lock CHRYSLER CARAVAN 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 81 of 2399

²A loose or missing clamp on the inner or outer

joint of the half shaft assembly.

²A damaged or worn half shaft CV joint.

SHUDDER OR VIBRATION DURING ACCELERATION

This problem could be a result of:

²A worn or damaged half shaft inner tripod joint.

²A sticking tripod joint spider assembly (inner tri-

pod joint only).

²Improper wheel alignment. (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE)

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of:

²Foreign material (mud, etc.) packed on the back-

side of the wheel(s).

²Out of balance tires or wheels. (Refer to 22 -

TIRES/WHEELS - STANDARD PROCEDURE)

²Improper tire and/or wheel runout. (Refer to 22 -

TIRES/WHEELS - DIAGNOSIS AND TESTING)

REMOVAL

(1) Raise vehicle.(2) Remove the cotter pin and nut lock (Fig. 2)

from the end of the half shaft.

Fig. 1 Unequal Length Half Shaft System

1 - STUB AXLE 8 - OUTER C/V JOINT

2 - OUTER C/V JOINT 9 - RIGHT HALFSHAFT

3 - OUTER C/V JOINT BOOT 10 - INNER TRIPOD JOINT BOOT

4 - TUNED RUBBER DAMPER WEIGHT 11 - INNER TRIPOD JOINT

5 - INTERCONNECTING SHAFT 12 - INNER TRIPOD JOINT

6 - OUTER C/V JOINT BOOT 13 - INNER TRIPOD JOINT BOOT

7 - STUB AXLE 14 - INTERCONNECTING SHAFT LEFT HALFSHAFT

Fig. 2 Half Shaft Retaining Nut

1 - HUB/BEARING

2 - NUT LOCK

3 - COTTER PIN

4 - STUB AXLE

3 - 2 HALF SHAFT - FRONTRS

HALF SHAFT - FRONT (Continued)

