CHEVROLET SUBURBAN 1994 Owners Manual

Manufacturer: CHEVROLET, Model Year: 1994, Model line: SUBURBAN, Model: CHEVROLET SUBURBAN 1994Pages: 385, PDF Size: 19.88 MB

Page 351 of 385

Explanation Of Scheduled Maintenance Services

Below are explanations of the services listed in the maintenance charts.

The proper fluids and lubricants to

use are listed in this section. Make sure

whoever services your vehicle uses these.

All parts should be replaced and

all necessary repairs done before you or anyone else drives the vehicle.

1. ENGINE OIL AND OIL FILTER CHANGE* -ALWAYS USE SH

ENERGY CONSERVIJTG TI (GASOLINE ENGINE) OR CF-4/SH

(DIESEL ENGINE) QUALITY OILS OF THE PROPER VISCOSITY.

To determine the preferred viscosity oil for your vehicle’s engine

(e.g.

SAE 5W-30 or low-30), see “Engine Oil” in the Index.

2. CHASSIS LUBRICATION - Lubricate the front suspension, king

pin bushings, steering linkage, transmission, and transfer case shift

linkage, parking brake cable guides, rear driveline center splines and

front axle propshaft splines, brake pedal springs, and clutch pedal

springs at the intervals specified.

Ball joints and king pin bushings should not be lubricated unless their

temperature is

10°F (-12”C), or higher. When the weather is cold, let

them warm up before lubrication or they could be damaged.

Also, be sure to check all the vehicle fluid levels at this time.

3. CLUTCH FORK BALL STUD LUBRICATION (5-SPEED

MANUAL TRANSMISSION

WITH DEEP LOW ) - Not

applicable to utility or wagon models.

4. COOLING SYSTEM SERVICE*? - Drain, flush and refill system

with new coolant. See “Engine Coolant’’

in the Index for the proper

coolant and mixture to use

in your vehicle.

Also inspect the hoses and replace them

if they are cracked, swollen, or

deteriorated. Tighten all

hose clamps (except constant tension clamps).

Remove debris and clean

the outside of the radiator and air

conditioning condenser. Wash the radiator

neck. To ensure proper

operation, pressure test the radiator and cap.

5. AIR CLEANER FILTER REPLACEMENT* - Replace at every

30,000 miles (50 000 km) or more often under dusty conditions. Ask

your dealer for the proper replacement intervals

for your driving

conditions.

6. FRONT WHEEL BEARING REPACK (2-WHEEL DRIVE

ONLY)

- Clean and repack the front wheel bearings at each brake

relining, or at the specified interval, whichever comes first.

4’ An Emission Control Service

*A fluid loss in these systems may indicate a problem. Have them

inspected and repaired at once.

7- 18

ProCarManuals.com

Page 352 of 385

7. TRANSMISSION SERVICE;-

Automatic Transmission

- Change the transmission fluid and filter

every 15,000 miles

(25 000 km) for vehicles under 8,600 GVWR or

every 12,000 miles

(20 000 km) for vehicles over 8,600 GVWR if the

vehicle

is mainly driven under one or more of these conditions:

In heavy city traffic.

0 Where the outside temperature regularly reaches 90°F (32°C) or

higher.

In hilly or mountainous terrain.

Frequent trailer pulling.

0 Uses such as taxi, police, delivery or other commercial service.

If the vehicle is not used mainly under any

of these conditions, change

the fluid and filter every

30,000 miles (50 000 km) for vehicles under

8,600 GVWR or every 24,000 miles (40 000 km) for vehicles over

8,600 GVWR see “Automatic Transmission Fluid” in the Index for

more information.

Manual Transmission - Transmission fluid does not require periodic

changing.

8. CDRV SYSTEM INSPECTION* - Check the Crankcase

Depression Regulator Valve System for

any worn, plugged or collapsed

hoses. Have the system checked as described in the Service Manual.

9. FUEL FILTER REPLACEMENT*$ - Replace the fuel filter at the

specified interval or sooner if clogged.

