jack points CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 41 of 2438

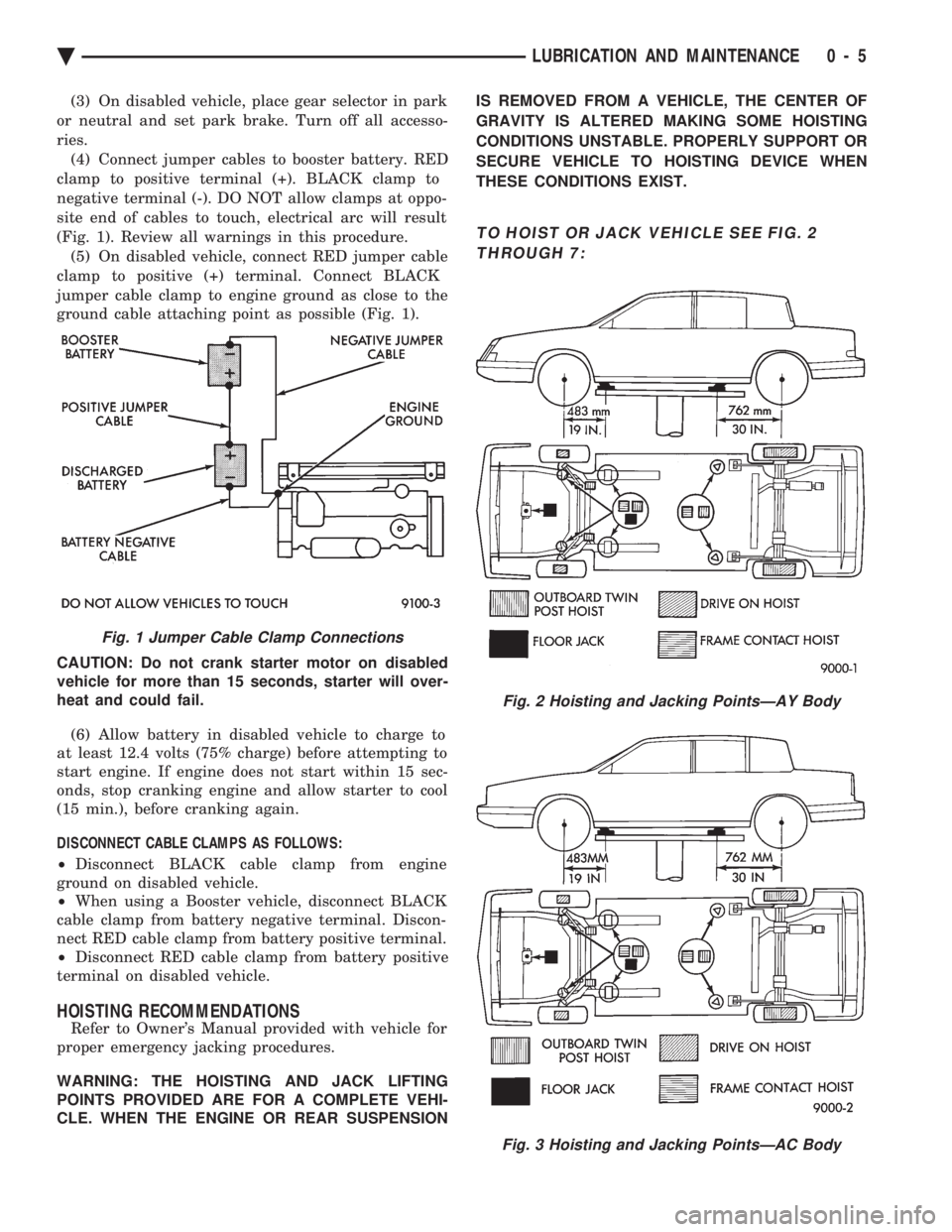

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries. (4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to

negative terminal (-). DO NOT allow clamps at oppo-

site end of cables to touch, electrical arc will result

(Fig. 1). Review all warnings in this procedure. (5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(6) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

² Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

² When using a Booster vehicle, disconnect BLACK

cable clamp from battery negative terminal. Discon-

nect RED cable clamp from battery positive terminal.

² Disconnect RED cable clamp from battery positive

terminal on disabled vehicle.

