cooling CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1301 of 2399

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.

(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

16).

(5) Connect the negative battery cable.

CYLINDER HEAD

DESCRIPTION

The aluminum cylinder heads (Fig. 17) are

designed to create high flow combustion chambers to

improve performance, while minimizing the change

to the burn rate in the chamber. The cylinder head

incorporates the combustion chamber. Two valves

per-cylinder are used with inserted valve seats and

guides. A multi-layer steel (MLS) type gasket is used

between the cylinder head and engine block.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Disconnect negative cable from battery.

(3) Remove upper and lower intake manifolds.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL)

WARNING: INTAKE MANIFOLD GASKET IS MADE

OF VERY THIN METAL AND MAY CAUSE PER-

SONAL INJURY, HANDLE WITH CARE.

9 - 100 ENGINE 3.3/3.8LRS

AIR CLEANER HOUSING (Continued)

ProCarManuals.com

Page 1304 of 2399

²Step 2: Bolts1±8to88N´m(65ft.lbs.)

²Step 3: Bolts1±8(again) to 88 N´m (65 ft. lbs.)

²Step 4: Bolts1±8turn an additional 1/4 Turn.

(Do not use a torque wrench for this step.)

NOTE: Bolt torque after 1/4 turn should be over 122

N´m (90 ft. lbs.). If not, replace the bolt.

(6) Inspect push rods and replace worn or bent

rods.

(7) Install the push rods.

(8) Install the rocker arm and shaft assemblies.

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARMS - INSTALLATION)

(9) Install the cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(10) Install the exhaust manifolds. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION)

(11) Install new O-ring on dipstick tube. Install

dipstick tube assembly (Fig. 18).

(12) Install the spark plugs.

(13) Install upper and lower intake manifolds.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION)

(14) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(15) Connect negative cable to battery.

CYLINDER HEAD COVER(S)

DESCRIPTION

The cylinder head covers are made of stamped

steel. The covers are sealed with steel reinforced sil-

icon rubber gaskets. The cylinder head cover uses

rubber isolators at each fastener location (Fig. 23).

NOTE: Due to the tight packaging near the cylinder

head covers, which makes spill clean-up difficult, a

spill during an engine oil change may be misinter-

preted as an oil leak. When investigating an oil leak

in the location of the cylinder head covers and

intake manifold, follow the procedure found in Oil

Leak Diagnosis (Refer to 9 - ENGINE - DIAGNOSISAND TESTING) for determining the source of a

leak.

CYLINDER HEAD COVER -

RIGHT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(3) Disconnect spark plug wires from plugs.

(4) Disconnect power steering pump supply hose

support clip from cylinder head cover (Fig. 24).

(5) Disconnect PCV hose from cylinder head cover

(Fig. 25).

(6) Remove cylinder head cover bolts.

(7) Remove cylinder head cover and gasket (Fig.

23).

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Inspect seal on the cover bolt for wear or dam-

age (Fig. 26). Replace bolt assembly as necessary.

NOTE: The cylinder head cover bolts contain a

torque limiter sleeve and a seal (Fig. 26). The seal

and torque sleeve is replaced with the bolt.

