seat memory CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 171 of 2399

(5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

57).

(6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopart

Brake Fluid or equivalent.

(11) Road test vehicle to ensure proper operation of

brakes.

INSTALLATION - RHD

CAUTION: Different types of master cylinders are

used on this vehicle depending on brake options. If

a new master cylinder is being installed, be sure it

is the correct master cylinder for the type of brake

system the vehicle is equipped with.

CAUTION: When replacing the master cylinder on a

vehicle, a NEW vacuum seal MUST be installed on

the master cylinder.

(1) Install a NEW vacuum seal on master cylinder

making sure seal fits squarely in groove of master

cylinder casting.

(2) Position master cylinder on studs of power

brake booster, aligning booster push rod with master

cylinder piston.

(3) Install the two master cylinder mounting nuts

(Fig. 59). Tighten both mounting nuts to a torque of

25 N´m (225 in. lbs.).

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion.

(4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

59). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.).

(5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

55).

(6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopart

Brake Fluid or equivalent.(11) Road test vehicle to ensure proper operation of

brakes.

PEDAL - ADJUSTABLE

DESCRIPTION

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The effort required for pedal application will not

change regardless of pedal position.

The adjustable pedal system allows the pedals to

adjust up to 3 inches (75 mm) at a rate of approxi-

mately 0.4 in./sec. (9 mm/sec.). An adjustment switch

is located on the left side of the steering column

lower shroud.

If the vehicle is equipped with Remote Keyless

Entry (RKE), an optional memory feature is avail-

able.

The serviceable components of the APS are:

²Adjustable pedal assembly (includes motor,

cables, pedals, gear box, sensor and module)

²Adjustable pedal module (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/

ADJUSTABLE PEDAL MODULE)

²Adjustable pedal switch

²Pedal position sensor

OPERATION

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor. The

pedal drive motor turns a screw that changes the

position of the accelerator pedal. The motor also

drives a cable connected to a gear box that changes

the brake pedal position the same distance as the

accelerator pedal. The pedals can be moved rearward

(closer to the driver) or forward (away from driver).

Each pedal is moved on its activating lever to a posi-

tion where the driver feels most comfortable. The

position and operation of the activating levers are not

changed.

Pedal adjustment is inhibited when the vehicle is

in reverse or when cruise control is engaged. The

Electronic Vehicle Information Center (EVIC) will

display a message when the Adjustable Pedal Module

(APM) is disabled. i.e.:9Adjustable Pedal Disabled -

Cruise Control Engaged9or9Adjustable Pedal Dis-

abled - Vehicle in Reverse9.

Foot pressure or debris can stall pedal adjustment.

In order to avoid damage to system components dur-

5 - 42 BRAKES - BASERS

MASTER CYLINDER (Continued)

ProCarManuals.com

Page 176 of 2399

(27) Install lower steering column cover/knee

blocker (Fig. 62).

(28) Install silencer panel below lower steering col-

umn cover/knee blocker.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery in following manor:

(a) Connect scan tool (DRBIIIt) to data link

diagnostic connector located below steering column.

(b) Turn ignition key to ON position. Exit vehi-

cle with scan tool leaving scan tool harness

plugged in.

(c) Ensuring that there are no occupants in vehi-

cle, connect ground (-) cable to the negative post of

the battery.

(d) Using scan tool, read and record any airbag

fault codes. Refer to Appropriate Diagnostic Infor-

mation if any faults are found.

(e) Through drivers open window, Reach around

back of steering wheel (between steering wheel and

instrument cluster) and turn ignition key to OFF,

then back ON while observing instrument cluster

airbag indicator lamp. It should go on for six to

eight seconds, then go out. This action indicates

that airbag system is functioning normally. If air-

bag indicator lamp fails to light, blinks on and off,

or goes on and stays on, there is an airbag system

malfunction. Refer to Appropriate Diagnostic Infor-

mation to diagnose the system malfunction.

(30) Using scan tool (DRBIIIt), check for and clear

any existing adjustable pedal fault codes. The adjust-

able pedal system is now activated.

(31) Turn key to OFF and remove scan tool from

vehicle.

(32) Test operation of adjustable pedals, memory

seats (if equipped), RKE (if equipped), and all func-

tions that are steering column operated. If applica-

ble, reset the radio and the clock.

(33) Road test the vehicle to ensure proper opera-

tion of the steering and brake systems.

