light CHEVROLET HHR 2011 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2011, Model line: HHR, Model: CHEVROLET HHR 2011 1.GPages: 430, PDF Size: 4.57 MB

Page 310 of 430

Black plate (34,1)Chevrolet HHR Owner Manual - 2011

Jump Starting

For more information about the vehicle battery, see

Battery on page 6‑33.

If the vehicle's battery has run down, you may want to

use another vehicle and some jumper cables to start the

vehicle. Be sure to use the following steps to do it

safely.

{WARNING:

Batteries can hurt you. They can be dangerous

because:

.They contain acid that can burn you.

.They contain gas that can explode or ignite.

.They contain enough electricity to burn you.

If you do not follow these steps exactly, some or

all of these things can hurt you.

Notice: Ignoring these steps could result in costly

damage to the vehicle that would not be covered by

the warranty.

Trying to start the vehicle by pushing or pulling it

will not work, and it could damage the vehicle.

1. Check the other vehicle. It must have a 12-volt battery with a negative ground system. Notice:

If the other vehicle's system is not a

12-volt system with a negative ground, both

vehicles can be damaged. Only use vehicles with

12-volt systems with negative grounds to jump start

your vehicle.

2. Get the vehicles close enough so the jumper cables can reach, but be sure the vehicles are not

touching each other. If they are, it could cause a

ground connection you do not want. You would not

be able to start the vehicle, and the bad grounding

could damage the electrical systems.

To avoid the possibility of the vehicles rolling, set

the parking brake firmly on both vehicles involved

in the jump start procedure. Put an automatic

transmission in P (Park) or a manual transmission

in N (Neutral) before setting the parking brake.

Notice: If you leave the radio or other accessories

on during the jump starting procedure, they could

be damaged. The repairs would not be covered by

the warranty. Always turn off the radio and other

accessories when jump starting the vehicle.

3. Turn off the ignition on both vehicles. Unplug unnecessary accessories plugged into the

cigarette lighter or the accessory power outlet.

Turn off the radio and all lamps that are not

needed. This will avoid sparks and help save both

batteries. And it could save the radio!

6-34

Page 312 of 430

Black plate (36,1)Chevrolet HHR Owner Manual - 2011

{WARNING:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing this,

and some have been blinded. Use a flashlight if

you need more light.

Be sure the battery has enough water. You do not

need to add water to the battery installed in your

new vehicle. But if a battery has filler caps, be

sure the right amount of fluid is there. If it is low,

add water to take care of that first. If you don't,

explosive gas could be present.

Battery fluid contains acid that can burn you. Do

not get it on you. If you accidentally get it in your

eyes or on your skin, flush the place with water

and get medical help immediately.

{WARNING:

Fans or other moving engine parts can injure you

badly. Keep your hands away from moving parts

once the engine is running.

5. Check that the jumper cables do not have loose or missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (−) will go to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−) or you

will get a short that would damage the battery and

maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

the dead battery because this can cause sparks.

6. Connect the red positive (+) cable to the positive (+) terminal location on the vehicle with the

dead battery. Use a remote positive (+) terminal if

the vehicle has one.

6-36

Page 314 of 430

Black plate (38,1)Chevrolet HHR Owner Manual - 2011

3. Disconnect the red positive (+) cable from thevehicle with the good battery.

4. Disconnect the red positive (+) cable from the other vehicle.

5. Return the positive (+) terminal cover to its original position.

Headlamp Aiming

The vehicle has a visual optical headlamp aiming

system. The aim has been preset at the factory and

should need no further adjustment.

However, if the vehicle is damaged in a crash, the

headlamp aim may be affected and adjustment may be

necessary.

If oncoming vehicles flash their high beams at you, this

may also mean the vertical aim needs to be adjusted.

It is recommended that the vehicle is taken to your

dealer for service if the headlamps need to be re-aimed.

It is possible however, to re-aim the headlamps as

described. The vehicle should:

.Be placed so the headlamps are 25 ft. (7.6 m) from

a light colored wall.

