wheel CHRYSLER ASPEN 2009 2.G Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2009, Model line: ASPEN, Model: CHRYSLER ASPEN 2009 2.GPages: 481, PDF Size: 9.28 MB

Page 349 of 481

This label contains the month and year of manufacture,

Gross Vehicle Weight Rating (GVWR), Gross Axle Weight

Rating (GAWR) front and rear, and Vehicle Identification

Number (VIN). A Month-Day-Hour (MDH) number is

included on this label and shows the month, day, and

hour of manufacture. The bar code that appears on the

bottom of the label is your Vehicle Identification Number

(VIN).

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your vehicle

including driver, passengers, vehicle, options, and cargo.

The label also specifies maximum capacities of front and

rear axle systems. Total load must be limited so that

GVWR is not exceeded.

Payload

The payload of a vehicle is defined as the allowable load

weight a vehicle can carry including the weight of the

driver, all passengers, options, and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the front

and rear axles. The load must be distributed in the cargo

area so that the GAWR of each axle is not exceeded.

Each axle GAWR is determined by the component in the

system with the lowest load carrying capacity (axle,

springs, tires, or wheels).

Heavier axles or suspension components sometimes

specified by purchasers for increased durability do not

necessarily increase the vehicle's GVWR.

Tire Size

This is the minimum allowable tire size for your vehicle.

Replacement tires must be equal to the load capacity of

this tire size.

Rim Size

This is the rim size that is appropriate for the tire size

listed.

STARTING AND OPERATING 347

5

Page 356 of 481

Trailer Hitch Classification

Class Max. GTW

(Gross Trailer Wt.)

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium

Duty3,500 lbs (1587 kg)

Class III - Heavy Duty 5,000 lbs (2268 kg)

Class IV - Extra

Heavy Duty10,000 lbs (4540 kg)

Fifth Wheel/

GooseneckGreater than 10,000 lbs

(4540 kg)

All trailer hitches should be professionally installed on

your vehicle.Trailer Towing Weights (Maximum Trailer Weight

Ratings)

NOTE:For additional trailer towing information (maxi-

mum trailer weight ratings) refer to the following website

addresses:

²http:// www.dodge.com/towing

²http:// www.dodge.ca(Canada)

Trailer and Tongue Weight

Always load a trailer with 60% to 65% of the weight in

the front of the trailer. This places 10% to 15% of the

Gross Trailer Weight (GTW) on the tow hitch of your

vehicle. Loads balanced over the wheels or heavier in the

rear can cause the trailer to swayseverelyside to side

which will cause loss of control of vehicle and trailer.

Failure to load trailers heavier in front is the cause of

many trailer accidents.

354 STARTING AND OPERATING

Page 358 of 481

Perform the maintenance listed in the Maintenance

Schedule. Refer to Section 8 of this manual. When towing

a trailer, never exceed the GAWR or GCWR ratings.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

²Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

²Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle automatic transmission in

PARK. For four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always, block or

9chock9the trailer wheels.

356 STARTING AND OPERATING

Page 365 of 481

WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

NEUTRAL position without first fully engaging the

parking brake. The transfer case NEUTRAL position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

even if the transmission is in PARK. The parking

brake should always be applied when the driver is

not in the vehicle.

CAUTION!

Internal damage to the transfer case will occur if a

front or rear wheel lift is used when recreational

towing.NOTE:The NV 244 Generation II transfer case must be

shifted into NEUTRAL for recreational towing. The NEU-

TRAL selection button is located on the lower left-hand

corner of the 4WD Control Switch. Shifts into and out of

transfer case NEUTRAL can take place with the selector

switch in any mode position.

Shifting into NEUTRAL

Use the following procedure to prepare your vehicle for

recreational towing.

CAUTION!

It is necessary to follow these steps to be certain that

the transfer case is fully in NEUTRAL before recre-

ational towing to prevent damage to internal parts.

1. Bring vehicle to a complete stop.

2. Shut engine OFF.

STARTING AND OPERATING 363

5

Page 369 of 481

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Flasher................. 368

mJacking Instructions.................... 369

NJack Location....................... 369

NRemoving The Spare Tire............... 370

NTire Changing Procedure............... 371

mJump±Starting Procedures................ 377mFreeing A Stuck Vehicle................. 379

mEmergency Tow Hooks Ð If Equipped....... 380

mTowing A Disabled Vehicle............... 381

NFour-Wheel Drive Vehicles.............. 381

NTwo-Wheel Drive Vehicles.............. 381

6

Page 370 of 481

HAZARD WARNING FLASHER

The hazard warning flasher switch is located on the top

of the steering column, just behind the steering wheel.To operate the hazard warning flashers press the switch

and all front and rear directional signals will flash

intermittently. Press the switch a second time to turn off

the hazard warning flashers.

This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

If it is necessary to leave the vehicle to go for service, the

hazard warning flasher system will continue to operate

with the ignition key removed and the vehicle locked.

NOTE:With extended use, the hazard warning flasher

may wear down your battery.

Hazard Warning Flasher Switch

368 WHAT TO DO IN EMERGENCIES

Page 373 of 481

3. Turn the wrench counterclockwise to lower the spare

tire. Continue to turn the wrench until the spare tire can

be pulled out from under the vehicle.

It is recommended that you stow the flat tire or spare to

avoid tangling the loose cable.

CAUTION!

The winch mechanism is designed for use with the

jack extension tube only. Use of an air wrench or

other power tools is not recommended and can dam-

age the winch.