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL)

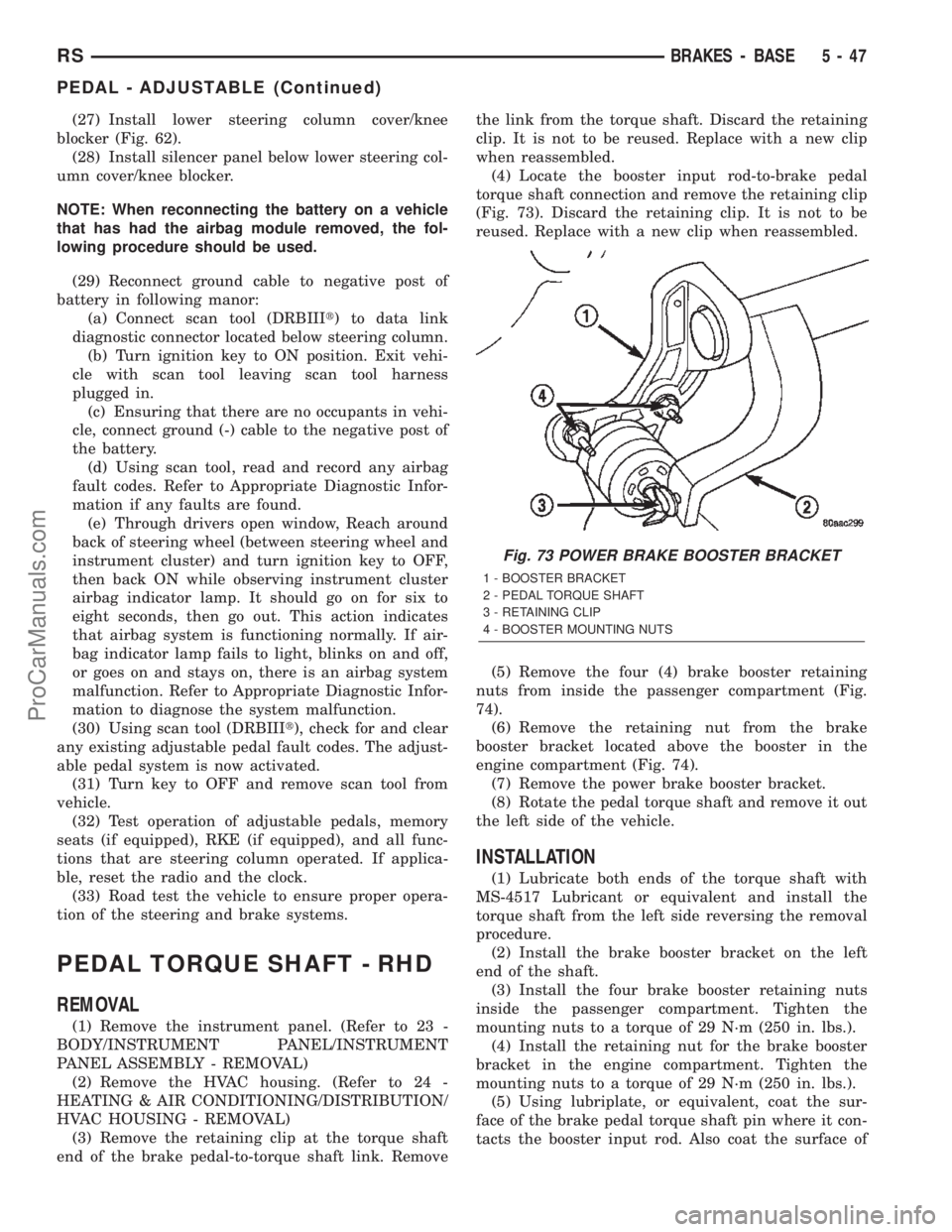

(3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Removethe link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled.

(4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 73). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled.

(5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

74).

(6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 74).

(7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.

