light CHEVROLET HHR 2010 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: HHR, Model: CHEVROLET HHR 2010 1.GPages: 480, PDF Size: 5.25 MB

Page 336 of 480

7. Start the engine and let it run until you can feel theupper radiator hose getting hot. Watch out for the

engine cooling fan.

8. By this time, the coolant level inside the radiator filler port may be lower. If the level is lower, add

more of the proper DEX-COOL

®coolant mixture

through the fill port until the level reaches the base

of the fill port.

9. Then replace the pressure cap. At any time during this procedure, if coolant begins to flow out of the

fill port, reinstall the pressure cap. Be sure the

pressure cap is hand-tight and fully seated.

10. When the engine has cooled, check the coolant in the coolant recovery tank. The level in the coolant

recovery tank should be at the COLD FILL line

when the engine is cold.

Engine Overheating

The vehicle has several indicators to warn of engine

overheating.

You will find a coolant temperature warning light and a

coolant temperature gauge on your vehicle's instrument

panel. See Engine Coolant Temperature Warning Light

on page 4‑34andEngine Coolant Temperature Gaugeon page 4‑34for more information.

You may decide not to lift the hood when this warning

appears, but instead get service help right away. See

Roadside Assistance Program on page 8‑6.

If you do decide to lift the hood, make sure the vehicle

is parked on a level surface.

Then check to see if the engine cooling fans are

running. If the engine is overheating, both fans should

be running. If they are not, do not continue to run the

engine and have the vehicle serviced.

Notice: Engine damage from running the engine

without coolant is not covered by the warranty.

Notice: If the engine catches fire because of being

driven with no coolant, your vehicle can be badly

damaged. The costly repairs would not be covered

by the vehicle warranty.

6-34

Page 339 of 480

Brakes

Brake Fluid

The brake master cylinder and, on manual transmission

vehicles, the clutch hydraulic system use the same

reservoir. SeeEngine Compartment Overview

on

page 6‑16for the location of the reservoir. The

reservoir is filled with DOT 3 brake fluid.

There are only two reasons why the brake fluid level in

the reservoir might go down:

.The brake fluid level goes down because of

normal brake lining wear. When new linings are

installed, the fluid level goes back up.

.A fluid leak in the brake and/or clutch hydraulic

system can also cause a low fluid level. Have the

brake and/or clutch hydraulic system fixed, since a

leak means that sooner or later the brakes and/or

clutch will not work well. Do not top off the brake/clutch fluid. Adding fluid does

not correct a leak. If fluid is added when the brake

linings are worn, there will be too much fluid when new

brake linings are installed. Add or remove fluid, as

necessary, only when work is done on the brake/clutch

hydraulic system.

{WARNING:

If too much brake fluid is added, it can spill on the

engine and burn, if the engine is hot enough. You

or others could be burned, and the vehicle could

be damaged. Add brake fluid only when work is

done on the brake and/or clutch hydraulic system.

When the brake fluid falls to a low level, the brake

warning light comes on. See Brake System Warning

Light on page 4‑30.

6-37

Page 341 of 480

Brake Wear

This vehicle has front disc brakes and could have rear

drum brakes or rear disc brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads are

worn and new pads are needed. The sound can come

and go or be heard all the time the vehicle is moving,

except when applying the brake pedal firmly.

{WARNING:

The brake wear warning sound means that soon

the brakes will not work well. That could lead to

an accident. When the brake wear warning sound

is heard, have the vehicle serviced.

Notice: Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates can cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

the brakes. Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to torque specifications in

Capacities and Specifications on page 6‑125.

If the vehicle has rear drum brakes, they do not

have wear indicators, but if a rear brake rubbing

noise is heard, have the rear brake linings inspected

immediately. Rear brake drums should be removed and

inspected each time the tires are removed for rotation or

changing. When the front brake pads are replaced,

have the rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase in

pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every time the brakes are applied, with or without the

vehicle moving, the brakes adjust for wear.

6-39

Page 343 of 480

Jump Starting

If the vehicle's battery has run down, you may want to

use another vehicle and some jumper cables to start the

vehicle. Be sure to use the following steps to do it

safely.

{WARNING:

Batteries can hurt you. They can be dangerous

because:

.They contain acid that can burn you.

.They contain gas that can explode or ignite.

.They contain enough electricity to burn you.

If you do not follow these steps exactly, some or

all of these things can hurt you.

Notice: Ignoring these steps could result in costly

damage to the vehicle that would not be covered by

the warranty.

Trying to start the vehicle by pushing or pulling it

will not work, and it could damage the vehicle.

