warning CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 6 of 2399

FASTENER USAGE

DESCRIPTION

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

DESCRIPTION - THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

INTERNATIONAL SYMBOLS

DESCRIPTION

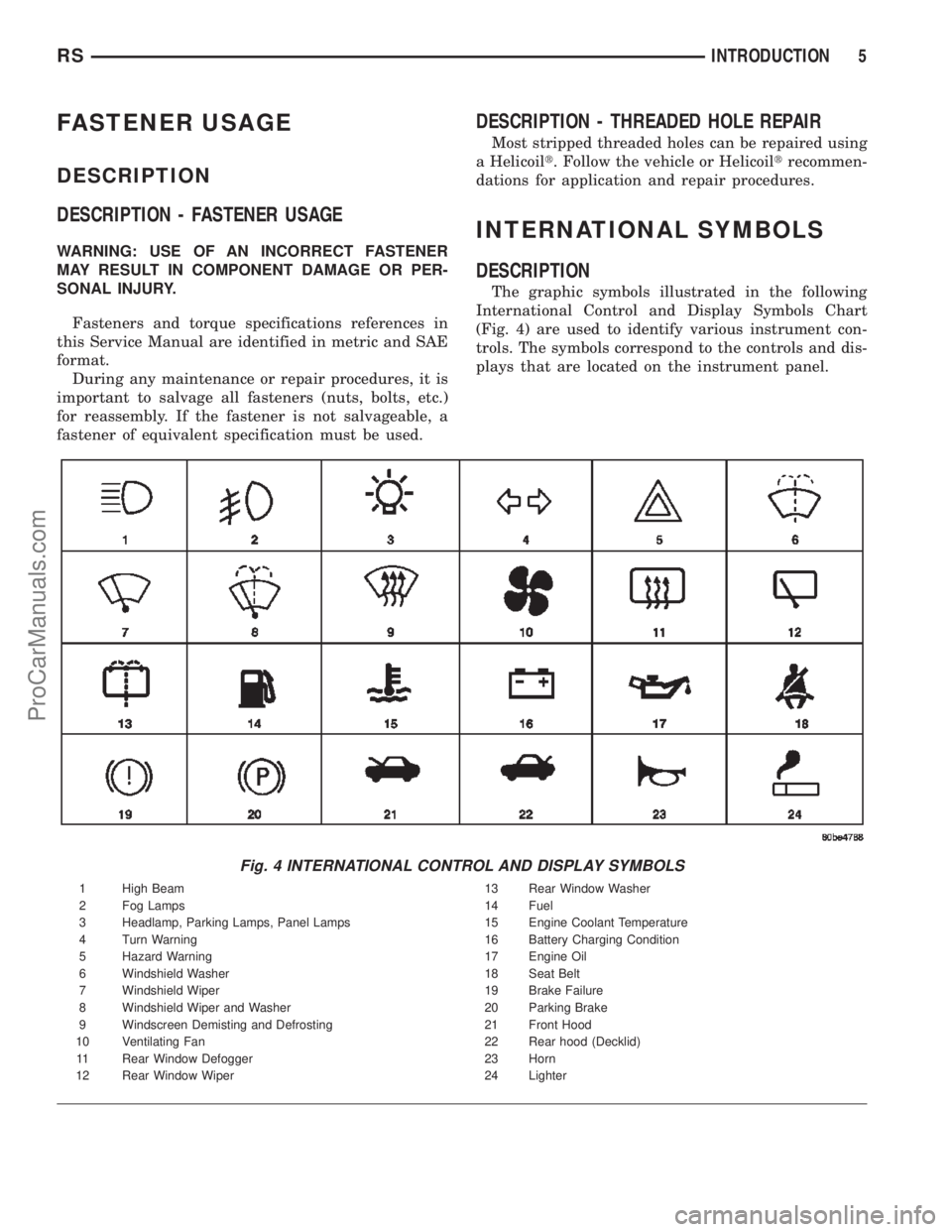

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 4) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 4 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

ProCarManuals.com

Page 15 of 2399

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 1).

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND LUBRICANTS

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopartprovides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

Only lubricants bearing designations defined by

the following organization should be used.

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API)

²National Lubricating Grease Institute (NLGI)

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Certified. MOPARt

provides engine oils, that meet or exceed this

requirement.

