horn CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 523 of 2399

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test turn signal, headlamp beam select and opti-

cal horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the resistance read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

MULTI-FUNCTION SWITCH RESISTANCE table.

MULTI-FUNCTION SWITCH RESISTANCE

SWITCH

POSITIONPIN NUMBER RESISTANCE

LEFT 2 AND 3 1.7V 5%

RIGHT 2 AND 3 1KV 5%

OPTICAL

HORN1 AND 3 4.87KV 5%

HI BEAM 1 AND 3 2.32KV 5%

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove upper and lower steering column

shrouds. Refer to Steering, Column, Shroud,

Removal.

(3) Disconnect wire connector from back of multi-

function switch.

(4) Remove screws holding multi-function switch to

steering column adapter collar.

(5) Remove the multi-function switch.

INSTALLATION

(1) Position the switch on to the steering column.

(2) Install the two retaining screws.

(3) Connect the wire harness connector.

(4) Install the upper and lower steering column

shrouds. Refer to Steering, Column, Shroud, Installa-

tion.

(5) Connect the battery negative cable.

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove headlamp retaining screws.

(3) Twist socket counter - clockwise and remove

(Fig. 26).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Twist socket into headlamp.(3) Install headlamp retaining screws.

(4) Reconnect battery negative cable.

PARK/TURN SIGNAL LAMP -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp unit.

(3) Twist bulb socket and remove from headlamp

unit (Fig. 27).

(4) Twist bulb and remove from bulb socket.

Fig. 26 PARK/TURN SIGNAL LAMP

1 - PARK/TURN SIGNAL LAMP

2 - LAMP SOCKET

Fig. 27 PARK/TURN SIGNAL LAMP

1 - LOW BEAM HEADLAMP

2 - PARK/TURN SIGNAL LAMP

8L - 22 LAMPS/LIGHTING - EXTERIORRS

MULTI-FUNCTION SWITCH (Continued)

ProCarManuals.com

Page 537 of 2399

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory / heated system. The

options include Yes and No. The default is No. When

Yes is selected, the memory system will recall the

Driver 1 or Driver 2 memory settings assigned to the

RKE transmitter being used to unlock the vehicle.

When No is selected, the memory system will only

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps willonly turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²RETRAIN TIRE SENSORS?- This program-

mable feature only applies to vehicles equipped with

the optional Tire Pressure Monitoring System. The

options include Yes and No. The default is No. When

Yes is selected, and the menu button is depressed the

EVIC will enter the training mode, starting with the

left front tire.

²POWER ACCESSORY DELAY?- The options

include Yes and No. The default is Yes. When No is

selected, the accessory powered components will turn

off automatically when the ignition key is turned off.

When Yes is selected, the accessory powered compo-

nents will remain on for 45 seconds when the igni-

tion key is turned off.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove overhead console. Refer to Overhead

Console Removal and Installation in this section(Re-

fer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(3) Remove the ten screws holding the EVIC mod-

ule in the overhead console.

(4) Remove EVIC module from console assembly.

NOTE: IF THE EVIC MODULE IS BEING REPLACED

THE TIRE PRESSURE MONITORING SYSTEM (if

equipped) MUST BE RETRAINED. REFER TO THE

TIRES/WHEELS SECTION OF THIS MANUAL FOR

DETAILED INSTRUCTIONS.

INSTALLATION

(1) Position the EVIC module in the overhead con-

sole.

(2) Install the ten screws holding the EVIC module

in the overhead console.

(3) Install the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION).

(4) Connect the battery negative cable.

NOTE: IF THE EVIC MODULE IS BEING REPLACED

THE TIRE PRESSURE MONITORING SYSTEM (if

equipped) MUST BE RETRAINED. REFER TO THE

TIRES/WHEELS SECTION OF THIS MANUAL FOR

DETAILED INSTRUCTIONS.

