light CHEVROLET EXPRESS CARGO 2021 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2021, Model line: EXPRESS CARGO, Model: CHEVROLET EXPRESS CARGO 2021Pages: 296, PDF Size: 6.68 MB

Page 199 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

198 Vehicle Care

There are only two reasons why the brake

fluid level in the reservoir may go down:

.Normal brake lining wear. When new

linings are installed, the fluid level goes

back up.

.A fluid leak in the brake hydraulic system.

Have the brake hydraulic system fixed.

With a leak, the brakes will not

work well.

Always clean the brake fluid reservoir cap

and the area around the cap before

removing it.

Do not top off the brake fluid. Adding fluid

does not correct a leak. If fluid is added

when the linings are worn, there will be too

much fluid when new brake linings are

installed. Add or remove fluid, as necessary,

only when work is done on the brake

hydraulic system.

{Warning

If too much brake fluid is added, it can

spill on the engine and burn, if the

engine is hot enough. You or others could

be burned, and the vehicle could be

damaged. Add brake fluid only when

work is done on the brake hydraulic

system. When the brake fluid falls to a low level,

the brake warning light comes on. See

Brake

System Warning Light 077.

Brake fluid absorbs water over time. Replace

brake fluid at the specified intervals to

prevent increased stopping distance. See

Maintenance Schedule 0251.

Checking Brake Fluid

Check brake fluid by looking at the brake

fluid reservoir. See Engine Compartment

Overview 0181.

The fluid level should be above MIN. If it is

not, have the brake hydraulic system

checked to see if there is a leak. After work is done on the brake hydraulic

system, make sure the level is above MIN

but not over the MAX mark.

What to Add

Use only GM approved DOT 3 brake fluid

from a clean, sealed container. See

Recommended Fluids and Lubricants

0257.

{Warning

The wrong or contaminated brake fluid

could result in damage to the brake

system. This could result in the loss of

braking leading to a possible injury.

Always use the proper GM approved

brake fluid.

Caution

If brake fluid is spilled on the vehicle's

painted surfaces, the paint finish can be

damaged. Immediately wash off any

painted surface.

Page 204 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

Vehicle Care 203

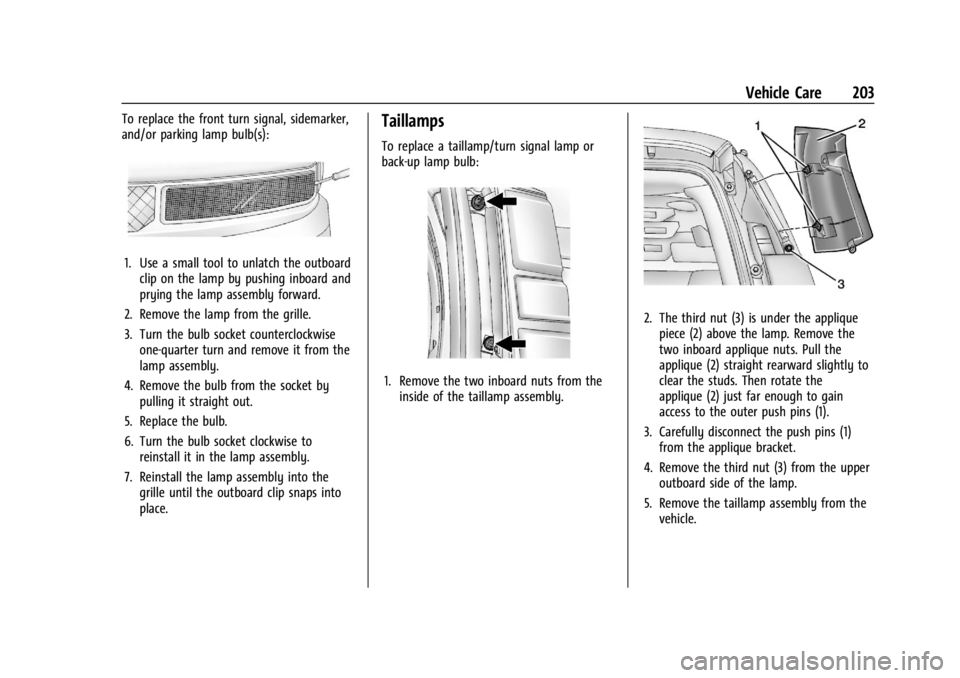

To replace the front turn signal, sidemarker,

and/or parking lamp bulb(s):

