CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 221 of 2438

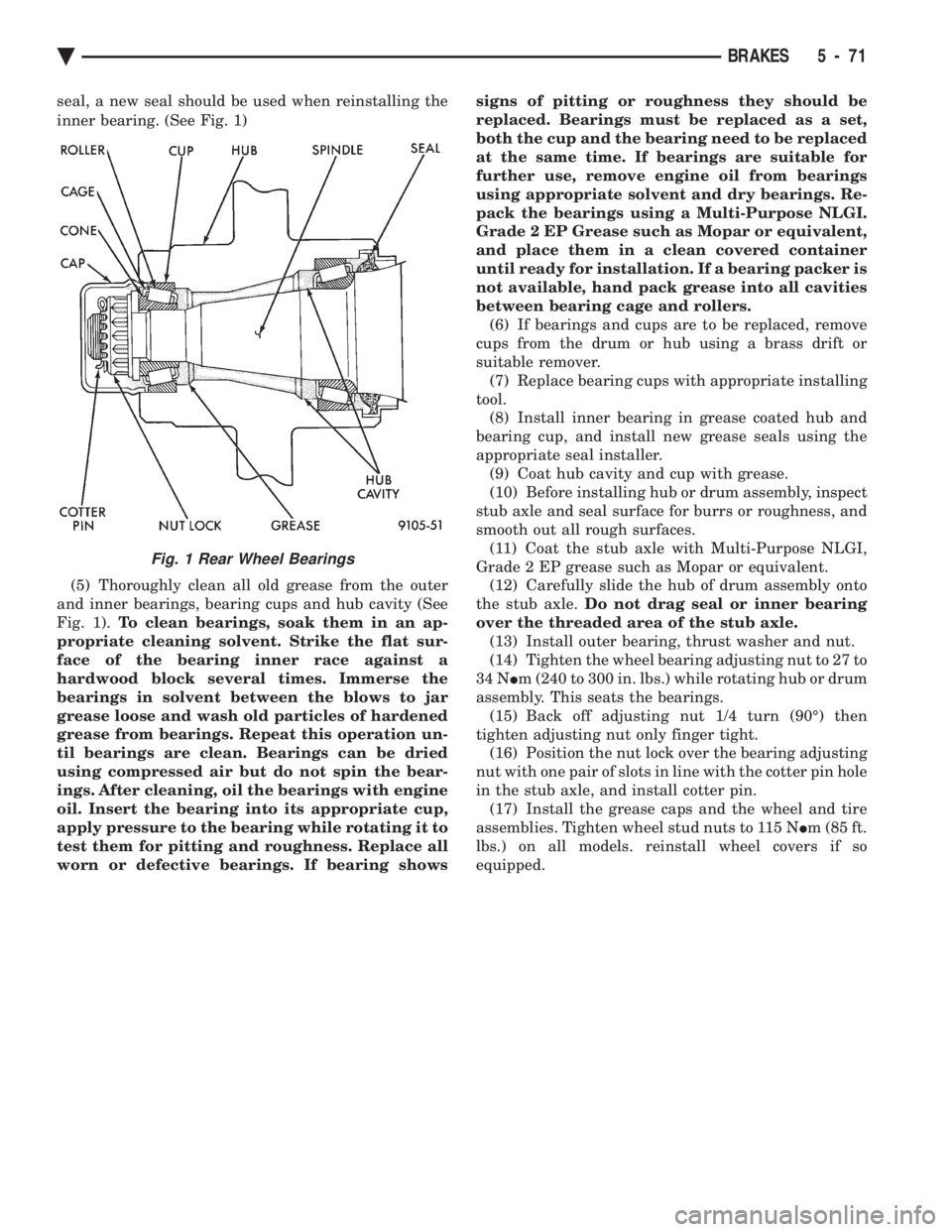

seal, a new seal should be used when reinstalling the

inner bearing. (See Fig. 1) (5) Thoroughly clean all old grease from the outer

and inner bearings, bearing cups and hub cavity (See

Fig. 1). To clean bearings, soak them in an ap-

propriate cleaning solvent. Strike the flat sur-

face of the bearing inner race against a

hardwood block several times. Immerse the

bearings in solvent between the blows to jar

grease loose and wash old particles of hardened

grease from bearings. Repeat this operation un-

til bearings are clean. Bearings can be dried

using compressed air but do not spin the bear-

ings. After cleaning, oil the bearings with engine

oil. Insert the bearing into its appropriate cup,

apply pressure to the bearing while rotating it to

test them for pitting and roughness. Replace all

worn or defective bearings. If bearing shows signs of pitting or roughness they should be

replaced. Bearings must be replaced as a set,

both the cup and the bearing need to be replaced

at the same time. If bearings are suitable for

further use, remove engine oil from bearings

using appropriate solvent and dry bearings. Re-

pack the bearings using a Multi-Purpose NLGI.

Grade 2 EP Grease such as Mopar or equivalent,

and place them in a clean covered container

until ready for installation. If a bearing packer is

not available, hand pack grease into all cavities

between bearing cage and rollers. (6) If bearings and cups are to be replaced, remove

cups from the drum or hub using a brass drift or

suitable remover. (7) Replace bearing cups with appropriate installing

tool. (8) Install inner bearing in grease coated hub and

bearing cup, and install new grease seals using the

appropriate seal installer. (9) Coat hub cavity and cup with grease.

(10) Before installing hub or drum assembly, inspect

stub axle and seal surface for burrs or roughness, and

smooth out all rough surfaces. (11) Coat the stub axle with Multi-Purpose NLGI,

Grade 2 EP grease such as Mopar or equivalent. (12) Carefully slide the hub of drum assembly onto

the stub axle. Do not drag seal or inner bearing

over the threaded area of the stub axle. (13) Install outer bearing, thrust washer and nut.

(14) Tighten the wheel bearing adjusting nut to 27 to

34 N Im (240 to 300 in. lbs.) while rotating hub or drum

assembly. This seats the bearings. (15) Back off adjusting nut 1/4 turn (90É) then

tighten adjusting nut only finger tight. (16) Position the nut lock over the bearing adjusting

nut with one pair of slots in line with the cotter pin hole

in the stub axle, and install cotter pin. (17) Install the grease caps and the wheel and tire

assemblies. Tighten wheel stud nuts to 115 N Im (85 ft.

lbs.) on all models. reinstall wheel covers if so

equipped.

Fig. 1 Rear Wheel Bearings

Ä BRAKES 5 - 71

Page 222 of 2438

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY INDEX

page page

ABS Brake System Diagnostic Features ....... 92

ABS Braking System Diagnosis .............. 87

ABS Controller Anti-Lock Brake (CAB) Service Precautions ........................... 88

ABS Equipped Vehicle Performance .......... 75

ABS Hydraulic Circuits and Valve Operation .... 85

ABS System Diagnostic Connector ........... 82

ABS System General Service Precautions ...... 88

ABS System Self-Diagnostics ............... 75

ABS Warning Systems Operation ............ 75

Anti-Lock Brake System Components ......... 76 Anti-Lock Brake System Definitions

........... 72

Anti-Lock Operation and Performance ......... 73

Anti-Lock System Relays and Warning Lamps . . . 82

Controller Anti-Lock Brake (CAB) ............. 80

Electronic Components ................... 103

General Information ....................... 72

General Service Precautions ................ 93

Major ABS Components ................... 73

Mechanical Diagnostics and Service Procedures . 89

Normal Braking System Function ............. 72

On Car Hydraulic ABS Component Service ..... 93

GENERAL INFORMATION

The purpose of the Anti-Lock Brake System (ABS)

is to prevent wheel lock-up under heavy braking con-

ditions on virtually any type of road surface. Anti-

Lock Braking is desirable because a vehicle which is

stopped without locking the wheels will retain direc-

tional stability and some steering capability. This al-

lows the driver to retain greater control of the

vehicle during heavy braking.

