coolant level CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 166 of 2399

(3) Install the four chassis brake tubes into the

outlet ports of the junction block. Tighten all 6 tube

nuts to a torque of 17 N´m (145 in. lbs.).

(4) If the vehicle is equipped with speed control,

perform the following:

(a) Install the speed control servo with its

mounting nuts.

(b) Connect the wiring harness to the speed con-

trol servo.

(c) Install the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION).

(d) Install the screw securing the coolant filler

neck to the battery tray.

(e) Reconnect the vacuum hose connector at the

tank built into the battery tray.

(f) Install the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION).

(g) Install the battery shield.

(5) Remove the brake pedal holder.

(6) Connect negative cable back on negative post of

the battery.

(7) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(8) Road test the vehicle to verify proper operation

of the brake system.

MASTER CYLINDER

DESCRIPTION

DESCRIPTION

The master cylinder is located on the power brake

booster in the engine compartment on the driver's

side (Fig. 54). This vehicle uses 3 different master

cylinders. Master cylinder usage depends on what

type of brake system the vehicle is equipped with.

CAUTION: Master cylinders are not interchangeable

between systems. Performance and stopping dis-

tance issues will result if the incorrect master cyl-

inder is installed on the vehicle.

For information on master cylinder application,

bore and type, view the following table:

BRAKE SYSTEMMASTER CYLINDER

BORE/TYPE

Disc/Drum - ABS23.8 mm (15/16 in.)

Conventional

Compensating Port

Disc/Drum - Non-ABS23.8 mm (15/16 in.)

Conventional

Compensating Port

Disc/Disc - ABS27.0 mm (1-1/16 in.)

Conventional

Compensating Port

Disc/Disc ABS With

Traction Control27.0 mm (1-1/16 in.) Dual

Center Port

CAUTION: When replacing a master cylinder, be

sure to use the correct master cylinder for the type

of brake system the vehicle is equipped with.

The body of the master cylinder is an anodized alu-

minum casting. It has a machined bore to accept the

master cylinder pistons and threaded ports with

seats for the hydraulic brake line connections.

The brake fluid reservoir is mounted on the top of

the master cylinder. It is made of a see-through

polypropylene type plastic for easy fluid level view-

ing. A brake fluid level switch is attached to the

brake fluid reservoir.

The master cylinder is not a repairable component

and must be replaced if diagnosed to be functioning

improperly. The brake fluid reservoir and brake fluid

level switch can be replaced separately.

Fig. 54 Master Cylinder And Booster Location

1 - MASTER CYLINDER

2 - POWER BRAKE BOOSTER

RSBRAKES - BASE5-37

JUNCTION BLOCK (Continued)

ProCarManuals.com

Page 179 of 2399

(4) Using vacuum line pliers, close off the vacuum

supply hose near the booster, but before the vacuum

gauge, then observe the vacuum gauge.

If the vacuum drop exceeds 1.0 inch Hg (3.3 kPa)

in one minute, repeat the above steps to confirm the

reading. The vacuum loss should be less than 1.0

inch Hg in one minute time span. If the loss is more

than 1.0 inch Hg, replace the power brake booster. If

it is not, continue on with this test.

(5) Remove the pliers from the hose temporarily.

(6) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary.

(7) Have an assistant reattach the vacuum line

pliers to the vacuum supply hose.

(8) Allow 5 seconds for stabilization, then observe

the vacuum gauge.

If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective.

(9) Remove the pliers and vacuum gauge.

REMOVAL

REMOVAL - LHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

(6) Remove screw securing engine coolant filler

tube to battery tray.

(7) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray.

(8) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray.

(9) If vehicle is equipped with speed control:(a) Disconnect wiring harness connector from

the speed control servo.

(b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(10) Remove the wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL)

(11) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 77).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(12) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

(13) Disconnect primary and secondary brake

tubes from ABS integrated control unit or non-ABS

junction block (Fig. 78). Install sealing plugs in the

now open brake tube ports and install caps on ends

of tubes.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(14) Remove two nuts attaching master cylinder to

power brake booster (Fig. 78).