1. Use a small tool to unlatch the outboardclip on the lamp by pushing inboard and

prying the lamp assembly forward.

2. Remove the lamp from the grille.

3. Turn the bulb socket counterclockwise one-quarter turn and remove it from the

lamp assembly.

4. Remove the bulb from the socket by pulling it straight out.

5. Replace the bulb.

6. Turn the bulb socket clockwise to reinstall it in the lamp assembly.

7. Reinstall the lamp assembly into the grille until the outboard clip snaps into

place.

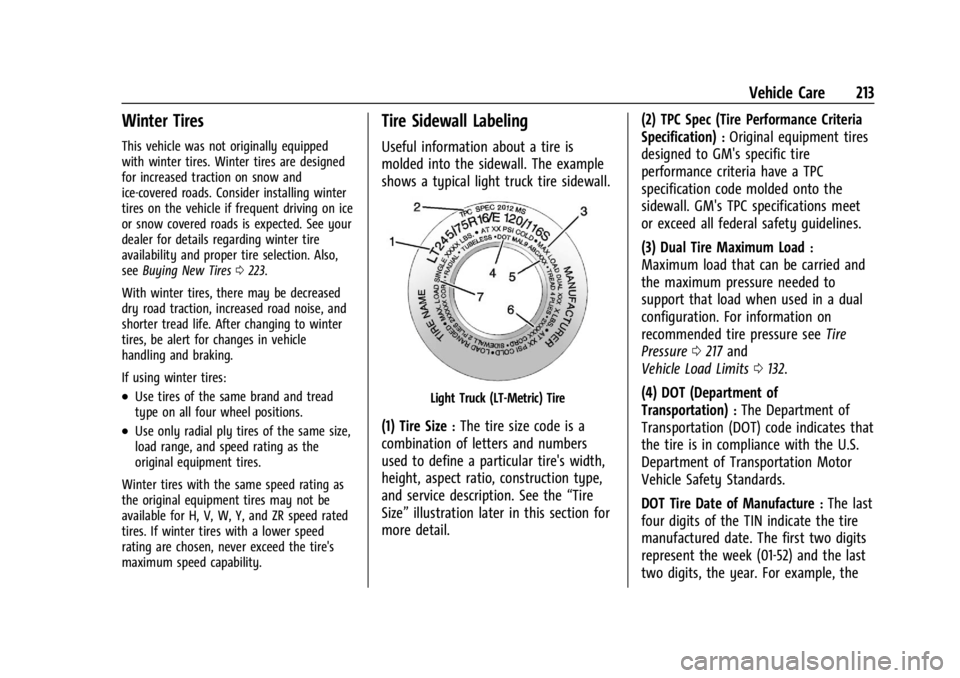

Taillamps

To replace a taillamp/turn signal lamp or

back-up lamp bulb:

1. Remove the two inboard nuts from theinside of the taillamp assembly.

2. The third nut (3) is under the appliquepiece (2) above the lamp. Remove the

two inboard applique nuts. Pull the

applique (2) straight rearward slightly to

clear the studs. Then rotate the

applique (2) just far enough to gain

access to the outer push pins (1).

