check oil CHRYSLER CARAVAN 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1228 of 2399

²Second All to 68 N´m (50 ft. lbs.)

²Third All to 68 N´m (50 ft. lbs.)

CAUTION: Do not use a torque wrench for the fol-

lowing step.

²Fourth Turn an additional 1/4 Turn,

(5) Install rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - INSTALLA-

TION)

(6) Install camshafts. (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and timing belt

idler pulley. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)

(10) Connect cam sensor and fuel injectors wiring

connectors.

(11) Install ignition coil and wires. Connect igni-

tion coil wiring connector.

(12) Install power steering pump reservoir and

line support bracket to cylinder head.

(13) Raise vehicle and install the exhaust pipe to

the manifold.

(14) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(15) Install heater tube support bracket to cylinder

head.

(16) Connect radiator upper and heater hoses to

intake manifold water outlet connections.

(17) Install upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

(18) Using new gaskets, install EGR tube and

tighten fasteners to 11 N´m (95 in. lbs.).

Fig. 16 Valve Guide Height

1 - VALVE GUIDE

2 - 13.25 - 13.75 MM

(.521 - .541 IN.)

3 - SPRING SEAT

Fig. 17 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 18 Cylinder Head Gasket Positioning

1 - PART NUMBER FACES UP

2 - NO. 1 CYLINDER

Fig. 19 Cylinder Head Tightening Sequence

RSENGINE 2.4L9-27

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1230 of 2399

CAMSHAFT(S)

DESCRIPTION

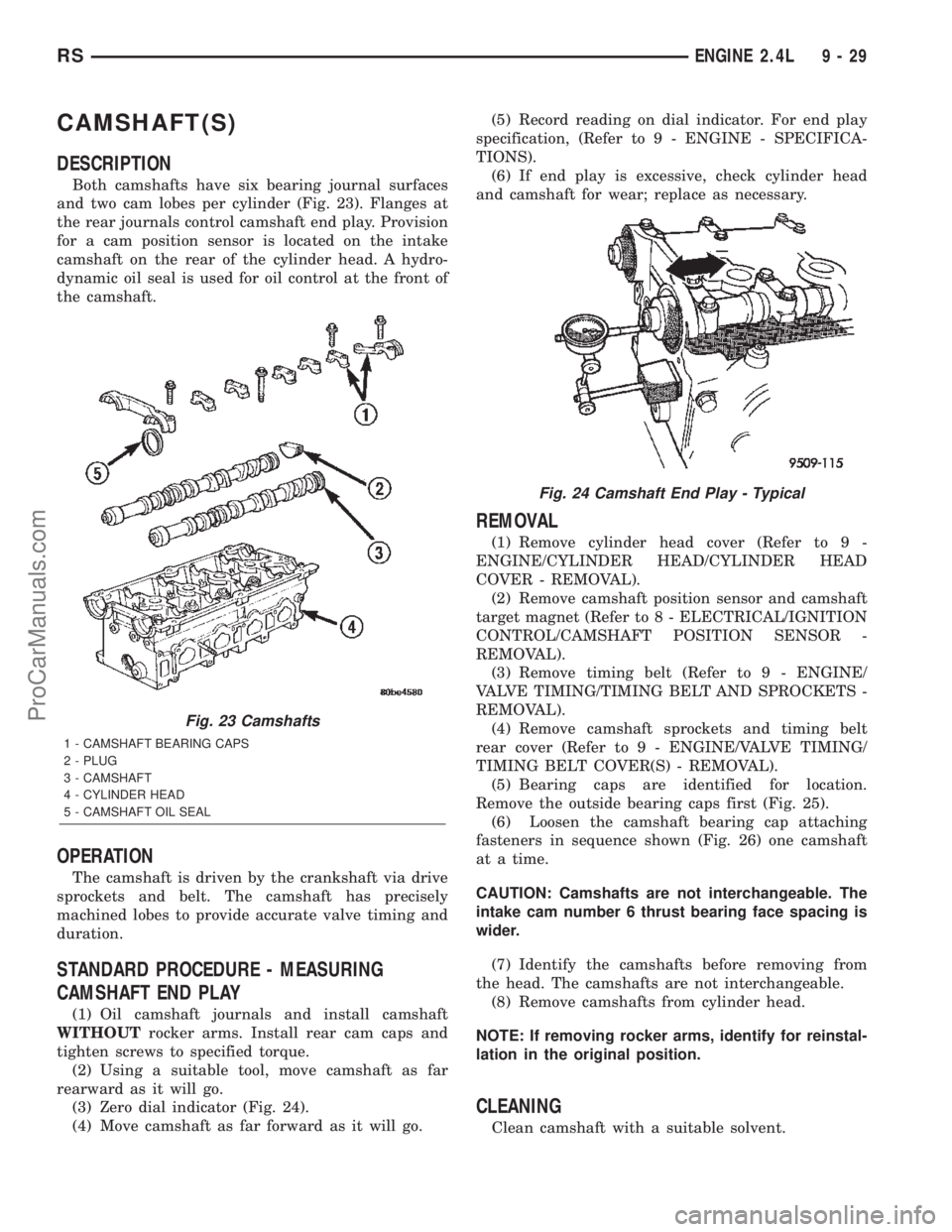

Both camshafts have six bearing journal surfaces

and two cam lobes per cylinder (Fig. 23). Flanges at

the rear journals control camshaft end play. Provision

for a cam position sensor is located on the intake

camshaft on the rear of the cylinder head. A hydro-

dynamic oil seal is used for oil control at the front of

the camshaft.

OPERATION

The camshaft is driven by the crankshaft via drive

sprockets and belt. The camshaft has precisely

machined lobes to provide accurate valve timing and

duration.

STANDARD PROCEDURE - MEASURING

CAMSHAFT END PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTrocker arms. Install rear cam caps and

tighten screws to specified torque.

(2) Using a suitable tool, move camshaft as far

rearward as it will go.

(3) Zero dial indicator (Fig. 24).

(4) Move camshaft as far forward as it will go.(5) Record reading on dial indicator. For end play

specification, (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

(6) If end play is excessive, check cylinder head

and camshaft for wear; replace as necessary.

REMOVAL

(1) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER - REMOVAL).

(2) Remove camshaft position sensor and camshaft

target magnet (Refer to 8 - ELECTRICAL/IGNITION

CONTROL/CAMSHAFT POSITION SENSOR -

REMOVAL).