ProCarManuals.com

Page 84 of 2399

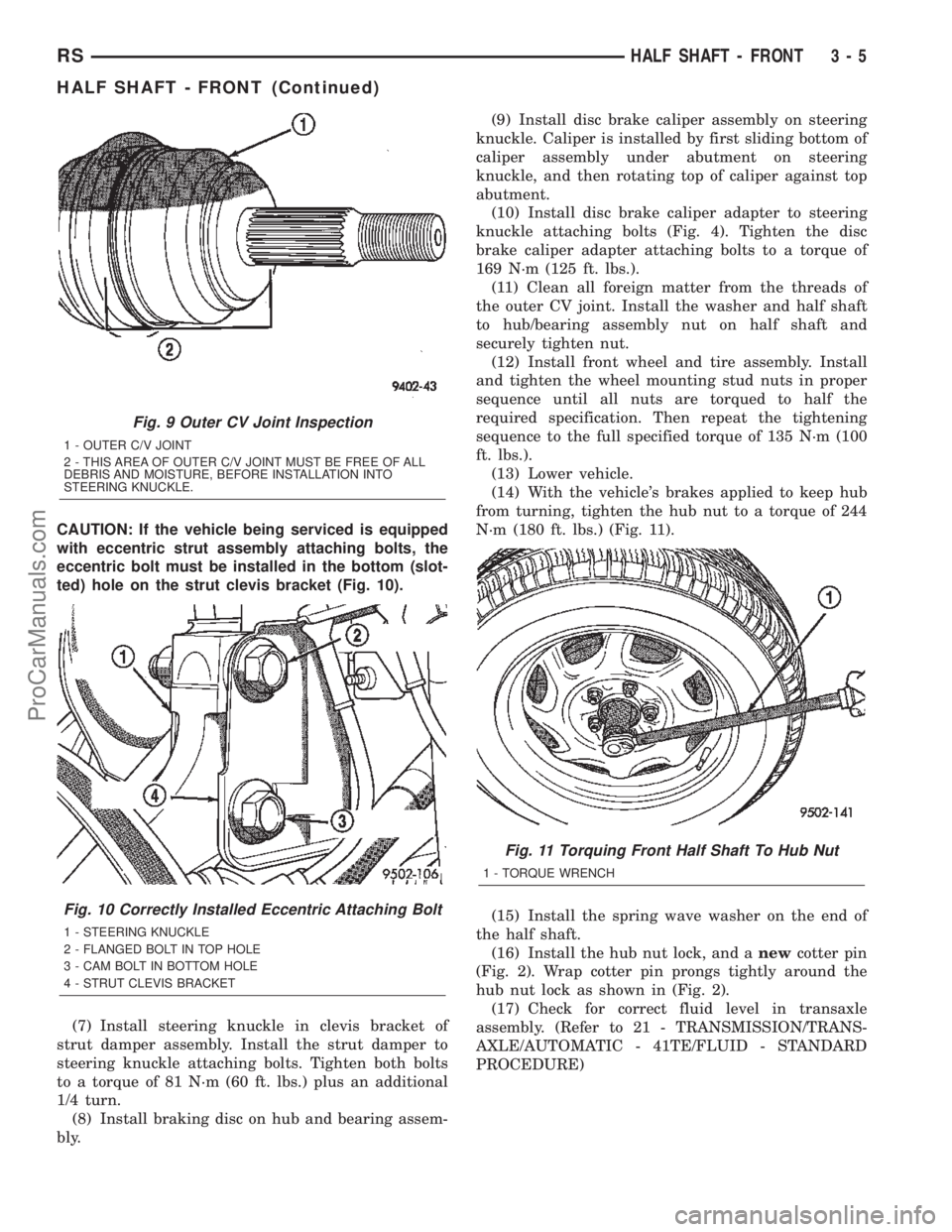

CAUTION: If the vehicle being serviced is equipped

with eccentric strut assembly attaching bolts, the

eccentric bolt must be installed in the bottom (slot-

ted) hole on the strut clevis bracket (Fig. 10).

(7) Install steering knuckle in clevis bracket of

strut damper assembly. Install the strut damper to

steering knuckle attaching bolts. Tighten both bolts

to a torque of 81 N´m (60 ft. lbs.) plus an additional

1/4 turn.

(8) Install braking disc on hub and bearing assem-

bly.(9) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding bottom of

caliper assembly under abutment on steering

knuckle, and then rotating top of caliper against top

abutment.

(10) Install disc brake caliper adapter to steering

knuckle attaching bolts (Fig. 4). Tighten the disc

brake caliper adapter attaching bolts to a torque of

169 N´m (125 ft. lbs.).

(11) Clean all foreign matter from the threads of

the outer CV joint. Install the washer and half shaft

to hub/bearing assembly nut on half shaft and

securely tighten nut.

(12) Install front wheel and tire assembly. Install

and tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half the

required specification. Then repeat the tightening

sequence to the full specified torque of 135 N´m (100

ft. lbs.).

(13) Lower vehicle.

(14) With the vehicle's brakes applied to keep hub

from turning, tighten the hub nut to a torque of 244

N´m (180 ft. lbs.) (Fig. 11).

(15) Install the spring wave washer on the end of

the half shaft.

(16) Install the hub nut lock, and anewcotter pin

(Fig. 2). Wrap cotter pin prongs tightly around the

hub nut lock as shown in (Fig. 2).

(17) Check for correct fluid level in transaxle

assembly. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 9 Outer CV Joint Inspection

1 - OUTER C/V JOINT

2 - THIS AREA OF OUTER C/V JOINT MUST BE FREE OF ALL

DEBRIS AND MOISTURE, BEFORE INSTALLATION INTO

STEERING KNUCKLE.

