ABS CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1599 of 2177

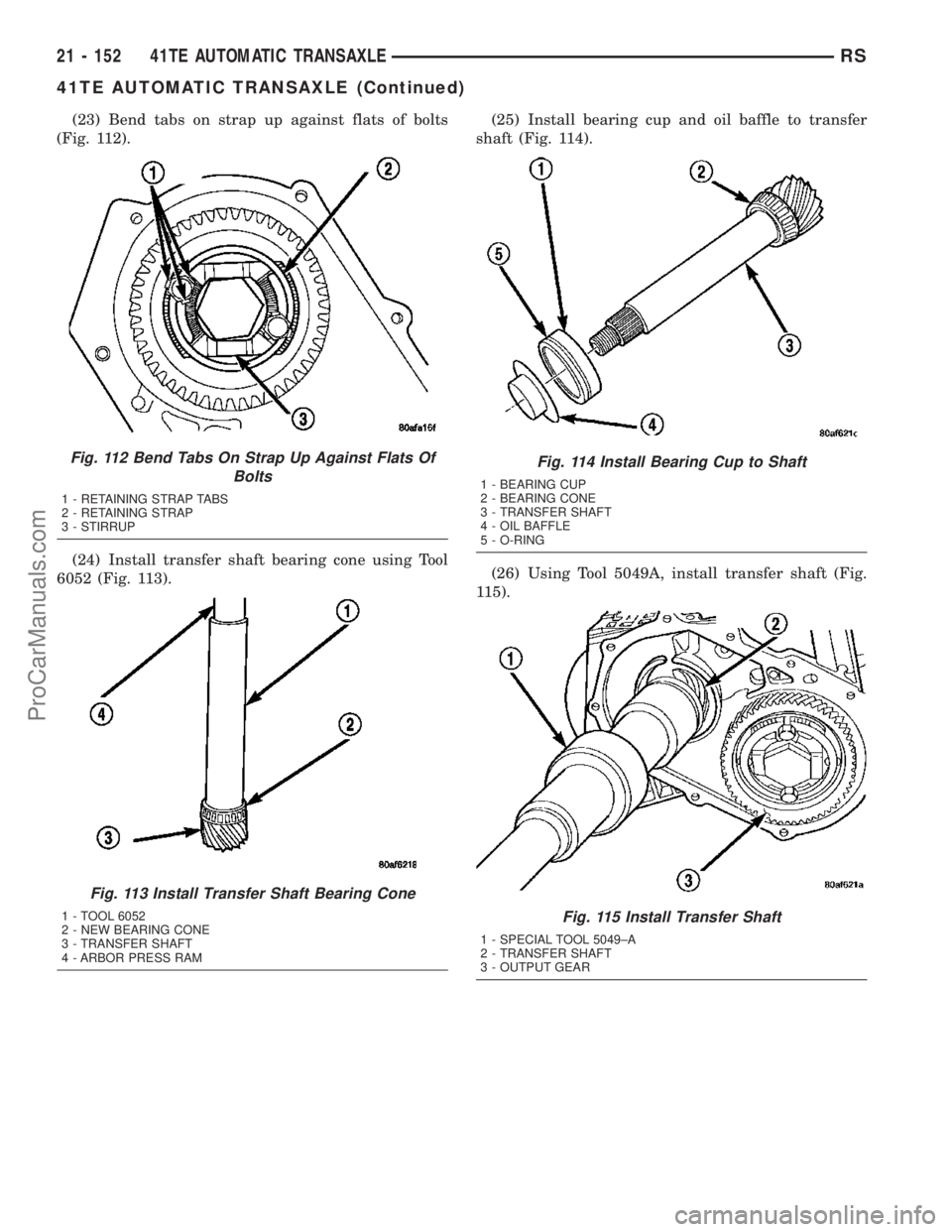

(23) Bend tabs on strap up against flats of bolts

(Fig. 112).

(24) Install transfer shaft bearing cone using Tool

6052 (Fig. 113).(25) Install bearing cup and oil baffle to transfer

shaft (Fig. 114).

(26) Using Tool 5049A, install transfer shaft (Fig.

115).