.Have all four tires on a level surface which is level

all the way to the wall.

.Be placed so it is perpendicular to the wall or other

flat surface.

.Not have any snow, ice, or mud on it.

.Be fully assembled and all other work stopped

while headlamp aiming is being performed.

.Normally loaded with a full tank of fuel and

one person or 160 lbs (75 kg) sitting on the

driver seat.

.Have all tires properly inflated.

.Have the spare tire is in its original location in the

vehicle.

Headlamp aiming is done with the vehicle's low-beam

headlamps. The high-beam headlamps will be correctly

aimed if the low-beam headlamps are aimed properly.

6-38

Page 315 of 430

Black plate (39,1)Chevrolet HHR Owner Manual - 2011

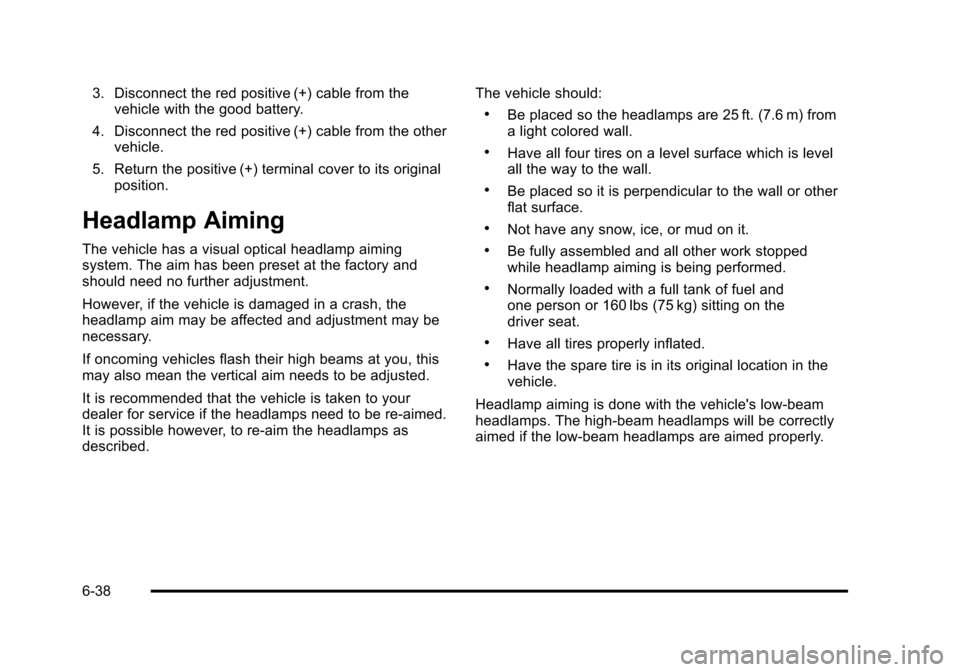

To adjust the vertical aim:1. Open the hood. See Hood Release

on page 6‑13for more information.

2. Find the aim dot on the lens of the low‐beam

headlamp.

3. Measure the distance from the ground to the aim dot on the low‐beam headlamp. Record the

distance.