Fig. 77 Master Cylinder And Booster

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

5 - 50 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 181 of 2399

REMOVAL - RHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4 or 5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

(6) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray.

(7) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray.

(8) If vehicle is equipped with speed control:

(a) Disconnect wiring harness connector from

the speed control servo.

(b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(9) If the vehicle is equipped with the 2.5L diesel

engine, remove the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

REMOVAL)

(10) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 82).CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(11) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the booster.

(12) Remove two nuts attaching master cylinder to

power brake booster (Fig. 83).

(13) Slide master cylinder straight out of power

brake booster. Lay master cylinder with primary and

secondary tubes to the side, out of the way.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(14) Disconnect vacuum hose from check valve

located on booster.DO NOT REMOVE CHECK

VALVE FROM POWER BRAKE BOOSTER.

(15) Under the instrument panel, remove booster

input rod trim cover.

(16) Locate the booster input rod to brake pedal

torque shaft connection under the instrument panel.

Fig. 81 Booster Removal/InstallationFig. 82 RHD Master Cylinder And Power Brake

Booster

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

5 - 52 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 184 of 2399

(12) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 77).

(13) Connect primary and secondary brake tubes

to ABS ICU or non-ABS junction block (Fig. 78).

Tighten the tube nuts to 17 N´m (145 in lbs.).

(14) Install wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(15) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(16) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(17) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(18) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing. Securely tighten hose clamp at air cleaner hous-

ing and throttle body.

(19) Secure the engine coolant filler neck to the

battery tray with its mounting screw.

(20) Install the battery, clamp and mounting nut.

(21) Install the positive battery cable on the bat-

tery.

(22) Install the negative battery cable on the bat-

tery.

(23) Install the battery thermal guard shield.

(24) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(25) Road test vehicle to ensure operation of the

brakes.

INSTALLATION - RHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 86).

(2) Below instrument panel, first install the two

upper nuts mounting the booster to the dash panel,

drawing it into place, then install the two lower

mounting nuts. Tighten the mounting nuts to a

torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod.

CAUTION: When installing the brake pedal torque

shaft pin on the power brake booster input rod, do

not re-use the old retaining clip.

(4) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 89).

(5) Install booster input rod trim cover.(6) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 90).

(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 83). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 82).

(12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION)

(13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

Fig. 89 Retaining Pin Installed On Brake Pedal Pin

(Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

RSBRAKES - BASE5-55

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 250 of 2399

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM........1

DESCRIPTION - HOSE CLAMPS...........1

OPERATION

OPERATION - COOLING SYSTEM.........2

OPERATION - HOSE CLAMPS............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAK TEST....................2

DIAGNOSIS AND TESTING - COOLING

SYSTEM FLOW CHECK.................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM AERATION....................4

DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION..................4

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING

SYSTEM DRAINING....................4STANDARD PROCEDURE - COOLING

SYSTEM FILLING......................4

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................4

STANDARD PROCEDURE - COOLANT

LEVEL CHECK........................5

SPECIFICATIONS

COOLING SYSTEM CAPACITY............6

ACCESSORY DRIVE BELT TENSION.......6

TORQUE.............................6

SPECIAL TOOLS

COOLING SYSTEM.....................7

ACCESSORY DRIVE.......................8

ENGINE...............................14

TRANSMISSION.........................38

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

The cooling system components consist of a radia-

tor, electric fan motors, shroud, pressure cap, thermo-

stat, transmission oil cooler, water pump, hoses,

clamps, coolant, and a coolant reserve system to com-

plete the circuit.

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopartequipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 1).

