transaxle CHEVROLET PLYMOUTH ACCLAIM 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 338 of 2438

(3) Clean the flywheel face with medium sandpa-

per (80-160 grade), then wipe the surface with min-

eral spirits. If the surface is severely scored, heat

checked, or warped, replace the flywheel.

CAUTION: Do not flat-machine the flywheel face.

The surface profile is tapered.

(4) The heavy side of the flywheel is indicated by a

daub of white paint near the outside diameter. To

minimize the effects of flywheel unbalance, perform

the following installation procedure: (a) Loose assemble the flywheel to the crank-

shaft. Use new flywheel attaching bolts which have

sealant on the threads. If new bolts are not avail-

able, apply Loctite sealant to the threads of the

original bolts. This sealant is required to prevent

engine oil leakage. (b) Rotate the flywheel and crankshaft until the

daub of white paint (heavy side) is at the 12 o'clock

position. (c) Torque flywheel attaching bolts to 95 N Im(70

ft. lbs.). Use a crisscross pattern when tightening

bolts.

(5) The disc assembly should be handled without

touching the facings. Replace disc if the facings show

evidence of grease or oil soakage, or wear to within

less than .38 mm (.015 inch) of the rivet heads. The

splines on the disc hub and transaxle input shaft

should be a snug fit without signs of excessive wear.

Metallic portions of disc assembly should be dry and

clean, and not been discolored from excessive heat.

Each of the arched springs between the facings

should not be broken and all rivets should be tight. (6) Wipe the friction surface of the pressure plate

with mineral spirits. (7) Using a straight edge, check clutch cover (pres-

sure plate) for flatness. The clutch cover (pressure

plate) friction area should be slightly concave, with

the inner diameter 0.02 mm to 0.1 mm (.0008 in. to

.0039 in.) below the outer diameter. It should also be

free from discoloration, burned areas, cracks,

grooves, or ridges. (8) Using a surface plate, test cover for flatness.

All sections around attaching bolt holes should be in

contact with surface plate within .015 inch. (9) The cover should be a snug fit on flywheel dow-

els. If the clutch assembly does not meet these re-

quirements, it should be replaced.

INSTALLATION

(1) Mount clutch assembly on flywheel,being care-

ful to properly align dowels and the alignment marks

made before removal. The flywheel side of the clutch

disc is marked for proper installation. If new clutch

or flywheel is installed, align cover balance spot as

close as possible to flywheel balance orange spot. Ap-

ply pressure to the alignment tool. Center the tip of the tool into the crankshaft and the sliding cone into

the clutch fingers. Tighten the clutch attaching bolts

sufficiently to hold the disc in position. (2) To avoid distortion of the clutch cover, bolts

should be tightened a few turns at a time, in a criss-

cross pattern, until they are all seated. Tighten bolts

to 28 N Im (250 in. lbs.) following a crisscross pattern

sequence. Remove clutch disc alignment tool. (3) Install transaxle. See group 21, Manual Tran-

saxle, for procedures.

RELEASE BEARING AND FORK

Remove the transaxle from the vehicle. See group

21 for removal and installation procedures.

REMOVAL AND INSTALLATION

(1) Remove clutch release shaft E-clip.

(2) Remove the clutch release shaft and then slide

the fork and bearing assembly off the bearing pilot. (3) Remove the fork from the bearing thrust plate.

(4) Examine the condition of the bearing. It is pre-

lubricated and sealed and should not be im-

mersed in oil or solvent. (5) The bearing should turn smoothly when held in

the hand under a light thrust load. A light drag

caused by the lubricant fill is normal. If the bearing

is noisy, rough, or dry, replace the complete bearing

assembly with a new bearing. (6) The bearing has a plastic sleeve pre-lubricated

at assembly. Wipe out the old grease. Refill the

sleeve cavities and coat the inner surface with mul-

tipurpose grease. If the liner is cracked or worn, re-

place the bearing assembly. (7) Check the condition of the spring clips. If the

clips are broken or distorted, replace the bearing as-

sembly. (8) Before assembling the fork, lubricate the

rounded thrust pads and the spring clip cavities with

multipurpose grease. (9) Assemble the fork to the bearing by sliding the

thrust pads under the spring clips. Be careful to

avoid distorting the spring clips. These clips prevent

the bearing thrust plate from rotating with the bear-

ing. (10) Slide the bearing and fork assembly onto the

input shaft bearing retainer. (11) Position the release shaft bushings in the

housing and install the release shaft. A small

amount of bearing grease between the release shaft

bushing and the shaft is beneficial but not required.

Install the retainer clip in the shaft groove near the

large bushing. (12) Install the release lever and retaining clip on

the outer end of the release shaft.

CLEANING PRECAUTIONS

Condensation from steam vapors tend to accumu-

late on the internal clutch mechanism when the ve-

6 - 6 MANUAL TRANSAXLE CLUTCH Ä

Page 339 of 2438

hicle is steam cleaned. The facing of the disc will

absorb moisture. The force exerted by the pressure

plate will bond the facings to flywheel and/or, pres-

sure plate, if vehicle is allowed to stand for some

time before use. If this condition occurs, it will re- quire replacement of disc assembly, flywheel, and/or

clutch assembly. After cleaning, drive the vehicle to

its normal clutch operating temperature. This will

dry off disc assembly, pressure plate, and flywheel.