ANTI-LOCK BRAKE SYSTEM DEFINITIONS

In this section of the manual several abbreviations

are used for the components that are in the Anti-

Lock Braking System They are listed below for your

reference.

² CABÐController Anti-Lock Brake

² ABSÐAnti-Lock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions much the same as a standard brake system

with a diagonally split master cylinder. The primary

difference is that power assist is provided by hydrau-

lic power assist instead of the conventional vacuum

assist. If a wheel locking tendency is noticed during a

brake application, the system will enter Anti-Lock

mode. During Anti-Lock braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel of the vehicle

has a set of electrical solenoid valves and hydraulic

line to provide hydraulic modulation. For vehicle sta-

bility, though both rear wheel valves receive the

same electrical signal. The system can build, hold or

reduce pressure at each wheel of the vehicle. This is

determined by the signals generated by the wheel

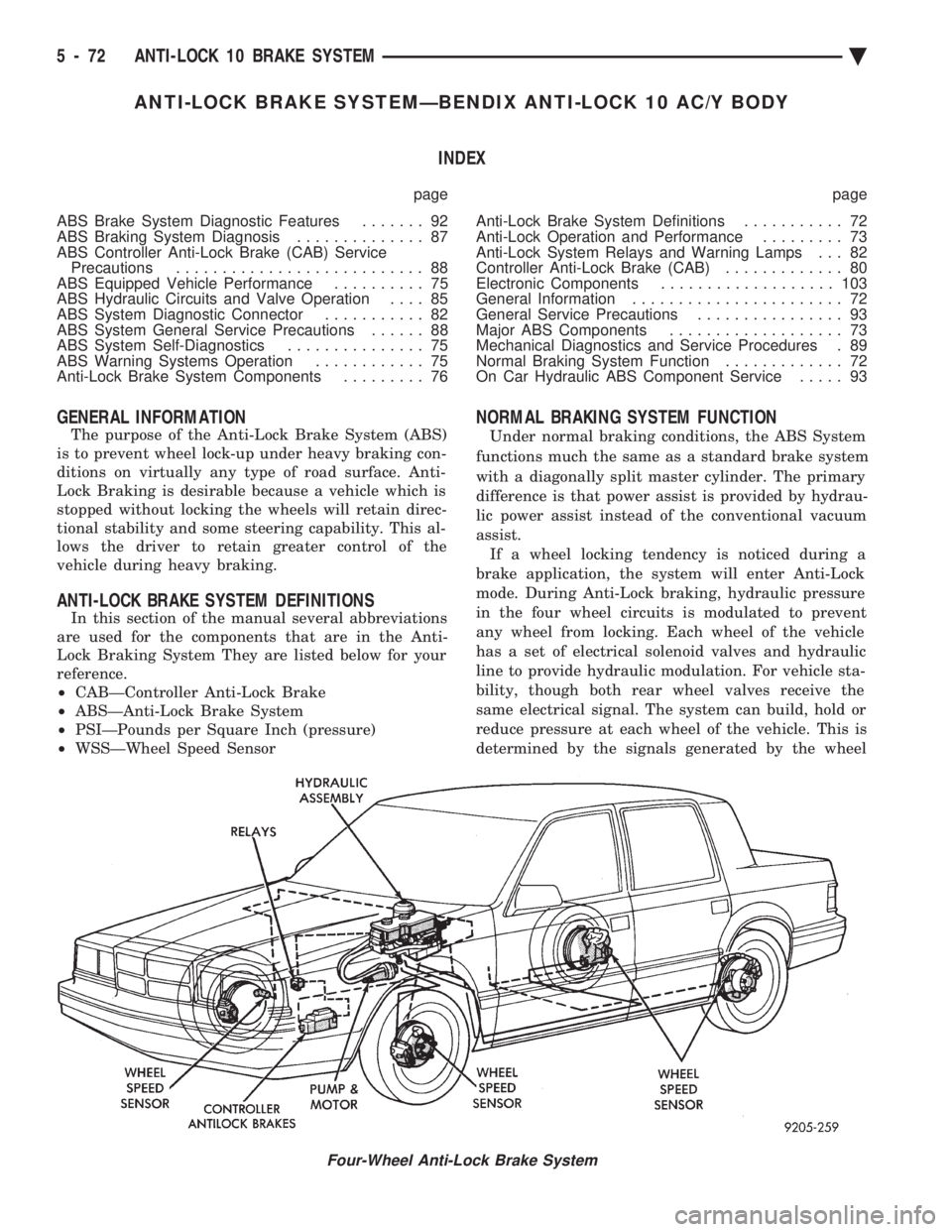

Four-Wheel Anti-Lock Brake System

5 - 72 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 223 of 2438

speed sensors (WSS) at each wheel and received at

the Controller-Anti-Lock Brake (CAB).

MAJOR ABS COMPONENTS

The following is a list of major system components.

Details of all components can be found later in this

section.

