transaxle CHEVROLET PLYMOUTH ACCLAIM 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 89 of 2438

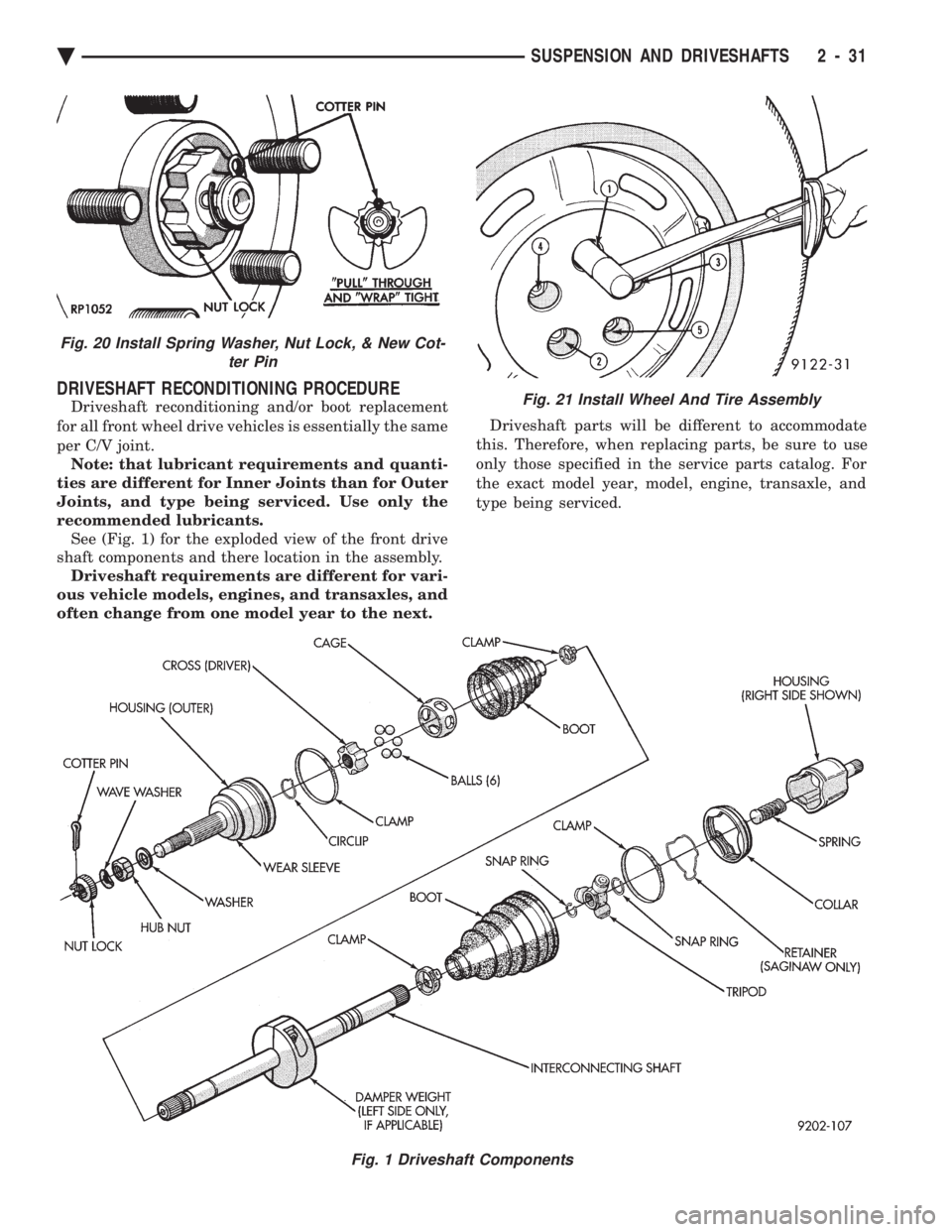

DRIVESHAFT RECONDITIONING PROCEDURE

Driveshaft reconditioning and/or boot replacement

for all front wheel drive vehicles is essentially the same

per C/V joint. Note: that lubricant requirements and quanti-

ties are different for Inner Joints than for Outer

Joints, and type being serviced. Use only the

recommended lubricants. See (Fig. 1) for the exploded view of the front drive

shaft components and there location in the assembly. Driveshaft requirements are different for vari-

ous vehicle models, engines, and transaxles, and

often change from one model year to the next. Driveshaft parts will be different to accommodate

this. Therefore, when replacing parts, be sure to use

only those specified in the service parts catalog. For

the exact model year, model, engine, transaxle, and

type being serviced.

