tire size CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1508 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Loose clamp on fluid supply hose. 4. Tighten or replace hose clamp.

SQUEAK OR RUBBING

SOUND1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing shaft.

3. Clockspring noisy. 3. Remove clockspring. Reinstall wheel.

If noise is gone, replace clockspring.

4. Seal lubrication inadequate. 4. Lube seal (if external).

5. Steering gear internally noisy. 5. Replace steering gear (if no other

cause can be found).

SCRUBBING OR

KNOCKING NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or wheel

with size used as original equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as necessary.

3. Steering gear internal stops worn

excessively allowing tires to be

steered excessively far.3. Replace steering gear.

NOTE: * There is some noise in all power steering

systems. One of the most common is a hissing

sound evident when turning the steering wheel

when at a standstill or when parking and the steer-

ing wheel is at the end of its travel. Hiss is a very

high frequency noise similar to that experienced

while slowly closing a water tap. The noise is

present in every valve and results when high veloc-

ity fluid passes valve orifice edges. There is no

relationship between this noise and the perfor-

mance of the steering system.

NOTE: ** A light clunk may be felt or heard during

steering wheel reversal while vehicle is stationary.This results from internal steering gear rack move-

ment at the bushings and in no way affects the per-

formance of the steering system. This movement

may be felt in the steering components during

steering wheel reversal.

NOTE: *** Power steering pump growl/moan/groan

results from the development of high pressure fluid

flow. Normally this noise level should not be high

enough to be objectionable.

STEERING WHEEL FEEL

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL/

COLUMN CLICKING,

CLUNKING OR RATTLING.1. Loose steering coupling pinch

bolt.1. Replace pinch bolt and torque to

specifications.

2. Steering column bearings. 2. Replace steering column.

3. Excessive intermediate shaft

coupling free-play.3. Replace intermediate shaft.

STEERING WHEEL HAS

FORE AND AFT

LOOSENESS.1. Steering wheel retaining nut not

properly tightened and torqued.1. Tighten the steering wheel retaining nut

to its specified torque.

RSSTEERING19-5

STEERING (Continued)

ProCarManuals.com

Page 1532 of 2399

(17) Remove the 3 bolts and nuts mounting the

steering gear to the front suspension cradle (Fig. 8).

NOTE: The next step must be done to allow the

removal of the steering gear from the front suspen-

sion cradle. The steering gear can not be removed

from the vehicle with the intermediate coupler

attached to the steering gear.

(18) Lower steering gear from suspension cradle

enough to allow access to the intermediate coupler

roll pin (Fig. 9). Install Remover/Installer Special

Tool 6831A through the center of the roll pin, secur-

ing with the knurled nut (Fig. 9). Hold threaded rod

stationary while turning nut, this will pull the roll

pin out of the intermediate coupler.

(19) Separate the coupler from the shaft of the

steering gear.(20) Remove the power steering gear from the

vehicle.

REMOVAL - RHD GEAR

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.

CAUTION: Locking the steering column in the

straight-ahead position will prevent the clockspring

from being accidentally over-extended when the

steering column is disconnected from the interme-

diate steering coupler.

(3) Position the steering wheel in the STRAIGHT-

AHEAD position. Lock the steering wheel in place

using a steering wheel holding tool.

(4) With the ignition key in the locked position

turn the steering wheel to the left until the steering

wheel is in the locked position.

(5) With the vehicle on the ground, disconnect the

steering column shaft coupler from the steering gear

intermediate coupler (Fig. 2).

(6) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(7) Remove front wheel and tire assemblies.

(8) If power steering cooler equipped, remove a

hose at power steering cooler and allow fluid to

drain.

(9) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 3).

(10) On both sides of vehicle, remove nut attaching

outer tie rod end to steering knuckle (Fig. 4).

Remove nut by holding tie rod end stud with a

socket while loosening and removing nut with

wrench.

(11) Remove both tie rod ends from steering

knuckles using Puller, Special Tool C-3894±A (Fig. 5).

(12) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of two different thread sizes. Note

the location of the various sizes.

(13) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 6). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

(14) If the vehicle is equipped with All-Wheel-

Drive, remove the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - REMOVAL).

Fig. 6 Cradle Crossmember Reinforcement

Attachment

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

RSGEAR19-29

GEAR (Continued)

ProCarManuals.com

Page 1536 of 2399

(12) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 3). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.). When installing mounting bolts, include pres-

sure hose routing clamp.

