lock CHRYSLER 200 2017 2.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2017, Model line: 200, Model: CHRYSLER 200 2017 2.GPages: 539, PDF Size: 5.18 MB

Page 368 of 539

WARNING!(Continued)

that could jeopardize the user ’s safety or the safety of

others.

ABS is designed to function with the OEM tires. Modifica-

tion may result in degraded ABS performance.

Anti-Lock Brake Warning Light

The yellow “Anti-Lock Brake Warning Light” will turn on

when the ignition switch is turned to the ON position and

may stay on for as long as four seconds.

If the “Anti-Lock Brake Warning Light” remains on or

comes on while driving, it indicates that the anti-lock

portion of the brake system is not functioning and that

service is required. However, the conventional brake sys-

tem will continue to operate normally if the “Brake System

Warning Light” is not on.

If the “Anti-Lock Brake Warning Light” is on, the brake

system should be serviced as soon as possible to restore the

benefits of anti-lock brakes. If the “Anti-Lock Brake Warn-

ing Light” does not come on when the ignition switch is

turned to the ON position, have the light repaired as soon

as possible.

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s braking

capability during emergency braking maneuvers. The sys-

tem detects an emergency braking situation by sensing the

rate and amount of brake application and then applies

optimum pressure to the brakes. This can help reduce

braking distances. The BAS complements the anti-lock

brake system (ABS). Applying the brakes very quickly

results in the best BAS assistance. To receive the benefit of

the system, you must apply continuous braking pressure

during the stopping sequence, (do not “pump” the brakes).

Do not reduce brake pedal pressure unless braking is no

longer desired. Once the brake pedal is released, the BAS is

deactivated.

WARNING!

The Brake Assist System (BAS) cannot prevent the

natural laws of physics from acting on the vehicle, nor

can it increase the traction afforded by prevailing road

conditions. BAS cannot prevent collisions, including

those resulting from excessive speed in turns, driving

on very slippery surfaces, or hydroplaning. The capa-

bilities of a BAS-equipped vehicle must never be

(Continued)

366 STARTING AND OPERATING

Page 407 of 539

Starting

The characteristics of E-85 fuel make it unsuitable for use

when ambient temperatures fall below 0°F (-18°C). In the

range of 0°F (-18°C) to 32°F (0°C), an increase in the time it

takes for your engine to start may be experienced, and a

deterioration in driveability (sags and/or hesitations) until

the engine is fully warmed up. These issues may be

improved with the use of seasonally adjusted E-85 fuel.

NOTE:Use of the engine block heater (if equipped) may

improve engine start time when using E-85 fuel when the

ambient temperature is less than 32°F (0°C).

Cruising Range

Because E-85 fuel contains less energy per gallon/liter than

gasoline, an increase in fuel consumption will be experi-

enced. The miles per gallon (mpg)/kilometers per liter and

the driving range will decrease by approximately 30%,

compared to gasoline operation.

Replacement Parts

All fuel and engine components in your Flexible Fuel

Vehicle (FFV) are designed to be compatible with ethanol.

Ethanol compatible service components are required.

CAUTION!

Replacing fuel system components with non-ethanol

compatible components can damage your vehicle.

Maintenance

CAUTION!

Do not use ethanol mixtures greater than 85% in your

vehicle. It will make it more difficult for your engine to

start under cold conditions, may affect drivability, and

could cause engine damage.

5

STARTING AND OPERATING 405

Page 408 of 539

ADDING FUEL

The fuel filler cap is located behind the fuel filler door, on

the passenger side of the vehicle. If the fuel filler cap is lost

or damaged, be sure the replacement fuel filler cap has

been designed for use with this vehicle.

1. Place the vehicle in PARK (P) position and switch theignition LOCK/OFF.

2. Push the center-rear edge of the fuel filler door and release to open. 3. Remove the fuel filler cap (gas cap) and hang by tether

hook on fuel filler door.