Fig. 1 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RSCOOLING7-1

ProCarManuals.com

Page 251 of 2399

OPERATION

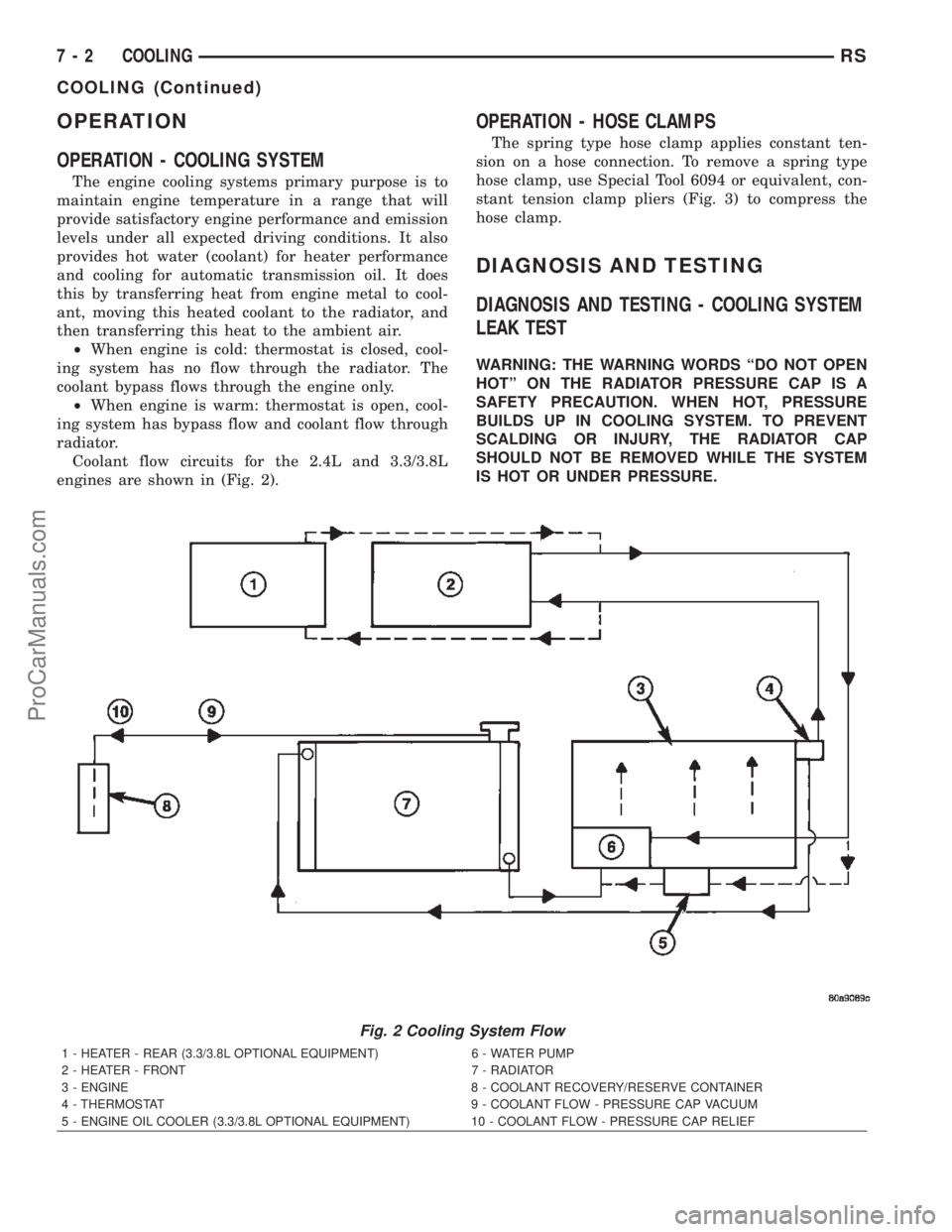

OPERATION - COOLING SYSTEM

The engine cooling systems primary purpose is to

maintain engine temperature in a range that will

provide satisfactory engine performance and emission

levels under all expected driving conditions. It also

provides hot water (coolant) for heater performance

and cooling for automatic transmission oil. It does

this by transferring heat from engine metal to cool-

ant, moving this heated coolant to the radiator, and

then transferring this heat to the ambient air.

