brake CHRYSLER CARAVAN 2000 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2000Pages: 436, PDF Size: 3.4 MB

Page 97 of 436

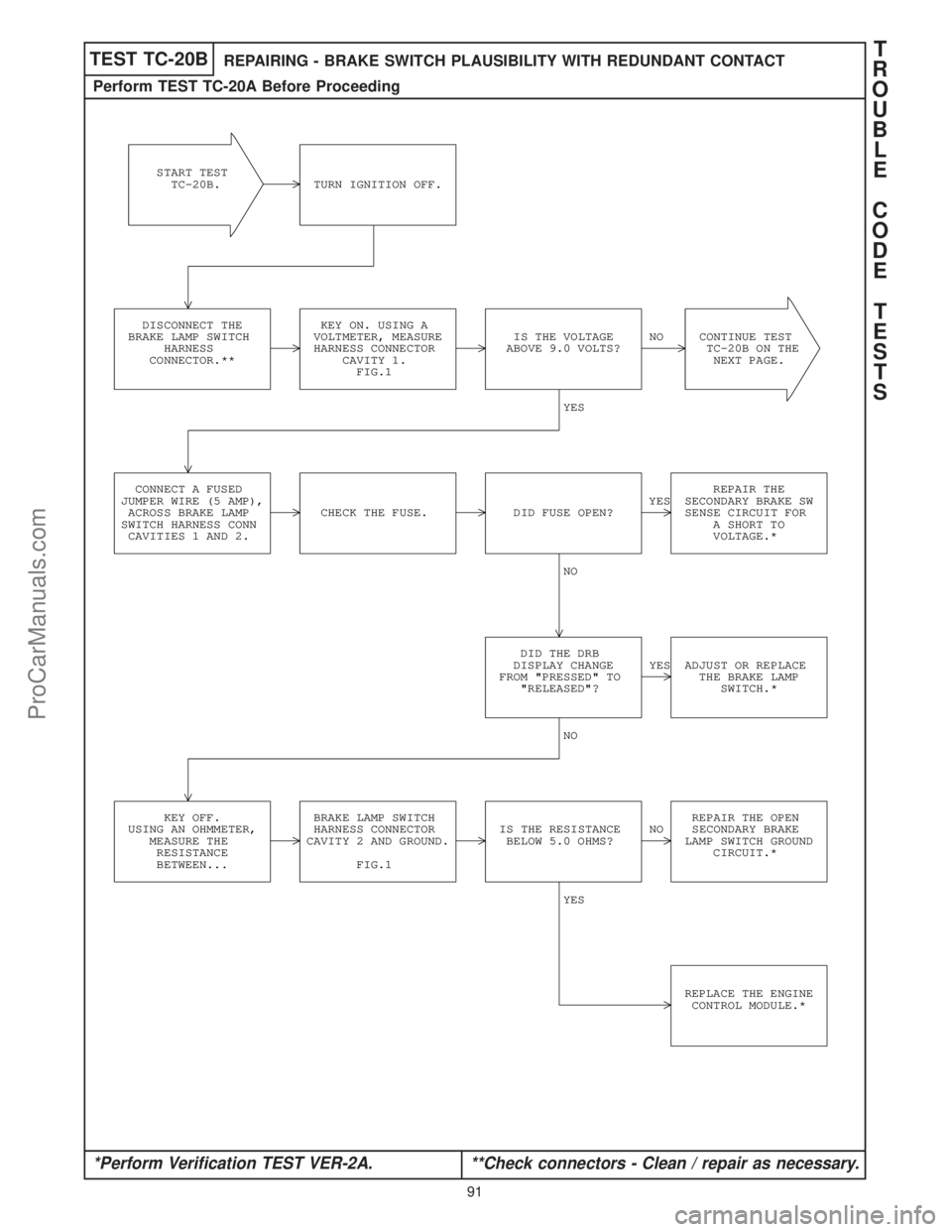

TEST TC-20BREPAIRING - BRAKE SWITCH PLAUSIBILITY WITH REDUNDANT CONTACT

Perform TEST TC-20A Before Proceeding

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

START TEST

TC-20B. TURN IGNITION OFF.

DISCONNECT THE KEY ON. USING A

BRAKE LAMP SWITCH VOLTMETER, MEASURE IS THE VOLTAGE NO CONTINUE TEST

HARNESS HARNESS CONNECTOR ABOVE 9.0 VOLTS? TC-20B ON THE

CONNECTOR.** CAVITY 1. NEXT PAGE.