8M - 8 MESSAGE SYSTEMSRS

ELECTRONIC VEHICLE INFO CENTER (Continued)

ProCarManuals.com

Page 580 of 2399

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION.........................39

OPERATION...........................40

DOOR CYLINDER LOCK SWITCH

DESCRIPTION.........................41

OPERATION...........................41

DIAGNOSIS AND TESTING - DOOR

CYLINDER LOCK SWITCH..............41

REMOVAL.............................42

INSTALLATION.........................42

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR .............................42

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK

SWITCH............................42

REMOVAL.............................43

INSTALLATION.........................43

KEYLESS ENTRY TRANSMITTER

STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE........................43STANDARD PROCEDURE - BATTERY

REPLACEMENT.......................43

SPECIFICATIONS

RANGE.............................43

BATTERY...........................43

REMOTE KEYLESS ENTRY MODULE

DESCRIPTION.........................44

OPERATION...........................44

DIAGNOSIS AND TESTING - REMOTE

KEYLESS ENTRY MODULE..............44

STANDARD PROCEDURE - PROGRAMMING

RKE MODULE........................44

REMOVAL.............................44

INSTALLATION.........................45

SLIDING DOOR LOCK MOTOR

REMOVAL.............................45

INSTALLATION.........................45

POWER LOCKS

DESCRIPTION

POWER DOOR LOCK SYSTEM

The front doors, sliding door(s) and liftgate are

equipped with actuator motors to lock or unlock the

latch mechanisms. The door lock actuator motor is

not serviced separately from the door latch, except

for the sliding door(s).

AUTOMATIC DOOR LOCK

The vehicle comes with two options for power door

locks:

²Rolling automatic lock (ENABLE), doors auto-

matically lock at approximately at 25.7 Km/h (16

mph).

²No rolling automatic lock (DISABLE), doors do

not automatically lock when the vehicle is moving.

AUTOMATIC DOOR UNLOCK

The doors will unlock automatically on vehicles

equipped with power door locks if:

²Auto door locks feature is enabled and automatic

unlock is enabled.²The transmission was in gear and speed is above

zero.

²The transmission in park or neutral and speed

is zero.

²Any door (excluding liftgate) opens.

DOOR LOCK INHIBIT

The BCM cancels out the door lock switch actua-

tion, when the key is in the Ignition Switch and

either front door is open.

Pressing the key fob RKE lock/unlock under these

conditions results in normal lock/unlock activation.

CENTRAL LOCKING

If equipped with Vehicle Theft Security System

(VTSS), all the doors can be locked with the key by

using any of the door lock cylinders. Turning the key

to the lock position will lock all the doors.

DOOR LOCK CIRCUIT PROTECTION

The door lock system is protected by a 40 amp fuse

located in the IPM. The BCM receives lock/unlock

input and will turn on the appropriate drivers and

provide a voltage level to the door lock motor for a

specific time. The IPM is located along the side of the

vehicle battery in the engine compartment.

RSPOWER LOCKS8N-39

ProCarManuals.com

Page 582 of 2399

DOOR LOCK CIRCUIT PROTECTION

The BCM controls the door lock output drivers. If

the door lock switch is actuated continuously for

more than one second the BCM will turn the output

driver OFF (the BCM would consider the switch

stuck). The lock motors are protected with Positive

Temperature Coefficient (PTC) device that prevents

motor burn out.

REMOTE KEYLESS ENTRY SYSTEM

²LOCK: Pressing the LOCK button locks all

doors and sounds horn (chirp) and arm the Vehicle

Theft Security System, if equipped. The chirp verifies

that the RKE receiver has sent a message to the

BCM for door lock operation. If a door has not been

closed before pressing the LOCK button, the vehicle

may not be secured and the VTSS will not arm until

the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's side doors and activate the

illuminated entry system and disarm Vehicle Theft

Security System, if equipped. Pressing the UNLOCK

button twice within five seconds will unlock all doors

and activate the illuminated entry system.

²LEFT SLIDING DOOR: Pressing the LEFT

SLIDING DOOR BUTTON opens/closes the left

power sliding door remotely.

²RIGHT SLIDING DOOR: Pressing the RIGHT

SLIDING DOOR BUTTON opens/closes the right

power sliding door remotely.

²LIFTGATE:

Pressing the LIFTGATE BUTTON

opens/closes the liftgate remotely, if equipped.If not

equipped with power liftgate, pressing the liftgate but-

ton will allow a one time 30 second access to liftgate.

²PANIC: Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the ignition

switch is turned to the RUN position.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s)

(VAC) in its memory even after vehicle power has

been interrupted.

NOTE: Additional features available to the customer

are described in the Vehicle Owners Manual.

