fuel cap release CHEVROLET PLYMOUTH ACCLAIM 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 1878 of 2438

3.0L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Idle Air Control Motor .................... 138

Canister Purge Solenoid Service ............ 143

Fuel Injector Rail Assembly ................ 139

Fuel Injectors .......................... 142

Fuel Pressure Regulator Service ............ 141

Fuel System Pressure Release Procedure ..... 138 Heated Oxygen Sensor (O

2Sensor)

......... 144

Manifold Absolute Pressure (MAP) Sensor ..... 143

PCM ................................. 143

Throttle Body ........................... 138

Throttle Body Service .................... 138

Throttle Position Sensor .................. 138

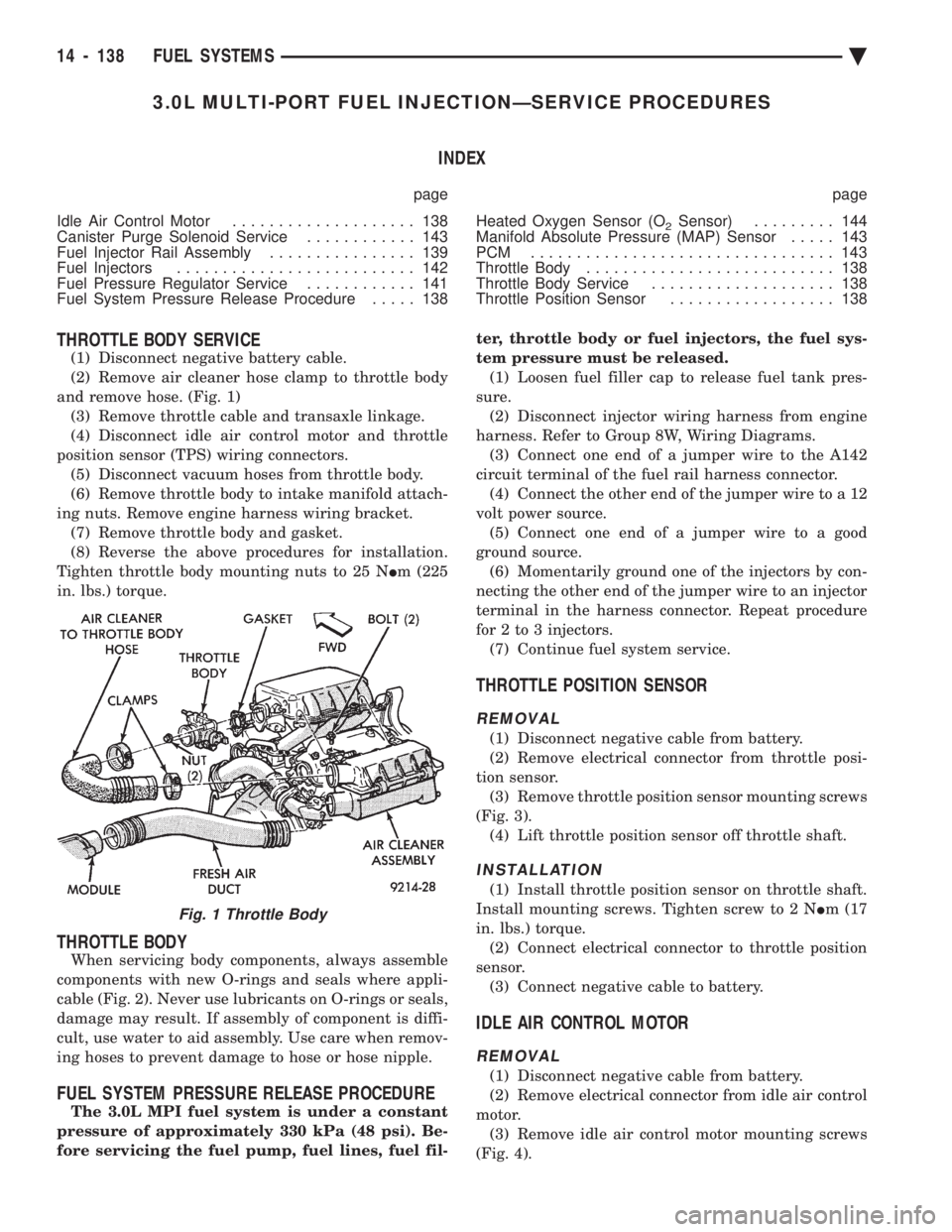

THROTTLE BODY SERVICE

(1) Disconnect negative battery cable.