(13) Reconnect previously disconnected hose at

power steering cooler and install clamp.

(14) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 135

N´m (100 ft. lbs.).

(15) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(16) Lower the vehicle to a level where the interior

of vehicle is accessible.

(17) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(18) Remove the steering wheel holding tool.

(19) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(20) Inspect system for leaks.

(21) Adjust front toe (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION - RHD GEAR

(1) Install the steering gear up in the front sus-

pension cradle crossmember, leaving room to install

intermediate coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 12). Hold threaded rod station-

ary while turning nut. This will pull the roll pin into

the intermediate coupler.

(4) Install power steering gear on the front suspen-

sion cradle. Install the 2 steering gear mounting

bolts and nuts. Tighten the M-14 size steering gear

to suspension cradle mounting bolt to a torque of 183

N´m (135 ft. lbs.). Tighten the M-12 size steering

gear to suspension cradle mounting bolt to a torque

of 95 N´m (70 ft. lbs.).CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Install the heat shield on the steering gear

(Fig. 10).

(6) Attach the power steering fluid pressure and

return hoses to the proper fittings on the steering

gear (Fig. 10). Do not fully tighten the fittings at this

time.

(7) Install the routing clamp with the bolt securing

the power steering fluid hoses to the rear of the cra-

dle crossmember (Fig. 11).

(8) Using a crowfoot wrench on a torque wrench,

tighten the power steering fluid hose tube nuts at the

gear to a torque of 31 N´m (275 in. lbs.).

(9) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 4), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 13), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(10) If the vehicle is equipped with All-Wheel-

Drive, install the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(11) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 6). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(12) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(13) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 6). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(14) If power steering cooler equipped, install the

previously disconnected power steering cooler hose on

the cooler. Install the clamp.

(15) If power steering cooler equipped, install the

power steering fluid cooler on the cradle crossmem-

ber reinforcement (Fig. 3). Install the mounting bolts

and tighten to 11 N´m (100 in. lbs.).

(16) Install the front tire and wheel assemblies on

vehicle. Install the wheel mounting lug nuts and

tighten to a torque to 135 N´m (100 ft. lbs.).

RSGEAR19-33

GEAR (Continued)

ProCarManuals.com

Page 1548 of 2399

FLUID COOLER

DESCRIPTION

All models (except 2.5L Diesel) are equipped with a

cooler for the power steering system fluid. The power

steering fluid cooler is located on the front suspen-

sion cradle crossmember reinforcement (Fig. 18).

There are two different size coolers depending on

model and options. There is a standard 6-inch and an

8-inch.

OPERATION

The purpose of the power steering fluid cooler is to

keep the temperature of the power steering system

fluid from rising to a level that would affect the per-

formance of the power steering system.

The cooler used on this vehicle is referred to as a

fluid-to-air type cooler. This means that the air flow

across the tubes (and fines surrounding them) of the

cooler is used to extract the heat from the cooler

which it has absorbed from the power steering fluid

flowing through it. The cooler is placed in the power

steering fluid return line, between the steering gear

and the power steering fluid reservoir.

REMOVAL

(1) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove the hose clamps at the cooler and

remove the hoses from the cooler inlet and outlet

tubes.

(4) Remove the 2 bolts attaching the power steer-

ing cooler cradle crossmember reinforcement (Fig.

18). Remove the cooler.

INSTALLATION

(1) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 18). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.).

(2) Install power steering fluid hoses on the cooler.

Be sure hose clamps are installed on hose past

the upset bead on the power steering cooler

tubes.(3) Lower the vehicle to a point where front tires

are just off the ground.

(4) Perform Power Steering Pump Initial Opera-

tion procedure. (Refer to 19 - STEERING/PUMP -

STANDARD PROCEDURE)

HOSE - POWER STEERING

PRESSURE

REMOVAL

REMOVAL - 2.4L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

Fig. 18 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

RSPUMP19-45

ProCarManuals.com

Page 1898 of 2399

(7) Install starter motor into position (Fig. 84).

Install and torque bolts to 54 N´m (40 ft. lbs.).

(8) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).

(9) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs (Fig. 85). Whiledepressing inward, rotate slave cylinder clockwise

60É into position until nylon locating tab rests within

transaxle case cutout, and hydraulic tube is vertical.