(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(4) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

Fig. 73 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

RSBRAKES - BASE5-47

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 338 of 2399

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................2

ADJUSTABLE PEDAL MODULE

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL MODULE.......................3

REMOVAL.............................3

INSTALLATION..........................3

BODY CONTROL MODULE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................5

INSTALLATION..........................5

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................6

INSTALLATION..........................6

DATA LINK CONNECTOR

DESCRIPTION..........................7

OPERATION............................7

FRONT CONTROL MODULE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................8

REMOVAL.............................8

INSTALLATION..........................8

HEATED SEAT MODULE

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE.............................9

REMOVAL.............................10

INSTALLATION.........................10

POWER LIFTGATE MODULE

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................11

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION........................11DIAGNOSTIC TROUBLE CODE...........13

OPERATION - SENSOR RETURN - PCM

INPUT..............................25

OPERATION - SCI RECEIVE - PCM INPUT . . 25

OPERATION - IGNITION SENSE - PCM

INPUT..............................25

OPERATION - PCM GROUND............25

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM

OUTPUT............................25

OPERATION - 5 VOLT SUPPLY - PCM

OUTPUT............................25

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES..........25

REMOVAL.............................26

INSTALLATION.........................26

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................26

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................27

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................28

OPERATION...........................28

STANDARD PROCEDURE

STANDARD PROCEDURE - PINION

FACTOR SETTING.....................31

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE........................31

REMOVAL.............................31

INSTALLATION.........................32

MEMORY SEAT/MIRROR MODULE

DESCRIPTION.........................33

OPERATION...........................33

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE................33

REMOVAL.............................33

INSTALLATION.........................33

SLIDING DOOR CONTROL MODULE

DESCRIPTION.........................33

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................34

RSELECTRONIC CONTROL MODULES8E-1

ProCarManuals.com

Page 340 of 2399

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

ADJUSTABLE PEDAL MODULE

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL MODULE

Refer to Appropriate Diagnostic Information.