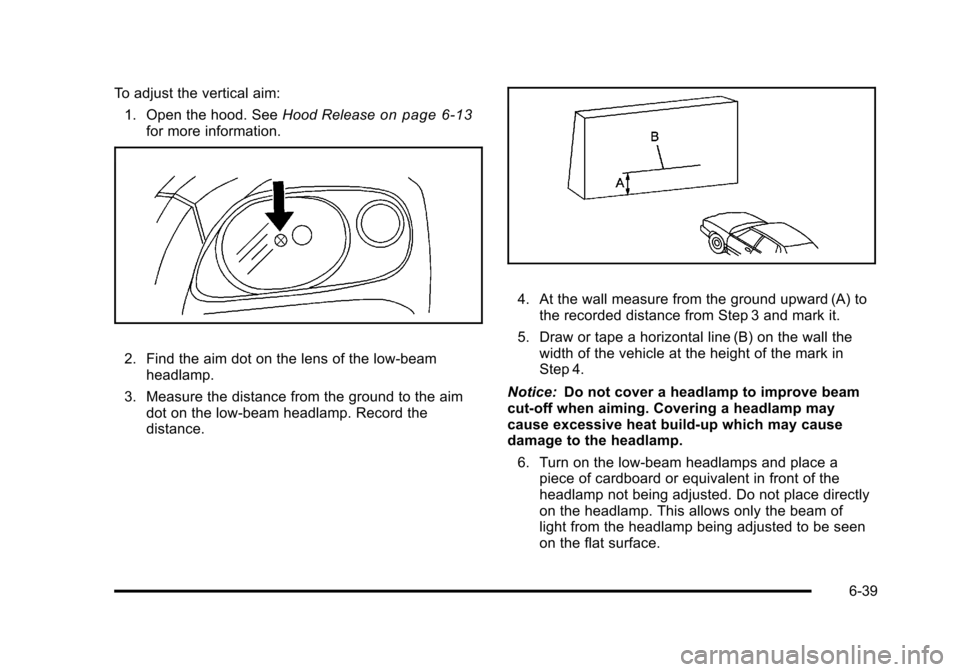

4. At the wall measure from the ground upward (A) tothe recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the vehicle at the height of the mark in

Step 4.

Notice: Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a piece of cardboard or equivalent in front of the

headlamp not being adjusted. Do not place directly

on the headlamp. This allows only the beam of

light from the headlamp being adjusted to be seen

on the flat surface.