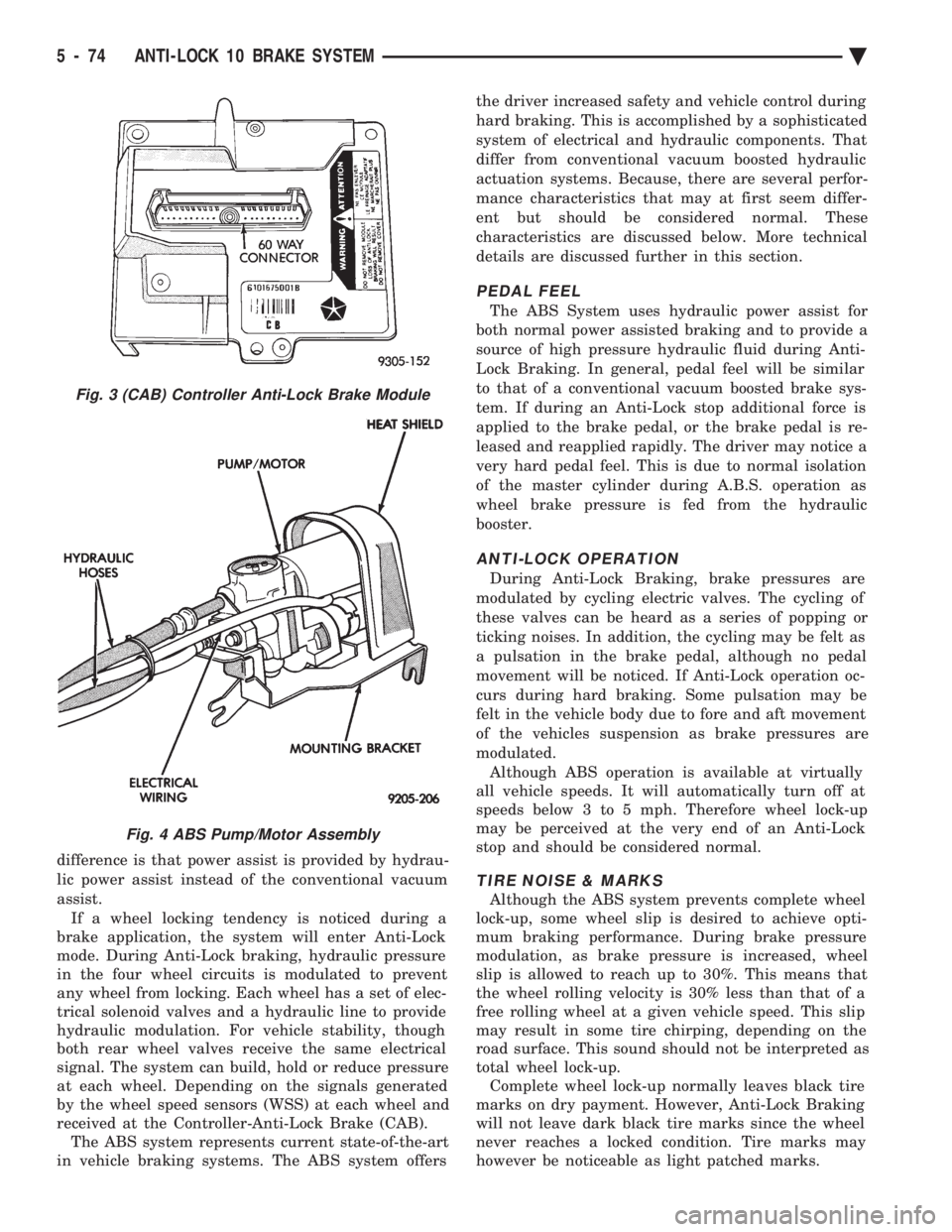

HYDRAULIC ASSEMBLY

The Hydraulic Assembly (Fig. 1) provides the func-

tion of an integral master cylinder and hydraulic

booster assembly. The hydraulic assembly contains

the wheel circuit valves used for brake pressure mod-

ulation.

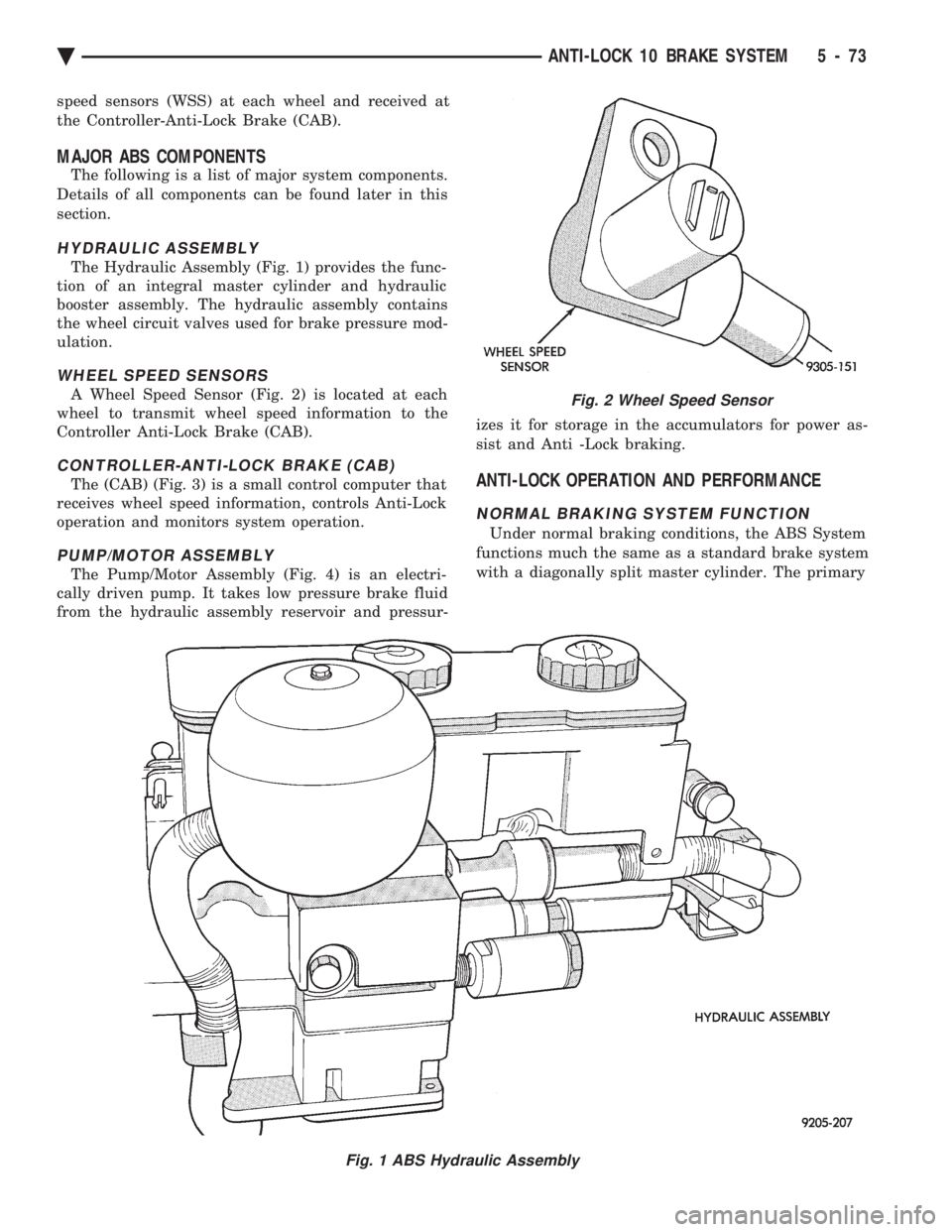

WHEEL SPEED SENSORS

A Wheel Speed Sensor (Fig. 2) is located at each

wheel to transmit wheel speed information to the

Controller Anti-Lock Brake (CAB).

CONTROLLER-ANTI-LOCK BRAKE (CAB)

The (CAB) (Fig. 3) is a small control computer that

receives wheel speed information, controls Anti-Lock

operation and monitors system operation.

PUMP/MOTOR ASSEMBLY

The Pump/Motor Assembly (Fig. 4) is an electri-

cally driven pump. It takes low pressure brake fluid

from the hydraulic assembly reservoir and pressur- izes it for storage in the accumulators for power as-

sist and Anti -Lock braking.

ANTI-LOCK OPERATION AND PERFORMANCE

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions much the same as a standard brake system

with a diagonally split master cylinder. The primary

Fig. 1 ABS Hydraulic Assembly

Fig. 2 Wheel Speed Sensor

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 73

Page 224 of 2438

difference is that power assist is provided by hydrau-

lic power assist instead of the conventional vacuum

assist. If a wheel locking tendency is noticed during a

brake application, the system will enter Anti-Lock

mode. During Anti-Lock braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel has a set of elec-

trical solenoid valves and a hydraulic line to provide

hydraulic modulation. For vehicle stability, though

both rear wheel valves receive the same electrical

signal. The system can build, hold or reduce pressure

at each wheel. Depending on the signals generated

by the wheel speed sensors (WSS) at each wheel and

received at the Controller-Anti-Lock Brake (CAB). The ABS system represents current state-of-the-art

in vehicle braking systems. The ABS system offers the driver increased safety and vehicle control during

hard braking. This is accomplished by a sophisticated

system of electrical and hydraulic components. That

differ from conventional vacuum boosted hydraulic

actuation systems. Because, there are several perfor-

mance characteristics that may at first seem differ-

ent but should be considered normal. These

characteristics are discussed below. More technical

details are discussed further in this section.

PEDAL FEEL

The ABS System uses hydraulic power assist for

both normal power assisted braking and to provide a

source of high pressure hydraulic fluid during Anti-

Lock Braking. In general, pedal feel will be similar

to that of a conventional vacuum boosted brake sys-

tem. If during an Anti-Lock stop additional force is

applied to the brake pedal, or the brake pedal is re-

leased and reapplied rapidly. The driver may notice a

very hard pedal feel. This is due to normal isolation

of the master cylinder during A.B.S. operation as

wheel brake pressure is fed from the hydraulic

booster.

