sensor CHEVROLET EXPRESS 2010 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: EXPRESS, Model: CHEVROLET EXPRESS 2010Pages: 440, PDF Size: 2.42 MB

Page 340 of 440

Dual Tire Operation

When the vehicle is new, or whenever a wheel, wheel bolt

or wheel nut is replaced, check the wheel nut torque after

100, 1,000 and 6,000 miles (160, 1 600 and 10 000 km)

of driving. For proper wheel nut tightening information,

see “Removing the Flat Tire and Installing the Spare

Tire” later in this section, underChanging a Flat Tire

on page 6-86. Also see “Wheel Nut Torque” under

Capacities and Speci�cations on page 6-116.

The outer tire on a dual wheel setup generally wears

faster than the inner tire. Your tires will wear more

evenly and last longer if you rotate the tires periodically.

SeeTire Inspection and Rotation on page 6-75. Also

seeScheduled Maintenance on page 7-3.

{WARNING:

If you operate your vehicle with a tire that is badly

underinflated, the tire can overheat. An overheated

tire can lose air suddenly or catch fire. You or

others could be injured. Be sure all tires (including

the spare) are properly inflated.

SeeTires on page 6-60andIn�ation - Tire Pressure on

page 6-68for more information on proper tire inflation.

Tire Pressure Monitor System

The Tire Pressure Monitor System (TPMS) uses radio

and sensor technology to check tire pressure levels.

The TPMS sensors monitor the air pressure in

your vehicle’s tires and transmit tire pressure readings

to a receiver located in the vehicle.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer

on the vehicle placard or tire inflation pressure label.

(If your vehicle has tires of a different size than the

size indicated on the vehicle placard or tire inflation

pressure label, you should determine the proper

tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been

equipped with a tire pressure monitoring system (TPMS)

that illuminates a low tire pressure telltale when one

or more of your tires is significantly under-inflated.

6-70

Page 342 of 440

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure Monitor

System (TPMS). The TPMS is designed to warn the

driver when a low tire pressure condition exists. TPMS

sensors are mounted onto each tire and wheel assembly,

excluding the spare tire and wheel assembly. The TPMS

sensors monitor the air pressure in the vehicle’s tires and

transmits the tire pressure readings to a receiver located

in the vehicle.

When a low tire pressure

condition is detected, the

TPMS will illuminate the

low tire pressure warning

symbol located on the

instrument panel cluster.

At the same time a message to check the pressure in a

specific tire appears on the Driver Information Center

(DIC) display. The low tire pressure warning light and the

DIC warning message come on at each ignition cycle

until the tires are inflated to the correct inflation pressure.If your vehicle has DIC buttons, tire pressure levels can

be viewed by the driver. For additional information and

details about the DIC operation and displays seeDIC

Operation and Displays on page 4-37andDIC Warnings

and Messages on page 4-44.

The low tire pressure warning light may come on in

cool weather when the vehicle is first started, and then

turn off as you start to drive. This could be an early

indicator that the air pressure in the tire(s) are getting

low and need to be inflated to the proper pressure.

A Tire and Loading Information label, attached to

your vehicle, shows the size of your vehicle’s original

equipment tires and the correct inflation pressure for

your vehicle’s tires when they are cold. SeeLoading the

Vehicle on page 5-19, for an example of the Tire and

Loading Information label and its location on your vehicle.

Also seeIn�ation - Tire Pressure on page 6-68.

Your vehicle’s TPMS can warn you about a low tire

pressure condition but it does not replace normal

tire maintenance. SeeTire Inspection and Rotation

on page 6-75andTires on page 6-60.

Notice:Liquid tire sealants could damage the Tire

Pressure Monitor System (TPMS) sensors. Sensor

damage caused by using a tire sealant is not

covered by your warranty. Do not use liquid tire

sealants.

6-72

Page 343 of 440

TPMS Malfunction Light and Message

The TPMS will not function properly if one or more of the

TPMS sensors are missing or inoperable. When the

system detects a malfunction, the low tire warning light

flashes for about one minute and then stays on for the

remainder of the ignition cycle. A DIC warning message

is also displayed. The low tire warning light and DIC

warning message come on at each ignition cycle until

the problem is corrected. Some of the conditions that

can cause the malfunction light and DIC message to

come on are:

•One of the road tires has been replaced with the

spare tire. The spare tire does not have a TPMS

sensor. The TPMS malfunction light and DIC

message should go off once you re-install the

road tire containing the TPMS sensor.

•The TPMS sensor matching process was started but

not completed or not completed successfully after

rotating the vehicle’s tires. The DIC message and

TPMS malfunction light should go off once the TPMS

sensor matching process is performed successfully.