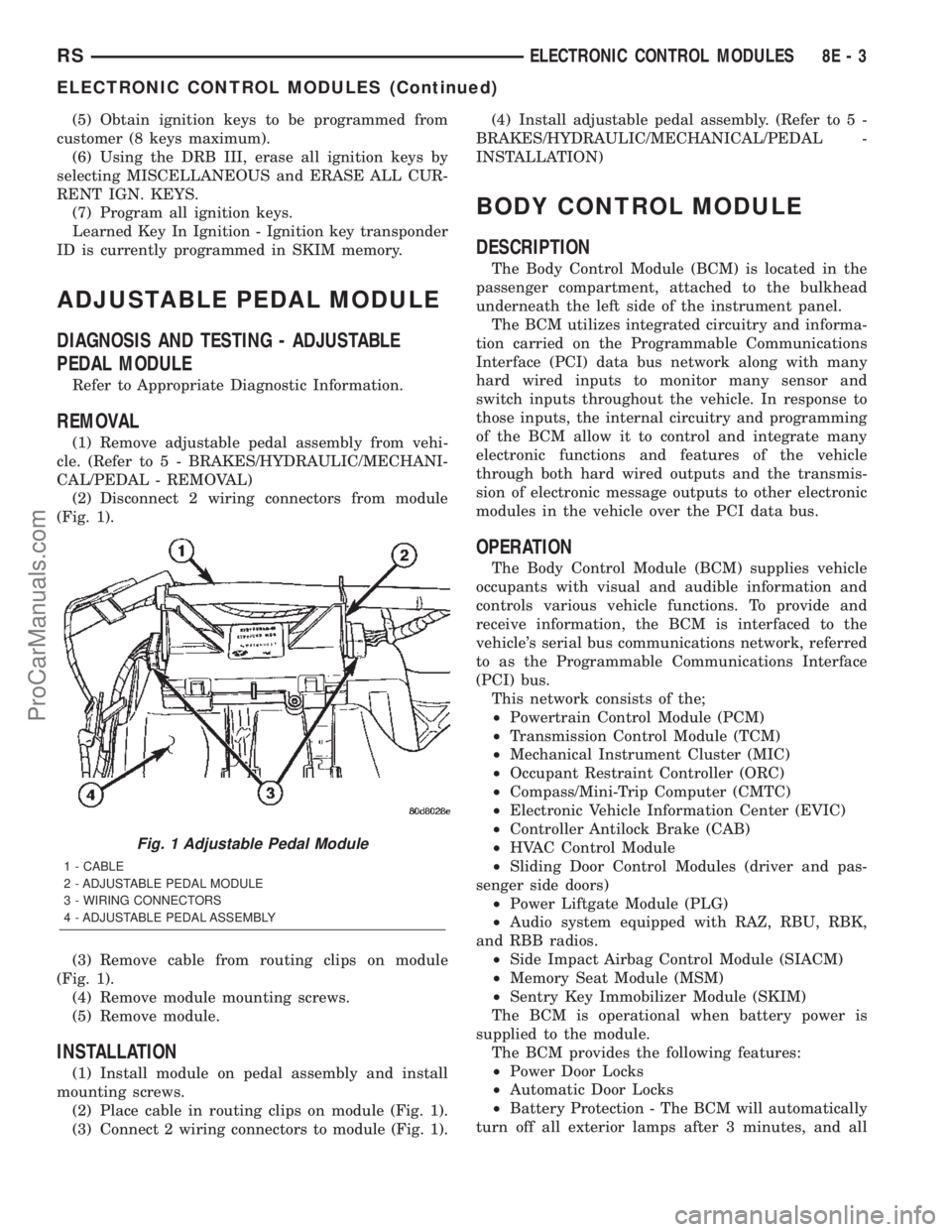

REMOVAL

(1) Remove adjustable pedal assembly from vehi-

cle. (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/PEDAL - REMOVAL)

(2) Disconnect 2 wiring connectors from module

(Fig. 1).

(3) Remove cable from routing clips on module

(Fig. 1).

(4) Remove module mounting screws.

(5) Remove module.

INSTALLATION

(1) Install module on pedal assembly and install

mounting screws.

(2) Place cable in routing clips on module (Fig. 1).

(3) Connect 2 wiring connectors to module (Fig. 1).(4) Install adjustable pedal assembly. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION)

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is located in the

passenger compartment, attached to the bulkhead

underneath the left side of the instrument panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Side Impact Airbag Control Module (SIACM)

²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

Fig. 1 Adjustable Pedal Module

1 - CABLE

2 - ADJUSTABLE PEDAL MODULE

3 - WIRING CONNECTORS

4 - ADJUSTABLE PEDAL ASSEMBLY

RSELECTRONIC CONTROL MODULES8E-3

ELECTRONIC CONTROL MODULES (Continued)

ProCarManuals.com

Page 341 of 2399

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Driver

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if theBCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

