horn CHRYSLER CARAVAN 2002 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1101 of 2399

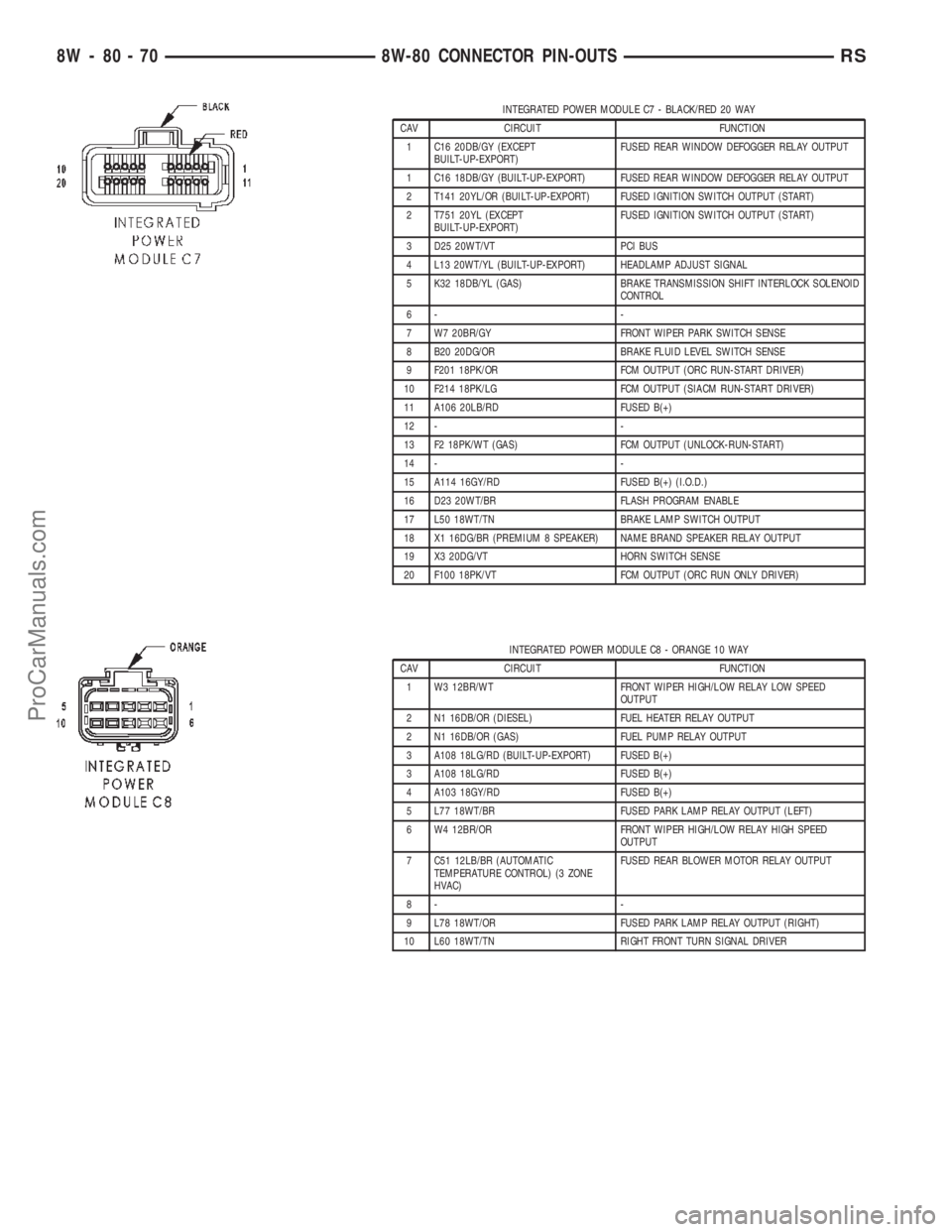

INTEGRATED POWER MODULE C7 - BLACK/RED 20 WAY

CAV CIRCUIT FUNCTION

1 C16 20DB/GY (EXCEPT

BUILT-UP-EXPORT)FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

1 C16 18DB/GY (BUILT-UP-EXPORT) FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

2 T141 20YL/OR (BUILT-UP-EXPORT) FUSED IGNITION SWITCH OUTPUT (START)

2 T751 20YL (EXCEPT

BUILT-UP-EXPORT)FUSED IGNITION SWITCH OUTPUT (START)