(3) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

(4) Remove camshaft sprockets and timing belt

rear cover (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT COVER(S) - REMOVAL).

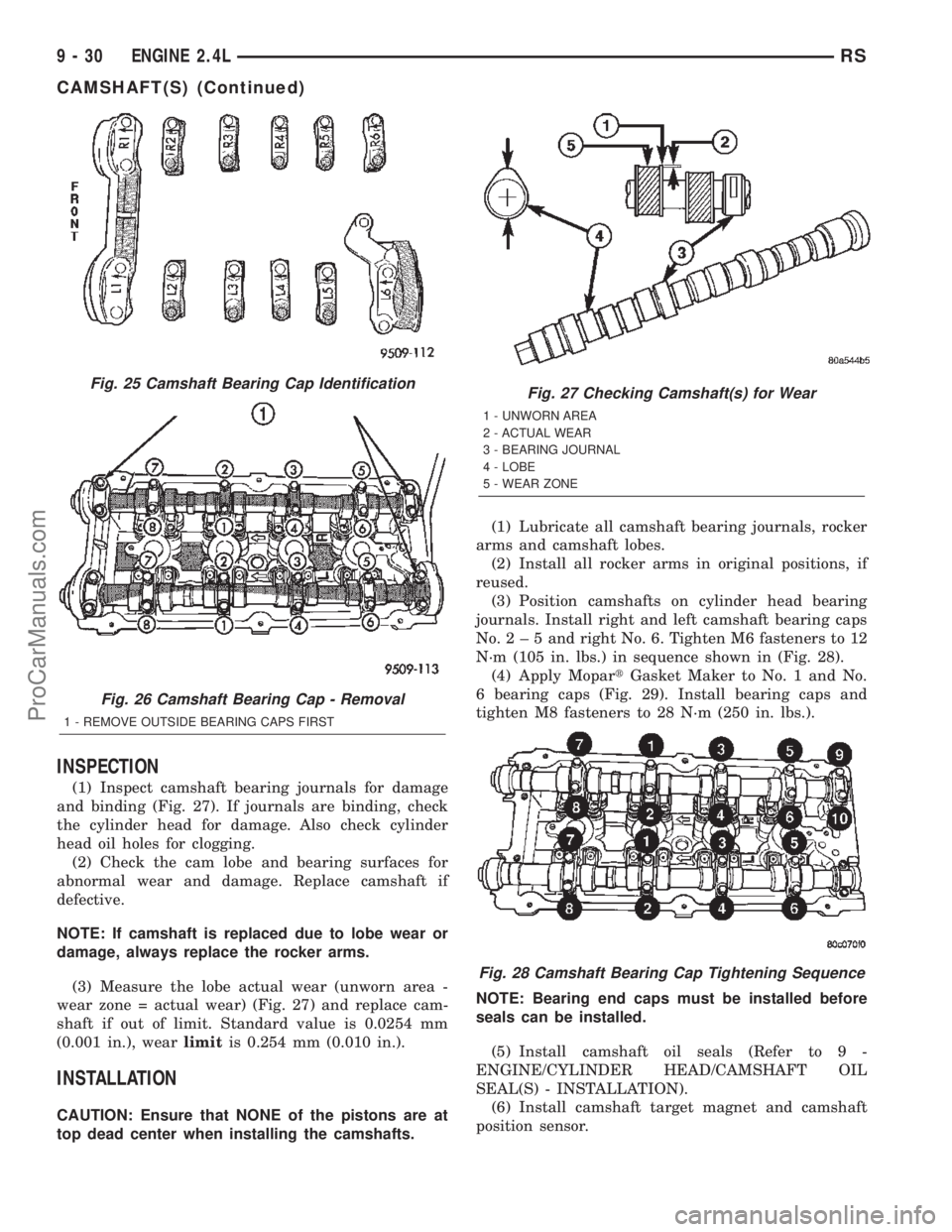

(5) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 25).

(6) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 26) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

(7) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

(8) Remove camshafts from cylinder head.

NOTE: If removing rocker arms, identify for reinstal-

lation in the original position.

CLEANING

Clean camshaft with a suitable solvent.

Fig. 23 Camshafts

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

Fig. 24 Camshaft End Play - Typical

RSENGINE 2.4L9-29

ProCarManuals.com

Page 1231 of 2399

INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 27). If journals are binding, check

the cylinder head for damage. Also check cylinder

head oil holes for clogging.

(2) Check the cam lobe and bearing surfaces for

abnormal wear and damage. Replace camshaft if

defective.

NOTE: If camshaft is replaced due to lobe wear or

damage, always replace the rocker arms.

(3) Measure the lobe actual wear (unworn area -

wear zone = actual wear) (Fig. 27) and replace cam-

shaft if out of limit. Standard value is 0.0254 mm

(0.001 in.), wearlimitis 0.254 mm (0.010 in.).

INSTALLATION

CAUTION: Ensure that NONE of the pistons are at

top dead center when installing the camshafts.(1) Lubricate all camshaft bearing journals, rocker

arms and camshaft lobes.

(2) Install all rocker arms in original positions, if

reused.

(3) Position camshafts on cylinder head bearing

journals. Install right and left camshaft bearing caps

No.2±5andright No. 6. Tighten M6 fasteners to 12

N´m (105 in. lbs.) in sequence shown in (Fig. 28).

(4) Apply MopartGasket Maker to No. 1 and No.

6 bearing caps (Fig. 29). Install bearing caps and

tighten M8 fasteners to 28 N´m (250 in. lbs.).

NOTE: Bearing end caps must be installed before

seals can be installed.

(5) Install camshaft oil seals (Refer to 9 -

ENGINE/CYLINDER HEAD/CAMSHAFT OIL

SEAL(S) - INSTALLATION).

(6) Install camshaft target magnet and camshaft

position sensor.

