check engine CHEVROLET MONTE CARLO 1973 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1973, Model line: MONTE CARLO, Model: CHEVROLET MONTE CARLO 1973 2.GPages: 86, PDF Size: 33.46 MB

Page 5 of 86

Downloaded from www.Manualslib.com manuals search engine BEFORE DRIVING YOUR MONTE CARLO

DRIVER CHECKLIST

Before Entering Car

1. See that windows , mirrors and

lights are clean.

2 . Visually note inflation condition

of tires.

3. Check that area to rear is clear

if about to back up.

Before Driving Off

1. Lock all doors.

2. Position seat and adjust head

restraints.

3. Adjust inside and outside mir

rors.

4 . Fasten seat belts.

5. Check that warning bulbs light

when key

is turned to start posi

tion.

6 . Release parking brake (and see

that brake warning light turns

off). 7

. Be sure you understand your

car and how to operate it safely.

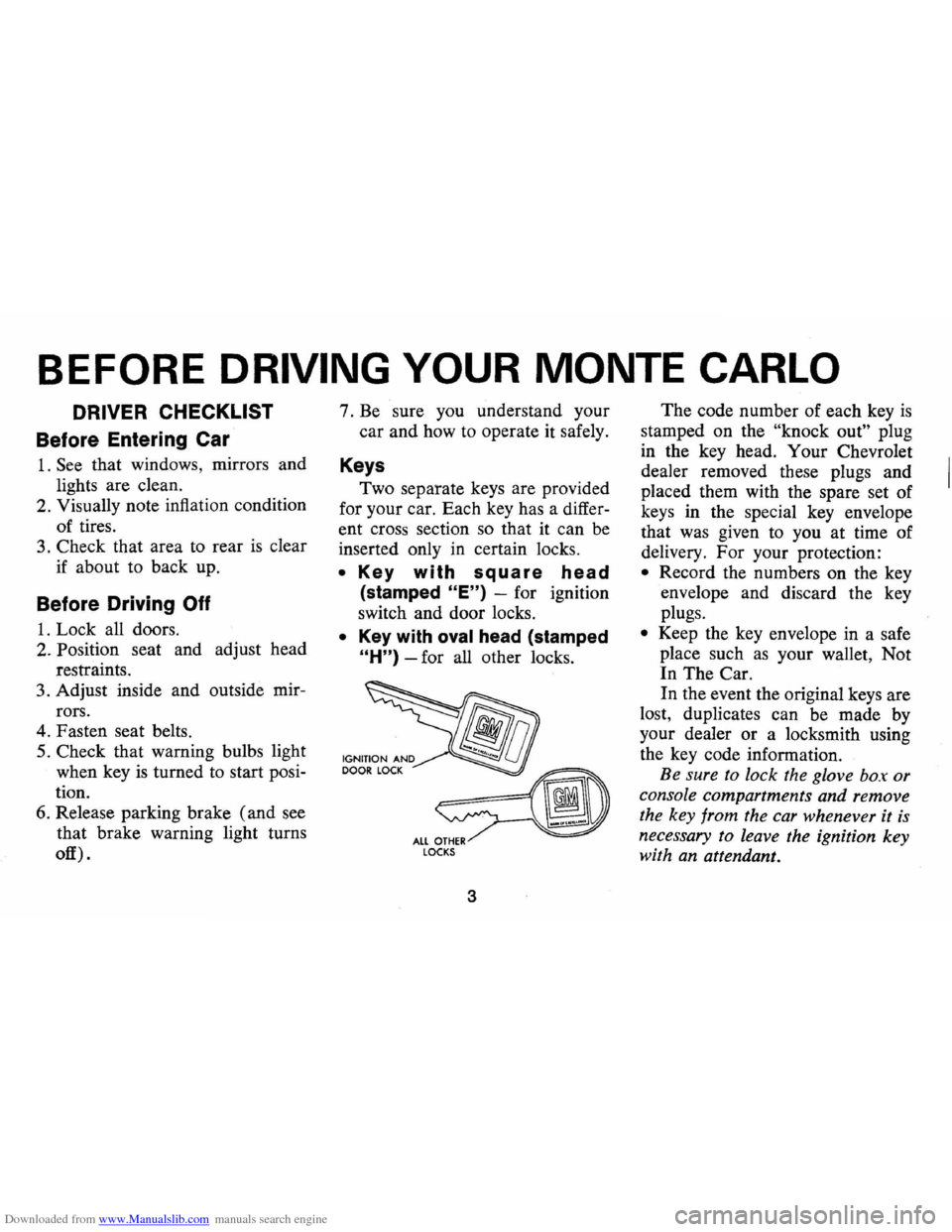

Keys

Two separate keys are provided

for your car. Each key has a differ

ent cross section so that it can be

inserted only

in certain locks.