3. Carefully disconnect the push pins (1) from the applique bracket.

4. Remove the third nut (3) from the upper outboard side of the lamp.

5. Remove the taillamp assembly from the vehicle.

Page 210 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

Vehicle Care 209

FusesUsage

68 Auxiliary stoplamps

69 External power for trailer

70 Upfitter stoplamps 71 Fuel heater/FlexFuel sensor

72 Body control module 6

73 Lighter/Data link connector

74 Front blower 75 Engine control module

76 Soot sensors (Diesel only)

77 O2 sensor 1

78 Engine control module/ Powertrain signal 1

79 Ignition coils/injectors - even Relays

Usage

15 Run/Crank

37 NOX Sensor (Diesel only)

38 Fuel pump

39 Crank

40 A/C compressor 48 Electro viscous fan clutch (Diesel only)

49 Powertrain 50 –

57 –

60 – Auxiliary Fuse Block

This component is near the fuse block in the

engine compartment

Fuses Usage

MR-1 Upfitter 1

MR-2 Upfitter 2

MR-3 Upfitter power control

Relays Usage

MR Rel 1 Upfitter 1

MR Rel 2 Upfitter 2

Page 214 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

Vehicle Care 213

Winter Tires

This vehicle was not originally equipped

with winter tires. Winter tires are designed

for increased traction on snow and

ice-covered roads. Consider installing winter

tires on the vehicle if frequent driving on ice

or snow covered roads is expected. See your

dealer for details regarding winter tire

availability and proper tire selection. Also,

seeBuying New Tires 0223.

With winter tires, there may be decreased

dry road traction, increased road noise, and

shorter tread life. After changing to winter

tires, be alert for changes in vehicle

handling and braking.

If using winter tires:

.Use tires of the same brand and tread

type on all four wheel positions.

.Use only radial ply tires of the same size,

load range, and speed rating as the

original equipment tires.

Winter tires with the same speed rating as

the original equipment tires may not be

available for H, V, W, Y, and ZR speed rated

tires. If winter tires with a lower speed

rating are chosen, never exceed the tire's

maximum speed capability.

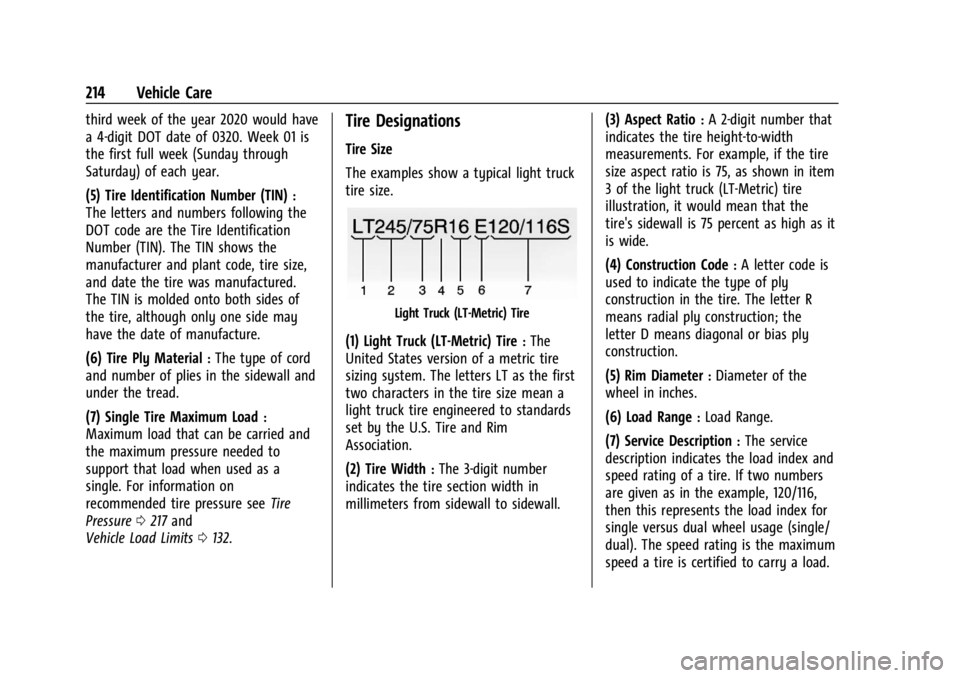

Tire Sidewall Labeling

Useful information about a tire is

molded into the sidewall. The example

shows a typical light truck tire sidewall.

