suspension CHRYSLER CARAVAN 2003 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1434 of 2177

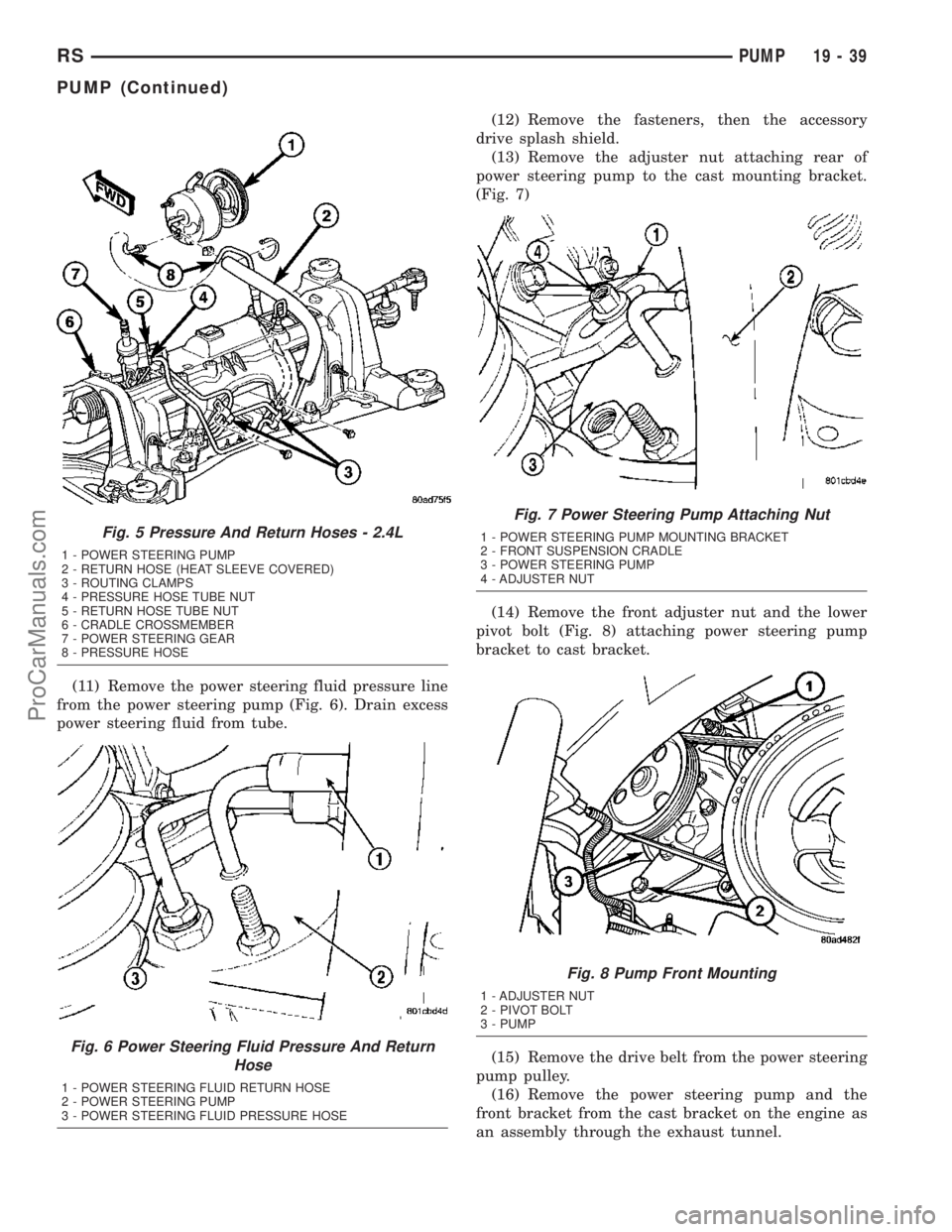

(11) Remove the power steering fluid pressure line

from the power steering pump (Fig. 6). Drain excess

power steering fluid from tube.(12) Remove the fasteners, then the accessory

drive splash shield.

(13) Remove the adjuster nut attaching rear of

power steering pump to the cast mounting bracket.

(Fig. 7)

(14) Remove the front adjuster nut and the lower

pivot bolt (Fig. 8) attaching power steering pump

bracket to cast bracket.

(15) Remove the drive belt from the power steering

pump pulley.

(16) Remove the power steering pump and the

front bracket from the cast bracket on the engine as

an assembly through the exhaust tunnel.

