change wheel CHEVROLET PLYMOUTH ACCLAIM 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 2151 of 2438

ponents. Under extremes of suspension and steering

travel tire damage may occur.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED RATING CAN

CAUSE SUDDEN TIRE FAILURE.

ROTATION

DIRECTIONAL TREAD PATTERN TIRES

Some vehicles are fitted with special high-perfor-

mance tires having a directional tread pattern de-

signed to improve traction on wet pavement. To obtain the full benefits of this design, the tires

must be installed so that they rotate in the correct

direction. This is indicated by arrows on the tire

sidewalls. When wheels and tires are being installed, extra

care is needed to ensure that this direction of rota-

tion is maintained. Refer to Owner's Manual for rotation schedule.

NONDIRECTIONAL TIRES

Tires on the front and rear axles of vehicles oper-

ate at different loads and perform different steering,

driving, and braking functions. For these reasons,

they wear at unequal rates, and tend to develop ir-

regular wear patterns. These effects can be reduced

by timely rotation of tires. Rotation will increase

tread life, help to maintain mud, snow, and wet trac-

tion levels, and contribute to a smooth, quiet ride. The suggested rotation method is the forward-cross

tire rotation method. This method takes advantage of

current tire industry practice which now allows cross

rotation of radial-ply tires. Refer to the owner's man-

ual (usually found in the glove box) for additional in-

formation. Other rotation methods may be used, but

may not have all the benefits of the recommended

method. Always check air pressure and wheel nut tightness

after rotation. Do NOT use oil or grease on studs

or nuts. Refer to Owner's Manual for rotation schedule.