3 D25 20WT/VT PCI BUS

4 L13 20WT/YL (BUILT-UP-EXPORT) HEADLAMP ADJUST SIGNAL

5 K32 18DB/YL (GAS) BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID

CONTROL

6- -

7 W7 20BR/GY FRONT WIPER PARK SWITCH SENSE

8 B20 20DG/OR BRAKE FLUID LEVEL SWITCH SENSE

9 F201 18PK/OR FCM OUTPUT (ORC RUN-START DRIVER)

10 F214 18PK/LG FCM OUTPUT (SIACM RUN-START DRIVER)

11 A106 20LB/RD FUSED B(+)

12 - -

13 F2 18PK/WT (GAS) FCM OUTPUT (UNLOCK-RUN-START)

14 - -

15 A114 16GY/RD FUSED B(+) (I.O.D.)

16 D23 20WT/BR FLASH PROGRAM ENABLE

17 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

18 X1 16DG/BR (PREMIUM 8 SPEAKER) NAME BRAND SPEAKER RELAY OUTPUT

19 X3 20DG/VT HORN SWITCH SENSE

20 F100 18PK/VT FCM OUTPUT (ORC RUN ONLY DRIVER)

INTEGRATED POWER MODULE C8 - ORANGE 10 WAY

CAV CIRCUIT FUNCTION

1 W3 12BR/WT FRONT WIPER HIGH/LOW RELAY LOW SPEED

OUTPUT

2 N1 16DB/OR (DIESEL) FUEL HEATER RELAY OUTPUT

2 N1 16DB/OR (GAS) FUEL PUMP RELAY OUTPUT

3 A108 18LG/RD (BUILT-UP-EXPORT) FUSED B(+)

3 A108 18LG/RD FUSED B(+)

4 A103 18GY/RD FUSED B(+)

5 L77 18WT/BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

6 W4 12BR/OR FRONT WIPER HIGH/LOW RELAY HIGH SPEED

OUTPUT

7 C51 12LB/BR (AUTOMATIC

TEMPERATURE CONTROL) (3 ZONE

HVAC)FUSED REAR BLOWER MOTOR RELAY OUTPUT

8- -

9 L78 18WT/OR FUSED PARK LAMP RELAY OUTPUT (RIGHT)

10 L60 18WT/TN RIGHT FRONT TURN SIGNAL DRIVER

8W - 80 - 70 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1113 of 2399

LIFTGATE CYLINDER LOCK SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z465 20BK/GY GROUND

2 G165 20VT/GY LIFTGATE CYLINDER LOCK SWITCH MUX

LIFTGATE LEFT PINCH SENSOR (POWER LIFTGATE) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q77 20OR/DB RIGHT PINCH SENSOR SIGNAL

2 Q76 20OR/LB PINCH SENSOR SIGNAL

LIFTGATE RIGHT PINCH SENSOR (POWER LIFTGATE) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q77 20OR/DB RIGHT PINCH SENSOR SIGNAL

2 Z78 20BK/OR GROUND

LOW NOTE HORN - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z298 18BK/DB GROUND

2 X2 18DG/OR HORN RELAY OUTPUT

MANIFOLD ABSOLUTE PRESSURE SENSOR (GAS) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K1 18VT/BR MANIFOLD ABSOLUTE PRESSURE SENSOR SIGNAL

2 K900 18DB/DG SENSOR GROUND

3 F855 18PK/YL (BUILT-UP-EXPORT) 5 VOLT SUPPLY

3 F855 18OR/PK (EXCEPT

BUILT-UP-EXPORT)5 VOLT SUPPLY

8W - 80 - 82 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1152 of 2399

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Fuel Injector No.3 BK At Fuel Injector N/S

