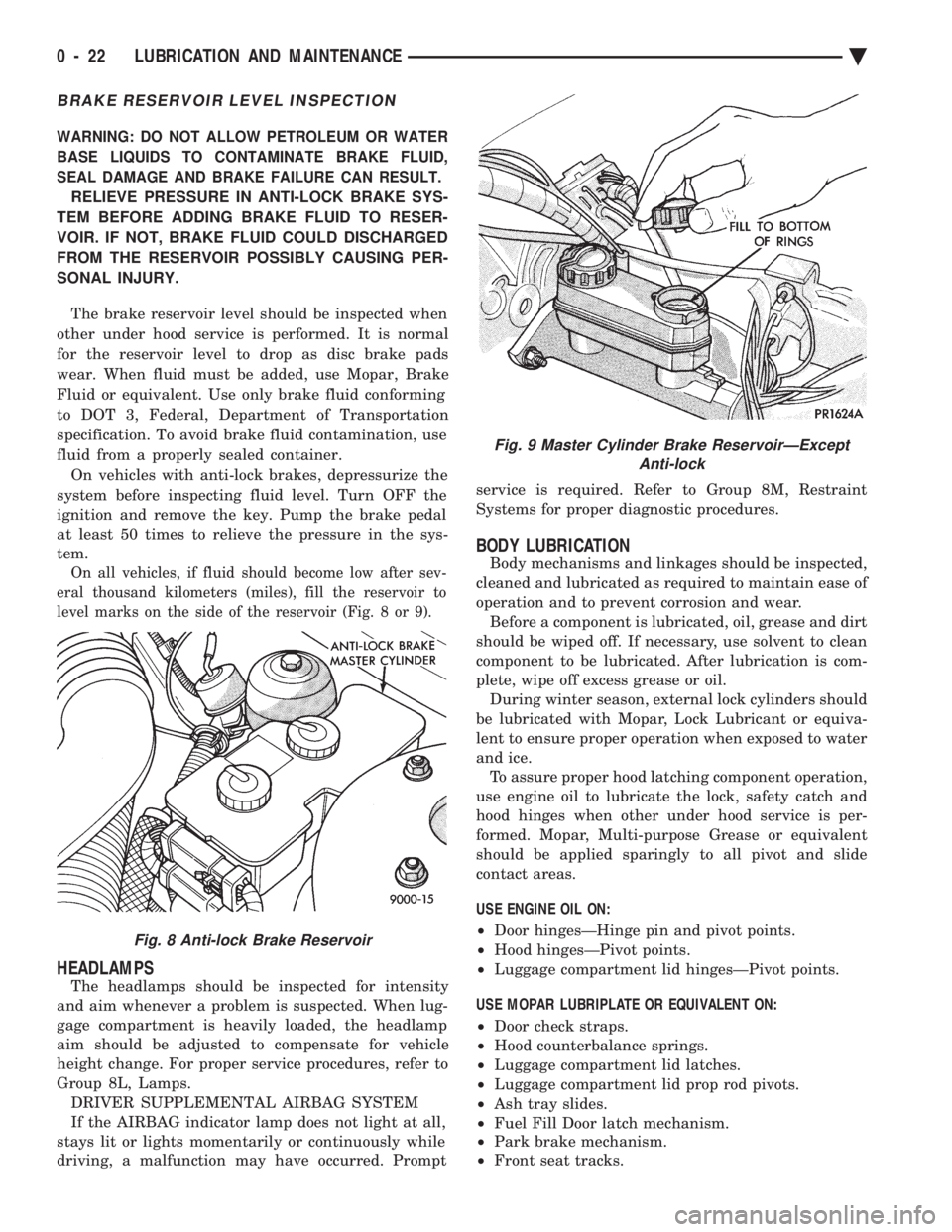

BRAKE RESERVOIR LEVEL INSPECTION

WARNING: DO NOT ALLOW PETROLEUM OR WATER

BASE LIQUIDS TO CONTAMINATE BRAKE FLUID,

SEAL DAMAGE AND BRAKE FAILURE CAN RESULT.

