shaft CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1078 of 2399

CRANKSHAFT POSITION SENSOR (GAS) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F888 18BR/PK 8 VOLT SUPPLY

2 K900 18DB/DG SENSOR GROUND

3 K24 18BR/LB CRANKSHAFT POSITION SENSOR SIGNAL

DATA LINK CONNECTOR - BLACK 16 WAY

CAV CIRCUIT FUNCTION

1- -

2 D25 20WT/VT PCI BUS

3- -

4 Z11 18BK/LG GROUND

5 Z111 18BK/WT (EXCEPT

BUILT-UP-EXPORT)GROUND

5 Z111 20BK/WT (BUILT-UP-EXPORT) GROUND

6 D20 20WT/LG (GAS) SCI RECEIVE

7 D21 20WT/BR (EXCEPT

BUILT-UP-EXPORT)SCI TRANSMIT

7 D21 20WT/DG (BUILT- UP-EXPORT) SCI TRANSMIT

8- -

9 D23 20WT/BR FLASH PROGRAM ENABLE

10 - -

11 - -

12 - -

13 - -

14 D16 20WT/OR (GAS) SCI RECEIVE

15 - -

16 A105 20DB/RD FUSED B(+)

DIAGNOSTIC JUNCTION PORT - BLACK 16 WAY

CAV CIRCUIT FUNCTION

1 D25 20WT/VT PCI BUS (PCM/SKIM/ECM/THATCHAM)

2 D25 20WT/VT PCI BUS (HVAC)

3 D25 20WT/VT PCI BUS (RADIO)

4 D25 20WT/VT PCI BUS (ORC)

5 D25 20WT/VT PCI BUS (CLUSTER)

6 D25 20WT/VT PCI BUS (BCM)

7 D25 20WT/VT PCI BUS (DLC)

8 D25 20WT/VT PCI BUS (OVERHEAD CONSOLE)

9 D25 20WT/VT PCI BUS (FCM/TCM/CAB)

10 D25 20WT/VT PCI BUS (LSIACM)

11 D25 20WT/VT (MEMORY) PCI BUS (MEMORY)

12 D25 20WT/VT PCI BUS (PWR DOOR LT/RT/LIFTGATE)

13 D25 20WT/VT PCI BUS (RSIACM)

14 - -

15 - -

16 - -

RS8W-80 CONNECTOR PIN-OUTS8W-80-47

ProCarManuals.com

Page 1086 of 2399

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY

CAV CIRCUIT FUNCTION

1 Z130 14BK/BR GROUND

2 Z131 14BK/DG GROUND

3 K20 14BR/GY GENERATOR FIELD CONTROL

4 K342 14BR/WT ECM/PCM RELAY OUTPUT

5 K342 14BR/WT ECM/PCM RELAY OUTPUT

6- -

7 D25 20WT/VT PCI BUS

8 K944 20BK/GY CAMSHAFT POSITION SENSOR SHIELD GROUND

9 K44 20DB/GY CAMSHAFT POSITION SENSOR SIGNAL

10 - -

11 K37 20DB/YL BOOST PRESSURE SENSOR SIGNAL

12 K55 20DB/OR MASS AIR FLOW SENSOR SIGNAL

13 K78 20GY FUEL PRESSURE SENSOR SIGNAL

14 - -

15 K22 20OR/DB ACCELERATOR PEDAL POSITION SENSOR SIGNAL

16 K80 20DB/TN FUEL PRESSURE SENSOR GROUND

17 - -

18 - -

19 N1 20DB/OR FUEL HEATER RELAY OUTPUT

20 Z138 20BK/OR GROUND

21 K900 20DB/DG SENSOR GROUND

22 F202 20PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

23 F851 20LB/PK SENSOR REFERENCE VOLTAGE B

24 K3 20BR/OR CRANKSHAFT POSITION SENSOR SIGNAL NO. 1

25 - -

26 - -

27 - -

28 - -

29 - -

30 G6 20VT/GY ENGINE OIL PRESSURE SENSOR SIGNAL

31 F853 20LG/PK WATER IN FUEL SENSOR SIGNAL

32 K25 20BR/TN BATTERY TEMPERATURE SENSOR SIGNAL

33 - -

34 K167 20BR/YL ACCELERATOR PEDAL POSITION SENSOR GROUND

35 K853 20DB/BR ACCELERATOR PEDAL POSITION SENSOR 5 VOLT

SUPPLY

36 C18 20LB/BR A/C PRESSURE SENSOR SIGNAL

37 K89 20DB/WT ENGINE OIL TEMPERATURE SENSOR SIGNAL

38 V37 20VT/TN SPEED CONTROL SWITCH SIGNAL

39 - -

40 K2 20TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

41 K21 20DB/LG INTAKE AIR TEMPERATURE SENSOR SIGNAL

42 Z122 18WT GROUND (DRAIN)

43 K24 20BR/LB CRANKSHAFT POSITION SENSOR SIGNAL NO. 2

44 - -

45 - -

46 - -

47 L50 20WT/TN BRAKE LAMP SWITCH OUTPUT

48 B29 20DG/WT SECONDARY BRAKE SWITCH SIGNAL

49 T751 20YL FUSED IGNITION SWITCH OUTPUT (START)

50 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

51 - -

52 K121 20DB BOOST PRESSURE SENSOR GROUND

53 - -

54 K957 20BK/OR MASS AIR FLOW SENSOR GROUND

RS8W-80 CONNECTOR PIN-OUTS8W-80-55

ProCarManuals.com

Page 1125 of 2399

POWER WINDOW SWITCH (LOWLINE) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 F304 16WT/PK FUSED WINDOW CIRCUIT BREAKER OUTPUT