Fuel Injector No.3 (Diesel) BK At Fuel Injector 11

Fuel Injector No.4 BK At Fuel Injector N/S

Fuel Injector No.4 (Diesel) BK At Fuel Injector 11

Fuel Injector No.5 BK At Fuel Injector N/S

Fuel Injector No.6 BK At Fuel Injector N/S

Fuel Pump Module LTGY Side of Fuel Tank N/S

Fuel Pressure Sensor (Diesel) BK Top Left of Engine 11

Generator BK Rear of Generator 10, 11, 13, 14

Glove Box Lamp BL Rear of Glove Box 18, 24

Glow Plug Relay (Diesel) BK Near Battery N/S

Halo Lamp WT Steering Column 15, 16, 17, 18, 26

Headlamp Switch BK Rear of Switch 15, 16, 25

Headlamp Washer Pump Motor At Motor N/S

High Note Horn BK Left Frame Rail 5

High Pressure Fuel Pump (Diesel) Rear of Pump 11

Hood Ajar Switch BK Left Fender 6

Idle Air Control Motor (2.4L) BK On Throttle Body 9

Idle Air Control Motor (3.3/3.8L) BK On Throttle Body 13

Ignition Coil Pack 2.4L BK Top of Valve Cover 9, 10

Ignition Coil Pack 3.3L, 3.8L DKGY Top of Engine 14

Ignition Switch BK Rear of Switch at Steering Column 15, 16, 17, 18, 26

Inlet Air Temperature Sensor BK Top Left of Engine N/S

Instrument Cluster BK Rear of Cluster 15, 16, 23

Instrument Panel Switch Bank BK Right Center of Instrument Panel 15, 18, 20

Instrument Panel Power Outlet NAT Center of Instrument Panel N/S

Integrated Power Module C1 LTGN Left Fender Shield 7

Integrated Power Module C2 GN/BL Left Fender Shield 7

Integrated Power Module C3

(Diesel)YL/RD Left Fender Shield 7

Integrated Power Module C3 (Gas) NAT/RD Left Fender Shield 7

Integrated Power Module C4 BL Left Fender Shield 7

Integrated Power Module C5 BK Left Fender Shield 7

Integrated Power Module C6 NAT Left Fender Shield 7

Integrated Power Module C7 BK/RD Left Fender Shield 7

Integrated Power Module C8 OR Left Fender Shield 7

Integrated Power Module C9 BK Left Fender Shield 7

Knock Sensor GY Front of Cylinder Block N/S

Leak Detection Pump LTGY At Pump 9, 10 14

Left B Pillar Switch GY Left B Pillar 34

Left Cinch/Release Motor GY Left Sliding Door N/S

Left Combination Relay BK Left Rear Quarter Panel N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-5

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1154 of 2399

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Liftgate Ajar Switch (Manual

Release)BK At Latch 42

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 42

Liftgate Cinch/Release Motor BL Liftgate N/S

Liftgate Cylinder Lock Switch BK At Switch 42

Liftgate Left Pinch Sensor BK Left Side of Liftgate N/S

Liftgate Right Pinch Sensor BK Right Side of Liftgate N/S

Low Note Horn BK Left Frame Rail 5

Manifold Absolute Pressure Sensor BK On Intake 10

Mass Air Flow Sensor (Diesel) OR Top of Engine 11, 12

Memory Seat/Mirror Module C1 GY Under Driver Seat N/S

Memory Seat/Mirror Module C2 GY Under Driver Seat N/S

Memory Seat/Mirror Module C3 WT Under Driver Seat N/S

Memory Seat/Mirror Module C4 GY Under Driver Seat N/S

Memory Seat Front Vertical Motor RD Under Seat N/S

Memory Seat Front Vertical

Position SensorBK Under Seat N/S

Memory Seat Horizontal Motor BK Under Seat N/S

Memory Seat Horizontal Position

SensorBK Under Seat N/S

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical Position

SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Seat Switch BK At Switch Driver Door N/S

