wiper fluid CHRYSLER CARAVAN 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1036 of 2399

Component Page

Right Rear Lamp Assembly........... 8W-80-107

Right Rear Pillar Speaker............ 8W-80-107

Right Rear Reading Lamp (Luxury).... 8W-80-107

Right Rear Speaker................. 8W-80-107

Right Rear Vent Motor.............. 8W-80-107

Right Rear Wheel Speed Sensor....... 8W-80-108

Right Remote Radio Switch........... 8W-80-108

Right Repeater Lamp

(Built-Up-Export)................ 8W-80-108

Right Seat Airbag.................. 8W-80-108

Right Side Impact Airbag

Control Module.................. 8W-80-108

Right Sliding Door Control Module C1

(Power Sliding Door).............. 8W-80-109

Right Sliding Door Control Module C2

(Power Sliding Door).............. 8W-80-109

Right Sliding Door Latch Sensing Switch

(Power Sliding Door).............. 8W-80-109

Right Sliding Door Lock Motor

(Power Sliding Door).............. 8W-80-110

Right Sliding Door Lock Motor/Ajar Switch

(Manual Sliding Door)............. 8W-80-110

Right Sliding Door Motor

(Power Sliding Door).............. 8W-80-110

Right Speed Control Switch.......... 8W-80-110

Right Stop/Turn Signal Relay

(Trailer Tow).................... 8W-80-110Component Page

Right Turn Signal Lamp

(Built-Up-Export)................. 8W-80-111

Right Visor/Vanity Lamp

(Premium/Luxury)................ 8W-80-111

Sentry Key Immobilizer Module....... 8W-80-111

Siren (United Kingdom).............. 8W-80-111

Solenoid/Pressure Switch Assy (EATX) . . 8W-80-111

Speed Control Servo (Gas)............ 8W-80-112

Thatcham Alarm Module C1

(United Kingdom)................ 8W-80-112

Thatcham Alarm Module C2

(United Kingdom)................ 8W-80-112

Throttle Position Sensor (Gas)......... 8W-80-112

Torque Converter Clutch Solenoid

(ATX).......................... 8W-80-113

Traction Control Switch.............. 8W-80-113

Trailer Tow Connector

(Except Built-Up-Export)........... 8W-80-113

Transmission Control Module (EATX) . . . 8W-80-114

Transmission Range Sensor (EATX).... 8W-80-115

TXV Solenoid (ATC)................ 8W-80-115

Vehicle Speed Sensor (MTX/ATX)...... 8W-80-115

Washer Fluid Level Switch........... 8W-80-115

Water In Fuel Sensor (Diesel)......... 8W-80-116

Wiper Module..................... 8W-80-116

RS8W-80 CONNECTOR PIN-OUTS8W-80-5

ProCarManuals.com

Page 1045 of 2399

BODY CONTROL MODULE C5 - BLACK/BLACK 34 WAY

CAV CIRCUIT FUNCTION

1 L91 20WT/DB HAZARD SWITCH SENSE

2- -

3- -

4- -

5- -

6- -

7- -

8- -

9- -

10 G20 20VT/BR IGNITION SWITCH SENSE

11 - -

12 - -

13 - -

14 - -

15 - -

16 G926 20VT/WT REAR WIPER SWITCH MUX RETURN

17 L900 20WT/YL HEADLAMP SWITCH MUX RETURN

18 L307 20WT/BR HEADLAMP SWITCH MUX

19 - -

20 - -

21 - -

22 - -

23 - -

24 - -

25 L36 20WT/DB (BUILT-UP-EXPORT) REAR FOG LAMP INDICATOR DRIVER

26 X20 20GY/WT RADIO CONTROL MUX

27 G194 20VT/LG HIGH BEAM/FRONT WASHER SWITCH MUX

28 W26 20BR/DB REAR WIPER SWITCH MUX

29 W52 20BR/YL FRONT WIPER SWITCH MUX

30 E2 20OR/BR PANEL LAMPS DIMMER SIGNAL

31 L305 20WT/LB TURN SIGNAL SWITCH MUX

32 - -

33 - -

34 L39 20WT/OR (HIGH LINE) FRONT FOG LAMP INDICATOR DRIVER

BOOST PRESSURE SENSOR (DIESEL) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 K121 20DB BOOST PRESSURE SENSOR GROUND