ANTI-LOCK OPERATION

During Anti-Lock Braking, brake pressures are

modulated by cycling electric valves. The cycling of

these valves can be heard as a series of popping or

ticking noises. In addition, the cycling may be felt as

a pulsation in the brake pedal, although no pedal

movement will be noticed. If Anti-Lock operation oc-

curs during hard braking. Some pulsation may be

felt in the vehicle body due to fore and aft movement

of the vehicles suspension as brake pressures are

modulated. Although ABS operation is available at virtually

all vehicle speeds. It will automatically turn off at

speeds below 3 to 5 mph. Therefore wheel lock-up

may be perceived at the very end of an Anti-Lock

stop and should be considered normal.

TIRE NOISE & MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired to achieve opti-

mum braking performance. During brake pressure

modulation, as brake pressure is increased, wheel

slip is allowed to reach up to 30%. This means that

the wheel rolling velocity is 30% less than that of a

free rolling wheel at a given vehicle speed. This slip

may result in some tire chirping, depending on the

road surface. This sound should not be interpreted as

total wheel lock-up. Complete wheel lock-up normally leaves black tire

marks on dry payment. However, Anti-Lock Braking

will not leave dark black tire marks since the wheel

never reaches a locked condition. Tire marks may

however be noticeable as light patched marks.

Fig. 3 (CAB) Controller Anti-Lock Brake Module

Fig. 4 ABS Pump/Motor Assembly

5 - 74 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 225 of 2438

ABS EQUIPPED VEHICLE PERFORMANCE

Anti-Lock Brakes provide the driver with some

steering control during hard braking. However there

are conditions where the system does not provide any

benefit. In particular, hydroplaning is still possible

when the tires ride on a film of water. Hydroplaning

results in the vehicle tires leaving the road surface

rendering the vehicle almost uncontrollable. In addi-

tion, extreme steering maneuvers at high speed or

high speed cornering beyond limits of tire adhesion

to the road surface may cause vehicle skidding. So,

the ABS system is termed Anti-Lock instead of Anti-

Skid. One of the significant benefits of the ABS system is

that of maintaining steering control during hard

braking or during braking on slippery surfaces. It is

therefore possible to steer the vehicle while braking

on almost any road surface.

ABS SYSTEM SELF-DIAGNOSTICS

The ABS system has been designed with Self Diag-

nostic Capability. There are two self checks the sys-

tems performs every time the vehicle is started.

First, when the key is turned on the system performs

an electrical check called Start-Up Cycle. During this

check, the Red Brake Warning Lamp and the Amber

Anti-Lock Warning Lamp are illuminated. Then

turned off at the end of the test, after about 1 to 2

seconds. When the vehicle reaches a speed of about 3

to 4 miles per hour. The system performs a func-

tional check called Drive-Off. During Drive-Off. hy-

draulic valves are activated briefly to test their

function. Drive-Off can be detected as a series of

rapid clicks upon driving off the first time the car is

started. If the brake pedal is applied during Drive-

Off, the test is by-passed. Both of these conditions

are a normal part of the system self test. Most fault

conditions will set a ABS Fault Code in the (CAB),

which can be retrieved to aid in fault diagnosis. De-

tails can be found in Diagnosis Section.

ABS WARNING SYSTEMS OPERATION

The ABS system uses two methods for notifying

the driver of a system malfunction. These include the

standard Red Brake Warning Lamp and an Amber

Anti-Lock Warning Lamp, both located in the instru-

ment cluster. The purpose of these two lamps are dis-

cussed in detail below.

RED BRAKE WARNING LAMP

The Red Brake Warning Lamp, located in the in-

strument cluster, will Turn On to warn the driver of

brake system conditions that may result in reduced

braking ability. The lamp is also turned on when the

parking brake is not fully released. Conditions which

may cause the Red Brake Warning Lamp to Turn On

include: ²

Parking brake not fully released. If the parking

brake is applied or not fully released. The switch on the

parking brake pedal assembly will ground the Red

Brake Warning Lamp circuit and cause the lamp to

turn on. On vehicles equipped with mechanical instru-

ment clusters, the Amber Anti-Lock Lamp will turn on

if the vehicle is driven above 3 miles per hour with the

Parking Brake applied.

² Low brake fluid. The fluid level sensor in the hy-

draulic assembly reservoir will ground the Red Brake

Warning Lamp circuit if low brake fluid level is de-

tected. In addition, ABS will be deactivated above 3

miles per hour and the Amber Anti-Lock Warning

Lamp will be illuminated. If the vehicle is equipped

with EVIC, a low fluid condition will also cause the

Low Brake Fluid message to appear.

² Low Accumulator Pressure. In the event of low

accumulator pressure, the dual function pressure

switch in the hydraulic assembly will signal the (CAB)

to ground the Red Brake Warning Lamp circuit. This

will cause the Red Brake Warning Lamp to turn on.

Low accumulator pressure also results in the activa-

tion of the Yellow Anti-Lock Warning Lamp. Low accu-

mulator pressure may result in loss of power assist.

² Modulator Or (CAB) Faults. The modulator assem-

bly or (CAB) may turn on the Yellow Anti-Lock Warn-

ing Lamp, if certain faults are detected in either the

modulator assembly or the (CAB).

² Bulb check. As a bulb check, the Red Brake Warning

Lamp will illuminate whenever the ignition switch is

placed in the crank position. Illumination of the red Brake Warning Lamp

may indicate reduced braking ability. A vehicle

that has the Red Brake Warning Lamp ON should

not be driven except to do diagnostic procedures

described in Section 2 of this manual. Most con-

ditions that turn on the Red Brake Warning

Lamp will also turn on the Amber Anti-Lock

Warning Lamp, consequently disabling the Anti-

Lock function.

ANTI-LOCK WARNING LAMP

The Anti-Lock Warning Lamp is located in the in-

strument cluster and is Amber in color. The Amber

Anti-Lock Warning Lamp is illuminated when the

(CAB) detects a condition that results in a shutdown of

Anti-Lock function. The Amber Anti-Lock Warning

Lamp is normally on until the (CAB) completes its self

tests and turns the lamp off. For example, if the (CAB)

is disconnected, the lamp is on. Display of the Amber Anti-Lock Warning Lamp

without the Red Brake Warning Lamp indicates

only that Anti-Lock function has been disabled.

Power assisted normal braking is unaffected.

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 75

Page 226 of 2438

NORMAL OPERATION OF WARNING LAMPS

With the ignition in the Crank position, the Red

Brake Warning Lamp will turn on as a bulb check.

The Amber Anti-Lock Warning Lamp will turn on

for as little as 1 second to as long as 30 seconds. If the car has not been started for several hours,

for example after sitting overnight. The Red Brake

Warning Lamp and the Amber Anti-Lock Warning

Lamp may both be turned on for as long as 60 sec-

onds after turning the ignition on. This condition is

caused by the loss of accumulator charge when the

vehicle is parked for extended periods, particularly in

cold weather. When the key is then turned on. The

Pump/Motor assembly must recharge the hydraulic

accumulator to its normal operating pressure. As re-

charging is completed, both warning lamps will turn

off when accumulator pressure reaches about (1,000

psi). Both lamps should remain off at all other times,

indicating normal operation.

ANTI-LOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Anti-

Lock Brake System components. For information on

servicing the other Non-ABS related components

that may be referred to in this section. See the Stan-

dard Brakes Section that refers to the specific com-

ponent.