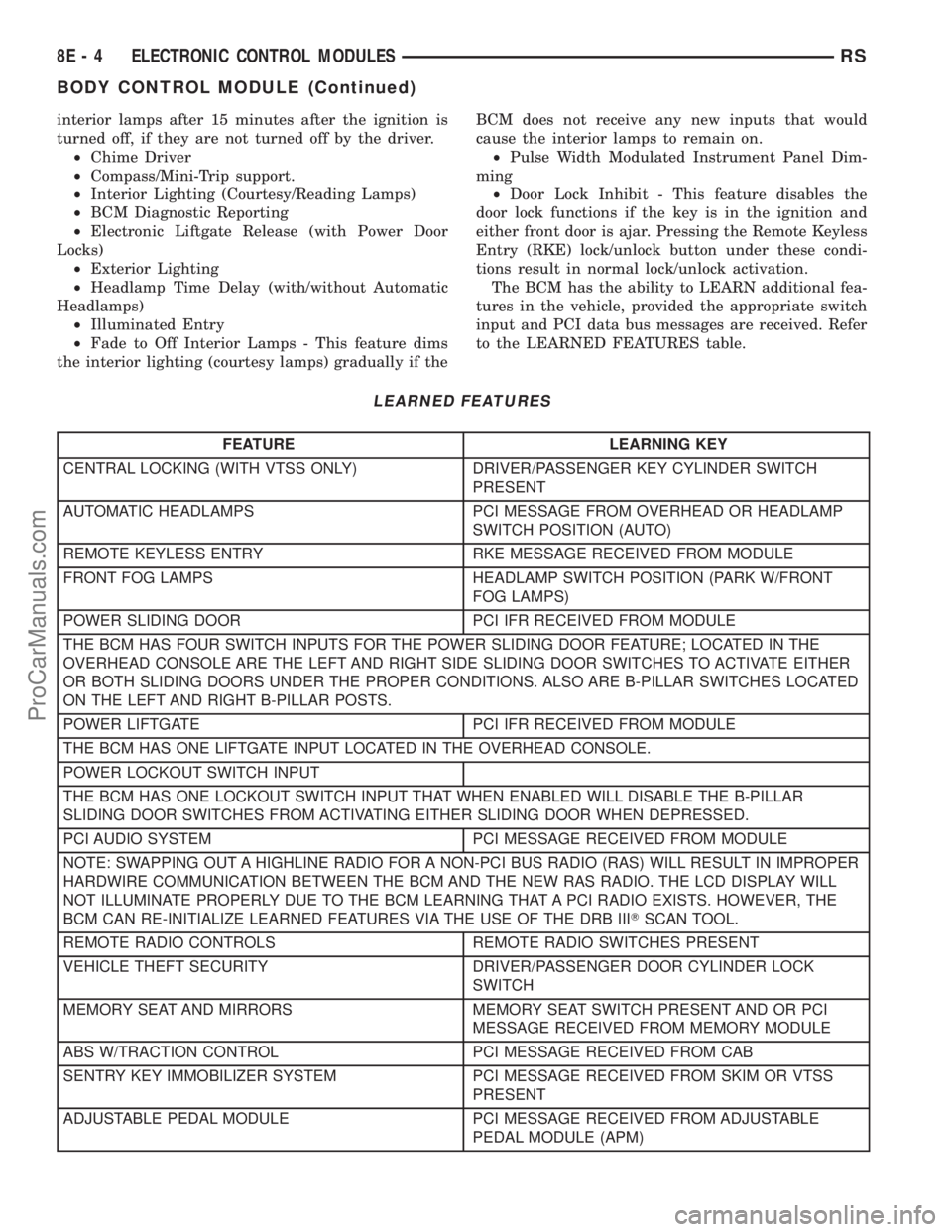

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

LEARNED FEATURES

FEATURE LEARNING KEY

CENTRAL LOCKING (WITH VTSS ONLY) DRIVER/PASSENGER KEY CYLINDER SWITCH

PRESENT

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY RKE MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

THE BCM HAS ONE LIFTGATE INPUT LOCATED IN THE OVERHEAD CONSOLE.

POWER LOCKOUT SWITCH INPUT

THE BCM HAS ONE LOCKOUT SWITCH INPUT THAT WHEN ENABLED WILL DISABLE THE B-PILLAR

SLIDING DOOR SWITCHES FROM ACTIVATING EITHER SLIDING DOOR WHEN DEPRESSED.

PCI AUDIO SYSTEM PCI MESSAGE RECEIVED FROM MODULE

NOTE: SWAPPING OUT A HIGHLINE RADIO FOR A NON-PCI BUS RADIO (RAS) WILL RESULT IN IMPROPER

HARDWIRE COMMUNICATION BETWEEN THE BCM AND THE NEW RAS RADIO. THE LCD DISPLAY WILL

NOT ILLUMINATE PROPERLY DUE TO THE BCM LEARNING THAT A PCI RADIO EXISTS. HOWEVER, THE

BCM CAN RE-INITIALIZE LEARNED FEATURES VIA THE USE OF THE DRB IIITSCAN TOOL.

REMOTE RADIO CONTROLS REMOTE RADIO SWITCHES PRESENT

VEHICLE THEFT SECURITY DRIVER/PASSENGER DOOR CYLINDER LOCK

SWITCH

MEMORY SEAT AND MIRRORS MEMORY SEAT SWITCH PRESENT AND OR PCI

MESSAGE RECEIVED FROM MEMORY MODULE

ABS W/TRACTION CONTROL PCI MESSAGE RECEIVED FROM CAB

SENTRY KEY IMMOBILIZER SYSTEM PCI MESSAGE RECEIVED FROM SKIM OR VTSS

PRESENT

ADJUSTABLE PEDAL MODULE PCI MESSAGE RECEIVED FROM ADJUSTABLE

PEDAL MODULE (APM)

8E - 4 ELECTRONIC CONTROL MODULESRS

BODY CONTROL MODULE (Continued)

ProCarManuals.com

Page 370 of 2399

MEMORY SEAT/MIRROR

MODULE

DESCRIPTION

Vehicles equipped with the memory seat/mirror

option, utilize a memory module located under the

drivers front seat. This module is basically wired in-

line between the power seat switch and the power

seat track/adjuster motors, or in-line between the

power mirror switch and the power side view mir-

ror(s) motor(s). The MSMM contains a central pro-

cessing unit that communicates with other modules

on the Programmable Communications Interface

(PCI) data bus network.

The Memory Seat/Mirror Module (MSMM) receives

hard wired inputs from the driver power seat switch

and the potentiometers on each of the driver side

power seat track motors, or from the power mirror

switch and the potentiometers on the side view mir-

ror. The MSMM receives messages over the PCI data

bus from the Body Control Module (BCM) (memory

switch status), the Powertrain Control Module (PCM)

(vehicle speed status). The MSMM will prevent the

seat memory recall function from being initiated if

the driver side seat belt is buckled, if the transmis-

sion gear selector lever is not in the Park or Neutral

positions, or if the vehicle is moving.