10. SPARK PLUG REPLACEMENT* - Replace spark plugs with the

type listed in Section

6. See “Specification Charts” in the Index.

1 1. SPARK PLUG WIRE INSPECTION - Clean wires and inspect for

burns, cracks or other damage. Check the wire boot fit at the distributor

and at the

spark plugs. Replace wires as needed.

‘% An Emission Control Service

$The California Air Resources Board has determined that the failure to

perform this maintenance item will

not nullify the emission warranty or

limit recall liability prior to the completion of the vehicle useful life.

General Motors, however, urges that all recommended maintenance

services be performed at the indicated intervals and the maintenance be

recorded.

?A fluid loss in

these systems may indicate a problem. Have them

inspected and repaired at once.

7-19 ProCarManuals.com

Page 353 of 385

12.

13.

14.

15.

16.

17.

18.

19.

20.

EGR SYSTEM INSPECTION* - Conduct EGR SYSTEM CHECK

as described in the Service Manual.

ELECTRONIC VACUUM REGULATOR VALVE (EVRV)

INSPECTION*

- Inspect filter for excessive contamination or

plugging. If required, clean element with a solution of biodegradable

soap and water, let dry and reinstall element.

ENGINE TIMING CHECK AND DISTRIBUTOR CHECK (SOME

MODELS)*$

- Adjust timing to underhood label specifications.

Inspect

the inside and outside of the distributor cap and rotor for cracks,

carbon tracking and corrosion. Clean

or replace as needed,

FUEL TANK, CAP AND LINES INSPECTION*$ - Inspect the

fuel tank, cap and lines for damage or leaks. Remove fuel cap, inspect

gasket for an even filler neck imprint, and any damage. Replace parts

as needed.

THERMOSTATICALLY CONTROLLED AIR CLEANER

INSPECTION*A

- (If so equipped.) Inspect all hoses and ducts for

proper hook-up.

Be sure the valve works properly.

SINGLE ENGINE ACCESSORY DRIVE (SERPENTINE) BELT

INSPECTION*

- Inspect belt. Look for cracks, fraying, wear, and

proper tension. Adjust or replace

as needed.

Check all

fuel and vapor lines and hoses for proper hookup, routing,

and condition. Check that the purge valve works properly,

if equipped.

Replace as needed.

SHIELDS AND UNDERHOOD INSULATION INSPECTIONAV

- Inspect shields and underhood insulation for damage or looseness.

Adjust or replace

as required.

AIR INTAKE SYSTEM INSPECTIONAV - Check the air intake

system installation to see that gaskets are sealed properly and all hose

connections, fasteners, and other components are tight. Also check to

be sure that

the air cleaner housing is properly seated, that the cover fits

tightly, and the wing nuts are tight. Tighten connections and fasteners

or replace damaged parts

as required.

'% An Emission Control Service

ANoise Emission Control Service

P'Applicable only to vehicles sold

in the United States

$The California Air Resources Board

has determined that the failure to

perform this maintenance item will not nullify

the emission warranty or

limit recall liability prior to the completion of the vehicle \

useful life.

General Motors, however, urges that

all recommended maintenance

services be performed at the indicated intervals and the maintenance be \

recorded.

EVAPORATIVE CONTROL SYSTEM (ECS) INSPECTION* -

7-20

ProCarManuals.com

Page 354 of 385

2 I. THERMOSTATICALLY CONTROLLED ENGINE COOLING FAN INSPECTIONAI/

- (If so equipped.) Inspect all hoses and

ducts for proper hook-up. Be sure the valve works properly.

22. EXHAUST PRESSURE REGULATOR VALVE INSPECTION” -

Check that the valve works properly, Correct any binding. Inspect

hoses for cracks, chafing or decay. Replace parts as needed.