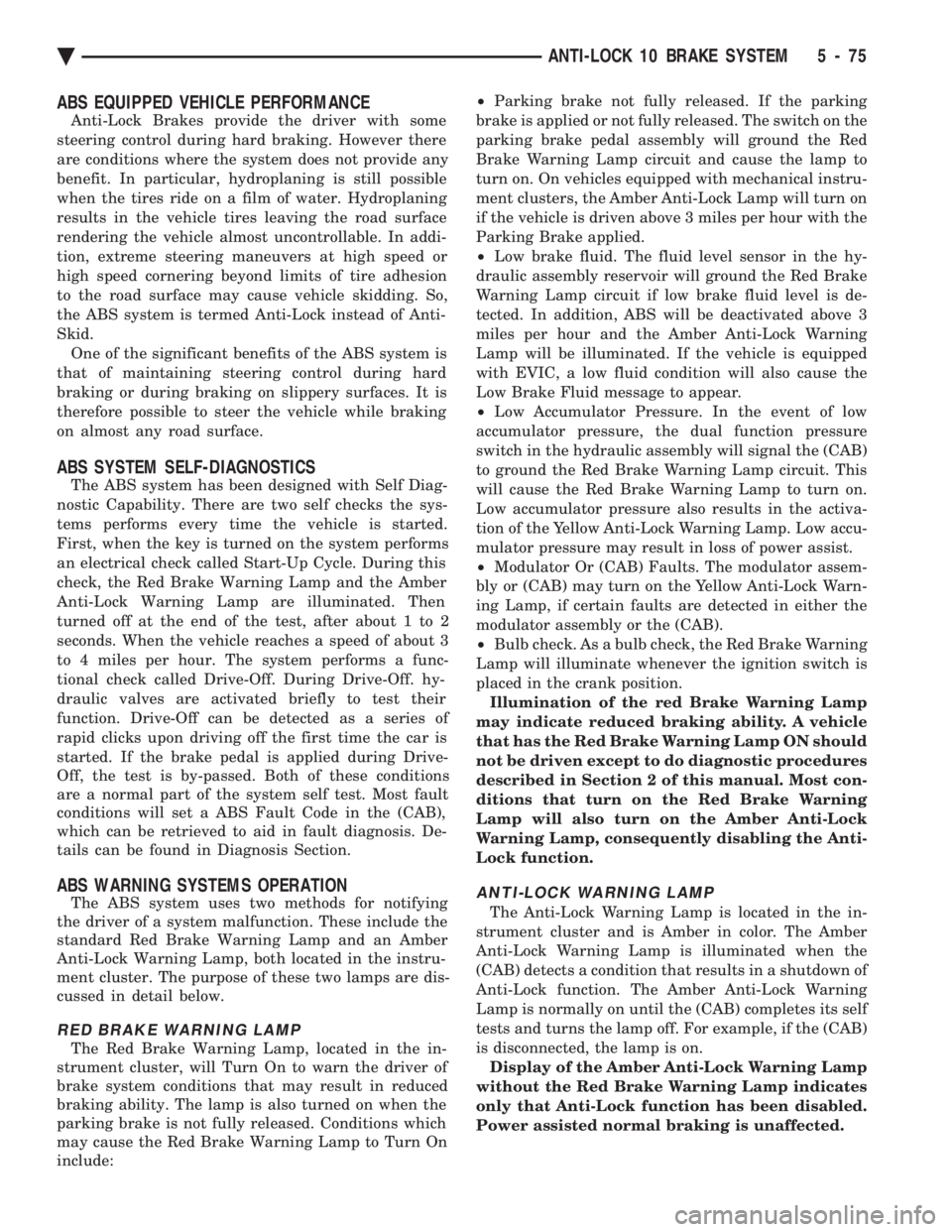

HYDRAULIC ASSEMBLY

The ABS system uses an integral Hydraulic Assem-

bly (Fig. 1). The hydraulic assembly includes a

Booster/Master Cylinder, Modulator, Hydraulic Blad-

der Accumulator and Fluid Reservoir. The Hydraulic

Assembly is located on the dash panel cowl on the

drivers side of the vehicle. The following is a descrip-

tion of the components that make up the Hydraulic

Assembly.

HYDRAULIC ASSEMBLY BRAKE FLUID RES- ERVOIR

A one piece Fluid Reservoir is attached to the hy-

draulic assembly with rubber seals. The Fluid Reser-

voir (Fig. 1) is internally separated into three fluid

sections. Most of the brake fluid is contained in the

Fluid Reservoir and hydraulic bladder accumulator

(Fig. 1). Additional fluid is contained in the

pump/motor assembly accumulator.

BOOSTER/MASTER CYLINDER

The Booster/Master Cylinder portion of the

hydraulic assembly is an integral component and

should never be disassembled. The Booster/Master Cylinder uses a diagonally split

configuration during normal braking. The two

Fig. 1 Hydraulic Assembly

5 - 76 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 227 of 2438

circuits are hydraulically isolated so a leak or mal-

function in one circuit will allow continued braking

ability in the other.When force is applied to the brake pedal, the input

pushrod applies force to the boost control valve. As

the boost control valve is moved, it allows the pres-

surized fluid from the accumulator to flow into the

master cylinder booster chamber. The pressure gen-

erated in the booster chamber is directly propor-

tioned to the brake pedal force exerted by the driver.

This pressure in the booster servo in turn applies

pressure to the primary master cylinder piston that

in turn applies pressure to the secondary master cyl-

inder piston. The pressure generated in the primary

and secondary circuits are used to apply the brakes

during normal braking.

WARNING: THE HYDRAULIC ACCUMULATORS

CONTAIN BRAKE FLUID AND NITROGEN GAS AT

HIGH PRESSURE. CERTAIN PORTIONS OF THE

BRAKE SYSTEM ALSO CONTAIN BRAKE FLUID AT

HIGH PRESSURE. REMOVAL OR DISASSEMBLY

MAY RESULT IN PERSONAL INJURY AND IM-

PROPER SYSTEM OPERATION. REFER TO THE AP-

PROPRIATE SERVICE MANUAL FOR PROPER

SERVICE PROCEDURES.

