drain bolt CHRYSLER CARAVAN 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 283 of 2399

(7) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- INSTALLATION).

(8) Install the generator mount bracket. (Fig. 24)

(9) Install the generator.

(10) Install right engine mount bracket and engine

mount (Refer to 9 - ENGINE/ENGINE MOUNTING/

RIGHT MOUNT - INSTALLATION).

(11) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(12) Install the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Lower vehicle and connect battery cable.

WATER PUMP - 3.3/3.8L

DESCRIPTION

The water pump has a die-cast aluminum body

and a plastic impeller. It bolts directly to the timing

chain case cover, using a rubber seal for sealing (Fig.

27). It is driven by the accessory drive belt.

OPERATION

The water pump is the heart of the cooling system.

The coolant is pumped through the engine block, cyl-

inder head, heater core, and radiator.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove the accessory drive belt shield.

(3) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove water pump pulley bolts (Fig. 27).

NOTE: To remove the water pump pulley, it MUST

first be positioned between water pump housing

and drive hub. The pulley can then be removed with

the water pump assembly.

(5) Rotate pulley until openings in pulley align

with water pump drive hub spokes (Fig. 28). Move

pulley inward between pump housing and hub (Fig.

28).

(6) Position pulley to allow access to water pump

mounting bolts. Remove water pump mounting bolts

(Fig. 29).

(7) Remove water pump with the pulley loosely

positioned between hub and the pump body.

(8) Remove and discard the seal.

Fig. 27 Water Pump - 3.3/3.8L Engine

1 - WATER PUMP

2 - PULLEY - WATER PUMP

3 - BOLT - PULLEY

4 - BOLT - WATER PUMP

5 - SEAL - WATER PUMP

Fig. 28 Water Pump Pulley Positioning

1 - HUB - WATER PUMP

2 - PULLEY - WATER PUMP

7 - 34 ENGINERS

WATER PUMP - 2.4L (Continued)

ProCarManuals.com

Page 285 of 2399

(5) Rotate pump by hand to check for freedom of

movement.

(6) Install the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(7) Install drive belt shield.

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

WATER PUMP INLET TUBE -

2.4L

DESCRIPTION

The 2.4L engine uses a metal tube to connect the

engine block to the lower radiator hose and heater

return (Fig. 32). The tube has an O-ring for block to

tube sealing and bolts attach the tube to the engine

block.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove radiator upper hose to access the hose

connections at the inlet tube.

(3) Remove radiator lower (Fig. 7) and heater

hoses from the inlet tube (Fig. 33).

(4) Remove the two fasteners that hold the inlet

tube to the block.

(5) Rotate tube while removing the tube from the

engine block.

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 32).(2) Lube O-ring with coolant and install inlet tube

into the cylinder block opening (Fig. 32).

(3) Install the two inlet tube fasteners and tighten

to 12 N´m (105 in. lbs.).

(4) Connect the radiator lower hose (Fig. 7) and

heater hose to inlet tube (Fig. 33).

(5) Install the radiator upper hose.

(6) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

WATER PUMP INLET TUBE -

3.3/3.8L

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Raise vehicle on hoist and remove the belt

splash shield.

(3) Remove the radiator lower hose from inlet tube

(Fig. 34).

(4) Remove the oil cooler outlet/heater return hose

from inlet tube (only if equipped with engine oil

cooler) (Fig. 35).

(5) Remove the inlet tube bolts (Fig. 36).

(6) Remove the inlet tube (Fig. 36). Discard the

O-ring seal.

INSTALLATION

(1) Clean the inlet tube O-ring sealing surfaces on

the timing cover housing and tube.

(2) Apply MopartDielectric Grease or equivalent

to the O-ring before installation.

(3) Position new O-ring seal on inlet tube (Fig. 36).

Fig. 32 Water Pump Inlet TubeÐ2.4L Engine

1 - O-RING

2 - WATER PUMP INLET TUBE

Fig. 33 Water Pump Inlet Tube Hose Connections

1 - WATER PUMP INLET TUBE

2 - HOSE - HEATER RETURN

3 - COOLANT INLET

7 - 36 ENGINERS

WATER PUMP - 3.3/3.8L (Continued)

ProCarManuals.com

Page 309 of 2399

ENGINE COOLANT

THERMOSTAT

DESCRIPTION

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator (Fig. 9).