The RKE system activates the optional memory

seat, mirror system and adjustable pedals, if

equipped. Two primary key fob transmitters can be

programmed to actuate memory seat and mirror set-

ting 1 or 2. Two additional key fob transmitters can be

added, but they will not be able to operate the mem-

ory seat and mirror system (Refer to 8 - ELECTRI-

CAL/POWER SEATS - OPERATION) and (Refer to 8 -

ELECTRICAL/POWER MIRRORS - OPERATION).

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The Door Cylinder Lock Switch is used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver and passenger door lock cylinders.

When installed on the rear of the cylinder, there is a

tab on the lock cylinder that aligns with the switch

to prevent it from turning. An anti-rotating device.

The door cylinder lock switch is a one time use

switch. Once it is removed from the rear of the door

lock cylinder, it may not be reinstalled and a new

switch must be used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch, via

the Programmable Communication Interface (PCI)

bus.

If turning the key cylinder once, toward the front

of the vehicle (for either driver or passenger doors),

this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle (either passenger or driver doors) once. This

will lock the door that you are using the key on. If

equipped with the central locking feature, this will

lock all the other doors and liftgate. Furthermore,

this will arm the vehicle theft security system and

turn off the illuminated entry.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

RSPOWER LOCKS8N-41

POWER LOCKS (Continued)

ProCarManuals.com

Page 584 of 2399

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove door trim panel. Refer to Body, Door -

Front, Trim Panel, Removal.

(3) Disconnect wire connector from back of door

lock switch.

(4) Remove two screws to door lock switch.

(5) Remove switch from vehicle.

INSTALLATION

(1) Install the switch into the vehicle.

(2) Install the two screws to door lock switch.

(3) Connect wire connector to back of door lock

switch.

(4) Install door trim panel. Refer to Body, Door -

Front, Trim Panel, Installation.

(5) Connect the battery negative cable.

KEYLESS ENTRY

TRANSMITTER

STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE

DISABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter.

To DISABLE (cancelling) the horn chirp feature,

press and hold the transmitter LOCK button for a

minimum of five seconds. While pressing the LOCK

button in, press the UNLOCK button. The horn chirp

feature will not function until the above procedure is

repeated.

ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter.

To ENABLE (reinstate) the horn chirp feature, use

any one of the four key fob transmitters and reverse

the above procedures. It will ENABLE the horn chirp

feature for all transmitters.