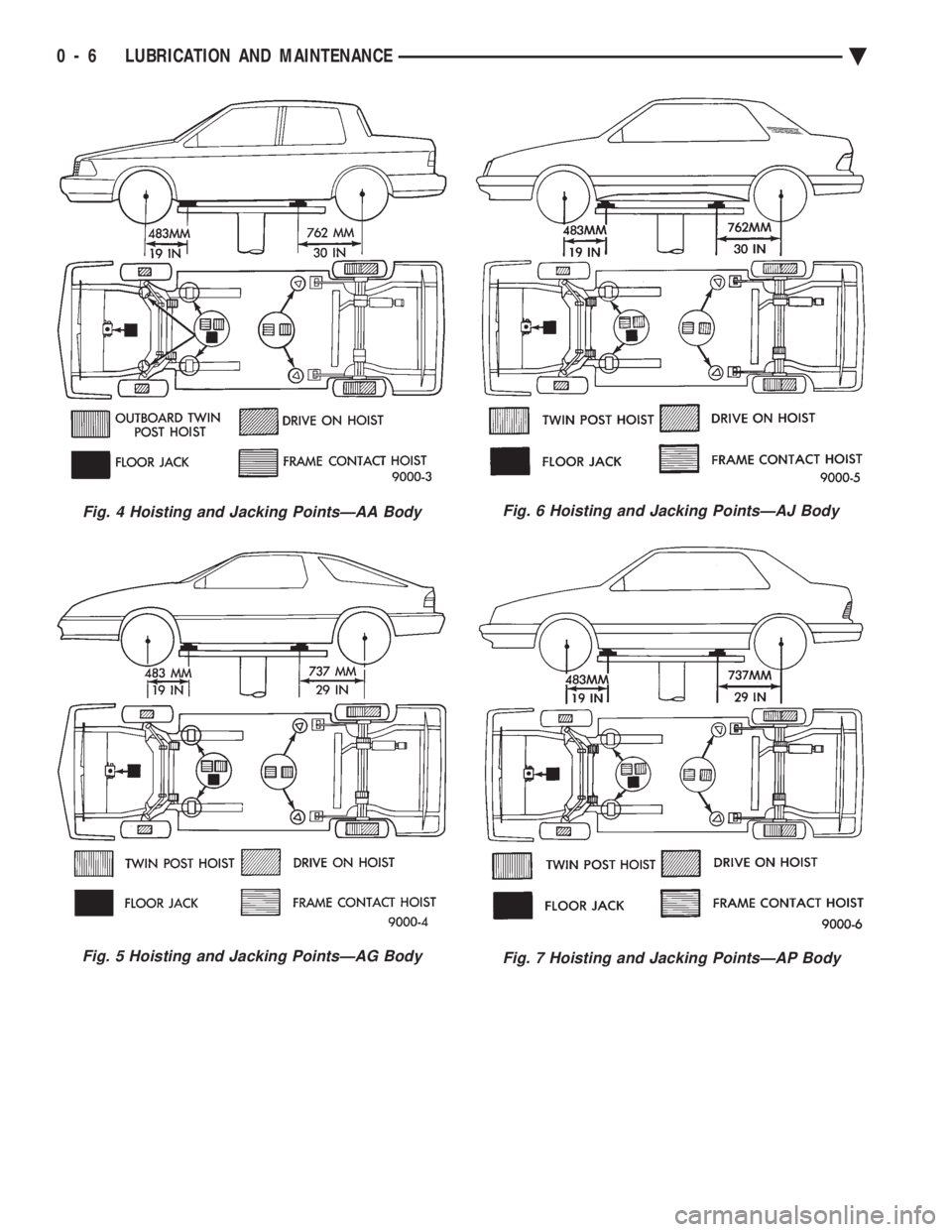

HOISTING RECOMMENDATIONS

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

TO HOIST OR JACK VEHICLE SEE FIG. 2 THROUGH 7:

Fig. 1 Jumper Cable Clamp Connections

Fig. 2 Hoisting and Jacking PointsÐAY Body

Fig. 3 Hoisting and Jacking PointsÐAC Body

Ä LUBRICATION AND MAINTENANCE 0 - 5

Page 42 of 2438

Fig. 4 Hoisting and Jacking PointsÐAA Body

Fig. 5 Hoisting and Jacking PointsÐAG Body

Fig. 6 Hoisting and Jacking PointsÐAJ Body

Fig. 7 Hoisting and Jacking PointsÐAP Body

0 - 6 LUBRICATION AND MAINTENANCE Ä

Page 204 of 2438

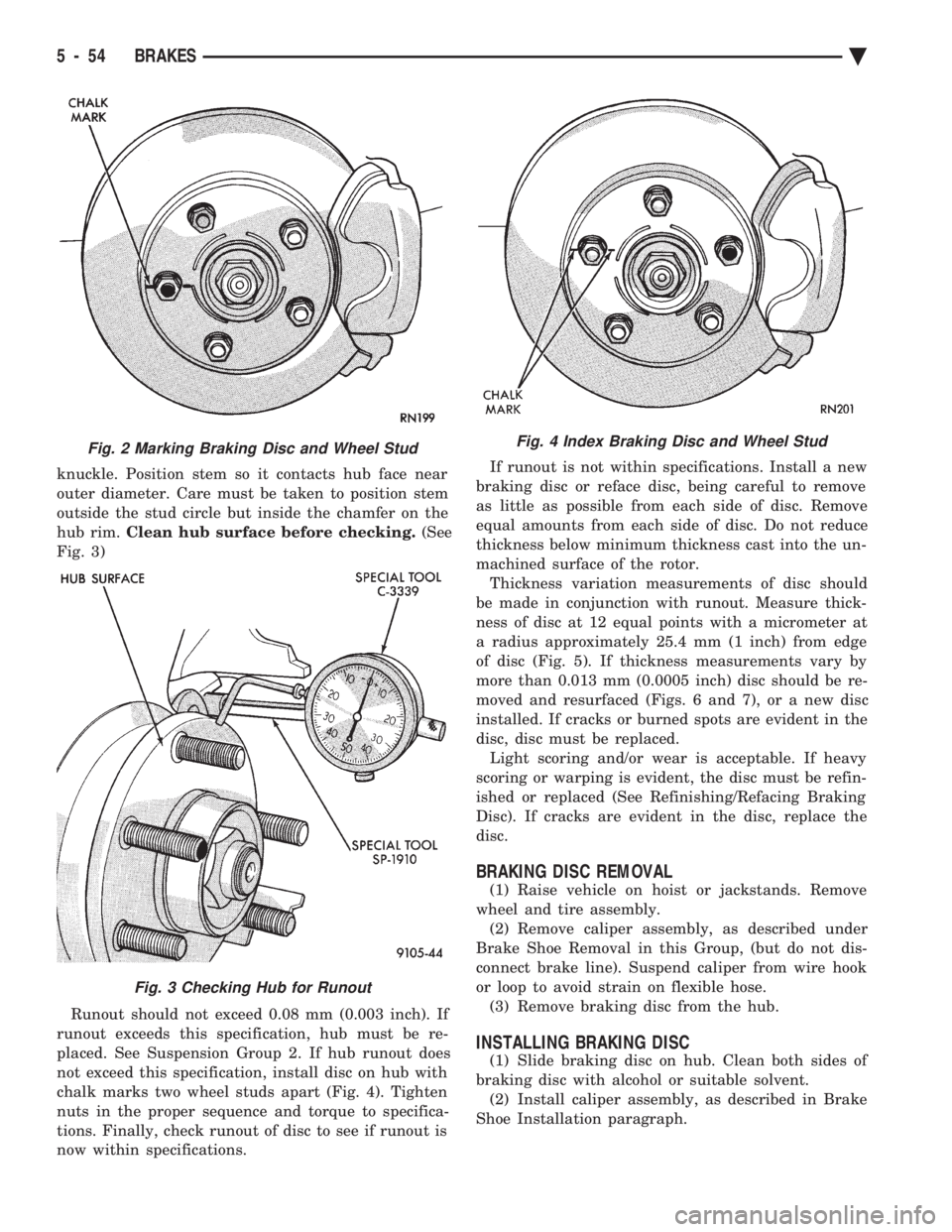

knuckle. Position stem so it contacts hub face near

outer diameter. Care must be taken to position stem

outside the stud circle but inside the chamfer on the

hub rim. Clean hub surface before checking. (See

Fig. 3)

Runout should not exceed 0.08 mm (0.003 inch). If

runout exceeds this specification, hub must be re-

placed. See Suspension Group 2. If hub runout does

not exceed this specification, install disc on hub with

chalk marks two wheel studs apart (Fig. 4). Tighten

nuts in the proper sequence and torque to specifica-

tions. Finally, check runout of disc to see if runout is

now within specifications. If runout is not within specifications. Install a new

braking disc or reface disc, being careful to remove

as little as possible from each side of disc. Remove

equal amounts from each side of disc. Do not reduce

thickness below minimum thickness cast into the un-

machined surface of the rotor. Thickness variation measurements of disc should

be made in conjunction with runout. Measure thick-

ness of disc at 12 equal points with a micrometer at

a radius approximately 25.4 mm (1 inch) from edge

of disc (Fig. 5). If thickness measurements vary by

more than 0.013 mm (0.0005 inch) disc should be re-

moved and resurfaced (Figs. 6 and 7), or a new disc

installed. If cracks or burned spots are evident in the

disc, disc must be replaced. Light scoring and/or wear is acceptable. If heavy

scoring or warping is evident, the disc must be refin-

ished or replaced (See Refinishing/Refacing Braking

Disc). If cracks are evident in the disc, replace the

disc.

BRAKING DISC REMOVAL

(1) Raise vehicle on hoist or jackstands. Remove

wheel and tire assembly. (2) Remove caliper assembly, as described under

Brake Shoe Removal in this Group, (but do not dis-

connect brake line). Suspend caliper from wire hook

or loop to avoid strain on flexible hose. (3) Remove braking disc from the hub.

INSTALLING BRAKING DISC

(1) Slide braking disc on hub. Clean both sides of

braking disc with alcohol or suitable solvent. (2) Install caliper assembly, as described in Brake

Shoe Installation paragraph.

Fig. 2 Marking Braking Disc and Wheel Stud

Fig. 3 Checking Hub for Runout

Fig. 4 Index Braking Disc and Wheel Stud

5 - 54 BRAKES Ä