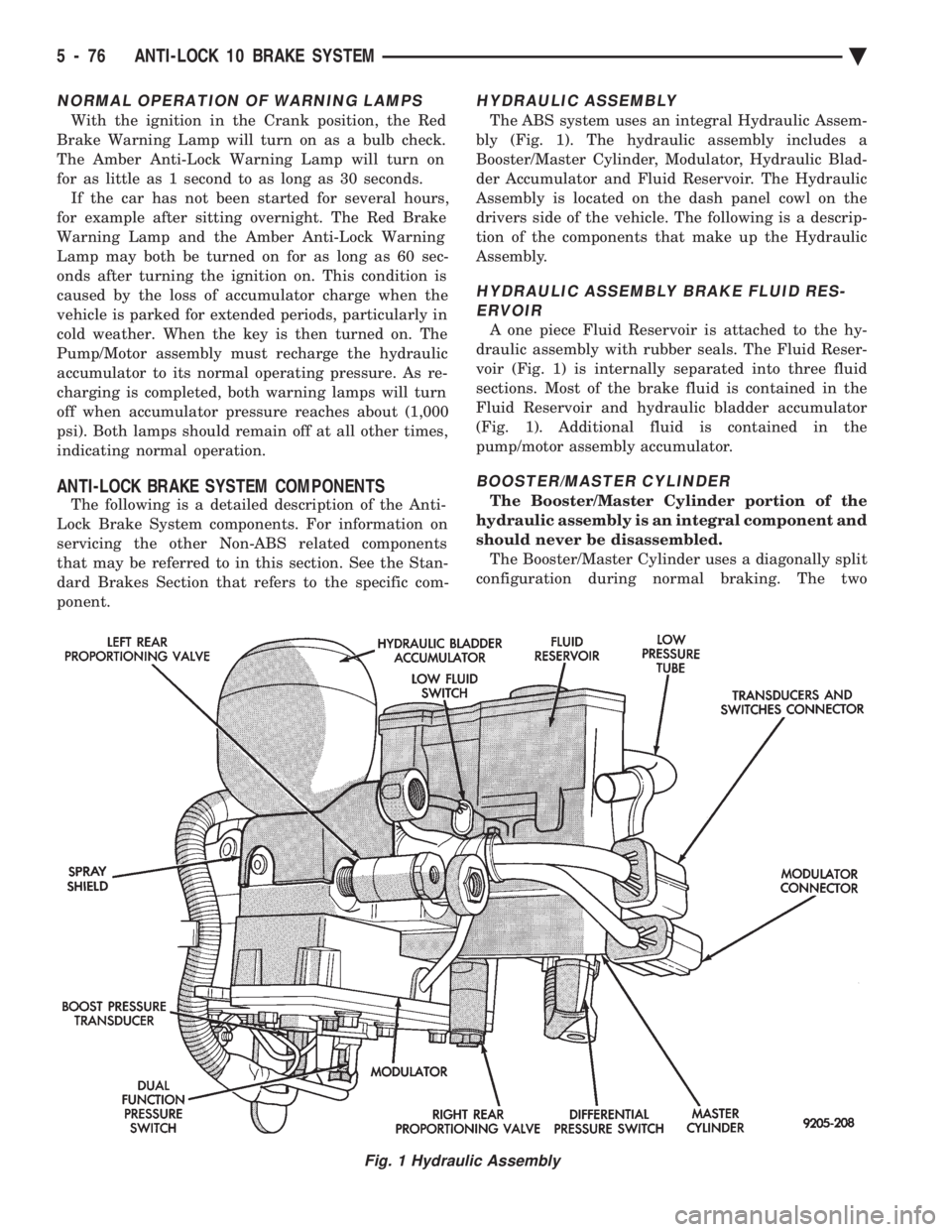

HYDRAULIC BLADDER ACCUMULATOR

A Hydraulic Bladder Accumulator (Fig. 2) is used

to store brake fluid at high pressure. The pressurized

fluid is used for Anti-Lock operation and for power

assisted normal braking. The accumulator uses an

elastomeric bladder configuration with a nitrogen

pre-charge of about 6,895 kPa (1,000 psi.) With no

brake fluid in the system, the nitrogen gas pre-

charge applies approximately 6,895 kPa (1,000 psi.)

to one side of the diaphragm (Fig. 2) Under normal operation, the Pump/Motor assembly

charges the accumulator to an operating pressure of

between 11,032 and 13,790 kPa (1600 psi to 2,000

psi.) As pressurized brake fluid enters the accumula-

tor, pushing against the opposite side of the dia-

phragm, (Fig. 2) the nitrogen gas is compressed and

increases in pressure.

DUAL FUNCTION PRESSURE SWITCH

The Dual Function Pressure Switch is located on

the bottom of the hydraulic assembly (Fig. 1) and

monitors Accumulator Pressure. The Dual Function

Pressure Switch, if found to be functioning improp-

erly using the ABS diagnostics, can be replaced. See

service procedure in Electronic Components area of

On Car ABS Service in this section of the service

manual. The primary function is to control operation

of the Pump/Motor assembly and thus maintain

proper accumulator operating pressure. When accu-

mulator pressure falls to or below 11,032 kPa (1600 psi.) the pump motor switch (internal to the dual

function pressure switch) will close. This provides a

ground, through Pin 1 of the Transducer and Switch,

10 way electrical connector to the Pump/Motor relay

coil. The energized coil pulls the relay contacts

closed, providing battery voltage to run the Pump/

Motor. When Accumulator Pressure reaches 13,790

kPa (2,000 psi.) the switch opens, de-energizing the

Pump/Motor Relay that turns off the Pump/Motor. NOTE: THE (CAB) DOES NOT REGULATE

OR CONTROL ACCUMULATOR PRESSURE. The second purpose of the Dual Function Pressure

Switch is to provide a signal to the (CAB) when the

Accumulator Pressure falls below 6,895 kPa (1,000

psi). A Warning Pressure Switch, internal to the

Dual Function Pressure Switch, is normally closed

above 6,895 kPa (1,000 psi.) This sends a ground sig-

nal to pin 17 at the (CAB). At or below 6,895 kPa

(1,000 psi.) the Warning Pressure Switch opens. In-

ternally, the (CAB) (pin 17) detects 12 volts and thus

low pressure. At this warning pressure, the (CAB)

will disable the Anti-Lock Braking functions, light

the Red Brake Warning Lamp and the Amber Anti-

Lock Warning Lamp. After two minutes of continu-

ous detection, a low accumulator fault is stored. Grounding for the Dual Function Pressure Switch.

Is provided through Pin 1 of the Transducer and

Switch, 10 way electrical connector and the Modula-

tor Assembly.

PRESSURE TRANSDUCERS

Two Pressure Transducers are used for brake sys-

tem fault detection. Both transducers generate a

voltage signal (between 0.25 volts and 5.0 volts) that

is proportional to pressure. These signals are com-

Fig. 2 Hydraulic Fluid Accumulator

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 77

Page 228 of 2438

pared by the (CAB) and used to detect brake system

faults that would require Anti -Lock Braking to be

disabled.The Boost Pressure Transducer is mounted on the

bottom of the hydraulic assembly, (Fig. 1) and moni-

tors booster servo pressure. The Primary Pressure

Transducer is mounted on the left side of the hydrau-

lic assembly and monitors primary master cylinder

pressure.

DIFFERENTIAL PRESSURE SWITCH

A non-latching Differential Pressure Switch is used

to detect a pressure difference greater than 2,068

kPa (300 psi.) between the primary and secondary

master cylinder hydraulic circuits. If detected, the

Differential Pressure Switch grounds the output of

the primary pressure transducer (circuit B-218). This

results in a 0.0 volt signal from the Primary Pres-

sure Transducer that is sensed by the (CAB) as a dif-

ferential pressure fault. The (CAB) will then light

the Red Brake Warning Lamp and the Amber Anti-

Lock Warning Lamp and disable the Anti-Lock brak-

ing function. See Fig. 1 for location of the differential

pressure switch.

PROPORTIONING VALVES

The ABS system uses screw-in Proportioning

Valves in place of the conventional Height Sensing Proportioning Valve. Each rear brake circuit has its

own screw-in Proportioning Valve that is attached to

the rear brake outlet ports of the hydraulic assembly

(Fig. 1). These valves limit brake pressure to the

rear brakes after a certain brake pressure is reached.

This improves front to rear wheel brake balance dur-

ing normal braking.

FILTERS-SERVICEABILITY

There is a screen filter in each of the two master

cylinder fill ports. There is also a low pressure filter

for the pump/motor. The filter is integral to the

Pump/Motor low pressure hose.

FLUID LEVEL SWITCH

A Low Fluid Switch is located in the hydraulic as-

sembly fluid reservoir, (Fig. 1). The switch consists of

a float and magnetic reed switch that closes when

low fluid is detected. The Low Fluid Switch is used

as an input, to the Red Brake Warning Lamp, the

(CAB), and the EVIC (if so equipped). When a low

fluid condition exists the switch will close, grounding

the low fluid circuit and illuminating the Red Brake

Warning Lamp. The (CAB) will disable the Anti-

Lock Function and light the Amber Anti-Lock Warn-

ing Lamp if vehicle is in motion above 3 mph. If

vehicle is not in motion, the Amber Anti-Lock Warn-

ing Lamp will NOT be lit.