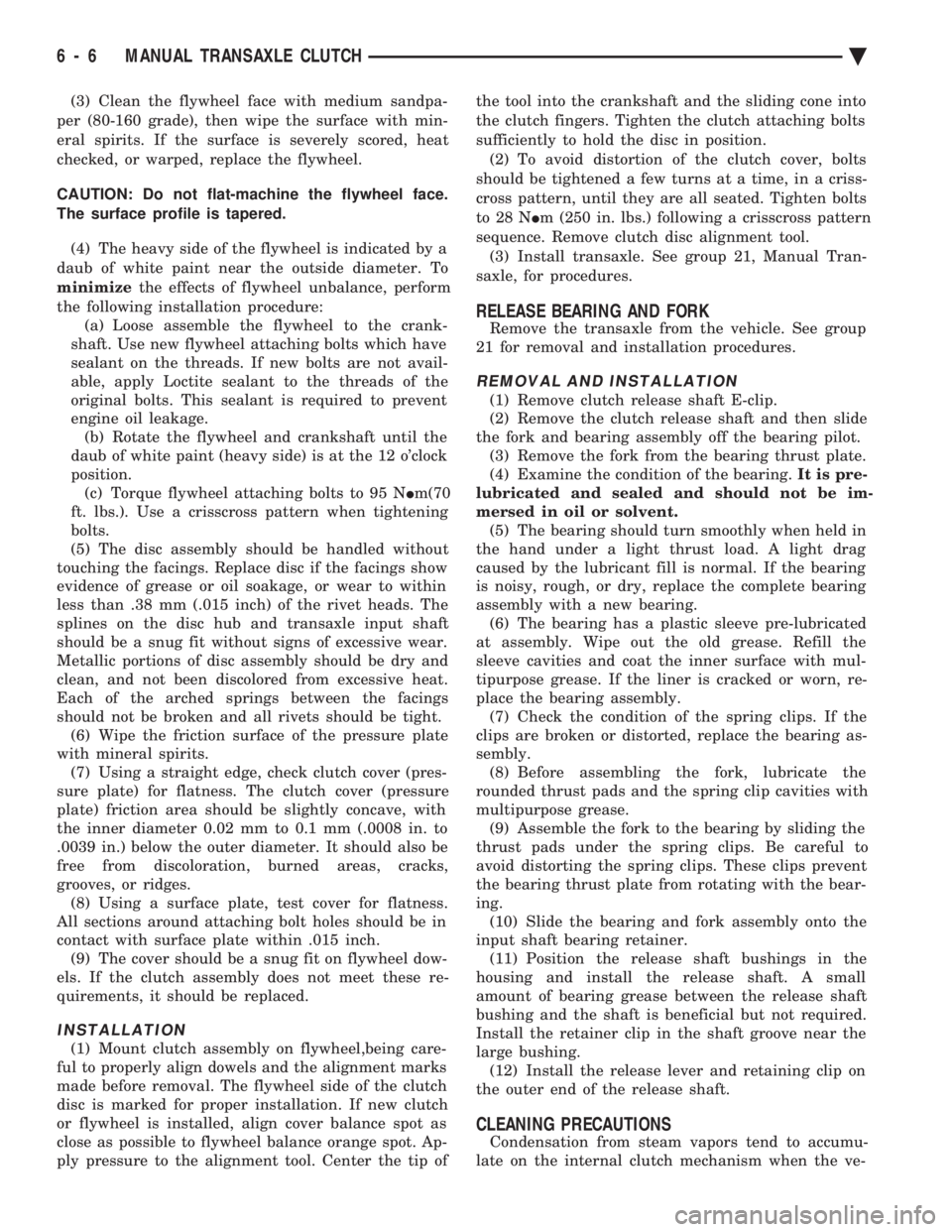

SERVICE DIAGNOSISÐCLUTCH GRAB/CHATTER

Ä MANUAL TRANSAXLE CLUTCH 6 - 7

Page 340 of 2438

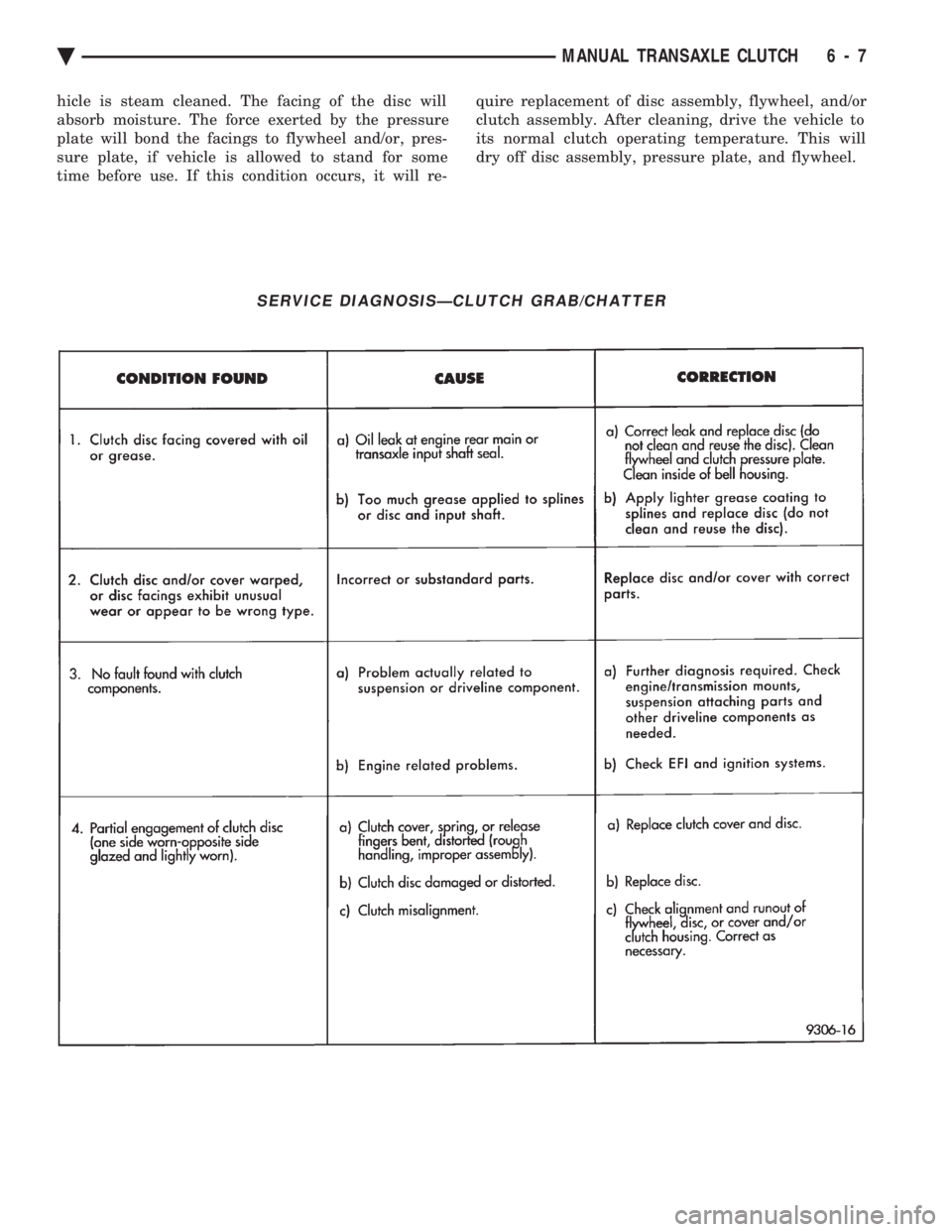

SERVICE DIAGNOSISÐCLUTCH SLIPS

6 - 8 MANUAL TRANSAXLE CLUTCH Ä

Page 341 of 2438

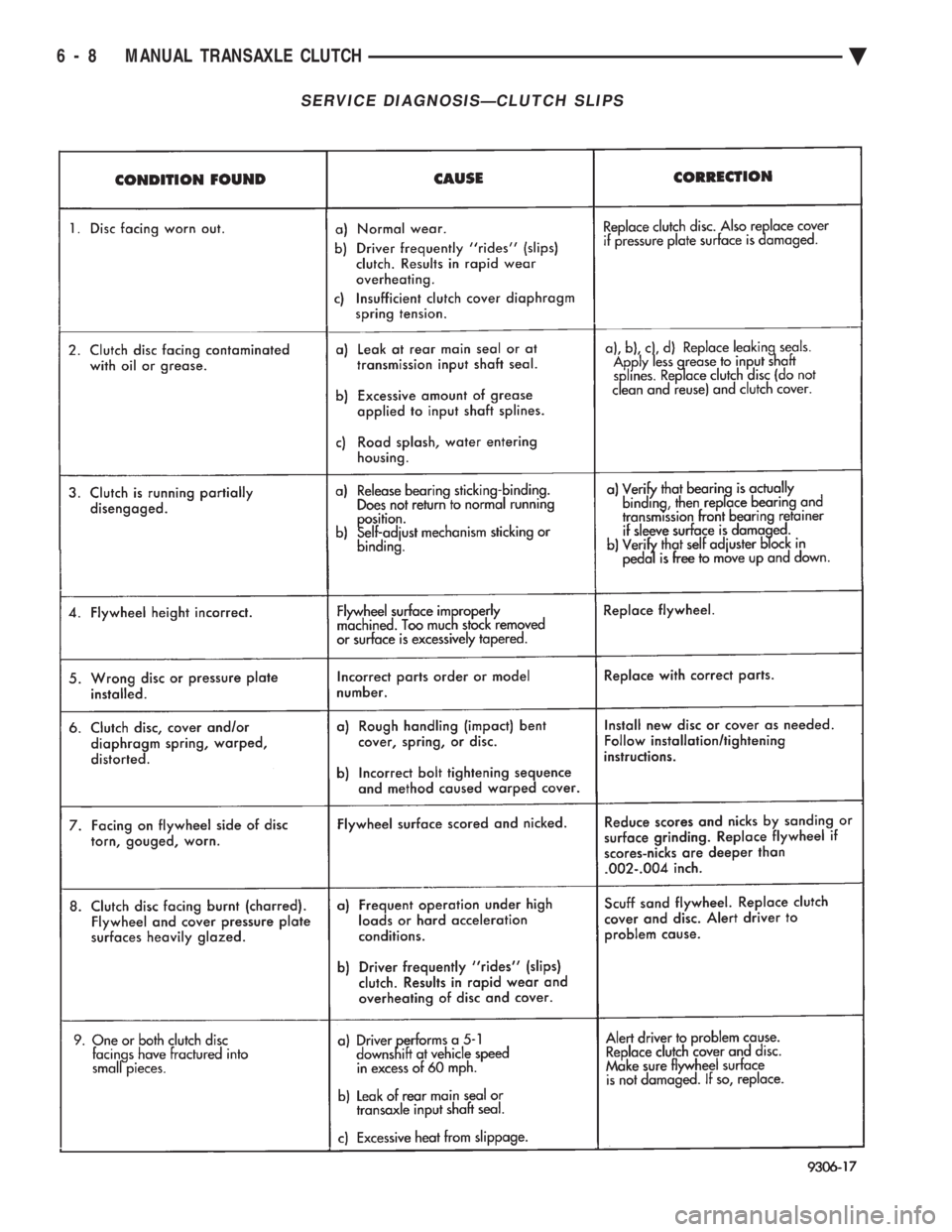

SERVICE DIAGNOSISÐIMPROPER CLUTCH RELEASE

