oil level CHRYSLER CARAVAN 2002 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1417 of 2399

(3) Install balance shaft assembly and retaining

bolts (Fig. 89). Torque bolts to 32.4N´m.

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Refill engine oil to proper level.

(6) Connect negative battery cable.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

REMOVAL - TIMING BELT OUTER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

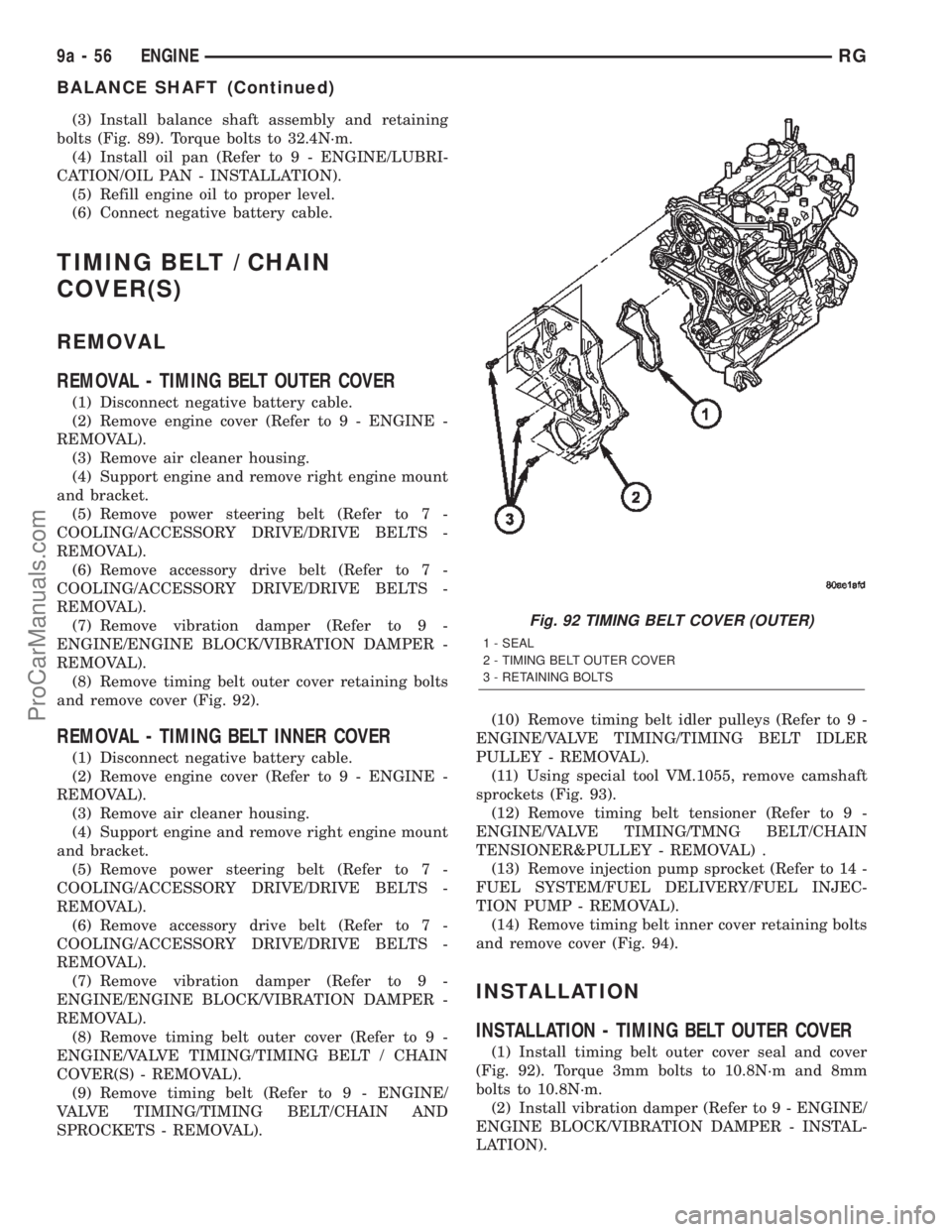

(8) Remove timing belt outer cover retaining bolts

and remove cover (Fig. 92).

REMOVAL - TIMING BELT INNER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).(10) Remove timing belt idler pulleys (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT IDLER

PULLEY - REMOVAL).

(11) Using special tool VM.1055, remove camshaft

sprockets (Fig. 93).

(12) Remove timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TMNG BELT/CHAIN

TENSIONER&PULLEY - REMOVAL) .