• Key with square head

(stamped "E") -for ignition

switch and door locks.

• Key with oval head (stamped

"H") -for all other locks.

fib

~ ALL OTHER LOCKS

3

The code number of each key is

stamped on the "knock out" plug

in the key head. Your Chevrolet

dealer removed these plugs and

placed them with the spare set of

keys in the special key envelope

that was given to you at time of

delivery. For your protection:

• Record the numbers on the key

envelope and discard the key

plugs.

• Keep the key envelope in a safe

place such

as your wallet, Not

In The Car.

In the event the original keys are

lost, duplicates can be made by

your dealer or a locksmith using

the key code information.

Be sure to lock the glove box or

console compartments and remove

the key from the car whenever it

is

necessary to leave the ignition key

with an attendant.

Page 11 of 86

Downloaded from www.Manualslib.com manuals search engine • To fasten the shoulder belt, un

stow it and place the knob on

the shoulder belt end in the

keyhole on the lap belt latch

plate. (The latch

is designed so

that this attachment can only be

completed before fastening the

lap belt.) Tilt the knob as neces

sary, to pass

it through the slot.

Pull the knob firmly upward to

seat it at the narrow end of the

keyhole, then fasten the lap belt.

• Shoulder belts are lengthened

and shortened in the same man

ner

as center seat lap belts.

• Shoulder belt should have suf

ficient slack to insert a fist's

width between your chest and

the belt. This can be checked

by inserting a clenched

fist be

tween the belt and your chest

with thumb against chest and

back of hand facing upward.