OPERATION

The thermostat starts to open at 80ÉC (176ÉF).

Above this temperature, coolant is allowed to flow to

the radiator. This provides quicker engine warmup

and overall temperature control.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

REMOVAL

NOTE: The thermostat is not serviced separately.

The thermostat and housing must be replaced as

an assembly.

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove front wiper unit to gain access to ther-

mostat housing(Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL).

(4) Disconnect upper radiator hose adapter tube,

water pump hose, and EGR hose at thermostat hous-

ing.

(5) Remove both thermostat housing attaching

bolts and housing (Fig. 10).

INSTALLATION

(1) Install thermostat housing, gasket, and retain-

ing bolts (Fig. 10). Torque bolts to 27.5N´m.

(2) Connect upper radiator hose adapter tube,

water pump hose, and EGR cooler hose to thermostat

housing.

Fig. 8 COOLANT TEMPERATURE SENSOR

LOCATION

1 - EGR SOLENOID

2 - UPPER RADIATOR HOSE

3 - COOLANT TEMPERATURE SENSOR

4 - INTAKE MANIFOLD INLET

5 - INTAKE MANIFOLD/CYLINDER HEAD COVER

Fig. 9 THERMOSTAT HOUSING LOCATION

1 - CYLINDER HEAD COVER

2 - THERMOSTAT HOUSING

3 - AIR BLEED

4 - WATER PUMP

5 - WATER PUMP HOUSING TO THERMOSTAT HOUSING

BYPASS HOSE

6 - E G R VA LV E

7a - 20 ENGINERG

ENGINE COOLANT THERMOSTAT (Continued)

ProCarManuals.com

Page 310 of 2399

(3) Install front wiper unit (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(4) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Connect negative battery cable.

RADIATOR

DESCRIPTION

The radiator is a cross-flow type (horizontal tubes)

with design features that provide greater strength

along with sufficient heat transfer capabilities to

keep the engine satisfactorily cooled. The radiator

has plastic side tanks and aluminum cooling tubes.

OPERATION

The radiator functions as a heat exchanger, using

air flow across the exterior of the radiator tubes. This

heat is then transferred from the coolant and into

the passing air.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove radiator upper crossmember support.

(Refer to 23 - BODY/EXTERIOR/GRILLE OPENING

REINFORCEMENT - REMOVAL)

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(3) Drain the cooling system (Refer to 7 - COOL-

ING/ENGINE/COOLANT - STANDARD PROCE-

DURE).

(4) Remove the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL)

(5) Disconnect coolant bypass hose (Fig. 11).

(6) Disconnect upper and lower hoses from the

radiator (Fig. 11).

(7) Remove the A/C condenser side brackets to

radiator attaching screws (Fig. 12). Separate the con-

denser from the radiator by lifting upward to disen-

gage from lower mounts (Fig. 12). Allow the

condenser to rest in front of radiator.

Fig. 10 THERMOSTAT HOUSING ASSEMBLY

1 - THERMOSTAT HOUSING GASKET

2 - THERMOSTAT HOUSING

3 - RETAINING BOLTS

4 - CYLINDER HEAD

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

Fig. 11 UPPER AND LOWER RADIATOR HOSES

1 - COOLANT BYPASS HOSE

2 - RADIATOR ASSEMBLY

3 - UPPER RADIATOR HOSE

4 - COOLING FAN

5 - LOWER RADIATOR HOSE

6 - CHARGE AIR COOLER

7 - RADIATOR BRACKET

RGENGINE7a-21

ENGINE COOLANT THERMOSTAT (Continued)

ProCarManuals.com

Page 312 of 2399

WATER PUMP

DESCRIPTION

The water pump on the 2.5L CRD diesel has a die

cast aluminum housing. It bolts to a aluminum hous-

ing which attaches to the engine block (Fig. 14).