Ä MANUAL TRANSAXLE CLUTCH 6 - 9

Page 342 of 2438

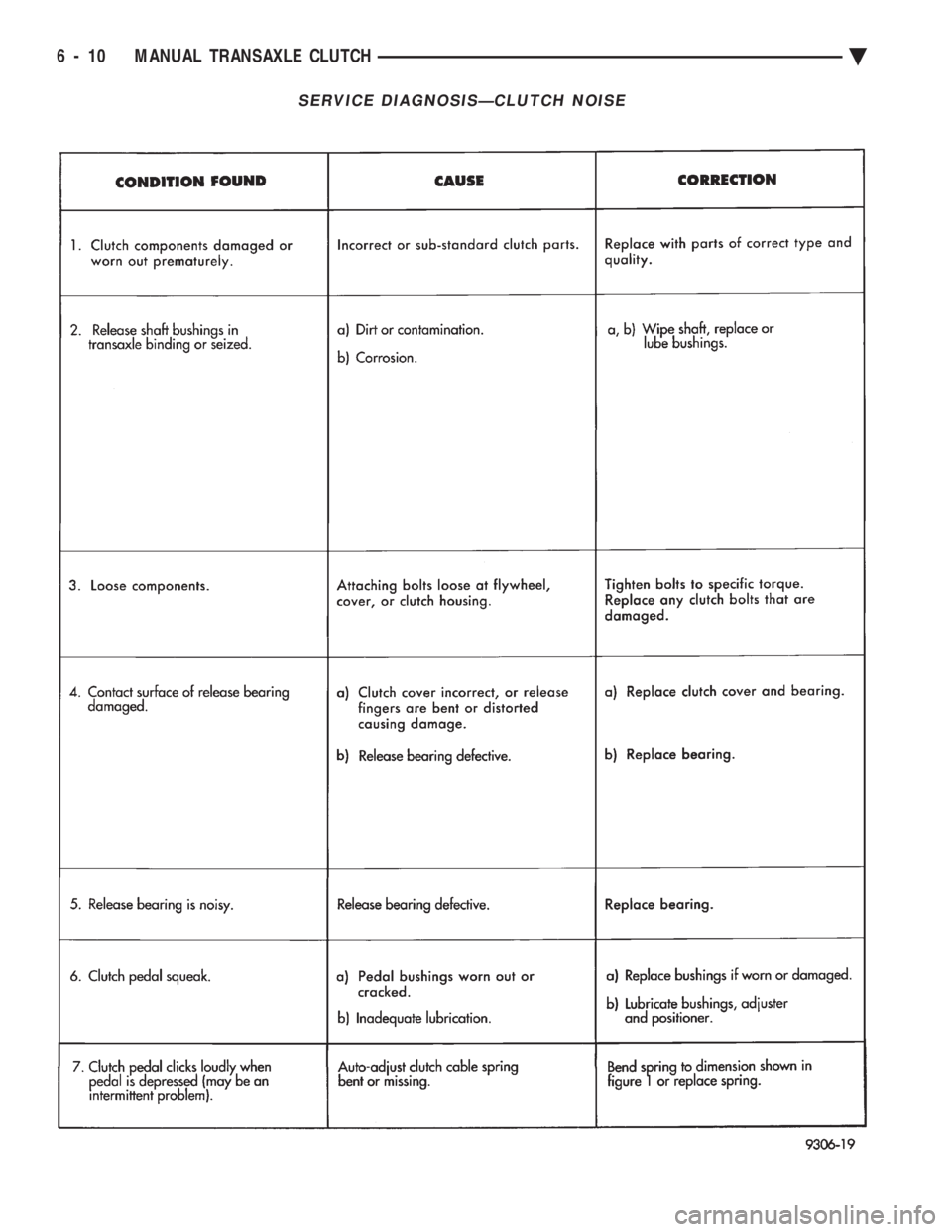

SERVICE DIAGNOSISÐCLUTCH NOISE

6 - 10 MANUAL TRANSAXLE CLUTCH Ä

Page 388 of 2438

relay to starter solenoid for loose or corroded connec-

tions. Particularly at starter terminals.

² Repeat test. If engine still fails to crank properly,