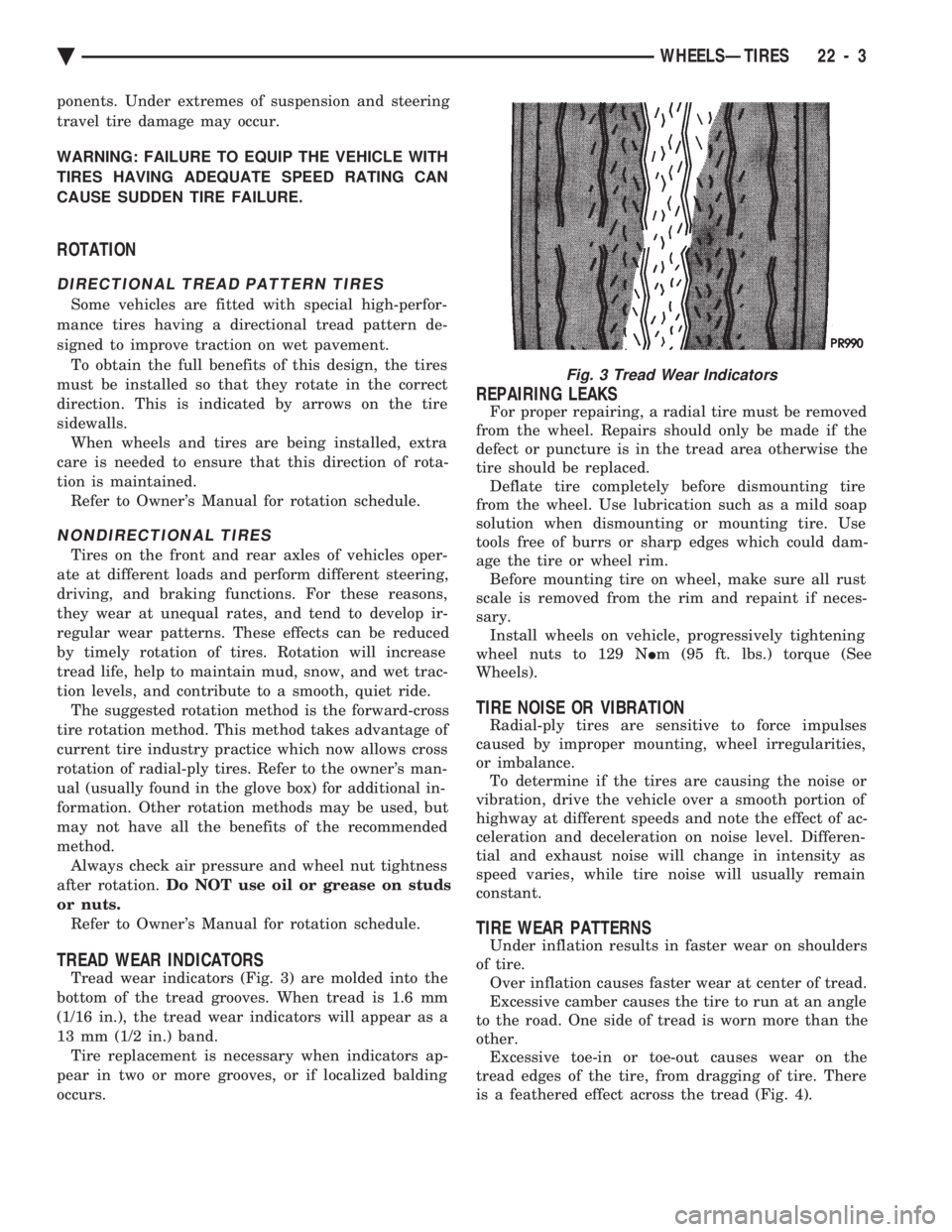

TREAD WEAR INDICATORS

Tread wear indicators (Fig. 3) are molded into the

bottom of the tread grooves. When tread is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band. Tire replacement is necessary when indicators ap-

pear in two or more grooves, or if localized balding

occurs.

REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect or puncture is in the tread area otherwise the

tire should be replaced. Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim. Before mounting tire on wheel, make sure all rust

scale is removed from the rim and repaint if neces-

sary. Install wheels on vehicle, progressively tightening

wheel nuts to 129 N Im (95 ft. lbs.) torque (See

Wheels).

TIRE NOISE OR VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, wheel irregularities,

or imbalance. To determine if the tires are causing the noise or

vibration, drive the vehicle over a smooth portion of

highway at different speeds and note the effect of ac-

celeration and deceleration on noise level. Differen-

tial and exhaust noise will change in intensity as

speed varies, while tire noise will usually remain

constant.

TIRE WEAR PATTERNS

Under inflation results in faster wear on shoulders

of tire. Over inflation causes faster wear at center of tread.

Excessive camber causes the tire to run at an angle

to the road. One side of tread is worn more than the

other. Excessive toe-in or toe-out causes wear on the

tread edges of the tire, from dragging of tire. There

is a feathered effect across the tread (Fig. 4).

Fig. 3 Tread Wear Indicators

Ä WHEELSÐTIRES 22 - 3

Page 2288 of 2438

(3) Loosen nuts holding roof rail weatherstrip re-

tainer to roof rail. Shift retainer inboard or outboard

to achieve proper alignment. (4) Tighten nuts to hold retainer to roof rail and

latch top header. (5) Verify weatherstrip sealing and door closing ef-

fort.

QUARTER GLASS AND ROLLER BRACKET

QUARTER GLASS

(1) Verify that door glass is properly aligned.

(2) Loosen nut holding top of quarter glass to rear

roof rail. (3) Shift quarter glass inboard or outboard, for-

ward or rearward to achieve proper alignment. (4) Tighten nut to hold top of quarter glass to rear

roof rail. (5) Verify door glass operation and weatherstrip

sealing.

ROLLER BRACKET

The roller bracket controls the in and out move-

ment at the bottom for the quarter glass. (1) Remove quarter trim panel as necessary to

gain access to the bottom of the quarter glass. (2) Lower convertible top.

(3) Loosen bolts holding roller bracket to quarter

panel reinforcement. (4) Align roller bracket to reduce quarter belt

weatherstrip contact when top is raised and proper

sash weatherstrip compression against the door

glass. (5) Tighten bolts to hold roller to quarter panel

and verify top operation and weatherstrip sealing.

TOP STACK DOWN-STOP

Adjust down-stop in or out to set top stack down

position height.

CAUTION: Avoid setting top stack position too low,

top cover can be pinched and cut between wheel-

house and fourth bow. Seal base of down-stop with silicone after adjust-

ing to prevent water leaks.