1. Check the other vehicle. It must have a 12-volt battery with a negative ground system. Notice:

If the other vehicle's system is not a 12-volt

system with a negative ground, both vehicles can

be damaged. Only use vehicles with 12-volt systems

with negative grounds to jump start your vehicle.

2. Get the vehicles close enough so the jumper cables can reach, but be sure the vehicles are not

touching each other. If they are, it could cause a

ground connection you do not want. You would not

be able to start the vehicle, and the bad grounding

could damage the electrical systems.

To avoid the possibility of the vehicles rolling, set

the parking brake firmly on both vehicles involved

in the jump start procedure. Put an automatic

transmission in P (Park) or a manual transmission

in N (Neutral) before setting the parking brake.

Notice: If you leave the radio or other accessories

on during the jump starting procedure, they could

be damaged. The repairs would not be covered by

the warranty. Always turn off the radio and other

accessories when jump starting the vehicle.

3. Turn off the ignition on both vehicles. Unplug unnecessary accessories plugged into the

cigarette lighter or the accessory power outlet.

Turn off the radio and all lamps that are not

needed. This will avoid sparks and help save

both batteries. And it could save the radio!

6-41

Page 345 of 480

{WARNING:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing this,

and some have been blinded. Use a flashlight if

you need more light.

Be sure the battery has enough water. You do not

need to add water to the battery installed in your

new vehicle. But if a battery has filler caps, be

sure the right amount of fluid is there. If it is low,

add water to take care of that first. If you don't,

explosive gas could be present.

Battery fluid contains acid that can burn you. Do

not get it on you. If you accidentally get it in your

eyes or on your skin, flush the place with water

and get medical help immediately.

{WARNING:

Fans or other moving engine parts can injure you

badly. Keep your hands away from moving parts

once the engine is running.

5. Check that the jumper cables do not have loose or missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go

to positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (−) will go to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−) or you

will get a short that would damage the battery and

maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

the dead battery because this can cause sparks.

6-43

Page 347 of 480

To disconnect the jumper cables from both vehicles:1. Disconnect the black negative (−) cable from the vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the vehicle with the good battery.

3. Disconnect the red positive (+) cable from the vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other vehicle.

5. Return the positive (+) terminal cover to its original position.

Headlamp Aiming

The vehicle has a visual optical headlamp aiming

system. The aim has been preset at the factory and

should need no further adjustment.

However, if the vehicle is damaged in a crash, the

headlamp aim may be affected and adjustment may be

necessary.

If oncoming vehicles flash their high beams at you, this

may also mean the vertical aim needs to be adjusted. It is recommended that the vehicle is taken to your

dealer/retailer for service if the headlamps need to be

re-aimed. It is possible however, to re-aim the

headlamps as described.

The vehicle should:

.Be placed so the headlamps are 25 ft. (7.6 m) from

a light colored wall.

.Have all four tires on a level surface which is level

all the way to the wall.

.Be placed so it is perpendicular to the wall or other

flat surface.

.Not have any snow, ice, or mud on it.

.Be fully assembled and all other work stopped

while headlamp aiming is being performed.

.Normally loaded with a full tank of fuel and one

person or 160 lbs (75 kg) sitting on the driver seat.

.Have all tires properly inflated.

.Have the spare tire is in its original location in the

vehicle.

6-45

Page 348 of 480

Headlamp aiming is done with the vehicle's low-beam

headlamps. The high-beam headlamps will be correctly

aimed if the low-beam headlamps are aimed properly.