2 Z421 12BK/BR GROUND

3 Z421 12BK/BR GROUND

4- -

5 Q26 12OR/GY MASTER WINDOW SWITCH PASSENGER DOWN

6 F304 16WT/PK FUSED WINDOW CIRCUIT BREAKER OUTPUT

7 Z421 20BK/BR GROUND

8 Q16 12OR/TN MASTER WINDOW SWITCH PASSENGER UP

POWERTRAIN CONTROL MODULE C1 (GAS) - GRAY/BLACK 40-WAY

CAV CIRCUIT FUNCTION

1- -

2 K18 16DB/OR (3.3L/3.8L) IGNITION COIL NO. 3 DRIVER

3 K17 16DB/TN IGNITION COIL NO. 2 DRIVER

4- -

5 V32 18VT/YL SPEED CONTROL ON/OFF SWITCH SENSE

6 K342 16BR/WT AUTOMATIC SHUT DOWN RELAY OUTPUT

7 K13 16BR/LB FUEL INJECTOR NO. 3 DRIVER

8 K20 18BR/GY GENERATOR FIELD CONTROL

9- -

10 Z130 18BK/BR GROUND

11 K19 16DB/DG IGNITION COIL NO. 1 DRIVER

12 G6 16VT/GY ENGINE OIL PRESSURE SWITCH SENSE

13 K11 16BR/YL FUEL INJECTOR NO. 1 DRIVER

14 K58 16BR/VT (3.3L/3.8L) FUEL INJECTOR NO. 6 DRIVER

15 K38 16BR/OR (3.3L/3.8L) FUEL INJECTOR NO. 5 DRIVER

16 K14 16BR/TN FUEL INJECTOR NO. 4 DRIVER

17 K12 16BR/DB FUEL INJECTOR NO. 2 DRIVER

18 K99 18BR/LG OXYGEN SENSOR 1/1 HEATER CONTROL

19 - -

20 F202 18PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

21 - -

22 - -

23 - -

24 - -

25 K42 18DB/YL (EXCEPT 3.3L/3.8L

BUILT-UP-EXPORT)KNOCK SENSOR SIGNAL

26 K2 18VT/OR ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

27 K902 18BR/DG OXYGEN SENSOR GROUND

28 - -

29 - -

30 K41 18DB/LB OXYGEN SENSOR 1/1 SIGNAL

31 T752 18DG/OR ENGINE STARTER MOTOR RELAY CONTROL

32 K24 18BR/LB CRANKSHAFT POSITION SENSOR SIGNAL

33 K44 18DB/GY CAMSHAFT POSITION SENSOR SIGNAL

34 - -

35 K22 18BR/OR THROTTLE POSITION SENSOR SIGNAL

36 K1 18VT/BR MANIFOLD ABSOLUTE PRESSURE SENSOR SIGNAL

37 K21 18DB/LG INTAKE AIR TEMPERATURE SENSOR SIGNAL

38 - -

39 - -

40 K35 18DB/VT EGR SOLENOID CONTROL

8W - 80 - 94 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1145 of 2399

TRANSMISSION CONTROL MODULE (EATX) - BLACK 60 WAY

CAV CIRCUIT FUNCTION

1 T1 18DG/LB TRS T1 SENSE

2- -

3 T3 18DG/DB TRS T3 SENSE

4- -

5- -

6 K24 18BR/LB CRANKSHAFT POSITION SENSOR SIGNAL

7 D21 18WT/BR SCI TRANSMIT

8 T751 18YL FUSED IGNITION SWITCH OUTPUT (START)

9 T9 18DG/TN OVERDRIVE PRESSURE SWITCH SENSE

10 T10 18DG/LG TORQUE MANAGEMENT REQUEST SENSE

11 F1 18PK/WT FCM OUTPUT (UNLOCK-RUN-START)

12 K22 18BR/OR THROTTLE POSITION SENSOR SIGNAL

13 T13 18DG/VT SPEED SENSOR GROUND

14 T14 18DG/BR OUTPUT SPEED SENSOR SIGNAL

15 T15 18YL/BR TRANSMISSION CONTROL RELAY CONTROL

16 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

17 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

18 - -

19 T19 18YL/DB 2-4 SOLENOID CONTROL

20 T20 18DG/WT LOW/REVERSE SOLENOID CONTROL

21 - -

22 - -

23 - -

24 - -

25 - -

26 - -

27 - -

28 - -

29 - -

30 - -