(2) Remove air cleaner hose clamp to throttle body

and remove hose. (Fig. 1) (3) Remove throttle cable and transaxle linkage.

(4) Disconnect idle air control motor and throttle

position sensor (TPS) wiring connectors. (5) Disconnect vacuum hoses from throttle body.

(6) Remove throttle body to intake manifold attach-

ing nuts. Remove engine harness wiring bracket. (7) Remove throttle body and gasket.

(8) Reverse the above procedures for installation.

Tighten throttle body mounting nuts to 25 N Im (225

in. lbs.) torque.

THROTTLE BODY

When servicing body components, always assemble

components with new O-rings and seals where appli-

cable (Fig. 2). Never use lubricants on O-rings or seals,

damage may result. If assembly of component is diffi-

cult, use water to aid assembly. Use care when remov-

ing hoses to prevent damage to hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

The 3.0L MPI fuel system is under a constant

pressure of approximately 330 kPa (48 psi). Be-

fore servicing the fuel pump, fuel lines, fuel fil- ter, throttle body or fuel injectors, the fuel sys-

tem pressure must be released. (1) Loosen fuel filler cap to release fuel tank pres-

sure. (2) Disconnect injector wiring harness from engine

harness. Refer to Group 8W, Wiring Diagrams. (3) Connect one end of a jumper wire to the A142

circuit terminal of the fuel rail harness connector. (4) Connect the other end of the jumper wire to a 12

volt power source. (5) Connect one end of a jumper wire to a good

ground source. (6) Momentarily ground one of the injectors by con-

necting the other end of the jumper wire to an injector

terminal in the harness connector. Repeat procedure

for 2 to 3 injectors. (7) Continue fuel system service.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor. (3) Remove throttle position sensor mounting screws

(Fig. 3). (4) Lift throttle position sensor off throttle shaft.

INSTALLATION

(1) Install throttle position sensor on throttle shaft.

Install mounting screws. Tighten screw to 2 N Im (17

in. lbs.) torque. (2) Connect electrical connector to throttle position

sensor. (3) Connect negative cable to battery.

IDLE AIR CONTROL MOTOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air control

motor. (3) Remove idle air control motor mounting screws

(Fig. 4).

Fig. 1 Throttle Body

14 - 138 FUEL SYSTEMS Ä

Page 1909 of 2438

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Camshaft Position Sensor Service ........... 176