trouble is within starter or starter mounted solenoid,

and it must be removed for repairs. Refer to Group

8B, Battery/Starter/Generator Service, Starter re-

placement.

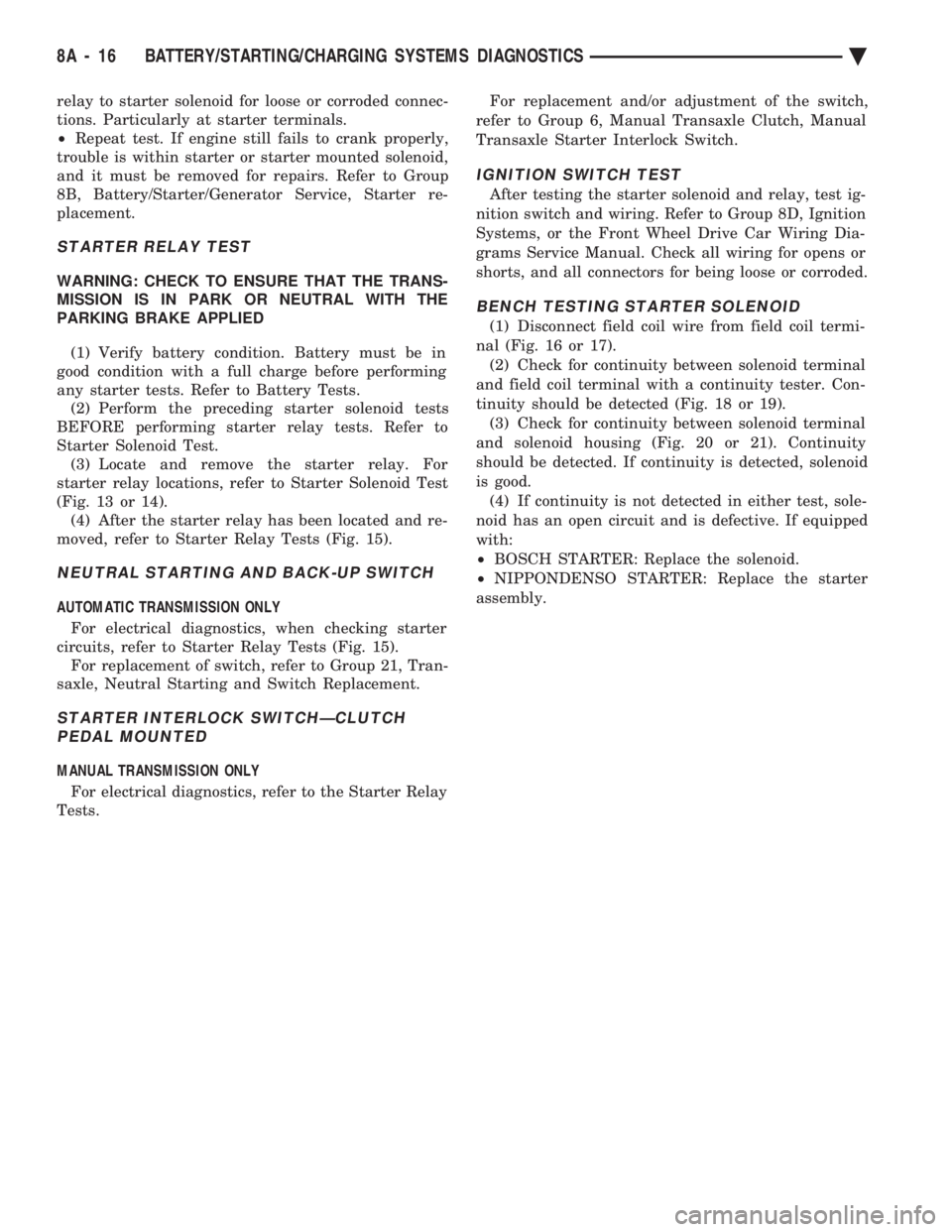

STARTER RELAY TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform the preceding starter solenoid tests