31 - -

32 - -

33 - -

34 - -

35 - -

36 - -

37 - -

38 - -

39 - -

40 - -

41 T41 18DG/GY (3.3L/3.8L) TRS T41 SENSE

41 T41 18YL/DB (2.4L) TRS T41 SENSE

42 T42 18DG/YL TRS T42 SENSE

43 D25 18WT/VT PCI BUS

44 - -

45 - -

46 D16 18WT/OR SCI RECEIVE

47 T47 18YL/DG 2-4 PRESSURE SWITCH SENSE

48 - -

49 - -

50 T50 18YL/TN LOW/REVERSE PRESSURE SWITCH SENSE

51 K900 18DB/DG SENSOR GROUND

52 T52 18DG/WT INPUT SPEED SENSOR SIGNAL

53 Z132 16BK/YL GROUND

54 T54 18DG/OR TRANSMISSION TEMPERATURE SENSOR SIGNAL

8W - 80 - 114 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1150 of 2399

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C325 BK Right Sliding Door 27

C326 YL At Driver Side Airbag N/S

C327 YL At Passenger Side Airbag N/S

C329 (Diesel) BK Left Rear Engine Compartment N/S

C330 (Diesel) LTGY Left Rear Engine Compartment N/S

C331 (Diesel) BK Left Rear Engine Compartment N/S

Cabin Heater Assist C1 (Diesel) BK Top of Engine 11, 12

Cabin Heater Assist C2 (Diesel) BK Top of Engine 11, 12

Camshaft Position Sensor (Gas) BK Rear of Cylinder Head

Right Side of EngineN/S

Camshaft Position Sensor (Diesel) BK Rear of Cylinder Head 11, 12

CD Changer Behind CD Changer N/S

Center Dome Lamp GY At Lamp N/S

Center High Mounted Stop Lamp BK At Lamp 42

Clockspring - C1 WT Steering Column 15, 16, 17, 18, 26

Clockspring - C2 YL Steering Column 15, 16, 17, 18, 26

Clockspring - C3 BK Steering Column N/S

Clockspring - C4 BK Steering Column N/S

Clockspring - C5 YL Steering Column N/S

Clutch Pedal Interlock Switch

(Diesel)RD At Switch/Driver Side 36

Clutch Pedal Upstop Switch

(Diesel)BK At Switch/Driver Side 36

Controller Anti-Lock Brake BK Right Side of Engine Compartment 9, 10, 12, 13, 14

Crank Case Ventilation Heater

(Diesel)BK Top of Cylinder Head 11

Crankshaft Position Sensor (Diesel) BK Rear of Engine 12

Crankshaft Position Sensor (Gas) BK Rear of Engine 9, 13

Data Link Connector WT Lower Instrument Panel Near Steering

Column35, 36

Diagnostic Junction Port BK Lower Instrument Panel Near Steering

Column35, 36

Dosing Pump BK Top of Engine N/S

Driver Airbag C1 BN Steering Column N/S

Driver Airbag C2 BK Steering Column N/S

Driver Blend Actuator (ATC) GY On HVAC N/S

Driver Blend Actuator (MTC) GY On HVAC N/S

Driver Door Courtesy Lamp GY At Lamp N/S

Driver Door Lock Switch BK At Switch N/S

Driver Heated Seat Back GN At Seat N/S

Driver Heated Seat Cushion BK At Seat N/S

Driver Heated Seat Module C1 GY Driver Heated Seat N/S

Driver Heated Seat Module C2 GY Driver Heated Seat Back N/S

Driver Heated Seat Module C3 GN At Seat N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1158 of 2399