Connect ªquick-connectº connection until an audible

ªclickº is heard. Verify connection by pulling outward

on connection.

(10) Install underbody splash panel.

(11) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(12) Lower vehicle.

(13) Install right mount bracket to transaxle (Fig.

86).

Fig. 85 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 84 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

Fig. 86 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

RST850 MANUAL TRANSAXLE21 - 341

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1971 of 2399

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each

wheel (Fig. 19). Each sensor has an internal battery

that lasts up to 10 years. The battery is not service-

able. At the time of battery failure, the sensor must

be replaced. The serviceable components of the tire

pressure sensor are:

²Sensor-To-Wheel Grommet

²Valve Stem Cap

²Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

CAUTION: Do not try to install a tire pressure sen-

sor in a steel wheel or aftermarket wheel. Use only

in original style factory wheels.

OPERATION

Tire pressure sensors are battery operated. They

transmit tire pressure data once every minute at

speeds above 20 mph (32 km/h) or up to once every

hour when stationary (parked). For additional infor-

mation, refer to Appropriate Diagnostic Information.

CAUTION

CAUTION: The use of tire sealants is strictly prohib-

ited for vehicles equipped with the Tire Pressure

Monitoring system. Tire sealants can clog tire pres-

sure sensors.

CAUTION: Tire pressure sensor valve stem caps

and cores are specially designed for the sensors.

Due to risk of corrosion, do not use a standard

valve stem cap or core in a tire pressure sensor in

place of the original equipment style sensor cap

and core.CAUTION: Do not attempt to install a tire pressure

sensor in a steel wheel or aftermarket wheel. Use

tire pressure sensors in original style factory

wheels only.

NOTE: TPM thresholds have been established for

the original tire size equipped on the vehicle. Use

original size tires only to maintain system accuracy.

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR

NOTE: Tire pressure may increase from 2 to 6 psi

(14 to 41 kPa) during normal driving conditions. Do

NOT reduce this normal pressure build up.

If a fault in the system is detected, always check

air pressure in the tires first with a known accurate

air gauge and correct the inflation pressure. If any

tire is low, inspectalltires.

If gauge-read pressure in the tires does not reflect

the reading on the EVIC, retrain the sensors, then

reevaluate (Refer to 22 - TIRES/WHEELS/TIRE

PRESSURE MONITORING/SENSOR - STANDARD

PROCEDURE). Refer to the appropriate diagnostic

information for complete diagnosis of the Tire Pres-

sure Monitoring System.

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN

WARNING: DEATH OR SERIOUS INJURY CAN

OCCUR IF MAGNETICALLY SENSITIVE DEVICES

ARE EXPOSED TO THE RELEARN MAGNET. MAG-

NETS CAN AFFECT PACEMAKERS.

CAUTION: Never attempt to train more than one

vehicle at a time. System is capable of reading tire

pressure sensor transmissions from other near-by

vehicles.

Each time a wheel rotation or tire pressure sensor

replacement occurs the tire pressure sensors must be

retrained. This is necessary to inform the Electronic

Vehicle Information Center (EVIC) that a sensor

change was made and where. Retraining is accom-

plished through the EVIC used in conjunction with a

Re-learn Magnet, Special Tool 8821.