Fig. 1 Driveshaft Components

Fig. 21 Install Wheel And Tire Assembly

Fig. 20 Install Spring Washer, Nut Lock, & New Cot- ter Pin

Ä SUSPENSION AND DRIVESHAFTS 2 - 31

Page 99 of 2438

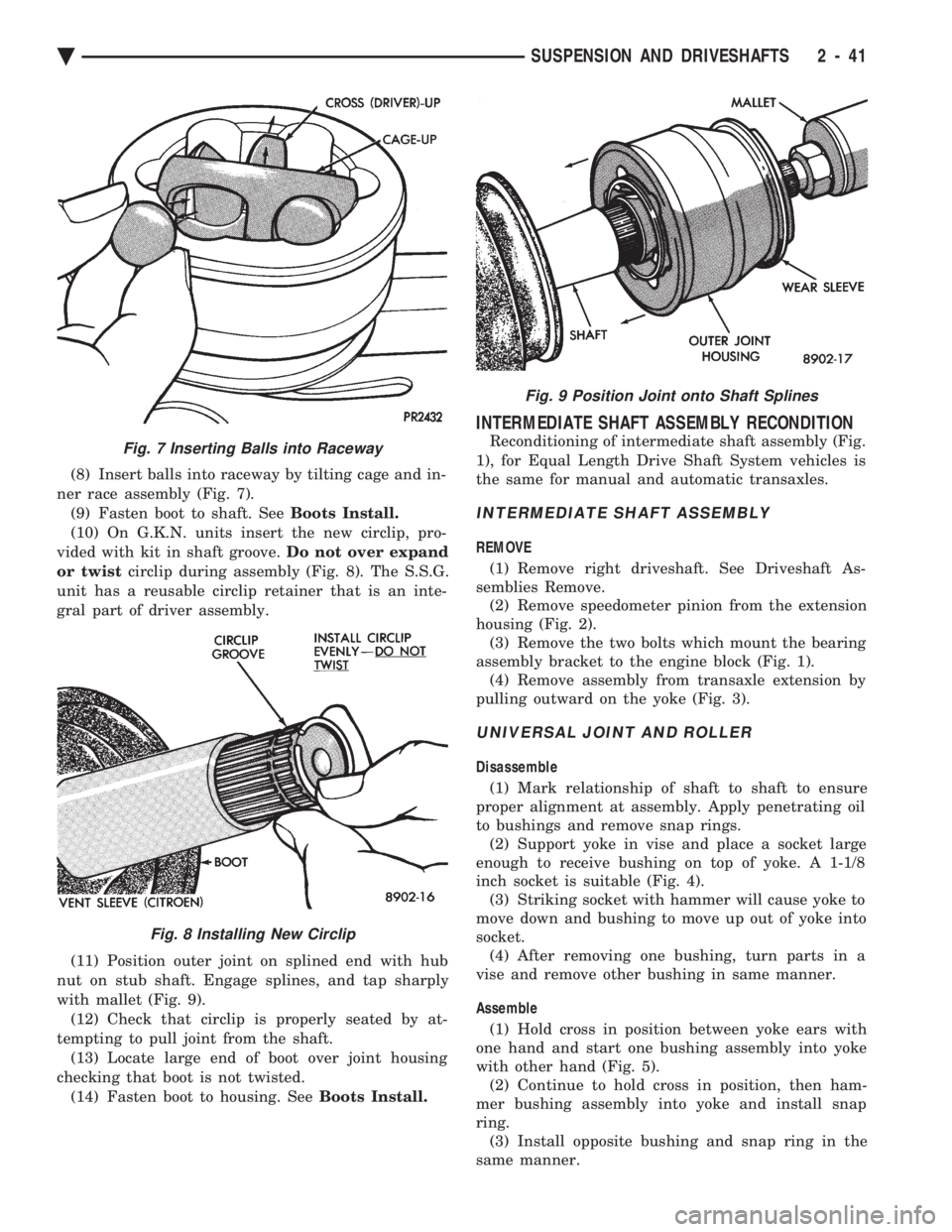

(8) Insert balls into raceway by tilting cage and in-

ner race assembly (Fig. 7). (9) Fasten boot to shaft. See Boots Install.

(10) On G.K.N. units insert the new circlip, pro-

vided with kit in shaft groove. Do not over expand

or twist circlip during assembly (Fig. 8). The S.S.G.

unit has a reusable circlip retainer that is an inte-

gral part of driver assembly.

(11) Position outer joint on splined end with hub

nut on stub shaft. Engage splines, and tap sharply

with mallet (Fig. 9). (12) Check that circlip is properly seated by at-

tempting to pull joint from the shaft. (13) Locate large end of boot over joint housing

checking that boot is not twisted. (14) Fasten boot to housing. See Boots Install.

INTERMEDIATE SHAFT ASSEMBLY RECONDITION

Reconditioning of intermediate shaft assembly (Fig.

1), for Equal Length Drive Shaft System vehicles is

the same for manual and automatic transaxles.

INTERMEDIATE SHAFT ASSEMBLY

REMOVE

(1) Remove right driveshaft. See Driveshaft As-

semblies Remove. (2) Remove speedometer pinion from the extension

housing (Fig. 2). (3) Remove the two bolts which mount the bearing

assembly bracket to the engine block (Fig. 1). (4) Remove assembly from transaxle extension by

pulling outward on the yoke (Fig. 3).

UNIVERSAL JOINT AND ROLLER

Disassemble

(1) Mark relationship of shaft to shaft to ensure

proper alignment at assembly. Apply penetrating oil

to bushings and remove snap rings. (2) Support yoke in vise and place a socket large

enough to receive bushing on top of yoke. A 1-1/8

inch socket is suitable (Fig. 4). (3) Striking socket with hammer will cause yoke to

move down and bushing to move up out of yoke into

socket. (4) After removing one bushing, turn parts in a

vise and remove other bushing in same manner.

Assemble (1) Hold cross in position between yoke ears with

one hand and start one bushing assembly into yoke

with other hand (Fig. 5). (2) Continue to hold cross in position, then ham-

mer bushing assembly into yoke and install snap

ring. (3) Install opposite bushing and snap ring in the

same manner.

Fig. 7 Inserting Balls into Raceway

Fig. 8 Installing New Circlip

Fig. 9 Position Joint onto Shaft Splines

Ä SUSPENSION AND DRIVESHAFTS 2 - 41

Page 101 of 2438

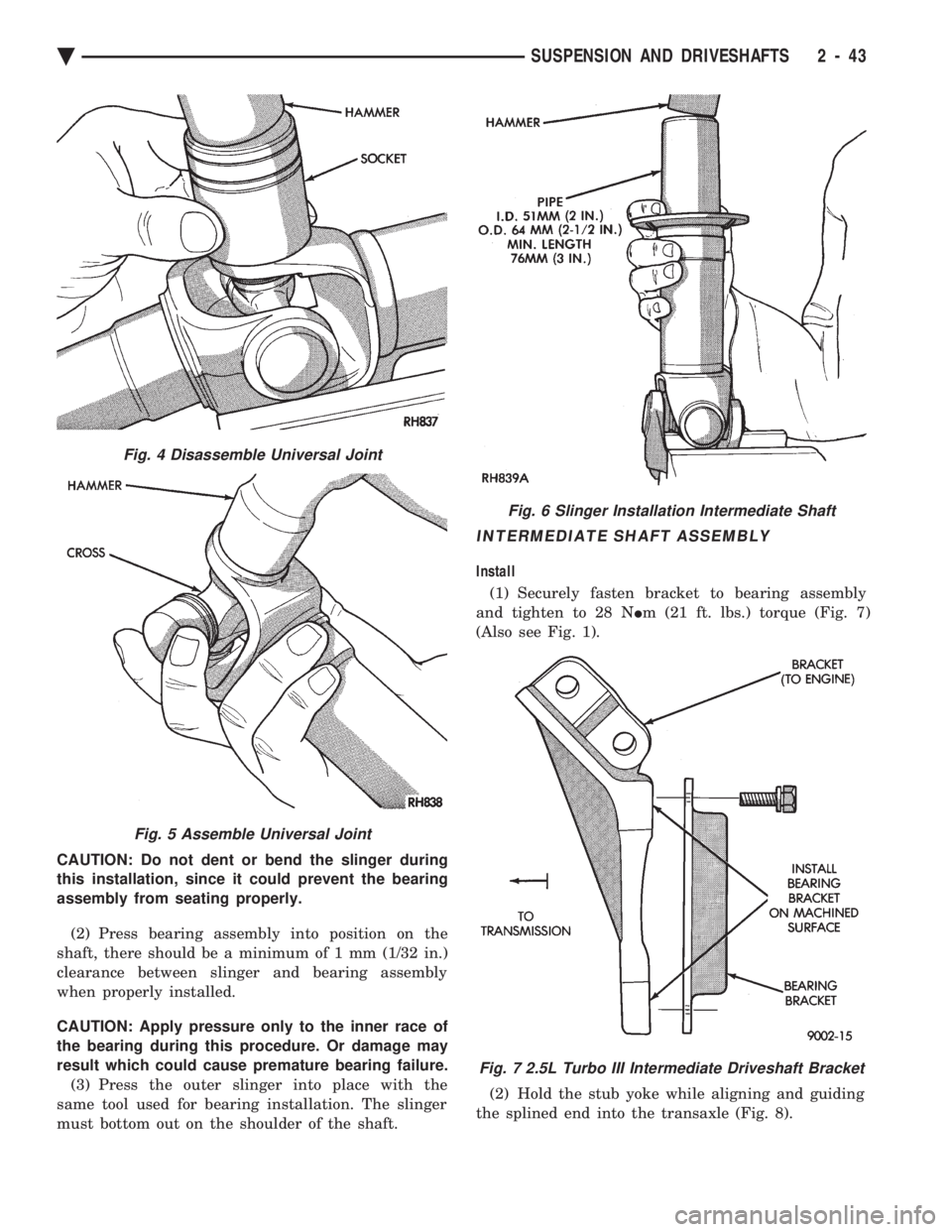

CAUTION: Do not dent or bend the slinger during

this installation, since it could prevent the bearing

assembly from seating properly. (2) Press bearing assembly into position on the

shaft, there should be a minimum of 1 mm (1/32 in.)