Fig. 112 Bend Tabs On Strap Up Against Flats Of

Bolts

1 - RETAINING STRAP TABS

2 - RETAINING STRAP

3 - STIRRUP

Fig. 113 Install Transfer Shaft Bearing Cone

1 - TOOL 6052

2 - NEW BEARING CONE

3 - TRANSFER SHAFT

4 - ARBOR PRESS RAM

Fig. 114 Install Bearing Cup to Shaft

1 - BEARING CUP

2 - BEARING CONE

3 - TRANSFER SHAFT

4 - OIL BAFFLE

5 - O-RING

Fig. 115 Install Transfer Shaft

1 - SPECIAL TOOL 5049±A

2 - TRANSFER SHAFT

3 - OUTPUT GEAR

21 - 152 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1607 of 2177

(49) Install rear sun gear and #7 needle bearing

(Fig. 138).

NOTE: The number seven needle bearing has three

anti-reversal tabs and is common with the number

five and number two position. The orientation

should allow the bearing to seat flat against the

rear sun gear (Fig. 137). A small amount of petrola-

tum can be used to hold the bearing to the rear sun

gear.

(50) Install front carrier/rear annulus assembly

and #6 needle bearing (Fig. 139).

(51) Install front sun gear assembly and #4 thrust

washer (Fig. 140).(52)DETERMINING #4 THRUST PLATE

THICKNESS / INPUT SHAFT END PLAY:

(a) Select the thinnest #4 thrust plate thickness

and install to input clutch assembly (Fig. 141). Use

petrolatum to retain.

(b) Install input clutch assembly into position

and verify that it is completely seated by viewing

through input speed sensor hole. If view through

input speed sensor hole is not as shown in (Fig.

142), the input clutch assembly is not seated prop-

erly.

(c) Remove oil pump o-ring (Fig. 143).Be sure

to reinstall oil pump o-ring after selecting the

proper #4 thrust plate.

Fig. 137 Number 7 Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 138 Install Rear Sun Gear and #7 Needle

Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 139 Install Front Carrier and Rear Annulus

Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 140 Install Front Sun Gear Assembly

1 - FRONT SUN GEAR ASSEMBLY

2 - #4 THRUST WASHER (FOUR TABS)

21 - 160 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1608 of 2177

(d) Install pump and gasket to transmission.

Install and torque bolts.

(e) Set up input shaft for measurement with

Indicator Set C3339 and End Play Set 8266 as

shown in (Fig. 144).

(f) Measure the input shaft end play with the

transaxle in the vertical position.Input shaft end

play must be within 0.005 to 0.025 inch.For

example, if end play reading is 0.055 inch, select

No. 4 Thrust Plate which is 0.071 to 0.074 thick.

This should provide an input shaft end play read-

ing of 0.020 inch which is within specifications.

(g) Refer to the No. 4 thrust plate chart to select

the proper No. 4 thrust plate:

Fig. 141 Select Thinnest No. 4 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #4 THRUST PLATE (SELECT)