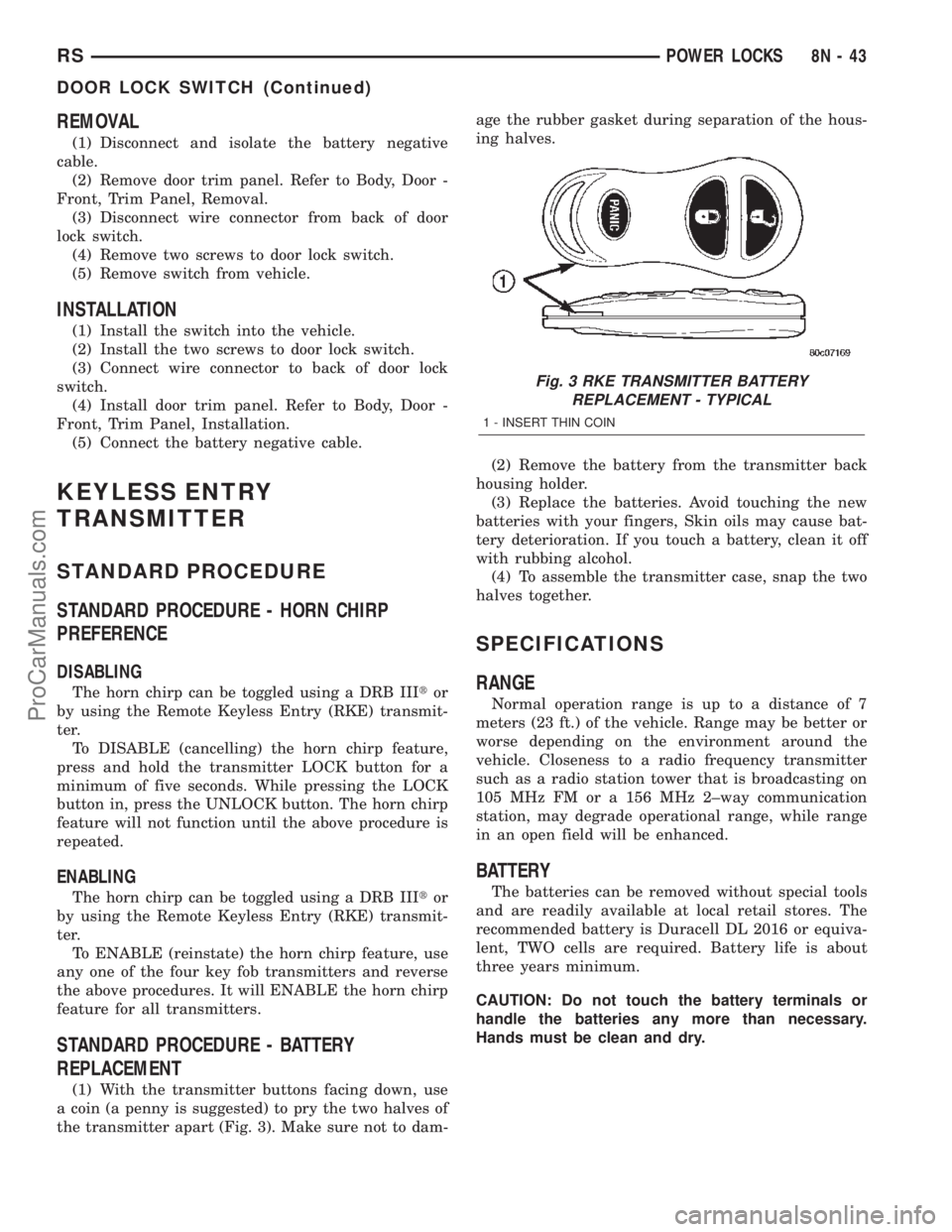

STANDARD PROCEDURE - BATTERY

REPLACEMENT

(1) With the transmitter buttons facing down, use

a coin (a penny is suggested) to pry the two halves of

the transmitter apart (Fig. 3). Make sure not to dam-age the rubber gasket during separation of the hous-

ing halves.

(2) Remove the battery from the transmitter back

housing holder.

(3) Replace the batteries. Avoid touching the new

batteries with your fingers, Skin oils may cause bat-

tery deterioration. If you touch a battery, clean it off

with rubbing alcohol.

(4) To assemble the transmitter case, snap the two

halves together.

SPECIFICATIONS

RANGE

Normal operation range is up to a distance of 7

meters (23 ft.) of the vehicle. Range may be better or

worse depending on the environment around the

vehicle. Closeness to a radio frequency transmitter

such as a radio station tower that is broadcasting on

105 MHz FM or a 156 MHz 2±way communication

station, may degrade operational range, while range

in an open field will be enhanced.

BATTERY

The batteries can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiva-

lent, TWO cells are required. Battery life is about

three years minimum.

CAUTION: Do not touch the battery terminals or

handle the batteries any more than necessary.

Hands must be clean and dry.

Fig. 3 RKE TRANSMITTER BATTERY

REPLACEMENT - TYPICAL

1 - INSERT THIN COIN

RSPOWER LOCKS8N-43

DOOR LOCK SWITCH (Continued)

ProCarManuals.com

Page 612 of 2399

(6) Refer to the proper Body Diagnostic Procedures

manual if any diagnostic codes are found in Step 4 or

Step 5.

(7) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Proper Body

Diagnostic Procedures Manual to diagnose the prob-

lem.If airbag warning lamp either fails to light,

or goes on and stays on, there is a system mal-

function. Refer to the proper Body Diagnostic

Procedures manual to diagnose the problem.

CLOCK SPRING

DESCRIPTION

The clock spring is screwed to a plastic mounting

platform on the steering column behind the steering

wheel. The clock spring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the drivers airbag.

OPERATION

This assembly consists of a flat ribbon like electri-

cally conductive tape which winds and unwinds with

the steering wheel rotation. The clock spring cannot

be repaired. If the clock spring is faulty, damaged, or

if the airbag has been deployed, the clock spring

must be replaced.

STANDARD PROCEDURE - CLOCK SPRING

CENTERING

If the rotating tape (wire coil) in the clock spring is

not positioned properly with the steering wheel and

the front wheels, the clock spring may fail. The fol-

lowing procedure MUST BE USED to center the

clock spring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Adjust the steering wheel so that the tires are

in a straight ahead position.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from back of airbag.