BEFORE performing starter relay tests. Refer to

Starter Solenoid Test. (3) Locate and remove the starter relay. For

starter relay locations, refer to Starter Solenoid Test

(Fig. 13 or 14). (4) After the starter relay has been located and re-

moved, refer to Starter Relay Tests (Fig. 15).

NEUTRAL STARTING AND BACK-UP SWITCH

AUTOMATIC TRANSMISSION ONLY

For electrical diagnostics, when checking starter

circuits, refer to Starter Relay Tests (Fig. 15). For replacement of switch, refer to Group 21, Tran-

saxle, Neutral Starting and Switch Replacement.

STARTER INTERLOCK SWITCHÐCLUTCH PEDAL MOUNTED

MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to the Starter Relay

Tests. For replacement and/or adjustment of the switch,

refer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

IGNITION SWITCH TEST

After testing the starter solenoid and relay, test ig-

nition switch and wiring. Refer to Group 8D, Ignition

Systems, or the Front Wheel Drive Car Wiring Dia-

grams Service Manual. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

BENCH TESTING STARTER SOLENOID

(1) Disconnect field coil wire from field coil termi-

nal (Fig. 16 or 17). (2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester. Con-

tinuity should be detected (Fig. 18 or 19). (3) Check for continuity between solenoid terminal

and solenoid housing (Fig. 20 or 21). Continuity

should be detected. If continuity is detected, solenoid

is good. (4) If continuity is not detected in either test, sole-

noid has an open circuit and is defective. If equipped

with:

² BOSCH STARTER: Replace the solenoid.

² NIPPONDENSO STARTER: Replace the starter

assembly.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 407 of 2438

(8) For installation, reverse above procedures.

Clean corrosion/dirt from the cable and wire termi-

nals before installing wiring to the solenoid.

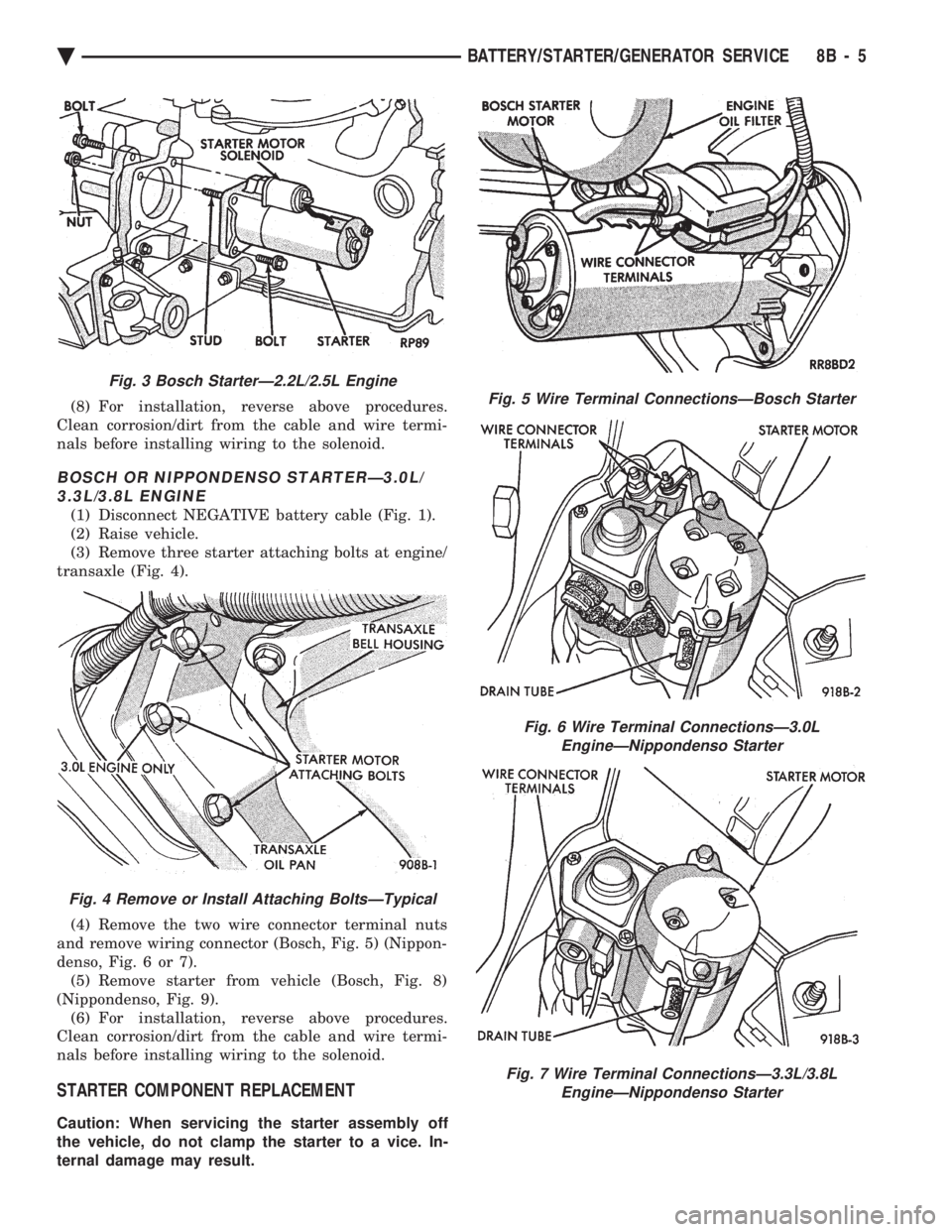

BOSCH OR NIPPONDENSO STARTERÐ3.0L/ 3.3L/3.8L ENGINE

(1) Disconnect NEGATIVE battery cable (Fig. 1).