6-39

Page 316 of 430

Black plate (40,1)Chevrolet HHR Owner Manual - 2011

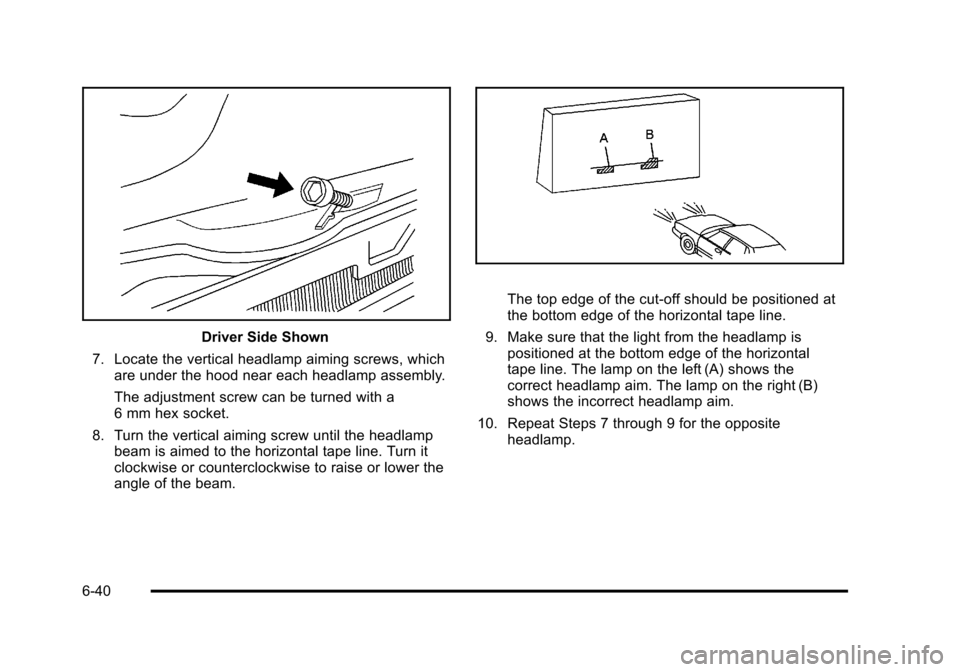

Driver Side Shown

7. Locate the vertical headlamp aiming screws, which are under the hood near each headlamp assembly.

The adjustment screw can be turned with a

6 mm hex socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

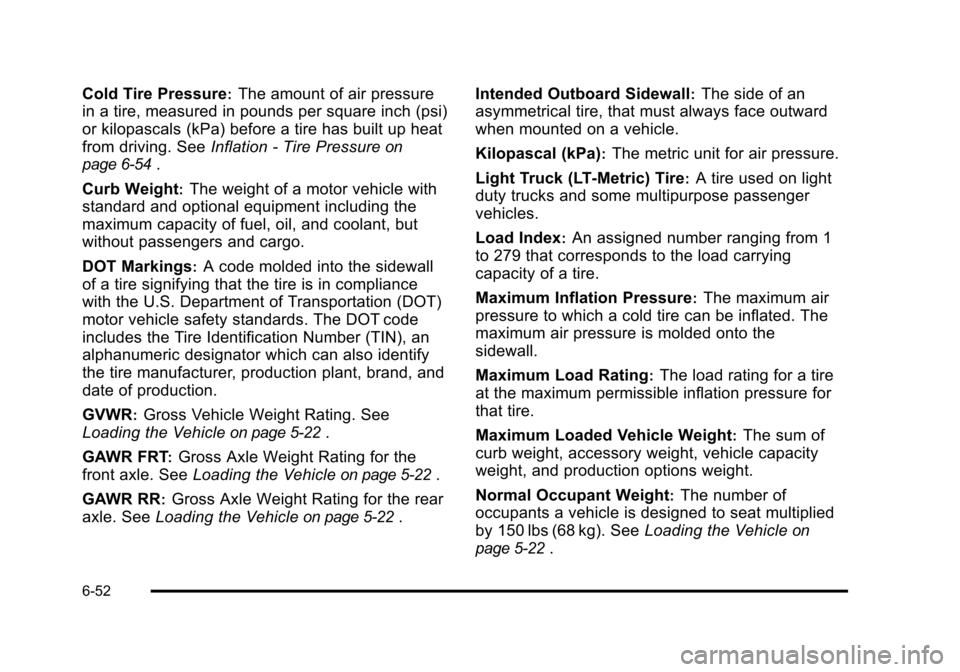

The top edge of the cut-off should be positioned at

the bottom edge of the horizontal tape line.

9. Make sure that the light from the headlamp is positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows the

correct headlamp aim. The lamp on the right (B)

shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

6-40

Page 328 of 430

Black plate (52,1)Chevrolet HHR Owner Manual - 2011

Cold Tire Pressure:The amount of air pressure

in a tire, measured in pounds per square inch (psi)

or kilopascals (kPa) before a tire has built up heat

from driving. See Inflation - Tire Pressure

on

page 6‑54

.

Curb Weight

:The weight of a motor vehicle with

standard and optional equipment including the

maximum capacity of fuel, oil, and coolant, but

without passengers and cargo.

DOT Markings

:A code molded into the sidewall

of a tire signifying that the tire is in compliance

with the U.S. Department of Transportation (DOT)

motor vehicle safety standards. The DOT code

includes the Tire Identification Number (TIN), an

alphanumeric designator which can also identify

the tire manufacturer, production plant, brand, and

date of production.

GVWR

:Gross Vehicle Weight Rating. See

Loading the Vehicle

on page 5‑22.

GAWR FRT

:Gross Axle Weight Rating for the

front axle. See Loading the Vehicle

on page 5‑22.

GAWR RR

:Gross Axle Weight Rating for the rear

axle. See Loading the Vehicle

on page 5‑22. Intended Outboard Sidewall

:The side of an

asymmetrical tire, that must always face outward

when mounted on a vehicle.

Kilopascal (kPa)

:The metric unit for air pressure.

Light Truck (LT‐Metric) Tire

:A tire used on light

duty trucks and some multipurpose passenger

vehicles.

Load Index

:An assigned number ranging from 1

to 279 that corresponds to the load carrying

capacity of a tire.

Maximum Inflation Pressure

:The maximum air

pressure to which a cold tire can be inflated. The

maximum air pressure is molded onto the

sidewall.