²When engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²When engine is warm: thermostat is open, cool-

ing system has bypass flow and coolant flow through

radiator.

Coolant flow circuits for the 2.4L and 3.3/3.8L

engines are shown in (Fig. 2).

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, use Special Tool 6094 or equivalent, con-

stant tension clamp pliers (Fig. 3) to compress the

hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAK TEST

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

Fig. 2 Cooling System Flow

1 - HEATER - REAR (3.3/3.8L OPTIONAL EQUIPMENT) 6 - WATER PUMP

2 - HEATER - FRONT 7 - RADIATOR

3 - ENGINE 8 - COOLANT RECOVERY/RESERVE CONTAINER

4 - THERMOSTAT 9 - COOLANT FLOW - PRESSURE CAP VACUUM

5 - ENGINE OIL COOLER (3.3/3.8L OPTIONAL EQUIPMENT) 10 - COOLANT FLOW - PRESSURE CAP RELIEF

7 - 2 COOLINGRS

COOLING (Continued)

ProCarManuals.com

Page 253 of 2399

DIAGNOSIS AND TESTING - COOLING SYSTEM

AERATION

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

at running and at operating temperature, the high

pressure inlet tank runs full and the low pressure

outlet tank drops, resulting in cooling system aera-

tion. Aeration will draw air into the water pump

resulting in the following:

²High reading shown on the temperature gauge.

²Loss of coolant flow through the heater core.

²Corrosion in the cooling system.

²Water pump seal may run dry, increasing the

risk of premature seal failure.

²Combustion gas leaks into the coolant can also

cause the above problems.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the coolant

recovery bottle by thermal expansion of the coolant.

It then escapes to the atmosphere in the coolant

recovery bottle and is replaced with coolant on cool

down.

To effectively deaerate the system, multiple ther-

mal cycles of the system may be required.

NOTE: Deaeration does not occur at engine idleÐ

higher engine speeds are required. Normal driving

will deaerate cooling system.

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE CAP, CYLINDER BLOCK

DRAIN PLUGS, OR THE DRAINCOCK WHEN THE

SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

(1)Without removing radiator pressure cap

and with system not under pressure, open the

draincock. The draincock is located on the lower left

side of radiator (Fig. 5).

(2) After the coolant recovery/reserve container is

empty, then remove coolant pressure cap (Fig. 6).

(3) Remove the cylinder block drain plug(s).

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

Remove radiator pressure cap (Fig. 6) and fill sys-

tem, using a 50/50 mix of MopartAntifreeze/Coolant,

5 Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

Fill coolant recovery/reserve container (Fig. 6) to at

least the MAX mark with 50/50 solution. It may be

necessary to add coolant to the recovery/reserve con-

tainer after three or four warm up/cool down cycles

to maintain coolant level between the MAX and MIN

mark. This will allow trapped air to be removed from

the system.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant recovery/re-

serve container (Fig. 6). Use only 50/50 mix of ethyl-

ene glycol type antifreeze and distilled water. For the

recommeded antifreeze/coolant type (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

Fig. 5 Draincock Location

1 - LEFT SIDE FRAME RAIL

2 - DRAINCOCK

7 - 4 COOLINGRS

COOLING (Continued)

ProCarManuals.com

Page 254 of 2399

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the recovery/reserve container (Fig. 7). The

coolant level should be between the MIN and MAX

marks.