Fig. 25 Camshaft Bearing Cap Identification

Fig. 26 Camshaft Bearing Cap - Removal

1 - REMOVE OUTSIDE BEARING CAPS FIRST

Fig. 27 Checking Camshaft(s) for Wear

1 - UNWORN AREA

2 - ACTUAL WEAR

3 - BEARING JOURNAL

4 - LOBE

5 - WEAR ZONE

Fig. 28 Camshaft Bearing Cap Tightening Sequence

9 - 30 ENGINE 2.4LRS

CAMSHAFT(S) (Continued)

ProCarManuals.com

Page 1235 of 2399

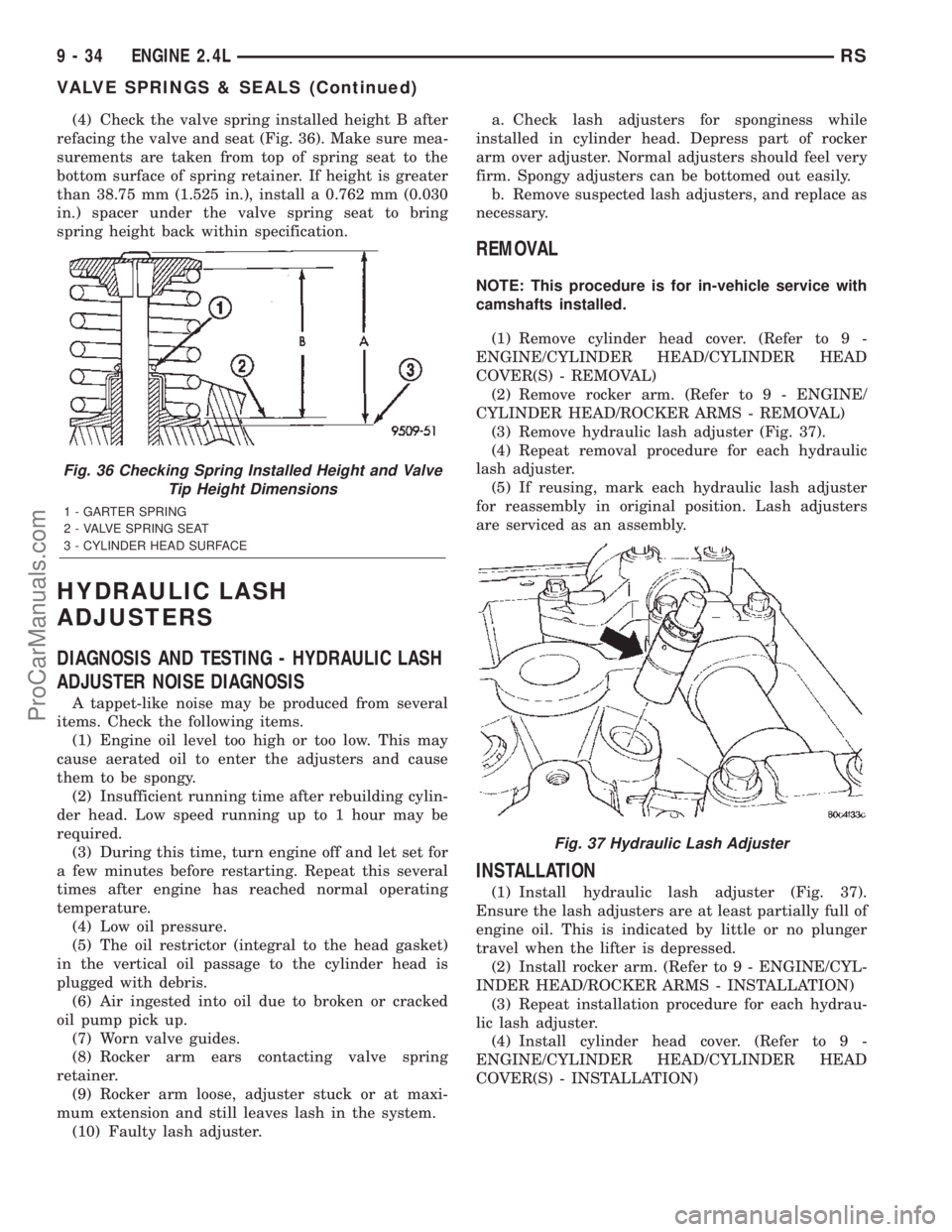

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 36). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a 0.762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.

HYDRAULIC LASH

ADJUSTERS

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor (integral to the head gasket)

in the vertical oil passage to the cylinder head is

plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace as

necessary.

REMOVAL

NOTE: This procedure is for in-vehicle service with

camshafts installed.

(1) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Remove rocker arm. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - REMOVAL)

(3) Remove hydraulic lash adjuster (Fig. 37).

(4) Repeat removal procedure for each hydraulic

lash adjuster.

(5) If reusing, mark each hydraulic lash adjuster

for reassembly in original position. Lash adjusters

are serviced as an assembly.

INSTALLATION

(1) Install hydraulic lash adjuster (Fig. 37).

Ensure the lash adjusters are at least partially full of

engine oil. This is indicated by little or no plunger

travel when the lifter is depressed.

(2) Install rocker arm. (Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARMS - INSTALLATION)

(3) Repeat installation procedure for each hydrau-

lic lash adjuster.

(4) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

Fig. 36 Checking Spring Installed Height and Valve

Tip Height Dimensions

1 - GARTER SPRING

2 - VALVE SPRING SEAT

3 - CYLINDER HEAD SURFACE

Fig. 37 Hydraulic Lash Adjuster

9 - 34 ENGINE 2.4LRS

VALVE SPRINGS & SEALS (Continued)