Fig. 22 CYLINDER HEAD TIGHTENING SEQUENCE

Fig. 23 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - BOLT

RSENGINE 3.3/3.8L9 - 103

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1323 of 2399

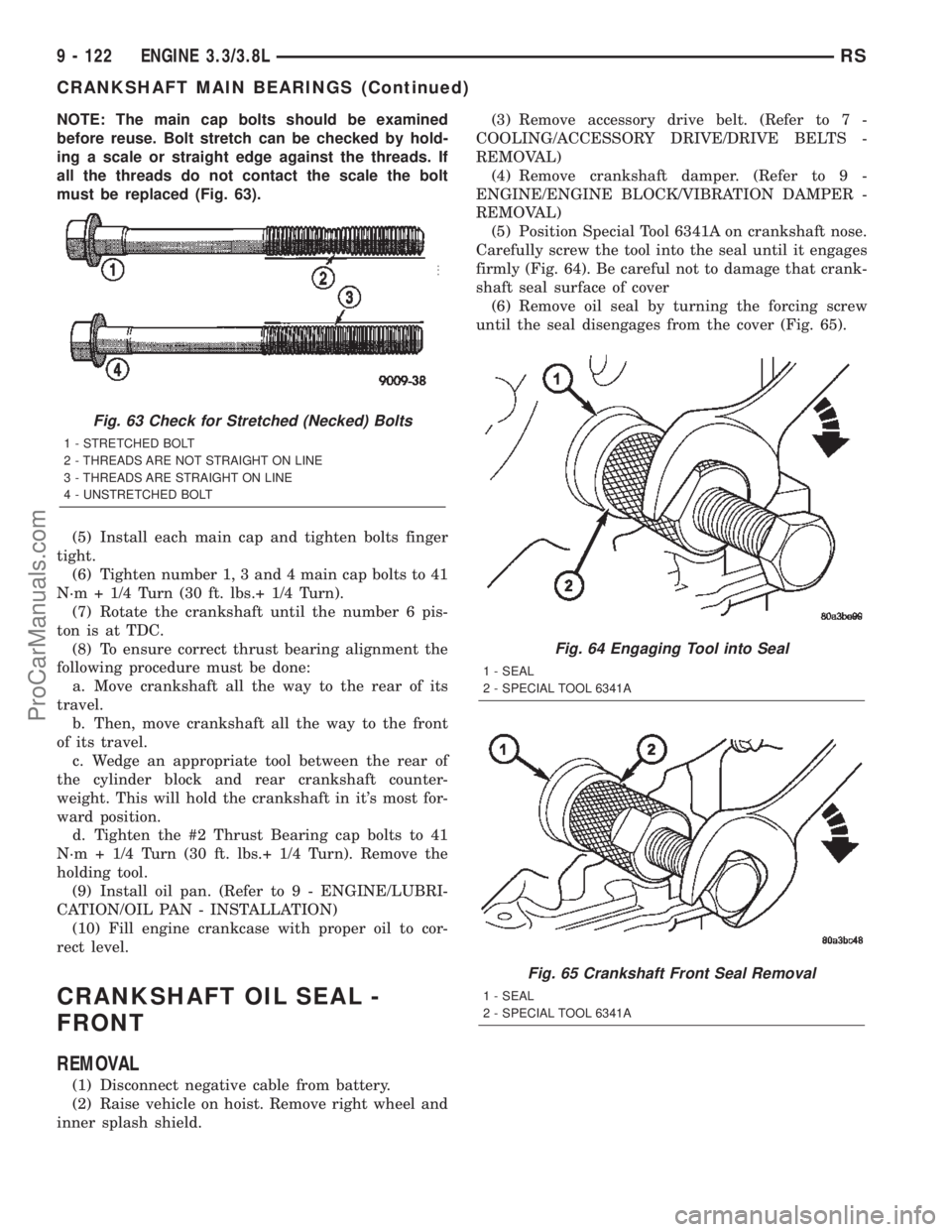

NOTE: The main cap bolts should be examined

before reuse. Bolt stretch can be checked by hold-

ing a scale or straight edge against the threads. If

all the threads do not contact the scale the bolt

must be replaced (Fig. 63).

(5) Install each main cap and tighten bolts finger

tight.

(6) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).

(7) Rotate the crankshaft until the number 6 pis-

ton is at TDC.

(8) To ensure correct thrust bearing alignment the

following procedure must be done:

a. Move crankshaft all the way to the rear of its

travel.

b. Then, move crankshaft all the way to the front

of its travel.

c. Wedge an appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.

d. Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(9) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(10) Fill engine crankcase with proper oil to cor-

rect level.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.(3) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL)

(5) Position Special Tool 6341A on crankshaft nose.

Carefully screw the tool into the seal until it engages

firmly (Fig. 64). Be careful not to damage that crank-

shaft seal surface of cover

(6) Remove oil seal by turning the forcing screw

until the seal disengages from the cover (Fig. 65).

Fig. 63 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 64 Engaging Tool into Seal