(13) Remove injection pump sprocket (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(14) Remove timing belt inner cover retaining bolts

and remove cover (Fig. 94).

INSTALLATION

INSTALLATION - TIMING BELT OUTER COVER

(1) Install timing belt outer cover seal and cover

(Fig. 92). Torque 3mm bolts to 10.8N´m and 8mm

bolts to 10.8N´m.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

Fig. 92 TIMING BELT COVER (OUTER)

1 - SEAL

2 - TIMING BELT OUTER COVER

3 - RETAINING BOLTS

9a - 56 ENGINERG

BALANCE SHAFT (Continued)

ProCarManuals.com

Page 1489 of 2399

Test all fuel supply lines for restrictions or block-

age. Flush or replace as necessary. Bleed fuel system

of air once a fuel supply line has been replaced. Refer

to Air Bleed Procedure for procedures.

To test for fuel line restrictions, a vacuum restric-

tion test may be performed.

HIGH-PRESSURE LINES

Restricted (kinked or bent) high-pressure lines can

cause starting problems, poor engine performance,

engine mis-fire and white smoke from exhaust.

Examine all high-pressure lines for any damage.

Each radius on each high-pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high-pres-

sure fuel lines with correct replacement line.

CAUTION: High pressure lines cannot contact each

other or other components. Do not attempt to weld

high-pressure fuel lines or to repair lines that are

damaged. If line is kinked or bent, it must be

replaced. Use only recommended lines when

replacement of high-pressure fuel line is necessary.

STANDARD PROCEDURE

STANDARD PROCEDURES - DRAINING WATER

FROM FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURE - FUEL SYSTEM AIR

PURGE

(1) Remove engine cover (Refer to 9 - ENGINE

COVER - REMOVAL).

(2) Remove cap from air purge fitting on the fuel

supply line. This fitting is located just behind the

alternator (Fig. 1).

(3) Attach a hose of about 1 or 2 meters to this fit-

ting using an appropriate connector.

(4) Direct the end of the hose into an appropriate

fuel container.

(5) Turn the ignition to the ªONº position,Do not

crank the engine.Keep key on until about 1 liter of

fuel has been pumped into the container.

(6) While keeping end of hose below fuel level in

conatiner, turn the ignition ªOFFº.

(7) Remove hose from air purge fitting on the fuel

supply line and replace cap.

(8) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM COMPONENTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines, fuel rail, and fuel injection

pump. Very tight tolerances are used with these

parts. Dirt contamination could cause rapid part

wear and possible plugging of fuel injector nozzle

tip holes. This in turn could lead to possible engine

misfire. Always wash/clean any fuel system compo-

nent thoroughly before disassembly and then air

dry. Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

Fig. 1 AIR PURGE VALVE

1 - AIR PURGE VALVE CAP

2 - AIR PURGE VALVE

3 - ALTERNATOR

4 - ENGINE FRONT COVER

14a - 2 FUEL SYSTEMRG

FUEL SYSTEM 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1529 of 2399

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION.........................26

OPERATION...........................26

WARNING

WARNINGS AND CAUTIONS.............26

REMOVAL

REMOVAL - LHD GEAR.................26

REMOVAL - RHD GEAR................29INSTALLATION

INSTALLATION - LHD GEAR.............32

INSTALLATION - RHD GEAR.............33

SPECIAL TOOLS

POWER STEERING GEAR..............34

OUTER TIE ROD

REMOVAL.............................34

INSTALLATION.........................34

GEAR

DESCRIPTION

This vehicle is equipped with a rack and pinion

power steering gear (Fig. 1). It is mounted to the

underside of the front suspension cradle/crossmem-

ber.

The steering column is attached to the gear

through the use of an intermediate shaft and cou-

plers. The outer ends of the power steering gear's

outer tie rods connect to the steering knuckles.

NOTE: The power steering gear should NOT be ser-

viced or adjusted unless DaimlerChrysler Corpora-

tion authorizes. If a malfunction or oil leak occurs,

the complete steering gear should be replaced.

Only the outer tie rods may be replaced separately

from the rest of the gear.

OPERATION

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth in the steer-

ing gear. This travel pushes and pulls the tie rods to

change the direction of the vehicle's front wheels.

Power assist steering provided by the power steer-

ing pump is controlled by an open center, rotary type

control valve which directs oil from the pump to

either side of the integral rack piston upon demand.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston

which, in turn, builds hydraulic pressure and assists

in the turning effort.Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

WARNING

WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

REMOVAL

REMOVAL - LHD GEAR

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.Use

care not to damage the filter mesh below the

fluid surface.