23. TIRE AND WHEEL ROTATION AND INSPECTION - For proper

wear and maximum tire life, rotate tires at the first 6,000 miles

(10 000

kilometers) for Schedule

I (+) or 7,500 miles (12 500 kilometers) for

Schedule

I1 (0) and then every 15,000 miles (25 000 kilometers)

thereafter. Follow the instructions and patterns shown

in Section 6.

Check tires for uneven wear or damage. If irregular or premature wear is

apparent, check wheel alignment. Also, check or damaged wheels. See

“Tires”

in the Index for more information.

For dual wheels, whenever the vehicle, wheels, or fasteners are new,

have the wheel fastener torque

set at the first 100, 1,000 and 6,000 miles

( 160, 1600 and 10 000 km).

Block the tires opposite

those being removed to keep the vehicle from

rolling.

24.

DRIVE AXLE SERVICE? - Check readfront axle fluid level and

add

as needed. Check constant velocity joints and axle seals for

leaking.

0 Locking differential - Drain fluid at first oil change and refill.

Check fluid

level and add as needed at subsequent oil changes. In

dusty areas, or trailer towing applications drain fluid at every

15,000 miles (24 135 kilometers) and refill.

Standard differential - Check fluid level and add as needed at

every oil change. In dusty areas, or trailer towing applications,

drain fluid every

15,000 miles (24 135 kilometers) and refill.

0 More frequent lubrication may be required on heavy-duty or

off-road

use.

:i: An Emission Control Service

ANoise Emission Control Service

VApplicable

only to vehicles sold in the United States

+A fluid

loss in these systems may indicate a problem. Have them

inspected and repaired

at once.

7-21 ProCarManuals.com

Page 355 of 385

25. BRAKE SYSTEM INSPECTION? - When the engine oil is

changed, inspect the

lines and hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Check

the parking brake adjust, and the fluid level

in the master cylinder.

A low fluid level can indicate worn disc brake

pads which may need to be serviced.

When the wheels are removed for rotation, inspect disc brake pads for

wear and rotors for surface condition. Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including drums, wheel

cylinders, parking brake, etc., at

the same time. Remove any rust or dirt

from the wheel and mounting surfaces before mounting

the wheel.

Inspect brakes more often if driving habits or conditions resul\

t in

frequent braking.

Owner Checks and Services

Listed below are owner checks and services which should be made at the

time period specified to help ensure proper safety, emission performance,

and dependability of your vehicle.

Be

sure any necessary repairs are completed at once. Whenever any fluids

or lubricants

are added to your vehicle, make sure they are the proper ones,

as shown in this Section.

At Least Once a Month

Tire inflation pressure check - Check the tires for proper inflation. If

they are low, inflate them to the level specified on the Certificatiomire

label or on the tire inflation charts. See “Loading Your Vehicle” or

“Inflation-Tire Pressure”

in the Index.

At Least Once a Year

Key lock cylinder lubrication - Lubricate key lock cylinders with engine

oil. See the “Recommended Fluid and Lubricants” chart

in this section.

Transmission neutral or clutch start switch operation -

?A fluid loss in these systems may indicate a problem. Have them inspected

and repaired at once.

7-22

ProCarManuals.com

Page 356 of 385

I. Before you start, be sure you have enough room around the vehicle.

2. Firmly apply both the manual parking brake and the Ye‘@lar brake. See

“Brakes” and “Parking Brake” in the Index.

Do not use the accelerator

pedal.

3. Be ready to turn off the engine immediately if it starts.

4. On automatic transmission vehicles, try to start the engine in each gear.

The starter should work only in

“P’ (Park) or “N” (Neutral).

On manual transmission vehicles, put the shift lever

in “N” (Neutral), push

the clutch down halfway, and try to start the engine. The starter should work

only when the clutch is pushed down all the way to the floor.

Steering column lock operation - While parked, try to turn the key to

LOCK in each gear shift position.

With an automatic transmission, the key should turn to

LOCK only when

the gear shift is in

“P” (Park).

On vehicles with a key release lever, try to turn the key to LOCK without

pressing the lever. The key should turn to

LOCK only with the key lever

depressed.