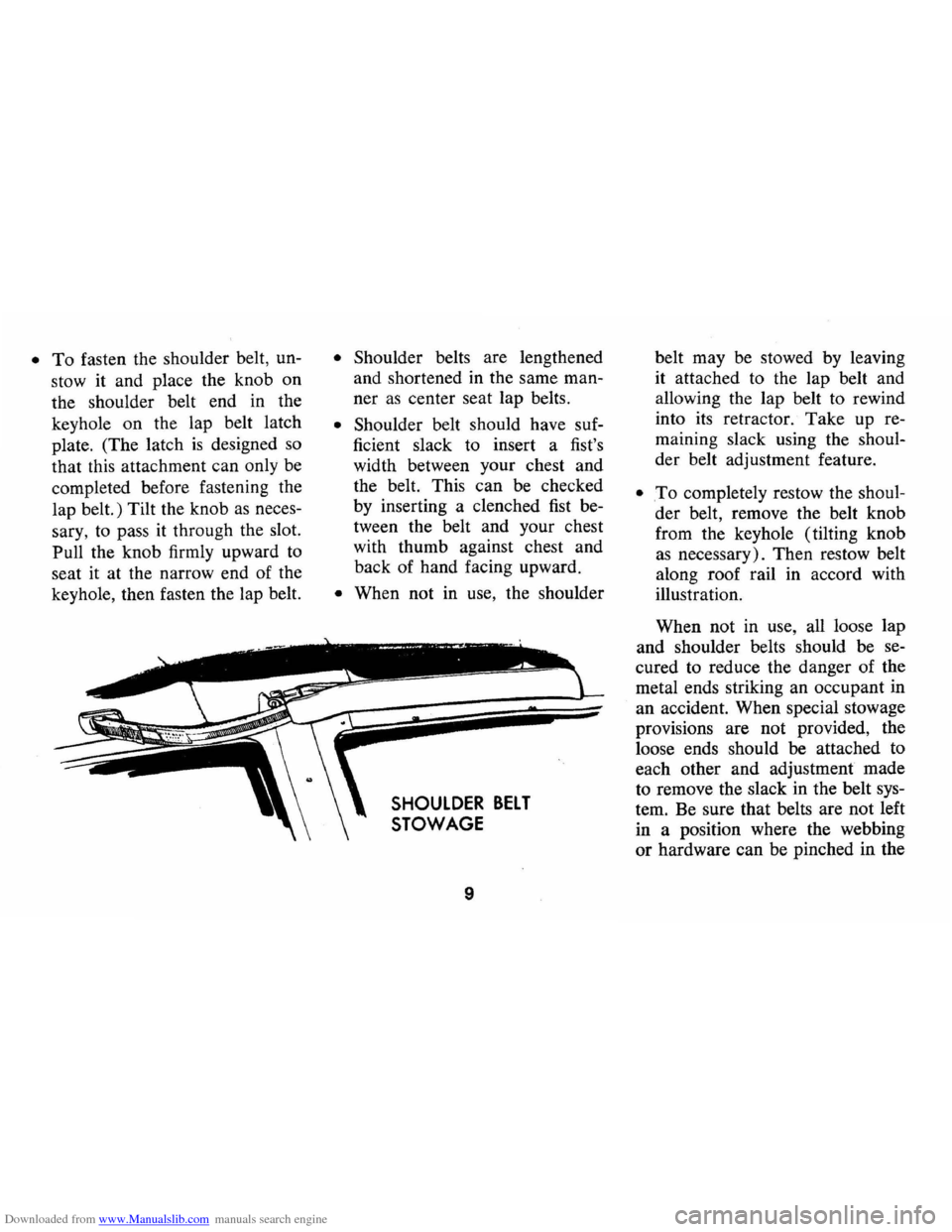

• When not in use, the shoulder

SHOULDER BELT

STOWAGE

9

belt may be stowed by leaving

it attached to the lap belt and

allowing the lap belt to rewind

into its retractor.

Take up re

maining slack using the shoul

der belt adjustment feature.

• .To completely restow the shoul

der belt, remove the belt knob

from the keyhole (tilting knob

as necessary). Then restow belt

along roof rail in accord with

illustration.

When not in use, all loose lap

and shoulder belts should be se

cured to reduce the danger of the

metal ends striking an occupant in

an accident. When special stowage

provisions are not provided, the

loose ends should be attached to

each other and adjustment made

to remove the slack in the belt sys

tem. Be sure that belts are not left

in a position where the webbing

or hardware can be pinched in the

Page 12 of 86

Downloaded from www.Manualslib.com manuals search engine seat structure or door, and thus

become damaged.

Seat Belt Inspection

• Periodically inspect belts, buck

les, retractors , and anchors for

damage that could lessen the

effectiveness of the restraint

system.

• Keep sharp edges and damaging

objects away from belts.

• Replace belts if cut, weakened,

frayed ,

or subjected to collision

loads.

• Check that anchor mounting

bolts are tight.

• Have questionable parts re

placed.

• Keep seat belts clean and dry.

• Clean only with mild soap solu

tion

and lukewarm water.

• Do not bleach or dye belts since

this may severely weaken belts.

Head Restraints

• Head restraints are designed to

help reduce injuries due to

"whiplash ."

• Select

one of the three positions

-full up, intermediate , or full

down-which places the top of

the head restraint closest to the

top of your ears.

• Do not use head restraint above

the full up

"detent" position.

• Head restraint can be raised by

pulling up until you feel it click

into the

"detent" at the inter

mediate position.

• To raise further, or to lower,

release latch at base of support

ing rod and push up

or down on

restraint.

• Do not operate vehicle with head

restraints removed, since occu

pants lose the protection pro

vided.

10

Child Restraint

Children in automobiles should

be restrained to lessen the risk of

injury in accidents, sudden stops

or other hazardous situations. Gen

eral motors dealers offer restraint

systems designed specifically for

use with infants.

In using any in

fant

or child restraint system, read

. and comply with all installation

'and usage instructions.

All unused seat belts near the

child should be stowed properly

to help prevent them from striking

him in the event of an accident.

Lap belts and shoulder belts with

out stowage provisions should

have buckles latched and belts

adjusted to remove slack.

Cars Not Equipped With

Special Child Restraints

If a child is traveling in a ve

hicle not equipped with a General

Motors infant restraint

or other

Page 14 of 86

Downloaded from www.Manualslib.com manuals search engine Detroit, Michigan 48202 (or in

Canada by writing to General

Moto rs of Canada Limited,

Owner

Relations Department , Oshawa,

Ontario) .

To assist in attaining good han

dling of the car-trailer combina

tion, it

is important that the trailer

tongue load be maintained at ap

proximately

10% of the loaded

trailer weight. Tongue loads can be

adjusted by proper distribution of

the load in the trailer, and can be

checked by weighing separately the

loaded trailer and then the tongue.