clearance between slinger and bearing assembly

when properly installed.

CAUTION: Apply pressure only to the inner race of

the bearing during this procedure. Or damage may

result which could cause premature bearing failure. (3) Press the outer slinger into place with the

same tool used for bearing installation. The slinger

must bottom out on the shoulder of the shaft.

INTERMEDIATE SHAFT ASSEMBLY

Install

(1) Securely fasten bracket to bearing assembly

and tighten to 28 N Im (21 ft. lbs.) torque (Fig. 7)

(Also see Fig. 1).

(2) Hold the stub yoke while aligning and guiding

the splined end into the transaxle (Fig. 8).

Fig. 4 Disassemble Universal Joint

Fig. 5 Assemble Universal Joint

Fig. 6 Slinger Installation Intermediate Shaft

Fig. 7 2.5L Turbo III Intermediate Driveshaft Bracket

Ä SUSPENSION AND DRIVESHAFTS 2 - 43

Page 102 of 2438

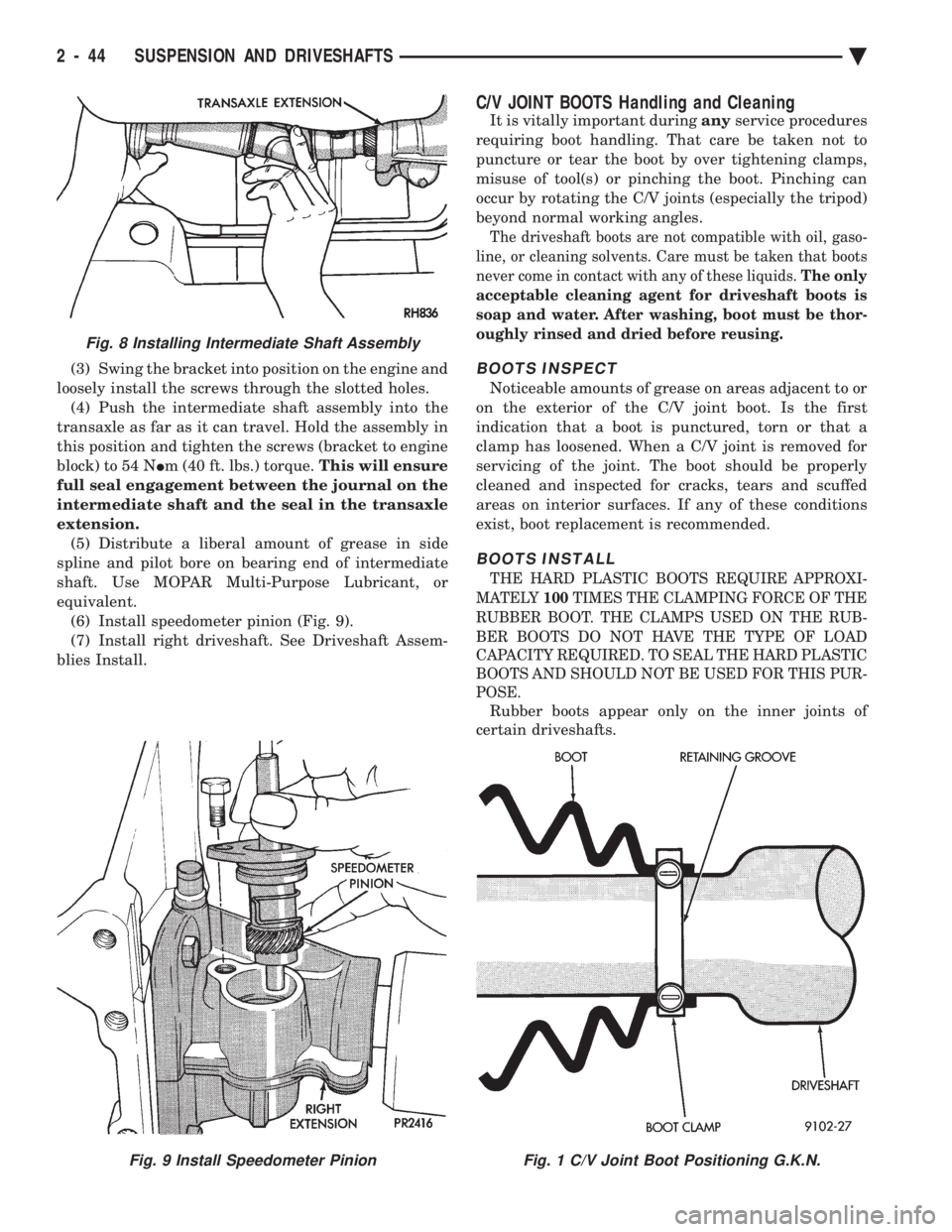

(3) Swing the bracket into position on the engine and

loosely install the screws through the slotted holes. (4) Push the intermediate shaft assembly into the

transaxle as far as it can travel. Hold the assembly in

this position and tighten the screws (bracket to engine

block) to 54 N Im (40 ft. lbs.) torque. This will ensure

full seal engagement between the journal on the

intermediate shaft and the seal in the transaxle

extension. (5) Distribute a liberal amount of grease in side

spline and pilot bore on bearing end of intermediate

shaft. Use MOPAR Multi-Purpose Lubricant, or

equivalent. (6) Install speedometer pinion (Fig. 9).

(7) Install right driveshaft. See Driveshaft Assem-

blies Install.

C/V JOINT BOOTS Handling and Cleaning

It is vitally important during anyservice procedures

requiring boot handling. That care be taken not to

puncture or tear the boot by over tightening clamps,

misuse of tool(s) or pinching the boot. Pinching can

occur by rotating the C/V joints (especially the tripod)

beyond normal working angles.

The driveshaft boots are not compatible with oil, gaso-

line, or cleaning solvents. Care must be taken that boots

never come in contact with any of these liquids. The only

acceptable cleaning agent for driveshaft boots is

soap and water. After washing, boot must be thor-

oughly rinsed and dried before reusing.