For diagnosis of the MSMM or the PCI data bus, a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual are recommended. The MSMM cannot

be repaired and, if faulty or damaged, it must be

replaced. Refer toMemory Systemin the Power

Seat or Power Mirror section of this manual for more

information on the memory system option.

OPERATION

When memory system operation is requested

(depressing of the memory switch), a resistor multi-

plexed signal is sent from the memory switch to the

body control module (BCM). The body control module

will then send the appropriate signals out to the

memory/mirror seat module, the memory/mirror seat

module then applies the voltage supply to the power

seat track or side-view mirror if the proper require-

ments are met. The vehicle speed must equal zero

and the transmission must be in park or neutral in

order for the memory system to function.

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE

Visually inspect the related wiring harness connec-

tors. Look for broken, bent, pushed out, or corroded

terminals. If any of the above conditions are present,

repair as necessary. If not, use a DRB IIItscan tool

and the proper Diagnostic Procedures Manual to testthe memory/mirror seat module. For complete circuit

diagrams, refer toWiring Diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front bucket seat

retaining nuts from under the vehicle (Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(3) Lift the drivers seat up and out of the mount-

ing holes in the floor pan and lay the seat rearward

to access the module located under the seat. It is not

necessary to disconnect the seat electrical, just use

care not to damage the wiring by over-extending.

(4) Disconnect the memory/mirror seat module

electrical connectors. Depress the retaining tab and

pull straight apart.

(5) Remove the module retaining bolts and remove

the module from the bracket.

INSTALLATION

(1) Position and install the module retaining bolts.

(2) Connect the memory/mirror seat module elec-

trical connectors.

(3) Position the drivers seat in the mounting holes

in the floor pan.

(4) Install the driver side front bucket seat retain-

ing nuts from under the vehicle (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION).

(5) Connect the battery negative cable.

SLIDING DOOR CONTROL

MODULE

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a sliding door control module. The sliding door con-

trol module is located behind the sliding door trim

panel in the center of the door, just above the sliding

door motor (Fig. 20). This module controls the opera-

tion of the door through the Programmable Commu-

nication Interface (PCI) J1850 data bus circuit and

the Body Control Module. The sliding door control

module contains software technology which enables it

to detect resistance to door travel and to reverse door

travel in order to avoid damage to the door or to

avoid possible personal injury if the obstruction is a

person. This feature functions in both the opening

and closing cycles. If the power sliding door system

develops any problems the control module will store

and recall Diagnostic Trouble Codes (DTC). The use

of a diagnostic scan tool, such as the DRB IIItis

required to read and troubleshoot these trouble

codes. The sliding door control module can be

RSELECTRONIC CONTROL MODULES8E-33

ProCarManuals.com

Page 582 of 2399

DOOR LOCK CIRCUIT PROTECTION

The BCM controls the door lock output drivers. If

the door lock switch is actuated continuously for

more than one second the BCM will turn the output

driver OFF (the BCM would consider the switch

stuck). The lock motors are protected with Positive

Temperature Coefficient (PTC) device that prevents

motor burn out.

REMOTE KEYLESS ENTRY SYSTEM

²LOCK: Pressing the LOCK button locks all

doors and sounds horn (chirp) and arm the Vehicle

Theft Security System, if equipped. The chirp verifies

that the RKE receiver has sent a message to the

BCM for door lock operation. If a door has not been

closed before pressing the LOCK button, the vehicle

may not be secured and the VTSS will not arm until

the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's side doors and activate the

illuminated entry system and disarm Vehicle Theft

Security System, if equipped. Pressing the UNLOCK

button twice within five seconds will unlock all doors

and activate the illuminated entry system.

²LEFT SLIDING DOOR: Pressing the LEFT

SLIDING DOOR BUTTON opens/closes the left

power sliding door remotely.

²RIGHT SLIDING DOOR: Pressing the RIGHT

SLIDING DOOR BUTTON opens/closes the right

power sliding door remotely.

²LIFTGATE:

Pressing the LIFTGATE BUTTON

opens/closes the liftgate remotely, if equipped.If not

equipped with power liftgate, pressing the liftgate but-

ton will allow a one time 30 second access to liftgate.

²PANIC: Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the ignition

switch is turned to the RUN position.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s)

(VAC) in its memory even after vehicle power has

been interrupted.

NOTE: Additional features available to the customer

are described in the Vehicle Owners Manual.