On all vehicles, the key should come out only in

LOCK.

Parking brake and transmission

“P’ (PARK) mechanism operation -

Park on a fairly steep hill, with the vehicle facing downhill. Keeping your

foot

on the regular brake, set the manual parking brake.

To check the parking brake: With the engine running and the

transmission in

“N” (Neutral), slowly remove foot pressure from the

regular brake pedal.

Do this until the vehicle is held by the parking

brake

only.

To check the “P” (Park) mechanism’s holding ability: Apply the regular

brake and shift to

“P’ (Park). Release the manual parking brake, then

slowly release the regular brake.

7-23 ProCarManuals.com

Page 357 of 385

Lap and Shoulder Belts Condition and Operation - Inspect belt system,

including webbing, buckles, latch plates, retractors, guide loops\

and

anchors. Have

a belt assembly replaced if the webbing has been cut or

otherwise damaged.

Body Lubrication Service - Lubricate all body door hinges with engine

oil.

Also lubricate the tailgate, tailgate handle pivot points, and tailgate

mounted spare tire carrier (if equipped). Lubricate the body hood,

fuel door

and rear compartment hinges, latches and locks including interior glove box

and console doors, and any folding seat hardware. Lubricate the hood safety

lever pivot and prop rod pivot. More frequent lubrication may be required

when exposed to

a corrosive environment.

Periodic Maintenance Inspections - Listed below are inspections and

services which should be performed at least twice

a year (for instance each

spring or fall). You should let your

GM dealer’s service department or other

qualified service center do

these jobs. Make sure any necessary repairs are

completed at once.

Steering and Suspension Inspection? - Inspect front and rear suspension

and steering system for damaged, loose or missing parts, signs

of wear or

lack of lubrication. Inspect power steering lines and hoses for proper

hook-up, binding, leaks, cracks, chafing, etc. Lubricate the steering linkage.

Accelerator Control System - On gasoline engines, lubricate the pivot at

the

TBI throttle lever stud with engine oil. Do not oil any accelerator or

cruise control cables. Replace any cables that have high effort or excessive

wear.

Exhaust System Inspection - Inspect the complete system including the

three-way catalytic converter. Inspect the body near

the exhaust system.

Look for broken, damaged, missing or out-of-position parts,

as well as,

open seams, holes, loose connections or other conditions which could cause

a heat buildup

in the floor pan or could let exhaust fumes seep into the

passenger compartments.

Drive Axle Service? - Check readfront axle tluid level and add as needed,

Check constant velocity joints and axle seals for leaking.

Transfer Case (Four-wheel Drive) Inspection+ - Every 12 months or at

oil change intervals, check front axle and transfer case and add lubricant

when necessary. Oil the control lever pivot point and all exposed control

linkage. Check

vent hose at transfer case for kinks and proper installation.

More frequent lubrication may be required on heavy-duty or off-road use.

?A fluid loss in these systems may indicate a problem. Have them inspected

and repaired at once.