BOOTS INSPECT

Noticeable amounts of grease on areas adjacent to or

on the exterior of the C/V joint boot. Is the first

indication that a boot is punctured, torn or that a

clamp has loosened. When a C/V joint is removed for

servicing of the joint. The boot should be properly

cleaned and inspected for cracks, tears and scuffed

areas on interior surfaces. If any of these conditions

exist, boot replacement is recommended.

BOOTS INSTALL

THE HARD PLASTIC BOOTS REQUIRE APPROXI-

MATELY 100TIMES THE CLAMPING FORCE OF THE

RUBBER BOOT. THE CLAMPS USED ON THE RUB-

BER BOOTS DO NOT HAVE THE TYPE OF LOAD

CAPACITY REQUIRED. TO SEAL THE HARD PLASTIC

BOOTS AND SHOULD NOT BE USED FOR THIS PUR-

POSE.

Rubber boots appear only on the inner joints of

certain driveshafts.

Fig. 9 Install Speedometer PinionFig. 1 C/V Joint Boot Positioning G.K.N.

Fig. 8 Installing Intermediate Shaft Assembly

2 - 44 SUSPENSION AND DRIVESHAFTS Ä

Page 107 of 2438

mount have been loosened for any reason, or if vehicle

has experienced front structural damage, driveshaft

lengths must be checked and corrected, if required. A

shorter than required driveshaft length can result in ob-

jectionable noise. A longer than required driveshaft

length may result in potential damage.

Use of the following procedure will ensure satisfac-

tory driveshaft engagement under all normal vehicle

operating conditions. (1) The vehicle must be completely assembled.

Front wheels must be properly aligned and in the

straight ahead position. The vehicle must be in a po-

sition so that the full weight of the body is distrib-

uted to all four tires. A platform hoist, or front end

alignment rack, is recommended.

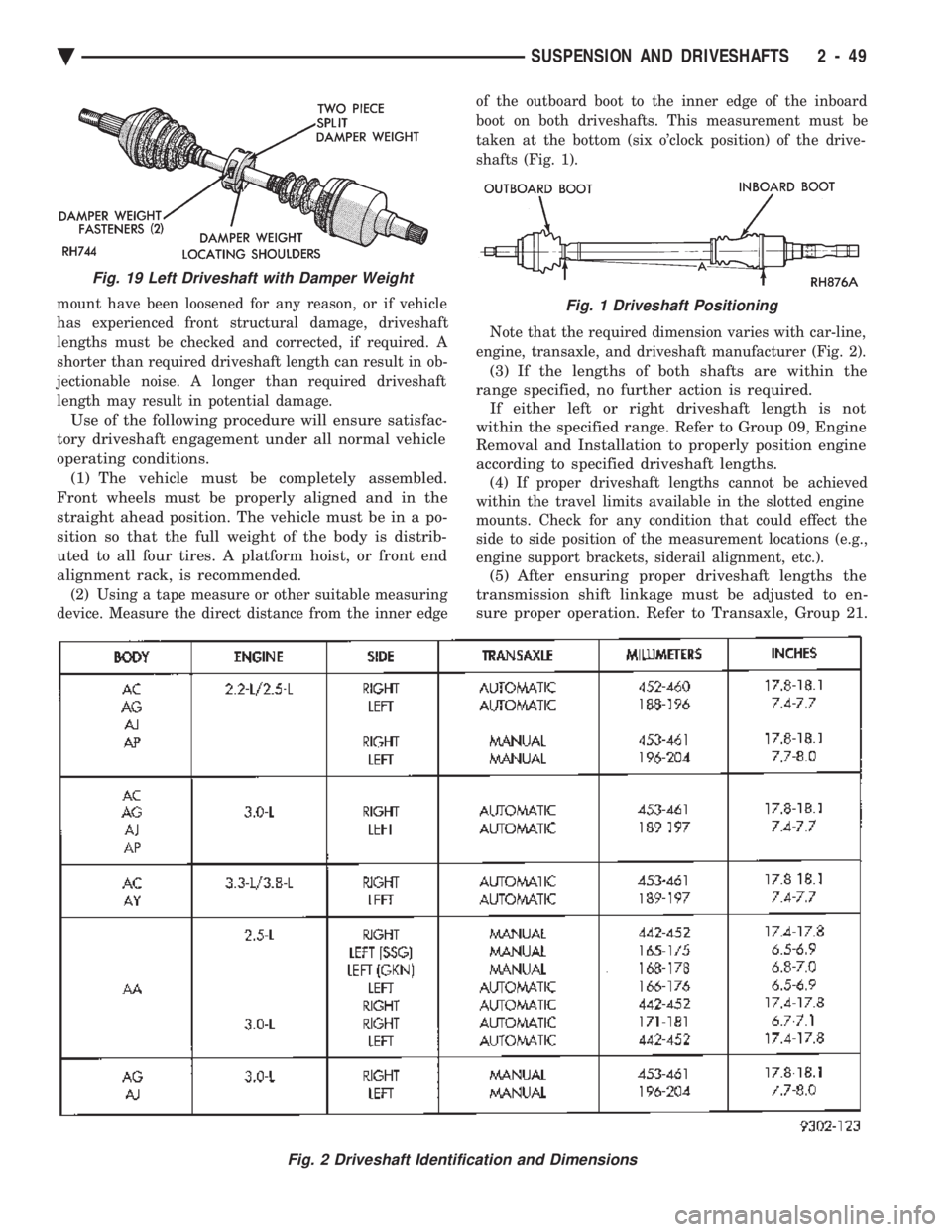

(2) Using a tape measure or other suitable measuring

device. Measure the direct distance from the inner edge of the outboard boot to the inner edge of the inboard

boot on both driveshafts. This measurement must be

taken at the bottom (six o'clock position) of the drive-

shafts (Fig. 1).