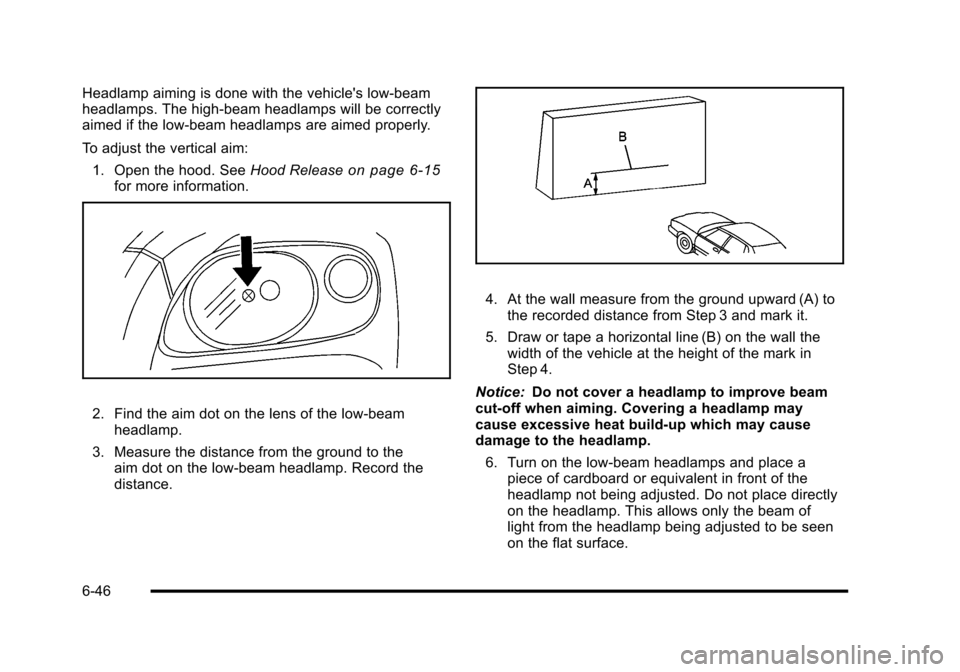

To adjust the vertical aim:1. Open the hood. See Hood Release

on page 6‑15for more information.

2. Find the aim dot on the lens of the low‐beam

headlamp.

3. Measure the distance from the ground to the aim dot on the low‐beam headlamp. Record the

distance.

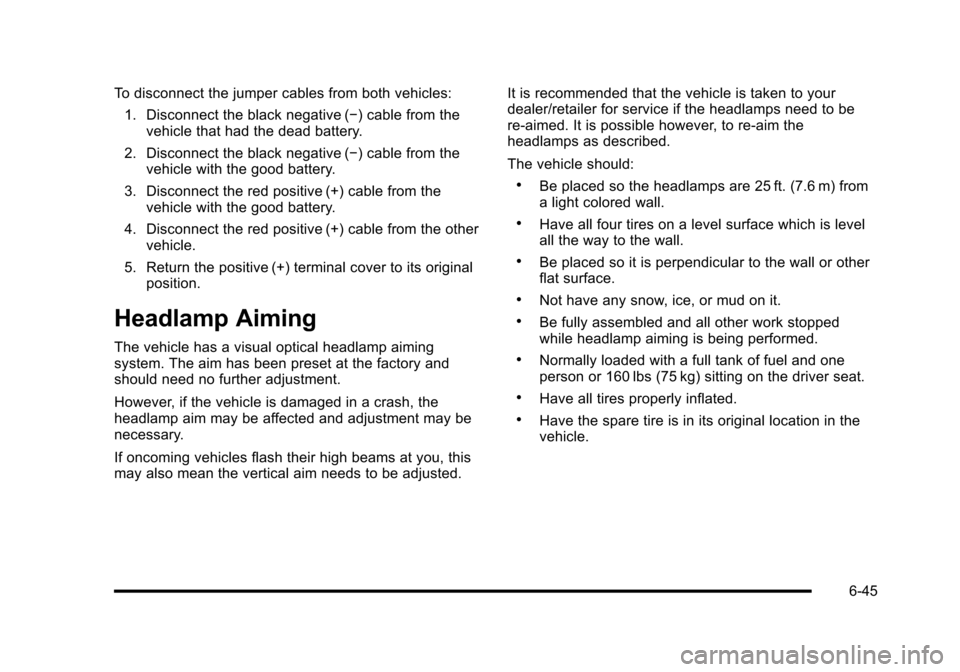

4. At the wall measure from the ground upward (A) tothe recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the vehicle at the height of the mark in

Step 4.

Notice: Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a piece of cardboard or equivalent in front of the

headlamp not being adjusted. Do not place directly

on the headlamp. This allows only the beam of

light from the headlamp being adjusted to be seen

on the flat surface.