ProCarManuals.com

Page 1237 of 2399

STANDARD PROCEDURE

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING

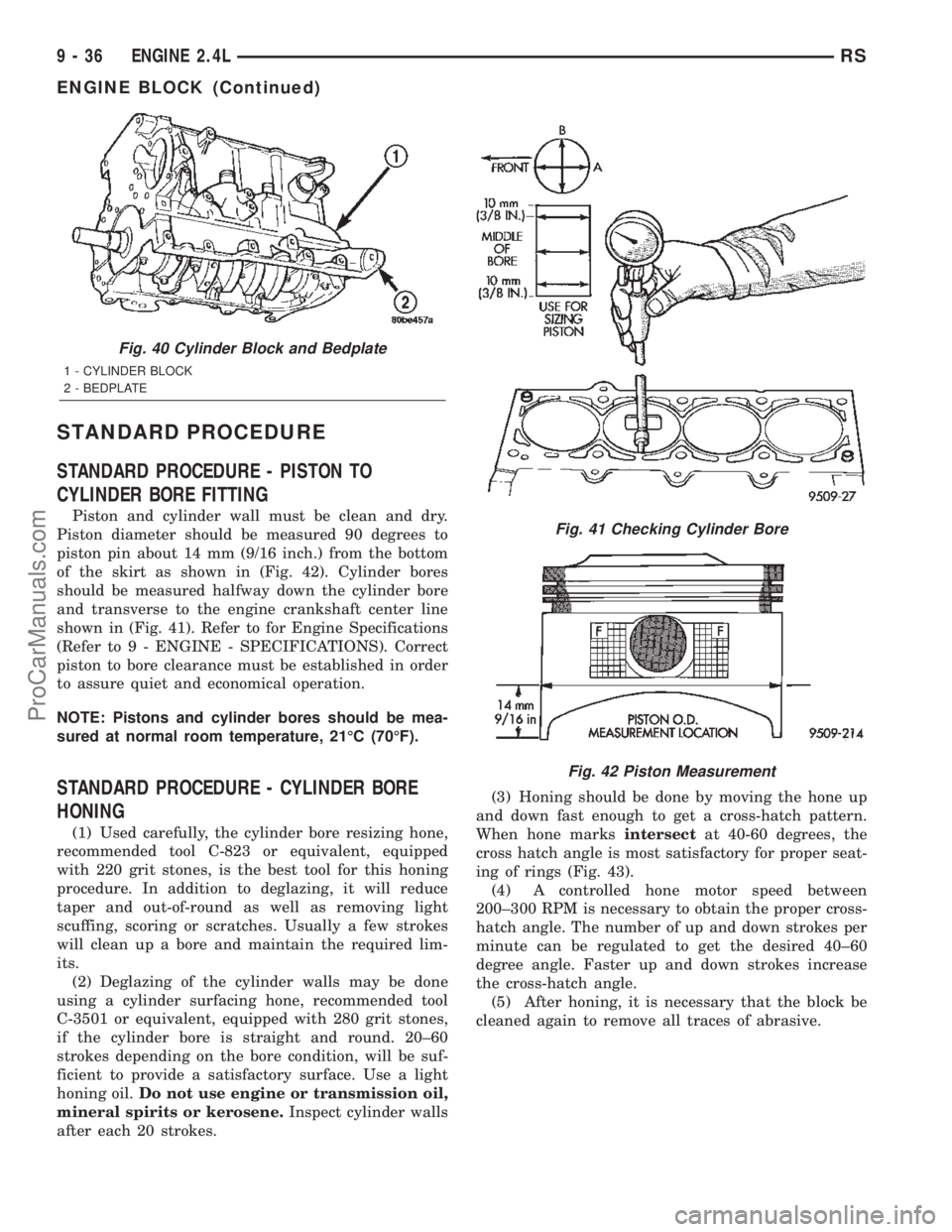

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 14 mm (9/16 inch.) from the bottom

of the skirt as shown in (Fig. 42). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 41). Refer to for Engine Specifications

(Refer to 9 - ENGINE - SPECIFICATIONS). Correct

piston to bore clearance must be established in order

to assure quiet and economical operation.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21ÉC (70ÉF).

STANDARD PROCEDURE - CYLINDER BORE

HONING

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended tool

C-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20±60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Use a light

honing oil.Do not use engine or transmission oil,

mineral spirits or kerosene.Inspect cylinder walls

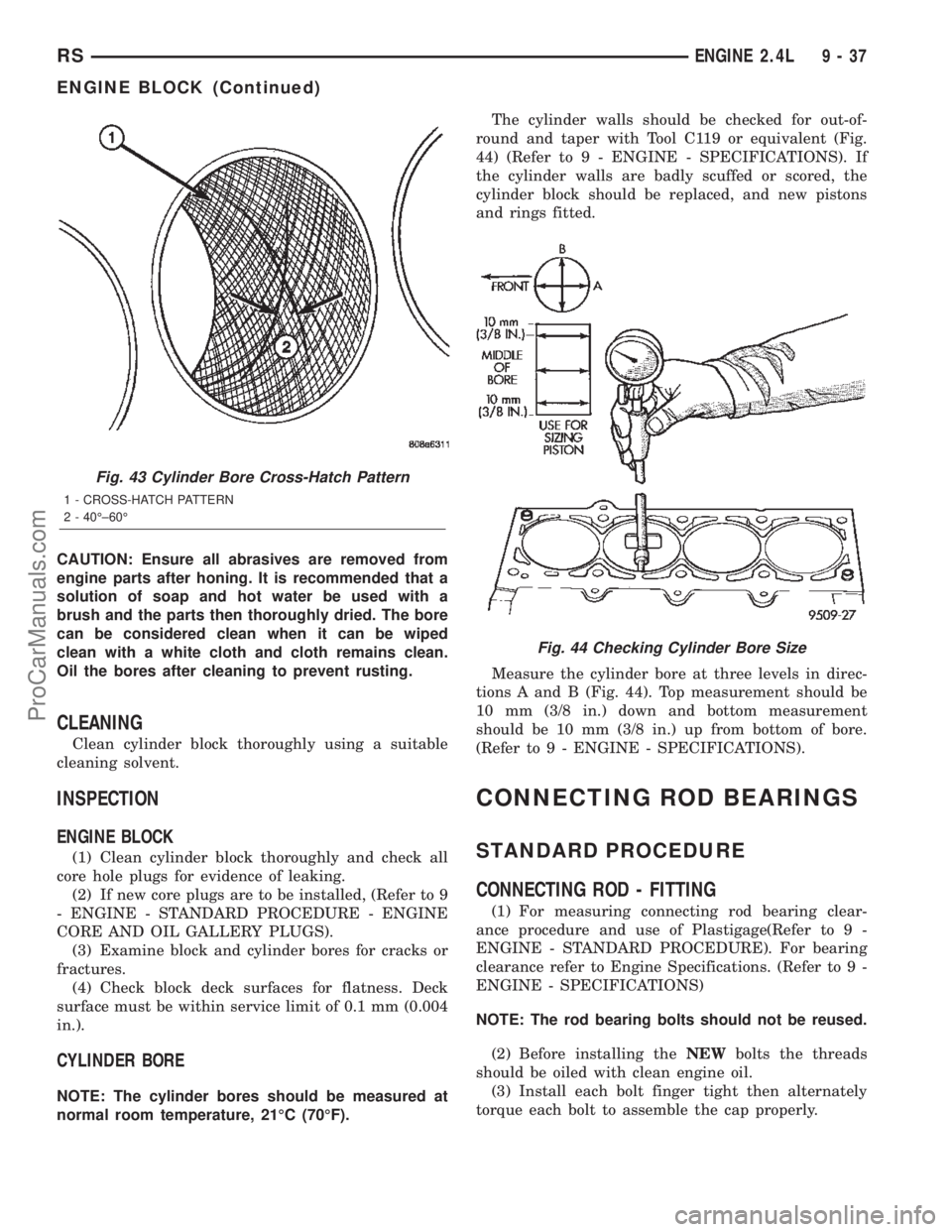

after each 20 strokes.(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 40-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 43).