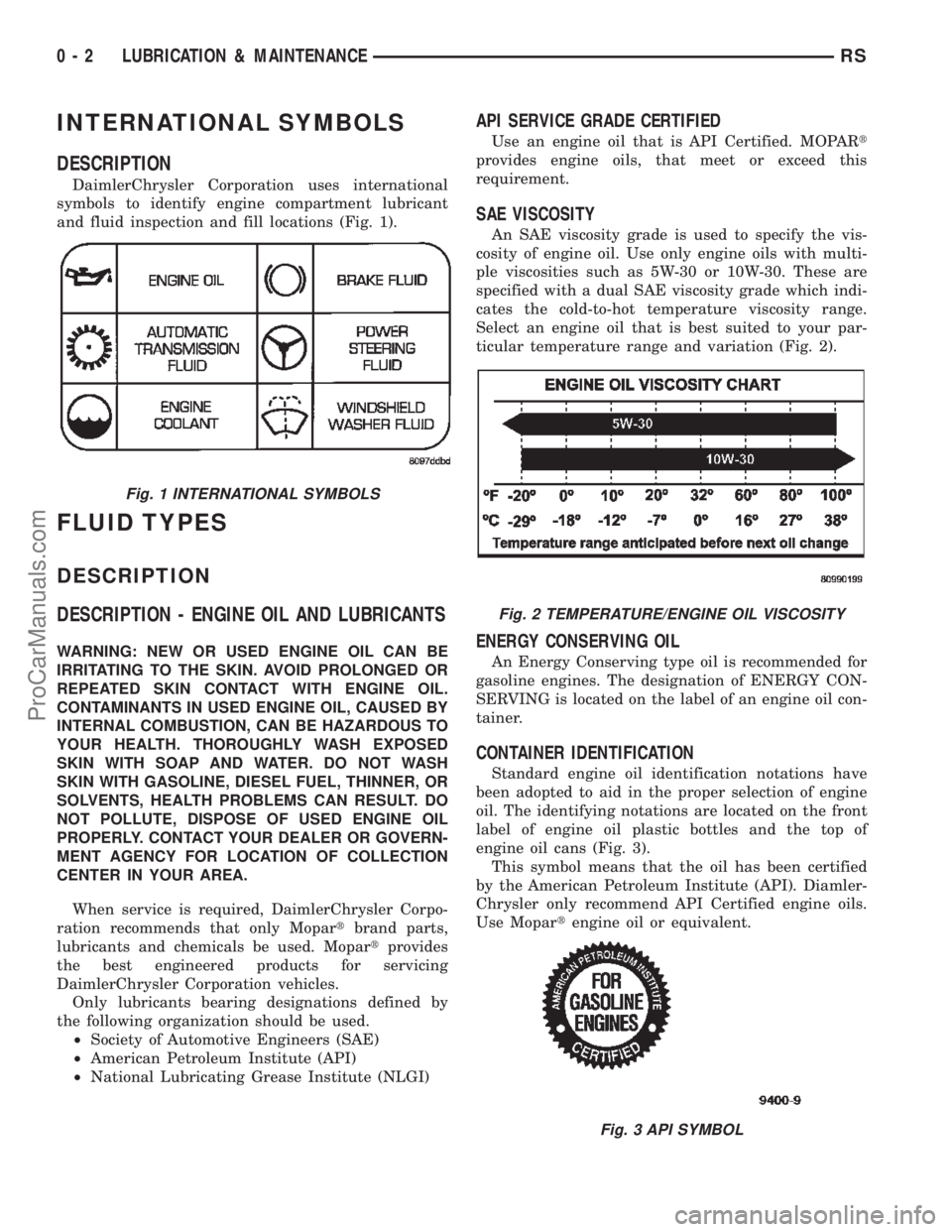

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 2).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