Fig. 10 Correctly Installed Eccentric Attaching Bolt

1 - STEERING KNUCKLE

2 - FLANGED BOLT IN TOP HOLE

3 - CAM BOLT IN BOTTOM HOLE

4 - STRUT CLEVIS BRACKET

Fig. 11 Torquing Front Half Shaft To Hub Nut

1 - TORQUE WRENCH

RSHALF SHAFT - FRONT3-5

HALF SHAFT - FRONT (Continued)

ProCarManuals.com

Page 89 of 2399

LATCHING TYPE BOOT CLAMP

If seal boot uses low profile latching type boot

clamp, use the following procedure to install the

retaining clamp.

(1) Place prongs of clamp locking tool in the holes

of the clamp (Fig. 25).

(2) Squeeze tool together until top band of clamp is

latched behind the two tabs on lower band of clamp

(Fig. 26).

(14) Install the half shaft back into the vehicle.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

CV BOOT - OUTER

REMOVAL

(1) Remove half shaft assembly requiring boot

replacement from vehicle. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)

(2) Remove large boot clamp retaining CV joint

sealing boot to CV joint housing (Fig. 27) and dis-

card.

(3) Remove small clamp that retains outer CV

joint sealing boot to interconnecting shaft and dis-

card.

(4) Remove sealing boot from outer CV joint hous-

ing and slide it down interconnecting shaft.

(5) Wipe away grease to expose outer CV joint to

interconnecting shaft retaining ring.

(6) Spread ears apart on CV joint assembly to

interconnecting shaft retaining ring (Fig. 28).

(7) Slide outer CV joint assembly off end of inter-

connecting shaft.

(8) Slide sealing boot off interconnecting shaft.

(9) Thoroughly clean and inspect outer CV joint

assembly and interconnecting joint for any signs of

excessive wear.If any parts show signs of exces-

sive wear, the half shaft assembly will require

replacement. Component parts of these half

shaft assemblies are not serviceable.

INSTALLATION

(1) Slide the new small diameter seal boot retain-

ing clamp onto the interconnecting shaft. Then slide

Fig. 25 Clamping Tool Installed on Sealing Boot

Clamp

1 - CLAMP

2 - TOOL YA3050, OR EQUIVALENT

3 - SEALING BOOT

Fig. 26 Sealing Boot Clamp Correctly Installed

1 - INNER TRIPOD JOINT HOUSING

2 - TOP BAND OF CLAMP MUST BE RETAINED BY TABS AS

SHOWN HERE TO CORRECTLY LATCH BOOT CLAMP

3 - SEALING BOOT

Fig. 27 Outer CV Joint Seal Boot Clamps

1 - SMALL CLAMP

2 - SEALING BOOT

3 - OUTER C/V JOINT HOUSING

4 - LARGE CLAMP

5 - INTERCONNECTING SHAFT

3 - 10 HALF SHAFT - FRONTRS

CV BOOT - INNER (Continued)

ProCarManuals.com

Page 94 of 2399

REMOVAL

(1) Lift vehicle on hoist so that the wheels hang

freely.

(2) Remove rear wheel.

(3) Remove cotter pin, nut lock, and wave washer

(Fig. 1).

(4) Remove hub nut and washer.

CAUTION: The half shaft outer CV joint, when

installed, acts as a bolt and secures the hub/bear-

ing assembly. If the vehicle is to be supported or

moved on its wheels, install and torque a bolt

through the hub. This will ensure that the hub/bear-

ing assembly cannot loosen.

(5) Remove inner half shaft retaining bolts (Fig. 2).(6) The half shaft is spring loaded. Compress inner

half shaft joint slightly and pull downward to clear

rear differential output flange. Then pull half shaft

assembly outward to remove (Fig. 3).

INSTALLATION

(1) Install the outer CV joint stub shaft through

the hub bearing (Fig. 4).

(2) The half shaft is spring loaded. Compress inner

half shaft joint slightly and push upward until the

inner CV joint flange engages the rear differential

output flange.

(3) Install the inner half shaft retaining bolts (Fig.

5). Torque the bolts to 61 N´m (45 ft.lbs.).