3 - 3 DABS OF PETROLATUM FOR RETENTION

Fig. 142 View Through Input Speed Sensor Hole

1 - INPUT CLUTCH RETAINER

2 - INPUT SPEED SENSOR HOLE

3 - OIL COOLER FITTINGS

Fig. 143 Remove Oil Pump O-Ring

1 - OIL PUMP ASSEMBLY

2 - O-RING

Fig. 144 Measure Input Shaft End Play Using End

Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

RS41TE AUTOMATIC TRANSAXLE21 - 161

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1643 of 2177

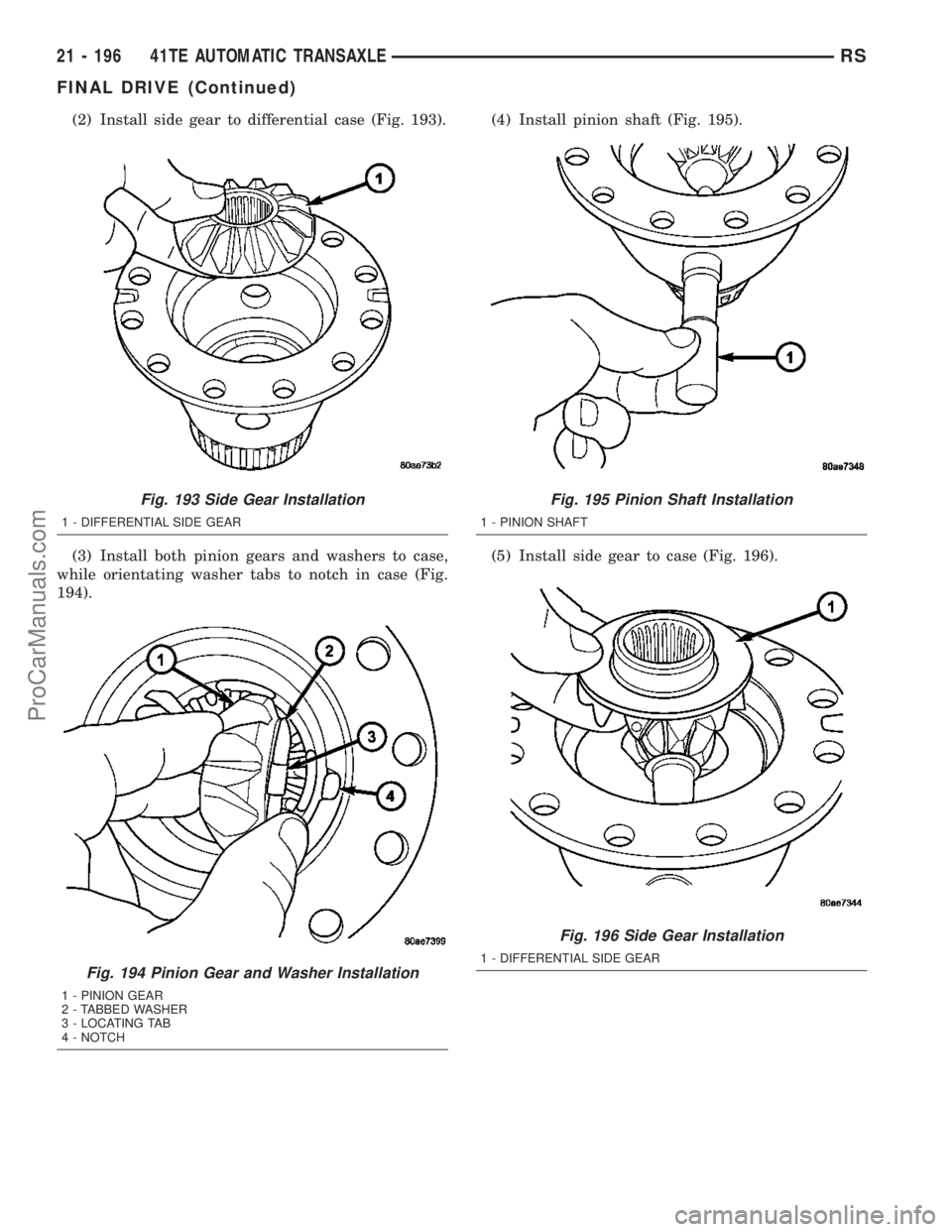

(2) Install side gear to differential case (Fig. 193).

(3) Install both pinion gears and washers to case,

while orientating washer tabs to notch in case (Fig.

194).(4) Install pinion shaft (Fig. 195).

(5) Install side gear to case (Fig. 196).