Fig. 5 Pressure And Return Hoses - 2.4L

1 - POWER STEERING PUMP

2 - RETURN HOSE (HEAT SLEEVE COVERED)

3 - ROUTING CLAMPS

4 - PRESSURE HOSE TUBE NUT

5 - RETURN HOSE TUBE NUT

6 - CRADLE CROSSMEMBER

7 - POWER STEERING GEAR

8 - PRESSURE HOSE

Fig. 6 Power Steering Fluid Pressure And Return

Hose

1 - POWER STEERING FLUID RETURN HOSE

2 - POWER STEERING PUMP

3 - POWER STEERING FLUID PRESSURE HOSE

Fig. 7 Power Steering Pump Attaching Nut

1 - POWER STEERING PUMP MOUNTING BRACKET

2 - FRONT SUSPENSION CRADLE

3 - POWER STEERING PUMP

4 - ADJUSTER NUT

Fig. 8 Pump Front Mounting

1 - ADJUSTER NUT

2 - PIVOT BOLT

3 - PUMP

RSPUMP19-39

PUMP (Continued)

ProCarManuals.com

Page 1440 of 2177

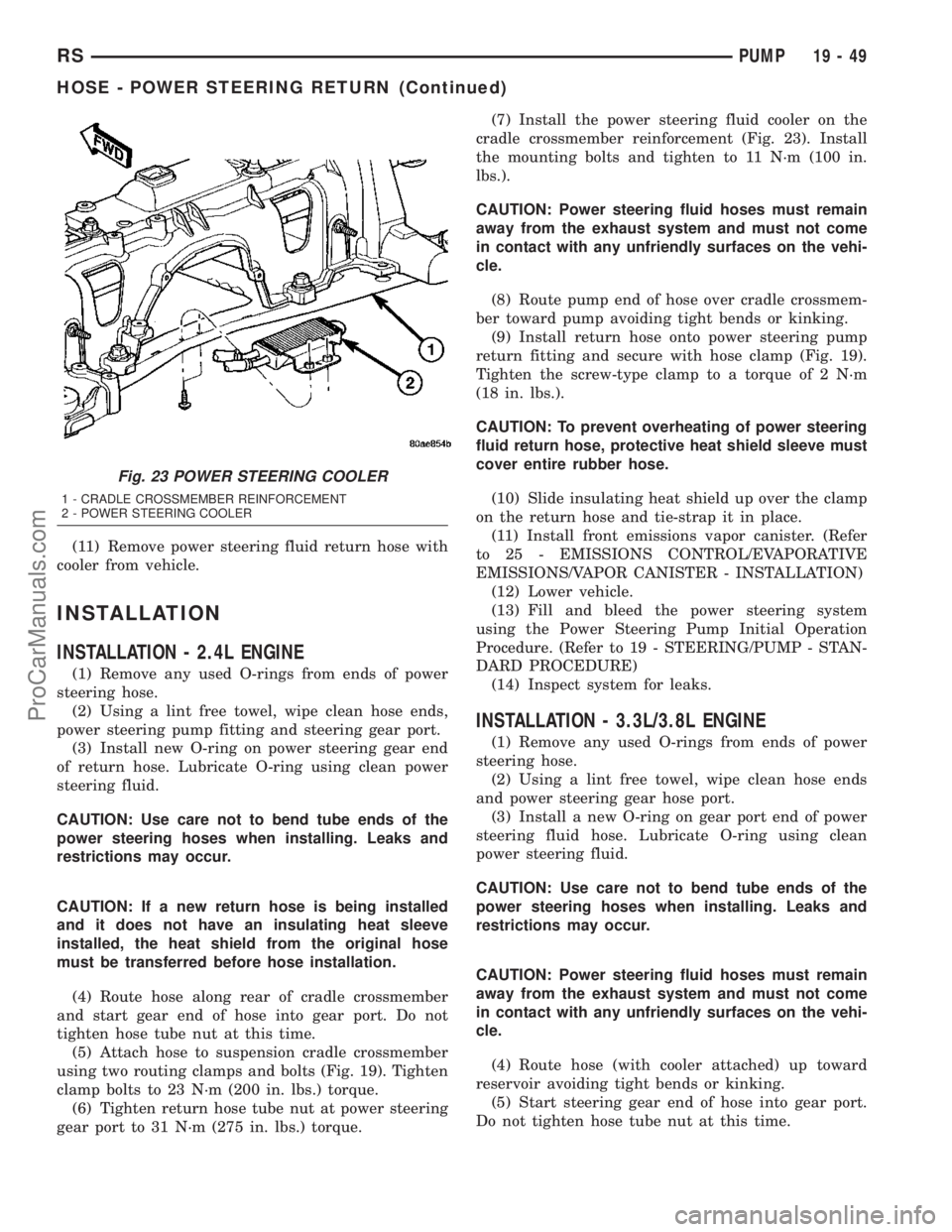

INSTALLATION

(1) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 18). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.).