Light Truck (LT-Metric) Tire

(1) Tire Size:The tire size code is a

combination of letters and numbers

used to define a particular tire's width,

height, aspect ratio, construction type,

and service description. See the “Tire

Size” illustration later in this section for

more detail. (2) TPC Spec (Tire Performance Criteria

Specification)

:Original equipment tires

designed to GM's specific tire

performance criteria have a TPC

specification code molded onto the

sidewall. GM's TPC specifications meet

or exceed all federal safety guidelines.

(3) Dual Tire Maximum Load

:

Maximum load that can be carried and

the maximum pressure needed to

support that load when used in a dual

configuration. For information on

recommended tire pressure see Tire

Pressure 0217 and

Vehicle Load Limits 0132.

(4) DOT (Department of

Transportation)

:The Department of

Transportation (DOT) code indicates that

the tire is in compliance with the U.S.

Department of Transportation Motor

Vehicle Safety Standards.

DOT Tire Date of Manufacture

:The last

four digits of the TIN indicate the tire

manufactured date. The first two digits

represent the week (01-52) and the last

two digits, the year. For example, the

Page 215 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

214 Vehicle Care

third week of the year 2020 would have

a 4-digit DOT date of 0320. Week 01 is

the first full week (Sunday through

Saturday) of each year.

(5) Tire Identification Number (TIN)

:

The letters and numbers following the

DOT code are the Tire Identification

Number (TIN). The TIN shows the

manufacturer and plant code, tire size,

and date the tire was manufactured.

The TIN is molded onto both sides of

the tire, although only one side may

have the date of manufacture.

(6) Tire Ply Material

:The type of cord

and number of plies in the sidewall and

under the tread.

(7) Single Tire Maximum Load

:

Maximum load that can be carried and

the maximum pressure needed to

support that load when used as a

single. For information on

recommended tire pressure see Tire

Pressure 0217 and

Vehicle Load Limits 0132.

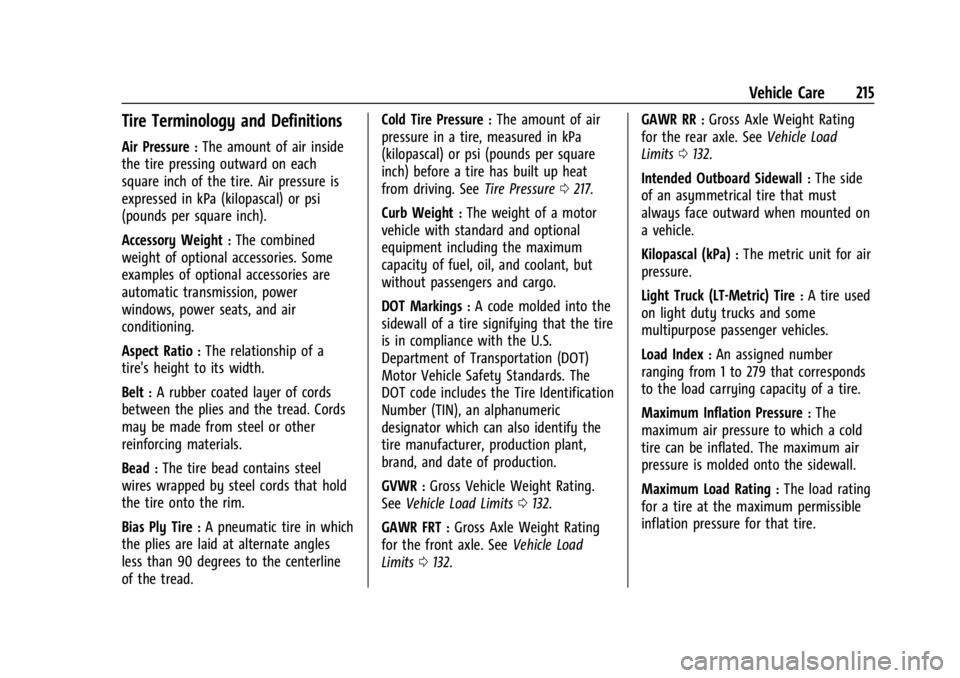

Tire Designations

Tire Size

The examples show a typical light truck

tire size.