2 K21 20DB/LG INTAKE AIR TEMPERATURE SENSOR SIGNAL

3 F851 18LB/PK SENSOR REFERENCE VOLTAGE B

4 K37 20DB/YL BOOST PRESSURE SENSOR SIGNAL

BRAKE FLUID LEVEL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

A B20 20DG/OR BRAKE FLUID LEVEL SWITCH SENSE

B Z420 20BK/OR GROUND

8W - 80 - 14 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1101 of 2399

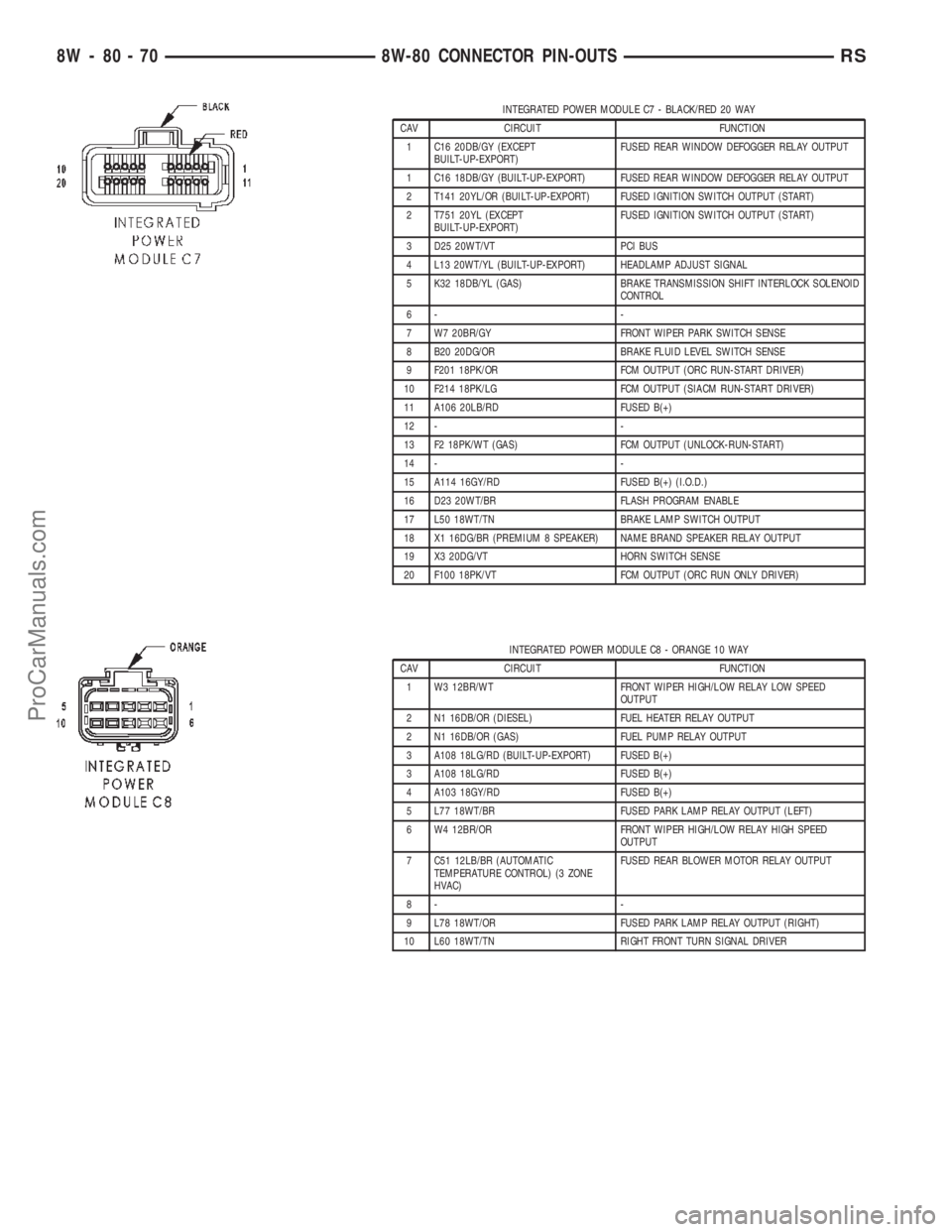

INTEGRATED POWER MODULE C7 - BLACK/RED 20 WAY

CAV CIRCUIT FUNCTION

1 C16 20DB/GY (EXCEPT

BUILT-UP-EXPORT)FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

1 C16 18DB/GY (BUILT-UP-EXPORT) FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

2 T141 20YL/OR (BUILT-UP-EXPORT) FUSED IGNITION SWITCH OUTPUT (START)

2 T751 20YL (EXCEPT

BUILT-UP-EXPORT)FUSED IGNITION SWITCH OUTPUT (START)