Message Center WT Rear of Message Center 15, 16, 23

Mode Door Actuator GY Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 15, 16, 17, 18, 26

Output Speed Sensor GY Front of Transmission 14

Overhead Console BK Front of Console N/S

Oxygen Sensor 1/1 Upstream BK Rear of Engine 9, 10, 14

Oxygen Sensor 1/2 Downstream BK Rear of Engine 9, 10, 14

Park/Neutral Positon Switch BK Front of Transmission 10

Passenger Airbag YL Passenger Side of Instrument Panel 15, 18, 19 24

Passenger Blend Door Actuator On HVAC N/S

Passenger Door Courtesy Lamp BK At Lamp 37

Passenger Door Lock Switch BK At Switch 37

Passenger Folding Mirror Relay BL Right Kick Panel N/S

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module C1 GY At Heated Seat N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1159 of 2399

SPLICE NUMBER LOCATION FIG.

S117 (2.4L) Neat T/O for G101 and G103 10

S117 (3.3L/3.8L) Near T/O for Output Speed Sensor 14

S118 (2.4L) Near T/O for Knock Sensor 10

S119 (2.5L) Near T/O for Engine Starter Motor 11

S120 (2.4L) Near T/O for Oxygen Sensors 9

S120 (3.3L/3.8L) Near T/O for Oxygen Sensors 14

S121 (3.3L/3.8L) Near T/O for Output Speed Sensor 14

S122 (2.4L) In T/O to Engine Starter Motor 10

S122 (3.3L/3.8L) In T/O to Engine Starter Motor 14

S123 In T/O to Low Note Horn 5

S124 (2.4L) Near T/O for Fuel Injector No.2 N/S

S124 (3.3L/3.8L) Near T/O for Fuel Injector No.5 and No.6 N/S

S125 (2.4L) In T/O for Manifold Absolute Pressure Sensor N/S

S126 In Right Headlamp Leveling Assembly N/S

S127 (2.5L) Near T/O for Engine Starter Motor N/S

S128 (2.5L) Near T/O for Engine Starter Motor 11

S129 (2.5L) Near T/O for Battery (+) N/S

S130 (2.5L) Near T/O for Battery (+) N/S

S131 (3.3L/3.8L) Near T/O for Transmission Control Module N/S

S132 (2.5L) Near T/O for Battery (+) N/S

S133 (2.5L) Near T/O for Intelligent Power Module C3 N/S

S134 Near T/O for Controller Antilock Brake N/S

S135 (2.5L) Near T/O for Glow Plug No.2 11

S136 (2.5L) Between T/O for Radiator Fan No.2 and T/O for G102 N/S

S137 (2.5L) Near T/O for A/C Compressor Clutch 11

S138 (2.5L) Between T/O for Radiator Fan No.2 and T/O for G102 N/S

S139 (2.5L) Between T/O for Engine Starter Motor and T/O for

Engine Control Module C112

S141 (2.4L) Near T/O for Powertrain Control Module N/S

S141 (2.5L) Near /t/O for G100 N/S

S141 (3.3L/3.8L) Near T/O for Powertrain Control Module N/S

S142 (3.3L/3.8L) Near T/O for A/C Compressor Clutch 14

S143 (2.5L) Near T/O for Engine Control Module C1 11

S143 (3.3L/3.8L) Near T/O for Intelligent Power Module - C3 N/S

S144 (2.5L) Between T/O for Battery Temperature Sensor and T/O

for C10311

S145 (2.5L) Near T/O for Battery (+) N/S

S148 (2.5L) Near T/O for Engine Starter Motor 11

S150 (2.5L) Between T/O for Battery Temperature Sensor and T/O

for C103N/S

S151 (2.5L) Near T/O for Radiator Fan Relay No.1 2

S152 (2.5L) Near T/O for Left Fog Lamp N/S

S157 (2.5L) Near T/O for Glow Plug No.1 11

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1526 of 2399

(10) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(11) Install the upper and lower shrouds (Refer to

19 - STEERING/COLUMN/LOWER SHROUD -

INSTALLATION).