1 - SEAL

2 - SPECIAL TOOL 6341A

Fig. 65 Crankshaft Front Seal Removal

1 - SEAL

2 - SPECIAL TOOL 6341A

9 - 122 ENGINE 3.3/3.8LRS

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com

Page 1333 of 2399

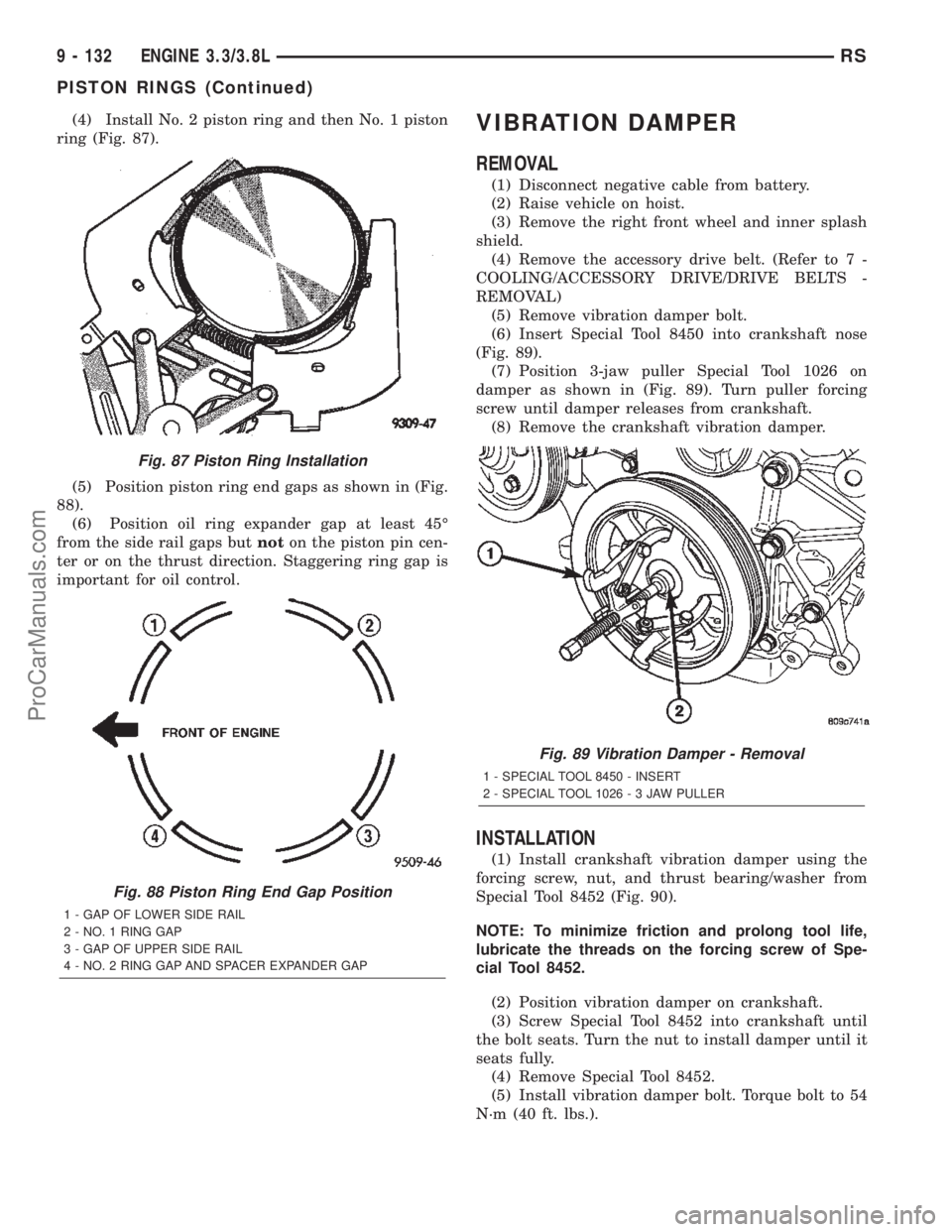

(4) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 87).

(5) Position piston ring end gaps as shown in (Fig.

88).

(6) Position oil ring expander gap at least 45É

from the side rail gaps butnoton the piston pin cen-

ter or on the thrust direction. Staggering ring gap is

important for oil control.VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove the right front wheel and inner splash

shield.

(4) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(5) Remove vibration damper bolt.

(6) Insert Special Tool 8450 into crankshaft nose

(Fig. 89).

(7) Position 3-jaw puller Special Tool 1026 on

damper as shown in (Fig. 89). Turn puller forcing

screw until damper releases from crankshaft.

(8) Remove the crankshaft vibration damper.

INSTALLATION

(1) Install crankshaft vibration damper using the

forcing screw, nut, and thrust bearing/washer from

Special Tool 8452 (Fig. 90).

NOTE: To minimize friction and prolong tool life,

lubricate the threads on the forcing screw of Spe-

cial Tool 8452.

(2) Position vibration damper on crankshaft.

(3) Screw Special Tool 8452 into crankshaft until

the bolt seats. Turn the nut to install damper until it

seats fully.

(4) Remove Special Tool 8452.

(5) Install vibration damper bolt. Torque bolt to 54

N´m (40 ft. lbs.).

Fig. 87 Piston Ring Installation

Fig. 88 Piston Ring End Gap Position

1 - GAP OF LOWER SIDE RAIL

2 - NO. 1 RING GAP

3 - GAP OF UPPER SIDE RAIL

4 - NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 89 Vibration Damper - Removal

1 - SPECIAL TOOL 8450 - INSERT

2 - SPECIAL TOOL 1026-3JAWPULLER

9 - 132 ENGINE 3.3/3.8LRS

PISTON RINGS (Continued)