FIG.1

YES

CONNECT A FUSEDREPAIR THE

JUMPER WIRE (5 AMP),YES SECONDARY BRAKE SW

ACROSS BRAKE LAMP CHECK THE FUSE. DID FUSE OPEN? SENSE CIRCUIT FOR

SWITCH HARNESS CONN A SHORT TO

CAVITIES 1 AND 2. VOLTAGE.*

NO

DID THE DRB

DISPLAY CHANGE YES ADJUST OR REPLACE

FROM "PRESSED" TO THE BRAKE LAMP

"RELEASED"? SWITCH.*

NO

KEY OFF. BRAKE LAMP SWITCH REPAIR THE OPEN

USING AN OHMMETER, HARNESS CONNECTOR IS THE RESISTANCE NO SECONDARY BRAKE

MEASURE THE CAVITY 2 AND GROUND. BELOW 5.0 OHMS? LAMP SWITCH GROUND

RESISTANCE CIRCUIT.*

BETWEEN... FIG.1

YES

REPLACE THE ENGINE

CONTROL MODULE.*

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

91

ProCarManuals.com

Page 98 of 436

TEST TC-20BCONTINUED - REPAIRING - BRAKE SWITCH PLAUSIBILITY WITH REDUNDANT

CONTACT

FIG.1

FIG. 2

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

92

ProCarManuals.com

Page 99 of 436

TEST TC-20BCONTINUED - REPAIRING - BRAKE SWITCH PLAUSIBILITY WITH REDUNDANT

CONTACT

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

TEST TC-20B KEY OFF.

CONTINUED FROM DISCONNECT THE ECM

THE PREVIOUS HARNESS

PAGE. CONNECTORS.**

OF THE SECONDARY REPAIR OPEN IN THE

USING AN OHMMETER, BRAKE LAMP SWITCH IS THE RESISTANCE NO SECONDARY BRAKE

MEASURE THE SIGNAL CIRCUIT. BELOW 5.0 OHMS? LAMP SWITCH SIGNAL

RESISTANCE...CIRCUIT.*

FIG.1

YES

USING AN OHMMETER, THE BRAKE LAMP REPAIR SHORT TO

MEASURE THE SWITCH HARNESS IS THE RESISTANCE YES GROUND IN THE

RESISTANCE CONNECTOR CAVITY 1 BELOW 5.0 OHMS? SECONDARY BRAKE

BETWEEN... AND GROUND. LAMP SWITCH SIGNAL

FIG.2 CIRCUIT.*

NO

REPLACE THE ENGINE

CONTROL MODULE.*

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

93

ProCarManuals.com

Page 285 of 436

TEST TC-91BREPAIRING - VEHICLE SPEED SENSOR TROUBLE CODES

Perform TEST TC-91A Before Proceeding

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

USING THE DRB

START TEST RECONNECT THE VSS RAISE AND SUPPORT OSCILLOSCOPE

TC-91B. AND ECM HARNESS THE VEHICLE DRIVE FUNCTION SELECT

CONNECTORS. AXLE. "LAB SCOPE".

SET VOLTAGE RANGE USING THE

TO +10.0v. SET TIME RANGE TO OSCILLOSCOPE LEAD,

SET PROBE TO x10. 40ms/Div. BACKPROBE ECM

HARNESS CONNECTOR

FIG.1 FIG.2 CAVITY 51. FIG.3

START THE ENGINE. SHIFT TRANSMISSION

INTO FIRST GEAR

ENGAGE THE PARKING AND ALLOW THE

BRAKE. WHEELS TO ROTATE

AT IDLE SPEED.

NOTE: A VALID VSS DOES THE DRB

OBSERVE THE DRB SIGNAL WILL CYCLE DISPLAY THE 5.0 NO REPLACE THE

OSCILLOSCOPE HI TO LOW SIMILAR VOLT VSS SIGNAL VEHICLE SPEED

PATTERN. TO THE PATTERN CYCLING HI AND SENSOR.*

SHOWN IN FIGURE 2. LOW?

YES

REPLACE THE ENGINE

CONTROL MODULE.*

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

279

ProCarManuals.com

Page 373 of 436

TEST NTC-12ACHECKING THE ENGINE MECHANICAL SYSTEMS

Perform TEST NTC-1A Before Proceeding

At this point in the diagnostic test procedure, you have determined that all of theengine electrical

systemsare operating as designed; therefore, theyare not the cause of the driveability problem.

The following additional items should be checked as possible mechanical causes of the problem.