OPERATION

The water pump is used to circulate coolant

through the cooling system. The coolant is pumped

through the engine block, cylinder head, heater core,

EGR cooler, cabin heater, and radiator.

REMOVAL

REMOVAL - WATER PUMP

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove timing belt inner and outer covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Remove water pump retaining bolts and pump

(Fig. 15).

REMOVAL - WATER PUMP HOUSING

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove both outer and inner timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Disconnect water pump housing to thermostat

housing bypass hose (Fig. 16).

(5) Remove the water pump housing retaining

nuts (Fig. 17).

(6) Remove water pump housing from engine block

(Fig. 17).

CLEANING

Clean gasket mating surfaces as necessary.

INSTALLATION

INSTALLATION - WATER PUMP

(1) Clean gasket mating surfaces as necessary.

(2) Place water pump and gasket in place. Install

water pump retaining bolts (Fig. 15). Torque bolts to

24.4N´m.

Fig. 14 WATER PUMP

1 - WATER PUMP HOUSING STUDS

2 - WATER PUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

Fig. 15 WATER PUMP LOCATION

1 - CYLINDER HEAD

2 - ENGINE BLOCK

3 - OIL COOLER

4 - OIL FILTER HOUSING

5 - WATER PUMP

RGENGINE7a-23

ProCarManuals.com

Page 393 of 2399

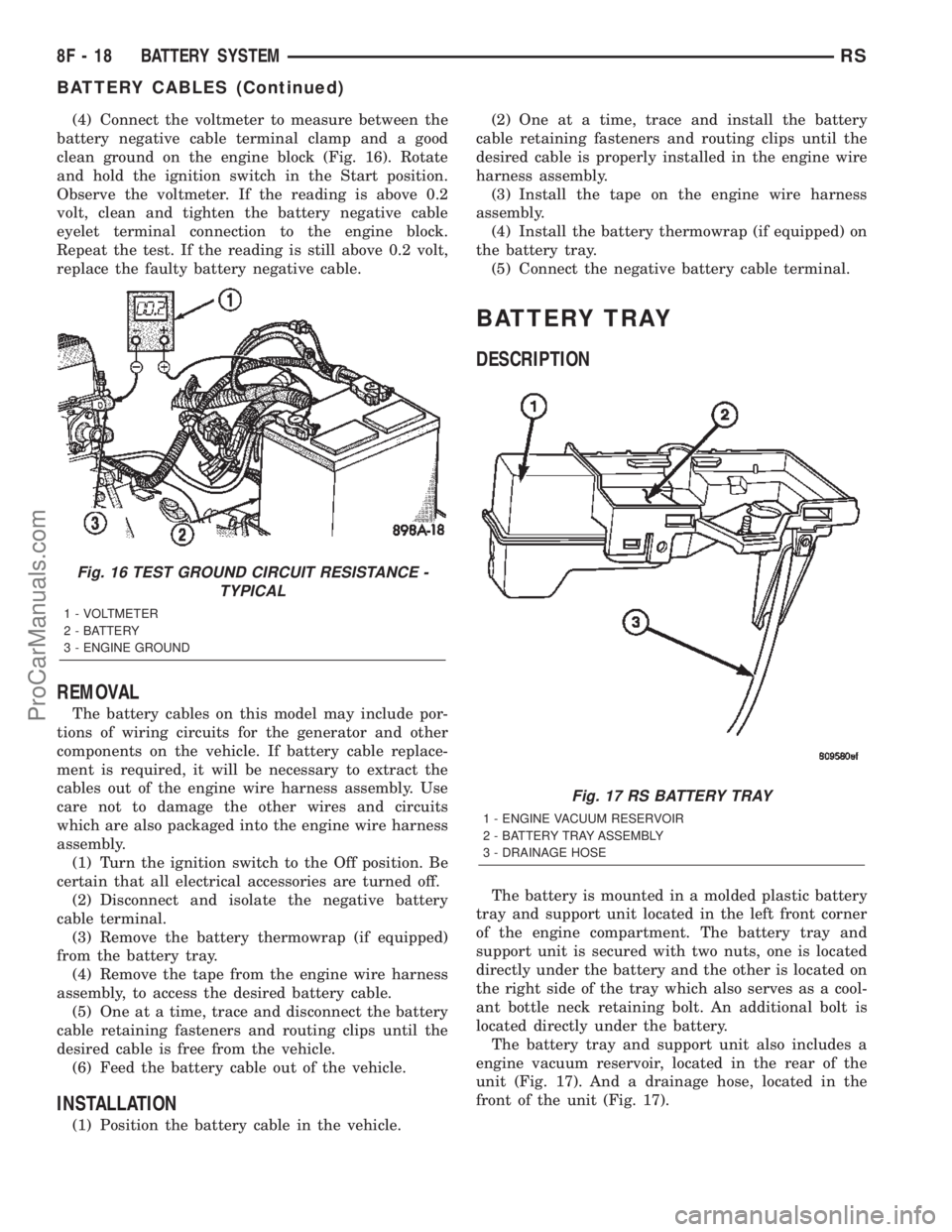

(4) Connect the voltmeter to measure between the

battery negative cable terminal clamp and a good

clean ground on the engine block (Fig. 16). Rotate

and hold the ignition switch in the Start position.

Observe the voltmeter. If the reading is above 0.2

volt, clean and tighten the battery negative cable

eyelet terminal connection to the engine block.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery negative cable.

REMOVAL

The battery cables on this model may include por-

tions of wiring circuits for the generator and other

components on the vehicle. If battery cable replace-

ment is required, it will be necessary to extract the

cables out of the engine wire harness assembly. Use

care not to damage the other wires and circuits

which are also packaged into the engine wire harness

assembly.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Disconnect and isolate the negative battery

cable terminal.

(3) Remove the battery thermowrap (if equipped)

from the battery tray.

(4) Remove the tape from the engine wire harness

assembly, to access the desired battery cable.

(5) One at a time, trace and disconnect the battery

cable retaining fasteners and routing clips until the

desired cable is free from the vehicle.

(6) Feed the battery cable out of the vehicle.

INSTALLATION

(1) Position the battery cable in the vehicle.(2) One at a time, trace and install the battery

cable retaining fasteners and routing clips until the

desired cable is properly installed in the engine wire

harness assembly.

(3) Install the tape on the engine wire harness

assembly.

(4) Install the battery thermowrap (if equipped) on

the battery tray.

(5) Connect the negative battery cable terminal.