Light Truck (LT-Metric) Tire

(1) Light Truck (LT-Metric) Tire:The

United States version of a metric tire

sizing system. The letters LT as the first

two characters in the tire size mean a

light truck tire engineered to standards

set by the U.S. Tire and Rim

Association.

(2) Tire Width

:The 3-digit number

indicates the tire section width in

millimeters from sidewall to sidewall. (3) Aspect Ratio

:A 2-digit number that

indicates the tire height-to-width

measurements. For example, if the tire

size aspect ratio is 75, as shown in item

3 of the light truck (LT-Metric) tire

illustration, it would mean that the

tire's sidewall is 75 percent as high as it

is wide.

(4) Construction Code

:A letter code is

used to indicate the type of ply

construction in the tire. The letter R

means radial ply construction; the

letter D means diagonal or bias ply

construction.

(5) Rim Diameter

:Diameter of the

wheel in inches.

(6) Load Range

:Load Range.

(7) Service Description

:The service

description indicates the load index and

speed rating of a tire. If two numbers

are given as in the example, 120/116,

then this represents the load index for

single versus dual wheel usage (single/

dual). The speed rating is the maximum

speed a tire is certified to carry a load.

Page 216 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

Vehicle Care 215

Tire Terminology and Definitions

Air Pressure:The amount of air inside

the tire pressing outward on each

square inch of the tire. Air pressure is

expressed in kPa (kilopascal) or psi

(pounds per square inch).

Accessory Weight

:The combined

weight of optional accessories. Some

examples of optional accessories are

automatic transmission, power

windows, power seats, and air

conditioning.

Aspect Ratio

:The relationship of a

tire's height to its width.

Belt

:A rubber coated layer of cords

between the plies and the tread. Cords

may be made from steel or other

reinforcing materials.

Bead

:The tire bead contains steel

wires wrapped by steel cords that hold

the tire onto the rim.

Bias Ply Tire

:A pneumatic tire in which

the plies are laid at alternate angles

less than 90 degrees to the centerline

of the tread. Cold Tire Pressure

:The amount of air

pressure in a tire, measured in kPa

(kilopascal) or psi (pounds per square

inch) before a tire has built up heat

from driving. See Tire Pressure0217.

Curb Weight

:The weight of a motor

vehicle with standard and optional

equipment including the maximum

capacity of fuel, oil, and coolant, but

without passengers and cargo.

DOT Markings

:A code molded into the

sidewall of a tire signifying that the tire

is in compliance with the U.S.

Department of Transportation (DOT)

Motor Vehicle Safety Standards. The

DOT code includes the Tire Identification

Number (TIN), an alphanumeric

designator which can also identify the

tire manufacturer, production plant,

brand, and date of production.

GVWR

:Gross Vehicle Weight Rating.

See Vehicle Load Limits 0132.

GAWR FRT

:Gross Axle Weight Rating

for the front axle. See Vehicle Load

Limits 0132. GAWR RR

:Gross Axle Weight Rating

for the rear axle. See Vehicle Load

Limits 0132.

Intended Outboard Sidewall

:The side

of an asymmetrical tire that must

always face outward when mounted on

a vehicle.

Kilopascal (kPa)

:The metric unit for air

pressure.

Light Truck (LT-Metric) Tire

:A tire used

on light duty trucks and some

multipurpose passenger vehicles.

Load Index

:An assigned number

ranging from 1 to 279 that corresponds

to the load carrying capacity of a tire.

Maximum Inflation Pressure

:The

maximum air pressure to which a cold

tire can be inflated. The maximum air

pressure is molded onto the sidewall.