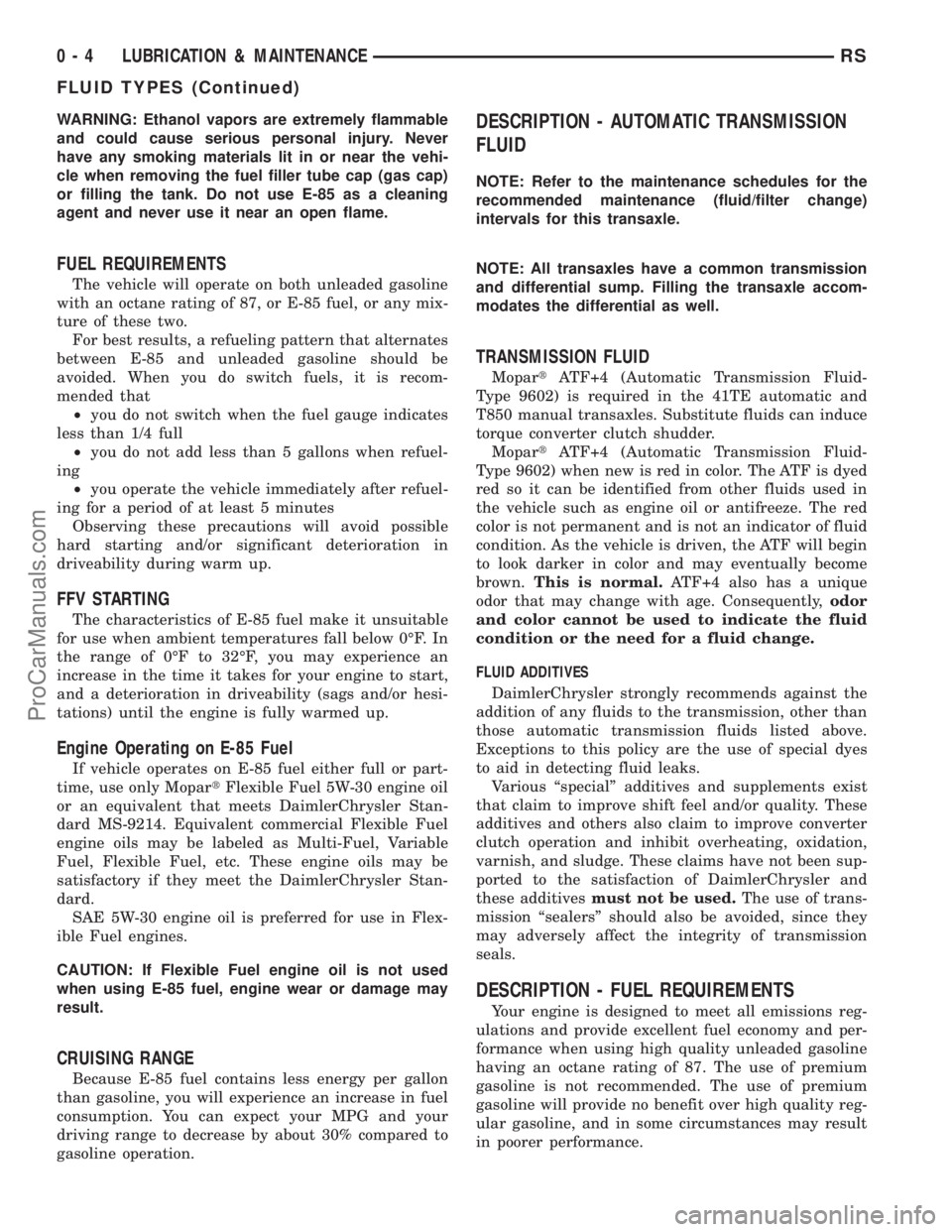

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the front

label of engine oil plastic bottles and the top of

engine oil cans (Fig. 3).

This symbol means that the oil has been certified

by the American Petroleum Institute (API). Diamler-

Chrysler only recommend API Certified engine oils.

Use Mopartengine oil or equivalent.

Fig. 1 INTERNATIONAL SYMBOLS

Fig. 2 TEMPERATURE/ENGINE OIL VISCOSITY

Fig. 3 API SYMBOL

0 - 2 LUBRICATION & MAINTENANCERS

ProCarManuals.com

Page 16 of 2399

GEAR LUBRICANTS

SAE ratings also apply to multigrade gear lubri-

cants. In addition, API classification defines the

lubricants usage. Such as API GL-5 and SAE 75W-

90.