Fig. 1 Cotter Pin, Nut Lock, And Wave Washer

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - SPRING WASHER

Fig. 2 Inner Half Shaft Bolts

1 - SHAFT

2 - FLANGE

Fig. 3 Half Shaft Removal

1 - BRAKE BACKING PLATE

2 - HALF SHAFT

Fig. 4 Half Shaft Installation

1 - BRAKE BACKING PLATE

2 - HALF SHAFT

RSHALF SHAFT - REAR3-15

HALF SHAFT - REAR (Continued)

ProCarManuals.com

Page 95 of 2399

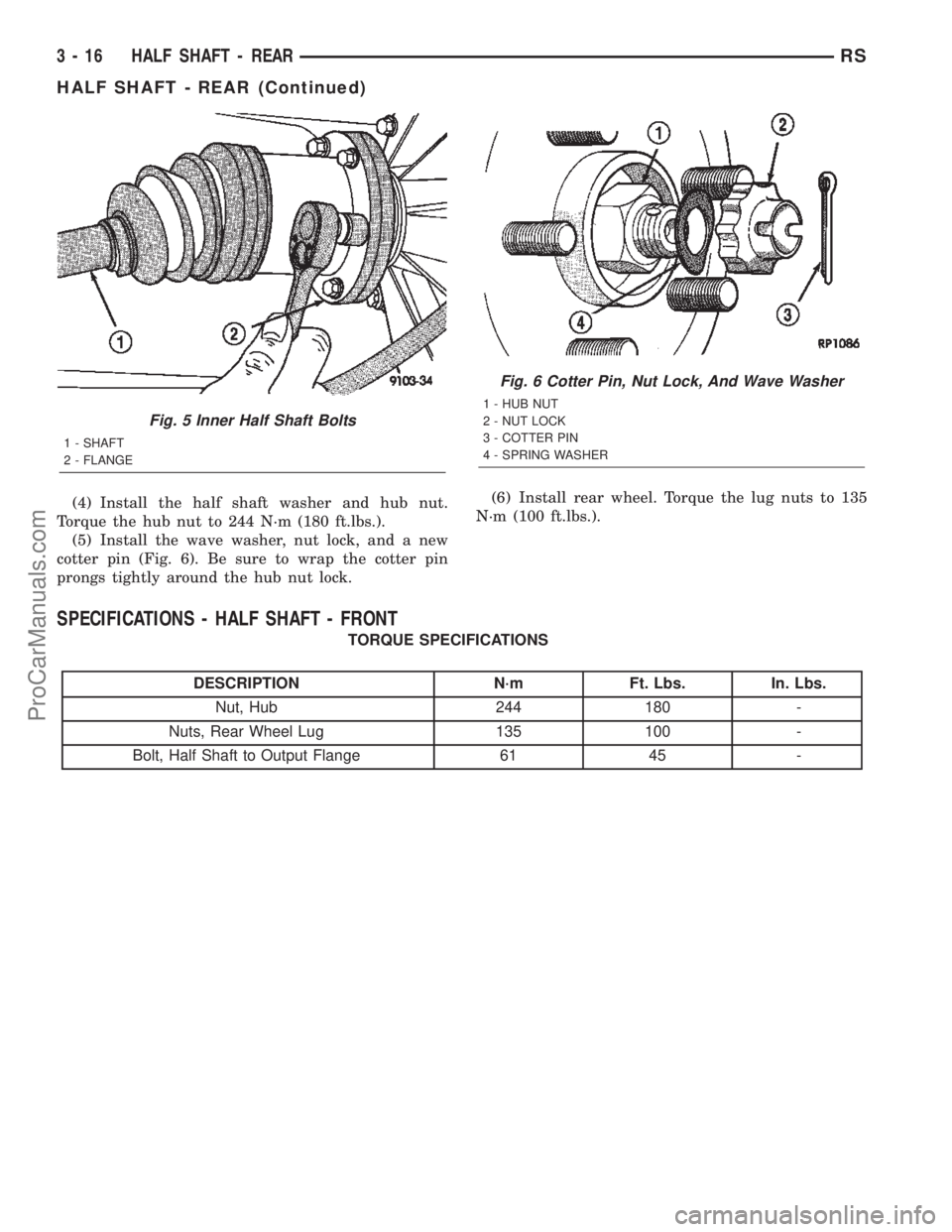

(4) Install the half shaft washer and hub nut.