Maximum Load Rating

:The load rating

for a tire at the maximum permissible

inflation pressure for that tire.

Page 217 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

216 Vehicle Care

Maximum Loaded Vehicle Weight:The

sum of curb weight, accessory weight,

vehicle capacity weight, and production

options weight.

Normal Occupant Weight

:The number

of occupants a vehicle is designed to

seat multiplied by 68 kg (150 lb). See

Vehicle Load Limits 0132.

Occupant Distribution

:Designated

seating positions.

Outward Facing Sidewall

:The side of

an asymmetrical tire that has a

particular side that faces outward when

mounted on a vehicle. The side of the

tire that contains a whitewall, bears

white lettering, or bears manufacturer,

brand, and/or model name molding

that is higher or deeper than the same

moldings on the other sidewall of

the tire.

Passenger (P-Metric) Tire

:A tire used

on passenger cars and some light duty

trucks and multipurpose vehicles. Recommended Inflation Pressure

:

Vehicle manufacturer's recommended

tire inflation pressure as shown on the

tire placard. See

Tire Pressure0217 and

Vehicle Load Limits 0132.

Radial Ply Tire

:A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim

:A metal support for a tire and

upon which the tire beads are seated.

Sidewall

:The portion of a tire between

the tread and the bead.

Speed Rating

:An alphanumeric code

assigned to a tire indicating the

maximum speed at which a tire can

operate.

Traction

:The friction between the tire

and the road surface. The amount of

grip provided.

Tread

:The portion of a tire that comes

into contact with the road. Treadwear Indicators

:Narrow bands,

sometimes called wear bars, that show

across the tread of a tire when only

1.6 mm (1/16 in) of tread remains. See

When It Is Time for New Tires 0223.

UTQGS (Uniform Tire Quality Grading

Standards)

:A tire information system

that provides consumers with ratings

for a tire's traction, temperature, and

treadwear. Ratings are determined by

tire manufacturers using government

testing procedures. The ratings are

molded into the sidewall of the tire.

See Uniform Tire Quality Grading 0225.

Vehicle Capacity Weight

:The number

of designated seating positions

multiplied by 68 kg (150 lb) plus the

rated cargo load. See Vehicle Load

Limits 0132.

Vehicle Maximum Load on the Tire

:

Load on an individual tire due to curb

weight, accessory weight, occupant

weight, and cargo weight.

Page 220 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

Vehicle Care 219

mounted onto each tire and wheel

assembly, excluding the spare tire and

wheel assembly. The TPMS sensors monitor

the air pressure in the tires and transmit the

tire pressure readings to a receiver located

in the vehicle.

When a low tire pressure condition is

detected, the TPMS illuminates the low tire

pressure warning light located on the

instrument cluster. If the warning light

comes on, stop as soon as possible and

inflate the tires to the recommended

pressure shown on the Tire and Loading

Information label. SeeVehicle Load Limits

0 132.

A message to check the pressure in a

specific tire displays in the Driver

Information Center (DIC). The low tire

pressure warning light and the DIC warning

message come on at each ignition cycle

until the tires are inflated to the correct

inflation pressure. If the vehicle has DIC

buttons, tire pressure levels can be viewed. For additional information and details about

the DIC operation and displays, see

Driver

Information Center (DIC) 081.

The low tire pressure warning light may

come on in cool weather when the vehicle is

first started, and then turn off as the vehicle

is driven. This could be an early indicator

that the air pressure is getting low and

needs to be inflated to the proper pressure.

A Tire and Loading Information label shows

the size of the original equipment tires and

the correct inflation pressure for the tires

when they are cold. See Vehicle Load Limits

0 132, for an example of the Tire and

Loading Information label and its location.

Also see Tire Pressure 0217.

The TPMS can warn about a low tire

pressure condition but it does not replace

normal tire maintenance. See Tire Inspection

0 221, Tire Rotation 0221 and

Tires 0212.