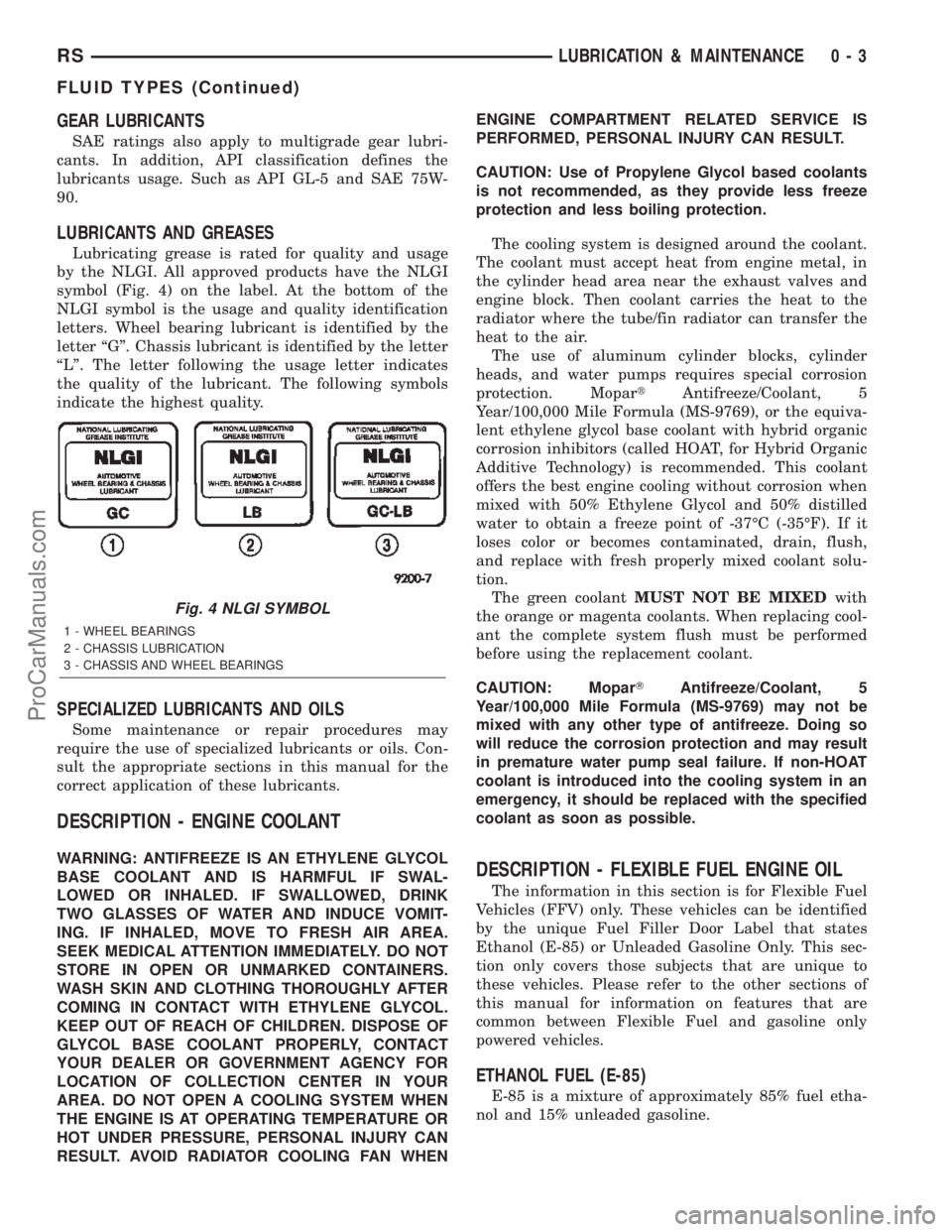

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 4) on the label. At the bottom of the

NLGI symbol is the usage and quality identification

letters. Wheel bearing lubricant is identified by the

letter ªGº. Chassis lubricant is identified by the letter

ªLº. The letter following the usage letter indicates

the quality of the lubricant. The following symbols

indicate the highest quality.

SPECIALIZED LUBRICANTS AND OILS

Some maintenance or repair procedures may

require the use of specialized lubricants or oils. Con-

sult the appropriate sections in this manual for the

correct application of these lubricants.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHENENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.DESCRIPTION - FLEXIBLE FUEL ENGINE OIL

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

Fig. 4 NLGI SYMBOL

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RSLUBRICATION & MAINTENANCE0-3

FLUID TYPES (Continued)

ProCarManuals.com

Page 17 of 2399

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

FUEL REQUIREMENTS

The vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

For best results, a refueling pattern that alternates

between E-85 and unleaded gasoline should be

avoided. When you do switch fuels, it is recom-

mended that

²you do not switch when the fuel gauge indicates

less than 1/4 full

²you do not add less than 5 gallons when refuel-

ing

²you operate the vehicle immediately after refuel-

ing for a period of at least 5 minutes

Observing these precautions will avoid possible

hard starting and/or significant deterioration in

driveability during warm up.