(4) Remove steering wheel.

(5) Rotate the clock spring rotor clockwise until

the rotor stops. Do not apply excessive force.

(6) From the end of travel, rotate the rotor two

turns counterclockwise until the wires end up at the

top.

(7) Install steering wheel and airbag.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood. Disconnect

and isolate the battery negative cable.

(3) Remove driver airbag from steering wheel.

(4) Disconnect wire connectors from back of driver

airbag.

(5) Disconnect the 2±way connector from remote

radio control harness and the 4-way connector from

the speed control/horn harness.

(6) Remove steering wheel.

(7) Remove steering column shrouds.

(8) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(9) Remove clock spring from housing assembly by

removing the two retaining screws retaining the

clock spring.

INSTALLATION

(1) Position the clock spring into the housing.

Install the two retaining screws to clock spring.

(2) Connect the 4-way and 6-way harness between

the clock spring and the instrument panel.

(3) Install the steering wheel. Refer to Steering,

Column, Steering Wheel, Installation.

(4) Connect the harness connector to the driver

airbag.

(5) Connect the remote radio control harness and

the speed control/horn harness.

(6) Install the driver airbag into the steering

wheel.

(7) Install the steering column upper and lower

shrouds.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

RSRESTRAINTS8O-3

RESTRAINTS (Continued)

ProCarManuals.com

Page 613 of 2399

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag

²Passenger Airbag

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - CLEAN UP

Roll or fold the driver airbag towards the steering

wheel and then tape the bag to the steering wheel.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

REMOVAL

DEPLOYED AIRBAG

The Driver Airbag and Driver Airbag Cover/Horn

Pad are serviced separately from each other.

(1) Clean powder residue from interior of vehicle,

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - STANDARD PROCEDURE ) Cleanup.

(2) Remove two screws attaching Driver Airbag to

steering wheel.

(3) Remove the driver airbag from steering wheel.

(4) Disconnect wire connectors from Airbag and

Clock Spring.

(5) Adjust the steering wheel so that the tires are

in a straight ahead position. Remove steering wheel,

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL)

(6) Disconnect the 2-way and 4-way connectors

between the clock spring and the instrument panel

wiring harness.(7) Remove upper and lower steering column

shrouds.

(8) Remove clock spring from the housing assem-

bly by depressing the 2 tabs on the clock spring.

UNDEPLOYED AIRBAG

(1) Remove screws attaching airbag/horn switch to

steering wheel.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from driver airbag

and clock spring.

INSTALLATION

DEPLOYED AIRBAG

(1) Perform cleanup procedure.(Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - STAN-

DARD PROCEDURE)

(2) Install a new steering column assembly and

lower steering column coupler. Refer to Steering, Col-

umn, Installation.

(3) Install the clock spring.

(4) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

UNDEPLOYED AIRBAG

(1) Position a new airbag into the airbag cavity.

(2) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG TRIM COVER

REMOVAL

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

(1) Disconnect and isolate the battery negative

cable.

WARNING: WAIT TWO MINUTES FOR THE AIRBAG

SYSTEM RESERVE CAPACITOR TO DISCHARGE.

8O - 4 RESTRAINTSRS

DRIVER AIRBAG (Continued)

ProCarManuals.com

Page 614 of 2399

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Remove the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(4) Remove the four nuts that secure the upper

and lower trim cover retainers to the studs on the

back of the driver airbag housing.

(5) Remove the upper and lower trim cover retain-

ers from the airbag housing studs.

(6) Remove the horn switch ground pigtail wire

eyelet terminal from the upper right airbag housing

stud.

(7) Disengage the six trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover.

INSTALLATION

(1) Install the housing into the cover. Engage the

six trim cover locking blocks to the lip around the

outside edge of the driver airbag housing.

(2) Install the horn switch ground pigtail wire eye-

let terminal to the upper right airbag housing stud.

(3) Install the upper and lower trim cover retain-

ers to the airbag housing studs.

(4) Install the four nuts that secure the upper and

lower trim cover retainers to the studs on the back of

the driver airbag housing.

(5) Install the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(6) Install the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. FIRST (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DIAGNOSIS AND TESTING - AIRBAG

SYSTEM).