22 - 10 TIRES/WHEELSRS

ProCarManuals.com

Page 1974 of 2399

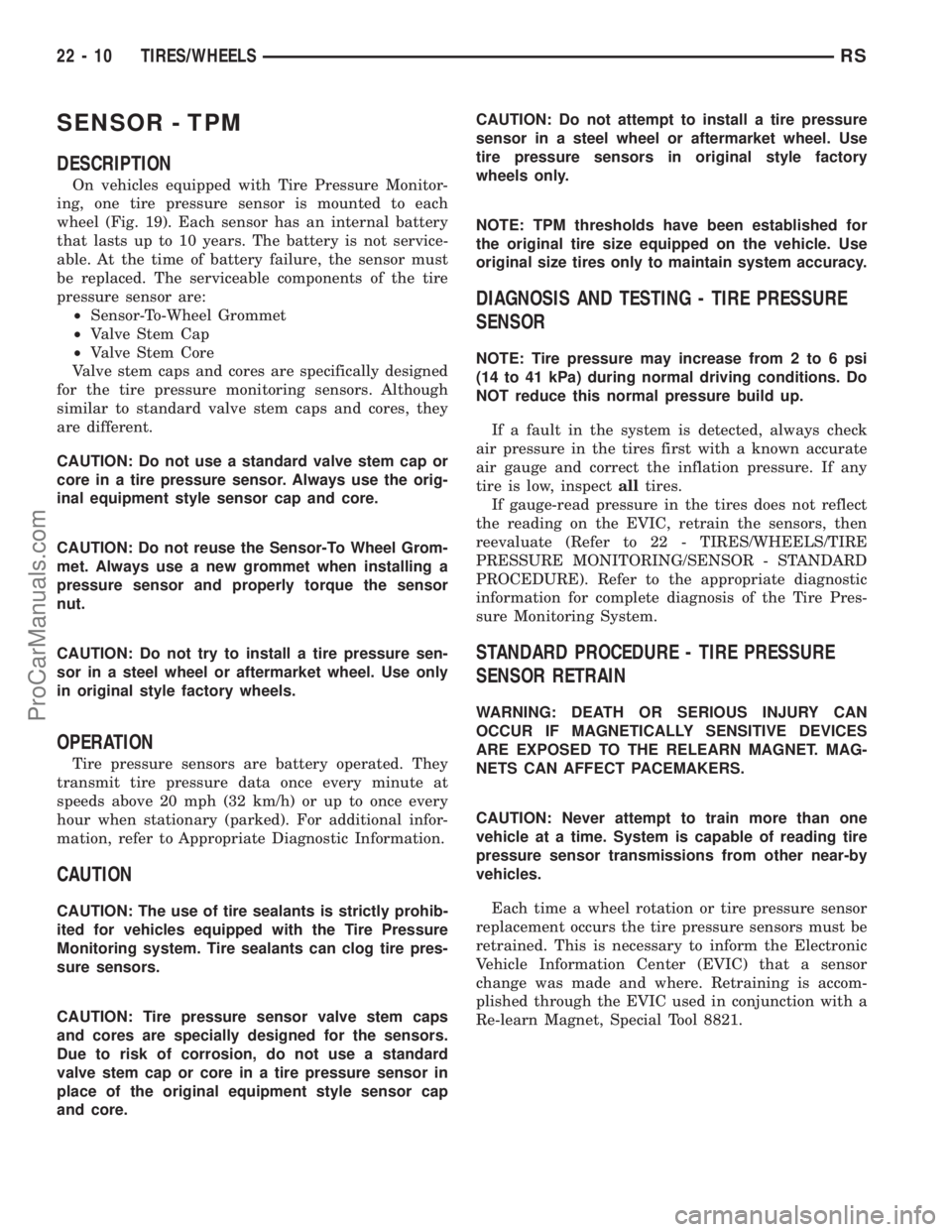

(6) Retrain tire pressure sensors. (Refer to 22 -

TIRES/WHEELS/TIRE PRESSURE MONITORING/

SENSOR - STANDARD PROCEDURE)