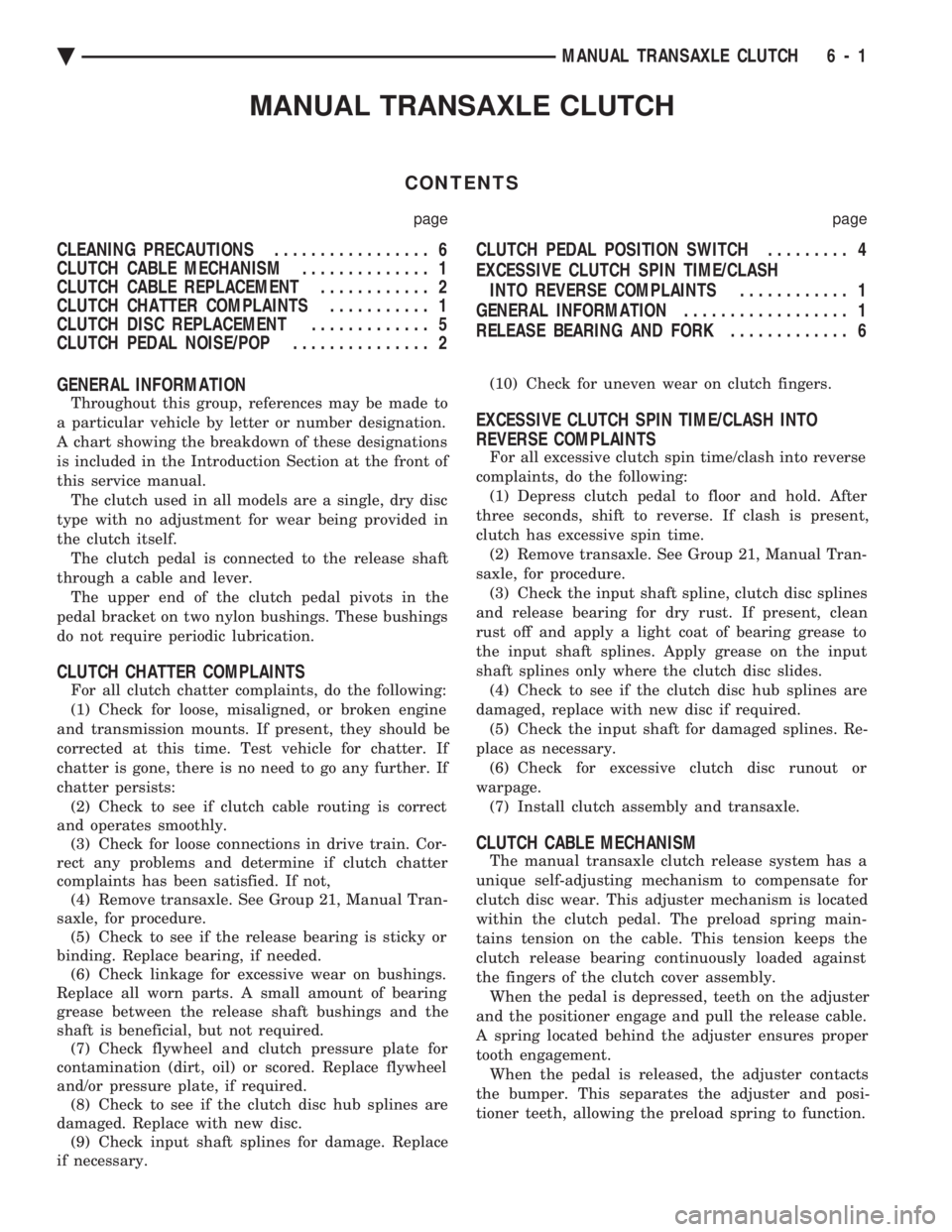

Note that the required dimension varies with car-line,

engine, transaxle, and driveshaft manufacturer (Fig. 2).

(3) If the lengths of both shafts are within the

range specified, no further action is required. If either left or right driveshaft length is not

within the specified range. Refer to Group 09, Engine

Removal and Installation to properly position engine

according to specified driveshaft lengths.

(4) If proper driveshaft lengths cannot be achieved

within the travel limits available in the slotted engine

mounts. Check for any condition that could effect the

side to side position of the measurement locations (e.g.,

engine support brackets, siderail alignment, etc.).

(5) After ensuring proper driveshaft lengths the

transmission shift linkage must be adjusted to en-

sure proper operation. Refer to Transaxle, Group 21.

Fig. 2 Driveshaft Identification and Dimensions

Fig. 19 Left Driveshaft with Damper Weight

Fig. 1 Driveshaft Positioning

Ä SUSPENSION AND DRIVESHAFTS 2 - 49

Page 333 of 2438

MANUAL TRANSAXLE CLUTCH

CONTENTS

page page

CLEANING PRECAUTIONS ................. 6

CLUTCH CABLE MECHANISM .............. 1

CLUTCH CABLE REPLACEMENT ............ 2

CLUTCH CHATTER COMPLAINTS ........... 1

CLUTCH DISC REPLACEMENT ............. 5

CLUTCH PEDAL NOISE/POP ............... 2 CLUTCH PEDAL POSITION SWITCH

......... 4

EXCESSIVE CLUTCH SPIN TIME/CLASH INTO REVERSE COMPLAINTS ............ 1

GENERAL INFORMATION .................. 1

RELEASE BEARING AND FORK ............. 6

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The clutch used in all models are a single, dry disc

type with no adjustment for wear being provided in

the clutch itself. The clutch pedal is connected to the release shaft

through a cable and lever. The upper end of the clutch pedal pivots in the

pedal bracket on two nylon bushings. These bushings

do not require periodic lubrication.

CLUTCH CHATTER COMPLAINTS

For all clutch chatter complaints, do the following:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further. If

chatter persists: (2) Check to see if clutch cable routing is correct

and operates smoothly. (3) Check for loose connections in drive train. Cor-

rect any problems and determine if clutch chatter

complaints has been satisfied. If not, (4) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (5) Check to see if the release bearing is sticky or

binding. Replace bearing, if needed. (6) Check linkage for excessive wear on bushings.

Replace all worn parts. A small amount of bearing

grease between the release shaft bushings and the

shaft is beneficial, but not required. (7) Check flywheel and clutch pressure plate for

contamination (dirt, oil) or scored. Replace flywheel

and/or pressure plate, if required. (8) Check to see if the clutch disc hub splines are

damaged. Replace with new disc. (9) Check input shaft splines for damage. Replace

if necessary. (10) Check for uneven wear on clutch fingers.

EXCESSIVE CLUTCH SPIN TIME/CLASH INTO

REVERSE COMPLAINTS

For all excessive clutch spin time/clash into reverse

complaints, do the following: (1) Depress clutch pedal to floor and hold. After

three seconds, shift to reverse. If clash is present,

clutch has excessive spin time. (2) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (3) Check the input shaft spline, clutch disc splines

and release bearing for dry rust. If present, clean

rust off and apply a light coat of bearing grease to

the input shaft splines. Apply grease on the input

shaft splines only where the clutch disc slides. (4) Check to see if the clutch disc hub splines are

damaged, replace with new disc if required. (5) Check the input shaft for damaged splines. Re-

place as necessary. (6) Check for excessive clutch disc runout or

warpage. (7) Install clutch assembly and transaxle.

CLUTCH CABLE MECHANISM

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch pedal. The preload spring main-

tains tension on the cable. This tension keeps the

clutch release bearing continuously loaded against

the fingers of the clutch cover assembly. When the pedal is depressed, teeth on the adjuster

and the positioner engage and pull the release cable.

A spring located behind the adjuster ensures proper

tooth engagement. When the pedal is released, the adjuster contacts

the bumper. This separates the adjuster and posi-

tioner teeth, allowing the preload spring to function.