OCCUPANT RESTRAINT

CONTROLLER

DESCRIPTION

The front driver and passenger airbag system is

designed to reduce the risk of fatality or serious

injury, caused by a frontal impact of the vehicle.

The Occupant Restraint Controller (ORC) contains

the impact sensor and energy reserve capacitor. It is

mounted on a bracket, under the instrument panel,just forward of the storage bin. The ORC monitors

the system to determine the system readiness. The

ORC contains on-board diagnostics and will light the

AIRBAG warning lamp in the message center when a

problem occurs.

OPERATION

The impact sensor provides verification of the

direction and severity of the impact. One impact sen-

sor is used. It is located inside the Occupant

Restraint Controller (ORC). The impact sensor is an

accelerometer that senses deceleration. The decelera-

tion pulses are sent to a microprocessor which con-

tains a decision algorithm. When an impact is severe

enough to require airbag protection, the ORC micro-

processor sends a signal that completes the electrical

circuit to the driver and passenger airbags. The

impact sensor is calibrated for the specific vehicle

and reacts to the severity and direction of an impact.

REMOVAL

NOTE: Diagnose the ORC using the service/diag-

nostic manual.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove storage bin from instrument panel.

Refer to Body, Instrument Panel, Storage Bin,

Removal.

(3) Remove three bolts holding ORC to floor

bracket.

(4) Disconnect the wire connector from ORC.

(5) Remove the ORC assembly from vehicle.

INSTALLATION

WARNING: DO NOT INSTALL ORC IF MOUNTING

LOCATION IS DEFORMED OR DAMAGED.

CAUTION: Use correct screws when installing the

ORC.

(1) Install the ORC assembly into vehicle.

(2) Connect the wire connector to the ORC.

(3) Install three bolts holding ORC to floor

bracket. Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel. Refer to Body, Instrument Panel, Storage Bin,

Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

RSRESTRAINTS8O-5

DRIVER AIRBAG TRIM COVER (Continued)

ProCarManuals.com

Page 632 of 2399

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM..................3

DIAGNOSIS AND TESTING - VEHICLE

THEFT SECURITY SYSTEM..............3

HOOD AJAR SWITCH

REMOVAL.............................3INSTALLATION..........................3

TRANSPONDER KEY

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING.......................4

VTSS/SKIS INDICATOR LAMP

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

VEHICLE THEFT SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, hood, liftgate, and

ignition action for unauthorized operation. The alarm

activates:

²Sounding of the horn

²Flashing of the park and tail lamps

²Flashing of the headlamps

²An engine kill feature (without SKIS)

SENTRY KEY IMMOBILIZER SYSTEM

The Sentry Key Immobilizer System (SKIS) is

available as a factory-installed option on this vehicle.

It is designed to provide passive protection against

unauthorized vehicle use by disabling the engine,

after two (2) seconds of running, whenever an invalid

key is used to start the vehicle. The SKIS is active

whenever the ignition is on and does not require any

customer intervention. The primary components of

the system are the Sentry Key Immobilizer Module

(SKIM), Sentry Key (ignition key w/ a transponder

molded into the head), indicator light, Body Control

Module (BCM), and the Powertrain Control Module

(PCM). The SKIM is mounted to the steering column

with the molded, integral antenna mounted on the

ignition housing. The indicator light, is located in the

message center.

OPERATION

VEHICLE THEFT SECURITY SYSTEM

Upon failure of proper SKIM communication to the

PCM, the PCM will shut off fuel after two seconds of

run time. The engine will not re-crank on the key

cycle that the failure occurred, a full key down

sequence must be performed for the engine to crank

again. After six consecutive fuel shut-offs, the engine

will no longer crank on subsequent key cycles. The

failure must be corrected and a valid communication

process between the SKIM and the PCM must occur

for the engine to crank and start again.

The electronics for the VTSS are part of the Body

Control Module (BCM). The system is armed when

the vehicle is locked using the:

²Power door lock switches (with any door ajar)

²Remote Keyless Entry transmitter.

²Door Cylinder Lock Switches.

For vehicles equipped with SKIS, the doors do not

have to be locked to enable the fuel shut off feature.

After the vehicle is locked and the last door is

closed, the set LED indicator in the top cover will

flash quickly for 16 seconds, indicating that arming

is in progress. If no monitored systems are activated

during this period, the system will arm. The LED

will extinguish unless the liftgate is open. If the lift-

gate is open, the LED will flash at a slower rate.