(2) Install power steering fluid hoses on the cooler.

Be sure hose clamps are installed on hose past

the upset bead on the power steering cooler

tubes.

(3) Lower the vehicle to a point where front tires

are just off the ground.

(4) Perform Power Steering Pump Initial Opera-

tion procedure. (Refer to 19 - STEERING/PUMP -

STANDARD PROCEDURE)

HOSE - POWER STEERING

PRESSURE

REMOVAL

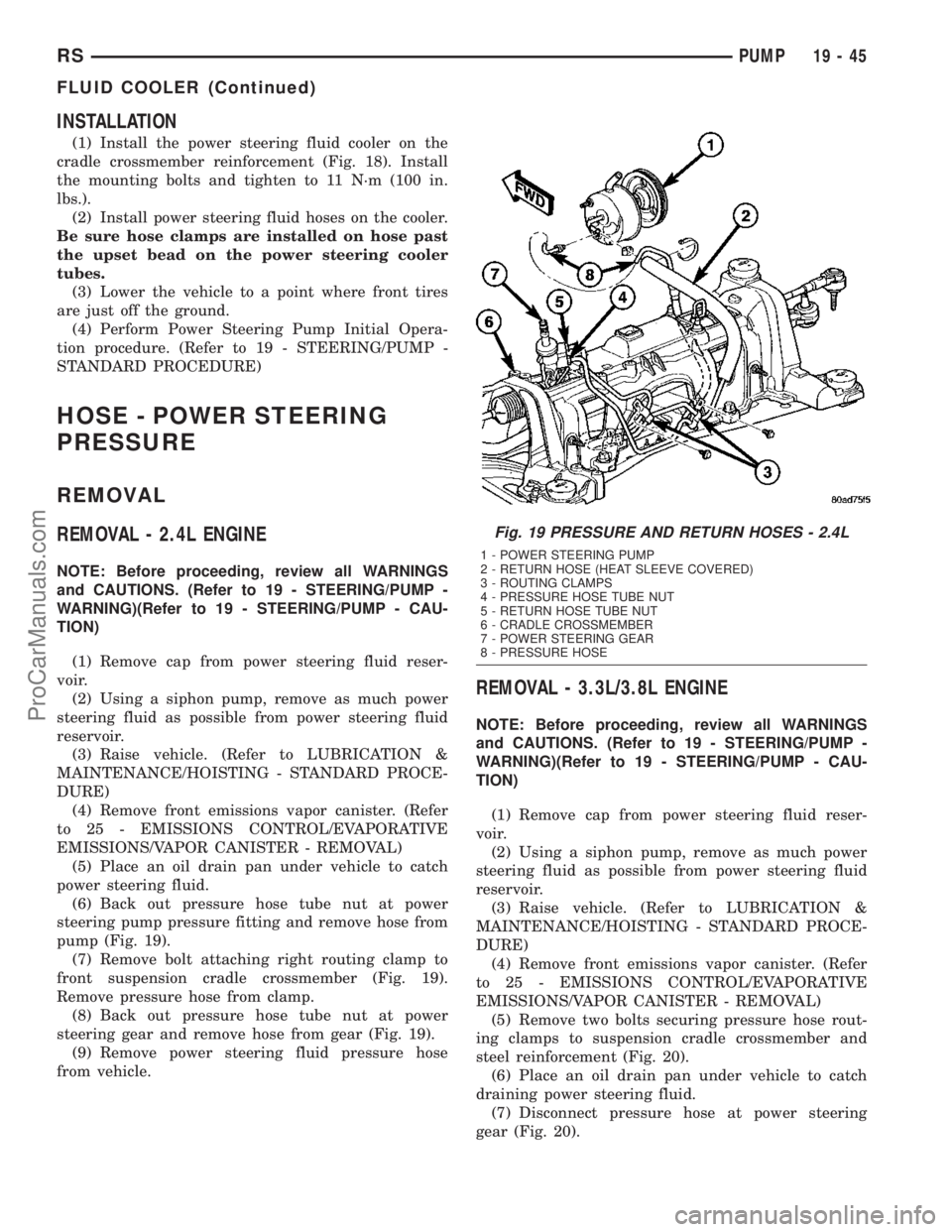

REMOVAL - 2.4L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Place an oil drain pan under vehicle to catch

power steering fluid.