Torque the hub nut to 244 N´m (180 ft.lbs.).

(5) Install the wave washer, nut lock, and a new

cotter pin (Fig. 6). Be sure to wrap the cotter pin

prongs tightly around the hub nut lock.(6) Install rear wheel. Torque the lug nuts to 135

N´m (100 ft.lbs.).

SPECIFICATIONS - HALF SHAFT - FRONT

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Nut, Hub 244 180 -

Nuts, Rear Wheel Lug 135 100 -

Bolt, Half Shaft to Output Flange 61 45 -

Fig. 5 Inner Half Shaft Bolts

1 - SHAFT

2 - FLANGE

Fig. 6 Cotter Pin, Nut Lock, And Wave Washer

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - SPRING WASHER

3 - 16 HALF SHAFT - REARRS

HALF SHAFT - REAR (Continued)

ProCarManuals.com

Page 100 of 2399

CRIMP TYPE BOOT CLAMP

If seal boot uses crimp type boot clamp, use the fol-

lowing procedure to install the retaining clamp.

(1) Place crimping tool C-4975-A over bridge of

clamp (Fig. 21).

(2) Tighten nut on crimping tool C-4975-A until

jaws on tool are closed completely together, face to

face (Fig. 22).

LATCHING TYPE BOOT CLAMP

If seal boot uses low profile latching type boot

clamp, use the following procedure to install the

retaining clamp.

(1) Place prongs of clamp locking tool in the holes

of the clamp (Fig. 23).

(2) Squeeze tool together until top band of clamp is

latched behind the two tabs on lower band of clamp

(Fig. 24).

(16) Install the half shaft into the vehicle. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/HALF SHAFT

- INSTALLATION)

Fig. 21 Crimping Tool Installed on Sealing Boot

Clamp - Typical

1 - CLAMP

2 - TRIPOD JOINT HOUSING

3 - SPECIAL TOOL C-4975-A

4 - SEALING BOOT

Fig. 22 Sealing Boot Retaining Clamp Installed -

Typical

1 - CLAMP

2 - TRIPOD HOUSING

3 - SPECIAL TOOL C-4975-A

4 - JAWS OF SPECIAL TOOL C-4975-A MUST BE CLOSED

COMPLETELY TOGETHER HERE

5 - SEALING BOOT

Fig. 23 Clamping Tool Installed on Sealing Boot

Clamp

1 - CLAMP

2 - TOOL YA3050, OR EQUIVALENT

3 - SEALING BOOT

Fig. 24 Sealing Boot Clamp Correctly Installed

1 - INNER TRIPOD JOINT HOUSING

2 - TOP BAND OF CLAMP MUST BE RETAINED BY TABS AS

SHOWN HERE TO CORRECTLY LATCH BOOT CLAMP

3 - SEALING BOOT

RSHALF SHAFT - REAR3-21

CV BOOT - INNER/OUTER (Continued)