TIRES

DESCRIPTION

DESCRIPTION - TIRE

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

²Operating vehicle with over or under inflated

tire pressuresRadial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

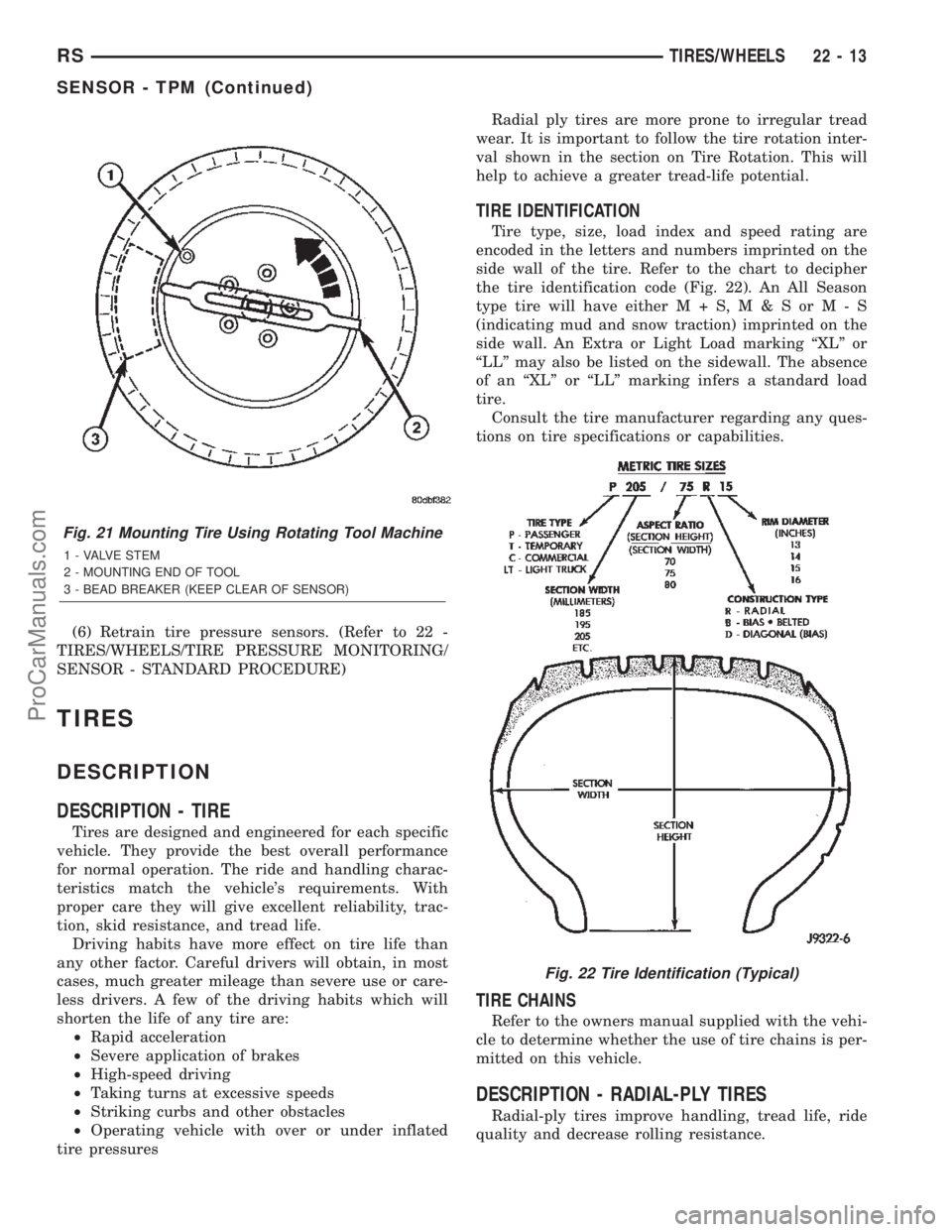

TIRE IDENTIFICATION

Tire type, size, load index and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 22). An All Season

type tire will have eitherM+S,M&SorM-S

(indicating mud and snow traction) imprinted on the

side wall. An Extra or Light Load marking ªXLº or

ªLLº may also be listed on the sidewall. The absence

of an ªXLº or ªLLº marking infers a standard load

tire.

Consult the tire manufacturer regarding any ques-

tions on tire specifications or capabilities.

TIRE CHAINS

Refer to the owners manual supplied with the vehi-

cle to determine whether the use of tire chains is per-

mitted on this vehicle.

DESCRIPTION - RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance.

Fig. 21 Mounting Tire Using Rotating Tool Machine

1 - VALVE STEM

2 - MOUNTING END OF TOOL

3 - BEAD BREAKER (KEEP CLEAR OF SENSOR)

Fig. 22 Tire Identification (Typical)

RSTIRES/WHEELS22-13

SENSOR - TPM (Continued)

ProCarManuals.com

Page 1975 of 2399

Radial-ply tires must always be used in sets of four

and under no circumstances should they be used on

the front only. It is recommended that tires from dif-

ferent manufacturers NOT be mixed. They may be

mixed with a temporary spare tire when necessary. A

maximum speed of 80 km/h (50 mph) is recom-

mended while a temporary spare is in use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

DESCRIPTION - REPLACEMENT TIRES

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

It is recommended that tires equivalent to the orig-

inal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The original equipment tires provide a proper com-

bination of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

The use of tires smaller than the minimum tire

size approved for the vehicle can result in tire over-

loading and failure.