Maximum Load Rating

:The load rating for a tire

at the maximum permissible inflation pressure for

that tire.

Maximum Loaded Vehicle Weight

:The sum of

curb weight, accessory weight, vehicle capacity

weight, and production options weight.

Normal Occupant Weight

:The number of

occupants a vehicle is designed to seat multiplied

by 150 lbs (68 kg). See Loading the Vehicle

on

page 5‑22

.

6-52

Page 329 of 430

Black plate (53,1)Chevrolet HHR Owner Manual - 2011

Occupant Distribution:Designated seating

positions.

Outward Facing Sidewall

:The side of an

asymmetrical tire that has a particular side that

faces outward when mounted on a vehicle. The

side of the tire that contains a whitewall, bears

white lettering, or bears manufacturer, brand, and/

or model name molding that is higher or deeper

than the same moldings on the other sidewall of

the tire.

Passenger (P-Metric) Tire

:A tire used on

passenger cars and some light duty trucks and

multipurpose vehicles.

Recommended Inflation Pressure

:Vehicle

manufacturer's recommended tire inflation

pressure as shown on the tire placard. See

Inflation - Tire Pressure

on page 6‑54and Loading

the Vehicle

on page 5‑22.

Radial Ply Tire

:A pneumatic tire in which the ply

cords that extend to the beads are laid at

90 degrees to the centerline of the tread.

Rim

:A metal support for a tire and upon which

the tire beads are seated.

Sidewall

:The portion of a tire between the tread

and the bead. Speed Rating

:An alphanumeric code assigned

to a tire indicating the maximum speed at which a

tire can operate.

Traction

:The friction between the tire and the

road surface. The amount of grip provided.

Tread

:The portion of a tire that comes into

contact with the road.

Treadwear Indicators

:Narrow bands, sometimes

called wear bars, that show across the tread of a

tire when only 1/16 inch (1.6 mm) of tread

remains. See When It Is Time for New Tires

on

page 6‑62

.

UTQGS (Uniform Tire Quality Grading

Standards)

:A tire information system that

provides consumers with ratings for a tire's

traction, temperature, and treadwear. Ratings are

determined by tire manufacturers using

government testing procedures. The ratings are

molded into the sidewall of the tire. See Uniform

Tire Quality Grading

on page 6‑65.

Vehicle Capacity Weight

:The number of

designated seating positions multiplied by 150 lbs

(68 kg) plus the rated cargo load. See Loading the

Vehicle

on page 5‑22.

6-53

Page 333 of 430

Black plate (57,1)Chevrolet HHR Owner Manual - 2011

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure Monitor System

(TPMS). The TPMS is designed to warn the driver when

a low tire pressure condition exists. If your vehicle has

this feature, TPMS sensors are mounted onto each tire

and wheel assembly, excluding the spare tire and wheel

assembly. The TPMS sensors monitor the air pressure

in the vehicle's tires and transmits the tire pressure

readings to a receiver located in the vehicle.