19 - 26 GEARRS

ProCarManuals.com

Page 1558 of 2399

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT..................1

31TH AUTOMATIC TRANSAXLE.............2141TE AUTOMATIC TRANSAXLE............161

T850 MANUAL TRANSAXLE...............308

POWER TRANSFER UNIT

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING

SEAL IDENTIFICATION..................3

FLUID LEAK DIAGNOSIS................4

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

INSPECTION..........................5

STANDARD PROCEDURE - PTU FLUID

CHANGE.............................5

REMOVAL.............................6

INSTALLATION..........................7

ADJUSTMENTS

OUTPUT FLANGE SHIM SELECTION.......7

SPECIFICATIONS

TORQUE.............................8

SPECIAL TOOLS

SDP POWER TRANSFER UNIT............8

DIFFERENTIAL CARRIER SEAL

REMOVAL.............................9

INSTALLATION..........................9

END COVER BALL BEARING

REMOVAL.............................9INSTALLATION.........................10

END COVER SEAL

REMOVAL.............................11

INSTALLATION.........................11

HALF SHAFT INNER SEAL

REMOVAL.............................12

INSTALLATION.........................13

INPUT SHAFT COVER SEAL

REMOVAL.............................13

INSTALLATION.........................14

INPUT SHAFT END SEAL

REMOVAL.............................16

INSTALLATION.........................16

INPUT SHAFT SEAL

REMOVAL.............................17

INSTALLATION.........................18

OUTER HALF SHAFT SEAL

REMOVAL.............................19

INSTALLATION.........................19

REAR COVER O-RING

REMOVAL.............................19

INSTALLATION.........................20

POWER TRANSFER UNIT

DESCRIPTION

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located.

The Power Transfer Unit is sealed from the trans-

axle and has its own oil sump. The Unit uses MopartSAE 80W-90 Gear and Axle Lubricant (MS-9020) and

holds 1.15 liters (1.22 quarts).

Service of the Power Transfer Unit is limited to:

²Fluid Change

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

RSTRANSMISSION/TRANSAXLE21-1

ProCarManuals.com

Page 1578 of 2399

31TH AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

31TH AUTOMATIC TRANSAXLE

DESCRIPTION.........................22

OPERATION...........................24

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

DIAGNOSIS..........................24

DIAGNOSIS AND TESTING - ROAD TEST . . . 31

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS....................32

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . . 35

DIAGNOSIS AND TESTING - CLUTCH AND

SERVO AIR PRESSURE TESTS..........35

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR......................37

REMOVAL.............................37

DISASSEMBLY.........................40

ASSEMBLY............................51

INSTALLATION.........................61

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC

SCHEMATICS........................64

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE..........72

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE..........75

ACCUMULATOR

DESCRIPTION.........................79

OPERATION...........................79

BANDS

DESCRIPTION

KICKDOWN (FRONT) BAND.............80

OPERATION

LOW/REVERSE (REAR) BAND...........80

ADJUSTMENTS

ADJUSTMENT - FRONT BAND...........80

ADJUSTMENTS - REAR BAND...........80

CLUTCH - FRONT

DESCRIPTION.........................82

OPERATION...........................82

DISASSEMBLY.........................82

ASSEMBLY............................84

CLUTCH - REAR

DESCRIPTION.........................86

OPERATION...........................86

DISASSEMBLY.........................87

ASSEMBLY............................89

FINAL DRIVE

DISASSEMBLY.........................91

ASSEMBLY............................94ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING . . 97