When towing trailers, tires

should be inflated to the highest inflation

pressures shown on the

placard affixed to the left front

door . The allowable passenger and

cargo load, also shown on the same

placard ,

is reduced by an amount

equal to

the trailer tongue load on

the trailer hitch.

Maintenance

More frequent vehicle mainte

nance

is required when using your

car to pull a trailer. Change the:

• Automatic transmission fluid

each

12 ,000 miles ,

• Rear axle fluid each 12,000

miles,

• Engine oil each 60 days or 3,000

12

miles , whichever occurs first.

• Positive crankcase ventilation

valve each 12 months or

12,000

miles, whichever occurs first.

Break-in Schedule

In addition to the new ca r

break-in instructions in this man

ual, it

is recommended that your

new Monte Carlo be operated for

500 miles before trailer towing. If

it is necessary to tow during this

period , avoid speeds over

50 MPH

and full throttle starts. The same

precautions should be observed

whenever a new engine, transmis

sion or axle

is installed in your car.

Page 22 of 86

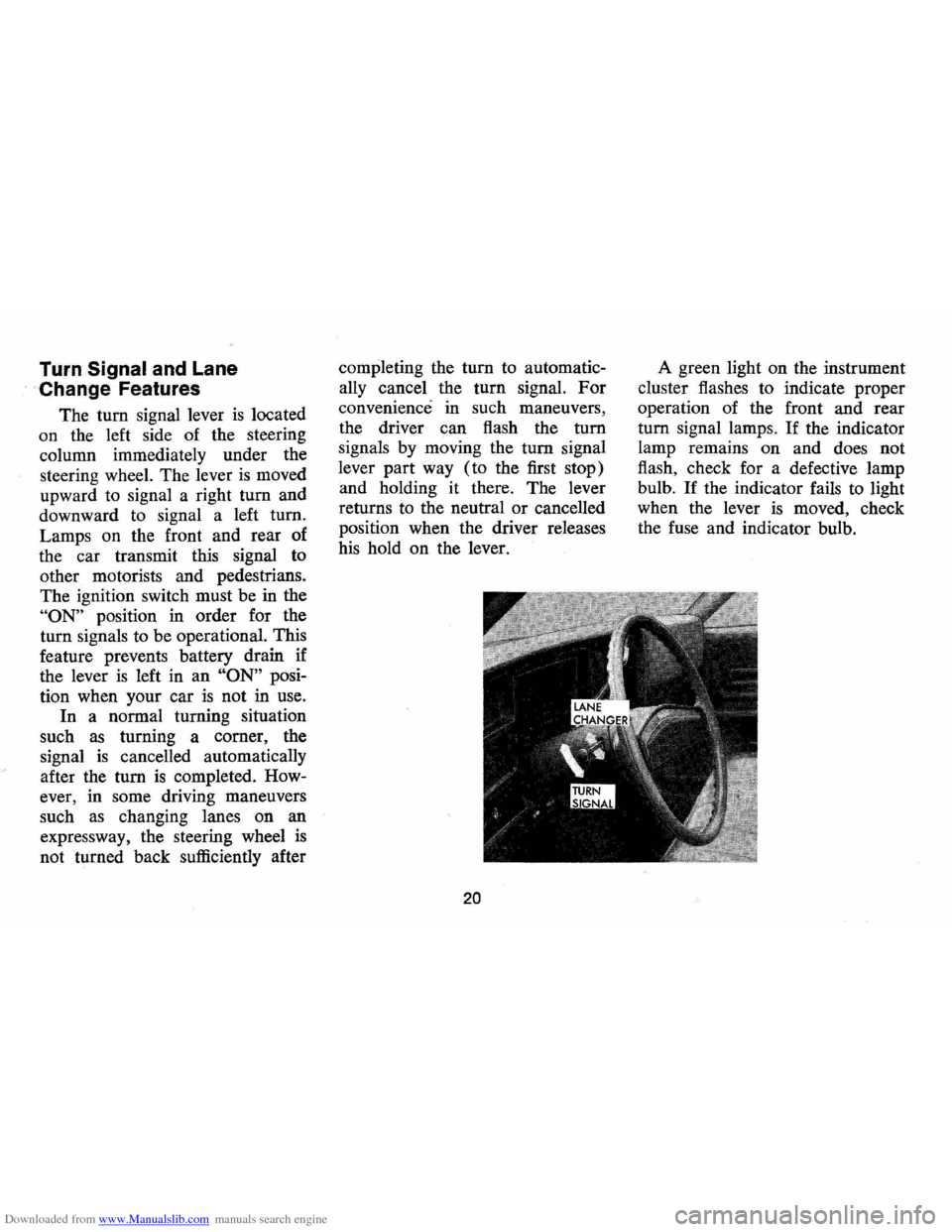

Downloaded from www.Manualslib.com manuals search engine Turn Signal and Lane

. Change Features

The tum signal lever is located

on the left side of the steering

column immediately under the

steering wheel. The lever

is moved

upward to signal a right

tum and

downward to signal a left tum.

Lamps on the front and rear of

the car transmit this signal to

other motorists and pedestrians.

The ignition switch must be in the

"ON" position in order for the

turn signals to be operational. This

feature prevents battery drain if

the lever

is left in an "ON" posi

tion when your car

is not in use.

In a normal turning situation

such

as turning a comer, the

signal

is cancelled automatically

after the tum

is completed. How

ever, in some driving maneuvers

such

as changing lanes on an

expressway, the steering wheel

is

not turned back sufficiently after completing

the

tum to automatic

ally cancel the turn signal.

For

convenience in such maneuvers,

the driver can flash the

tum

signals by moving the tum signal

lever part way (to the first stop)

and holding it there. The lever

returns to the neutral

or cancelled

position when the driver releases

his hold on the lever.

20

A green light on the instrument

cluster flashes to indicate proper

operation of the front and rear

tum signal lamps. If the indicator

lamp remains on and does not

flash, check for a defective lamp

bulb.

If the indicator fails to light

when the lever

is moved, check

the fuse and indicator bulb.

Page 25 of 86

Downloaded from www.Manualslib.com manuals search engine FLOOR CONTROLS

Braking System

The service brake system is de

signed for braking performance

under a wide range of driving con

ditions even when the vehicle

is

loaded to its full rated vehicle load.

Power Brakes

• On cars with power brakes if