Use tires that have the approved load rating for

the vehicle and never overload them. Failure to equip

the vehicle with tires having adequate speed capabil-

ity can result in sudden tire failure and loss of vehi-

cle control.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

DESCRIPTION - SPARE TIRE (TEMPORARY)

The temporary (convenience) spare tire is designed

for emergency use only. The original tire should be

repaired and reinstalled, or replaced with a new, at

the first opportunity.

The temporary (convenience) spare tire should be

inflated to the pressure listed on its sidewall. Do not

exceed speeds of 80 km/h (50 mph) when the tempo-

rary spare tire is in use on the vehicle. Refer to the

Owner's Manual for more details.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE

Unusual tire noise can be associated with tire and

wheel vibration or irregular tire wear. For vibration,

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING). For irregular tire wear, (Refer to 22 -

TIRES/WHEELS/TIRES - DIAGNOSIS AND TEST-

ING).

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD

Use the following Vehicle Lead Diagnosis And Cor-

rection Chart to diagnose and correct a vehicle lead

or drift problem.

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 23).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 23).

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 24).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE INFLATION

PRESSURES

The specified tire pressures have been chosen to

provide safe operation, vehicle stability, and a smooth

ride. The proper tire pressure specification can be

found on the Tire Inflation Pressure Label provided

with the vehicle (usually on the rear face of the driv-

er's door).

A quality air pressure gauge is recommended to

check tire air pressure. Tire pressure should be

checked cold once per month. Check tire pressure

more frequently when the weather temperature var-

ies widely. Tire pressure will decrease when the out-

22 - 14 TIRES/WHEELSRS

TIRES (Continued)

ProCarManuals.com

Page 1980 of 2399

SPECIFICATIONS

WHEEL

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Wheel Mounting (Lug)

Nut Hex Size19 mm

Wheel Mounting Stud

SizeM12 x 1.5 mm

TORQUE SPECIFICATIONS

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Wheel Mounting (Lug ) Nut 135 100 Ð