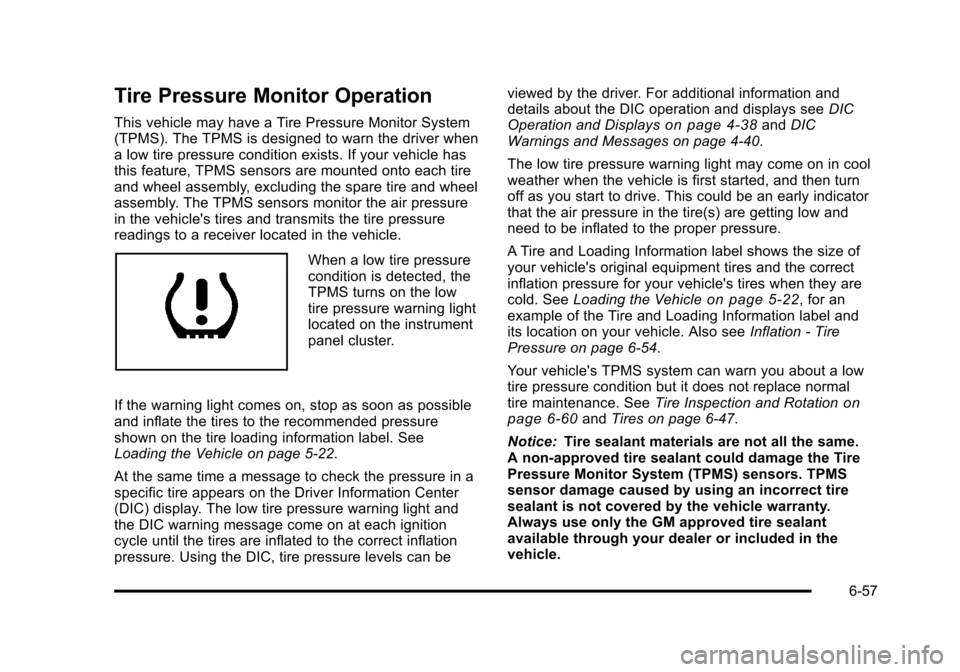

When a low tire pressure

condition is detected, the

TPMS turns on the low

tire pressure warning light

located on the instrument

panel cluster.

If the warning light comes on, stop as soon as possible

and inflate the tires to the recommended pressure

shown on the tire loading information label. See

Loading the Vehicle on page 5‑22.

At the same time a message to check the pressure in a

specific tire appears on the Driver Information Center

(DIC) display. The low tire pressure warning light and

the DIC warning message come on at each ignition

cycle until the tires are inflated to the correct inflation

pressure. Using the DIC, tire pressure levels can be viewed by the driver. For additional information and

details about the DIC operation and displays see

DIC

Operation and Displays

on page 4‑38and DIC

Warnings and Messages on page 4‑40.

The low tire pressure warning light may come on in cool

weather when the vehicle is first started, and then turn

off as you start to drive. This could be an early indicator

that the air pressure in the tire(s) are getting low and

need to be inflated to the proper pressure.

A Tire and Loading Information label shows the size of

your vehicle's original equipment tires and the correct

inflation pressure for your vehicle's tires when they are

cold. See Loading the Vehicle

on page 5‑22, for an

example of the Tire and Loading Information label and

its location on your vehicle. Also see Inflation - Tire

Pressure on page 6‑54.

Your vehicle's TPMS system can warn you about a low

tire pressure condition but it does not replace normal

tire maintenance. See Tire Inspection and Rotation

on

page 6‑60and Tires on page 6‑47.

Notice: Tire sealant materials are not all the same.

A non-approved tire sealant could damage the Tire

Pressure Monitor System (TPMS) sensors. TPMS

sensor damage caused by using an incorrect tire

sealant is not covered by the vehicle warranty.

Always use only the GM approved tire sealant

available through your dealer or included in the

vehicle.

6-57

Page 334 of 430

Black plate (58,1)Chevrolet HHR Owner Manual - 2011

Factory-installed Tire Inflator Kits use a GM approved

liquid tire sealant. Using non-approved tire sealants

could damage the TPMS sensors. SeeTire Sealant and

Compressor Kit

on page 6‑70for information regarding

the inflator kit materials and instructions.

TPMS Malfunction Light and Message

The TPMS will not function properly if one or more of

the TPMS sensors are missing or inoperable. When the

system detects a malfunction, the low tire warning light

flashes for about one minute and then stays on for the

remainder of the ignition cycle. A DIC warning message

is also displayed. The low tire warning light and DIC

warning message come on at each ignition cycle until

the problem is corrected. Some of the conditions that

can cause the malfunction light and DIC message to

come on are:

.One of the road tires has been replaced with the

spare tire. The spare tire does not have a TPMS

sensor. The TPMS malfunction light and DIC

message should go off once you re‐install the road

tire containing the TPMS sensor.