RELIEVE PRESSURE IN ANTI-LOCK BRAKE SYS-

TEM BEFORE ADDING BRAKE FLUID TO RESER-

VOIR. IF NOT, BRAKE FLUID COULD DISCHARGED

FROM THE RESERVOIR POSSIBLY CAUSING PER-

SONAL INJURY.

The brake reservoir level should be inspected when

other under hood service is performed. It is normal

for the reservoir level to drop as disc brake pads

wear. When fluid must be added, use Mopar, Brake

Fluid or equivalent. Use only brake fluid conforming

to DOT 3, Federal, Department of Transportation

specification. To avoid brake fluid contamination, use

fluid from a properly sealed container. On vehicles with anti-lock brakes, depressurize the

system before inspecting fluid level. Turn OFF the

ignition and remove the key. Pump the brake pedal

at least 50 times to relieve the pressure in the sys-

tem.

On all vehicles, if fluid should become low after sev-

eral thousand kilometers (miles), fill the reservoir to

level marks on the side of the reservoir (Fig. 8 or 9).

HEADLAMPS

The headlamps should be inspected for intensity

and aim whenever a problem is suspected. When lug-

gage compartment is heavily loaded, the headlamp

aim should be adjusted to compensate for vehicle

height change. For proper service procedures, refer to

Group 8L, Lamps. DRIVER SUPPLEMENTAL AIRBAG SYSTEM

If the AIRBAG indicator lamp does not light at all,

stays lit or lights momentarily or continuously while

driving, a malfunction may have occurred. Prompt service is required. Refer to Group 8M, Restraint

Systems for proper diagnostic procedures.

BODY LUBRICATION

Body mechanisms and linkages should be inspected,

cleaned and lubricated as required to maintain ease of

operation and to prevent corrosion and wear. Before a component is lubricated, oil, grease and dirt

should be wiped off. If necessary, use solvent to clean

component to be lubricated. After lubrication is com-

plete, wipe off excess grease or oil. During winter season, external lock cylinders should

be lubricated with Mopar, Lock Lubricant or equiva-

lent to ensure proper operation when exposed to water

and ice. To assure proper hood latching component operation,

use engine oil to lubricate the lock, safety catch and

hood hinges when other under hood service is per-

formed. Mopar, Multi-purpose Grease or equivalent

should be applied sparingly to all pivot and slide

contact areas.

USE ENGINE OIL ON:

² Door hingesÐHinge pin and pivot points.

² Hood hingesÐPivot points.

² Luggage compartment lid hingesÐPivot points.

USE MOPAR LUBRIPLATE OR EQUIVALENT ON:

² Door check straps.

² Hood counterbalance springs.

² Luggage compartment lid latches.

² Luggage compartment lid prop rod pivots.

² Ash tray slides.

² Fuel Fill Door latch mechanism.

² Park brake mechanism.

² Front seat tracks.