ProCarManuals.com

Page 1334 of 2399

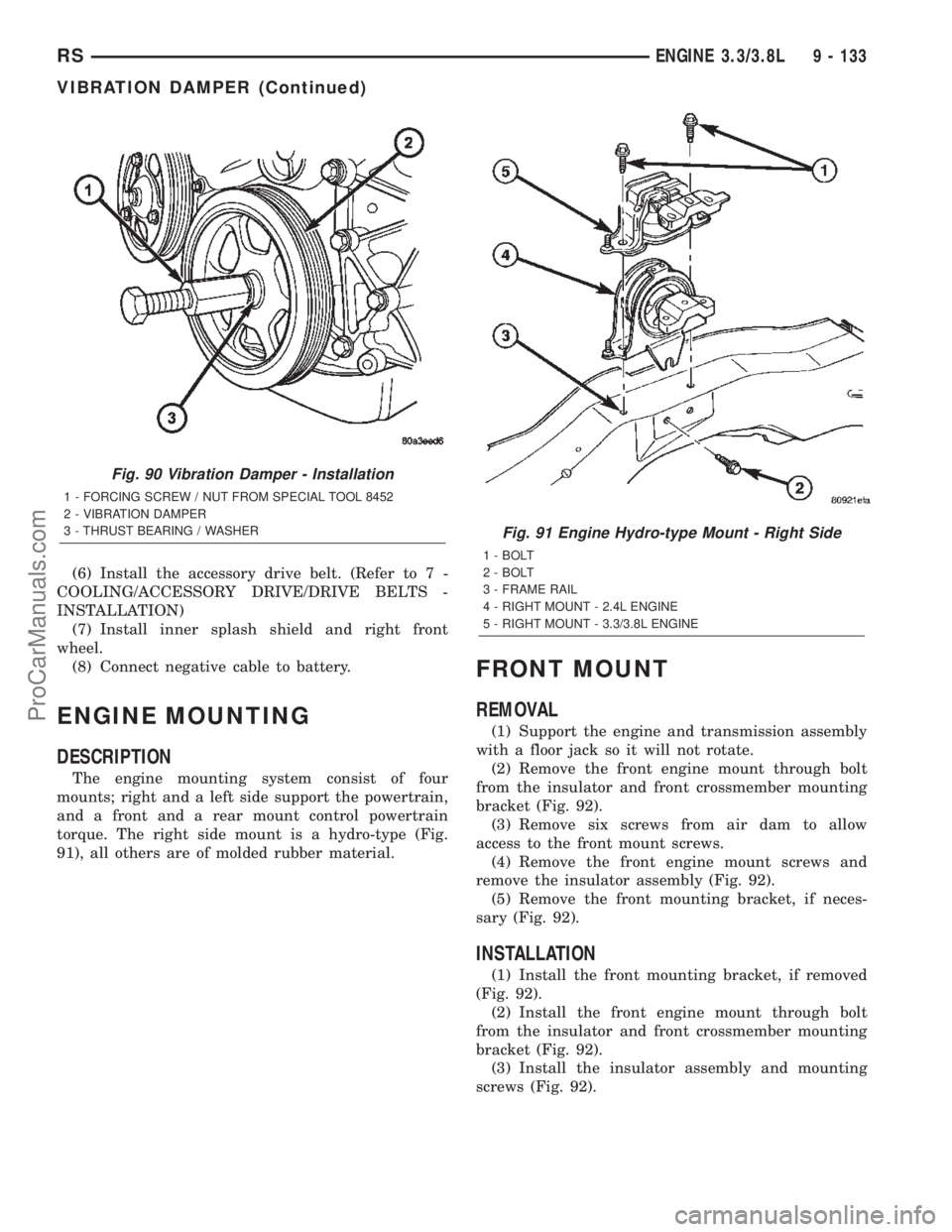

(6) Install the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(7) Install inner splash shield and right front

wheel.

(8) Connect negative cable to battery.

ENGINE MOUNTING

DESCRIPTION

The engine mounting system consist of four

mounts; right and a left side support the powertrain,

and a front and a rear mount control powertrain

torque. The right side mount is a hydro-type (Fig.

91), all others are of molded rubber material.

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 92).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly (Fig. 92).

(5) Remove the front mounting bracket, if neces-

sary (Fig. 92).

INSTALLATION

(1) Install the front mounting bracket, if removed

(Fig. 92).

(2) Install the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 92).

(3) Install the insulator assembly and mounting

screws (Fig. 92).

Fig. 90 Vibration Damper - Installation

1 - FORCING SCREW / NUT FROM SPECIAL TOOL 8452

2 - VIBRATION DAMPER

3 - THRUST BEARING / WASHER

Fig. 91 Engine Hydro-type Mount - Right Side

1 - BOLT

2 - BOLT

3 - FRAME RAIL

4 - RIGHT MOUNT - 2.4L ENGINE

5 - RIGHT MOUNT - 3.3/3.8L ENGINE

RSENGINE 3.3/3.8L9 - 133

VIBRATION DAMPER (Continued)

ProCarManuals.com

Page 1341 of 2399

OIL COOLER & LINES

DESCRIPTION

An engine oil cooler is used on 3.3/3.8L engines

(Heavy Duty Cooling Only) (Fig. 104). The cooler is a

coolant-to-oil type and mounted between the oil filter

and engine block.

OPERATION

Engine oil travels from the oil filter and into the

oil cooler. Engine oil then exits the cooler into the

main gallery. Engine coolant flows into the cooler

from the heater return tube and exits into the water

pump inlet.

REMOVAL

(1) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING).

(2) Disconnect oil cooler inlet and outlet hoses

(Fig. 103).

(3) Remove oil filter.

(4) Remove oil cooler attachment fitting (Fig. 104).

(5) Remove oil cooler.

INSTALLATION

(1) Lubricate seal and position oil cooler to connec-

tor fitting on oil filter adapter (Fig. 104).

NOTE: Position the flat side of oil cooler parallel to

oil pan rail.(2) Install oil cooler attachment fitting and tighten

to 27 N´m (20 ft. lbs.) (Fig. 104).

(3) Install oil filter.

(4) Connect oil cooler inlet and outlet hoses (Fig.

103).

(5) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE - COOLING SYSTEM

FILLING).

OIL FILTER

REMOVAL

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can-to-base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

(1) Using suitable oil filter wrench, turn filter

counterclockwise to remove from oil filter adapter

(Fig. 105). Properly discard used oil filter.