Caution

Tire sealant materials are not all the

same. A non-approved tire sealant could

damage the TPMS sensors. TPMS sensor

damage caused by using an incorrect tire

(Continued)

Caution (Continued)

sealant is not covered by the vehicle

warranty. Always use only the GM

approved tire sealant available through

your dealer or included in the vehicle.

TPMS Malfunction Light and Message

The TPMS will not function properly if one

or more of the TPMS sensors are missing or

inoperable. When the system detects a

malfunction, the low tire pressure warning

light flashes for about one minute and then

stays on for the remainder of the ignition

cycle. A DIC warning message also displays.

The malfunction light and DIC warning

message come on at each ignition cycle

until the problem is corrected. Some of the

conditions that can cause these to come

on are:

.One of the road tires has been replaced

with the spare tire. The spare tire does

not have a TPMS sensor. The malfunction

light and the DIC message should go off

after the road tire is replaced and the

sensor matching process is performed

successfully. See "TPMS Sensor Matching

Process" later in this section.

Page 221 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

220 Vehicle Care

.The TPMS sensor matching process was

not done or not completed successfully

after rotating the tires. The malfunction

light and the DIC message should go off

after successfully completing the sensor

matching process. See "TPMS Sensor

Matching Process" later in this section.

.One or more TPMS sensors are missing or

damaged. The malfunction light and the

DIC message should go off when the

TPMS sensors are installed and the sensor

matching process is performed

successfully. See your dealer for service.

.Replacement tires or wheels do not match

the original equipment tires or wheels.

Tires and wheels other than those

recommended could prevent the TPMS

from functioning properly. SeeBuying

New Tires 0223.

.Operating electronic devices or being near

facilities using radio wave frequencies

similar to the TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning properly, it

cannot detect or signal a low tire pressure

condition. See your dealer for service if the

TPMS malfunction light and DIC message

come on and stay on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique

identification code. The identification code

needs to be matched to a new tire/wheel

position after rotating the vehicle’s tires or

replacing one or more of the TPMS sensors.

Also, the TPMS sensor matching process

should be performed after replacing a spare

tire with a road tire containing the TPMS

sensor. The malfunction light and the DIC

message should go off at the next ignition

cycle. The sensors are matched to the tire/

wheel positions, using a TPMS relearn tool,

in the following order: driver side front tire,

passenger side front tire, passenger side rear

tire, and driver side rear. See your dealer for

service or to purchase a relearn tool.

A TPMS relearn tool can also be purchased.

See Tire Pressure Monitor Sensor Activation

Tool at www.gmtoolsandequipment.com or

call 1-800-GM TOOLS (1-800-468-6657).

There are two minutes to match the first

tire/wheel position, and five minutes overall

to match all four tire/wheel positions. If it

takes longer, the matching process stops

and must be restarted.

The TPMS sensor matching process is: 1. Set the parking brake. 2. Turn the ignition on without starting the

vehicle. See Ignition Positions 0135.

3. Press the Remote Keyless Entry (RKE) transmitter's

QandKbuttons at the

same time for approximately

five seconds. The horn sounds twice to

signal the receiver is in relearn mode

and TIRE LEARNING ACTIVE message

displays on the DIC screen.

If the vehicle does not have RKE, press

the Driver Information Center (DIC)

vehicle information button until the

PRESS VTO RELEARN TIRE POSITIONS

message displays. The horn sounds twice

to signal the receiver is in relearn mode

and TIRE LEARNING ACTIVE message

displays on the DIC screen.

4. Start with the driver side front tire.

5. Place the relearn tool against the tire sidewall, near the valve stem. Then press

the button to activate the TPMS sensor.

A horn chirp confirms that the sensor

identification code has been matched to

this tire and wheel position.

6. Proceed to the passenger side front tire, and repeat the procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeat the procedure in Step 5.

