ECU CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1860 of 2399

(4) Verify that all retainers are installed as shown

in (Fig. 371). Retainers should be flush or below

valve body surface.

(5) Install check balls into position as shown in

(Fig. 372). If necessary, secure them with petrolatum

or transmission assembly gel for assembly ease.

Fig. 372 Ball Check Location

1 - (#4) BALL CHECK LOCATION

2 - (#2) BALL CHECK LOCATION

3 - RETAINER

4 - (#3) BALL CHECK LOCATION5 - LOW/REVERSE SWITCH VALVE

6 - T/C LIMIT VALVE

Fig. 371 Valve Retainer Location

1 - RETAINER

2 - RETAINER

RS41TE AUTOMATIC TRANSAXLE21 - 303

VALVE BODY (Continued)

ProCarManuals.com

Page 1875 of 2399

DIAGNOSIS AND TESTING - COMMON

PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

²Improper operation

HARD SHIFTING

Hard shifting may be caused by a misadjusted

crossover cable. If hard shifting is accompanied by

gear clash, synchronizer clutch and stop rings or gear

teeth may be worn or damaged.

Hard shifting may also be caused by a binding or

broken shift cover mechanism. Remove shift cover

and verify smooth operation. Replace as necessary.

Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, keys, balls, or springs can cause shift prob-

lems.

NOISY OPERATION

Transaxle noise is most often a result of worn or

damaged components. Chipped, broken gear or syn-

chronizer teeth, and brinnelled, spalled bearings all

cause noise.

Abnormal wear and damage to the internal compo-

nents is frequently the end result of insufficient

lubricant.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, or worn teeth

on the drive gears or synchronizer components. Incor-

rect assembly also causes gear disengagement. Check

for missing snap rings.

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

REMOVAL

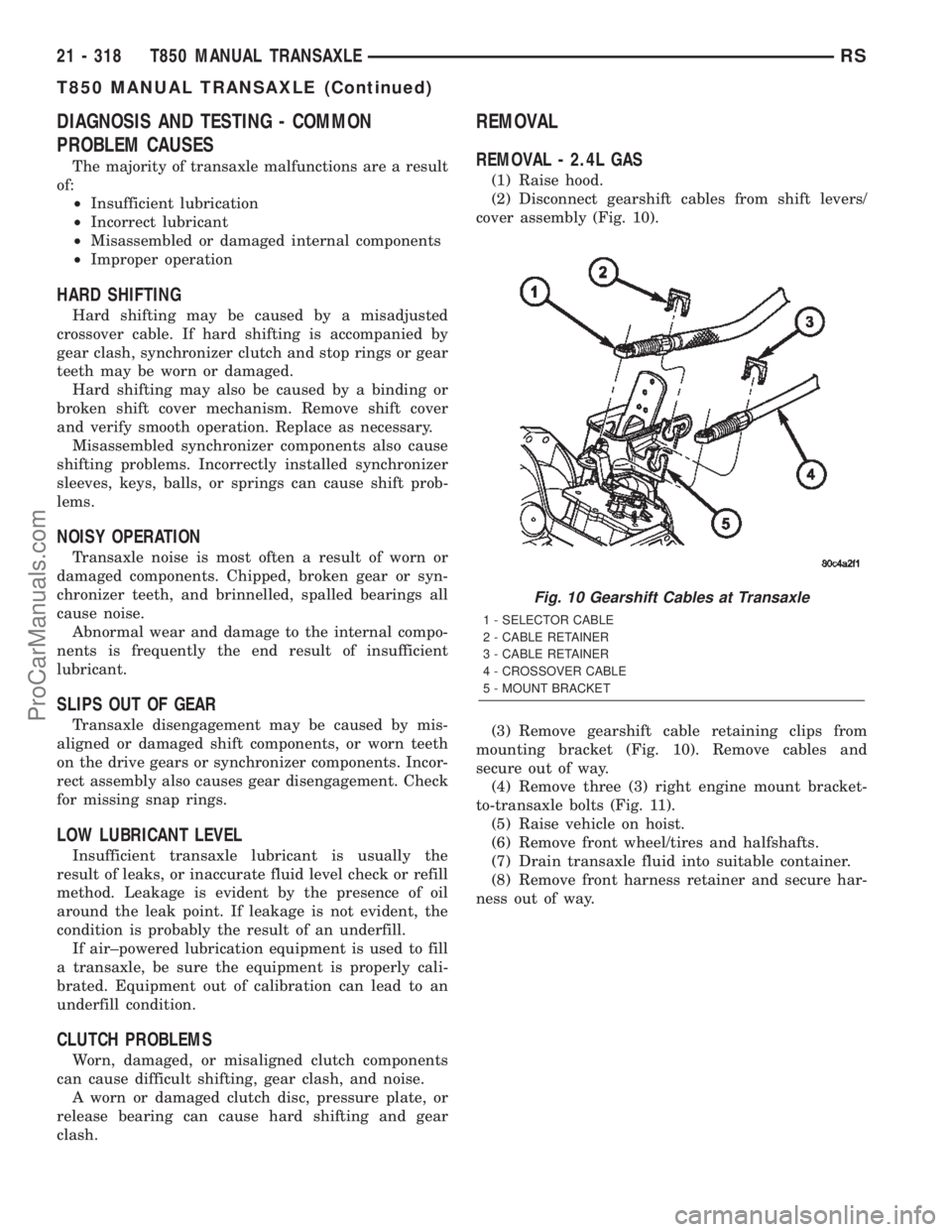

REMOVAL - 2.4L GAS

(1) Raise hood.