FLUID

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

AND CONDITION CHECK...............99

STANDARD PROCEDURE - FLUID AND

FILTER CHANGE......................99

GEAR SHIFT CABLE

REMOVAL............................101

INSTALLATION........................102

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......104

GOVERNOR

DESCRIPTION........................104

OPERATION..........................104

CLEANING...........................104

INSPECTION.........................104

OIL PUMP

DESCRIPTION........................105

OPERATION..........................105

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................105

DISASSEMBLY........................106

CLEANING...........................106

INSPECTION.........................106

ASSEMBLY...........................107

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING - PARK/NEUTRAL

POSITION SWITCH...................107

REMOVAL............................107

INSTALLATION........................107

PLANETARY GEARTRAIN

DISASSEMBLY........................108

ASSEMBLY...........................109

SEAL - OIL PUMP

REMOVAL............................110

INSTALLATION........................110

SERVO - KICKDOWN

DESCRIPTION........................111

OPERATION..........................111

DISASSEMBLY........................111

CLEANING...........................112

INSPECTION..........................113

ASSEMBLY...........................113

SERVO - LOW/REVERSE

DESCRIPTION........................113

OPERATION..........................113

DISASSEMBLY........................114

CLEANING...........................114

RS31TH AUTOMATIC TRANSAXLE21-21

ProCarManuals.com

Page 1579 of 2399

ASSEMBLY...........................115

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................115

OPERATION..........................115

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................117

REMOVAL............................117

INSTALLATION........................118

SOLENOID - TCC

DESCRIPTION........................119

OPERATION..........................119

REMOVAL............................119

INSTALLATION........................120

THROTTLE VALVE CABLE

REMOVAL............................120

INSTALLATION........................121

ADJUSTMENTS

THROTTLE VALVE LINKAGE

ADJUSTMENT.......................122

TORQUE CONVERTER

DESCRIPTION........................122

OPERATION..........................126

REMOVAL............................127

INSTALLATION........................127

TRANSFER SYSTEM - OUTPUT SHAFT/GEAR/

BEARING

REMOVAL............................128INSTALLATION........................131

ADJUSTMENTS

ADJUSTMENT - OUTPUT SHAFT BEARING . 135

TRANSFER SYSTEM - TRANSFER SHAFT/

GEAR/BEARING

REMOVAL............................137

INSTALLATION........................141

ADJUSTMENTS

ADJUSTMENT - TRANSFER SHAFT

BEARING...........................145

VALVE BODY

REMOVAL............................146

DISASSEMBLY........................148

CLEANING...........................154

INSPECTION.........................155

ASSEMBLY...........................155

INSTALLATION........................158

ADJUSTMENTS

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS......................160

VEHICLE SPEED SENSOR/PINION GEAR

REMOVAL............................160

INSTALLATION........................160

31TH AUTOMATIC

TRANSAXLE

DESCRIPTION

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heatexchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