FFV STARTING

The characteristics of E-85 fuel make it unsuitable

for use when ambient temperatures fall below 0ÉF. In

the range of 0ÉF to 32ÉF, you may experience an

increase in the time it takes for your engine to start,

and a deterioration in driveability (sags and/or hesi-

tations) until the engine is fully warmed up.

Engine Operating on E-85 Fuel

If vehicle operates on E-85 fuel either full or part-

time, use only MopartFlexible Fuel 5W-30 engine oil

or an equivalent that meets DaimlerChrysler Stan-

dard MS-9214. Equivalent commercial Flexible Fuel

engine oils may be labeled as Multi-Fuel, Variable

Fuel, Flexible Fuel, etc. These engine oils may be

satisfactory if they meet the DaimlerChrysler Stan-

dard.

SAE 5W-30 engine oil is preferred for use in Flex-

ible Fuel engines.

CAUTION: If Flexible Fuel engine oil is not used

when using E-85 fuel, engine wear or damage may

result.

CRUISING RANGE

Because E-85 fuel contains less energy per gallon

than gasoline, you will experience an increase in fuel

consumption. You can expect your MPG and your

driving range to decrease by about 30% compared to

gasoline operation.

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules for the

recommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: All transaxles have a common transmission

and differential sump. Filling the transaxle accom-

modates the differential as well.

TRANSMISSION FLUID

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) is required in the 41TE automatic and

T850 manual transaxles. Substitute fluids can induce

torque converter clutch shudder.

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown.This is normal.ATF+4 also has a unique

odor that may change with age. Consequently,odor

and color cannot be used to indicate the fluid

condition or the need for a fluid change.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

DESCRIPTION - FUEL REQUIREMENTS

Your engine is designed to meet all emissions reg-

ulations and provide excellent fuel economy and per-

formance when using high quality unleaded gasoline

having an octane rating of 87. The use of premium

gasoline is not recommended. The use of premium

gasoline will provide no benefit over high quality reg-

ular gasoline, and in some circumstances may result

in poorer performance.

0 - 4 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

ProCarManuals.com

Page 19 of 2399

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of

DaimlerChrysler Corporation and may not be covered

under the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

WARNING: DO NOT USE ALCOHOL OR GASOLINE

AS A FUEL BLENDING AGENT. THEY CAN BE

UNSTABLE UNDER CERTAIN CONDITIONS AND

HAZARDOUS OR EXPLOSIVE WHEN MIXED WITH

DIESEL FUEL.

Use good quality diesel fuel from a reputable sup-

plier. For most year-round service, number 2 diesel

fuel meeting ASTM specification D-975 will provide

good performance. If the vehicle is exposed to

extreme cold (below -18ÉC/0ÉF) or is required to oper-

ate at colder than normal conditions for prolonged

periods, use climatize No. 2 diesel fuel or dilute the

No. 2 diesel fuel with 50% No. 1 diesel fuel. This will

provide better protection from fuel gelling or wax

plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good quality fuel and fol-

low the cold weather advice above, fuel conditioners

should not be required in your vehicle. If available in

your area, a high cetane ªpremiumº diesel fuel may

offer improved cold starting and warm up perfor-

mance.

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationCD or higherorCCML

D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is

recommended that SAE Grade 10W-40 engine oilsthat meet Chrysler material standard MS-6395, be

used. European Grade 10W-40 oils are also accept-

able.

Oils of the SAE 5W-40 or 8W-80 grade number are

preferred when minimum temperatures consistently

fall below -12ÉC.

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill point locations are located in

each applicable service manual section.

LUBRICATION POINTS

DESCRIPTION

Lubrication point locations are located in each

applicable Sections.