(2) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 10).

(3) Remove gearshift cable retaining clips from

mounting bracket (Fig. 10). Remove cables and

secure out of way.

(4) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 11).

(5) Raise vehicle on hoist.

(6) Remove front wheel/tires and halfshafts.

(7) Drain transaxle fluid into suitable container.

(8) Remove front harness retainer and secure har-

ness out of way.

Fig. 10 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

21 - 318 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1877 of 2399

(18) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 14).

(19) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(20) Remove transaxle from engine.

(21) Inspect modular clutch assembly, clutch

release components, and engine drive plate.

REMOVAL - 2.5L TD

(1) Raise hood.

(2) Disconnect both battery cables.

(3) Remove battery thermal shield (Fig. 15).

(4) Remove battery hold down bolt, clamp, and

battery (Fig. 16).

Fig. 14 Transaxle Upper Mount

1 - MOUNT

2 - BOLT (4)

Fig. 15 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 16 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

21 - 320 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1878 of 2399

(5) Remove battery tray (Fig. 17). Disconnect bat-

tery temperature sensor.

(6) Remove coolant recovery bottle from bracket.

(7) Remove coolant recovery bottle mounting

bracket (Fig. 18).

(8) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 19).

(9) Remove gearshift cable retaining clips from

mounting bracket (Fig. 19). Remove cables and

secure out of way.(10) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 20).

Fig. 17 Battery Tray

1 - BATTERY TRAY

Fig. 18 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 19 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 20 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

RST850 MANUAL TRANSAXLE21 - 321

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1879 of 2399

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove front harness retainer and secure

harness out of way.

(16) Using Tool 6638A, disconnect clutch hydrau-

lic circuit quick connect (located on slave cylinder

tube). Remove clutch slave cylinder by depressing

towards case and rotating counter-clockwise 60É,

while lifting anti-rotation tab out of case slot with

screwdriver (Fig. 21).

(17) Remove engine left mount bracket (Fig. 22).

(18) Remove starter motor (Fig. 23).

(19) Disconnect back-up lamp switch connector.

(20) Position screw jack and wood block to engine

oil pan.

(21) Remove transmission upper mount through-

bolt from left frame rail.

(22) Lower engine/transaxle assembly on screw

jack.

Fig. 21 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 22 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

Fig. 23 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

21 - 322 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1880 of 2399

(23) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 24).

(24) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(25) Remove transaxle from engine (Fig. 25).

(26) Inspect clutch, clutch release components, and

flywheel.DISASSEMBLY

(1) Remove clutch release lever and bearing (Fig.

26). Inspect release lever pivot balls and replace if

necessary (Fig. 27). Use slide hammer C-3752 and

remover/installer 6891 (Fig. 28) if pivot ball replace-

ment is necessary.

Fig. 25 Transaxle Removal/Installation

1 - TRANSAXLE

2 - BOLT

Fig. 24 Transaxle Upper Mount

1 - MOUNT

2 - BOLT (4)

Fig. 26 Release Bearing and Lever

1 - RELEASE LEVER

2 - RELEASE BEARING

RST850 MANUAL TRANSAXLE21 - 323

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1896 of 2399

(11) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(12) Lower vehicle.

(13) Install right mount bracket to transaxle (Fig.

80).

(14) Connect gearshift cables to shift levers/cover

assembly (Fig. 81). Install cables into position at

mount bracket and secure with retaining clips.

(15) Connect battery cables.

(16) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

Fig. 80 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

Fig. 81 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

RST850 MANUAL TRANSAXLE21 - 339

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1899 of 2399

(14) Connect gearshift cables to shift levers/cover

assembly (Fig. 87). Install cables into position at

mount bracket and secure with retaining clips.

(15) Install coolant recovery bottle bracket (Fig.

88).(16) Install coolant recovery bottle to bracket.

(17) Connect battery temperature sensor and

install battery tray (Fig. 89).

(18) Install battery, hold-down clamp and nut (Fig.

90).

Fig. 87 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 88 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 89 Battery Tray

1 - BATTERY TRAY

Fig. 90 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

21 - 342 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1917 of 2399

(2) Remove gearshift boot from center console by

disengaging three (3) retaining clips (Fig. 130).

INSTALLATION

(1) Install gearshift boot to console and secure

with three (3) retaining clips (Fig. 130).

(2) Install gearshift knob (Fig. 129). Orient shift

pattern

1¤4-turn clockwise, press down, and rotate1¤4-

turn counter-clockwise.

(3) Secure gearshift boot to base of knob.

GEARSHIFT CABLE -

CROSSOVER

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating

1¤4-turn clock-wise (Fig. 131).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 132).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

Fig. 130 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 131 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 132 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

21 - 360 T850 MANUAL TRANSAXLERS

GEARSHIFT BOOT (Continued)

ProCarManuals.com

Page 1920 of 2399

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 141).

(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 142).

(16) Remove crossover cable retainer clip and dis-

engage cable from mount bracket (Fig. 142).(17) Raise vehicle on hoist.

(18) Remove crossover cable from engine compart-

ment, then remove cable from passenger compart-

ment through opening in floor pan.

INSTALLATION

(1) From underneath vehicle, install gearshift

crossover cable into passenger compartment through

floor pan hole. Install remainder of cable into posi-

tion in engine compartment.

(2) Lower vehicle.

(3) Install crossover cable to mount bracket and

secure with retainer clip (Fig. 143).

(4) Install cable to transaxle crossover lever (Fig.

143).

Fig. 141 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 142 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 143 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

RST850 MANUAL TRANSAXLE21 - 363

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com