This indicates that the system is armed. If fault is

detected on any key cylinder input, the indicator

LED will remain solid during the arming process,

although the system will still arm. If the indicator

LED does not illuminate at all upon door closing it

indicates that the system is not arming.

RSVEHICLE THEFT SECURITY8Q-1

ProCarManuals.com

Page 633 of 2399

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the ignition key/

remote transmitter. This disarming will also halt the

alarm once it has been activated.

A tamper alert exists to notify the driver that the

VTSS had been activated. This alert consists of 3

horn pulses when the vehicle is disarmed.

NOTE: The VTSS will not arm by pushing down the

door lock mechanism. This will manually override

the system.

For Door Cylinder Lock Switch Removal and

Installation, refer to Electrical, Power Locks, Door

Cylinder Lock Switch.

If the VTSS is triggered, the horn will pulse, head-

lamps/marker lamps will flash, and the VTSS warn-

ing lamp will flash. If BCM determines the threat to

be false and the VTSS is not triggered again, the sys-

tem will shut down and rearm itself after three min-

utes. If a trigger is still active, the alarm will

continue for an additional 15 minutes without the

horn. The VTSS monitoring portion of the system is

split into two sections. The engine compartment sec-

tion and the passenger compartment section. If a

malfunction occurs in the engine compartment sec-

tion, the passenger compartment section would still

arm and function normally.

NOTE: If hood is not secure during the arming

sequence, the lamp will stay lit and not flash. The

system will arm with hood not secured (hood ajar

switch closed) and the liftgate open (liftgate ajar

switch closed). System will not arm if passenger

compartment is not secure (all switches closed)

ARMING THE VTSS - METHOD A

(1) With the key removed from the ignition lock

and any door open (excluding liftgate), actuate one of

the following:

²Power door lock button to LOCK,

²Key fob LOCK button

²Door lock key cylinder to locked position.

(2) Close all opened doors. Liftgate can remain

open.

(3) After the last door is closed, an arming time-

out period of sixteen seconds will start, then the

VTSS will become armed.

ARMING THE VTSS - METHOD B

Actuating the key fob transmitter LOCK button,

key locking the front doors with the doors closed and

the ignition locked will begin the arming time-out

period. If method A, 16 second time-out sequence was

in process when method B was actuated, the 16 sec-ond time-out will restart from the time of the second

actuation.

If the security lamp does not illuminate at all upon

final door closure, it indicates that the system is not

arming.

The current VTSS status armed or disarmed shall

be maintained in memory to prevent battery discon-

nects from disarming the system.

TRIGGERING THE VTSS

After the VTSS is armed, the following actions will

trigger the alarm:

²Opening any door (excluding liftgate).

²Opening the hood

²Turning the ignition to the ACC, or UNLOCK

position.

NOTE: When the VTSS is ARMED, the interior

power door lock switch ªUNLOCKº will be disabled

until the vehicle is disarmed.

CAUTION: The VTSS indicator LED will trigger and

engine will continue to run if the vehicle is

equipped with SKIS and the proper key is used to

start the vehicle. This condition will occur if the

VTSS has been triggered. If valid key is used, VTSS

will disarm

SENTRY KEY IMMOBILIZER SYSTEM

The SKIS includes keys from the factory which are

pre-programmed. Each SKIM will recognize a maxi-

mum of eight Sentry Keys. If the customer would

like to own additional keys other than those provided

with the vehicle, they can be purchased from any

authorized dealer. These keys must be programmed

to the SKIM on the vehicle in order for the system to

recognize them as valid keys. This can be done by

the dealer with a DRB IIItscan tool or by a cus-

tomer if this feature is available in their market and

they have two (2) valid keys already available to

them. Refer to the Service Procedures portion of this

system for additional details. The SKIS performs a

self-test each time the ignition switch is turned to

the ON position and will store Diagnostic Trouble

Codes (DTC's) if a system malfunction is detected.

The SKIS can be diagnosed and any stored DTC's

can be retrieved using a DRB IIItscan tool as

described in the appropriate Body Diagnostic Proce-

dures manual.

8Q - 2 VEHICLE THEFT SECURITYRS

VEHICLE THEFT SECURITY (Continued)

ProCarManuals.com