Fig. 193 Side Gear Installation

1 - DIFFERENTIAL SIDE GEAR

Fig. 194 Pinion Gear and Washer Installation

1 - PINION GEAR

2 - TABBED WASHER

3 - LOCATING TAB

4 - NOTCH

Fig. 195 Pinion Shaft Installation

1 - PINION SHAFT

Fig. 196 Side Gear Installation

1 - DIFFERENTIAL SIDE GEAR

21 - 196 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

ProCarManuals.com

Page 1658 of 2177

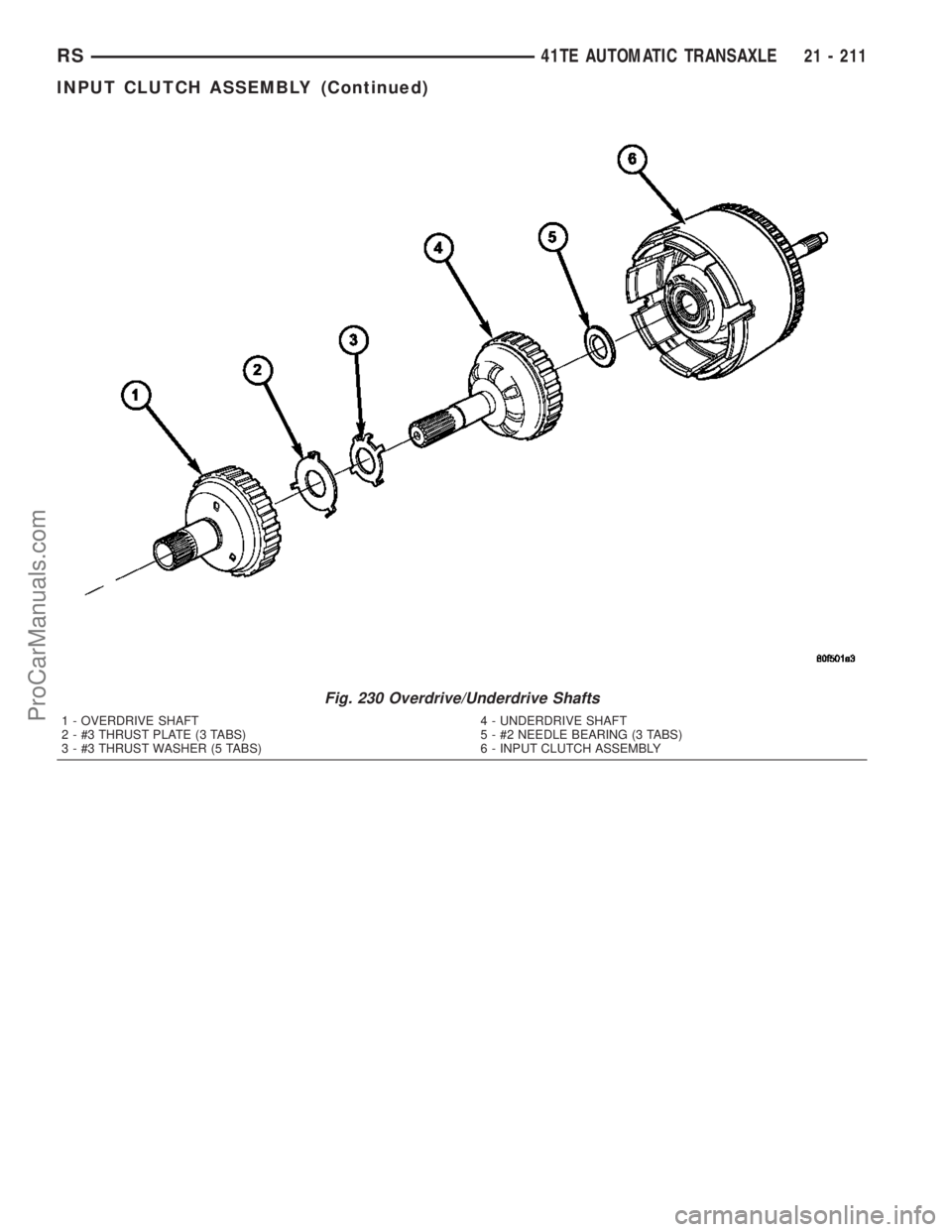

Fig. 230 Overdrive/Underdrive Shafts

1 - OVERDRIVE SHAFT

2 - #3 THRUST PLATE (3 TABS)

3 - #3 THRUST WASHER (5 TABS)4 - UNDERDRIVE SHAFT

5 - #2 NEEDLE BEARING (3 TABS)