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 10

G102 Left Headlamp Area 1

G103 Above Starter 10

G200 Right Side of Instrument Panel 15, 19, 24

G201 Right Side of Instrument Panel 15, 19, 24

G202 Near Radio N/S

G300 Left B Pillar 27

G301 Right B Pillar 28, 33

G302 Left Rear Quarter N/S

G400 Liftgate Ground N/S

SPLICES

SPLICE NUMBER LOCATION FIG.

S101 800mm from T/O for G102 1

S102 500mm from T/O for G102 1

S103 (2.5L) Between T/O for Battery Temperature Sensor and T/O

for C10211

S103 (3.3L/3.8L) Near T/O for C100 N/S

S104 Near T/O for G102 1

S105 (3.3L/3.8L) Near T/O for Battery (+) N/S

S106 (2.4L) 40mm from T/O for Torque Converter Clutch Solenoid 10

S106 (2.5L) Near T/O for Battery Temperature Sensor 11

S106 (3.3L/3.8L) Near T/O for G103 14

S107 (2.4L) In T/O for EGR Solenoid 10

S107 (2.5L) Between T/O for Engine Starter Motor and T/O for

Engine Control Module C112

S107 (3.3L/3.8L) In T/O for EGR Solenoid 14

S108 (3.3L/3.8L) Near T/O for Powertrain Control Module N/S

S109 (3.3L/3.8L) Near T/O for Camshaft Position Sensor N/S

S110 Near T/O to G102 N/S

S111 (2.4L) Near T/O for C101 N/S

S111 (2.5L) Near T/O for Battery (-) N/S

S111 (3.3L/3.8L) Near T/O for Powertrain Control Module N/S

S112 Near T/O for Intelligent Power Module - C3 N/S

S113 (2.4L) Near T/O for Park/Neutral Position Switch N/S

S114 (3.3L/3.8L) In T/O to Transmission Control Module N/S

S115 (3.3L/3.8L) In T/O to Transmission Control Module N/S

S116 (2.4L) 180mm from T/O for Torque Converter Clutch Solenoid 10

S116 (2.5L) Near T/O for Mass Air Flow Sensor 12

S116 (3.3L/3.8L) Near T/O for Ignition Coil Pack 14

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1202 of 2399

ENGINE

TABLE OF CONTENTS

page page

ENGINE 2.4L.............................. 1ENGINE 3.3/3.8L......................... 74

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............3

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............4

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL..............6

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................8

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........9

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................9

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............10

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........10

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE.....................10

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........11

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................12

REMOVAL - ENGINE ASSEMBLY...........12

INSTALLATION - ENGINE ASSEMBLY........16

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........17

SPECIFICATIONS - TORQUE............20

SPECIAL TOOLS

2.4L ENGINE.........................21AIR CLEANER ELEMENT

REMOVAL.............................24

INSTALLATION.........................24

AIR CLEANER HOUSING

REMOVAL.............................24

INSTALLATION.........................24

CYLINDER HEAD

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET............................24

REMOVAL - CYLINDER HEAD.............25

CLEANING............................26

INSPECTION..........................26

INSTALLATION - CYLINDER HEAD..........26

CAMSHAFT OIL SEAL(S)

REMOVAL.............................28

INSTALLATION.........................28

CAMSHAFT(S)