ProCarManuals.com

Page 104 of 2399

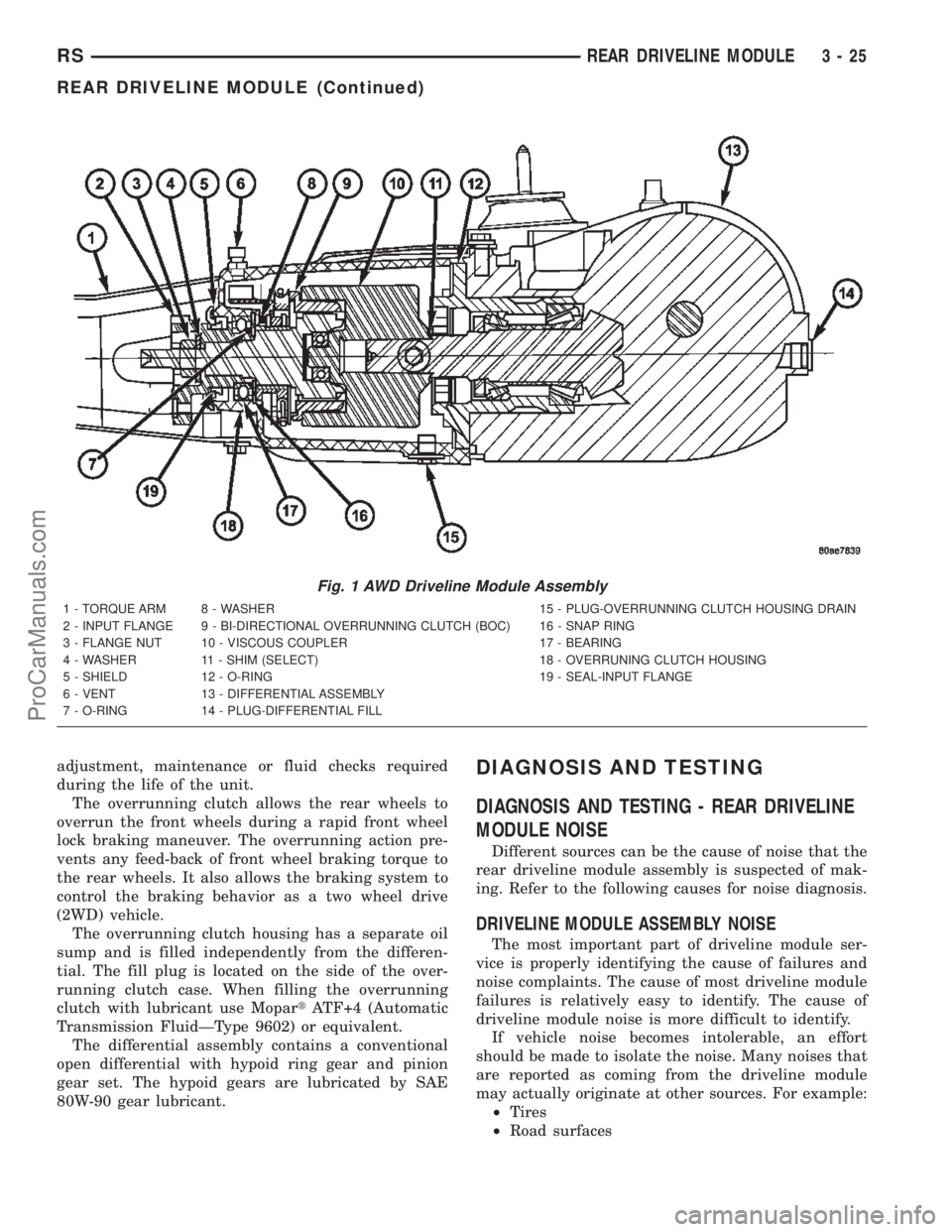

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

²Tires

²Road surfaces

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM 8 - WASHER 15 - PLUG-OVERRUNNING CLUTCH HOUSING DRAIN

2 - INPUT FLANGE 9 - BI-DIRECTIONAL OVERRUNNING CLUTCH (BOC) 16 - SNAP RING

3 - FLANGE NUT 10 - VISCOUS COUPLER 17 - BEARING

4 - WASHER 11 - SHIM (SELECT) 18 - OVERRUNING CLUTCH HOUSING

5 - SHIELD 12 - O-RING 19 - SEAL-INPUT FLANGE

6 - VENT 13 - DIFFERENTIAL ASSEMBLY

7 - O-RING 14 - PLUG-DIFFERENTIAL FILL

RSREAR DRIVELINE MODULE3-25

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 109 of 2399

(12) Remove overrunning clutch housing large

o-ring from differential assembly (Fig. 14).