6 - INPUT CLUTCH ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 211

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1660 of 2177

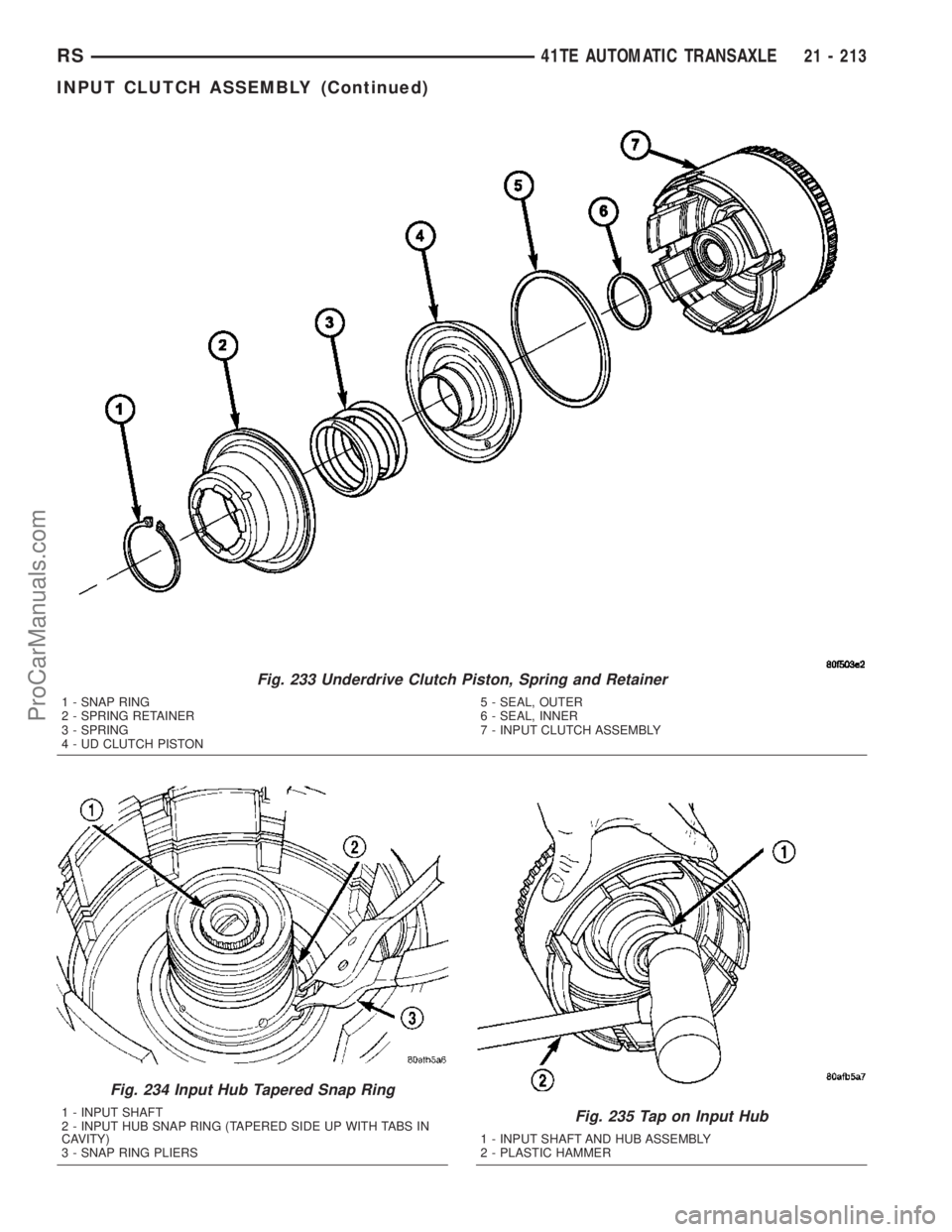

Fig. 233 Underdrive Clutch Piston, Spring and Retainer

1 - SNAP RING

2 - SPRING RETAINER

3 - SPRING

4 - UD CLUTCH PISTON5 - SEAL, OUTER

6 - SEAL, INNER

7 - INPUT CLUTCH ASSEMBLY

Fig. 234 Input Hub Tapered Snap Ring

1 - INPUT SHAFT

2 - INPUT HUB SNAP RING (TAPERED SIDE UP WITH TABS IN

CAVITY)