See “TPMS Sensor Matching Process” later in this

section.

•One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

•Replacement tires or wheels do not match your

vehicle’s original equipment tires or wheels. Tires

and wheels other than those recommended for your

vehicle could prevent the TPMS from functioning

properly. SeeBuying New Tires on page 6-79.

•Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or

signal a low tire condition. See your dealer/retailer for

service if the TPMS malfunction light and DIC message

comes on and stays on.

6-73

Page 344 of 440

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you rotate your vehicle’s tires or replace one

or more of the TPMS sensors, the identification codes

will need to be matched to the new tire/wheel position.

The sensors are matched to the tire/wheel positions in

the following order: driver side front tire, passenger side

front tire, passenger side rear tire, and driver side rear tire

using a TPMS diagnostic tool. See your dealer/retailer for

service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the

tire’s air pressure. If increasing the tire’s air pressure,

do not exceed the maximum inflation pressure indicated

on the tire’s sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gage, or a key.

You have two minutes to match the first tire/wheel

position, and five minutes overall to match all four

tire/wheel positions. If it takes longer than two minutes, to

match the first tire and wheel, or more than five minutes

to match all four tire and wheel positions the matching

process stops and you need to start over.The TPMS sensor matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the

engine off.

3. Press the Remote Keyless Entry (RKE) transmitter’s

LOCK and UNLOCK buttons at the same time

for approximately five seconds. The horn sounds

twice to signal the receiver is in relearn mode and

TIRE LEARNING ACTIVE message displays on the

DIC screen.

If your vehicle does not have RKE, press the Driver

Information Center (DIC) vehicle information button

until the PRESS

VTO RELEARN TIRE POSITIONS

message displays. The horn sounds twice to signal

the receiver is in relearn mode and TIRE LEARNING

ACTIVE message displays on the DIC screen.

If your vehicle does not have RKE or DIC buttons,

press the trip odometer reset stem located on the

instrument panel cluster until the PRESS

VTO

RELEARN TIRE POSITIONS message displays.

The horn sounds twice to signal the receiver is in

relearn mode and TIRE LEARNING ACTIVE

message displays on the DIC screen.

6-74

Page 345 of 440

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPMS sensor by increasing or

decreasing the tire’s air pressure for five seconds,

or until a horn chirp sounds. The horn chirp, which

may take up to 30 seconds to sound, confirms that

the sensor identification code has been matched to

this tire and wheel position.

6. Proceed to the passenger side front tire, and repeat

the procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeat

the procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the

procedure in Step 5. The horn sounds two times to

indicate the sensor identification code has been

matched to the driver side rear tire, and that the

TPMS sensor matching process is no longer active.

The TIRE LEARNING ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.Tire Inspection and Rotation

Inspect tires regularly for signs of wear or damage.

Also inspect the spare tire. For more information

on tire inspection, seeWhen It Is Time for

New Tires on page 6-78.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). SeeScheduled Maintenance

on page 7-3.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This will

ensure that the vehicle continues to perform most

like it did when the tires were new. The first rotation

is the most important. SeeScheduled Maintenance

on page 7-3.

Any time you notice unusual wear, rotate the tires

as soon as possible and check wheel alignment.

Also check for damaged tires or wheels. SeeWhen

It Is Time for New Tires on page 6-78andWheel

Replacement on page 6-82.