7-24

ProCarManuals.com

Page 358 of 385

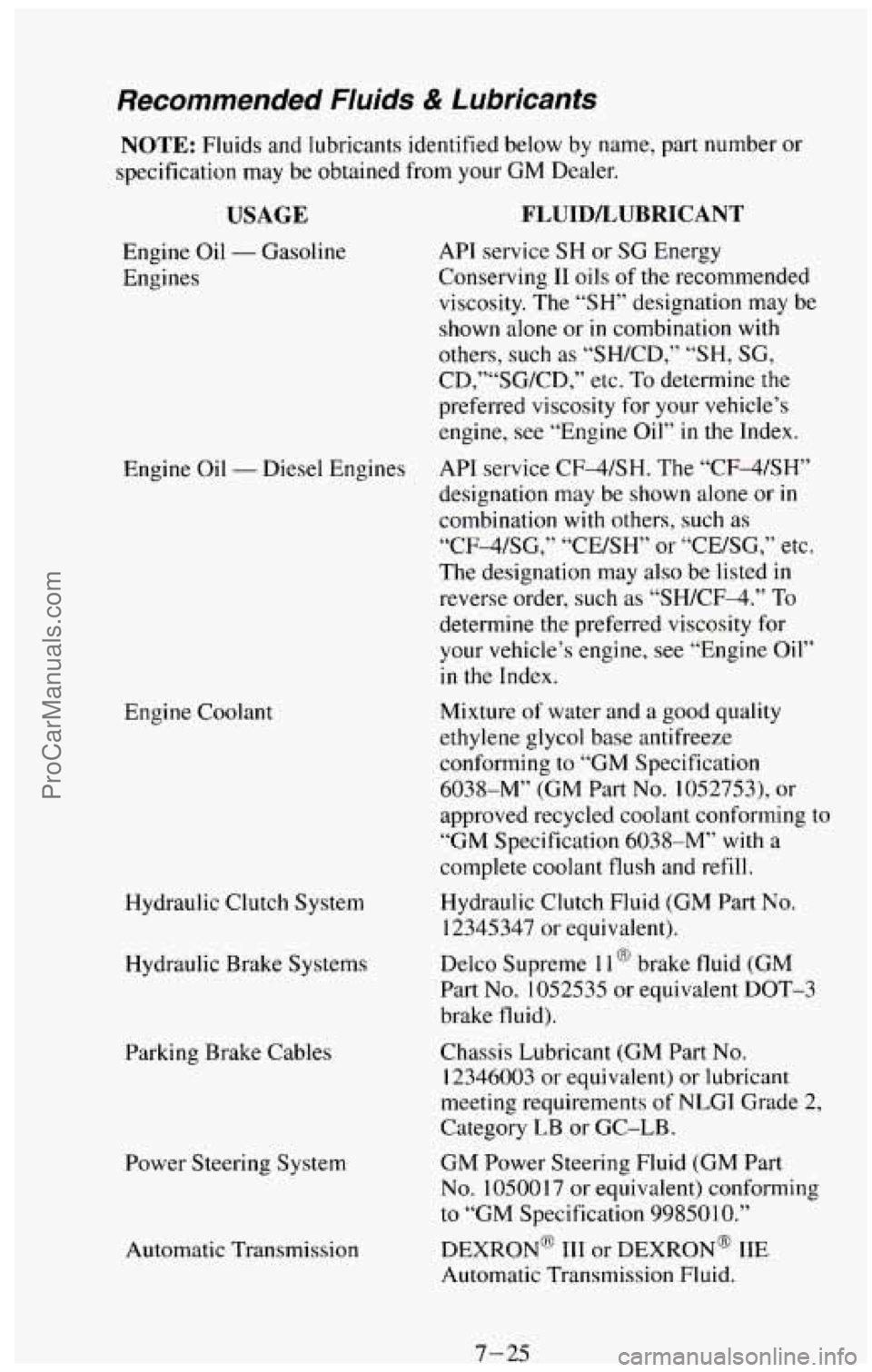

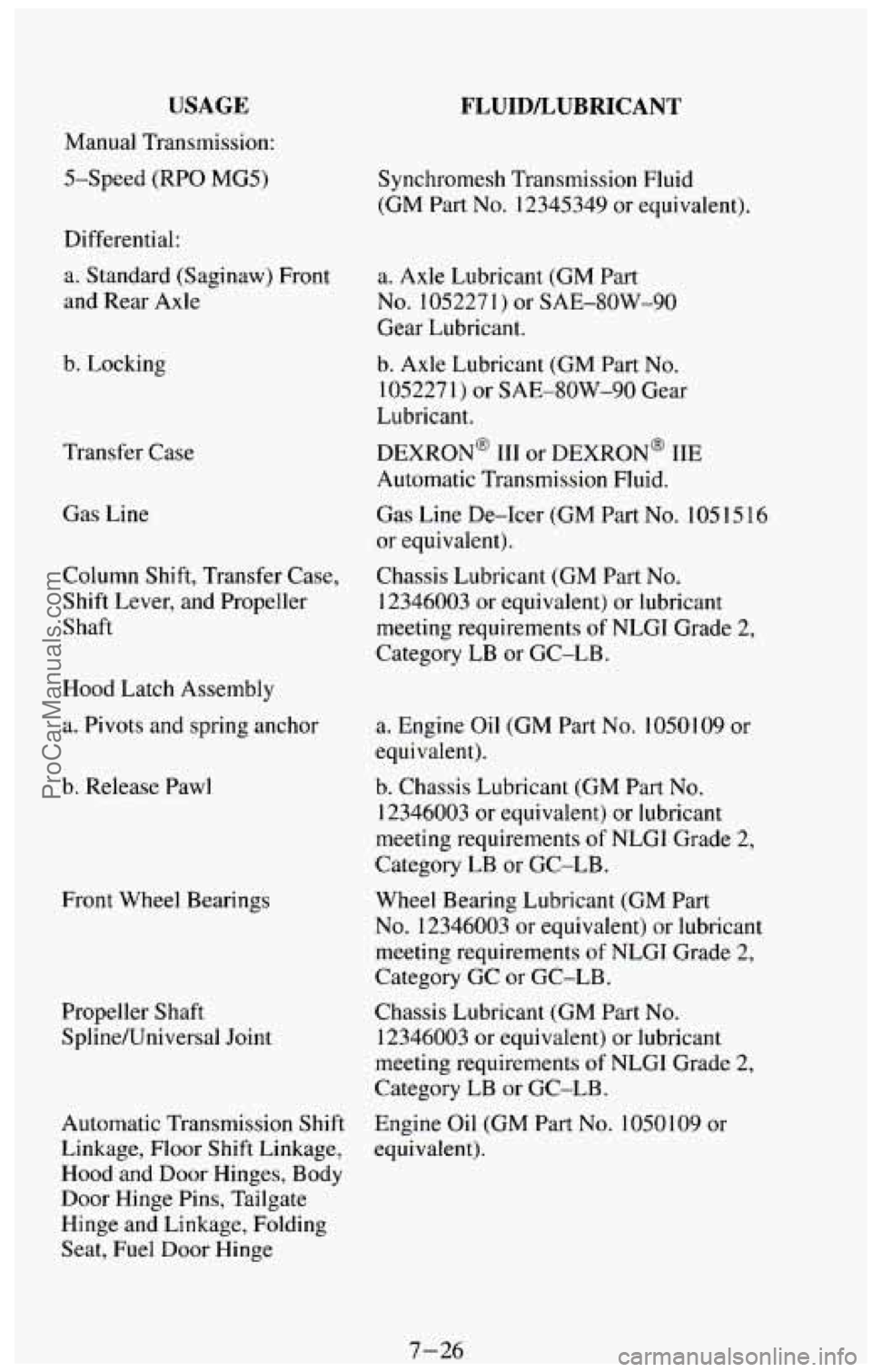

Recommended FIuids & Lubricants

NOTE: Fluids and lubricants identified below by name, part number or

specification may

be obtained from your GM Dealer.

USAGE

Engine Oil - Gasoline

Engines

Engine Oil

- Diesel Engines

Engine Coolant Hydraulic Clutch System

Hydraulic Brake Systems Parking Brake Cables

Power Steering System Automatic Transmission

FLUIDLUBRICANT

API service SH or SG Energy

Conserving

I1 oils of the recommended

viscosity. The

“SH” designation may be

shown alone or

in combination with

others, such as “SH/CD,”

“SH, SG,

CD,”“SG/CD,” etc. To determine the

preferred viscosity for your vehicle’s

engine, see “Engine Oil”

in the Index.

API service CF4SH. The “CF4SH”

designation may be shown alone or

in

combination with others, such as

“CF-4/SG,” “CE/SH” or “CE/SG,” etc.