Crankshaft Position Sensor ................ 176

EVAP Canister Purge Solenoid Service ....... 175

Fuel Injector ........................... 174

Fuel Injector Rail Assembly ................ 170

Fuel Pressure Regulator .................. 173

Fuel System Pressure Release Procedure ..... 169 Heated Oxygen Sensor (O

2Sensor) Service . . . 177

Idle Air Control Motor .................... 170

Manifold Absolute Pressure (MAP) Sensor ..... 175

PCM Service ........................... 175

Throttle Body ........................... 169

Throttle Body Removal ................... 169

Throttle Position Sensor .................. 169

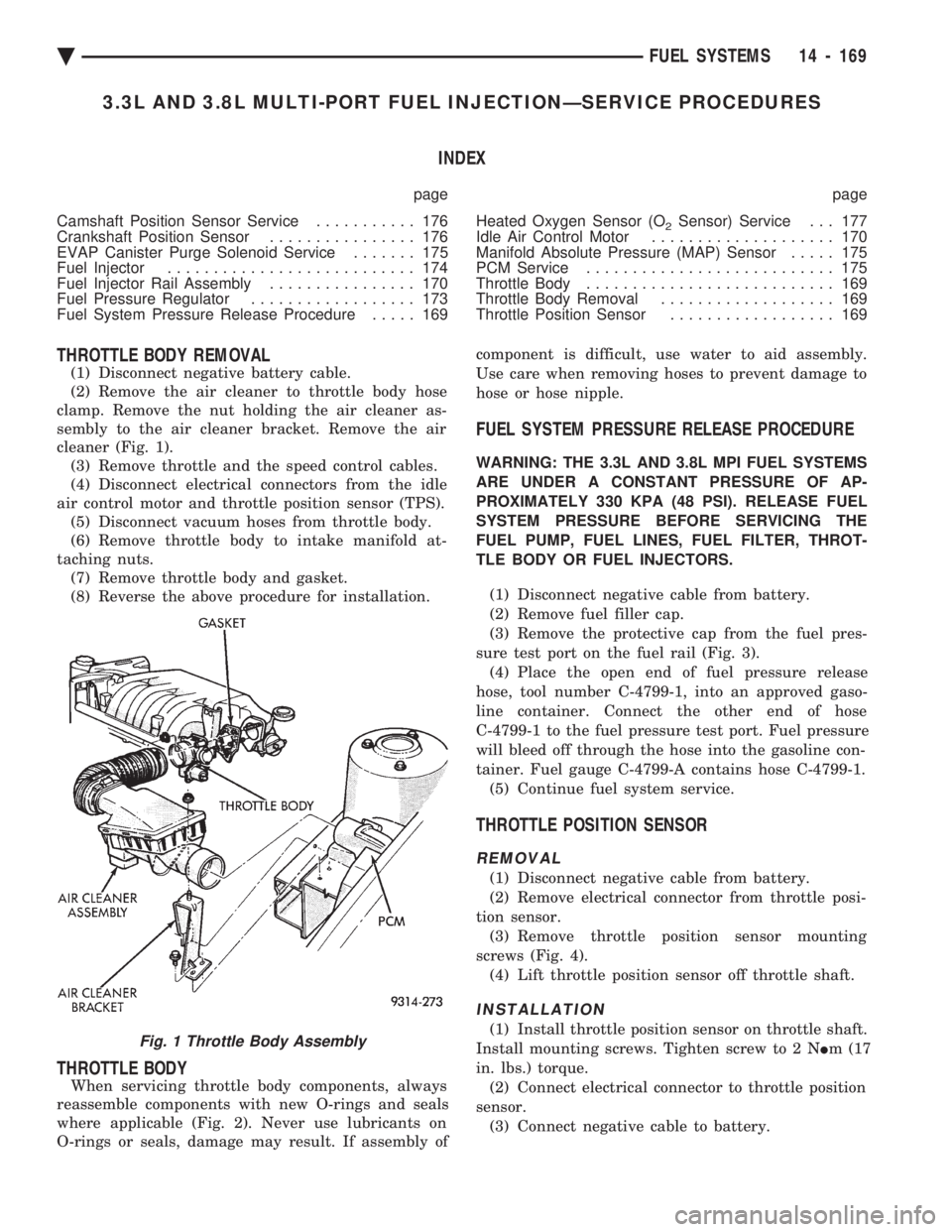

THROTTLE BODY REMOVAL

(1) Disconnect negative battery cable.

(2) Remove the air cleaner to throttle body hose

clamp. Remove the nut holding the air cleaner as-

sembly to the air cleaner bracket. Remove the air

cleaner (Fig. 1). (3) Remove throttle and the speed control cables.

(4) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS). (5) Disconnect vacuum hoses from throttle body.

(6) Remove throttle body to intake manifold at-

taching nuts. (7) Remove throttle body and gasket.

(8) Reverse the above procedure for installation.

THROTTLE BODY

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable (Fig. 2). Never use lubricants on

O-rings or seals, damage may result. If assembly of component is difficult, use water to aid assembly.

Use care when removing hoses to prevent damage to

hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE 3.3L AND 3.8L MPI FUEL SYSTEMS

ARE UNDER A CONSTANT PRESSURE OF AP-

PROXIMATELY 330 KPA (48 PSI). RELEASE FUEL

SYSTEM PRESSURE BEFORE SERVICING THE

FUEL PUMP, FUEL LINES, FUEL FILTER, THROT-

TLE BODY OR FUEL INJECTORS.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 3). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container. Connect the other end of hose

C-4799-1 to the fuel pressure test port. Fuel pressure

will bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1. (5) Continue fuel system service.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor. (3) Remove throttle position sensor mounting

screws (Fig. 4). (4) Lift throttle position sensor off throttle shaft.

INSTALLATION

(1) Install throttle position sensor on throttle shaft.

Install mounting screws. Tighten screw to 2 N Im (17

in. lbs.) torque. (2) Connect electrical connector to throttle position

sensor. (3) Connect negative cable to battery.Fig. 1 Throttle Body Assembly

Ä FUEL SYSTEMS 14 - 169