MAINTENANCE SCHEDULES

DESCRIPTION

9Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.9

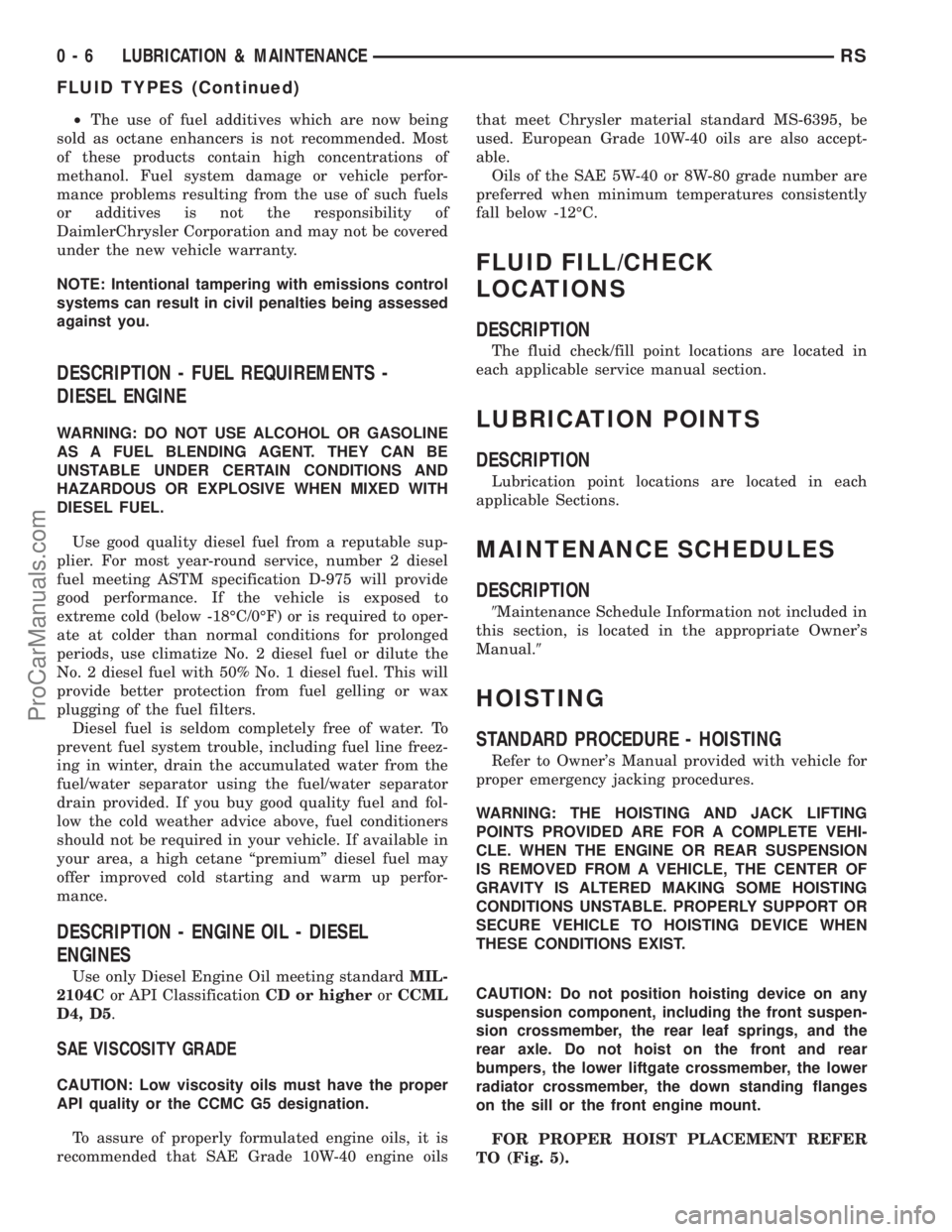

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 5).

0 - 6 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

ProCarManuals.com

Page 20 of 2399

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 5). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250 mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS. (Refer to 8 - ELECTRICAL/BAT-

TERY SYSTEM/BATTERY - STANDARD PROCE-

DURE).

WARNING: DO NOT JUMP START A FROZEN BAT-

TERY, PERSONAL INJURY CAN RESULT.

WARNING: DO NOT JUMP START WHEN MAINTE-

NANCE FREE BATTERY INDICATOR DOT IS BRIGHT

COLOR.

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERY

WARNING: REMOVE METALLIC JEWELRY WORN

ON HANDS OR WRISTS TO AVOID INJURY BY

ACCIDENTAL ARCING OF BATTERY CURRENT.