WHEEL COVER

DESCRIPTION

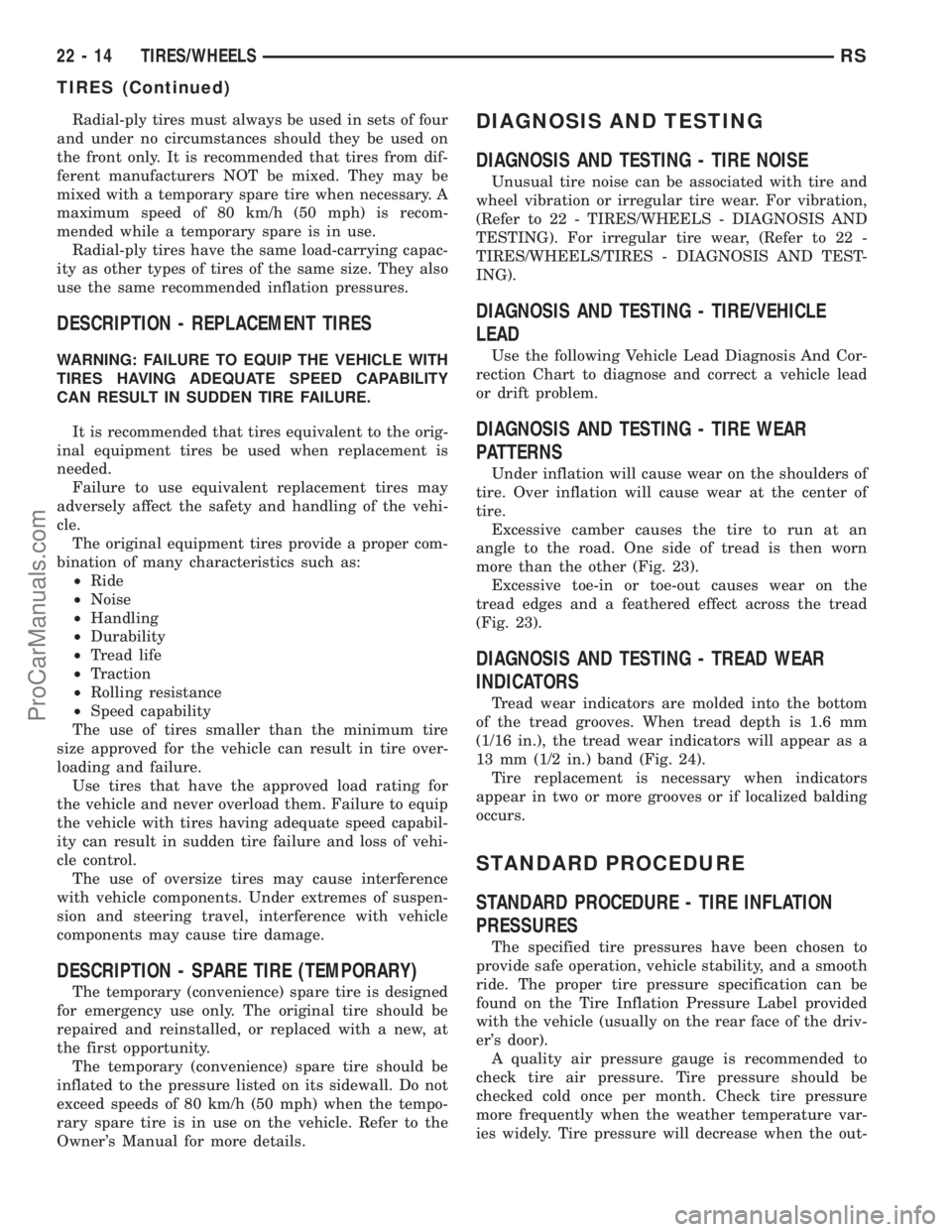

This vehicle uses a bolt-on type wheel cover (Fig.

30).

This bolt-on wheel cover cannot be removed from

the wheel until three of the five wheel mounting nuts

shown are removed (Fig. 30). The bolt-on wheel cover

can then be removed with the remaining two wheel

nuts tightened in place.

REMOVAL

(1) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 30).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