(12) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(13) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

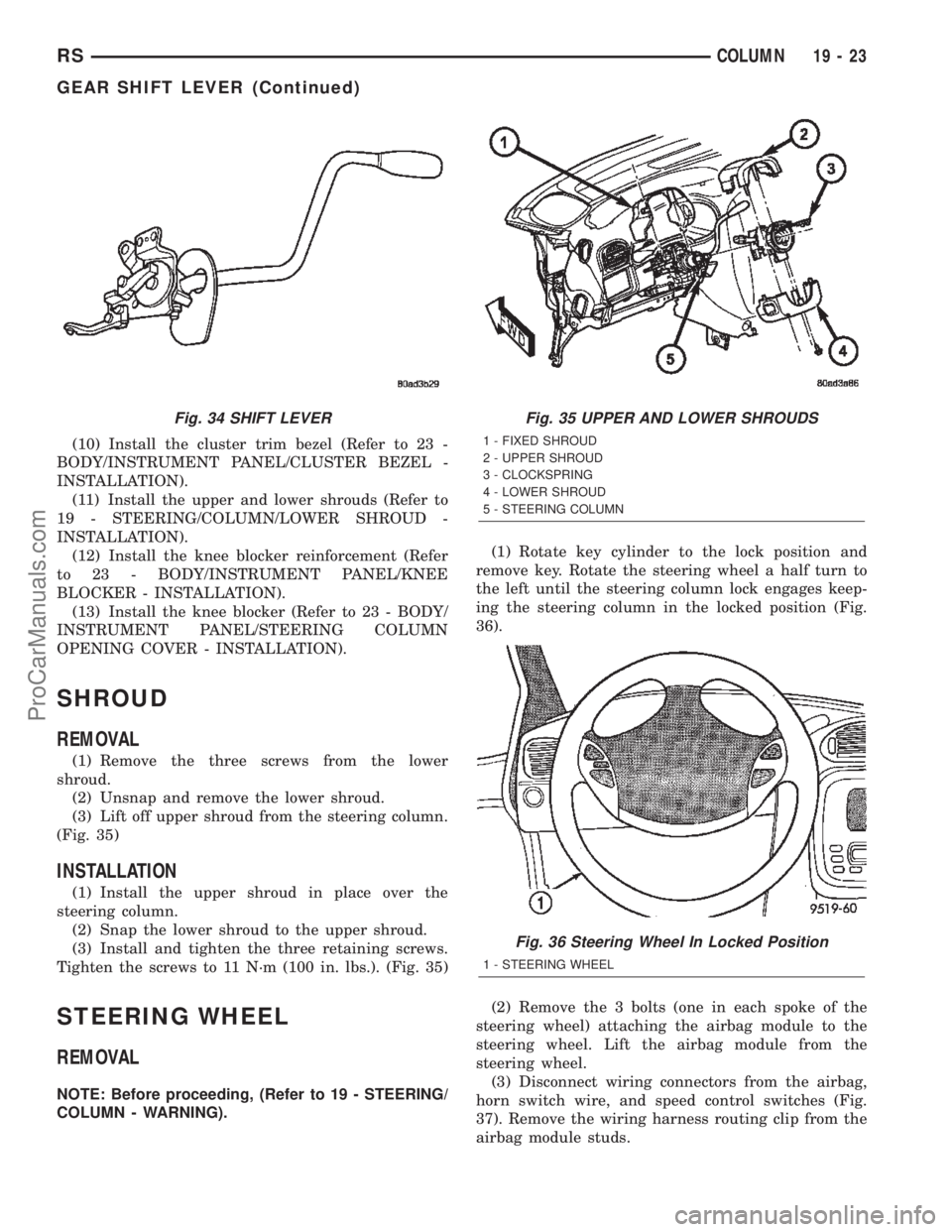

SHROUD

REMOVAL

(1) Remove the three screws from the lower

shroud.

(2) Unsnap and remove the lower shroud.

(3) Lift off upper shroud from the steering column.