TOP STACK UP-STOP

Adjust up-stop in or out to change the contact with

the rear rail. This will effect the fore/aft position of

the No. 1 bow.

FOURTH ROOF BOW SLAT

Adjust the fourth roof bow slat to reduce wrinkles

and bagging around rear window and sail panels. (1) Verify convertible top is up and latched.

(2) Loosen bolts holding the slat to the fourth roof

bow. (3) Slide the bow up or down as necessary and

tighten bolts.

REAR TENSIONER PLATE

Adjust rear tensioner plate by loosening screws, po-

sitioning plate forward or backward, and tightening

screws. Tension can be adjusted on the back of the

top cover by varying contact.

23 - 132 AP/27 CONVERTIBLE Ä

Page 2409 of 2438

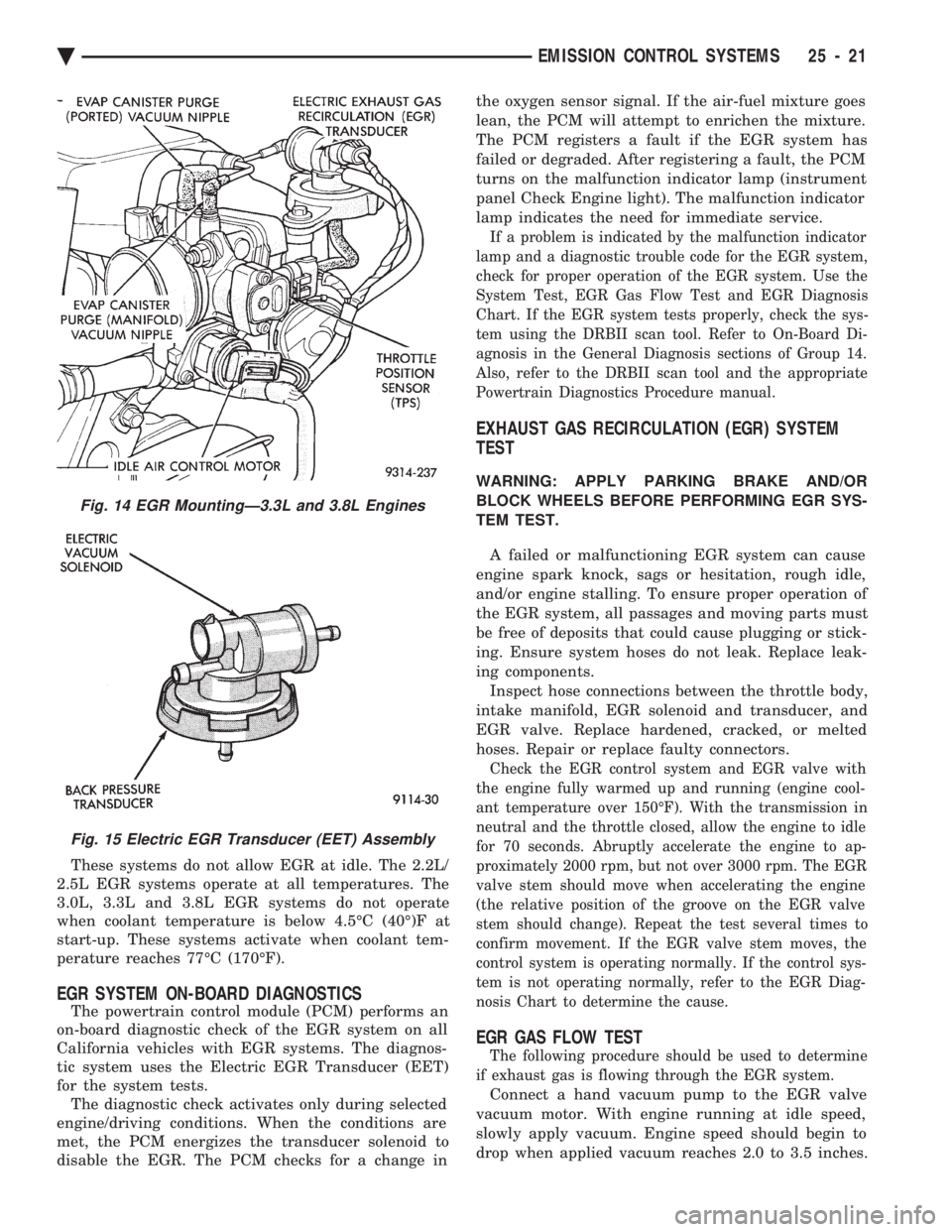

These systems do not allow EGR at idle. The 2.2L/

2.5L EGR systems operate at all temperatures. The

3.0L, 3.3L and 3.8L EGR systems do not operate

when coolant temperature is below 4.5ÉC (40É)F at

start-up. These systems activate when coolant tem-

perature reaches 77ÉC (170ÉF).

EGR SYSTEM ON-BOARD DIAGNOSTICS

The powertrain control module (PCM) performs an

on-board diagnostic check of the EGR system on all

California vehicles with EGR systems. The diagnos-

tic system uses the Electric EGR Transducer (EET)

for the system tests. The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes

lean, the PCM will attempt to enrichen the mixture.

The PCM registers a fault if the EGR system has

failed or degraded. After registering a fault, the PCM

turns on the malfunction indicator lamp (instrument

panel Check Engine light). The malfunction indicator

lamp indicates the need for immediate service.

If a problem is indicated by the malfunction indicator

lamp and a diagnostic trouble code for the EGR system,

check for proper operation of the EGR system. Use the

System Test, EGR Gas Flow Test and EGR Diagnosis

Chart. If the EGR system tests properly, check the sys-

tem using the DRBII scan tool. Refer to On-Board Di-

agnosis in the General Diagnosis sections of Group 14.

Also, refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedure manual.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING EGR SYS-

TEM TEST.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

and/or engine stalling. To ensure proper operation of