(6) Back out pressure hose tube nut at power

steering pump pressure fitting and remove hose from

pump (Fig. 19).

(7) Remove bolt attaching right routing clamp to

front suspension cradle crossmember (Fig. 19).

Remove pressure hose from clamp.

(8) Back out pressure hose tube nut at power

steering gear and remove hose from gear (Fig. 19).

(9) Remove power steering fluid pressure hose

from vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Remove two bolts securing pressure hose rout-

ing clamps to suspension cradle crossmember and

steel reinforcement (Fig. 20).

(6) Place an oil drain pan under vehicle to catch

draining power steering fluid.

(7) Disconnect pressure hose at power steering

gear (Fig. 20).

Fig. 19 PRESSURE AND RETURN HOSES - 2.4L

1 - POWER STEERING PUMP

2 - RETURN HOSE (HEAT SLEEVE COVERED)

3 - ROUTING CLAMPS

4 - PRESSURE HOSE TUBE NUT

5 - RETURN HOSE TUBE NUT

6 - CRADLE CROSSMEMBER

7 - POWER STEERING GEAR

8 - PRESSURE HOSE

RSPUMP19-45

FLUID COOLER (Continued)

ProCarManuals.com

Page 1443 of 2177

CAUTION: Use care not to bend tube ends of the

power steering hoses when installing. Leaks and

restrictions may occur.

CAUTION: Power steering fluid hoses must remain

away from the exhaust system and must not come

in contact with any unfriendly surfaces on the vehi-

cle.

(4) Route hose up behind engine toward pump

avoiding tight bends or kinking.

(5) Install power steering pressure hose end into

pump pressure outlet fitting (Fig. 21). Thread tube

nut into outlet fitting, but do not tighten at this time.

(6) Attach pressure hose routing bracket to engine

(Fig. 21). Tighten bolt to 23 N´m (200 in. lbs.) torque.

(7) Tighten hose tube nut at pump outlet fitting to

31 N´m (275 in. lbs.) torque.

(8) Route hose behind cradle crossmember and

start hose end into gear port. Do not tighten hose

tube nut at this time.

(9) Attach hose to suspension cradle crossmember

and steel reinforcement using two routing clamps

and bolts (Fig. 20). Tighten clamp bolt at steel rein-

forcement to 11 N´m (100 in. lbs.) torque. Tighten

clamp bolt at cradle crossmember to 23 N´m (200 in.

lbs.) torque.

(10) Tighten hose tube nut at power steering gear

port to 31 N´m (275 in. lbs.) torque.

(11) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(12) Lower vehicle.

(13) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(14) Inspect system for leaks.

HOSE - POWER STEERING

RETURN

REMOVAL

REMOVAL - 2.4L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Place an oil drain pan under vehicle to catch

power steering fluid.

(6) Cut tie-strap securing insulating heat sleeve to

power steering fluid return hose near power steering

pump. Pull back heat sleeve to expose hose clamp.

(7) Remove clamp, then return hose from power

steering pump (Fig. 19).