(13) Remove output flanges using suitable screw-

drivers and wood blocks to protect casting (Fig. 12).(14) Remove output flange seals (Fig. 13).

ASSEMBLY

(1) Install output flange seals using tools C4171

and 8493 (Fig. 15).

(2) Install large overrunning clutch housing o-ring

to differential assembly (Fig. 14).

(3) Install shim to differential pinion shaft (Fig.

16).

Fig. 12 Output Flange Removal

1 - WOOD BLOCK

2 - PRYBAR

3 - OUTPUT SHAFT

4 - PRYBAR

5 - WOOD BLOCK

6 - DIFFERENTIAL CASE

Fig. 13 Output Flange Seal Removal

1 - OUTPUT FLANGE SEAL

2 - SCREWDRIVER

3 - 30 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 111 of 2399

(4) Install viscous coupler to differential pinion

shaft (Fig. 17).

(5) Install overrunning clutch assembly to viscous

coupler (Fig. 18).(6) Install washer to overrunning clutch (Fig. 14).

(7) Install o-ring to overrunning clutch (Fig. 14).

(8) Align overrunning clutch ground tab to 12

o'clock position (Fig. 19).

(9) Install overrunning clutch housing into posi-

tion, making sure ground tab engages with notch in

housing (Fig. 20).

Fig. 17 Viscous Coupler

1 - VISCOUS COUPLER

2 - DIFFERENTIAL PINION

Fig. 18 Overrunning Clutch

1 - OVERRUNNING CLUTCH

2 - VISCOUS COUPLER

Fig. 19 Grounding Tab at 12 O'clock

1 - OVERRUNNING CLUTCH

2 - GROUND TAB

Fig. 20 Overrunning Clutch Housing

1 - OVERRUNNING CLUTCH HOUSING

2 - NOTCH

3 - 32 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 115 of 2399

BI-DIRECTIONAL

OVERRUNNING CLUTCH

DESCRIPTION

The bi-directional overrunning clutch (BOC) (Fig.

28) works as a mechanical disconnect between the

front and rear axles, preventing torque from being

transferred from the rear axle to the front. The BOC

is a simply an overrunning clutch which works in

both clockwise and counter-clockwise rotations. This

means that when the output (the rear axle) is rotat-

ing faster in one direction than the input (front axle),

there is no torque transmission. But when the input

speed is equal to the output speed, the unit becomes

locked. The BOC provides significant benefits regard-

ing braking stability, handling, and driveline durabil-

ity. Disconnecting the front and the rear driveline

during braking helps to maintain the braking stabil-

ity of an AWD vehicle. In an ABS/braking event, the

locking of the rear wheels must be avoided for stabil-

ity reasons. Therefore brake systems are designed to

lock the front wheels first. Any torque transfer from

the rear axle to the front axle disturbs the ABS/brak-

ing system and causes potential instabilities on aslippery surface. The BOC de-couples the rear driv-

eline as soon the rear wheels begin to spin faster

than the front wheels (front wheels locked) in order

to provide increased braking stability. Furthermore

the BOC also reduces the likelihood of throttle off

over-steer during cornering. In a throttle off maneu-

ver, the BOC once again de-couples the rear driveline

forcing all the engine brake torque to the front

wheels. This eliminates the chance of lateral slip on

the rear axle and increases it on the front. The vehi-

cle will therefore tend to understeer, a situation

which is considered easier to manage in most circum-

stances. During this maneuver, and during the ABS

braking event, the BOC does not transmit torque

through to the rear wheels. The rear driveline mod-

ule, with the BOC, will perform the same as a front

wheel drive vehicle during these events. The gear

ratio offset between the front and rear differentials

force the BOC into the overrunning mode most of the

time. This allows BOC to significantly reduce the

rolling resistance of the vehicle, which improves fuel

consumption, allows the downsizing of the driveline

components, and prevents the PTU and propshaft

joints from overheating.

3 - 36 REAR DRIVELINE MODULERS

ProCarManuals.com