Page 223 of 296

Chevrolet Express Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

14583525) - 2021 - CRC - 12/9/20

222 Vehicle Care

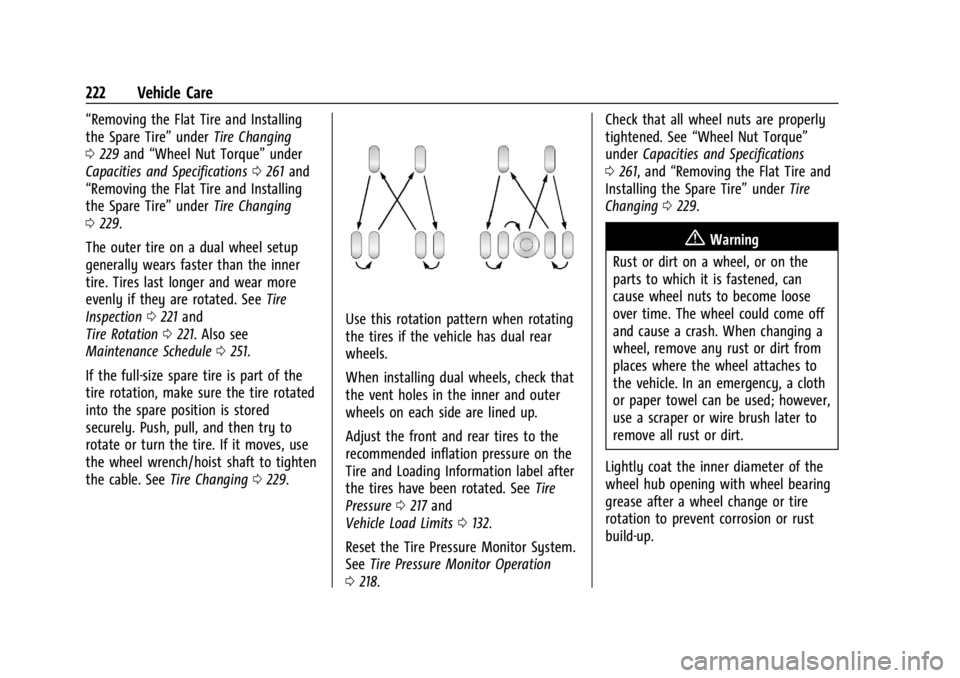

“Removing the Flat Tire and Installing

the Spare Tire”underTire Changing

0 229 and “Wheel Nut Torque” under

Capacities and Specifications 0261 and

“Removing the Flat Tire and Installing

the Spare Tire” underTire Changing

0 229.

The outer tire on a dual wheel setup

generally wears faster than the inner

tire. Tires last longer and wear more

evenly if they are rotated. See Tire

Inspection 0221 and

Tire Rotation 0221. Also see

Maintenance Schedule 0251.

If the full-size spare tire is part of the

tire rotation, make sure the tire rotated

into the spare position is stored

securely. Push, pull, and then try to

rotate or turn the tire. If it moves, use

the wheel wrench/hoist shaft to tighten

the cable. See Tire Changing0229.

Use this rotation pattern when rotating

the tires if the vehicle has dual rear

wheels.

When installing dual wheels, check that

the vent holes in the inner and outer

wheels on each side are lined up.

Adjust the front and rear tires to the

recommended inflation pressure on the

Tire and Loading Information label after

the tires have been rotated. See Tire

Pressure 0217 and

Vehicle Load Limits 0132.

Reset the Tire Pressure Monitor System.

See Tire Pressure Monitor Operation

0 218. Check that all wheel nuts are properly

tightened. See

“Wheel Nut Torque”

under Capacities and Specifications

0 261, and “Removing the Flat Tire and

Installing the Spare Tire” underTire

Changing 0229.

{Warning

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

cause wheel nuts to become loose

over time. The wheel could come off

and cause a crash. When changing a

wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, a cloth

or paper towel can be used; however,

use a scraper or wire brush later to

remove all rust or dirt.

Lightly coat the inner diameter of the

wheel hub opening with wheel bearing

grease after a wheel change or tire

rotation to prevent corrosion or rust

build-up.