The designation may also be listed

in

reverse order, such as “SH/CF-4.” To

determine the preferred viscosity for

your vehicle’s engine, see “Engine Oil”

in the Index.

Mixture

of water and a good quality

ethylene glycol base antifreeze

conforming to “GM Specification

6038-M” (GM Part

No. 1052753), or

approved recycled coolant conforming to

“GM Specification 6038-M” with a

complete coolant flush and refill.

Hydraulic Clutch Fluid

(GM Part No.

12345347 or equivalent).

Delco Supreme

11 @ brake fluid (GM

Part

No. 1052535 or equivalent DOT-3

brake fluid).

Chassis Lubricant (GM Part

No.

12346003 or equivalent) or lubricant

meeting requirements of

NLGI Grade 2,

Category LB or GC-LB.

GM

Power Steering Fluid (GM Part

No. 10500 17 or equivalent) conforming

to “GM Specification

99850 10.”

DEXRON~ TTI or DEXRON~ IIE

Automatic Transmission Fluid.

7-25 ProCarManuals.com

Page 359 of 385

USAGE

Manual Transmission:

5-Speed

(RPO MG5)

Differential:

a. Standard (Saginaw) Front

and Rear Axle

b. Locking

Transfer Case

Gas Line

FLUIDLLUBRICANT

Synchromesh Transmission Fluid

(GM Part

No. I2345349 or equivalent).

a. Axle Lubricant (GM Part

No. 105227

I ) or SAE-80W-90

Gear Lubricant.

b. Axle Lubricant (GM Part

No.

1052271) or SAE-SOW-90 Gear

Lubricant.

DEXRON~ 111 or DEXRON~ IIE

Automatic Transmission Fluid.

Gas Line De-Icer (GM Part

No. 105 15 16

or equivalent).

Column Shift, Transfer Case,

Chassis Lubricant (GM Part

No.

Shift Lever, and Propeller

12346003 or equivalent) or lubricant

Shaft meeting requirements

of NLGI Grade 2,

Category LB or GC-LB.

Hood Latch Assembly

a. Pivots and spring anchor

b. Release Pawl

Front Wheel Bearings

Propeller Shaft

Spline/Universal Joint a.

Engine Oil (GM Part

No. 1050109 or

equivalent).

b. Chassis Lubricant (GM Part

No.

12346003 or equivalent) or lubricant

meeting requirements of NLGI Grade 2,

Category LB or GC-LB.

Wheel Bearing Lubricant (GM Part

No. 12346003 or equivalent) or lubricant

meeting requirements

of NLGI Grade 2,

Category GC

or GC-LB.

Chassis Lubricant (GM Part

No.

12346003 or equivalent) or lubricant

meeting requirements

of NLGI Grade 2,

Category LB or GC-LB.

Automatic Transmission Shift Engine

Oil (GM Part No. 1050109 or

Linkage, Floor Shift Linkage, equivalent).