Push To Open

Fuel Filler Door

1— Tether Hook

406 STARTING AND OPERATING

Page 426 of 539

NOTE:If the tire becomes over-inflated, push the Defla-

tion Button to reduce the tire pressure to the recommended

inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and unplug from 12

Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized dealer as soon as possible.

Refer to (F) “Sealant Bottle and Hose Replacement.”

NOTE: When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose of it

accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns with the hose slot in the front

of the housing. Push the bottle into the housing. An

audible click will be heard indicating the bottle is locked

into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (6) and return the hose to its storage

area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

424 WHAT TO DO IN EMERGENCIES

Page 428 of 539

3. Remove the fastener securing the jack and spare tire.

4. Remove the scissors jack, wheel bolt wrench and wheelchocks from the spare wheel as an assembly. Remove the

chocks from the jack assembly. Turn the jack screw to the

left to loosen the wheel bolt wrench, and remove the

wrench from the jack assembly.

5. Remove the spare tire.WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Preparations For Jacking

1. Park the vehicle on a firm level surface as far from the edge of the roadway as possible. Avoid icy or slippery

areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shifter into the park position.

5. Turn the ignition off to the LOCK position.

Jack And Spare Tire Fastener

426 WHAT TO DO IN EMERGENCIES

Page 431 of 539

2. Chock both the front and rear of the wheel diagonallyopposite of the jacking position. For example, if chang-

ing the right front tire, chock the left rear wheel. Place

both chocks under the tire.

3. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the wheel bolt wrench to pry

the center cap off carefully before raising the vehicle. 4. Before raising the vehicle, use the wheel bolt wrench to

loosen, but not remove, the wheel bolts on the wheel

with the flat tire. Turn the wheel bolts counterclockwise

one turn while the wheel is still on the ground.