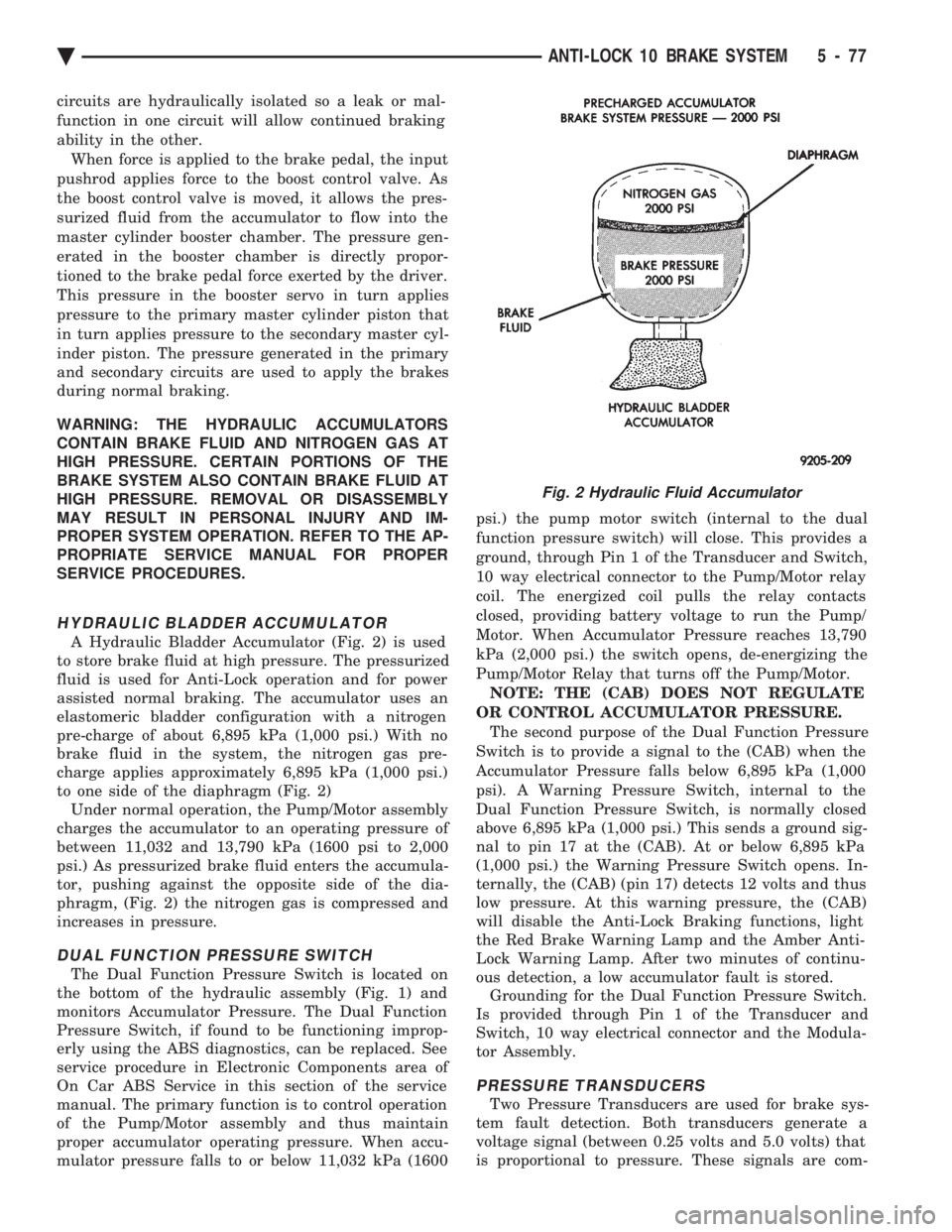

DUAL FUNCTION PRESSURE SWITCH WIRING DIAGRAM

5 - 78 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 229 of 2438

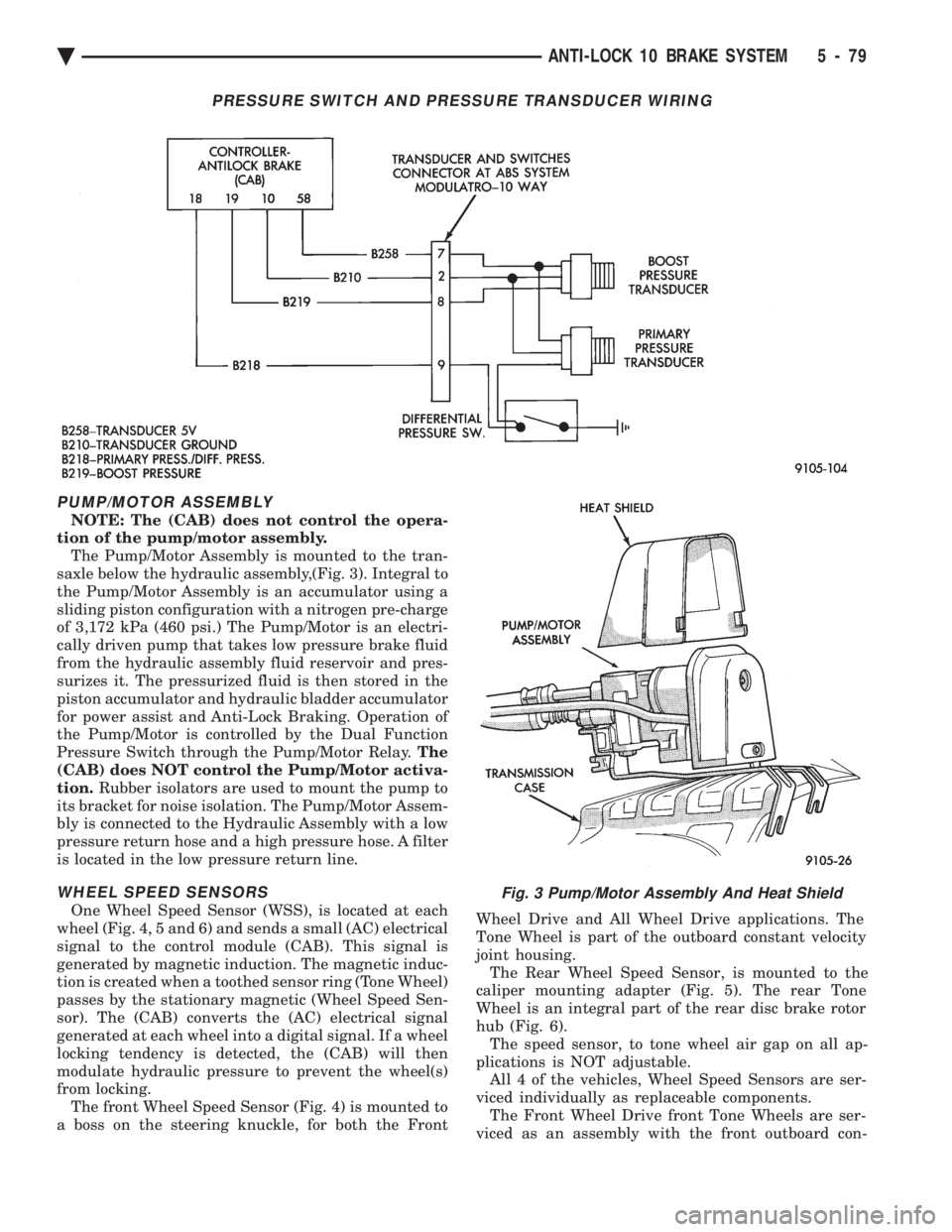

PUMP/MOTOR ASSEMBLY

NOTE: The (CAB) does not control the opera-

tion of the pump/motor assembly. The Pump/Motor Assembly is mounted to the tran-

saxle below the hydraulic assembly,(Fig. 3). Integral to

the Pump/Motor Assembly is an accumulator using a

sliding piston configuration with a nitrogen pre-charge

of 3,172 kPa (460 psi.) The Pump/Motor is an electri-

cally driven pump that takes low pressure brake fluid

from the hydraulic assembly fluid reservoir and pres-

surizes it. The pressurized fluid is then stored in the

piston accumulator and hydraulic bladder accumulator

for power assist and Anti-Lock Braking. Operation of

the Pump/Motor is controlled by the Dual Function

Pressure Switch through the Pump/Motor Relay. The

(CAB) does NOT control the Pump/Motor activa-

tion. Rubber isolators are used to mount the pump to

its bracket for noise isolation. The Pump/Motor Assem-

bly is connected to the Hydraulic Assembly with a low

pressure return hose and a high pressure hose. A filter

is located in the low pressure return line.