WARNING: WHEN USING A HIGH OUTPUT BOOST-

ING DEVICE, DO NOT ALLOW BATTERY VOLTAGE

TO EXCEED 16 VOLTS.

WARNING: REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: DO NOT ATTEMPT TO PUSH OR TOW

THE VEHICLE TO START IT. THE VEHICLE CANNOT

BE STARTED THIS WAY. PUSHING WITH ANOTHER

VEHICLE MAY DAMAGE THE TRANSAXLE OR THE

REAR OF THE VEHICLE.

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Clear or bright color test indicator, if equipped.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

Fig. 5 HOISTING AND JACKING POINTS

1- DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

2 - CHASSIS LIFT (NON-AXLE DUAL POST)

2 - OUTBOARD LIFT (DUAL POST)

2 - FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

RSLUBRICATION & MAINTENANCE0-7

HOISTING (Continued)

ProCarManuals.com

Page 21 of 2399

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter may over-

heat and could fail.

(7) If engine does not start within 15 seconds, stop

cranking engine and allow starter to cool (15 min-

utes), before cranking again.DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

Fig. 6 JUMPER CABLE CLAMP CONNECTIONS

1 - BATTERY NEGATIVE TERMINAL

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR (IF EQUIPPED)

4 - BATTERY POSITIVE TERMINAL

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

0 - 8 LUBRICATION & MAINTENANCERS

JUMP STARTING (Continued)

ProCarManuals.com

Page 43 of 2399

The coil spring controls ride quality and maintains

proper ride height.

The spring isolators isolate the coil spring at the

top and bottom from coming into metal-to-metal con-

tact with the upper seat and strut.

The jounce bumper limits suspension travel and

metal-to-metal contact under full jounce condition.

The strut dampens jounce and rebound motions of

the coil spring and suspension.

During steering maneuvers, the strut assembly

(through a pivot bearing in the upper strut mount)

and steering knuckle (through the lower ball joint)

turn as an assembly.

DIAGNOSIS AND TESTING - STRUT ASSEMBLY

(1) Inspect for damaged or broken coil springs

(Fig. 38).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 38).

(3) Inspect the coil spring isolator on the lower

spring seat for any signs of damage or deterioration.

(4) Lift dust boot (Fig. 39) and inspect strut

assembly for evidence of fluid running from the

upper end of fluid reservoir. (Actual leakage will be astream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage

between the strut rod and strut shaft seal is not

unusual and does not affect performance of the strut

assembly (Fig. 39). Also inspect jounce bumpers for

signs of damage or deterioration.

REMOVAL - STRUT ASSEMBLY

WARNING: DO NOT REMOVE THE NUT FROM THE

STRUT ROD WHILE STRUT ASSEMBLY IS

INSTALLED IN VEHICLE, OR BEFORE STRUT

ASSEMBLY SPRING IS COMPRESSED.

(1) Raise the vehicle. See Hoisting in Lubrication

and Maintenance.

(2) Remove the wheel and tire assembly from loca-

tion on front of vehicle requiring strut removal.

(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

(4) Remove the hydraulic brake hose routing

bracket and the speed sensor cable routing bracket

from the strut damper brackets (Fig. 40).

Fig. 38 STRUT ASSEMBLY

1 - NUT 6 - COIL SPRING

2 - UPPER MOUNT 7 - DUST SHIELD

3 - PIVOT BEARING 8 - JOUNCE BUMPER

4 - UPPER SPRING SEAT 9 - LOWER SPRING ISOLATOR

5 - UPPER SPRING ISOLATOR 10 - STRUT (DAMPER)

2 - 20 FRONT SUSPENSIONRS

STRUT (Continued)

ProCarManuals.com

Page 45 of 2399

(7) Remove the 3 nuts attaching the strut assem-

bly upper mount to the strut tower (Fig. 43) and

remove the strut assembly from the vehicle.

(8) To disassemble the strut assembly, (Refer to 2 -

SUSPENSION/FRONT/STRUT - DISASSEMBLY).

DISASSEMBLY - STRUT ASSEMBLY

The strut assembly must be removed from the

vehicle for it to be disassembled and assembled.