Fig. 8 Anti-lock Brake Reservoir

Fig. 9 Master Cylinder Brake ReservoirÐExcept

Anti-lock

0 - 22 LUBRICATION AND MAINTENANCE Ä

Page 118 of 2438

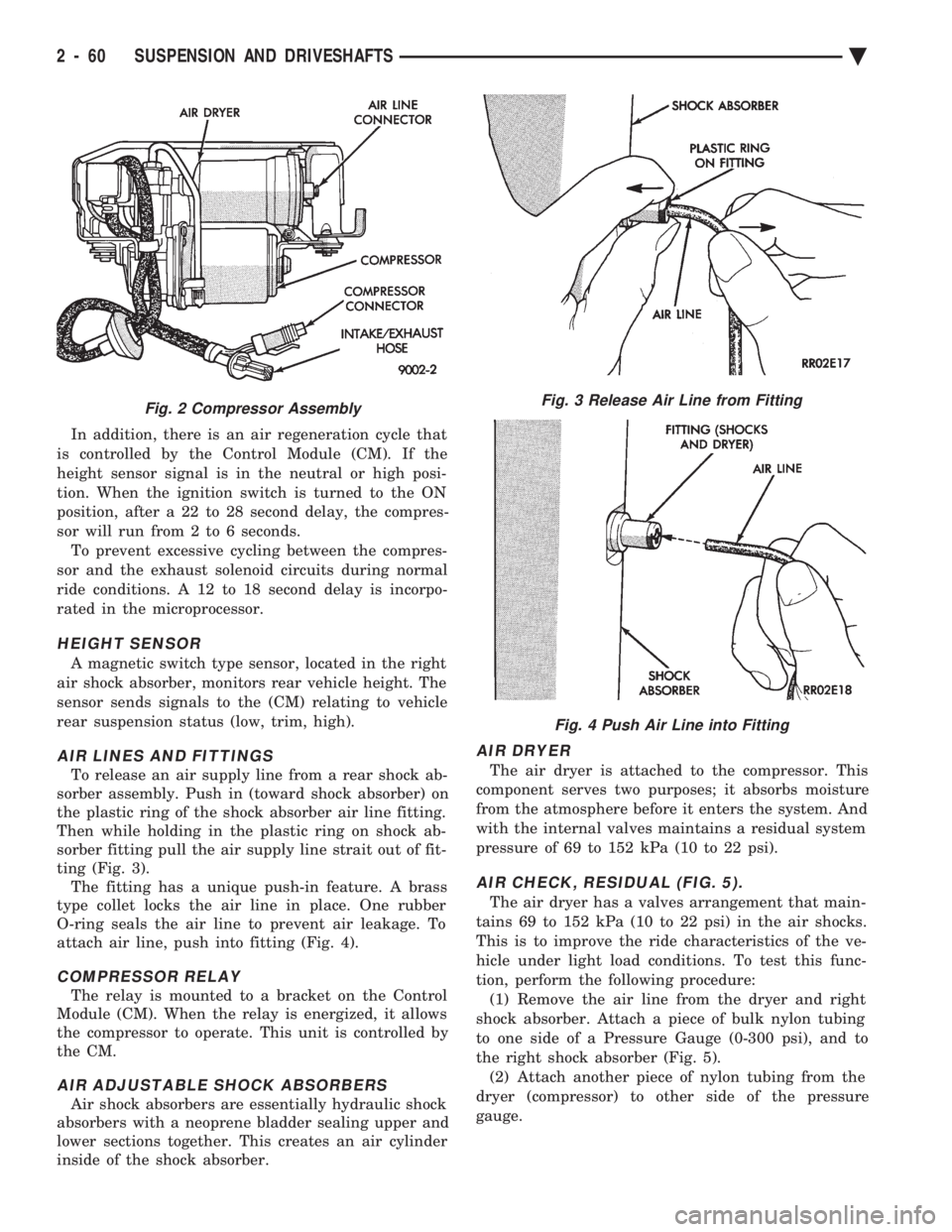

In addition, there is an air regeneration cycle that

is controlled by the Control Module (CM). If the

height sensor signal is in the neutral or high posi-

tion. When the ignition switch is turned to the ON

position, after a 22 to 28 second delay, the compres-

sor will run from 2 to 6 seconds. To prevent excessive cycling between the compres-

sor and the exhaust solenoid circuits during normal

ride conditions. A 12 to 18 second delay is incorpo-

rated in the microprocessor.

HEIGHT SENSOR

A magnetic switch type sensor, located in the right

air shock absorber, monitors rear vehicle height. The

sensor sends signals to the (CM) relating to vehicle

rear suspension status (low, trim, high).

AIR LINES AND FITTINGS

To release an air supply line from a rear shock ab-

sorber assembly. Push in (toward shock absorber) on

the plastic ring of the shock absorber air line fitting.

Then while holding in the plastic ring on shock ab-

sorber fitting pull the air supply line strait out of fit-

ting (Fig. 3). The fitting has a unique push-in feature. A brass

type collet locks the air line in place. One rubber

O-ring seals the air line to prevent air leakage. To

attach air line, push into fitting (Fig. 4).

COMPRESSOR RELAY

The relay is mounted to a bracket on the Control

Module (CM). When the relay is energized, it allows

the compressor to operate. This unit is controlled by

the CM.

AIR ADJUSTABLE SHOCK ABSORBERS

Air shock absorbers are essentially hydraulic shock

absorbers with a neoprene bladder sealing upper and

lower sections together. This creates an air cylinder

inside of the shock absorber.