1. ENGINE VALVE TIMING- must be within specifications

2. ENGINE COMPRESSION- must be within specifications

3. CAMSHAFT LOBES- check for abnormal wear

4. ENGINE SPEED SENSOR PICK-UP- check flywheel slots for debris/deterioration

5. ENGINE EXHAUST SYSTEM- must be free of any restrictions

6. ENGINE DRIVE SPROCKET- must be properly positioned

7. POWER BRAKE BOOSTER- no internal vacuum leaks

8. FUEL- must be free of contamination

9. FUEL INJECTOR- plugged or restricted injector

10. FUEL INJECTION PUMP- must be properly timed

NOTE:Always look for any Technical Service Bulletins that may relate to the problem.

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

367

ProCarManuals.com

Page 379 of 436

TEST SC-1ACHECKING SPEED CONTROL OPERATION

*Perform Verification TEST VER-3A. **Check connectors - Clean / repair as necessary.

START TEST KEY ON. WITH THE

SC-1A. DRB, SELECT

"SENSOR DISPLAY".

PRESS EACH OF THE PRESSING EACH SWITCH DID EACH SWITCH

CRUISE SWITCH SHOULD RESULT IN A PROVIDE THE NO PERFORM TEST

BUTTONS WHILE VOLTAGE INPUT SHOWN CORRECT VOLTAGE SC-2A.

OBSERVING CRUISE IN FIG.1. INPUT.

SWITCH VOLTS.

YES

WITH THE DRB, DID THE DRB INDICATE

MONITOR THE WHILE PRESSING AND THE CORRECT CHANGE NO PERFORM TEST

PRIMARY AND RELEASING THE OF STATE FROM SC-3A.

SECONDARY BRAKE BRAKE PEDAL. "RELEASED" TO

SWITCH INPUT... "PRESSED".

YES

DID THE DRB INDICATE

WITH THE DRB, WHILE PRESSING AND THE CORRECT CHANGE NO PERFORM TEST

MONITOR THE CLUTCH RELEASING THE OF STATE FROM SC-4A.

SWITCH INPUT. CLUTCH PEDAL. "RELEASED" TO

"PRESSED".

YES

WITH THE DRB,

MONITOR VEHICLE DOES THE DRB NO PERFORM TEST

SPEED WHILE DISPLAY ACCURATE SC-6A.

DRIVING THE VEHICLE SPEED?

VEHICLE.

YES

DRIVE VEHICLE AND ATTEMPT TO SET DID THE SPEED YES

GENERATE A SPEED SPEED CONTROL. CONTROL MAINTAIN TEST COMPLETED.*

ABOVE 35KM/H. SET VEHICLE SPEED?

NO

CONTINUE TEST

SC-1A ON THE

NEXT PAGE.

S

P

E

E

D

C

O

N

T

R

O

L

T

E

S

T

S

373

ProCarManuals.com

Page 381 of 436

TEST SC-1ACONTINUED - CHECKING SPEED CONTROL OPERATION

*Perform Verification TEST VER-3A. **Check connectors - Clean / repair as necessary.

TEST SC-1A

CONTINUED FROM

THE PREVIOUS TURN IGNITION OFF.

PAGE.

USING THE SCHEMATIC

AS A GUIDE, INSPECT WERE ANY PROBLEMS YES REPAIR AS

THE WIRING AND FOUND? NECESSARY.*

CONNECTORS.

FIG.1

NO

CHECK THE BRAKE LAMP ARE THE BRAKE LAMP

SWITCH AND CLUTCH SWITCH AND CLUTCH NO ADJUST OR REPLACE

PEDAL SWITCH PEDAL SWITCH AS NECESSARY.*

ADJUSTMENTS. ADJUSTED CORRECTLY?

YES

REPLACE THE ENGINE

CONTROL MODULE.*

S

P

E

E

D

C

O

N

T

R

O

L

T

E

S

T

S

375

ProCarManuals.com

Page 387 of 436

TEST SC-3ACONTINUED - CHECKING SPEED CONTROL OPERATION

*Perform Verification TEST VER-3A. **Check connectors - Clean / repair as necessary.

TEST SC-3A KEY OFF.