(Fig. 35)

INSTALLATION

(1) Install the upper shroud in place over the

steering column.

(2) Snap the lower shroud to the upper shroud.

(3) Install and tighten the three retaining screws.

Tighten the screws to 11 N´m (100 in. lbs.). (Fig. 35)

STEERING WHEEL

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING).(1) Rotate key cylinder to the lock position and

remove key. Rotate the steering wheel a half turn to

the left until the steering column lock engages keep-

ing the steering column in the locked position (Fig.

36).

(2) Remove the 3 bolts (one in each spoke of the

steering wheel) attaching the airbag module to the

steering wheel. Lift the airbag module from the

steering wheel.

(3) Disconnect wiring connectors from the airbag,

horn switch wire, and speed control switches (Fig.

37). Remove the wiring harness routing clip from the

airbag module studs.

Fig. 34 SHIFT LEVERFig. 35 UPPER AND LOWER SHROUDS

1 - FIXED SHROUD

2 - UPPER SHROUD

3 - CLOCKSPRING

4 - LOWER SHROUD

5 - STEERING COLUMN

Fig. 36 Steering Wheel In Locked Position

1 - STEERING WHEEL

RSCOLUMN19-23

GEAR SHIFT LEVER (Continued)

ProCarManuals.com

Page 1527 of 2399

If the steering wheel is equipped with remote radio

controls, disconnect the connector from the clock-

spring. Release the connector by depressing the tang

as shown (Fig. 38), then slide the connector apart.

(4) Remove the steering wheel retaining nut (Fig.

39) from the steering column shaft.

(5) Remove the steering wheel damper (Fig. 39)

from the steering wheel.

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.CAUTION: When installing steering wheel puller

bolts in steering wheel, (Fig. 40) do not thread bolt

into steering wheel more than a half inch. If bolts

are threaded into the steering wheel more than a

half inch they will contact and damage the clock-

spring.

(6) Remove the steering wheel from steering col-

umn shaft using a steering wheel puller (Fig. 40).

Fig. 37 Airbag Module Wiring Connections

1 - WIRING HARNESS ROUTING CLIP

2 - AIRBAG MODULE CONNECTOR

3 - HORN SWITCH CONNECTOR

4 - SPEED CONTROL SWITCH CONNECTORS

Fig. 38 Releasing Remote Radio Control Connector

1 - STEERING WHEEL

2 - REMOTE RADIO CONTROL CONNECTOR

Fig. 39 Steering Wheel Retaining Nut

1 - STEERING COLUMN SHAFT

2 - STEERING WHEEL DAMPER

3 - STEERING WHEEL RETAINING NUT

4 - CLOCKSPRING

5 - CLOCKSPRING WIRING HARNESS

6 - STEERING WHEEL

Fig. 40 Removing Steering Wheel From Steering

Column Shaft

1 - STEERING WHEEL

2 - CLOCK SPRING WIRING HARNESS

19 - 24 COLUMNRS

STEERING WHEEL (Continued)

ProCarManuals.com

Page 1528 of 2399

INSTALLATION

CAUTION: Do not force steering wheel onto steer-

ing column shaft by driving it on. Pull steering

wheel down onto shaft using only the steering

wheel retaining nut.

(1) Align master splines on steering wheel and

steering shaft, and flats on steering wheel with for-

mations on clockspring. Install the steering wheel on

the steering column shaft. All wiring leads from the

clockspring must be routed as shown (Fig. 41).NOTE: Before installing the damper on the steering

wheel, inspect the damper to ensure the rubber iso-

lator on the damper is not deteriorated or damaged.

If the damper is installed with a damaged isolator a

buzz, squeak or rattle condition may develop.

(2) Install the steering wheel damper on the steer-

ing wheel. When damper is installed, it must be posi-

tioned on the steering wheel as shown in (Fig. 39).

(3) Install the steering wheel retaining nut.

Tighten the steering wheel retaining nut to a torque

of 61 N´m (45 ft. lbs.).