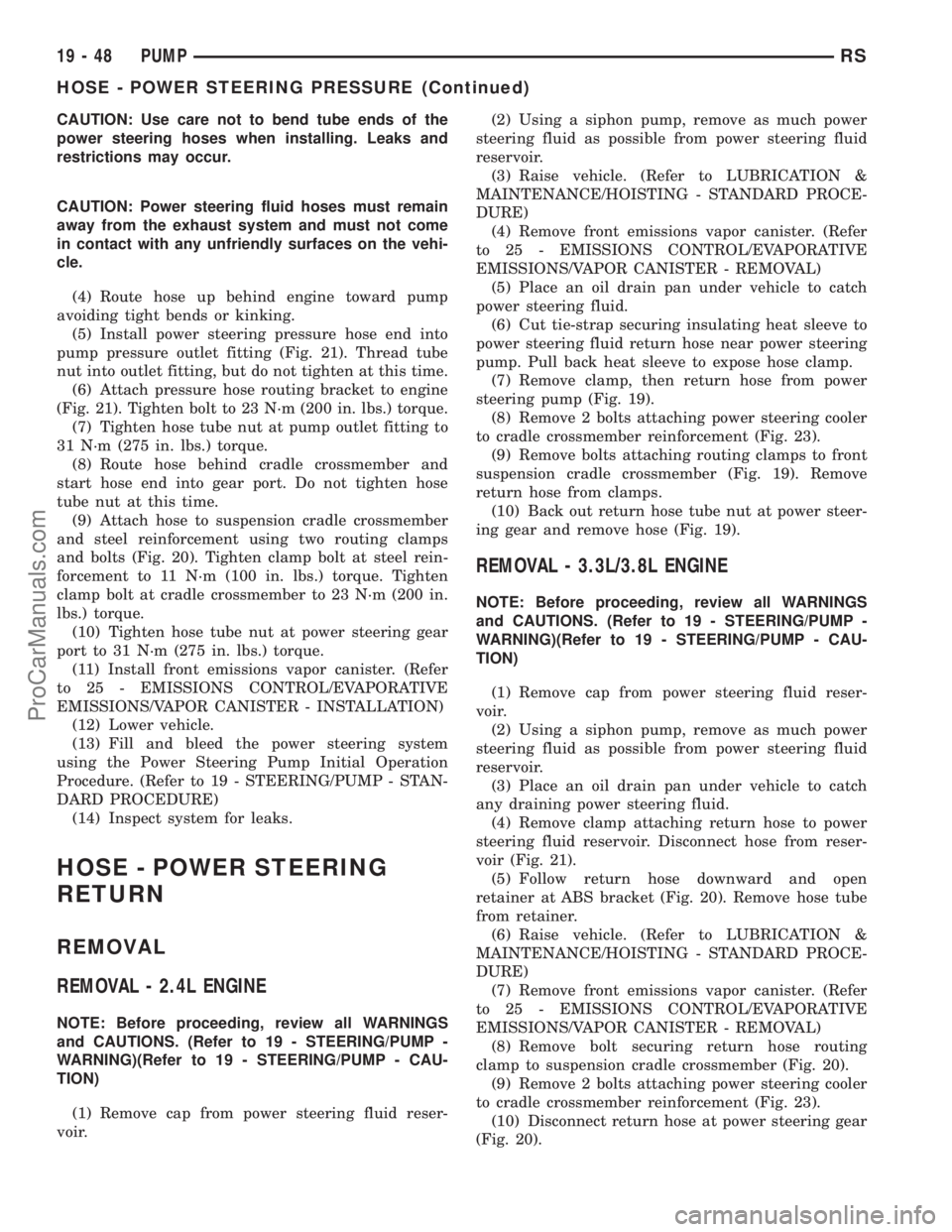

(8) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 23).

(9) Remove bolts attaching routing clamps to front

suspension cradle crossmember (Fig. 19). Remove

return hose from clamps.

(10) Back out return hose tube nut at power steer-

ing gear and remove hose (Fig. 19).

REMOVAL - 3.3L/3.8L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching return hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Follow return hose downward and open

retainer at ABS bracket (Fig. 20). Remove hose tube

from retainer.

(6) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(7) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(8) Remove bolt securing return hose routing

clamp to suspension cradle crossmember (Fig. 20).

(9) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 23).

(10) Disconnect return hose at power steering gear

(Fig. 20).

19 - 48 PUMPRS

HOSE - POWER STEERING PRESSURE (Continued)

ProCarManuals.com

Page 1444 of 2177

(11) Remove power steering fluid return hose with

cooler from vehicle.

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Remove any used O-rings from ends of power

steering hose.

(2) Using a lint free towel, wipe clean hose ends,

power steering pump fitting and steering gear port.

(3) Install new O-ring on power steering gear end

of return hose. Lubricate O-ring using clean power

steering fluid.

CAUTION: Use care not to bend tube ends of the

power steering hoses when installing. Leaks and

restrictions may occur.

CAUTION: If a new return hose is being installed

and it does not have an insulating heat sleeve

installed, the heat shield from the original hose

must be transferred before hose installation.

(4) Route hose along rear of cradle crossmember

and start gear end of hose into gear port. Do not

tighten hose tube nut at this time.

(5) Attach hose to suspension cradle crossmember

using two routing clamps and bolts (Fig. 19). Tighten

clamp bolts to 23 N´m (200 in. lbs.) torque.

(6) Tighten return hose tube nut at power steering

gear port to 31 N´m (275 in. lbs.) torque.(7) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 23). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.).

CAUTION: Power steering fluid hoses must remain

away from the exhaust system and must not come

in contact with any unfriendly surfaces on the vehi-

cle.

(8) Route pump end of hose over cradle crossmem-

ber toward pump avoiding tight bends or kinking.

(9) Install return hose onto power steering pump

return fitting and secure with hose clamp (Fig. 19).

Tighten the screw-type clamp to a torque of 2 N´m

(18 in. lbs.).