21 - 22 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1582 of 2399

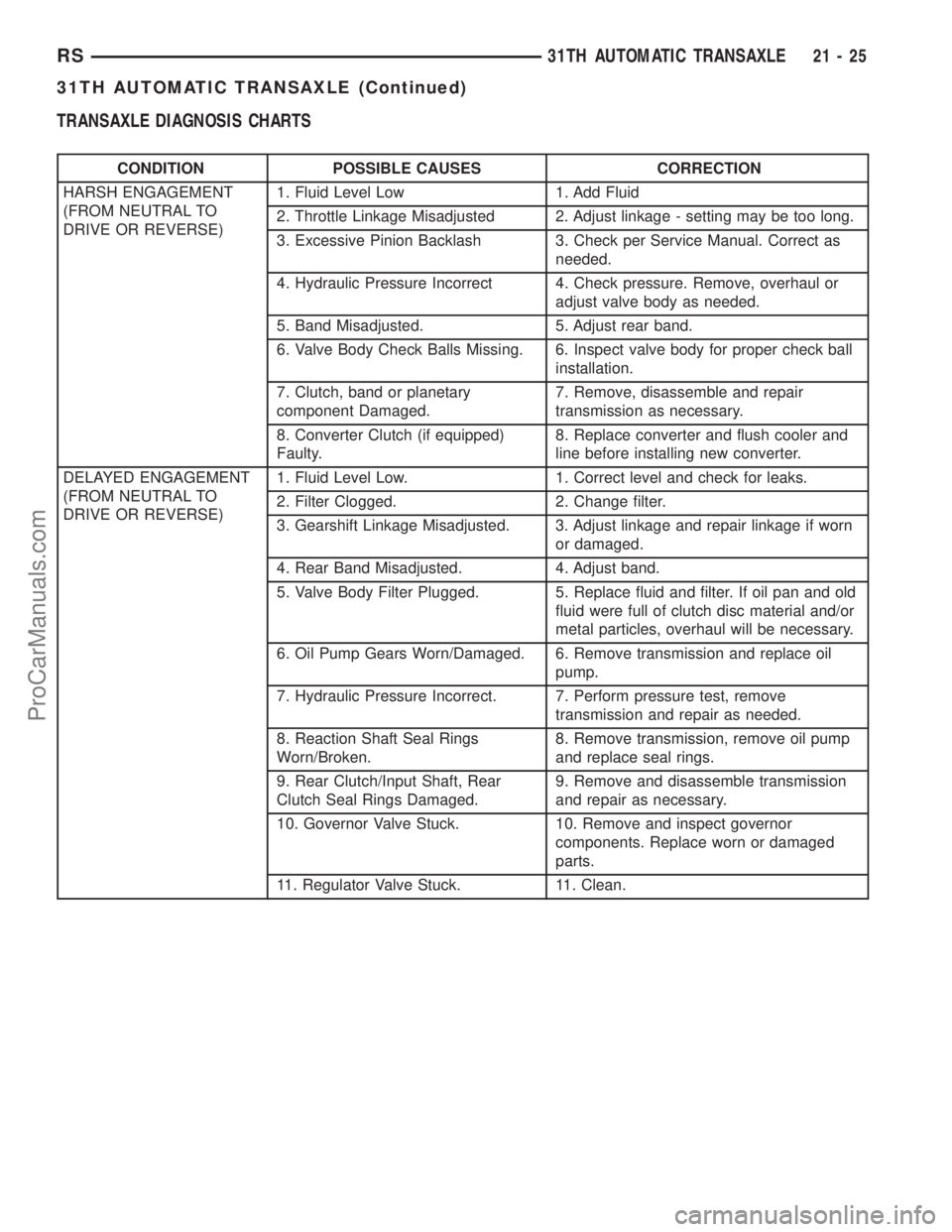

TRANSAXLE DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low 1. Add Fluid

2. Throttle Linkage Misadjusted 2. Adjust linkage - setting may be too long.

3. Excessive Pinion Backlash 3. Check per Service Manual. Correct as

needed.

4. Hydraulic Pressure Incorrect 4. Check pressure. Remove, overhaul or

adjust valve body as needed.

5. Band Misadjusted. 5. Adjust rear band.

6. Valve Body Check Balls Missing. 6. Inspect valve body for proper check ball

installation.

7. Clutch, band or planetary

component Damaged.7. Remove, disassemble and repair

transmission as necessary.

8. Converter Clutch (if equipped)

Faulty.8. Replace converter and flush cooler and

line before installing new converter.

DELAYED ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Misadjusted. 3. Adjust linkage and repair linkage if worn

or damaged.

4. Rear Band Misadjusted. 4. Adjust band.

5. Valve Body Filter Plugged. 5. Replace fluid and filter. If oil pan and old

fluid were full of clutch disc material and/or

metal particles, overhaul will be necessary.

6. Oil Pump Gears Worn/Damaged. 6. Remove transmission and replace oil

pump.

7. Hydraulic Pressure Incorrect. 7. Perform pressure test, remove

transmission and repair as needed.

8. Reaction Shaft Seal Rings

Worn/Broken.8. Remove transmission, remove oil pump

and replace seal rings.

9. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.9. Remove and disassemble transmission

and repair as necessary.

10. Governor Valve Stuck. 10. Remove and inspect governor

components. Replace worn or damaged

parts.