INSTALLATION

(1) Wipe oil filter adapter base clean and inspect

gasket contact surface.

(2) Lubricate gasket of new filter with clean

engine oil.

(3) Install new filter until gasket contacts base

(Fig. 105). Tighten filter 1 turn or 20 N´m (15 ft.

lbs.). Use filter wrench if necessary.

(4) Start engine and check for leaks.

Fig. 103 Engine Oil Cooler Hoses

1 - OIL COOLER INLET TUBE

2 - INLET HOSE

3 - OIL COOLER OUTLET TUBE

4 - OUTLET HOSE

5 - WATER PUMP INLET TUBE

Fig. 104 Engine Oil Cooler - 3.3/3.8L (Heavy Duty

Cooling)

1 - OIL FILTER ADAPTER

2 - CONNECTOR

3 - ENGINE OIL COOLER

4 - OIL COOLER ATTACHMENT FITTING

5 - OIL FILTER

9 - 140 ENGINE 3.3/3.8LRS

ProCarManuals.com

Page 1351 of 2399

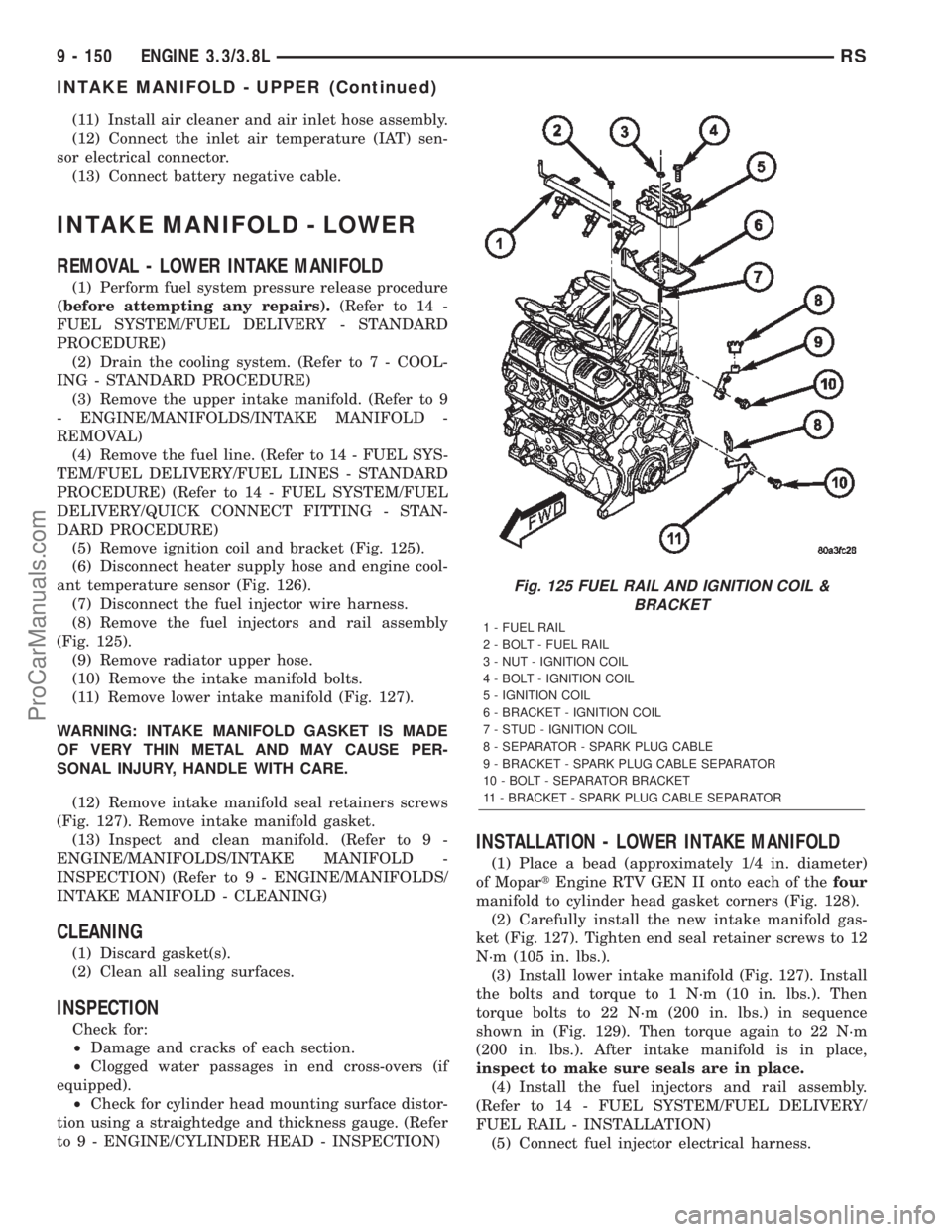

(11) Install air cleaner and air inlet hose assembly.

(12) Connect the inlet air temperature (IAT) sen-

sor electrical connector.

(13) Connect battery negative cable.