CAUTION: To prevent overheating of power steering

fluid return hose, protective heat shield sleeve must

cover entire rubber hose.

(10) Slide insulating heat shield up over the clamp

on the return hose and tie-strap it in place.

(11) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(12) Lower vehicle.

(13) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(14) Inspect system for leaks.

INSTALLATION - 3.3L/3.8L ENGINE

(1) Remove any used O-rings from ends of power

steering hose.

(2) Using a lint free towel, wipe clean hose ends

and power steering gear hose port.

(3) Install a new O-ring on gear port end of power

steering fluid hose. Lubricate O-ring using clean

power steering fluid.

CAUTION: Use care not to bend tube ends of the

power steering hoses when installing. Leaks and

restrictions may occur.

CAUTION: Power steering fluid hoses must remain

away from the exhaust system and must not come

in contact with any unfriendly surfaces on the vehi-

cle.

(4) Route hose (with cooler attached) up toward

reservoir avoiding tight bends or kinking.

(5) Start steering gear end of hose into gear port.

Do not tighten hose tube nut at this time.

Fig. 23 POWER STEERING COOLER

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

RSPUMP19-49

HOSE - POWER STEERING RETURN (Continued)

ProCarManuals.com

Page 1445 of 2177

(6) Attach return hose tubes to suspension cradle

crossmember using routing clamp and bolt (Fig. 20).

Tighten clamp bolt to 23 N´m (200 in. lbs.) torque.

(7) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 23). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.). When installing mounting bolts, include pres-

sure hose routing clamp.

(8) Tighten hose tube nut at power steering gear

port to 31 N´m (275 in. lbs.) torque.

(9) Install front emissions vapor canister. (Refer to

25 - EMISSIONS CONTROL/EVAPORATIVE EMIS-

SIONS/VAPOR CANISTER - INSTALLATION)

(10) Lower vehicle.

(11) Install return hose tube into retainer on ABS

bracket (Fig. 20). Close the bracket.

(12) Install return hose onto reservoir (Fig. 21).

Slide the hose clamp into position on fluid reservoir

and attach it.Be sure hose clamp in installed

past bead on fluid reservoir fitting.

(13) Fill and bleed power steering system using

the Power Steering Pump Initial Operation Proce-

dure. (Refer to 19 - STEERING/PUMP - STANDARD

PROCEDURE)

(14) Inspect system for leaks.

HOSE - POWER STEERING

SUPPLY

REMOVAL

REMOVAL - 2.4L ENGINE

(1) Remove filler cap from power steering fluid res-

ervoir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove hose clamp securing supply hose to

power steering pump, then remove supply hose from

pump fitting.

(5) Lower vehicle.

(6) Remove hose clamp attaching power steering

fluid supply hose to power steering fluid reservoir,

then remove supply hose.

(7) Remove the power steering fluid supply hose

from the vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching supply hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Pull upward on hose routing clip releasing it

from bracket on cylinder head cover (Fig. 21).

NOTE: It may be necessary to remove air cleaner

housing to gain greater access to supply hose at

power steering pump. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL)

(6) Remove clamp attaching supply hose to power

steering pump. Disconnect hose from pump and

remove from vehicle (Fig. 21).

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Install and correctly route power steering fluid

supply hose from remote fluid reservoir to power

steering pump.

(2) Install fluid supply hose onto power steering

fluid reservoir. Install hose clamp.Be sure hose

clamp is installed past bead on fluid reservoir

fitting.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Install power steering fluid supply hose on

power steering pump supply fitting. Install hose

clamp.Be sure hose clamp is installed past bead

on pump fitting.

(5) Lower vehicle.

(6) Fill and bleed power steering system using

Power Steering Pump Initial Operation Procedure.

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE)

(7) Inspect system for leaks.

INSTALLATION - 3.3L/3.8L ENGINE

(1) Install supply hose onto supply fitting on power

steering pump (Fig. 21). Slide the hose clamp into

position on fluid reservoir and attach it.Be sure

hose clamp in installed past bead on fluid res-

ervoir fitting.

19 - 50 PUMPRS

HOSE - POWER STEERING RETURN (Continued)

ProCarManuals.com

Page 1787 of 2177

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 14). Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install radiator sight shield.

(10) Install hood prop rod.

(11) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(12) Install bolts attaching hood latch to cross-

member. Tighten bolts to 13.5 N´m (10 ft. lbs.)

torque.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

(2) Remove front wheel.

(3) Remove push pin fasteners attaching splash

shield to frame rail forward of suspension.

(4) Remove push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender and front bumper fascia.