(4) A controlled hone motor speed between

200±300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40±60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

Fig. 40 Cylinder Block and Bedplate

1 - CYLINDER BLOCK

2 - BEDPLATE

Fig. 41 Checking Cylinder Bore

Fig. 42 Piston Measurement

9 - 36 ENGINE 2.4LRS

ENGINE BLOCK (Continued)

ProCarManuals.com

Page 1238 of 2399

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

CLEANING

Clean cylinder block thoroughly using a suitable

cleaning solvent.

INSPECTION

ENGINE BLOCK

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are to be installed, (Refer to 9

- ENGINE - STANDARD PROCEDURE - ENGINE

CORE AND OIL GALLERY PLUGS).

(3) Examine block and cylinder bores for cracks or

fractures.

(4) Check block deck surfaces for flatness. Deck

surface must be within service limit of 0.1 mm (0.004

in.).

CYLINDER BORE

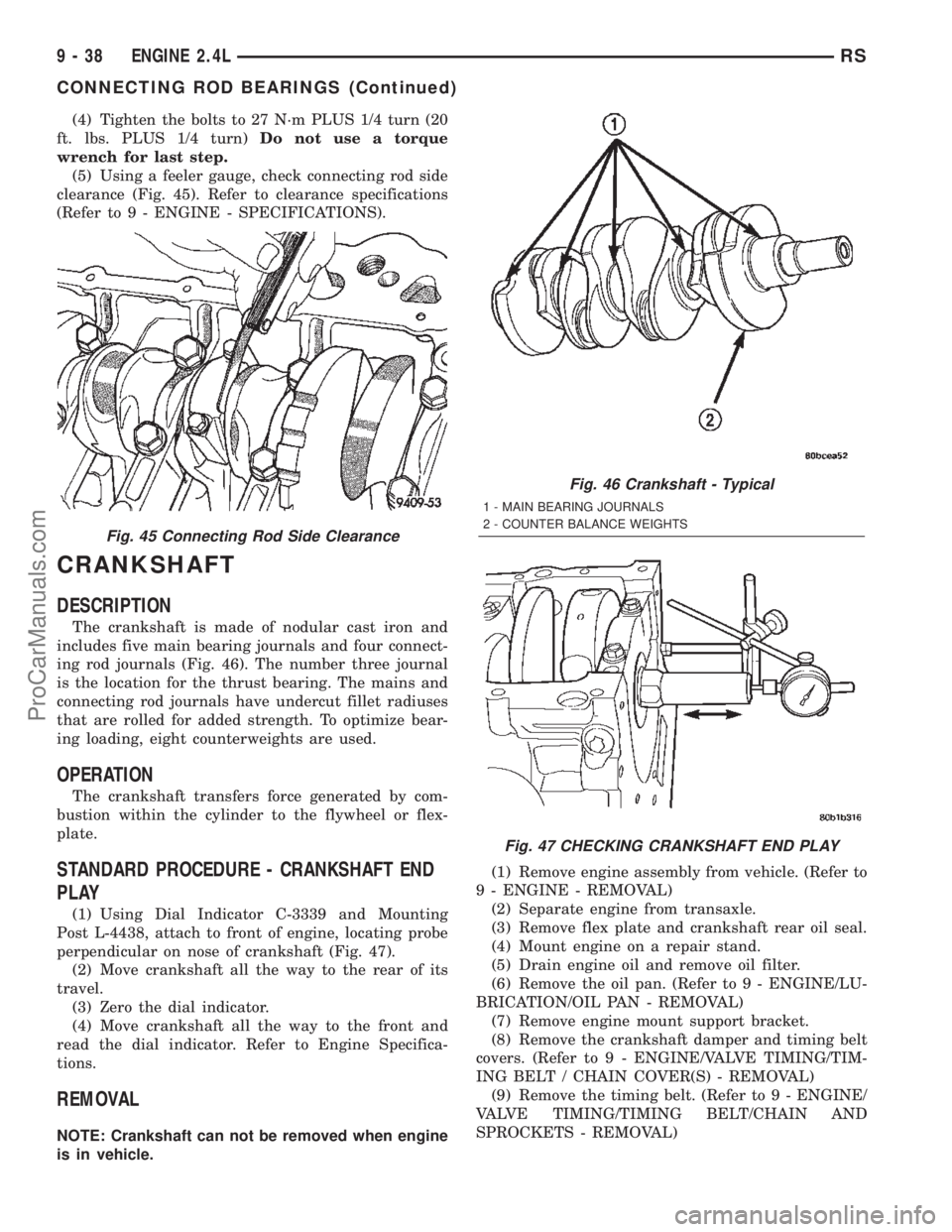

NOTE: The cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).The cylinder walls should be checked for out-of-

round and taper with Tool C119 or equivalent (Fig.

44) (Refer to 9 - ENGINE - SPECIFICATIONS). If

the cylinder walls are badly scuffed or scored, the

cylinder block should be replaced, and new pistons

and rings fitted.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 44). Top measurement should be

10 mm (3/8 in.) down and bottom measurement

should be 10 mm (3/8 in.) up from bottom of bore.

(Refer to 9 - ENGINE - SPECIFICATIONS).

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING

(1) For measuring connecting rod bearing clear-

ance procedure and use of Plastigage(Refer to 9 -

ENGINE - STANDARD PROCEDURE). For bearing

clearance refer to Engine Specifications. (Refer to 9 -

ENGINE - SPECIFICATIONS)

NOTE: The rod bearing bolts should not be reused.

(2) Before installing theNEWbolts the threads

should be oiled with clean engine oil.

(3) Install each bolt finger tight then alternately

torque each bolt to assemble the cap properly.

Fig. 43 Cylinder Bore Cross-Hatch Pattern

1 - CROSS-HATCH PATTERN

2 - 40ɱ60É

Fig. 44 Checking Cylinder Bore Size

RSENGINE 2.4L9-37

ENGINE BLOCK (Continued)

ProCarManuals.com

Page 1239 of 2399

(4) Tighten the bolts to 27 N´m PLUS 1/4 turn (20

ft. lbs. PLUS 1/4 turn)Do not use a torque

wrench for last step.

(5) Using a feeler gauge, check connecting rod side

clearance (Fig. 45). Refer to clearance specifications

(Refer to 9 - ENGINE - SPECIFICATIONS).