power assist to the brakes

is

interrupted due to a stalled en

gine

or some malfunction, two

or more brake applications can

be made using reverse power.

• If the brake pedal is held down ,

the system

is designed to bring

the car to a full stop on reserve

power. However, the reserve

power

is partially depleted each

time the brake pedal

is applied

and released.

• When reserve power is ex- hausted,

the vehicle can still be

stopped by applying greater

force to the pedal.

Parking Brake

• To set parking brake, fully de

press foot pedal at far left side.

• For maximum holding power,

depress regular brake pedal with

the other foot at the same time.

• To release parking brake, pull

"BRAKE RELEASE" lever on

lower left instrument panel.

• As a reminder, the brake system

warning light

is designed to glow

whenever the parking brake con

trol

is not fully released, and the

ignition

is on.

• Never drive car with parking

brake set

as this may overheat

or otherwise damage rear brakes.

23

Clutch Adjustment

Clut8h adjustment should be

checked and adjusted periodically

as necessary to compensate for

clutch facing wear.

To check, de

press pedal by hand until resist

ance

is felt. Free travel of pedal

should be approximately one inch;

if very little

or no free travel is

evident, clutch adjustment is re

quired.

Page 29 of 86

Downloaded from www.Manualslib.com manuals search engine Generator Indicator Light

This light provides a quick

check on the generating system

of your car. The red light will

go on when the ignition key

is

in the "on" position, but before

the engine

is started. After the

engine starts, the light should go

out and remain out.

If the light

remains on when engine

is run

ning , have your Authorized Chev

rolet Dealer locate and correct

the trouble

as soon as possible.

Engine Temperature

Indicator Light

This indicator light is provided

in the

instrument cluster to

quickly warn of an overheated

engine. With the ignition switch

in the

START position, the red

TEMP indicator will light to let

you know that it

is operating

properly. When the engine

is started, the red

light will go out immediately.

It will light up at no other time

unless for some reason the engine

reaches a dangerously high oper

ating temperature.

If the red light

should come on, the engine must

be stopped until the cause of the

overheating

is corrected. Glance

at instrument cluster frequently

as

you drive to see if this light is on.

Brake System Warning Light

The service brake system is

designed so that half of the brake

system will provide some braking

action in the event of a hydraulic

leak in the other half of the

sys

tem. If the warning light located

below the fuel gauge glows con

tinuously when the ignition

is on

and after the brakes have been

firmly applied, it may indicate that

there

is a malfunction in one half

of the brake hydraulic system.