Hood and

Door Hinges, Body

Door Hinge Pins, Tailgate

Hinge and Linkage, Folding

Seat, Fuel Door Hinge

7-26 ProCarManuals.com

Page 360 of 385

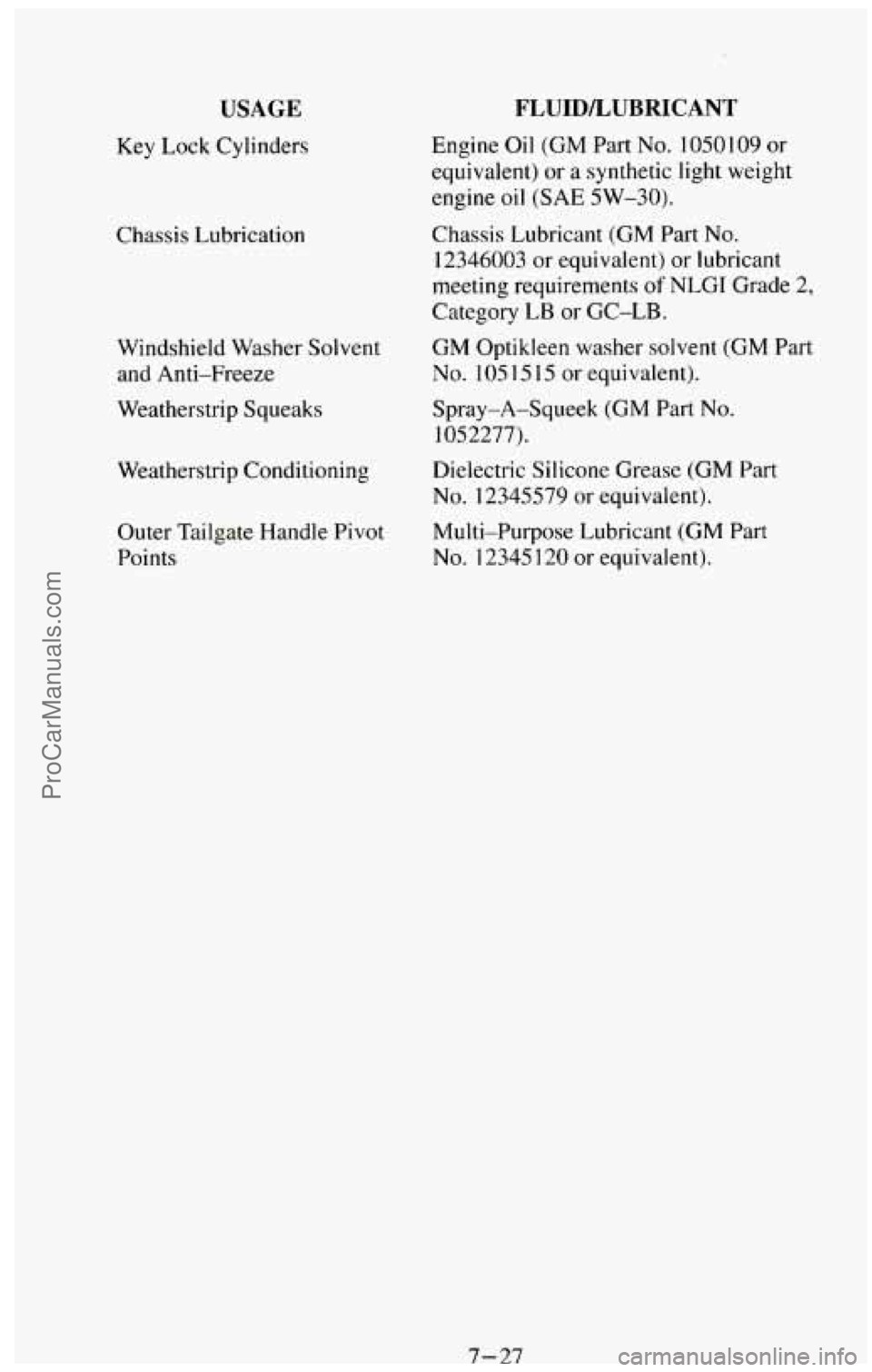

USAGE

Key Lock Cylinders

Chassis Lubrication

Windshield Washer Solvent

and Anti-Freeze

Weatherstrip Squeaks

Weatherstrip Conditioning

Outer Tailgate Handle Pivot

Points

FLUIDLUBRICANT

Engine Oil (GM Part No. 1050109 or

equivalent) or

a synthetic light weight

engine oil

(SAE 5W-30).

Chassis Lubricant

(GM Part No.

I2346003 or equivalent) or lubricant

meeting requirements

of NLGI Grade 2,

Category LB or GC-LB.

GM Optikleen washer solvent

(GM Part

No. 105 I5 15 or equivalent).

Spray-A-Squeek

(GM Part No.

1052277).

Dielectric Silicone Grease (GM Part

No. 12345579 or equivalent).

Multi-Purpose Lubricant

(GM Part

No. 12345 120 or equivalent).

7-27 ProCarManuals.com