INTAKE MANIFOLD - LOWER

REMOVAL - LOWER INTAKE MANIFOLD

(1) Perform fuel system pressure release procedure

(before attempting any repairs).(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE)

(2) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(3) Remove the upper intake manifold. (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(4) Remove the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL LINES - STANDARD

PROCEDURE) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE)

(5) Remove ignition coil and bracket (Fig. 125).

(6) Disconnect heater supply hose and engine cool-

ant temperature sensor (Fig. 126).

(7) Disconnect the fuel injector wire harness.

(8) Remove the fuel injectors and rail assembly

(Fig. 125).

(9) Remove radiator upper hose.

(10) Remove the intake manifold bolts.

(11) Remove lower intake manifold (Fig. 127).

WARNING: INTAKE MANIFOLD GASKET IS MADE

OF VERY THIN METAL AND MAY CAUSE PER-

SONAL INJURY, HANDLE WITH CARE.

(12) Remove intake manifold seal retainers screws

(Fig. 127). Remove intake manifold gasket.

(13) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSPECTION) (Refer to 9 - ENGINE/MANIFOLDS/

INTAKE MANIFOLD - CLEANING)

CLEANING

(1) Discard gasket(s).

(2) Clean all sealing surfaces.

INSPECTION

Check for:

²Damage and cracks of each section.

²Clogged water passages in end cross-overs (if

equipped).

²Check for cylinder head mounting surface distor-

tion using a straightedge and thickness gauge. (Refer

to 9 - ENGINE/CYLINDER HEAD - INSPECTION)

INSTALLATION - LOWER INTAKE MANIFOLD

(1) Place a bead (approximately 1/4 in. diameter)

of MopartEngine RTV GEN II onto each of thefour

manifold to cylinder head gasket corners (Fig. 128).

(2) Carefully install the new intake manifold gas-

ket (Fig. 127). Tighten end seal retainer screws to 12

N´m (105 in. lbs.).

(3) Install lower intake manifold (Fig. 127). Install

the bolts and torque to 1 N´m (10 in. lbs.). Then

torque bolts to 22 N´m (200 in. lbs.) in sequence

shown in (Fig. 129). Then torque again to 22 N´m

(200 in. lbs.). After intake manifold is in place,

inspect to make sure seals are in place.

(4) Install the fuel injectors and rail assembly.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL RAIL - INSTALLATION)

(5) Connect fuel injector electrical harness.

Fig. 125 FUEL RAIL AND IGNITION COIL &

BRACKET

1 - FUEL RAIL

2 - BOLT - FUEL RAIL

3 - NUT - IGNITION COIL

4 - BOLT - IGNITION COIL

5 - IGNITION COIL

6 - BRACKET - IGNITION COIL

7 - STUD - IGNITION COIL

8 - SEPARATOR - SPARK PLUG CABLE

9 - BRACKET - SPARK PLUG CABLE SEPARATOR

10 - BOLT - SEPARATOR BRACKET

11 - BRACKET - SPARK PLUG CABLE SEPARATOR

9 - 150 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1352 of 2399

(6) Connect the engine coolant temperature sensor

(Fig. 126).

(7) Connect the heater supply (Fig. 126) and radi-

ator upper hoses to manifold.

(8) Connect the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(9) Install the upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

(10) Connect negative battery cable.

(11) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

Fig. 126 ECT SENSOR & HEATER SUPPLY

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

Fig. 127 INTAKE MANIFOLD - LOWER

1 - INTAKE MANIFOLD - LOWER

2 - BOLT - GASKET END SEAL RETAINER

3 - GASKET

4 - BOLT - LOWER INTAKE MANIFOLD

Fig. 128 Intake Manifold Gasket Sealing

1 - SEALER LOCATIONS

RSENGINE 3.3/3.8L9 - 151

INTAKE MANIFOLD - LOWER (Continued)

ProCarManuals.com

Page 1356 of 2399

(3) Position heat shield on manifold (Fig. 136).

(4) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(5) Install and tighten heat shield attaching nut to

12 N´m (105 in. lbs.) (Fig. 136).

(6) Connect battery negative cable.