27

• As a check on bulb condition

the light should glow with the

parking brake applied and the

ignition on. (Light

is also a

reminder to release parking

brake) .

• Have system repaired if light

does not come on during check.

• This warning light is not a sub

stitute for the visual check of

brake fluid level required

as

part of normal maintenance.

If the light glows red:

• The parking brake control is not

fully released or,

• The service brake system is

partially inoperative

What to do:

1. Check that the parking brake

is released. If it is ...

2. Pull off the road and stop,

carefully- remembering that:

Page 30 of 86

Downloaded from www.Manualslib.com manuals search engine • Stopping distances may be

greater.

• Greater pedal effort may be

required .

• Pedal travel may be greater.

3.

Tryout braking operation by

starting and stopping on road

shoulder -then:

• If you judge such operation

to be safe , proceed cautious

ly

at a s afe speed to nearest

dealer for repair.

• Or have car towed to dealer

for repair.

Continued operation of the car

in this condition

is dangerous.

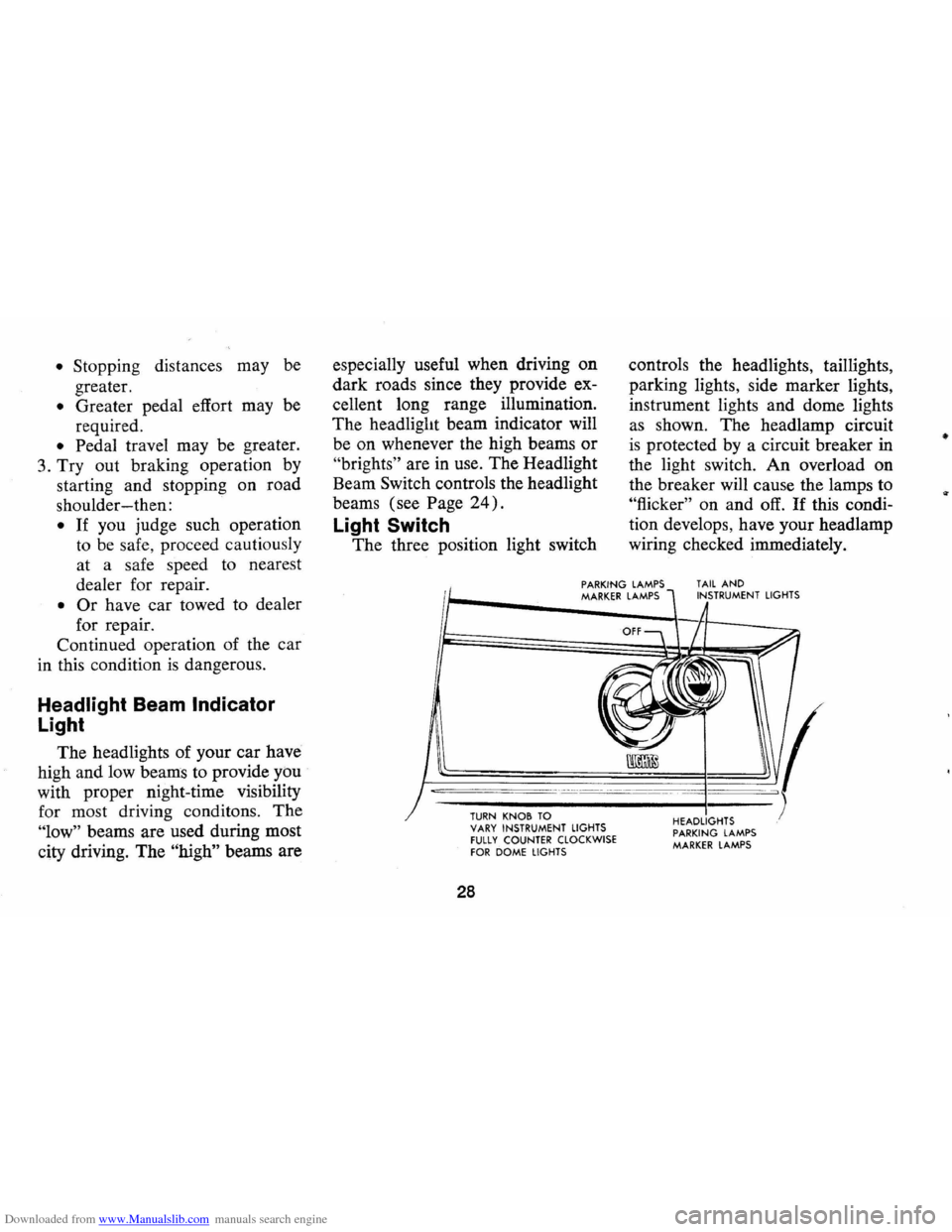

Headlight Beam Indicator

Light

The headlights of your car have

high and low beams to provide

ybu

with proper night-time visibility

for most driving conditons . The

"low" beams are used during most

city driving. The "high" beams are especially

useful when driving

on

dark roads since they provide ex

cellent long range illumination.

The headlight beam indicator will

be on whenever the high beams

or

"brights" are in use. The Headlight

Beam Switch controls the headlight

beams (see

Page 24).

Light Switch

The three position light switch controls

the headlights, taillights,

parking lights, side marker lights,

instrument lights and dome lights

as shown. The headlamp circuit

is protected by a circuit breaker in

the light switch. An overload on

the breaker will cause the lamps to

"flicker" on and off. If this condi

tion develops, have your headlamp

wiring checked immediately.

PARKING LAMPS MARKER LAMPS TAIL AND INSTRUMENT LIGHTS

--,---.---~------ -- --------

TURN KNOB TO VARY INSTRUMENT LIGHTS fULLY COUNTER CLOCKWISE fOR DOME LIGHTS

28

HEADLIGHTS PARKING LAMPS MARKER LAMPS