6-75

Page 347 of 440

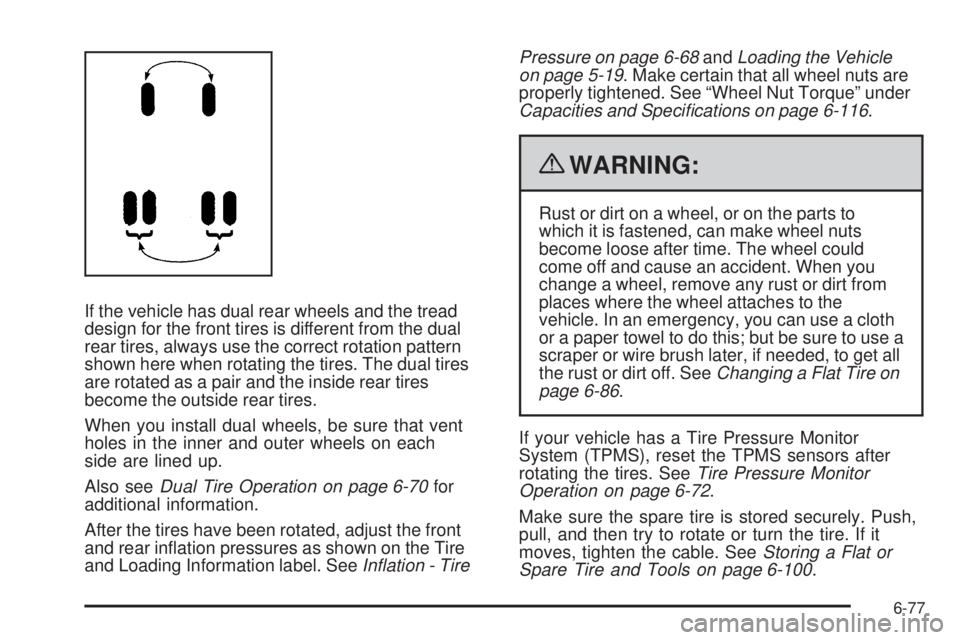

If the vehicle has dual rear wheels and the tread

design for the front tires is different from the dual

rear tires, always use the correct rotation pattern

shown here when rotating the tires. The dual tires

are rotated as a pair and the inside rear tires

become the outside rear tires.

When you install dual wheels, be sure that vent

holes in the inner and outer wheels on each

side are lined up.

Also seeDual Tire Operation on page 6-70for

additional information.

After the tires have been rotated, adjust the front

and rear inflation pressures as shown on the Tire

and Loading Information label. SeeIn�ation - TirePressure on page 6-68andLoading the Vehicle

on page 5-19. Make certain that all wheel nuts are

properly tightened. See “Wheel Nut Torque” under

Capacities and Speci�cations on page 6-116.

{WARNING:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the

vehicle. In an emergency, you can use a cloth

or a paper towel to do this; but be sure to use a

scraper or wire brush later, if needed, to get all

the rust or dirt off. SeeChanging a Flat Tire on

page 6-86.

If your vehicle has a Tire Pressure Monitor

System (TPMS), reset the TPMS sensors after

rotating the tires. SeeTire Pressure Monitor

Operation on page 6-72.

Make sure the spare tire is stored securely. Push,

pull, and then try to rotate or turn the tire. If it

moves, tighten the cable. SeeStoring a Flat or

Spare Tire and Tools on page 6-100.

6-77

Page 353 of 440

Your dealer/retailer will know the kind of wheel

you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset and be mounted

the same way as the one it replaces.

If you need to replace any of the wheels, wheel bolts,

wheel nuts or Tire Pressure Monitor System (TPMS)

sensors, replace them only with new GM original

equipment parts. This way, you will be sure to have

the right wheel, wheel bolts, wheel nuts, and TPMS

sensors for the vehicle.

{WARNING:

Using the wrong replacement wheels, wheel bolts,

or wheel nuts on your vehicle can be dangerous.

It could affect the braking and handling of your

vehicle, make your tires lose air and make you

lose control. You could have a collision in which

you or others could be injured. Always use the

correct wheel, wheel bolts, and wheel nuts for

replacement.Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance, and tire or tire chain

clearance to the body and chassis.

Whenever a wheel, wheel bolt or wheel nut is replaced

on a dual wheel setup, check the wheel nut torque after

100, 1,000 and 6,000 miles (160, 1 600 and 10 000 km)

of driving. For proper torque, see “Wheel Nut Torque”

underCapacities and Speci�cations on page 6-116.

SeeChanging a Flat Tire on page 6-86for more

information.

Used Replacement Wheels

{WARNING:

Putting a used wheel on the vehicle is dangerous.

You cannot know how it has been used or how

far it has been driven. It could fail suddenly and

cause a crash. If you have to replace a wheel,

use a new GM original equipment wheel.

6-83

Page 381 of 440

Floor Console Fuse Block

The floor console fuse block is located under the

driver seat.

Mini-Fuse Usage

F1 Empty

F2 Steering Wheel Sensor

F3 Auxiliary Parking Lamps (Cut-Away)

F4 Front Park Lamps

F5 Trailer Park Lamps

F6 Upfitter Park Lamps

F7 Right Rear Park Lamp

F8 Left Rear Park Lamp

F9 Outside Rear View Mirror Switch

F10 Airbag/AOS

F11 Empty

F12 Empty

F13Heating, Ventilation and

Air Conditioning 2

F14Heating, Ventilation and

Air Conditioning 1

F15 Empty

F17 Outside Rear View Mirror Heater

F18 Rear Window Defogger

F19 Compass

F20 Radio/Chime

F21Remote Function Actuator/

Tire Pressure Monitor

6-111

Page 382 of 440

Mini-Fuse Usage

F22Ignition Switch/Discrete Logic

Ignition Sensor (PK3)