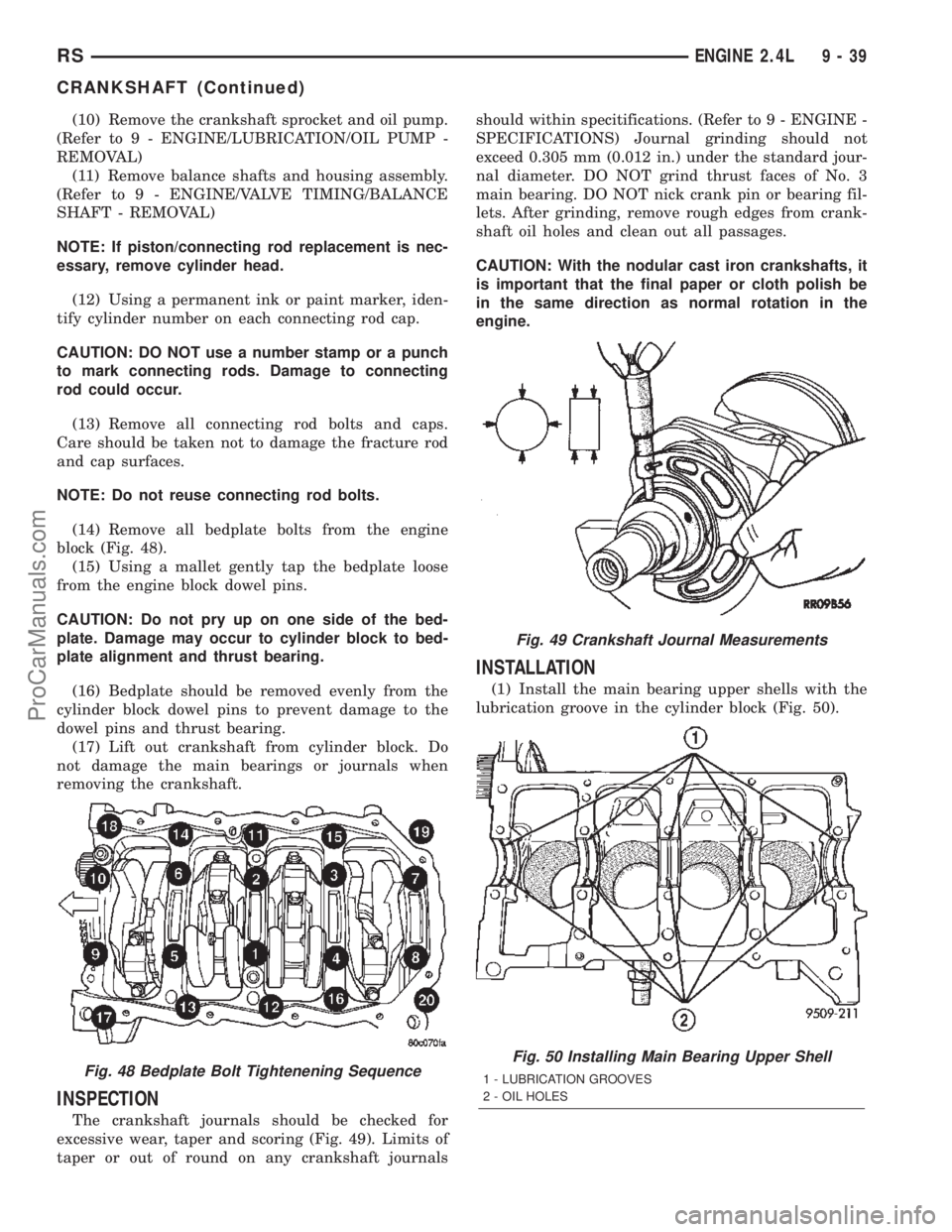

CRANKSHAFT

DESCRIPTION

The crankshaft is made of nodular cast iron and

includes five main bearing journals and four connect-

ing rod journals (Fig. 46). The number three journal

is the location for the thrust bearing. The mains and

connecting rod journals have undercut fillet radiuses

that are rolled for added strength. To optimize bear-

ing loading, eight counterweights are used.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder to the flywheel or flex-

plate.

STANDARD PROCEDURE - CRANKSHAFT END

PLAY

(1) Using Dial Indicator C-3339 and Mounting

Post L-4438, attach to front of engine, locating probe

perpendicular on nose of crankshaft (Fig. 47).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

REMOVAL

NOTE: Crankshaft can not be removed when engine

is in vehicle.(1) Remove engine assembly from vehicle. (Refer to

9 - ENGINE - REMOVAL)

(2) Separate engine from transaxle.

(3) Remove flex plate and crankshaft rear oil seal.

(4) Mount engine on a repair stand.

(5) Drain engine oil and remove oil filter.

(6) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)

(7) Remove engine mount support bracket.

(8) Remove the crankshaft damper and timing belt

covers. (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT / CHAIN COVER(S) - REMOVAL)

(9) Remove the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

Fig. 45 Connecting Rod Side Clearance

Fig. 46 Crankshaft - Typical

1 - MAIN BEARING JOURNALS

2 - COUNTER BALANCE WEIGHTS

Fig. 47 CHECKING CRANKSHAFT END PLAY

9 - 38 ENGINE 2.4LRS

CONNECTING ROD BEARINGS (Continued)

ProCarManuals.com

Page 1240 of 2399

(10) Remove the crankshaft sprocket and oil pump.

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

REMOVAL)

(11) Remove balance shafts and housing assembly.

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - REMOVAL)

NOTE: If piston/connecting rod replacement is nec-

essary, remove cylinder head.

(12) Using a permanent ink or paint marker, iden-

tify cylinder number on each connecting rod cap.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(13) Remove all connecting rod bolts and caps.

Care should be taken not to damage the fracture rod

and cap surfaces.

NOTE: Do not reuse connecting rod bolts.