(4) Connect the wiring lead from the clockspring to

the remote radio control connector (Fig. 38).

(5) Install the wiring leads from the clockspring on

the airbag, horn switch wire, and speed control

switches (Fig. 37). Attach the wire routing clip to the

studs on the airbag module.

(6) Install the airbag module in the steering wheel.

(7) Install the 3 bolts (1 in each spoke of the steer-

ing wheel) attaching the airbag module to the steer-

ing wheel. Tighten the 3 airbag module attaching

nuts to a torque of 11 N´m (100 in. lbs.).

Fig. 41 Steering Wheel And Clock Spring Wire

Routing

1 - STEERING WHEEL

2 - CLOCK SPRING

3 - CLOCK SPRING WIRING LEADS

RSCOLUMN19-25

STEERING WHEEL (Continued)

ProCarManuals.com

Page 1972 of 2399

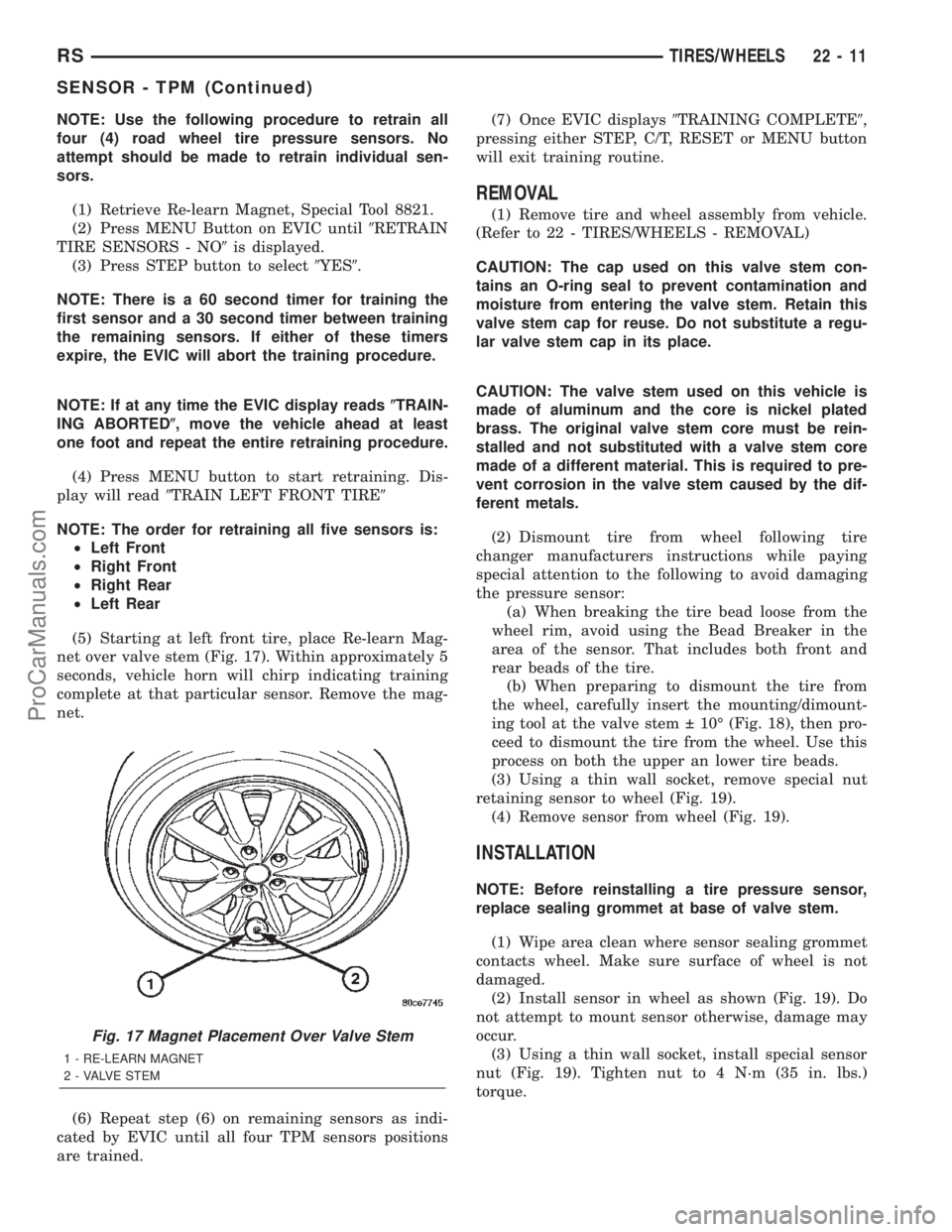

NOTE: Use the following procedure to retrain all

four (4) road wheel tire pressure sensors. No

attempt should be made to retrain individual sen-

sors.

(1) Retrieve Re-learn Magnet, Special Tool 8821.

(2) Press MENU Button on EVIC until9RETRAIN

TIRE SENSORS - NO9is displayed.

(3) Press STEP button to select9YES9.

NOTE: There is a 60 second timer for training the

first sensor and a 30 second timer between training

the remaining sensors. If either of these timers

expire, the EVIC will abort the training procedure.

NOTE: If at any time the EVIC display reads(TRAIN-

ING ABORTED(, move the vehicle ahead at least

one foot and repeat the entire retraining procedure.

(4) Press MENU button to start retraining. Dis-

play will read9TRAIN LEFT FRONT TIRE9

NOTE: The order for retraining all five sensors is:

²Left Front

²Right Front

²Right Rear

²Left Rear

(5) Starting at left front tire, place Re-learn Mag-

net over valve stem (Fig. 17). Within approximately 5

seconds, vehicle horn will chirp indicating training

complete at that particular sensor. Remove the mag-

net.

(6) Repeat step (6) on remaining sensors as indi-

cated by EVIC until all four TPM sensors positions

are trained.(7) Once EVIC displays9TRAINING COMPLETE9,