F23 Instrument Panel Cluster

F25Heating, Ventilation and

Air Conditioning Control

F26 Auxiliary/Trailer Backup

F27 Tail Lamps Backup

F30 Upfitter Courtesy Lamps

F31 Front Door Lock

F32 Rear Door Lock

F33 Cargo Door Unlock

F34 Passenger Door Unlock

F35 Rear Passenger Door Unlock

F36 Driver Door Unlock

F37 Empty

F38 Empty

J-Case Fuse Usage

F16 Upfitter Auxiliary 1

F24 Empty

F28 Upfitter Auxiliary 2 Reading Lamps

F29 Rear Blower

Relays Usage

K1 Run (High Current Micro)

K2 Empty (High Current Micro)

K3 Park Lamps (High Current Micro)

K4Upfitter Auxiliary 2

(High Current Mini)

K5 Rear Defogger (High Current Micro)

K6Retained Accessory Power (RAP)

(High Current Micro)

Circuit Breaker Usage

CB1 Power Seats

CB2 Power Windows

Engine Compartment Fuse Block

The fuse block is located in the engine compartment on

the driver side of the vehicle.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

6-112

Page 384 of 440

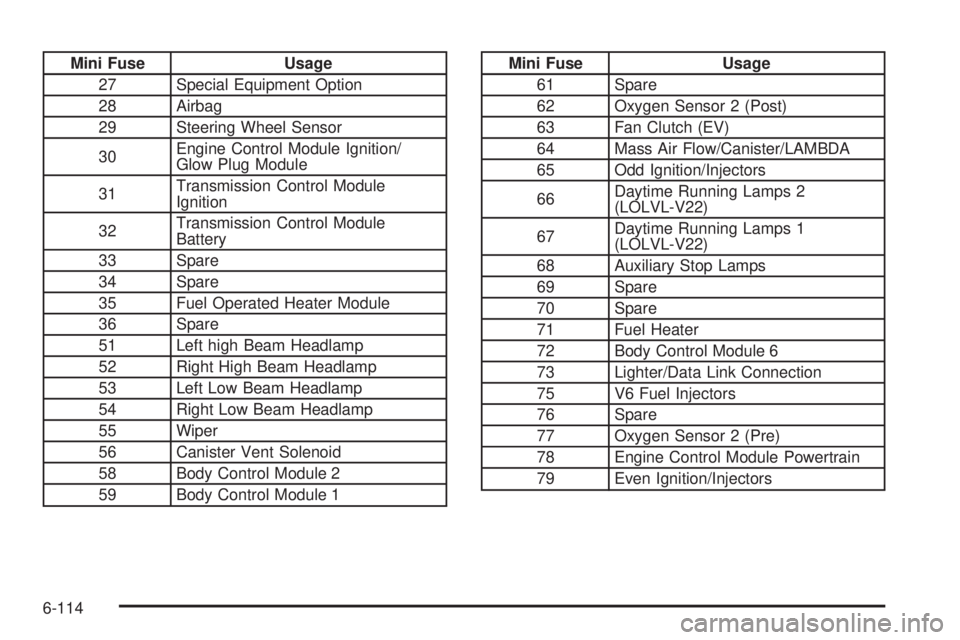

Mini Fuse Usage

27 Special Equipment Option

28 Airbag

29 Steering Wheel Sensor

30Engine Control Module Ignition/

Glow Plug Module

31Transmission Control Module

Ignition

32Transmission Control Module

Battery

33 Spare

34 Spare

35 Fuel Operated Heater Module

36 Spare

51 Left high Beam Headlamp

52 Right High Beam Headlamp

53 Left Low Beam Headlamp

54 Right Low Beam Headlamp

55 Wiper

56 Canister Vent Solenoid

58 Body Control Module 2

59 Body Control Module 1Mini Fuse Usage

61 Spare

62 Oxygen Sensor 2 (Post)

63 Fan Clutch (EV)

64 Mass Air Flow/Canister/LAMBDA

65 Odd Ignition/Injectors

66Daytime Running Lamps 2

(LOLVL-V22)

67Daytime Running Lamps 1

(LOLVL-V22)

68 Auxiliary Stop Lamps

69 Spare

70 Spare

71 Fuel Heater

72 Body Control Module 6

73 Lighter/Data Link Connection

75 V6 Fuel Injectors

76 Spare

77 Oxygen Sensor 2 (Pre)

78 Engine Control Module Powertrain

79 Even Ignition/Injectors

6-114