AIR DRYER

The air dryer is attached to the compressor. This

component serves two purposes; it absorbs moisture

from the atmosphere before it enters the system. And

with the internal valves maintains a residual system

pressure of 69 to 152 kPa (10 to 22 psi).

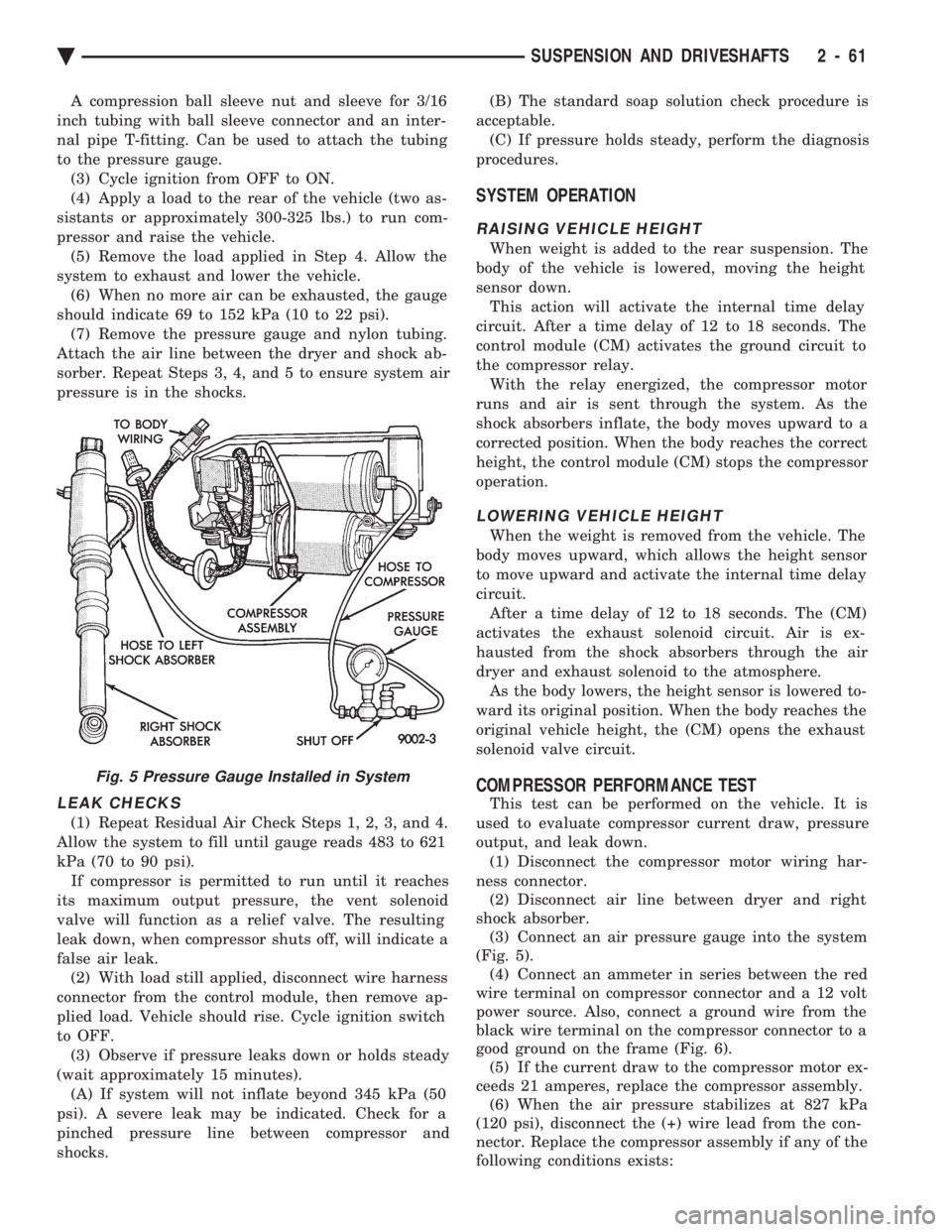

AIR CHECK, RESIDUAL (FIG. 5).

The air dryer has a valves arrangement that main-

tains 69 to 152 kPa (10 to 22 psi) in the air shocks.