•

Page 33 of 86

Downloaded from www.Manualslib.com manuals search engine Clock

Reset the clock , by pulling out

the knob and turning the hands

clockwise

if slow, counterclockwise

if fast. This will, if the clock error

is five minutes or more, automati

cally compensate for time gain or

lag . Several resettings, several days

apart, may be needed to propertly

adjust the clock mechanism. Have

your clock cleaned and oiled by a

competent clock serviceman at

least every two years.

Cigarette Lighter

The cigarette lighter is located

on the instrument panel face.

To

operate, push it in. When it be

comes heated, it automatically pops

out ready for use.

Windshield Wiper and

Washer

The windshield wiping system

operates at two speeds and

is de

signed to wipe clear specific areas of

the windshield under most in

clement weather conditions . The

windshield wipers work electrically

and are not affected by engine op

eration. Push the control lever to the

right to start the electric wind

shield wiper. The two-speed elec

tric wiper has both a "low" and a

"high" speed position.

31

Pressing the control will send a

measured amount of water or other

cleaning agent onto the windshield

and will also cause the wiper lever

to move thus starting the wiper

motor. The wiper will continue to

operate until manually turned off

at the wiper lever.

Fill the washer jar only

% full

during the winter to allow for ex

pansion if the temperature should

fall low enough to freeze the solu

tion .

• Check washer fluid level regu

larly-do it frequently when the

weather is bad .

• Use a fluid such as GM OPTI

KLEEN to prevent freezing

damage, and to provide better

cleaning.

• Do not use radiator anti-freeze

in windshield washer; it could

cause paint damage.

• In cold weather, warm the wind

shield with defrosters before

Page 45 of 86

Downloaded from www.Manualslib.com manuals search engine or property damage. All General

Motors cars have negative-ground

electrical systems and can be used

to jump start one another.

If you

cannot determine how the other

vehicle

is grounded (by checking

specifications in the owner's man

ual, etc.) we recommend that you

attempt no jump starting with that

vehicle.