3 D25 20WT/VT PCI BUS

4 L13 20WT/YL (BUILT-UP-EXPORT) HEADLAMP ADJUST SIGNAL

5 K32 18DB/YL (GAS) BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID

CONTROL

6- -

7 W7 20BR/GY FRONT WIPER PARK SWITCH SENSE

8 B20 20DG/OR BRAKE FLUID LEVEL SWITCH SENSE

9 F201 18PK/OR FCM OUTPUT (ORC RUN-START DRIVER)

10 F214 18PK/LG FCM OUTPUT (SIACM RUN-START DRIVER)

11 A106 20LB/RD FUSED B(+)

12 - -

13 F2 18PK/WT (GAS) FCM OUTPUT (UNLOCK-RUN-START)

14 - -

15 A114 16GY/RD FUSED B(+) (I.O.D.)

16 D23 20WT/BR FLASH PROGRAM ENABLE

17 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

18 X1 16DG/BR (PREMIUM 8 SPEAKER) NAME BRAND SPEAKER RELAY OUTPUT

19 X3 20DG/VT HORN SWITCH SENSE

20 F100 18PK/VT FCM OUTPUT (ORC RUN ONLY DRIVER)

INTEGRATED POWER MODULE C8 - ORANGE 10 WAY

CAV CIRCUIT FUNCTION

1 W3 12BR/WT FRONT WIPER HIGH/LOW RELAY LOW SPEED

OUTPUT

2 N1 16DB/OR (DIESEL) FUEL HEATER RELAY OUTPUT

2 N1 16DB/OR (GAS) FUEL PUMP RELAY OUTPUT

3 A108 18LG/RD (BUILT-UP-EXPORT) FUSED B(+)

3 A108 18LG/RD FUSED B(+)

4 A103 18GY/RD FUSED B(+)

5 L77 18WT/BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

6 W4 12BR/OR FRONT WIPER HIGH/LOW RELAY HIGH SPEED

OUTPUT

7 C51 12LB/BR (AUTOMATIC

TEMPERATURE CONTROL) (3 ZONE

HVAC)FUSED REAR BLOWER MOTOR RELAY OUTPUT

8- -

9 L78 18WT/OR FUSED PARK LAMP RELAY OUTPUT (RIGHT)

10 L60 18WT/TN RIGHT FRONT TURN SIGNAL DRIVER

8W - 80 - 70 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1157 of 2399

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Seat Airbag YL At Passenger Seat N/S

Right Side Impact Airbag Control

ModuleYL/RD Right B Pillar 33

Right Sliding Door Control Module

C1BK Rear of Door 38, 39

Right Sliding Door Control Module

C2BK/RD Rear of Door 38, 39

Right Sliding Door Latch Sensing

SwitchBK At Sliding Door 38

Right Sliding Door Lock Motor BK Rear of Door 38

Right Sliding Door Lock Motor/Ajar

SwitchBK At Latch N/S

Right Sliding Door Motor BK At Sliding Door 38

Right Speed Control Switch BK At Steering Wheel N/S

Right Stop/Turn Signal Relay BK LT Quarter Panel N/S

Right Turn Signal Lamp OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

Sentry Key Immobilizer Module BK At Steering Column 15, 16, 17, 18, 26

Siren (United Kingdom) BK Left Front Body N/S

Solenoid/Pressure Switch

Assembly (EATX)BK Side of Transmission N/S

Speed Control Servo BK Near Controller Antilock Brake 14

Thatcham Alarm Module C1 BK Top Right Side of Instrument Panel

Near SpeakerN/S

Thatcham Alarm Module C1 WT Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor GY On Throttle Body 9, 13