Ä MANUAL TRANSAXLE CLUTCH 6 - 1

Page 334 of 2438

CLUTCH PEDAL NOISE/POP

The mechanism which automatically adjusts the

clutch cable to compensate for clutch wear may emit

a loud clicking or pop noise under certain circum-

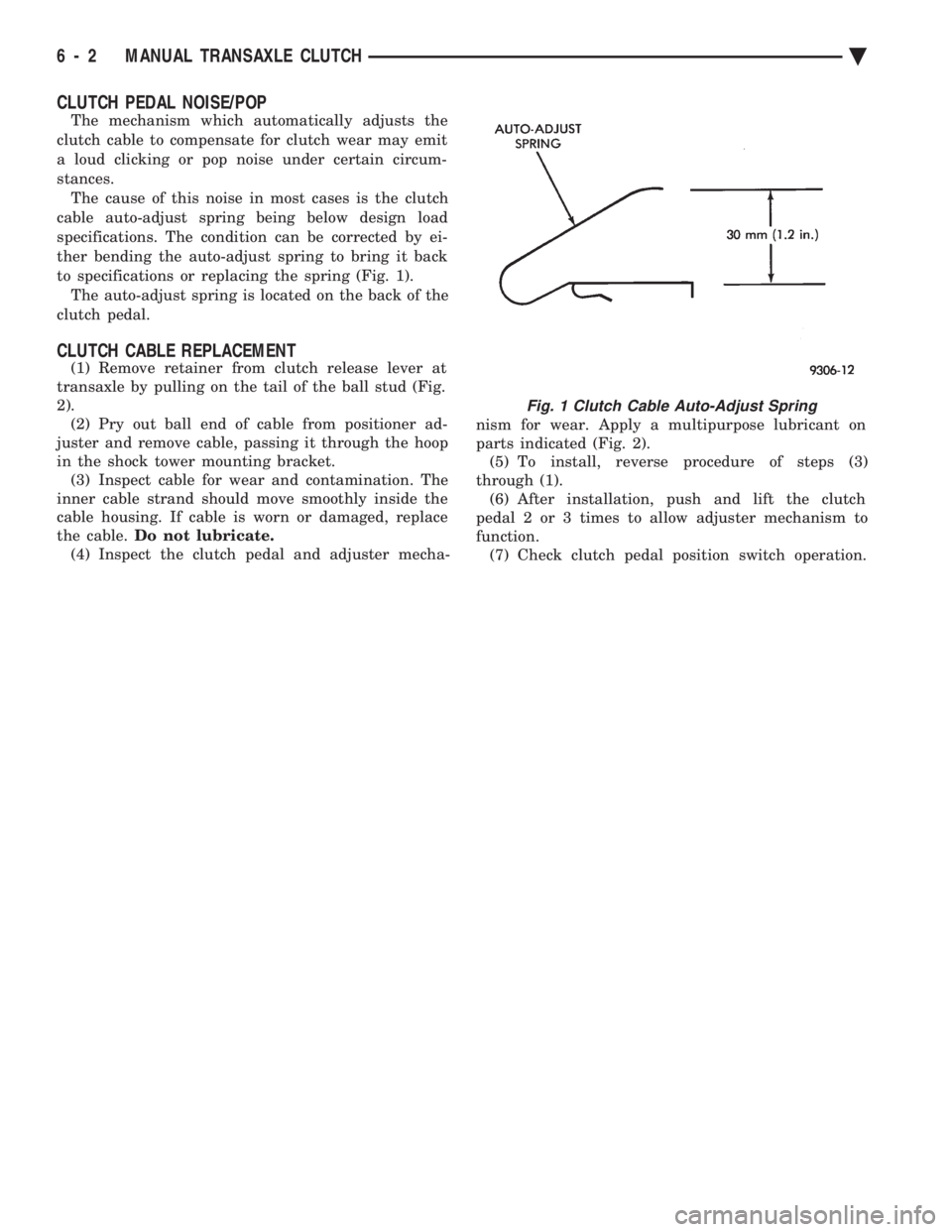

stances. The cause of this noise in most cases is the clutch

cable auto-adjust spring being below design load

specifications. The condition can be corrected by ei-

ther bending the auto-adjust spring to bring it back

to specifications or replacing the spring (Fig. 1). The auto-adjust spring is located on the back of the

clutch pedal.