CONTINUED FROM

THE PREVIOUS DISCONNECT THE BRAKE

PAGE. LAMP SWITCH HARNESS

CONNECTOR.**

USING A VOLTMETER, REPAIR THE BRAKE

PROBE BRAKE LAMP IS THE VOLTAGE NO LAMP SWITCH FUSED

SWITCH HARNESS ABOVE 9.0 VOLTS? BATTERY SUPPLY

CONNECTOR CAVITY 6. CIRCUIT FOR AN

FIG.1 OPEN.*

YES

CONNECT A JUMPER DOES THE DRB

BETWEEN BRAKE LAMP DISPLAY CHANGE YES ADJUST OR REPLACE

SWITCH HARNESS TURN IGNITION ON. FROM "RELEASED" TO THE BRAKE LAMP

CONNECTOR CAVITIES "PRESSED"? SWITCH.*

5 AND 6. FIG.1

NO

REMOVE THE JUMPER. AT THE BRAKE LAMP REPAIR THE PRIMARY

USING A VOLTMETER, SWITCH HARNESS IS THE VOLTAGE NO BRAKE SWITCH

MEASURE THE CONNECTOR CAVITY 5. BELOW 1.0 VOLT? SIGNAL CIRCUIT FOR

PRIMARY SWITCH A SHORT TO

SIGNAL CIRCUIT... FIG.1 VOLTAGE.*

YES

KEY OFF. USING AN OHMMETER, REPAIR THE PRIMARY

MEASURE RESISTANCE IS THE RESISTANCE NO BRAKE SWITCH

DISCONNECT THE ECM OF THE PRIMARY BRAKE BELOW 5.0 OHMS? SIGNAL CIRCUIT FOR

HARNESS SW SIGNAL CKT. AN OPEN.*

CONNECTORS.** FIG.2

YES

REPLACE THE ENGINE

CONTROL MODULE.*

S

P

E

E

D

C

O

N

T

R

O

L

T

E

S

T

S

381

ProCarManuals.com

Page 389 of 436

TEST SC-3BCHECKING SPEED CONTROL OPERATION

Perform TEST SC-3A Before Proceeding

*Perform Verification TEST VER-3A. **Check connectors - Clean / repair as necessary.

START TEST

SC-3B. TURN IGNITION OFF.

DISCONNECT THE KEY ON. USING A

BRAKE LAMP SWITCH VOLTMETER, MEASURE IS THE VOLTAGE NO CONTINUE TEST

HARNESS VOLTAGE AT CAVITY 1. ABOVE 9.0 VOLTS? SC-3B ON THE

CONNECTOR.** NEXT PAGE.

FIG.1

YES

USING A JUMPER WHILE MONITORING DID THE DRB

WIRE, CONNECT THE DRB. DISPLAY CHANGE YES ADJUST OR REPLACE

BRAKE LAMP SWITCH FROM "PRESSED" TO THE BRAKE LAMP

CONNECTOR CAVITY 1 "RELEASED"? SWITCH.*

TO GROUND... FIG.1

NO

USING AN OHMMETER,REPAIR THE OPEN

MEASURE THE IS THE RESISTANCE YES SECONDARY BRAKE

RESISTANCE BETWEEN ABOVE 10.0 OHMS? LAMP SWITCH GROUND

CONNECTOR CAVITY 2CIRCUIT.*

AND GROUND. FIG.1

NO

REPLACE THE ENGINE

CONTROL MODULE.*

S

P

E

E

D

C

O

N

T

R

O

L

T

E

S

T

S

383

ProCarManuals.com

Page 391 of 436

TEST SC-3BCONTINUED - CHECKING SPEED CONTROL OPERATION

*Perform Verification TEST VER-3A. **Check connectors - Clean / repair as necessary.

TEST SC-3B

CONTINUED FROM DISCONNECT THE ECM

THE PREVIOUS TURN IGNITION OFF. HARNESS

PAGE. CONNECTORS.**

OF THE SECONDARY REPAIR OPEN IN THE

USING AN OHMMETER, BRAKE LAMP SWITCH IS THE RESISTANCE NO SECONDARY BRAKE

MEASURE THE SIGNAL CIRCUIT. BELOW 5.0 OHMS? LAMP SWITCH SIGNAL

RESISTANCE...CIRCUIT.*

FIG.1

YES

THE BRAKE LAMP REPAIR SHORT TO

USING AN OHMMETER, SWITCH CONNECTOR IS THE RESISTANCE YES GROUND IN THE

MEASURE RESISTANCE CAVITY 1 AND GROUND. BELOW 5.0 OHMS? SECONDARY BRAKE

BETWEEN... LAMP SWITCH SIGNAL

FIG.2 CIRCUIT.*

NO

REPLACE THE ENGINE

CONTROL MODULE.*

S

P

E

E

D

C

O

N

T

R

O

L

T

E

S

T

S

385

ProCarManuals.com