Torque Converter Clutch Solenoid BK Front of Transmission 10

Traction Control Switch BK Rear of Swtich 16, 17, 26

Trailer Tow Connector BK Left Quarter Panel N/S

Transmission Control Module BK Top of Transmission 14

Transmission Range Sensor GY Top of Transmission 14

Vehicle Speed Sensor BK Rear of Transmission 9, 12

Washer Fluid Level Switch BK Bottom of Reservoir 3

Water in Fuel Sensor (Diesel) Left Rear Engine Compartment N/S

Wiper Module BK Left Side Cowl 6

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1543 of 2399

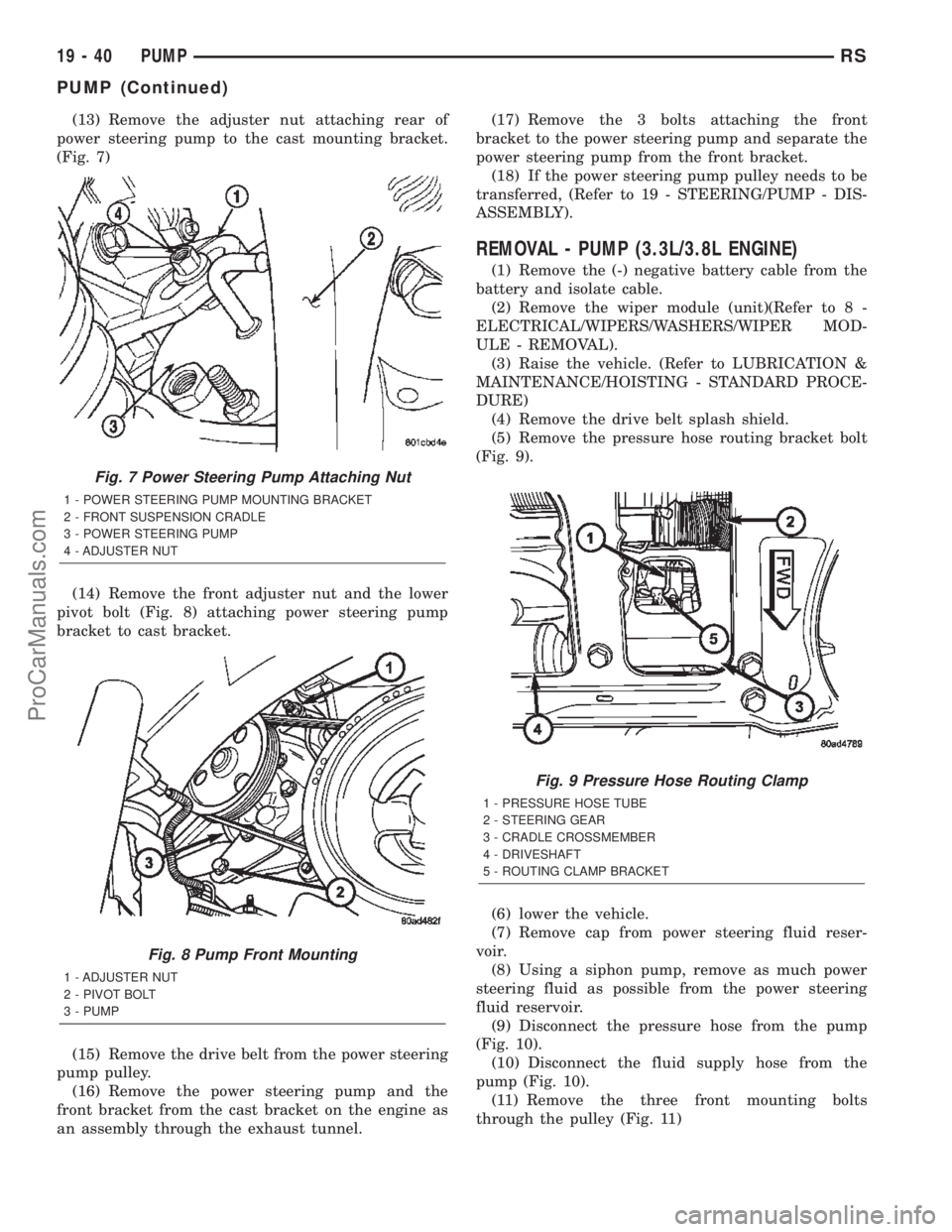

(13) Remove the adjuster nut attaching rear of

power steering pump to the cast mounting bracket.

(Fig. 7)

(14) Remove the front adjuster nut and the lower

pivot bolt (Fig. 8) attaching power steering pump

bracket to cast bracket.

(15) Remove the drive belt from the power steering

pump pulley.

(16) Remove the power steering pump and the

front bracket from the cast bracket on the engine as

an assembly through the exhaust tunnel.(17) Remove the 3 bolts attaching the front

bracket to the power steering pump and separate the

power steering pump from the front bracket.