DESCRIPTION.........................29

OPERATION...........................29

STANDARD PROCEDURE - MEASURING

CAMSHAFT END PLAY.................29

REMOVAL.............................29

CLEANING............................29

INSPECTION..........................30

INSTALLATION.........................30

CYLINDER HEAD COVER

REMOVAL.............................31

CLEANING............................31

INSPECTION..........................31

INSTALLATION.........................31

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................32

CLEANING............................32

RSENGINE9-1

ProCarManuals.com

Page 1203 of 2399

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........32

REMOVAL - CYLINDER HEAD OFF........33

INSPECTION..........................33

INSTALLATION

INSTALLATION - CYLINDER HEAD ON.....33

INSTALLATION - CYLINDER HEAD OFF....33

HYDRAULIC LASH ADJUSTERS

DIAGNOSIS AND TESTING - HYDRAULIC

LASH ADJUSTER NOISE DIAGNOSIS......34

REMOVAL.............................34

INSTALLATION.........................34

ROCKER ARMS

REMOVAL.............................35

INSPECTION..........................35

INSTALLATION.........................35

ENGINE BLOCK

DESCRIPTION.........................35

STANDARD PROCEDURE

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING..............36

STANDARD PROCEDURE - CYLINDER

BORE HONING.......................36

CLEANING............................37

INSPECTION..........................37

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING...........37

CRANKSHAFT

DESCRIPTION.........................38

OPERATION...........................38

STANDARD PROCEDURE - CRANKSHAFT

ENDPLAY ...........................38

REMOVAL.............................38

INSPECTION..........................39

INSTALLATION.........................39

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - MAIN BEARING -

FITTING.............................41

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................42

INSTALLATION.........................43

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................43

INSTALLATION.........................44

PISTON & CONNECTING ROD

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................46

PISTON RINGS

STANDARD PROCEDURE

PISTON RING - FITTING................47

VIBRATION DAMPER

REMOVAL.............................48

INSTALLATION.........................48STRUCTURAL COLLAR

REMOVAL.............................49

INSTALLATION.........................49

ENGINE MOUNTING

DESCRIPTION.........................49

FRONT MOUNT

REMOVAL.............................49

INSTALLATION.........................50

LEFT MOUNT

REMOVAL.............................50

INSTALLATION.........................50

REAR MOUNT

REMOVAL.............................51

INSTALLATION.........................51

RIGHT MOUNT

REMOVAL.............................52

INSTALLATION.........................52

LUBRICATION

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE................53

OIL

STANDARD PROCEDURE

ENGINE OIL LEVEL CHECK.............53

STANDARD PROCEDURE - ENGINE OIL

AND FILTER CHANGE..................54

OIL FILTER

DESCRIPTION.........................54

REMOVAL.............................54

INSTALLATION.........................55

OIL PAN

REMOVAL.............................55

INSTALLATION.........................55

OIL PRESSURE SWITCH

REMOVAL.............................55

INSTALLATION.........................55

OIL PUMP

REMOVAL.............................55

DISASSEMBLY.........................56

CLEANING............................57

INSPECTION..........................57

ASSEMBLY............................58

INSTALLATION.........................58

INTAKE MANIFOLD

DESCRIPTION.........................59

OPERATION...........................59

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS.....................59

INTAKE MANIFOLD - UPPER

REMOVAL.............................60

INSPECTION..........................61

INSTALLATION.........................61

INTAKE MANIFOLD - LOWER

REMOVAL.............................61

INSPECTION..........................61

INSTALLATION.........................61

9 - 2 ENGINE 2.4LRS

ProCarManuals.com

Page 1204 of 2399

EXHAUST MANIFOLD

DESCRIPTION.........................62

OPERATION...........................62

REMOVAL.............................62

CLEANING............................62

INSPECTION..........................62

INSTALLATION.........................62

TIMING BELT COVER(S)

REMOVAL.............................63

INSTALLATION.........................63

TIMING BELT AND SPROCKET(S)

REMOVAL

REMOVAL - TIMING BELT...............64REMOVAL - CRANKSHAFT SPROCKET....66

CLEANING............................66

INSTALLATION

INSTALLATION - CRANKSHAFT SPROCKET . 66

INSTALLATION - TIMING BELT...........67

TIMING BELT TENSIONER & PULLEY

REMOVAL.............................68

INSTALLATION.........................69

BALANCE SHAFTS AND CARRIER ASSEMBLY

DESCRIPTION.........................69

OPERATION...........................70

REMOVAL.............................70

INSTALLATION.........................71

ENGINE 2.4L

DESCRIPTION

The 2.4 Liter (148 cu. in.) in-line four cylinder

engine is a double over head camshaft with hydraulic

lash adjusters and four valve per cylinder design.

The engine is free-wheeling; meaning it has provi-

sions for piston-to-valve clearance. However valve-to-

valve interference can occur, if camshafts are rotated

independently.