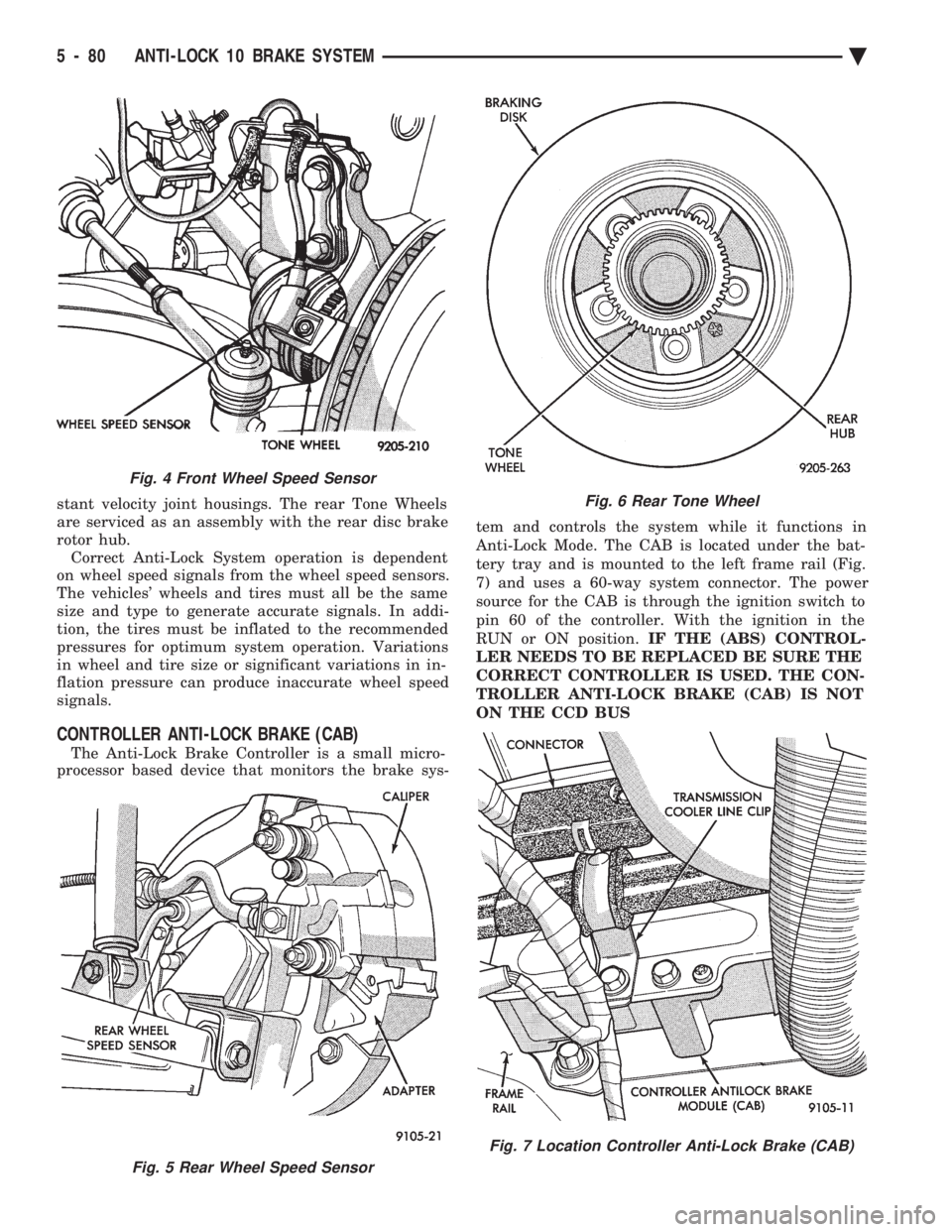

WHEEL SPEED SENSORS

One Wheel Speed Sensor (WSS), is located at each

wheel (Fig. 4, 5 and 6) and sends a small (AC) electrical

signal to the control module (CAB). This signal is

generated by magnetic induction. The magnetic induc-

tion is created when a toothed sensor ring (Tone Wheel)

passes by the stationary magnetic (Wheel Speed Sen-

sor). The (CAB) converts the (AC) electrical signal

generated at each wheel into a digital signal. If a wheel

locking tendency is detected, the (CAB) will then

modulate hydraulic pressure to prevent the wheel(s)

from locking. The front Wheel Speed Sensor (Fig. 4) is mounted to

a boss on the steering knuckle, for both the Front Wheel Drive and All Wheel Drive applications. The

Tone Wheel is part of the outboard constant velocity

joint housing. The Rear Wheel Speed Sensor, is mounted to the

caliper mounting adapter (Fig. 5). The rear Tone

Wheel is an integral part of the rear disc brake rotor

hub (Fig. 6). The speed sensor, to tone wheel air gap on all ap-

plications is NOT adjustable. All 4 of the vehicles, Wheel Speed Sensors are ser-

viced individually as replaceable components. The Front Wheel Drive front Tone Wheels are ser-

viced as an assembly with the front outboard con-

Fig. 3 Pump/Motor Assembly And Heat Shield

PRESSURE SWITCH AND PRESSURE TRANSDUCER WIRING

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 79

Page 230 of 2438

stant velocity joint housings. The rear Tone Wheels

are serviced as an assembly with the rear disc brake

rotor hub. Correct Anti-Lock System operation is dependent

on wheel speed signals from the wheel speed sensors.

The vehicles' wheels and tires must all be the same

size and type to generate accurate signals. In addi-

tion, the tires must be inflated to the recommended

pressures for optimum system operation. Variations

in wheel and tire size or significant variations in in-

flation pressure can produce inaccurate wheel speed

signals.

CONTROLLER ANTI-LOCK BRAKE (CAB)

The Anti-Lock Brake Controller is a small micro-

processor based device that monitors the brake sys- tem and controls the system while it functions in

Anti-Lock Mode. The CAB is located under the bat-

tery tray and is mounted to the left frame rail (Fig.

7) and uses a 60-way system connector. The power

source for the CAB is through the ignition switch to

pin 60 of the controller. With the ignition in the

RUN or ON position. IF THE (ABS) CONTROL-

LER NEEDS TO BE REPLACED BE SURE THE

CORRECT CONTROLLER IS USED. THE CON-

TROLLER ANTI-LOCK BRAKE (CAB) IS NOT

ON THE CCD BUS

Fig. 5 Rear Wheel Speed Sensor

Fig. 4 Front Wheel Speed Sensor

Fig. 6 Rear Tone Wheel

Fig. 7 Location Controller Anti-Lock Brake (CAB)

5 - 80 ANTI-LOCK 10 BRAKE SYSTEM Ä