(2) Raise vehicle.

(3) Remove three starter attaching bolts at engine/

transaxle (Fig. 4).

(4) Remove the two wire connector terminal nuts

and remove wiring connector (Bosch, Fig. 5) (Nippon-

denso, Fig. 6 or 7). (5) Remove starter from vehicle (Bosch, Fig. 8)

(Nippondenso, Fig. 9). (6) For installation, reverse above procedures.

Clean corrosion/dirt from the cable and wire termi-

nals before installing wiring to the solenoid.

STARTER COMPONENT REPLACEMENT

Caution: When servicing the starter assembly off

the vehicle, do not clamp the starter to a vice. In-

ternal damage may result.

Fig. 3 Bosch StarterÐ2.2L/2.5L Engine

Fig. 4 Remove or Install Attaching BoltsÐTypical

Fig. 5 Wire Terminal ConnectionsÐBosch Starter

Fig. 6 Wire Terminal ConnectionsÐ3.0L EngineÐNippondenso Starter

Fig. 7 Wire Terminal ConnectionsÐ3.3L/3.8L EngineÐNippondenso Starter

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 5

Page 410 of 2438

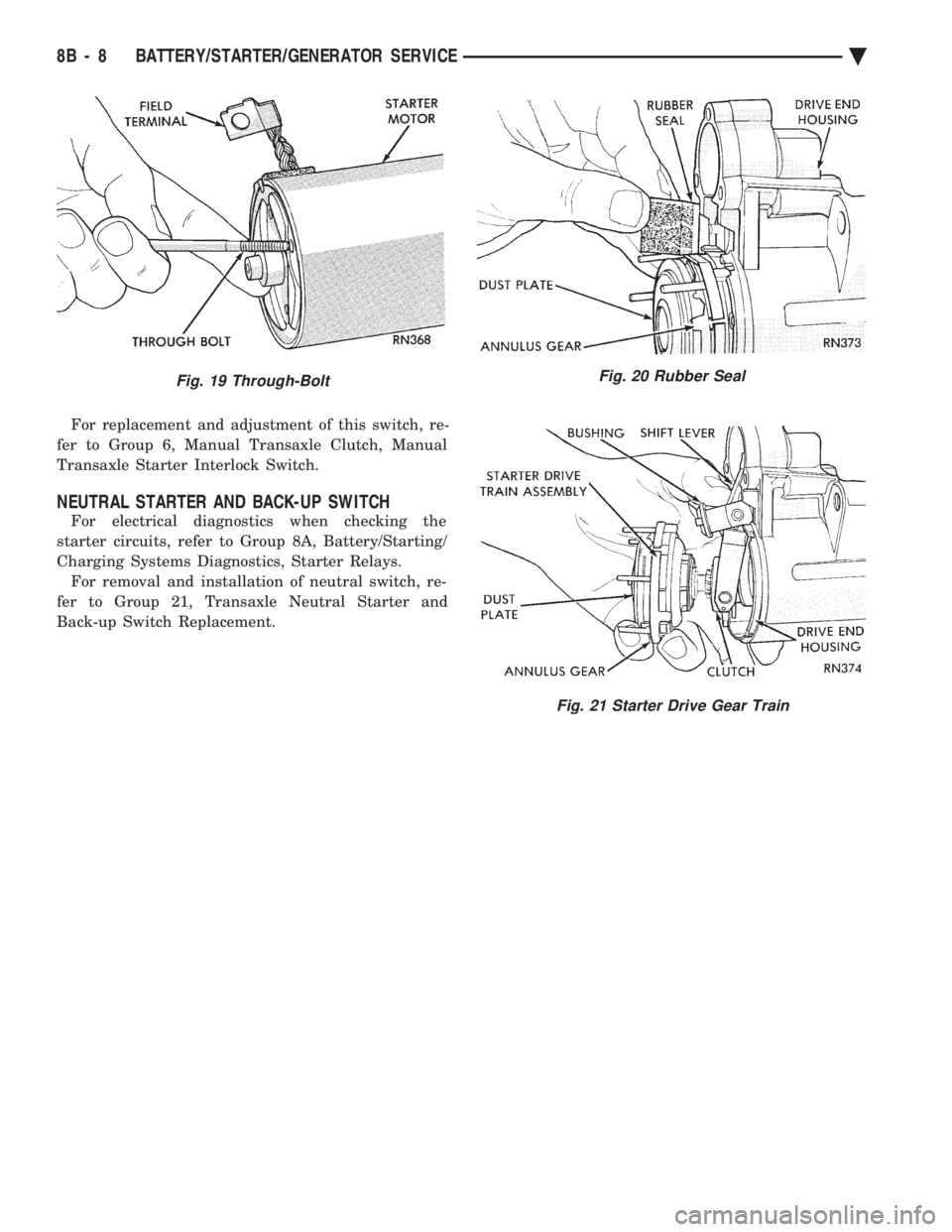

For replacement and adjustment of this switch, re-

fer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

NEUTRAL STARTER AND BACK-UP SWITCH

For electrical diagnostics when checking the

starter circuits, refer to Group 8A, Battery/Starting/

Charging Systems Diagnostics, Starter Relays. For removal and installation of neutral switch, re-

fer to Group 21, Transaxle Neutral Starter and

Back-up Switch Replacement.

Fig. 19 Through-BoltFig. 20 Rubber Seal

Fig. 21 Starter Drive Gear Train

8B - 8 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 458 of 2438

(3) Inspect the spark plug condition. Refer to Spark

Plug Condition in this section.