11. Regulator Valve Stuck. 11. Clean.

RS31TH AUTOMATIC TRANSAXLE21-25

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1583 of 2399

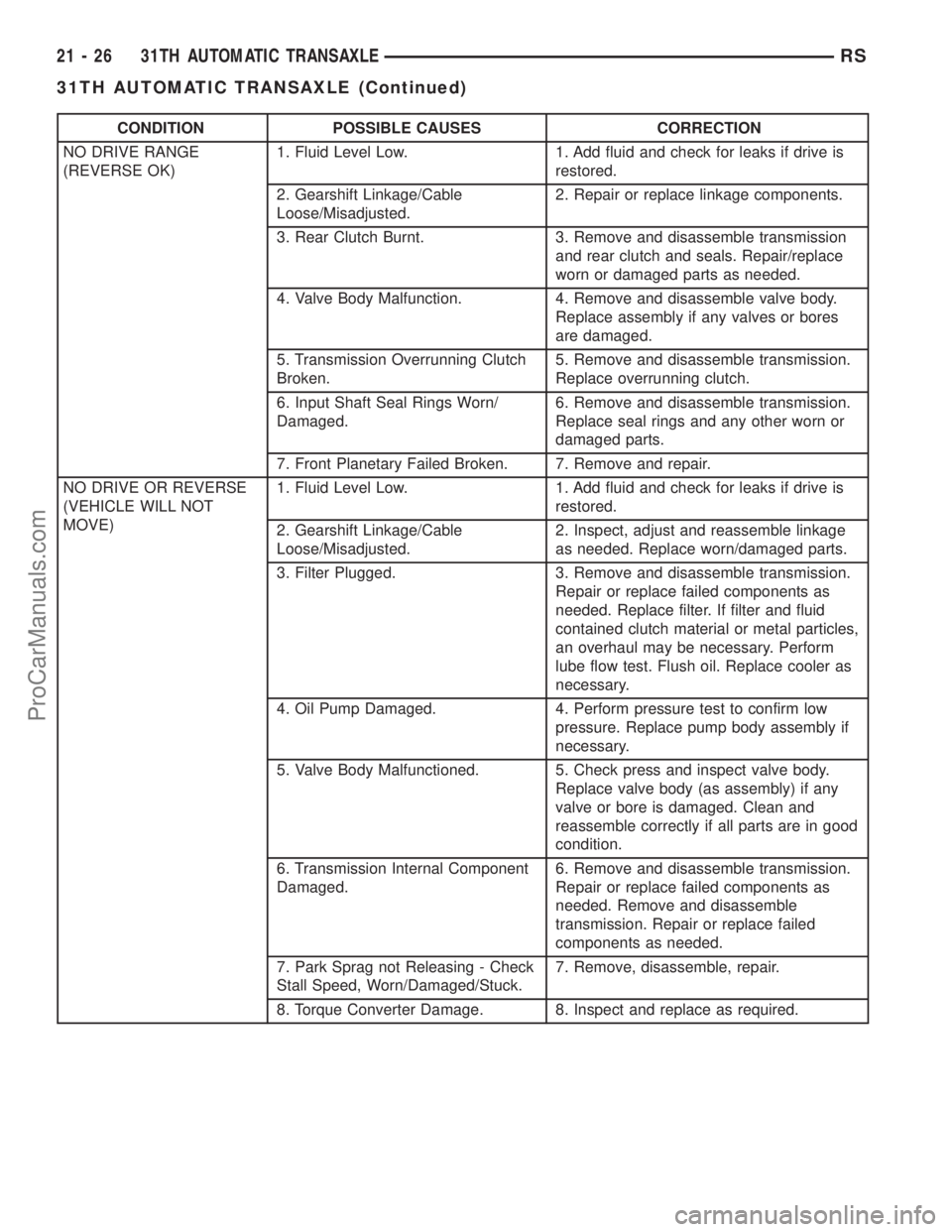

CONDITION POSSIBLE CAUSES CORRECTION

NO DRIVE RANGE

(REVERSE OK)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Repair or replace linkage components.

3. Rear Clutch Burnt. 3. Remove and disassemble transmission

and rear clutch and seals. Repair/replace

worn or damaged parts as needed.

4. Valve Body Malfunction. 4. Remove and disassemble valve body.

Replace assembly if any valves or bores

are damaged.

5. Transmission Overrunning Clutch

Broken.5. Remove and disassemble transmission.

Replace overrunning clutch.

6. Input Shaft Seal Rings Worn/

Damaged.6. Remove and disassemble transmission.

Replace seal rings and any other worn or

damaged parts.

7. Front Planetary Failed Broken. 7. Remove and repair.

NO DRIVE OR REVERSE

(VEHICLE WILL NOT

MOVE)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Inspect, adjust and reassemble linkage

as needed. Replace worn/damaged parts.

3. Filter Plugged. 3. Remove and disassemble transmission.

Repair or replace failed components as

needed. Replace filter. If filter and fluid

contained clutch material or metal particles,

an overhaul may be necessary. Perform

lube flow test. Flush oil. Replace cooler as

necessary.

4. Oil Pump Damaged. 4. Perform pressure test to confirm low

pressure. Replace pump body assembly if

necessary.

5. Valve Body Malfunctioned. 5. Check press and inspect valve body.

Replace valve body (as assembly) if any

valve or bore is damaged. Clean and

reassemble correctly if all parts are in good

condition.

6. Transmission Internal Component

Damaged.6. Remove and disassemble transmission.

Repair or replace failed components as

needed. Remove and disassemble

transmission. Repair or replace failed

components as needed.

7. Park Sprag not Releasing - Check

Stall Speed, Worn/Damaged/Stuck.7. Remove, disassemble, repair.