BATTERY TRAY

DESCRIPTION

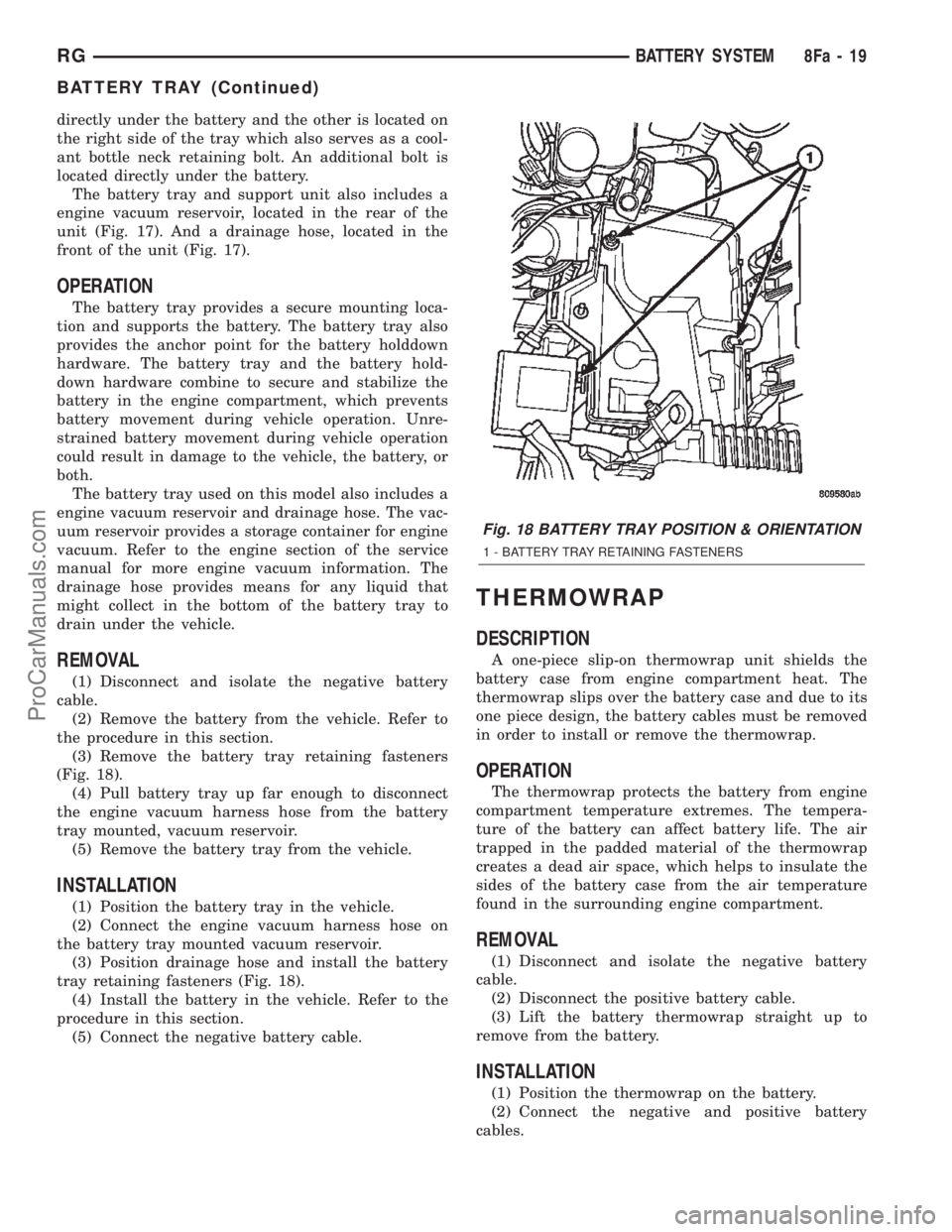

The battery is mounted in a molded plastic battery

tray and support unit located in the left front corner

of the engine compartment. The battery tray and

support unit is secured with two nuts, one is located

directly under the battery and the other is located on

the right side of the tray which also serves as a cool-

ant bottle neck retaining bolt. An additional bolt is

located directly under the battery.

The battery tray and support unit also includes a

engine vacuum reservoir, located in the rear of the

unit (Fig. 17). And a drainage hose, located in the

front of the unit (Fig. 17).

Fig. 16 TEST GROUND CIRCUIT RESISTANCE -

TYPICAL

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 17 RS BATTERY TRAY

1 - ENGINE VACUUM RESERVOIR

2 - BATTERY TRAY ASSEMBLY

3 - DRAINAGE HOSE

8F - 18 BATTERY SYSTEMRS

BATTERY CABLES (Continued)

ProCarManuals.com

Page 430 of 2399

directly under the battery and the other is located on

the right side of the tray which also serves as a cool-

ant bottle neck retaining bolt. An additional bolt is

located directly under the battery.

The battery tray and support unit also includes a

engine vacuum reservoir, located in the rear of the

unit (Fig. 17). And a drainage hose, located in the

front of the unit (Fig. 17).

OPERATION

The battery tray provides a secure mounting loca-

tion and supports the battery. The battery tray also

provides the anchor point for the battery holddown

hardware. The battery tray and the battery hold-

down hardware combine to secure and stabilize the

battery in the engine compartment, which prevents

battery movement during vehicle operation. Unre-

strained battery movement during vehicle operation

could result in damage to the vehicle, the battery, or

both.

The battery tray used on this model also includes a

engine vacuum reservoir and drainage hose. The vac-

uum reservoir provides a storage container for engine

vacuum. Refer to the engine section of the service

manual for more engine vacuum information. The

drainage hose provides means for any liquid that

might collect in the bottom of the battery tray to

drain under the vehicle.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the battery from the vehicle. Refer to

the procedure in this section.