This is to improve the ride characteristics of the ve-

hicle under light load conditions. To test this func-

tion, perform the following procedure: (1) Remove the air line from the dryer and right

shock absorber. Attach a piece of bulk nylon tubing

to one side of a Pressure Gauge (0-300 psi), and to

the right shock absorber (Fig. 5). (2) Attach another piece of nylon tubing from the

dryer (compressor) to other side of the pressure

gauge.

Fig. 2 Compressor AssemblyFig. 3 Release Air Line from Fitting

Fig. 4 Push Air Line into Fitting

2 - 60 SUSPENSION AND DRIVESHAFTS Ä

Page 119 of 2438

A compression ball sleeve nut and sleeve for 3/16

inch tubing with ball sleeve connector and an inter-

nal pipe T-fitting. Can be used to attach the tubing

to the pressure gauge. (3) Cycle ignition from OFF to ON.

(4) Apply a load to the rear of the vehicle (two as-

sistants or approximately 300-325 lbs.) to run com-

pressor and raise the vehicle. (5) Remove the load applied in Step 4. Allow the

system to exhaust and lower the vehicle. (6) When no more air can be exhausted, the gauge

should indicate 69 to 152 kPa (10 to 22 psi). (7) Remove the pressure gauge and nylon tubing.

Attach the air line between the dryer and shock ab-

sorber. Repeat Steps 3, 4, and 5 to ensure system air

pressure is in the shocks.

LEAK CHECKS

(1) Repeat Residual Air Check Steps 1, 2, 3, and 4.

Allow the system to fill until gauge reads 483 to 621

kPa (70 to 90 psi). If compressor is permitted to run until it reaches

its maximum output pressure, the vent solenoid

valve will function as a relief valve. The resulting

leak down, when compressor shuts off, will indicate a

false air leak. (2) With load still applied, disconnect wire harness

connector from the control module, then remove ap-

plied load. Vehicle should rise. Cycle ignition switch

to OFF. (3) Observe if pressure leaks down or holds steady

(wait approximately 15 minutes). (A) If system will not inflate beyond 345 kPa (50

psi). A severe leak may be indicated. Check for a

pinched pressure line between compressor and

shocks. (B) The standard soap solution check procedure is

acceptable. (C) If pressure holds steady, perform the diagnosis

procedures.

SYSTEM OPERATION

RAISING VEHICLE HEIGHT

When weight is added to the rear suspension. The

body of the vehicle is lowered, moving the height

sensor down. This action will activate the internal time delay

circuit. After a time delay of 12 to 18 seconds. The

control module (CM) activates the ground circuit to

the compressor relay. With the relay energized, the compressor motor

runs and air is sent through the system. As the

shock absorbers inflate, the body moves upward to a

corrected position. When the body reaches the correct

height, the control module (CM) stops the compressor

operation.

LOWERING VEHICLE HEIGHT

When the weight is removed from the vehicle. The

body moves upward, which allows the height sensor

to move upward and activate the internal time delay

circuit. After a time delay of 12 to 18 seconds. The (CM)

activates the exhaust solenoid circuit. Air is ex-

hausted from the shock absorbers through the air

dryer and exhaust solenoid to the atmosphere. As the body lowers, the height sensor is lowered to-

ward its original position. When the body reaches the

original vehicle height, the (CM) opens the exhaust

solenoid valve circuit.

COMPRESSOR PERFORMANCE TEST

This test can be performed on the vehicle. It is

used to evaluate compressor current draw, pressure

output, and leak down. (1) Disconnect the compressor motor wiring har-

ness connector. (2) Disconnect air line between dryer and right

shock absorber. (3) Connect an air pressure gauge into the system

(Fig. 5). (4) Connect an ammeter in series between the red

wire terminal on compressor connector and a 12 volt

power source. Also, connect a ground wire from the

black wire terminal on the compressor connector to a

good ground on the frame (Fig. 6). (5) If the current draw to the compressor motor ex-

ceeds 21 amperes, replace the compressor assembly. (6) When the air pressure stabilizes at 827 kPa

(120 psi), disconnect the (+) wire lead from the con-

nector. Replace the compressor assembly if any of the

following conditions exists:

Fig. 5 Pressure Gauge Installed in System

Ä SUSPENSION AND DRIVESHAFTS 2 - 61