The RKE system activates the optional memory

seat, mirror system and adjustable pedals, if

equipped. Two primary key fob transmitters can be

programmed to actuate memory seat and mirror set-

ting 1 or 2. Two additional key fob transmitters can be

added, but they will not be able to operate the mem-

ory seat and mirror system (Refer to 8 - ELECTRI-

CAL/POWER SEATS - OPERATION) and (Refer to 8 -

ELECTRICAL/POWER MIRRORS - OPERATION).

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The Door Cylinder Lock Switch is used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver and passenger door lock cylinders.

When installed on the rear of the cylinder, there is a

tab on the lock cylinder that aligns with the switch

to prevent it from turning. An anti-rotating device.

The door cylinder lock switch is a one time use

switch. Once it is removed from the rear of the door

lock cylinder, it may not be reinstalled and a new

switch must be used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch, via

the Programmable Communication Interface (PCI)

bus.

If turning the key cylinder once, toward the front

of the vehicle (for either driver or passenger doors),

this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle (either passenger or driver doors) once. This

will lock the door that you are using the key on. If

equipped with the central locking feature, this will

lock all the other doors and liftgate. Furthermore,

this will arm the vehicle theft security system and

turn off the illuminated entry.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

RSPOWER LOCKS8N-41

POWER LOCKS (Continued)

ProCarManuals.com

Page 585 of 2399

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

The RKE module is capable of retaining up to four

different Vehicle Access Codes.

OPERATION

Whenever the vehicle battery power is interrupted

the RKE Module will retain all vehicle access codes

in its memory. When replacing or adding a key fob

transmitter (maximum 4) a DRB IIItscan tool is

required to program the RKE Module to accept the

new Vehicle Access Code if a customer owned trans-

mitter is not available. Refer to Electrical, Remote

Keyless Entry Module, Standard Procedure - Pro-

gramming RKE Module or the Proper Body Diagnos-

tic Procedures manual.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY MODULE

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Refer to the

proper Body Diagnostic Procedures Manual for test-

ing the Remote Keyless Entry system using a DRB

IIItscan tool. Also refer to other interrelated sys-

tems groups within this manual:

²Vehicle Theft Security System

²Power Seats

²Power Mirrors

STANDARD PROCEDURE - PROGRAMMING

RKE MODULE

(1) Using a functional key fob transmitter, unlock

the vehicle and disarm the Vehicle Theft Security

System.

(2) Insert ignition key into the ignition switch.

(3) Turn the ignition switch to RUN position with-

out starting engine.

(4) Using a functional key fob transmitter, press

and hold the UNLOCK button for a minimum five

seconds (maximum ten seconds).

(5) While still holding UNLOCK button, and

before ten seconds passes, press the PANIC button

and release both at the same time. A single chime

will sound to verify that the RKE module is set to

receive the new Vehicle Access Code(s).

(6) Within 30 seconds of the chime, press and

release the ªLOCKº and ªUNLOCKº buttons on the

transmitter at the same time. Then press and release

any one of the buttons. The BCM will sound anabbreviated chime to acknowledge that the program-

ming of the transmitter has been completed and was

successful.

(7) Repeat step 6 for all transmitters that will be

used with this vehicle (up to 4 total).

(8) Programming mode will last for 30 seconds. To

get out of programming mode sooner, turn the igni-

tion OFF. A single chime will sound to verify that the

RKE module will no longer accept additional Vehicle

Access Code(s).

(9) When Vehicle Access Code(s) programming is

complete, turn the ignition switch to the OFF posi-

tion and verify RKE system operation using each key

fob.

NOTE:

Only the two key fob transmitters that have been

programmed to the memory seat and mirror system

will operate it. If any key fob is replaced, the mem-

ory seat and mirror module will require program-

ming. (Refer to 8 - ELECTRICAL/POWER SEATS -

DIAGNOSIS AND TESTING).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel top cover (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP PAD - REMOVAL).

(3) Remove screws holding RKE module to instru-

ment panel.

(4) Disconnect wire connector from RKE module

(Fig. 4).

(5) Remove the RKE module from vehicle.