VALVE TIMING

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE TIMING

VERIFICATION

(1) Remove front cylinder head cover and all 6

spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further clock-

wise as intake valve might bottom and result in

serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

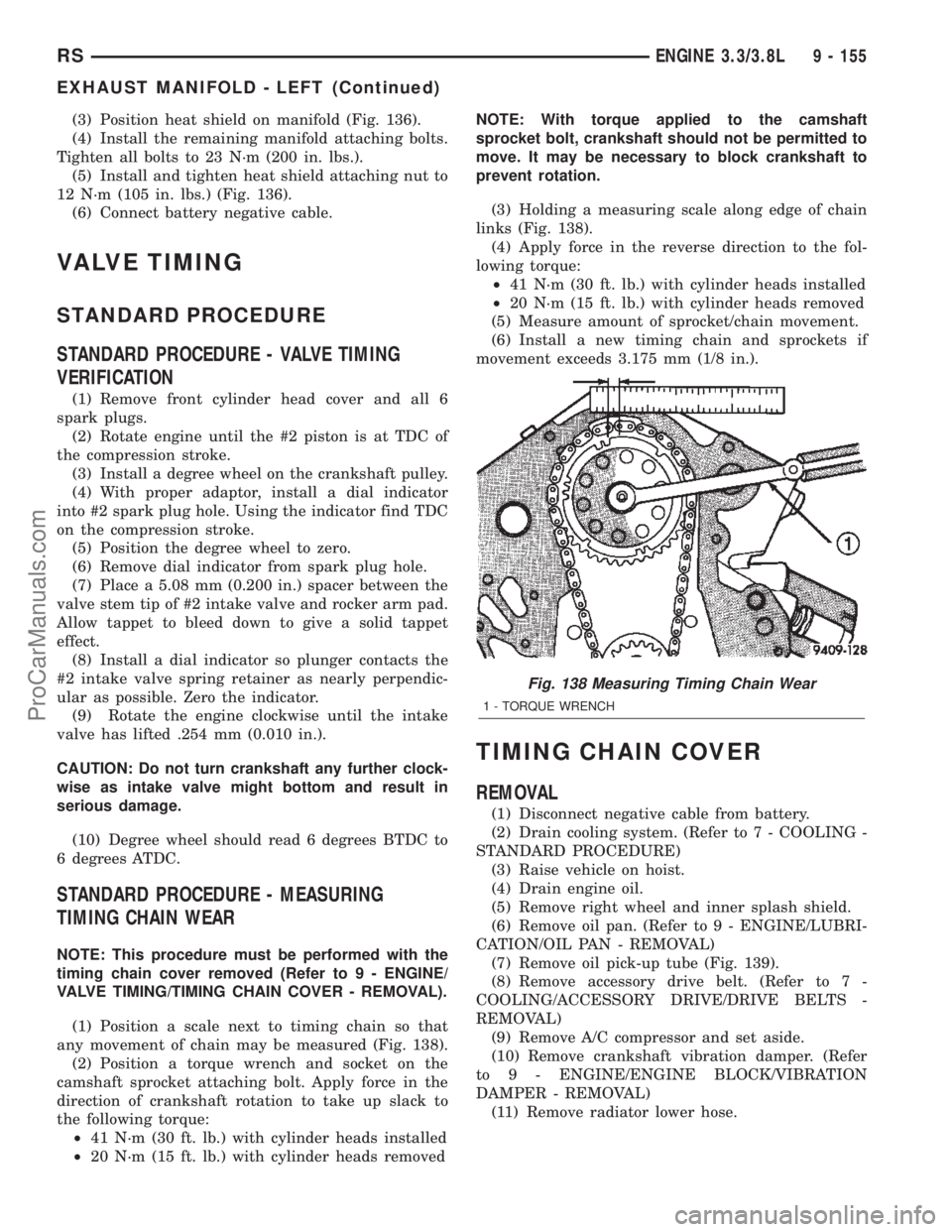

STANDARD PROCEDURE - MEASURING

TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER - REMOVAL).

(1) Position a scale next to timing chain so that

any movement of chain may be measured (Fig. 138).

(2) Position a torque wrench and socket on the

camshaft sprocket attaching bolt. Apply force in the

direction of crankshaft rotation to take up slack to

the following torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removedNOTE: With torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block crankshaft to

prevent rotation.

(3) Holding a measuring scale along edge of chain

links (Fig. 138).

(4) Apply force in the reverse direction to the fol-

lowing torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removed

(5) Measure amount of sprocket/chain movement.

(6) Install a new timing chain and sprockets if

movement exceeds 3.175 mm (1/8 in.).

TIMING CHAIN COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(3) Raise vehicle on hoist.

(4) Drain engine oil.

(5) Remove right wheel and inner splash shield.