(6) Remove splash shield from vehicle (Fig. 15).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

15).

(2) Install push pin fasteners attaching splash

shield to frame rail forward of suspension.

(3) Install push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install screws attaching wheelhouse splash

shield to front fender.

(5) Install front wheel.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail

(Fig. 16).

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 17).

Fig. 15 FRONT WHEELHOUSE SPLASH SHIELD

1 - FRONT FENDER WHEELHOUSE SPLASH SHIELD

2 - PUSH PIN FASTENERS

3 - ACCESSORY DRIVE SPLASH SHIELD

4 - SCREWS

Fig. 16 LUGGAGE RACK RISER COVER

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

23 - 54 EXTERIORRS

GRILLE OPENING REINFORCEMENT (Continued)

ProCarManuals.com

Page 1886 of 2177

STUCTURAL ADHESIVE

LOCATIONS

SPECIFICATIONS - STRUCTURAL ADHESIVE LOCATIONS

INDEX

DESCRIPTION FIGURE

UPPER COWL PLENUM, UPPER AND

LOWER DASH PANEL52

ROOF AND REAR QUARTER PANELS -

LONG WHEEL BASE ONLY53

FLOOR PAN - LONG WHEEL BASE

ONLY54

SUSPENSION HANGER

REINFORCEMENTS - LONG WHEEL

BASE ONLY55

FRONT HINGE PILLAR

REINFORCEMENTS - LONG WHEEL

BASE ONLY56

DESCRIPTION FIGURE

ROOF AND REAR QUARTER PANELS -

SHORT WHEEL BASE ONLY57

FLOOR PAN - SHORT WHEEL BASE

ONLY58

FRONT SIDE RAILS/OUTER CROSS

MEMBER BRACKETS59

OUTER ROOF PANEL/UPPER

WINDSHIELD FRAME60

COWL SIDE PANEL/ BODY SIDE

APERTURE, B-PILLAR/SLIDING DOOR

TRACK SUPPORT61

Fig. 52 UPPER COWL PLENUM, UPPER AND LOWER DASH PANEL

RSBODY STRUCTURE23 - 153

ProCarManuals.com

Page 1889 of 2177

Fig. 55 SUSPENSION HANGER REINFORCEMENTS - LONG WHEEL BASE ONLY

Fig. 56 FRONT HINGE PILLAR REINFORCEMENTS - LONG WHEEL BASE ONLY

23 - 156 BODY STRUCTURERS

STUCTURAL ADHESIVE LOCATIONS (Continued)