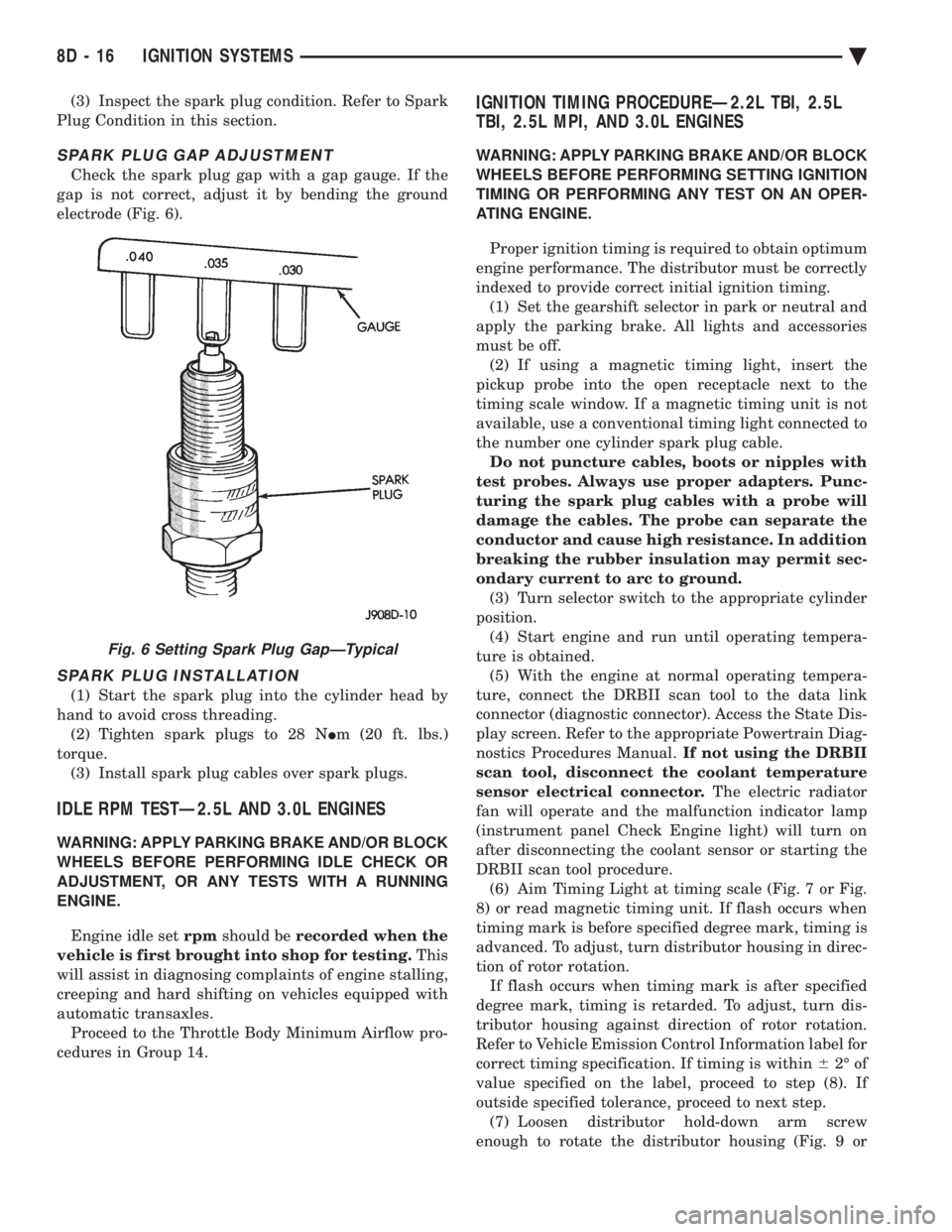

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TESTÐ2.5L AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING IDLE CHECK OR

ADJUSTMENT, OR ANY TESTS WITH A RUNNING

ENGINE.

Engine idle set rpmshould be recorded when the

vehicle is first brought into shop for testing. This

will assist in diagnosing complaints of engine stalling,

creeping and hard shifting on vehicles equipped with

automatic transaxles. Proceed to the Throttle Body Minimum Airflow pro-

cedures in Group 14.

IGNITION TIMING PROCEDUREÐ2.2L TBI, 2.5L

TBI, 2.5L MPI, AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING SETTING IGNITION

TIMING OR PERFORMING ANY TEST ON AN OPER-

ATING ENGINE.

Proper ignition timing is required to obtain optimum

engine performance. The distributor must be correctly

indexed to provide correct initial ignition timing. (1) Set the gearshift selector in park or neutral and

apply the parking brake. All lights and accessories

must be off. (2) If using a magnetic timing light, insert the

pickup probe into the open receptacle next to the

timing scale window. If a magnetic timing unit is not

available, use a conventional timing light connected to

the number one cylinder spark plug cable. Do not puncture cables, boots or nipples with

test probes. Always use proper adapters. Punc-

turing the spark plug cables with a probe will

damage the cables. The probe can separate the

conductor and cause high resistance. In addition

breaking the rubber insulation may permit sec-

ondary current to arc to ground. (3) Turn selector switch to the appropriate cylinder

position. (4) Start engine and run until operating tempera-

ture is obtained. (5) With the engine at normal operating tempera-

ture, connect the DRBII scan tool to the data link

connector (diagnostic connector). Access the State Dis-

play screen. Refer to the appropriate Powertrain Diag-

nostics Procedures Manual. If not using the DRBII

scan tool, disconnect the coolant temperature

sensor electrical connector. The electric radiator

fan will operate and the malfunction indicator lamp

(instrument panel Check Engine light) will turn on

after disconnecting the coolant sensor or starting the

DRBII scan tool procedure. (6) Aim Timing Light at timing scale (Fig. 7 or Fig.

8) or read magnetic timing unit. If flash occurs when

timing mark is before specified degree mark, timing is

advanced. To adjust, turn distributor housing in direc-

tion of rotor rotation. If flash occurs when timing mark is after specified

degree mark, timing is retarded. To adjust, turn dis-

tributor housing against direction of rotor rotation.