pressing either STEP, C/T, RESET or MENU button

will exit training routine.

REMOVAL

(1) Remove tire and wheel assembly from vehicle.

(Refer to 22 - TIRES/WHEELS - REMOVAL)

CAUTION: The cap used on this valve stem con-

tains an O-ring seal to prevent contamination and

moisture from entering the valve stem. Retain this

valve stem cap for reuse. Do not substitute a regu-

lar valve stem cap in its place.

CAUTION: The valve stem used on this vehicle is

made of aluminum and the core is nickel plated

brass. The original valve stem core must be rein-

stalled and not substituted with a valve stem core

made of a different material. This is required to pre-

vent corrosion in the valve stem caused by the dif-

ferent metals.

(2) Dismount tire from wheel following tire

changer manufacturers instructions while paying

special attention to the following to avoid damaging

the pressure sensor:

(a) When breaking the tire bead loose from the

wheel rim, avoid using the Bead Breaker in the

area of the sensor. That includes both front and

rear beads of the tire.

(b) When preparing to dismount the tire from

the wheel, carefully insert the mounting/dimount-

ing tool at the valve stem 10É (Fig. 18), then pro-

ceed to dismount the tire from the wheel. Use this

process on both the upper an lower tire beads.

(3) Using a thin wall socket, remove special nut

retaining sensor to wheel (Fig. 19).

(4) Remove sensor from wheel (Fig. 19).

INSTALLATION

NOTE: Before reinstalling a tire pressure sensor,

replace sealing grommet at base of valve stem.

(1) Wipe area clean where sensor sealing grommet

contacts wheel. Make sure surface of wheel is not

damaged.

(2) Install sensor in wheel as shown (Fig. 19). Do

not attempt to mount sensor otherwise, damage may

occur.

(3) Using a thin wall socket, install special sensor

nut (Fig. 19). Tighten nut to 4 N´m (35 in. lbs.)

torque.

Fig. 17 Magnet Placement Over Valve Stem

1 - RE-LEARN MAGNET

2 - VALVE STEM

RSTIRES/WHEELS22-11

SENSOR - TPM (Continued)

ProCarManuals.com