ProCarManuals.com

Page 1894 of 2177

WELD LOCATIONS

SPECIFICATIONS - WELD LOCATIONS

INDEX

DESCRIPTION FIGURE

FRONT FENDER SHIELD - RIGHT 62

FRONT FENDER SHIELD - LEFT 63

STRUT TOWER AND REINFORCEMENTS - RIGHT 64

SUSPENSION RETAINERS AND REINFORCEMENTS - RIGHT 65

STRUT TOWER AND REINFORCEMENTS - LEFT 66

SUSPENSION RETAINERS AND REINFORCEMENTS - LEFT 67

FLOOR PAN REINFORCEMENTS - SIDE RAILS 68

REAR SUSPENSION BRACKETS 69

FLOOR PAN CROSS MEMBERS 70

SEAT REINFORCEMENTS - LONG WHEEL BASE ONLY 71

STRIKER REINFORCEMENTS - LONG WHEEL BASE ONLY 72

FUEL TANK MOUNTING/REAR SEAT AND SUSPENSION 73

REAR SUSPENSION HANGER BRACKETS - LONG WHEEL BASE 74

FRONT SEAT CROSS MEMBER 75

FLOOR PAN SIDE RAIL REINFORCEMENT 76

SILL BULKHEAD REINFORCEMENTS 77

FLOOR PAN CROSS MEMBER REINFORCEMENTS 78

FRONT SEAT CROSS MEMBER 79

SEAT REINFORCEMENT CROSS MEMBERS - SHORT WHEEL BASE 80

CENTER CONSOLE REINFORCEMENT - SHORT WHEEL BASE 81

REAR SUSPENSION HANGER BRACKETS - SHORT WHEEL BASE 82

LOWER LIFTGATE PANEL LATCH REINFORCEMENT 83

ENGINE MOUNTING PLATE AND TOW BRACKET 84

HEADLAMP MOUNTING PLATE 85

LOWER RADIATOR CROSS MEMBER BRACKETS 86

CROSS MEMBER EXTENSIONS 87

JACK MOUNTING BRACKET - LONG WHEEL BASE SHOWN, SHORT SIMILAR 88

FRONT SEAT CROSS MEMBER - LONG WHEELBASE ONLY 89

FRONT SEAT CROSS MEMBER - ALL WHEEL DRIVE ONLY 90

FUEL TANK SUPPORT CROSS MEMBERS - LONG WHEEL BASE ONLY 91

REAR SUPPORT AND TIRE STOWAGE CROSS MEMBERS - LONG WHEEL BASE

ONLY92

INNER SIDE SILLS - LONG WHEEL BASE ONLY 93

WHEELHOUSES, SIDE SILLS, SUSPENSION BRACKETS - LONG WHEEL BASE ONLY 94

REAR SEAT REINFORCEMENTS - SHORT WHEEL BASE ONLY 95

FUEL TANK SUPPORT AND TIRE STOWAGE - SHORT WHEEL BASE ONLY 96

INNER SIDE SILLS - SHORT WHEEL BASE ONLY 97

RSBODY STRUCTURE23 - 161

ProCarManuals.com

Page 1896 of 2177

DESCRIPTION FIGURE

OUTER WHEELHOUSE - SHORT WHEEL BASE ONLY 139

LEFT REAR INNER QUARTER PANEL - SHORT WHEEL BASE ONLY 140

LATCH REINFORCEMENT - SHORT WHEEL BASE ONLY 141

D-PILLAR REINFORCEMENT - SHORT WHEEL BASE ONLY 142

OUTER WHEELHOUSE - SHORT WHEEL BASE ONLY 143

BODY SIDE APERTURE RIGHT SIDE- LONG WHEEL BASE ONLY 144

BODY SIDE APERTURE LEFT SIDE - LONG WHEEL BASE ONLY 145

BODY SIDE APERTURE RIGHT SIDE - SHORT WHEEL BASE ONLY 146

BODY SIDE APERTURE LEFT SIDE - SHORT WHEEL BASE ONLY 147

LOWER SLIDING DOOR TRACK 148

LIFTGATE UPPER FRAME 149

UPPER WINDSHIELD FRAME 150

FRONT FENDER SHIELD BEAM 151

FRONT FENDER SHIELD BEAM/COWL SIDE PANEL 152

HINGE PILLAR REINFORCEMENT 153

INNER SIDE SILL - LONG WHEEL BASE ONLY 154

INNER SIDE SILL/OUTER SIDE SILL - LONG WHEEL BASE ONLY 155

LOWER SLIDING DOOR TRACK REINFORCEMENT - LONG WHEEL BASE ONLY 156

UPPER WINDSHIELD FRAME/ROOF PANEL - LONG WHEEL BASE ONLY 157

ROOF BOWS/INNER ROOF SIDE RAILS 158

OUTER ROOF PANEL - LONG WHEEL BASE ONLY 159

INNER SIDE SILL - SHORT WHEEL BASE ONLY 160

INNER/OUTER SIDE SILLS - SHORT WHEEL BASE ONLY 161

LOWER SLIDING DOOR TRACK - SHORT WHEEL BASE ONLY 162

UPPER WINDSHIELD FRAME/OUTER ROOF PANEL - SHORT WHEEL BASE ONLY 163

REAR SUSPENSION HANGERS - LONG WHEEL BASE SHOWN, SHORT WHEEL BASE

TYPICAL164

FRONT LOWER LIFTGATE OPENING 165

REAR JACKING REINFORCEMENT - LONG WHEEL BASE ONLY 166

INNER WHEELHOUSE - LONG WHEEL BASE ONLY 167

SUSPENSION HANGER REINFORCEMENT - LONG WHEEL BASE ONLY 168

LOWER LIFTGATE OPENING PANEL - LONG WHEEL BASE ONLY 169

ROOF BOWS/UPPER LIFTGATE FRAME - LONG WHEEL BASE ONLY 170

BODY SIDE APERTURE/INNER QUARTER PANEL - LONG WHEEL BASE ONLY 171

REAR JACKING REINFORCEMENT - SHORT WHEEL BASE ONLY 172

INNER WHEELHOUSE/INNER QUARTER PANEL - SHORT WHEEL BASE ONLY 173

SUSPENSION HANGER REINFORCEMENT - SHORT WHEEL BASE ONLY 174

LOWER LIFTGATE OPENING - SHORT WHEEL BASE ONLY 175

ROOF PANEL/ROOF RAIL - SHORT WHEEL BASE ONLY 176

RSBODY STRUCTURE23 - 163

WELD LOCATIONS (Continued)

ProCarManuals.com