the EGR system, all passages and moving parts must

be free of deposits that could cause plugging or stick-

ing. Ensure system hoses do not leak. Replace leak-

ing components. Inspect hose connections between the throttle body,

intake manifold, EGR solenoid and transducer, and

EGR valve. Replace hardened, cracked, or melted

hoses. Repair or replace faulty connectors.

Check the EGR control system and EGR valve with

the engine fully warmed up and running (engine cool-

ant temperature over 150ÉF). With the transmission in

neutral and the throttle closed, allow the engine to idle

for 70 seconds. Abruptly accelerate the engine to ap-

proximately 2000 rpm, but not over 3000 rpm. The EGR

valve stem should move when accelerating the engine

(the relative position of the groove on the EGR valve

stem should change). Repeat the test several times to

confirm movement. If the EGR valve stem moves, the

control system is operating normally. If the control sys-

tem is not operating normally, refer to the EGR Diag-

nosis Chart to determine the cause.

EGR GAS FLOW TEST

The following procedure should be used to determine

if exhaust gas is flowing through the EGR system.

Connect a hand vacuum pump to the EGR valve

vacuum motor. With engine running at idle speed,

slowly apply vacuum. Engine speed should begin to

drop when applied vacuum reaches 2.0 to 3.5 inches.

Fig. 14 EGR MountingÐ3.3L and 3.8L Engines

Fig. 15 Electric EGR Transducer (EET) Assembly

Ä EMISSION CONTROL SYSTEMS 25 - 21

Page 2413 of 2438

CHRYSLER

CORPORATION

SERVICE MANUAL and SUPPLEMENTS

1993 FRONT WHEEL DRIVE PASSENGER VEHICLES

To order the special service tools used and

illustrated, please refer to the instructions on

inside back cover.

NO PART OF THIS PUBLICATION MAY BE

REPRODUCED, STORED IN A RETRIEVAL

SYSTEM, OR TRANSMITTED, IN ANY FORM

OR BY ANY MEANS, ELECTRONIC, ME-

CHANICAL, PHOTOCOPYING, RECORDING,

OR OTHERWISE, WITHOUT THE PRIOR

WRITTEN PERMISSION OF CHRYSLER

CORPORATION.

Chrysler Corporation reserves the right to make changes in design or to make

additions to or improvements in its products without imposing any obligations

upon itself to install them on its products previously manufactured.

Litho in U.S.A. Copyright 1992 Chrysler Corporation 30M0792

NEXT PAGE ©