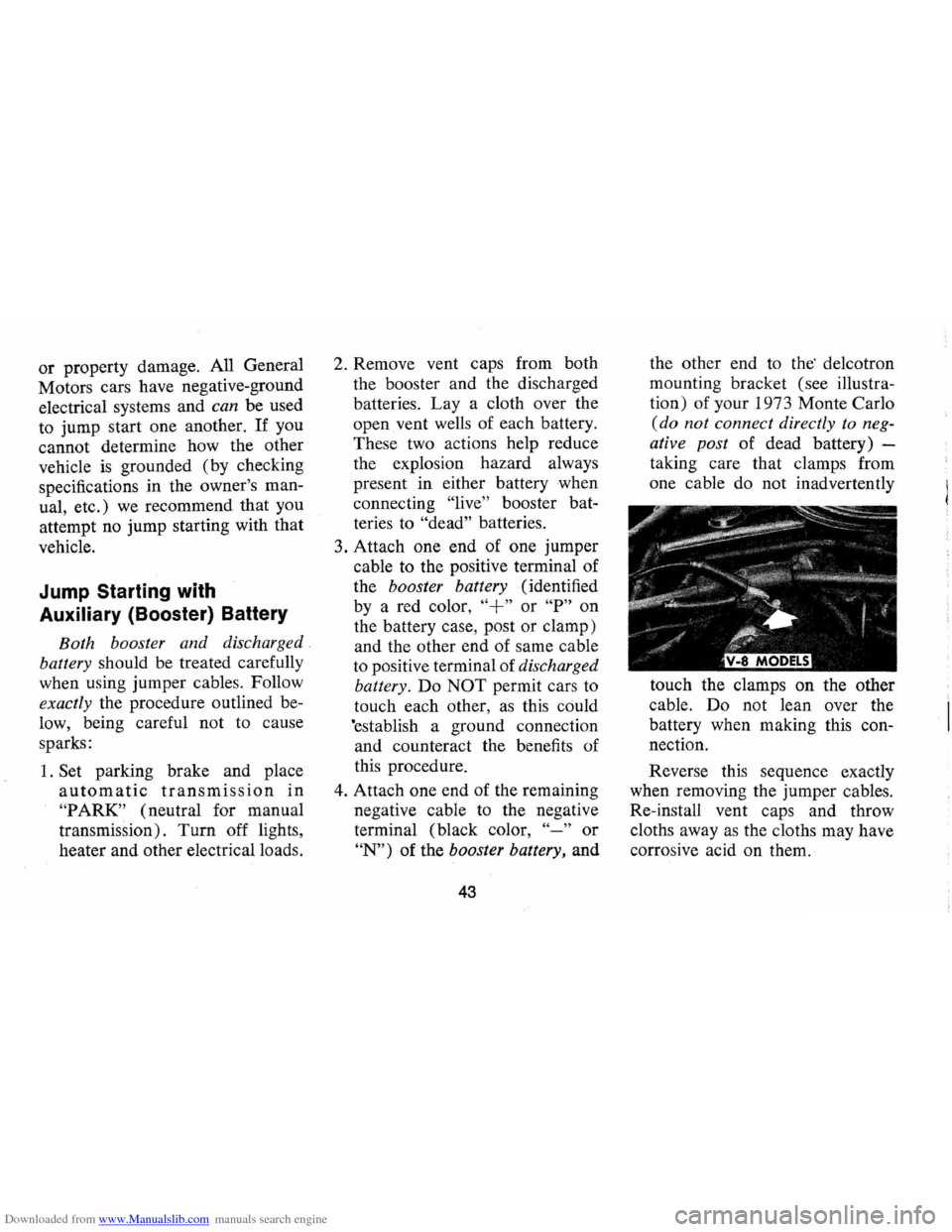

Jump Starting with

Auxiliary (Booster) Battery

Both booster and discharged

battery should be treated carefully

when using jumper cables. Follow

exactly the procedure outlined be

low, being careful not to cause

sparks:

1.

Set parking brake and place

automatic transmission in

"PARK" (neutral for manual

transmission).

Turn off lights,

heater and other electrical loads. 2.

Remove vent caps from both

the booster and the discharged

batteries. Lay a cloth over the

open vent wells of each battery.

These two actions help reduce

the explosion hazard always

present in either battery when

connecting

"live" booster bat

teries to

"dead" batteries.

3. Attach one end of one jumper

cable to the positive terminal of

the booster battery (identified

by a red color,

"+" or "P" on

the battery case, post or clamp)

and the other end of same cable

to positive terminal of discharged

battery. Do

NOT permit cars to

touch each other,

as this could

'establish a ground connection

and counteract the benefits of

this procedure.

4. Attach one end of the remaining

negative cable to the negative

terminal (black color,

"-" or

"N") of the booster battery, and

43

the other end to the' de1cotron

mounting bracket (see illustra

tion) of your 1973 Monte Carlo

(do not connect directly to neg

ative post of dead battery) -

taking care that clamps from

one cable do not inadvertently

touch the clamps on the other

cable. Do not lean over the

battery when making this con

nection.

Reverse this sequence exactly

when removing the jumper cables.

Re-install vent caps and throw

cloths away

as the cloths may have

corrosive acid on them.