(3) Remove the battery tray retaining fasteners

(Fig. 18).

(4) Pull battery tray up far enough to disconnect

the engine vacuum harness hose from the battery

tray mounted, vacuum reservoir.

(5) Remove the battery tray from the vehicle.

INSTALLATION

(1) Position the battery tray in the vehicle.

(2) Connect the engine vacuum harness hose on

the battery tray mounted vacuum reservoir.

(3) Position drainage hose and install the battery

tray retaining fasteners (Fig. 18).

(4) Install the battery in the vehicle. Refer to the

procedure in this section.

(5) Connect the negative battery cable.

THERMOWRAP

DESCRIPTION

A one-piece slip-on thermowrap unit shields the

battery case from engine compartment heat. The

thermowrap slips over the battery case and due to its

one piece design, the battery cables must be removed

in order to install or remove the thermowrap.

OPERATION

The thermowrap protects the battery from engine

compartment temperature extremes. The tempera-

ture of the battery can affect battery life. The air

trapped in the padded material of the thermowrap

creates a dead air space, which helps to insulate the

sides of the battery case from the air temperature

found in the surrounding engine compartment.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Disconnect the positive battery cable.

(3) Lift the battery thermowrap straight up to

remove from the battery.

INSTALLATION

(1) Position the thermowrap on the battery.

(2) Connect the negative and positive battery

cables.

Fig. 18 BATTERY TRAY POSITION & ORIENTATION

1 - BATTERY TRAY RETAINING FASTENERS

RGBATTERY SYSTEM8Fa-19

BATTERY TRAY (Continued)

ProCarManuals.com

Page 656 of 2399

CLEANING

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, (refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

ADJUSTMENTS).

INSTALLATION

(1) Position the blade onto the arm.

(2) Engage the blade to the retainer by pulling up

on the blade until the tabs snap into position (Fig. 8).

WIPER LINKAGE

REMOVAL

(1) Remove the front windshield wiper unit from

vehicle (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER MODULE - REMOVAL).

(2) Place the wiper unit on a suitable work sur-

face.

(3) Remove nuts holding the cowl cover brackets to

the wiper unit.

(4) Remove cowl cover brackets from the wiper

unit.

(5) Remove nuts holding linkage to the wiper unit.

(6) Remove the wiper linkage from the wiper unit.

(7) Disconnect the wire connectors from back of

the wiper motor.

INSTALLATION

(1) Connect the wire harness connector.

(2) Install the linkage on the wiper unit.

(3) Install the nut holding the linkage to the wiper

unit.

(4) Install the cowl cover brackets to the wiper

nut.

(5) Install the front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).(6) Install the cowl cover.

(7) Install the wiper arms and blades.

WIPER MODULE

REMOVAL

(1) Release the hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the wiper arms.

(4) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

(5) Disconnect the positive lock on the wiper mod-

ule wire connector (Fig. 10).

(6) Disconnect the wiper module wire connector

from the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling outside the module.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper module.

(9) Remove nuts holding wiper module to lower

windshield fence.

(10) Remove bolts holding the wiper module to the

dash panel (Fig. 11).

(11) Lift wiper module from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(12) Remove wiper module.

Fig. 10 WIPER MODULE WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER MODULE

RSWIPERS/WASHERS8R-19

WIPER BLADES (Continued)

ProCarManuals.com

Page 657 of 2399

INSTALLATION

(1) Position the wiper module into the cowl.

(2) Install the bolts that secure the wiper module

to the dash (Fig. 11).

(3) Install the nuts that retain the wiper module.

(4) Connect the drain tubes to the nipples on the

wiper module.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper module (Fig. 11).

(7) Connect the positive lock on the wiper module

wire connector (Fig. 10).

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(8) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(9) Install the wiper arms and blades.

(10) Connect the battery negative cable.

(11) Close the hood.

Fig. 11 WIPER MODULE

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER MODULE

5 - WINDSHIELD

8R - 20 WIPERS/WASHERSRS

WIPER MODULE (Continued)

ProCarManuals.com

Page 1213 of 2399

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 3)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 3)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 4). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

Fig. 3 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 4 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com