.The TPMS sensor matching process was started

but not completed or not completed successfully

after rotating the vehicle's tires. The DIC message

and TPMS malfunction light should go off once the

TPMS sensor matching process is performed

successfully. See “TPMS Sensor Matching

Process” later in this section.

.One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your dealer

for service.

.Replacement tires or wheels do not match your

vehicle's original equipment tires or wheels. Tires

and wheels other than those recommended for

your vehicle could prevent the TPMS from

functioning properly. See Buying New Tires

on

page 6‑62.

.Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signal

a low tire condition. See your dealer for service if the

TPMS malfunction light and DIC message comes on

and stays on.

6-58

Page 337 of 430

Black plate (61,1)Chevrolet HHR Owner Manual - 2011

Any time you notice unusual wear, rotate the tires

as soon as possible and check wheel alignment.

Also check for damaged tires or wheels. See

When It Is Time for New Tires

on page 6‑62and

Wheel Replacement

on page 6‑67.

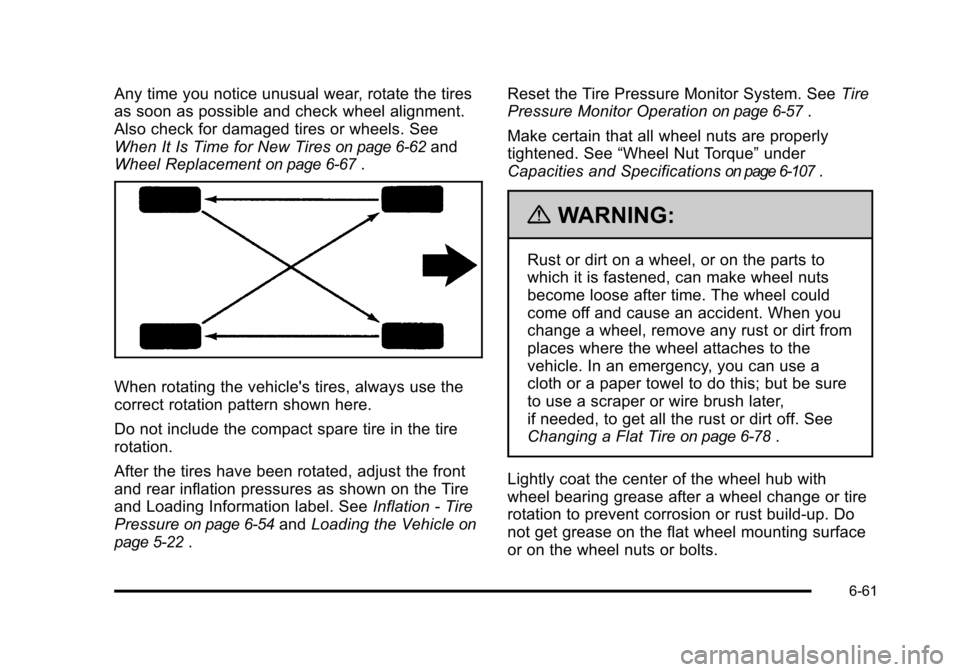

When rotating the vehicle's tires, always use the

correct rotation pattern shown here.

Do not include the compact spare tire in the tire

rotation.

After the tires have been rotated, adjust the front

and rear inflation pressures as shown on the Tire

and Loading Information label. See Inflation - Tire

Pressure

on page 6‑54and Loading the Vehicleon

page 5‑22

. Reset the Tire Pressure Monitor System. See

Tire

Pressure Monitor Operation

on page 6‑57.

Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and Specifications

on page 6‑107.

{WARNING:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the

vehicle. In an emergency, you can use a

cloth or a paper towel to do this; but be sure

to use a scraper or wire brush later,

if needed, to get all the rust or dirt off. See

Changing a Flat Tire

on page 6‑78.

Lightly coat the center of the wheel hub with

wheel bearing grease after a wheel change or tire

rotation to prevent corrosion or rust build-up. Do

not get grease on the flat wheel mounting surface

or on the wheel nuts or bolts.

6-61