CLUTCH CABLE REPLACEMENT

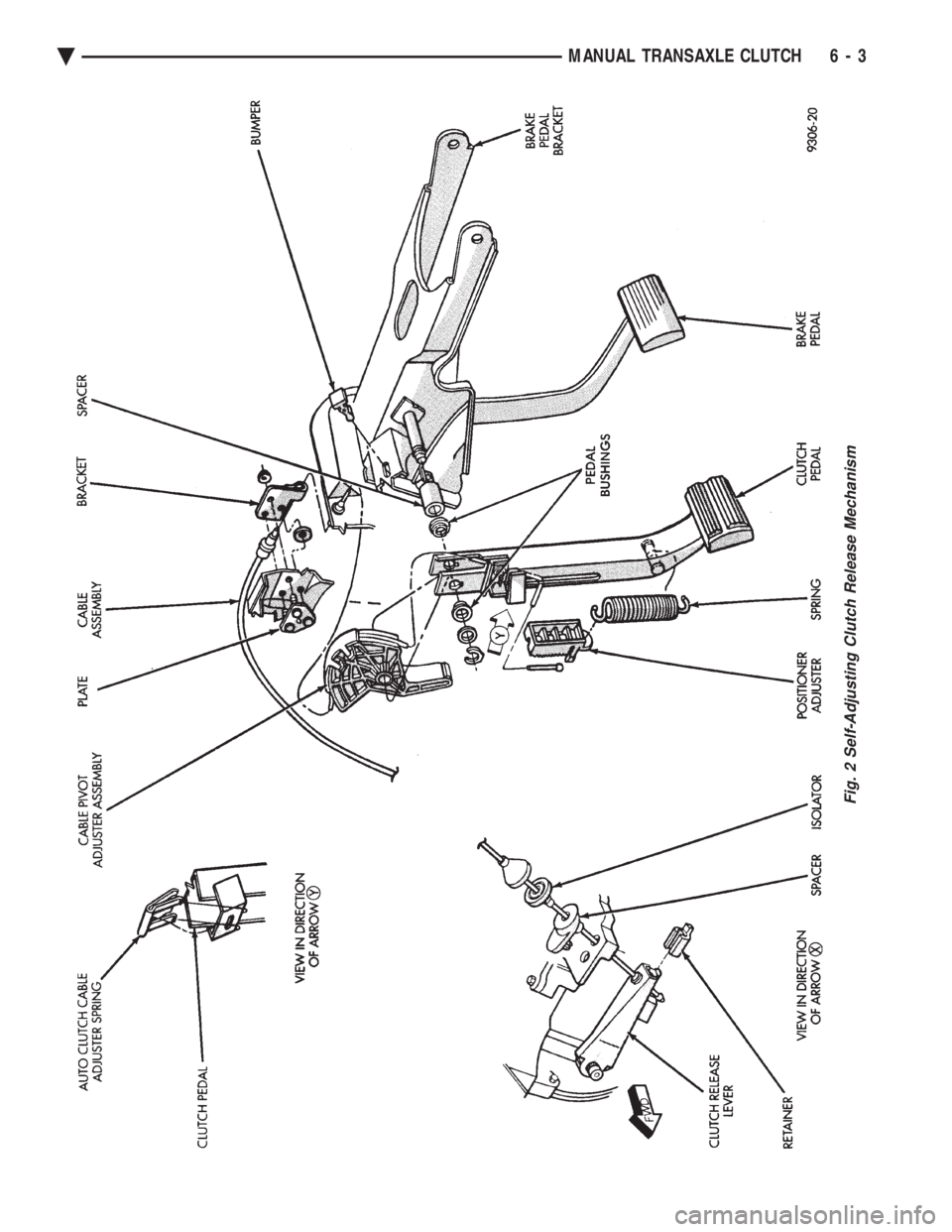

(1) Remove retainer from clutch release lever at

transaxle by pulling on the tail of the ball stud (Fig.

2). (2) Pry out ball end of cable from positioner ad-

juster and remove cable, passing it through the hoop

in the shock tower mounting bracket. (3) Inspect cable for wear and contamination. The

inner cable strand should move smoothly inside the

cable housing. If cable is worn or damaged, replace

the cable. Do not lubricate.

(4) Inspect the clutch pedal and adjuster mecha- nism for wear. Apply a multipurpose lubricant on

parts indicated (Fig. 2). (5) To install, reverse procedure of steps (3)

through (1). (6) After installation, push and lift the clutch

pedal 2 or 3 times to allow adjuster mechanism to

function. (7) Check clutch pedal position switch operation.

Fig. 1 Clutch Cable Auto-Adjust Spring

6 - 2 MANUAL TRANSAXLE CLUTCH Ä

Page 335 of 2438

Fig. 2 Self-Adjusting Clutch Release Mechanism

Ä MANUAL TRANSAXLE CLUTCH 6 - 3

Page 336 of 2438

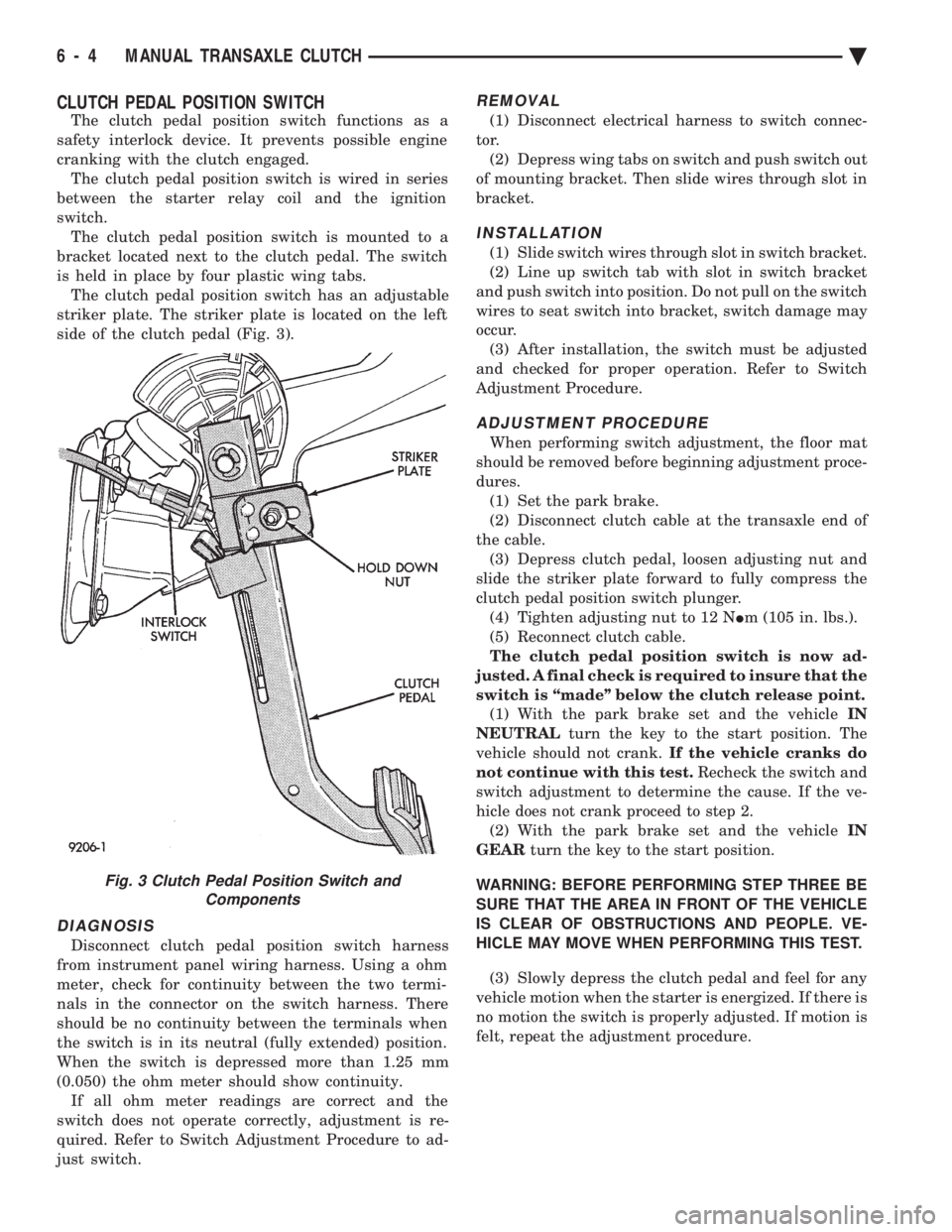

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch functions as a

safety interlock device. It prevents possible engine

cranking with the clutch engaged. The clutch pedal position switch is wired in series

between the starter relay coil and the ignition

switch. The clutch pedal position switch is mounted to a

bracket located next to the clutch pedal. The switch

is held in place by four plastic wing tabs. The clutch pedal position switch has an adjustable

striker plate. The striker plate is located on the left

side of the clutch pedal (Fig. 3).

DIAGNOSIS

Disconnect clutch pedal position switch harness

from instrument panel wiring harness. Using a ohm

meter, check for continuity between the two termi-

nals in the connector on the switch harness. There

should be no continuity between the terminals when

the switch is in its neutral (fully extended) position.

When the switch is depressed more than 1.25 mm

(0.050) the ohm meter should show continuity. If all ohm meter readings are correct and the

switch does not operate correctly, adjustment is re-

quired. Refer to Switch Adjustment Procedure to ad-

just switch.

REMOVAL

(1) Disconnect electrical harness to switch connec-

tor. (2) Depress wing tabs on switch and push switch out

of mounting bracket. Then slide wires through slot in

bracket.

INSTALLATION

(1) Slide switch wires through slot in switch bracket.