5. Place the jack underneath the notched lift area that is closest to the flat tire.

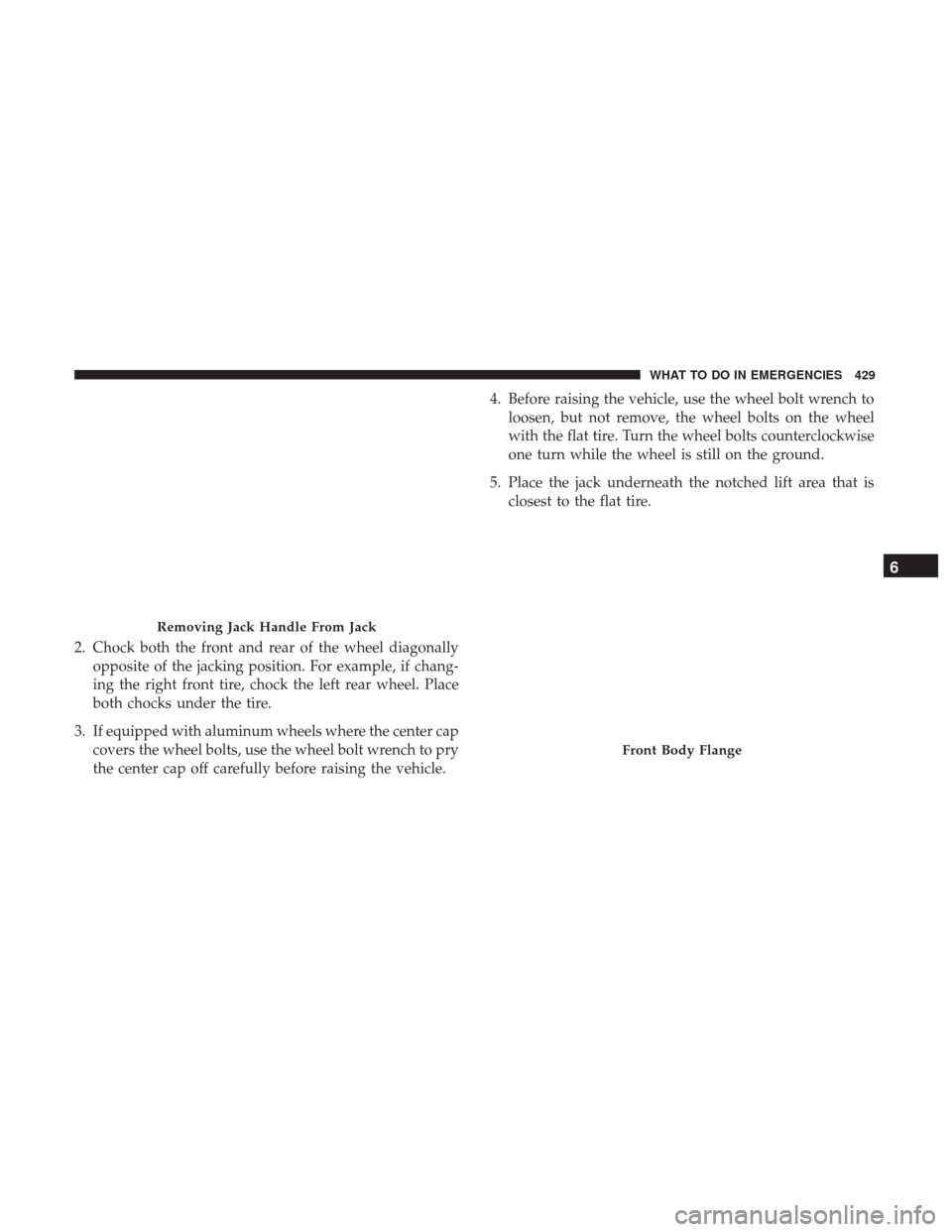

Removing Jack Handle From Jack

Front Body Flange

6

WHAT TO DO IN EMERGENCIES 429

Page 433 of 539

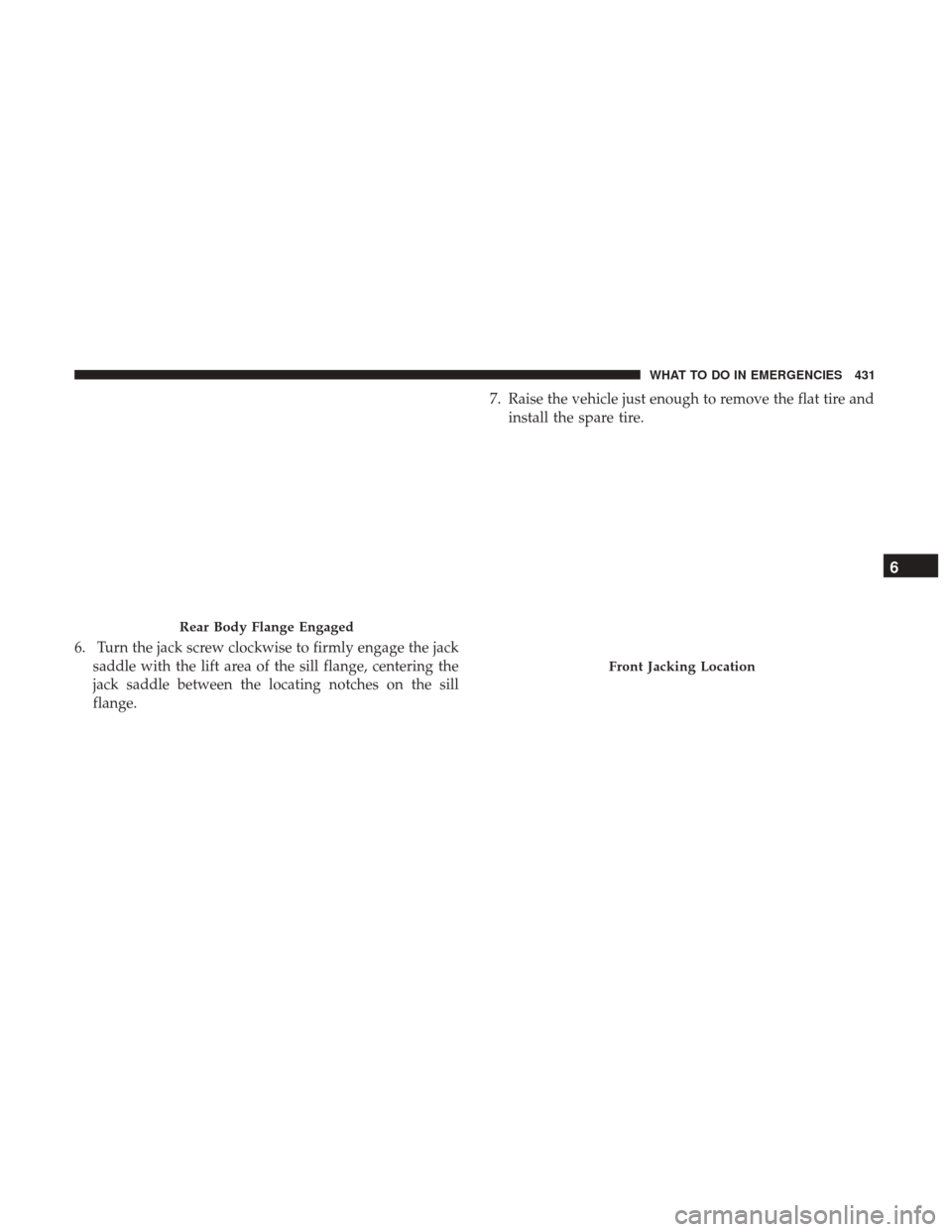

6. Turn the jack screw clockwise to firmly engage the jacksaddle with the lift area of the sill flange, centering the

jack saddle between the locating notches on the sill

flange. 7. Raise the vehicle just enough to remove the flat tire and

install the spare tire.

Rear Body Flange Engaged

Front Jacking Location

6

WHAT TO DO IN EMERGENCIES 431

Page 435 of 539

NOTE:•For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires—General Information” in “Start-

ing And Operating” for additional warnings, cautions,

and information about the spare tire, its use, and

operation.

10. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the wheel

bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the wheel bolts until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

11. Lower the vehicle to the ground by turning the jack handle counterclockwise.

12. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for proper lug

bolt torque. If in doubt about the correct tightness, have

them checked with a torque wrench by your autho-

rized dealer or at a service station.

13. Lower the jack until it is free. Remove the wheel chocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Securely stow the

jack, tools, chocks and flat tire. Release the parking

brake before driving the vehicle.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels withwheel covers, install two wheel bolts on the wheel