The cylinders are numbered from front of the

engine to the rear. The firing order is 1±3±4±2.

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Hydraulic Lash Adjuster Noise Diagnosis

²Engine Oil Leak Inspection

Fig. 1 Engine Identification

1 - ENGINE IDENTIFICATION LOCATION

RSENGINE 2.4L9-3

ProCarManuals.com

Page 1207 of 2399

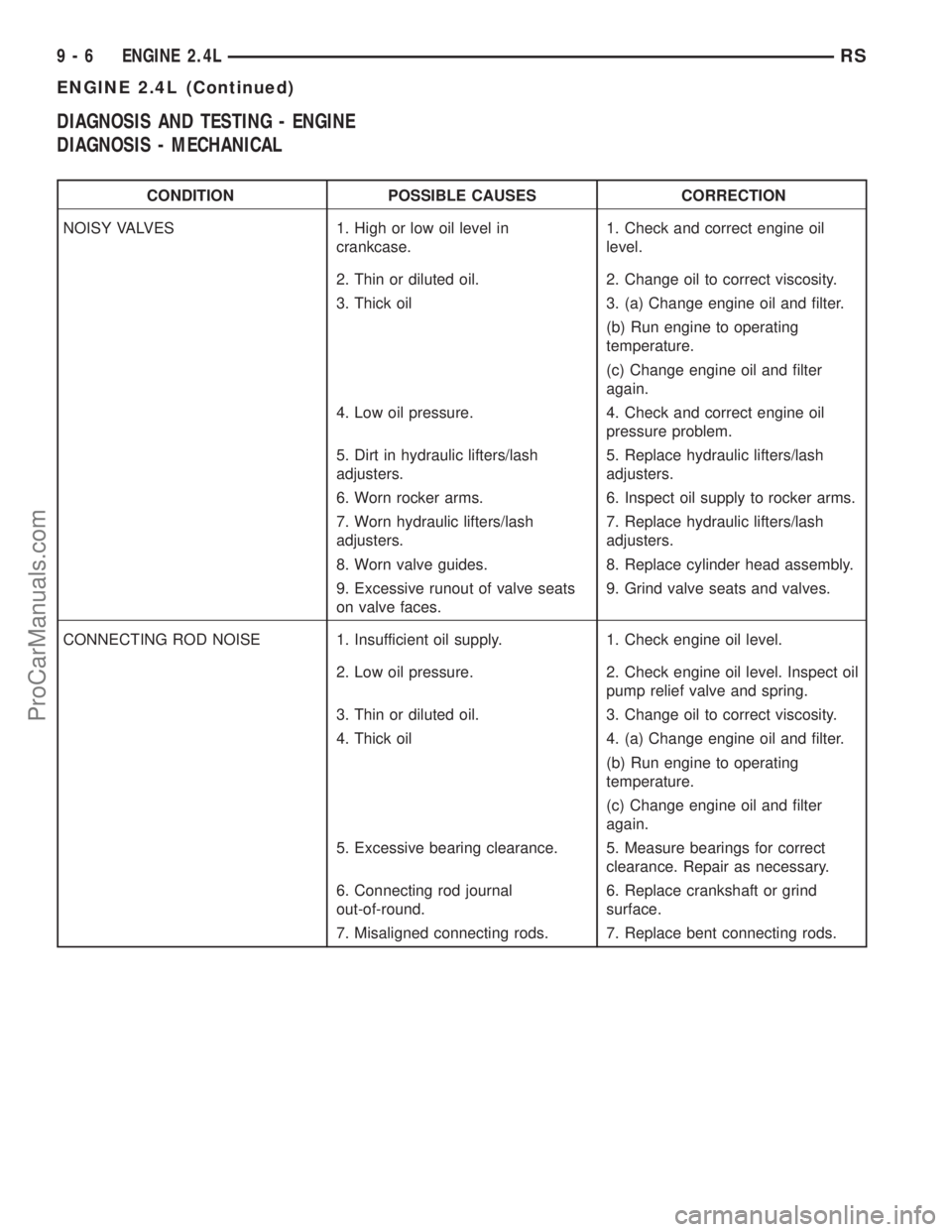

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

pressure problem.

5. Dirt in hydraulic lifters/lash

adjusters.5. Replace hydraulic lifters/lash

adjusters.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn hydraulic lifters/lash

adjusters.7. Replace hydraulic lifters/lash

adjusters.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

9 - 6 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com