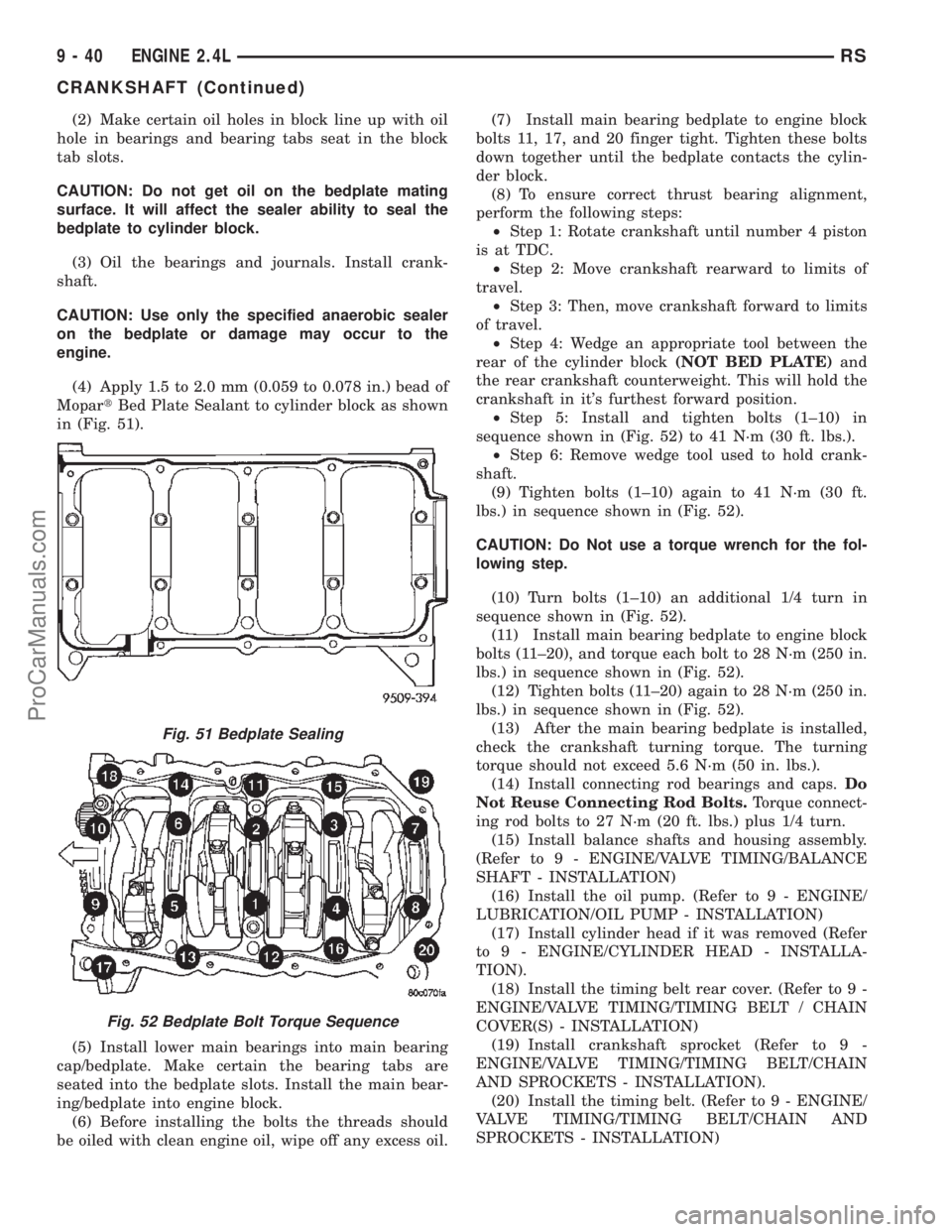

(14) Remove all bedplate bolts from the engine

block (Fig. 48).

(15) Using a mallet gently tap the bedplate loose

from the engine block dowel pins.

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block to bed-

plate alignment and thrust bearing.

(16) Bedplate should be removed evenly from the

cylinder block dowel pins to prevent damage to the

dowel pins and thrust bearing.

(17) Lift out crankshaft from cylinder block. Do

not damage the main bearings or journals when

removing the crankshaft.

INSPECTION

The crankshaft journals should be checked for

excessive wear, taper and scoring (Fig. 49). Limits of

taper or out of round on any crankshaft journalsshould within specitifications. (Refer to 9 - ENGINE -

SPECIFICATIONS) Journal grinding should not

exceed 0.305 mm (0.012 in.) under the standard jour-

nal diameter. DO NOT grind thrust faces of No. 3

main bearing. DO NOT nick crank pin or bearing fil-

lets. After grinding, remove rough edges from crank-

shaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts, it

is important that the final paper or cloth polish be

in the same direction as normal rotation in the

engine.

INSTALLATION

(1) Install the main bearing upper shells with the

lubrication groove in the cylinder block (Fig. 50).

Fig. 48 Bedplate Bolt Tightenening Sequence

Fig. 49 Crankshaft Journal Measurements

Fig. 50 Installing Main Bearing Upper Shell

1 - LUBRICATION GROOVES

2 - OIL HOLES

RSENGINE 2.4L9-39

CRANKSHAFT (Continued)

ProCarManuals.com

Page 1241 of 2399

(2) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block

tab slots.

CAUTION: Do not get oil on the bedplate mating

surface. It will affect the sealer ability to seal the

bedplate to cylinder block.

(3) Oil the bearings and journals. Install crank-

shaft.

CAUTION: Use only the specified anaerobic sealer

on the bedplate or damage may occur to the

engine.

(4) Apply 1.5 to 2.0 mm (0.059 to 0.078 in.) bead of

MopartBed Plate Sealant to cylinder block as shown

in (Fig. 51).

(5) Install lower main bearings into main bearing

cap/bedplate. Make certain the bearing tabs are

seated into the bedplate slots. Install the main bear-

ing/bedplate into engine block.

(6) Before installing the bolts the threads should

be oiled with clean engine oil, wipe off any excess oil.(7) Install main bearing bedplate to engine block

bolts 11, 17, and 20 finger tight. Tighten these bolts

down together until the bedplate contacts the cylin-

der block.

(8) To ensure correct thrust bearing alignment,

perform the following steps:

²Step 1: Rotate crankshaft until number 4 piston

is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.

²Step 3: Then, move crankshaft forward to limits

of travel.

²Step 4: Wedge an appropriate tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.

²Step 5: Install and tighten bolts (1±10) in

sequence shown in (Fig. 52) to 41 N´m (30 ft. lbs.).

²Step 6: Remove wedge tool used to hold crank-

shaft.

(9) Tighten bolts (1±10) again to 41 N´m (30 ft.

lbs.) in sequence shown in (Fig. 52).

CAUTION: Do Not use a torque wrench for the fol-

lowing step.

(10) Turn bolts (1±10) an additional 1/4 turn in

sequence shown in (Fig. 52).

(11) Install main bearing bedplate to engine block

bolts (11±20), and torque each bolt to 28 N´m (250 in.

lbs.) in sequence shown in (Fig. 52).