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to a service center

where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The scissor

jack is designed as a tool for changing tires on this vehicle

only. It is not recommended that the jack be used for

service purposes or to lift more than one wheel at a time.

WHAT TO DO IN EMERGENCIES 371

6

Page 374 of 481

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the shift

lever in PARK (automatic transmission). On 4-wheel

drive vehicles, shift the transfer case to the ª4Lº position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the hazard warning flasher.

²Block both the front and rear of the

wheel diagonally opposite the jack-

ing position. For example, if the

right front wheel is being changed,

block the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

Jack Warning Label

372 WHAT TO DO IN EMERGENCIES

Page 375 of 481

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

²Always park on a firm, level surface as far from

the edge of the roadway as possible before raising

the vehicle.

²Block the wheel diagonally opposite the wheel to

be raised.

²Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

²Never start or run the engine with the vehicle on a

jack.

²Do not let anyone sit in the vehicle when it is on a

jack.

²Do not get under the vehicle when it is on a jack.

(Continued)

WARNING! (Continued)

²Only use the jack in the positions indicated and

for lifting this vehicle during a tire change.

²If working on or near a roadway, be extremely

careful of motor traffic.

²To assure that spare tires, flat or inflated are

securely stowed, spares must be stowed with the

valve stem facing the ground.

²Turn on the Hazard warning flasher.

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

WHAT TO DO IN EMERGENCIES 373

6

Page 376 of 481

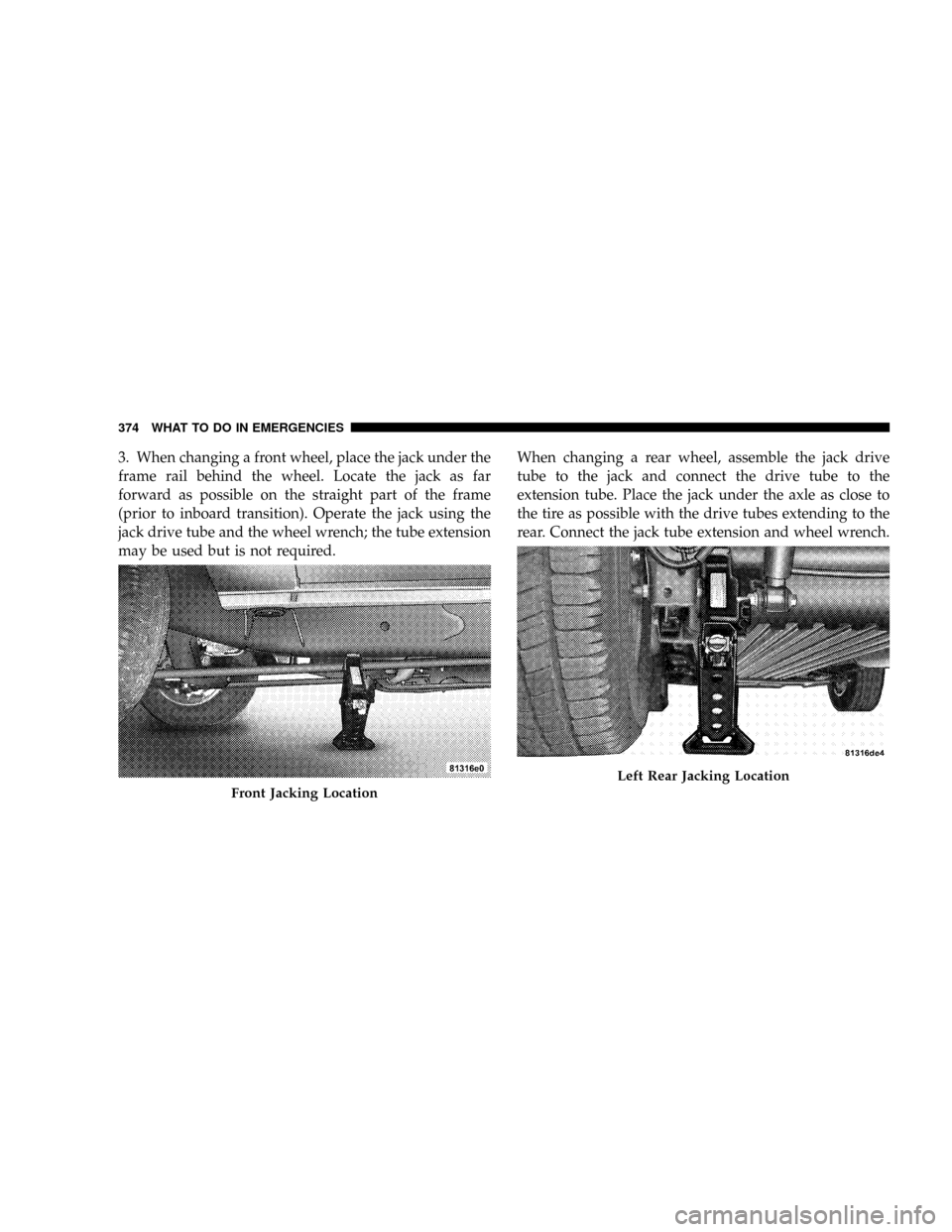

3. When changing a front wheel, place the jack under the

frame rail behind the wheel. Locate the jack as far

forward as possible on the straight part of the frame

(prior to inboard transition). Operate the jack using the

jack drive tube and the wheel wrench; the tube extension

may be used but is not required.When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle as close to

the tire as possible with the drive tubes extending to the

rear. Connect the jack tube extension and wheel wrench.

Front Jacking Location

Left Rear Jacking Location

374 WHAT TO DO IN EMERGENCIES