(2) Line up switch tab with slot in switch bracket

and push switch into position. Do not pull on the switch

wires to seat switch into bracket, switch damage may

occur. (3) After installation, the switch must be adjusted

and checked for proper operation. Refer to Switch

Adjustment Procedure.

ADJUSTMENT PROCEDURE

When performing switch adjustment, the floor mat

should be removed before beginning adjustment proce-

dures. (1) Set the park brake.

(2) Disconnect clutch cable at the transaxle end of

the cable. (3) Depress clutch pedal, loosen adjusting nut and

slide the striker plate forward to fully compress the

clutch pedal position switch plunger. (4) Tighten adjusting nut to 12 N Im (105 in. lbs.).

(5) Reconnect clutch cable.

The clutch pedal position switch is now ad-

justed. A final check is required to insure that the

switch is ``made'' below the clutch release point. (1) With the park brake set and the vehicle IN

NEUTRAL turn the key to the start position. The

vehicle should not crank. If the vehicle cranks do

not continue with this test. Recheck the switch and

switch adjustment to determine the cause. If the ve-

hicle does not crank proceed to step 2. (2) With the park brake set and the vehicle IN

GEAR turn the key to the start position.

WARNING: BEFORE PERFORMING STEP THREE BE

SURE THAT THE AREA IN FRONT OF THE VEHICLE

IS CLEAR OF OBSTRUCTIONS AND PEOPLE. VE-

HICLE MAY MOVE WHEN PERFORMING THIS TEST.

(3) Slowly depress the clutch pedal and feel for any

vehicle motion when the starter is energized. If there is

no motion the switch is properly adjusted. If motion is

felt, repeat the adjustment procedure.

Fig. 3 Clutch Pedal Position Switch and Components

6 - 4 MANUAL TRANSAXLE CLUTCH Ä

Page 337 of 2438

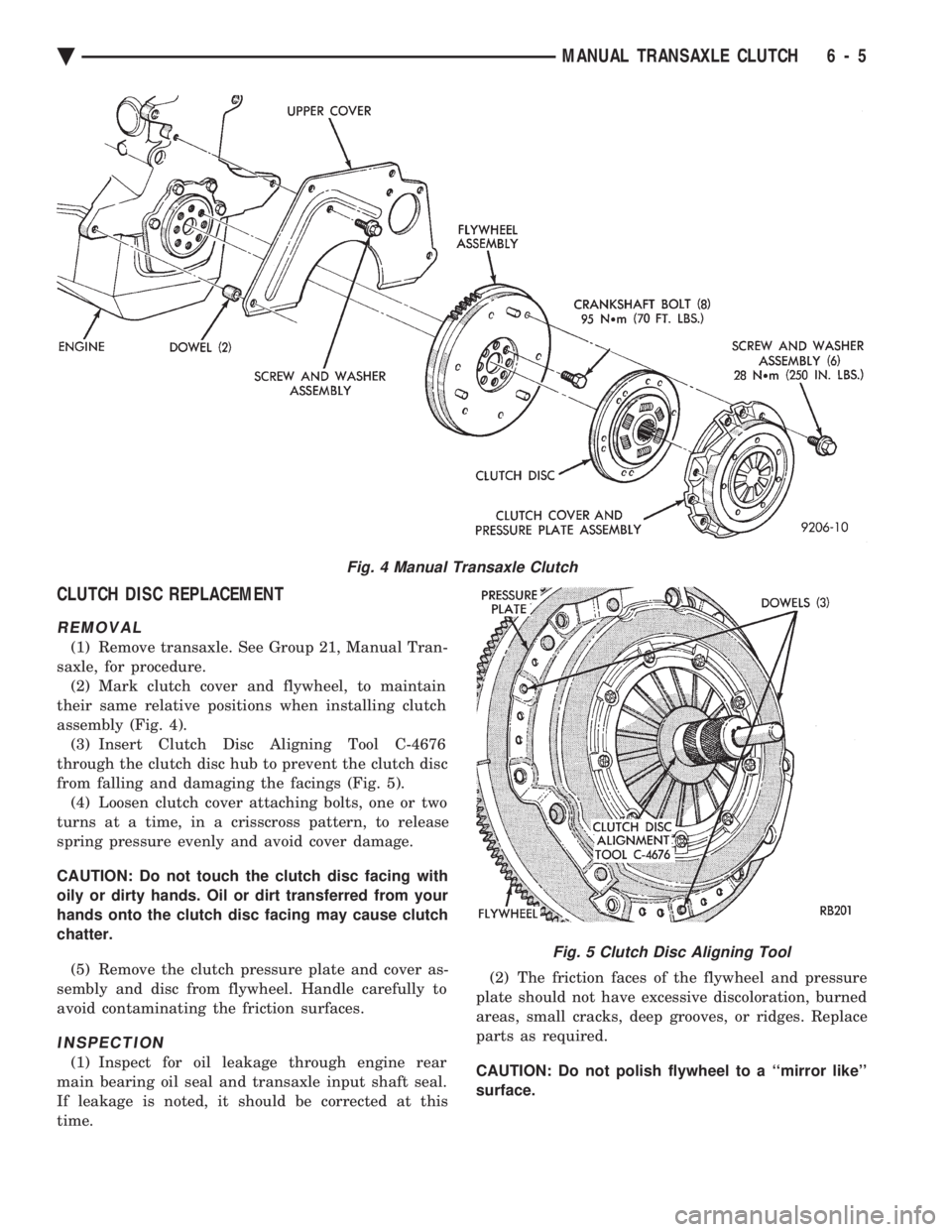

CLUTCH DISC REPLACEMENT

REMOVAL

(1) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (2) Mark clutch cover and flywheel, to maintain

their same relative positions when installing clutch

assembly (Fig. 4). (3) Insert Clutch Disc Aligning Tool C-4676

through the clutch disc hub to prevent the clutch disc

from falling and damaging the facings (Fig. 5). (4) Loosen clutch cover attaching bolts, one or two

turns at a time, in a crisscross pattern, to release

spring pressure evenly and avoid cover damage.

CAUTION: Do not touch the clutch disc facing with

oily or dirty hands. Oil or dirt transferred from your

hands onto the clutch disc facing may cause clutch

chatter.

(5) Remove the clutch pressure plate and cover as-

sembly and disc from flywheel. Handle carefully to

avoid contaminating the friction surfaces.

INSPECTION

(1) Inspect for oil leakage through engine rear

main bearing oil seal and transaxle input shaft seal.

If leakage is noted, it should be corrected at this

time. (2) The friction faces of the flywheel and pressure

plate should not have excessive discoloration, burned

areas, small cracks, deep grooves, or ridges. Replace

parts as required.

CAUTION: Do not polish flywheel to a ``mirror like''

surface.

Fig. 4 Manual Transaxle Clutch

Fig. 5 Clutch Disc Aligning Tool

Ä MANUAL TRANSAXLE CLUTCH 6 - 5