(12) Tighten bolts (11±20) again to 28 N´m (250 in.

lbs.) in sequence shown in (Fig. 52).

(13) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(14) Install connecting rod bearings and caps.Do

Not Reuse Connecting Rod Bolts.Torque connect-

ing rod bolts to 27 N´m (20 ft. lbs.) plus 1/4 turn.

(15) Install balance shafts and housing assembly.

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - INSTALLATION)

(16) Install the oil pump. (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - INSTALLATION)

(17) Install cylinder head if it was removed (Refer

to 9 - ENGINE/CYLINDER HEAD - INSTALLA-

TION).

(18) Install the timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(19) Install crankshaft sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

(20) Install the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 51 Bedplate Sealing

Fig. 52 Bedplate Bolt Torque Sequence

9 - 40 ENGINE 2.4LRS

CRANKSHAFT (Continued)

ProCarManuals.com

Page 1243 of 2399

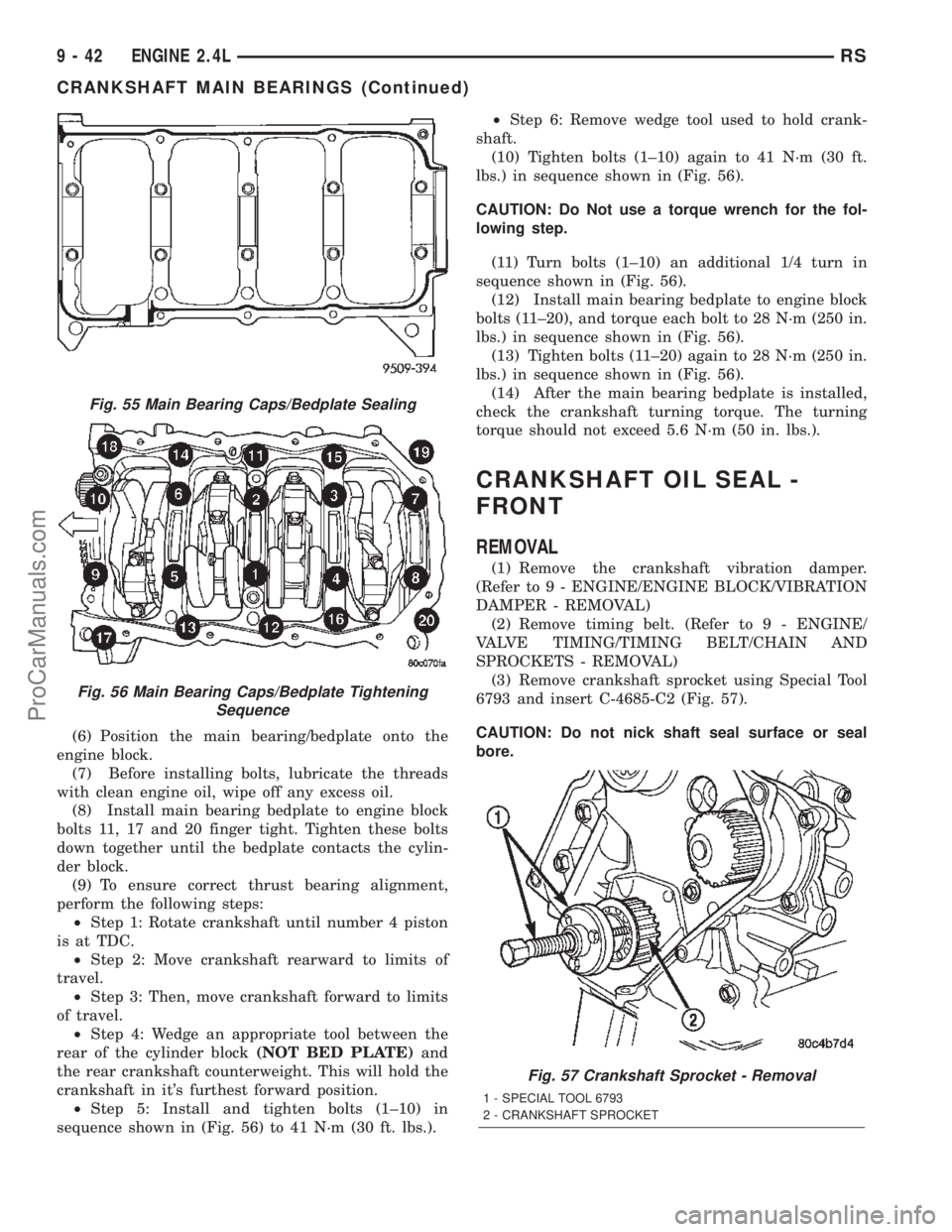

(6) Position the main bearing/bedplate onto the

engine block.

(7) Before installing bolts, lubricate the threads

with clean engine oil, wipe off any excess oil.

(8) Install main bearing bedplate to engine block

bolts 11, 17 and 20 finger tight. Tighten these bolts

down together until the bedplate contacts the cylin-

der block.

(9) To ensure correct thrust bearing alignment,

perform the following steps:

²Step 1: Rotate crankshaft until number 4 piston

is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.

²Step 3: Then, move crankshaft forward to limits

of travel.

²Step 4: Wedge an appropriate tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.

²Step 5: Install and tighten bolts (1±10) in

sequence shown in (Fig. 56) to 41 N´m (30 ft. lbs.).²Step 6: Remove wedge tool used to hold crank-

shaft.

(10) Tighten bolts (1±10) again to 41 N´m (30 ft.

lbs.) in sequence shown in (Fig. 56).

CAUTION: Do Not use a torque wrench for the fol-

lowing step.

(11) Turn bolts (1±10) an additional 1/4 turn in

sequence shown in (Fig. 56).

(12) Install main bearing bedplate to engine block

bolts (11±20), and torque each bolt to 28 N´m (250 in.

lbs.) in sequence shown in (Fig. 56).

(13) Tighten bolts (11±20) again to 28 N´m (250 in.

lbs.) in sequence shown in (Fig. 56).

(14) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Remove the crankshaft vibration damper.

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 57).

CAUTION: Do not nick shaft seal surface or seal

bore.

Fig. 55 Main Bearing Caps/Bedplate Sealing

Fig. 56 Main Bearing Caps/Bedplate Tightening

Sequence

Fig. 57 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - CRANKSHAFT SPROCKET

9 - 42 ENGINE 2.4LRS

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com