8. Torque Converter Damage. 8. Inspect and replace as required.

21 - 26 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1586 of 2399

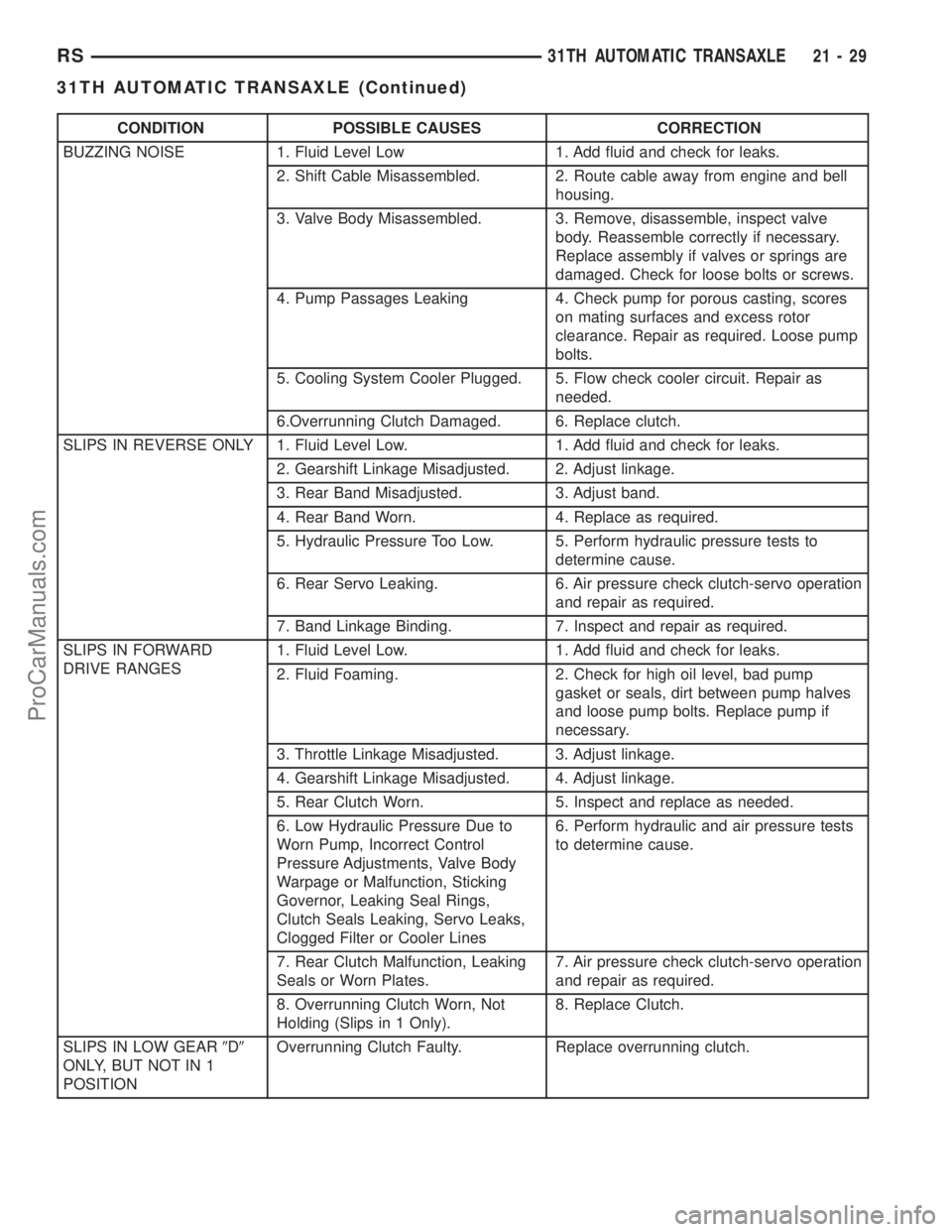

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Misassembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Misassembled. 3. Remove, disassemble, inspect valve

body. Reassemble correctly if necessary.

Replace assembly if valves or springs are

damaged. Check for loose bolts or screws.

4. Pump Passages Leaking 4. Check pump for porous casting, scores

on mating surfaces and excess rotor

clearance. Repair as required. Loose pump

bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as

needed.

6.Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE ONLY 1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Misadjusted. 2. Adjust linkage.

3. Rear Band Misadjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Hydraulic Pressure Too Low. 5. Perform hydraulic pressure tests to

determine cause.

6. Rear Servo Leaking. 6. Air pressure check clutch-servo operation

and repair as required.

7. Band Linkage Binding. 7. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump

gasket or seals, dirt between pump halves

and loose pump bolts. Replace pump if

necessary.

3. Throttle Linkage Misadjusted. 3. Adjust linkage.

4. Gearshift Linkage Misadjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking

Governor, Leaking Seal Rings,

Clutch Seals Leaking, Servo Leaks,

Clogged Filter or Cooler Lines6. Perform hydraulic and air pressure tests

to determine cause.