6

WHAT TO DO IN EMERGENCIES 433

Page 436 of 539

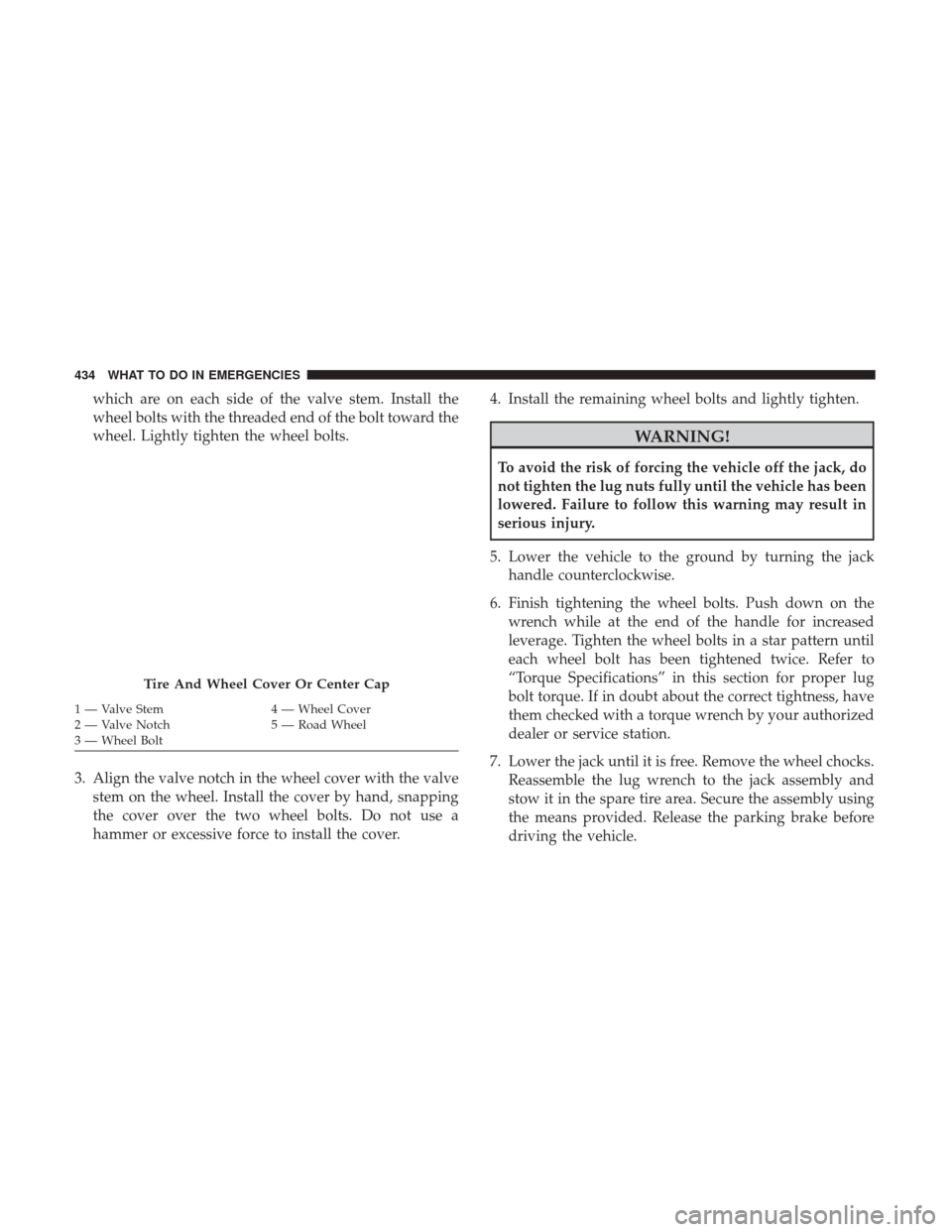

which are on each side of the valve stem. Install the

wheel bolts with the threaded end of the bolt toward the

wheel. Lightly tighten the wheel bolts.

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand, snapping

the cover over the two wheel bolts. Do not use a

hammer or excessive force to install the cover. 4. Install the remaining wheel bolts and lightly tighten.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for proper lug

bolt torque. If in doubt about the correct tightness, have

them checked with a torque wrench by your authorized

dealer or service station.

7. Lower the jack until it is free. Remove the wheel chocks. Reassemble the lug wrench to the jack assembly and

stow it in the spare tire area. Secure the assembly using

the means provided. Release the parking brake before

driving the vehicle.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Bolt 434 WHAT TO DO IN EMERGENCIES

Page 437 of 539

8. After 25 miles (40 km) check the wheel bolt torque witha torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts and lightly tighten.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for the proper lug

bolt torque. If in doubt about the correct tightness, have

them checked with a torque wrench by your authorized

dealer or service station. 5. Lower the jack until it is free. Remove the wheel chocks.

Reassemble the lug wrench to the jack assembly and

stow it in the spare tire area. Secure the assembly using

the means provided. Release the parking brake before

driving the vehicle.

6. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery it can be jump-

started using a set of jumper cables and a battery in another

vehicle or by using a portable battery booster pack. Jump-

starting can be dangerous if done improperly so please

follow the procedures in this section carefully.

NOTE: When using a portable battery booster pack follow

the manufacturer ’s operating instructions and precautions.

WARNING!

Do not attempt jump-starting if the battery is frozen. It

could rupture or explode and cause personal injury.

6

WHAT TO DO IN EMERGENCIES 435