(18) If the power steering pump pulley needs to be

transferred, (Refer to 19 - STEERING/PUMP - DIS-

ASSEMBLY).

REMOVAL - PUMP (3.3L/3.8L ENGINE)

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL).

(3) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove the drive belt splash shield.

(5) Remove the pressure hose routing bracket bolt

(Fig. 9).

(6) lower the vehicle.

(7) Remove cap from power steering fluid reser-

voir.

(8) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(9) Disconnect the pressure hose from the pump

(Fig. 10).

(10) Disconnect the fluid supply hose from the

pump (Fig. 10).

(11) Remove the three front mounting bolts

through the pulley (Fig. 11)

Fig. 7 Power Steering Pump Attaching Nut

1 - POWER STEERING PUMP MOUNTING BRACKET

2 - FRONT SUSPENSION CRADLE

3 - POWER STEERING PUMP

4 - ADJUSTER NUT

Fig. 8 Pump Front Mounting

1 - ADJUSTER NUT

2 - PIVOT BOLT

3 - PUMP

Fig. 9 Pressure Hose Routing Clamp

1 - PRESSURE HOSE TUBE

2 - STEERING GEAR

3 - CRADLE CROSSMEMBER

4 - DRIVESHAFT

5 - ROUTING CLAMP BRACKET

19 - 40 PUMPRS

PUMP (Continued)

ProCarManuals.com

Page 1546 of 2399

INSTALLATION

INSTALLATION - PUMP (2.4L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket (Fig. 7), then install the nut and

bolt attaching the front bracket to the cast bracket

(Fig. 8).Do not fully tighten at this time..

(3) Install the rear nut (Fig. 7).

(4) Install the power steering pump drive belt on

pulley and adjust (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - INSTALLATION).

(5) Tighten the two adjustment slot bolts and the

one pivot bolt to 54 N´m (40 ft. lbs.) torque.

(6) Install the accessory drive splash shield.

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(7) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 6). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(8) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 6).Be sure hose clamps are properly

reinstalled.

(9) Install the power steering fluid supply hose on

the power steering pump fluid fitting.Be sure hose

is clear of accessory drive belts all hose clamps

are properly reinstalled.

CAUTION: Heat sleeve must cover entire rubber

portion of return hose to ensure desired thermal

protection from exhaust.

(10) Properly position the protective heat sleeve

over the power steering return hose. Securely tie

strap the heat sleeve to the power steering hose to

keep in it's proper position.

(11) Install the exhaust system (Fig. 4). Install all

exhaust system isolators/hangers on the exhaust sys-

tem brackets, then the four bolts and flag nuts (Fig.

3).

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness.

(13) Lower vehicle.

(14) Connect the negative battery cable on the

negative battery post.

(15) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)(16) Inspect for leaks.

INSTALLATION - PUMP (3.3L/3.8L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

engine compartment of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket.

(3) Install the 3 front power steering pump mount-

ing bolts (Fig. 11). Tighten the 3 front power steering

pump mounting bolts to a torque of 54 N´m (40 ft.

lbs.).

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure line

into the pressure output fitting of the power steering

pump (Fig. 10).Do not fully tighten tube nut at

this time.

(5) Install the power steering fluid supply hose on

the power steering pump supply fitting (Fig. 10).Be

sure hose clamp is properly installed.

(6) Raise the vehicle.

(7) Install the routing clip on the engine for the

pressure hose (Fig. 9) and tighten fastener.

(8) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(9) Install the drive belt splash shield.

(10) Lower the vehicle.

(11) Tighten the pressure line to pump pressure

fitting tube nut to a torque of 31 N´m (275 in. lbs.).

(12) Install the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(13) Connect the negative battery cable on the

negative battery post.

(14) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(15) Inspect for leaks.

INSTALLATION - PUMP (2.5L DIESEL)

(1) Install the power steering pump on its cast

mounting bracket.

(2) Install the three front power steering pump

mounting bolts. Tighten the mounting bolts to a

torque of 54 N´m (40 ft. lbs.).

(3) Install the rear mounting bolt fastening the

stamped bracket to the cast bracket (Fig. 13).

Tighten the mounting bolt to a torque of 54 N´m (40

ft. lbs.).

RSPUMP19-43

PUMP (Continued)

ProCarManuals.com