6-46

Page 349 of 480

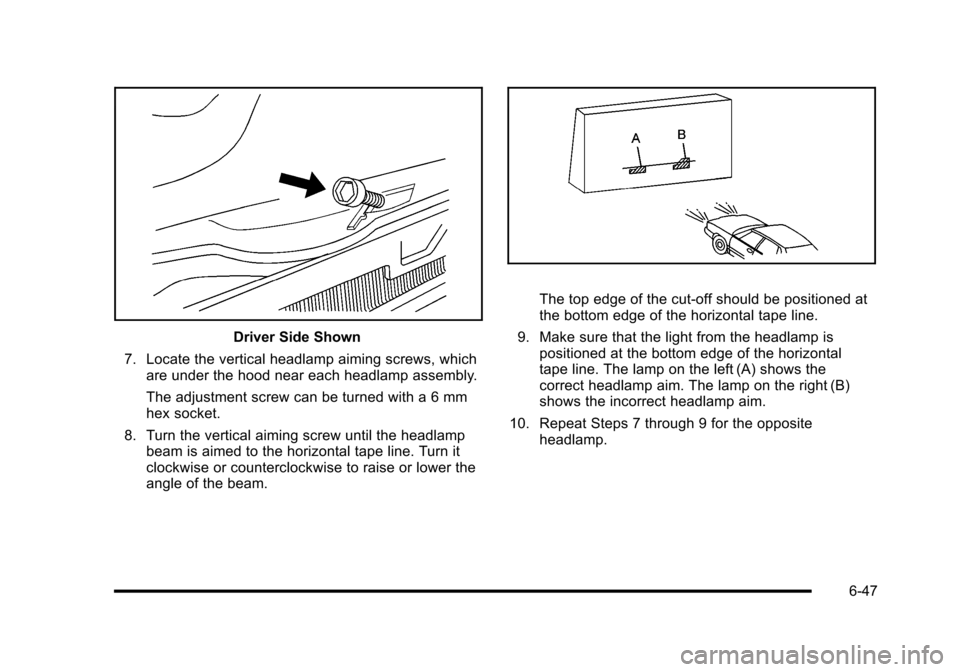

Driver Side Shown

7. Locate the vertical headlamp aiming screws, which are under the hood near each headlamp assembly.

The adjustment screw can be turned with a 6 mm

hex socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

The top edge of the cut-off should be positioned at

the bottom edge of the horizontal tape line.

9. Make sure that the light from the headlamp is positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows the

correct headlamp aim. The lamp on the right (B)

shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

6-47

Page 363 of 480

GAWR RR:Gross Axle Weight Rating for the rear

axle. See Loading the Vehicle

on page 5‑24.

Intended Outboard Sidewall

:The side of an

asymmetrical tire, that must always face outward

when mounted on a vehicle.

Kilopascal (kPa)

:The metric unit for air pressure.

Light Truck (LT‐Metric) Tire

:A tire used on light

duty trucks and some multipurpose passenger

vehicles.

Load Index

:An assigned number ranging from

1 to 279 that corresponds to the load carrying

capacity of a tire.

Maximum Inflation Pressure

:The maximum air

pressure to which a cold tire can be inflated. The

maximum air pressure is molded onto the

sidewall.

Maximum Load Rating

:The load rating for a tire

at the maximum permissible inflation pressure for

that tire. Maximum Loaded Vehicle Weight

:The sum of

curb weight, accessory weight, vehicle capacity

weight, and production options weight.

Normal Occupant Weight

:The number of

occupants a vehicle is designed to seat multiplied

by 150 lbs (68 kg). See Loading the Vehicle

on

page 5‑24

.

Occupant Distribution

:Designated seating

positions.

Outward Facing Sidewall

:The side of an

asymmetrical tire that has a particular side that

faces outward when mounted on a vehicle. The

side of the tire that contains a whitewall, bears

white lettering, or bears manufacturer, brand,

and/or model name molding that is higher or

deeper than the same moldings on the other

sidewall of the tire.

Passenger (P-Metric) Tire

:A tire used on

passenger cars and some light duty trucks

and multipurpose vehicles.

6-61

Page 367 of 480

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver's responsibility to

maintain correct tire pressure, even if under‐inflation

has not reached the level to trigger illumination of the

TPMS low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is

not operating properly. The TPMS malfunction indicator

is combined with the low tire pressure telltale. When

the system detects a malfunction, the telltale will flash

for approximately one minute and then remain

continuously illuminated. This sequence will continue

upon subsequent vehicle start‐ups as long as the

malfunction exists.

When the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may occur

for a variety of reasons, including the installation of

replacement or alternate tires or wheels on the

vehicle that prevent the TPMS from functioning

properly. Always check the TPMS malfunction telltale

after replacing one or more tires or wheels on your

vehicle to ensure that the replacement or alternate tires

and wheels allow the TPMS to continue to function

properly.

SeeTire Pressure Monitor Operation

on page 6‑65for

additional information.

Federal Communications Commission

(FCC) and Industry Canada

See Radio Frequency Statementon page 8‑17for

information regarding Part 15 of the Federal

Communications Commission (FCC) Rules and

RSS-210/211 of Industry Canada.

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure Monitor System

(TPMS). The TPMS is designed to warn the driver when

a low tire pressure condition exists. If your vehicle has

this feature, TPMS sensors are mounted onto each tire

and wheel assembly, excluding the spare tire and wheel

assembly. The TPMS sensors monitor the air pressure

in the vehicle's tires and transmits the tire pressure

readings to a receiver located in the vehicle.

When a low tire pressure

condition is detected, the

TPMS turns on the low

tire pressure warning light

located on the instrument

panel cluster.

6-65