Fig. 4 RKE MODULE

1 - REMOTE KEYLESS ENTRY MODULE

2 - INSTRUMENT PANEL

3 - DEMISTER DUCT

8N - 44 POWER LOCKSRS

ProCarManuals.com

Page 592 of 2399

POWER SEAT SYSTEM

TABLE OF CONTENTS

page page

POWER SEAT SYSTEM

DESCRIPTION

DESCRIPTION........................51

DESCRIPTION - MEMORY SYSTEM.......52

OPERATION

OPERATION - POWER SEAT SYSTEM.....53

OPERATION - MEMORY SYSTEM.........53

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM............................53

DIAGNOSIS AND TESTING - MEMORY

SYSTEM............................54

DRIVER SEAT SWITCH

DESCRIPTION.........................54

OPERATION...........................55

DIAGNOSIS AND TESTING - DRIVER SEAT

SWITCH............................55

REMOVAL.............................55

INSTALLATION.........................56

MEMORY SET SWITCH

DESCRIPTION.........................56

OPERATION...........................56

DIAGNOSIS AND TESTING - MEMORY

SWITCH............................57

REMOVAL.............................57

INSTALLATION.........................57

PASSENGER SEAT SWITCH

DESCRIPTION.........................57OPERATION...........................57

DIAGNOSIS AND TESTING - PASSENGER

SEAT SWITCH........................58

REMOVAL.............................58

INSTALLATION.........................59

MEMORY MIRROR/SEAT MODULE

DESCRIPTION.........................59

OPERATION...........................59

DIAGNOSIS AND TESTING - MEMORY

MIRROR/SEAT MODULE................59

REMOVAL.............................59

INSTALLATION.........................59

DRIVER POWER SEAT TRACK

DESCRIPTION.........................60

OPERATION...........................60

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK.........................60

REMOVAL.............................61

INSTALLATION.........................61

PASSENGER POWER SEAT TRACK

DESCRIPTION.........................61

OPERATION...........................62

DIAGNOSIS AND TESTING - POWER SEAT

TRACK.............................62

REMOVAL.............................62

INSTALLATION.........................63

POWER SEAT SYSTEM

DESCRIPTION

DESCRIPTION

The power seat system option allows the driver

and front seat passenger to electrically adjust their

seating positions for optimum control and comfort

using the power seat switches located on the out-

board seat cushion side shield of each front seat.

Both power front seats can be adjusted in eight dif-

ferent directions up, down, front up, front down, rear

up, rear down, forward, rearward and recliner for-

ward and rearward.

The power seat system receives battery current

through a 40 amp fuse in the Intelligent Power Mod-

ule and a 30 amp circuit breaker under the seat sothat the power seats remain operational, regardless

of the ignition switch position.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

A eight-way power seat is standard on highline

models and optional on others. This option includes a

eight-way adjustable seat cushion track and a two-

way power seat back.

RSPOWER SEAT SYSTEM8N-51

ProCarManuals.com

Page 593 of 2399

The eight-way power seat is also available with the

heated seat and memory seat system that automati-

cally positions the power seat for two different driv-

ers. Refer toHeated Seatsfor more information on

the heated seat option. Refer toDescription Mem-

ory Seat Systemin this section for more informa-

tion on the memory seat system.

The power seat system includes the following com-

ponents:

²Power seat recliners

²Power seat switches

²Power seat tracks

²Circuit breaker

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Heated Seat Module (HSM)

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

²Programmable Communications Interface (PCI)

data bus network

Refer to Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions and opera-

tions for the major components in the power seat

system and memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is available on some

models. The memory system is able to store and

recall the driver side power seat positions (including

the power recliner position) and both outside side

view mirrors positions for two drivers. On vehicles

equipped with a factory radio, the memory system is

also able to store and recall radio station presets for

two drivers. The memory system also will store and

recall the last station listened to for each driver, even

if it is not one of the preset stations.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

EVIC module, which is located in the overhead con-

sole.

A Memory Seat Mirror Module (MSMM) is used on

some models to control and integrate the many elec-

tronic functions and features included in the memory

seat and mirror systems.

The memory system includes the following compo-

nents:

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Position potentiometers on both outside side

view mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Electronic Vehicle Information Center (EVIC)

²Radio receiver (if PCI data bus capable).

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) J1850 data bus network. The PCI

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor

current loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and

allows the addition of many new feature capabilities.

Initial diagnosis of these electronic modules or the

PCI data bus network requires the use of a DRB IIIt

scan tool and the proper Diagnostic Procedures man-

ual. If this method does not prove conclusive, the use

of a automotive meter such as the Fluket, the proper

wiring schematics and the service manual diagnostic

routines are required.

The other electronic modules that may affect mem-

ory system operation are as follows:

Fig. 1 Identifying a Side Airbag Equipped Seat

1 - Airbag Label

8N - 52 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

ProCarManuals.com