INSTALLATION

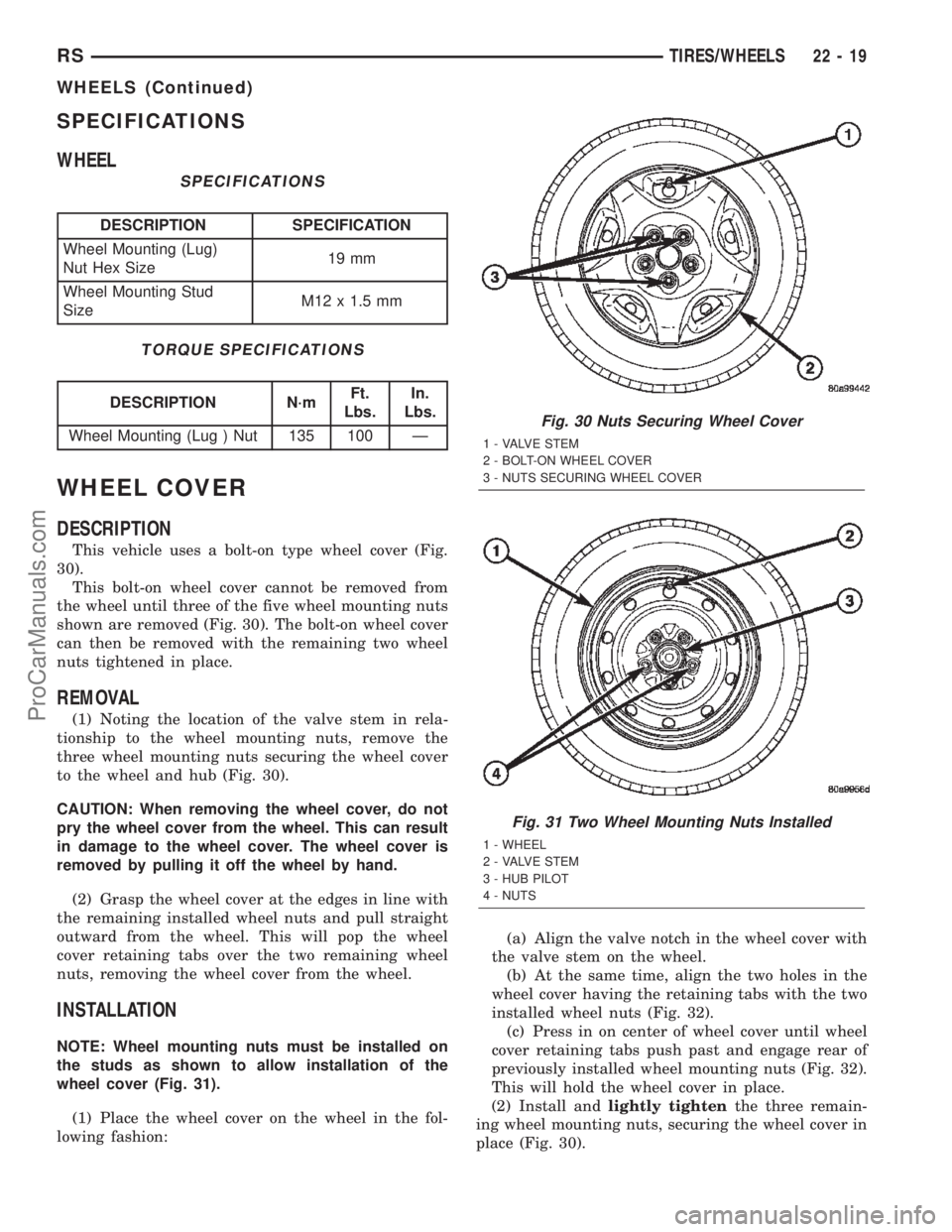

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 31).

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 32).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 32).

This will hold the wheel cover in place.

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 30).

Fig. 30 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 31 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

RSTIRES/WHEELS22-19

WHEELS (Continued)

ProCarManuals.com

Page 2244 of 2399

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - SINGLE ZONE...........1

DESCRIPTION - DUAL ZONE.............1

DESCRIPTION - MANUAL THREE ZONE.....1

DESCRIPTION - THREE ZONE AUTOMATIC

TEMPERATURE CONTROL...............2

OPERATION

OPERATION - DUAL ZONE...............3

OPERATION - MANUAL THREE ZONE......3

OPERATION - THREE ZONE ATC..........4

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C COOL

DOWN TEST..........................5DIAGNOSIS AND TESTING - A/C

PERFORMANCE TEST..................5

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST..................6

SPECIFICATIONS - HEATER-A/C SYSTEM.....7

CONTROLS - FRONT......................8

CONTROLS - REAR......................29

DISTRIBUTION - FRONT...................39

DISTRIBUTION - REAR....................51

PLUMBING - FRONT.....................59

PLUMBING - REAR......................97

DIESEL SUPPLEMENTAL HEATER - DCHA -

BUX.................................109

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - SINGLE ZONE

A single zone heating and air conditioning system

allows one temperature setting for the entire vehicle.

The full range of temperatures that the system can

produce are available by rotating the temperature

control located in control panel.

The control panel and integral computer is

mounted in the instrument panel.

DESCRIPTION - DUAL ZONE

A manual Dual Zone Heating and Air Conditioning

system allows completely independent side-to-side

tempeture control of the discharge air.

The Dual Zone Heating and Air Conditioning sys-

tem includes a dust and odor air filter. The filter ele-

ment is the same size as the air conditioning

evaporator to ensure ample capacity. A door at the

base of the heating and air conditioning housing

below the glove box provides easy access to the filter

element.

The control panel and integral computer is located

in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²a power button which allows the system to be

completely turned off. Contains an LED that illumi-

nates to show when the function is operational.²rear window defogger on/off switch. Contains an

LED that illuminates to show when the function is

operational.

²slide controls for completely independent side-to-

side temperature control of the discharged air. The

full range of temperature that the system can pro-

duce in any mode is available on either side of the

vehicle by independently positioning the slide con-

trols on the instrument panel.

²air recirculation on/off switch. The Recirculate

button contains an LED that illuminates to show

when the function is in operation.

²air conditioning on/off switch. The Snowflake

button contains an LED that illuminates to shown

when the function is in operation.

²rotary knob for fan speed selection.

²a rotary knob for mode control.

DESCRIPTION - MANUAL THREE ZONE

The fully adjustable Three-Zone front and rear

heating and air conditioning system allows interme-

diate seat passengers the ability to regulate air tem-

perature as well as fan speed. All controls are

identified by ISO graphic symbols.

The Three Zone Heating and Air Conditioning sys-

tem includes a dust and odor air filter. The filter ele-

ment is the same size as the air conditioning

evaporator to ensure ample capacity. A door at the

base of the heating and air conditioning housing

below the glove box provides easy access to the filter

element.

RSHEATING & AIR CONDITIONING24-1

ProCarManuals.com