Fig. 6 Cooling System Service Locations

1 - COOLANT RECOVERY CONTAINER 3 - ENGINE OIL LEVEL DIPSTICK

2 - ENGINE OIL FILL CAP 4 - RADIATOR PRESSURE CAP

Fig. 7 Coolant Recovery Container

RSCOOLING7-5

COOLING (Continued)

ProCarManuals.com

Page 264 of 2399

ENGINE

DIAGNOSIS AND TESTING - ENGINE COOLING

SYSTEM

Establish what driving condition caused the cooling

system complaint. The problem may be caused by an

abnormal load on the system such as the following:

prolonged idle, very high ambient temperature, slight

tail wind at idle, slow traffic speed, traffic jam, high

speed, steep grade.

DRIVING TECHNIQUES

To avoid overheating the cooling system:

(1) Idle with A/C off when temperature gauge is at

end of normal range.

(2) Do not increase engine speed for more air flow

and coolant flow because the electric motor fan sys-

tems are not responsive to engine RPM. The added

cooling from higher coolant flow rate is more than

offset by increased heat rejection (engine heat added

to coolant).

TRAILER TOWING

Consult the owner's manual under Trailer Towing

and do not exceed specified limits.

VISUAL INSPECTION

If the cooling system problem is not caused by a

driving condition, perform a visual inspection to

determine if there was a recent service or accident

repair, including the following:

²Loose/damaged water pump drive belt

²Incorrect cooling system refilling (trapped air or

low level)

²Brakes possibly dragging

²Damaged hoses

²Loose/damaged hose clamps

²Damaged/incorrect engine thermostat

²Damaged cooling fan motor, fan blade and fan

shroud

²Damaged head gasket

²Damaged water pump

²Damaged radiator

²Damaged coolant recovery system

²Damaged heater core

²Open/shorted electrical circuits

If the visual inspection reveals none of the above

as cause for a cooling system complaint, refer to the

following diagnostic charts.

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.1. Check condition of radiator cap

and cap seal. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING) Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING)

RSENGINE7-15

ProCarManuals.com

Page 265 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

DETONATION OR PRE-IGNITION

(NOT CAUSED BY IGNITION

SYSTEM). GAUGE MAY NOT BE

READING HIGH.1. Engine overheating. 1. Check reason for overheating

and repair as necessary.

2. Freeze point of coolant not

correct. Mixture too concentrated or

too diluted.2. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

3. Incorrect cooling system

pressure cap.3. Install correct pressure cap.

HOSE(S) COLLAPSE AS ENGINE

COOLS DOWN.1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

recovery system.1. (a) Pressure cap relief valve

stuck. (Refer to 7 - COOLING/

ENGINE/RADIATOR PRESSURE

CAP - DIAGNOSIS AND TESTING)

Replace as necessary.

(b) Hose between the radiator and

overflow container is plugged or

pinched. Clean and repair as

necessary.

(c) Vent at coolant reserve/overflow

container is plugged. Clean vent

and repair as necessary.

(d) Reserve/overflow container is

internally blocked. Clean and repair

as necessary.

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED).1. Radiator and/or A/C condenser is

restricted, obstructed, or dirty

(insects, leaves, etc.).1. Remove restriction and/or clean

as necessary.

2. Electrical radiator fan not

operating when A/C is operated.2. For test procedure (Refer to

appropriate Diagnostic Information).

Repair as necessary.

3. Engine is overheating (heat may

be transferred from radiator to A/C

condenser). High underhood

temperatures due to engine

overheating may also transfer heat

to A/C components.3. Correct overheating condition.

4. All models are equipped with air

seals at the radiator and/or A/C

condenser. If these seals are

missing or damaged, not enough

air flow will be pulled through the

radiator and A/C condenser.4. Check for missing or damaged air

seals and repair as necessary.

INADEQUATE HEATER

PERFORMANCE.1. Check for a Diagnostic trouble

code (DTC).1. For procedures, (Refer to

appropriate Diagnostic Information).

Repair as necessary.

2. Coolant level low. 2. (Refer to 7 - COOLING -

STANDARD PROCEDURE) Repair

as necessary.

7 - 16 ENGINERS

ENGINE (Continued)

ProCarManuals.com