(6) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

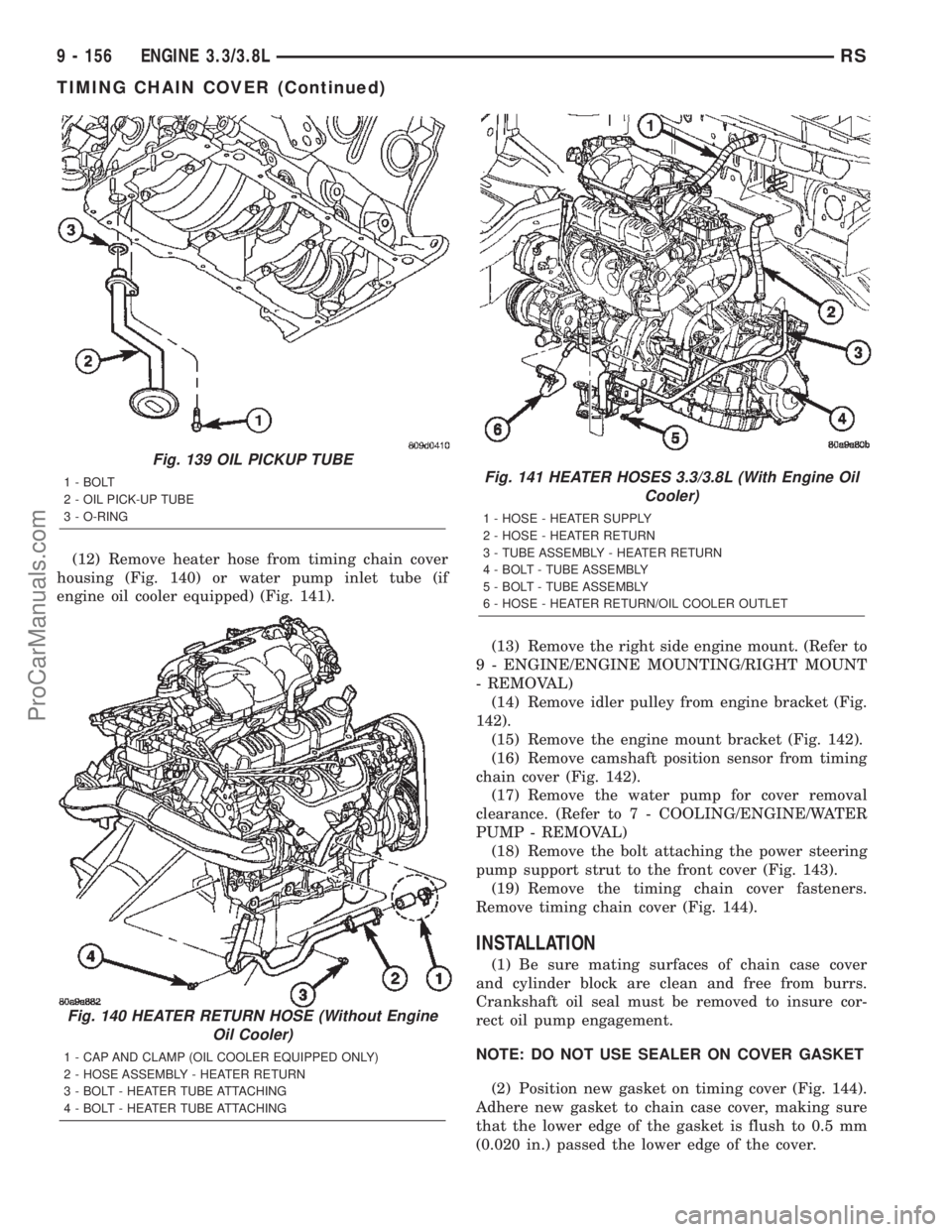

(7) Remove oil pick-up tube (Fig. 139).

(8) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Remove A/C compressor and set aside.

(10) Remove crankshaft vibration damper. (Refer

to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(11) Remove radiator lower hose.

Fig. 138 Measuring Timing Chain Wear

1 - TORQUE WRENCH

RSENGINE 3.3/3.8L9 - 155

EXHAUST MANIFOLD - LEFT (Continued)

ProCarManuals.com

Page 1357 of 2399

(12) Remove heater hose from timing chain cover

housing (Fig. 140) or water pump inlet tube (if

engine oil cooler equipped) (Fig. 141).

(13) Remove the right side engine mount. (Refer to

9 - ENGINE/ENGINE MOUNTING/RIGHT MOUNT

- REMOVAL)

(14) Remove idler pulley from engine bracket (Fig.

142).

(15) Remove the engine mount bracket (Fig. 142).

(16) Remove camshaft position sensor from timing

chain cover (Fig. 142).

(17) Remove the water pump for cover removal

clearance. (Refer to 7 - COOLING/ENGINE/WATER

PUMP - REMOVAL)

(18) Remove the bolt attaching the power steering

pump support strut to the front cover (Fig. 143).

(19) Remove the timing chain cover fasteners.

Remove timing chain cover (Fig. 144).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

Crankshaft oil seal must be removed to insure cor-

rect oil pump engagement.

NOTE: DO NOT USE SEALER ON COVER GASKET

(2) Position new gasket on timing cover (Fig. 144).

Adhere new gasket to chain case cover, making sure

that the lower edge of the gasket is flush to 0.5 mm

(0.020 in.) passed the lower edge of the cover.

Fig. 139 OIL PICKUP TUBE

1 - BOLT

2 - OIL PICK-UP TUBE

3 - O-RING

Fig. 140 HEATER RETURN HOSE (Without Engine

Oil Cooler)

1 - CAP AND CLAMP (OIL COOLER EQUIPPED ONLY)

2 - HOSE ASSEMBLY - HEATER RETURN

3 - BOLT - HEATER TUBE ATTACHING

4 - BOLT - HEATER TUBE ATTACHING

Fig. 141 HEATER HOSES 3.3/3.8L (With Engine Oil

Cooler)

1 - HOSE - HEATER SUPPLY

2 - HOSE - HEATER RETURN

3 - TUBE ASSEMBLY - HEATER RETURN

4 - BOLT - TUBE ASSEMBLY

5 - BOLT - TUBE ASSEMBLY

6 - HOSE - HEATER RETURN/OIL COOLER OUTLET

9 - 156 ENGINE 3.3/3.8LRS

TIMING CHAIN COVER (Continued)

ProCarManuals.com