7. Rear Clutch Malfunction, Leaking

Seals or Worn Plates.7. Air pressure check clutch-servo operation

and repair as required.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).8. Replace Clutch.

SLIPS IN LOW GEAR9D9

ONLY, BUT NOT IN 1

POSITIONOverrunning Clutch Faulty. Replace overrunning clutch.

RS31TH AUTOMATIC TRANSAXLE21-29

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1587 of 2399

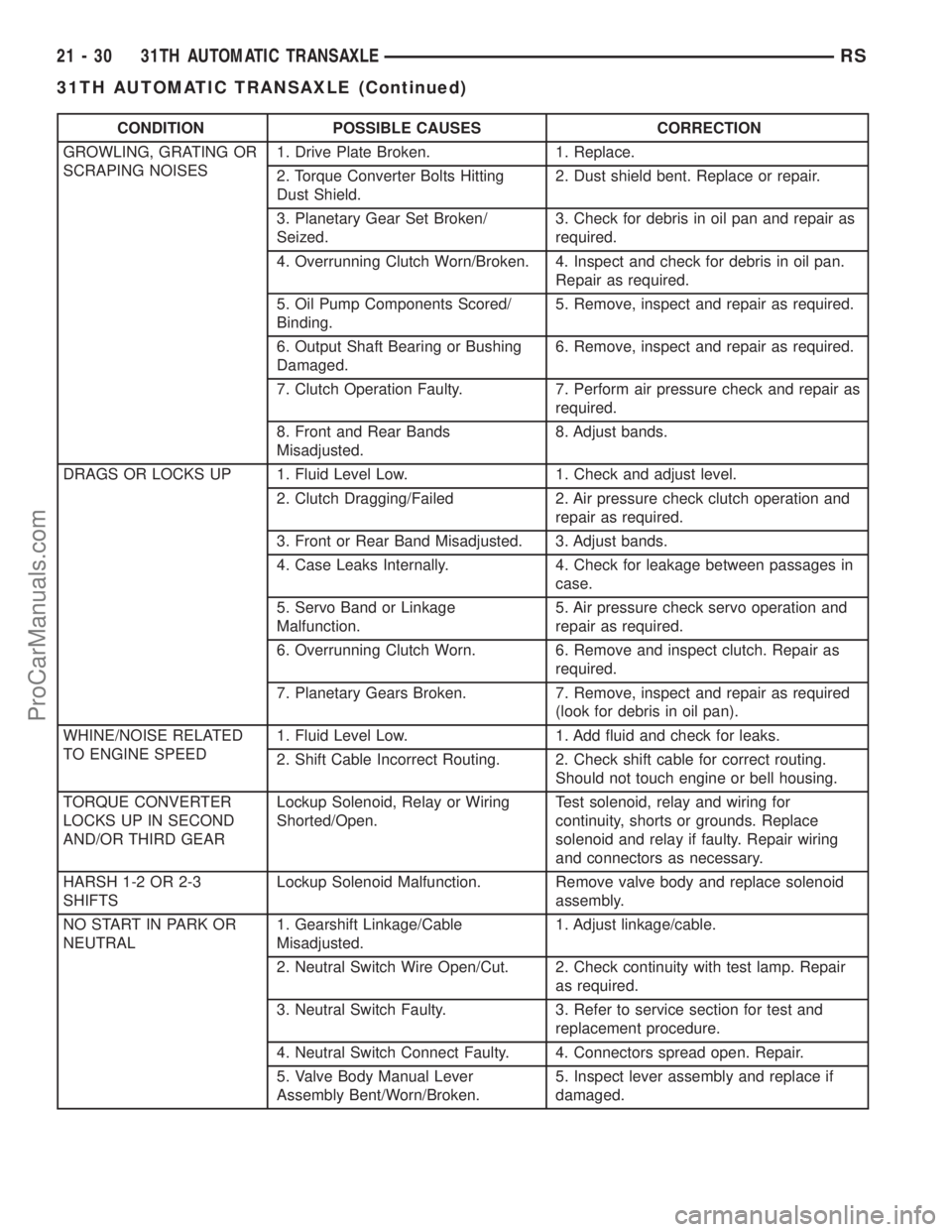

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

Repair as required.

5. Oil Pump Components Scored/

Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Misadjusted.8. Adjust bands.

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

repair as required.

3. Front or Rear Band Misadjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and

repair as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

(look for debris in oil pan).

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK OR

NEUTRAL1. Gearshift Linkage/Cable

Misadjusted.1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

21 - 30 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com