For the disassembly and assembly of the strut

assembly, use of Strut Spring Compressor, Pentastar

Service Equipment (PSE) tool W-7200, or the equiva-

lent, is recommended to compress the coil spring.

Follow the manufacturer's instructions closely.

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT BEFORE THE COIL SPRING IS COMPRESSED.

THE COIL SPRING IS HELD UNDER PRESSURE

AND MUST BE COMPRESSED, REMOVING SPRING

TENSION FROM THE UPPER MOUNT AND PIVOT

BEARING, BEFORE THE SHAFT NUT IS REMOVED.

(1) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions. Position the lower hooks on the coil

spring first. The strut clevis bracket should be posi-

tioned straight outward from the compressor.

(2) Turn the upper mount of the strut assembly

toward the inside of the compressor as shown to

allow positioning of the compressor upper hooks (Fig.

44). Position the upper hooks on top of the coil spring

upper seat approximately 1 inch from outside diame-

ter of seat (Fig. 47).Do not allow hooks to be

placed closer to edge.Place a clamp on the lowerend of the coil spring, so the strut is held in place

once the strut shaft nut is removed.

(3) Compress the coil spring until all coil spring

tension is removed from the upper mount.

(4) Install Strut Nut Socket, Special Tool 6864, on

the strut shaft retaining nut (Fig. 45). Next, install a

10 mm socket on the hex on the end of the strut

shaft. While holding the strut shaft from turning,

remove the nut from the strut shaft.

(5) Remove the upper mount from the strut shaft.

(6) If the pivot bearing needs to be serviced,

remove it from the top of the coil spring upper seat

by pulling it straight up.

(7) Remove the clamp from the bottom of the coil

spring and remove the strut out through the bottom

of the coil spring.

NOTE: If the coil spring or upper spring seat needs

to be serviced, proceed with the next step, other-

wise, proceed with step 10.

(8) Release the tension from the coil spring by

backing off the compressor drive fully. Push back the

compressor upper hooks and remove the upper spring

seat with upper spring isolator.

(9) Remove the coil spring from the spring com-

pressor.

(10) Remove the dust shield and jounce bumper as

an assembly from the strut shaft by pulling both

straight up and off the strut shaft. The dust shield

cannot be separated from the jounce bumper until

after it is removed from strut shaft.

Fig. 43 Strut Assembly To Strut Tower Attaching

Nuts (Typical)

1 - WINDSHIELD WIPER MODULE

2 - STRUT TOWER

3 - STRUT MOUNT ATTACHING BOLTS

4 - UPPER STRUT MOUNT

Fig. 44 Mount Rotated And Hooks Positioned

1 - UPPER MOUNT TURNED TOWARD COMPRESSOR

2 - COMPRESSOR UPPER HOOKS

3 - UPPER SPRING SEAT

2 - 22 FRONT SUSPENSIONRS

STRUT (Continued)

ProCarManuals.com

Page 101 of 2399

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DESCRIPTION.........................22

OPERATION...........................22REMOVAL.............................23

INSTALLATION.........................23

SPECIFICATIONS - PROPELLER SHAFT.....23

PROPELLER SHAFT

DESCRIPTION

WARNING: Due to propeller shaft imbalance con-

cerns, the propeller shaft can only be serviced as

an assembly.

AWD models utilize a ªtwo-pieceº propeller shaft

(Fig. 1) to transmit power to the rear driveline mod-

ule assembly. This two-piece design consists of:

²Front and rear shaft segments.

²Plunging center CV joint²Center support bearing

²Rubber coupler at driveline module flange

The front shaft segment utilizes a CV joint at the

power transfer unit connection, and a plunging CV

joint at the center bearing location.

The rear shaft segment utilizes a center support

bearing at the forward position, and a rubber coupler

at the driveline module flange.

OPERATION

The propeller shaft (Fig. 1) is used to transmit

torque from the transaxle power transfer unit (PTU)

Fig. 1 Propeller Shaft Removal/Installation

1 - PTU FLANGE 3 - REAR DRIVELINE MODULE 5 - BOLT-CENTER SUPPORT BEARING-TO-

CROSSMEMBER

2 - CROSSMEMBER 4 - BOLT-PROPELLER SHAFT COUPLER-

T0-DRIVELINE MODULE6 - PROPELLER SHAFT ASSEMBLY

3 - 22 PROPELLER SHAFTRS

ProCarManuals.com