Refer to Vehicle Emission Control Information label for

correct timing specification. If timing is within 62É of

value specified on the label, proceed to step (8). If

outside specified tolerance, proceed to next step. (7) Loosen distributor hold-down arm screw

enough to rotate the distributor housing (Fig. 9 or

Fig. 6 Setting Spark Plug GapÐTypical

8D - 16 IGNITION SYSTEMS Ä

Page 471 of 2438

tion (Fig. 16 or Fig. 17). The sensor generates pulses

that are the input sent to the PCM. The PCM inter-

prets the camshaft position sensor input (along with

the crankshaft position sensor input) to determine

crankshaft position. The PCM uses the crankshaft

position sensor input to determine injector sequence

and ignition timing.

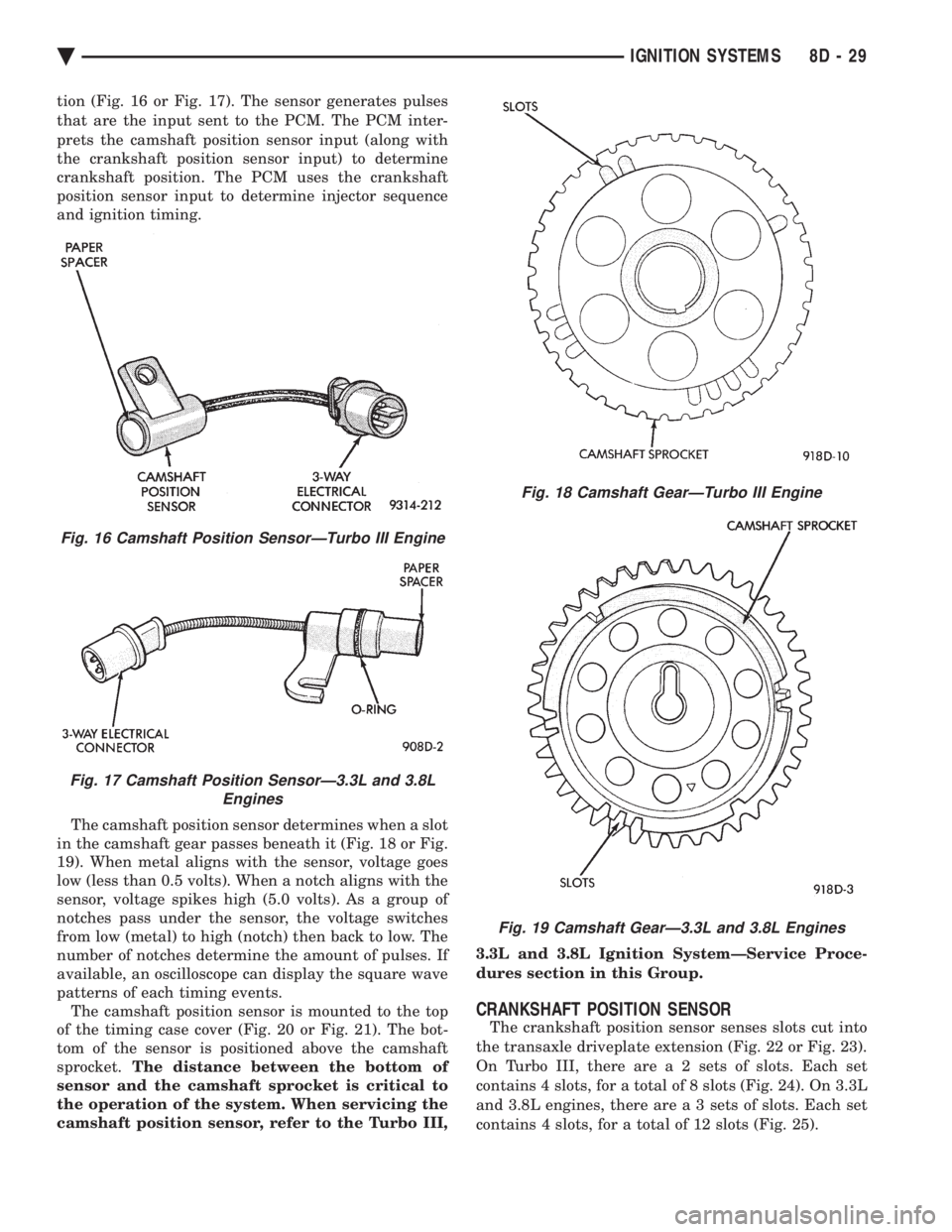

The camshaft position sensor determines when a slot

in the camshaft gear passes beneath it (Fig. 18 or Fig.

19). When metal aligns with the sensor, voltage goes

low (less than 0.5 volts). When a notch aligns with the

sensor, voltage spikes high (5.0 volts). As a group of

notches pass under the sensor, the voltage switches

from low (metal) to high (notch) then back to low. The

number of notches determine the amount of pulses. If

available, an oscilloscope can display the square wave

patterns of each timing events. The camshaft position sensor is mounted to the top

of the timing case cover (Fig. 20 or Fig. 21). The bot-

tom of the sensor is positioned above the camshaft

sprocket. The distance between the bottom of

sensor and the camshaft sprocket is critical to

the operation of the system. When servicing the

camshaft position sensor, refer to the Turbo III, 3.3L and 3.8L Ignition SystemÐService Proce-

dures section in this Group.

CRANKSHAFT POSITION SENSOR

The crankshaft position sensor senses slots cut into

the transaxle driveplate extension (Fig. 22 or Fig. 23).

On Turbo III, there ar e a 2 sets of slots. Each set

contains 4 slots, for a total of 8 slots (Fig. 24). On 3.3L

and 3.8L engines, there ar e a 3 sets of slots. Each set

contains 4 slots, for a total of 12 slots (Fig. 25).

Fig. 16 Camshaft Position SensorÐTurbo III Engine

Fig. 17 Camshaft Position SensorÐ3.3L and 3.8L Engines

Fig. 18 Camshaft GearÐTurbo III Engine

Fig. 19 Camshaft GearÐ3.3L and 3.8L Engines

Ä IGNITION SYSTEMS 8D - 29