3 - SNAP RING PLIERSFig. 235 Tap on Input Hub

1 - INPUT SHAFT AND HUB ASSEMBLY

2 - PLASTIC HAMMER

RS41TE AUTOMATIC TRANSAXLE21 - 213

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1664 of 2177

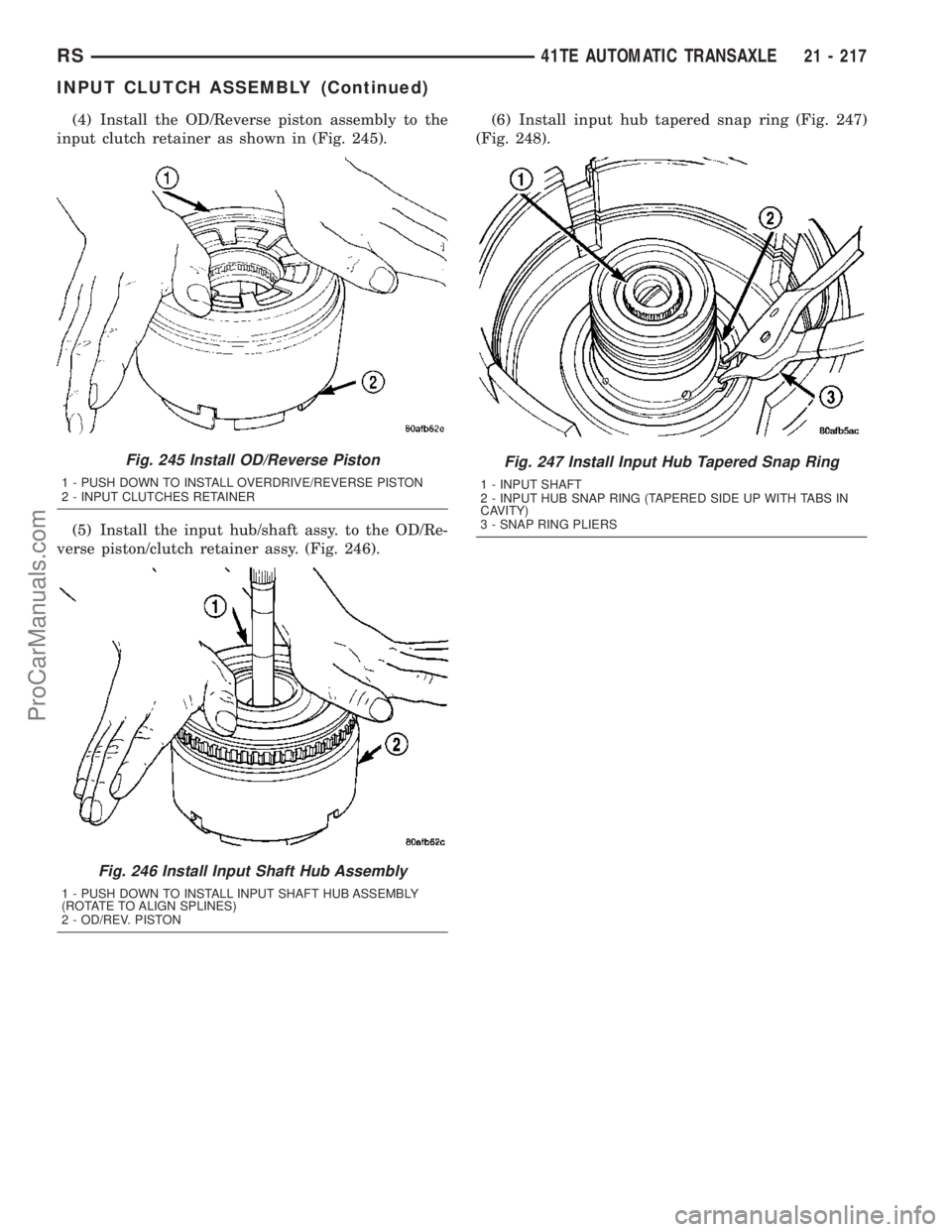

(4) Install the OD/Reverse piston assembly to the

input clutch retainer as shown in (Fig. 245).

(5) Install the input hub/shaft assy. to the OD/Re-

verse piston/clutch retainer assy. (Fig. 246).(6) Install input hub tapered snap ring (Fig. 247)

(Fig. 248).

Fig. 245 Install OD/Reverse Piston

1 - PUSH DOWN TO INSTALL OVERDRIVE/REVERSE PISTON

2 - INPUT CLUTCHES RETAINER

Fig. 246 Install Input Shaft Hub Assembly

1 - PUSH DOWN TO INSTALL INPUT SHAFT HUB ASSEMBLY

(ROTATE TO ALIGN SPLINES)

2 - OD/REV. PISTON

Fig. 247 Install Input Hub Tapered Snap Ring

1 - INPUT SHAFT

2 - INPUT HUB SNAP RING (TAPERED SIDE UP WITH TABS IN

CAVITY)

3 - SNAP RING PLIERS

RS41TE AUTOMATIC TRANSAXLE21 - 217

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1675 of 2177

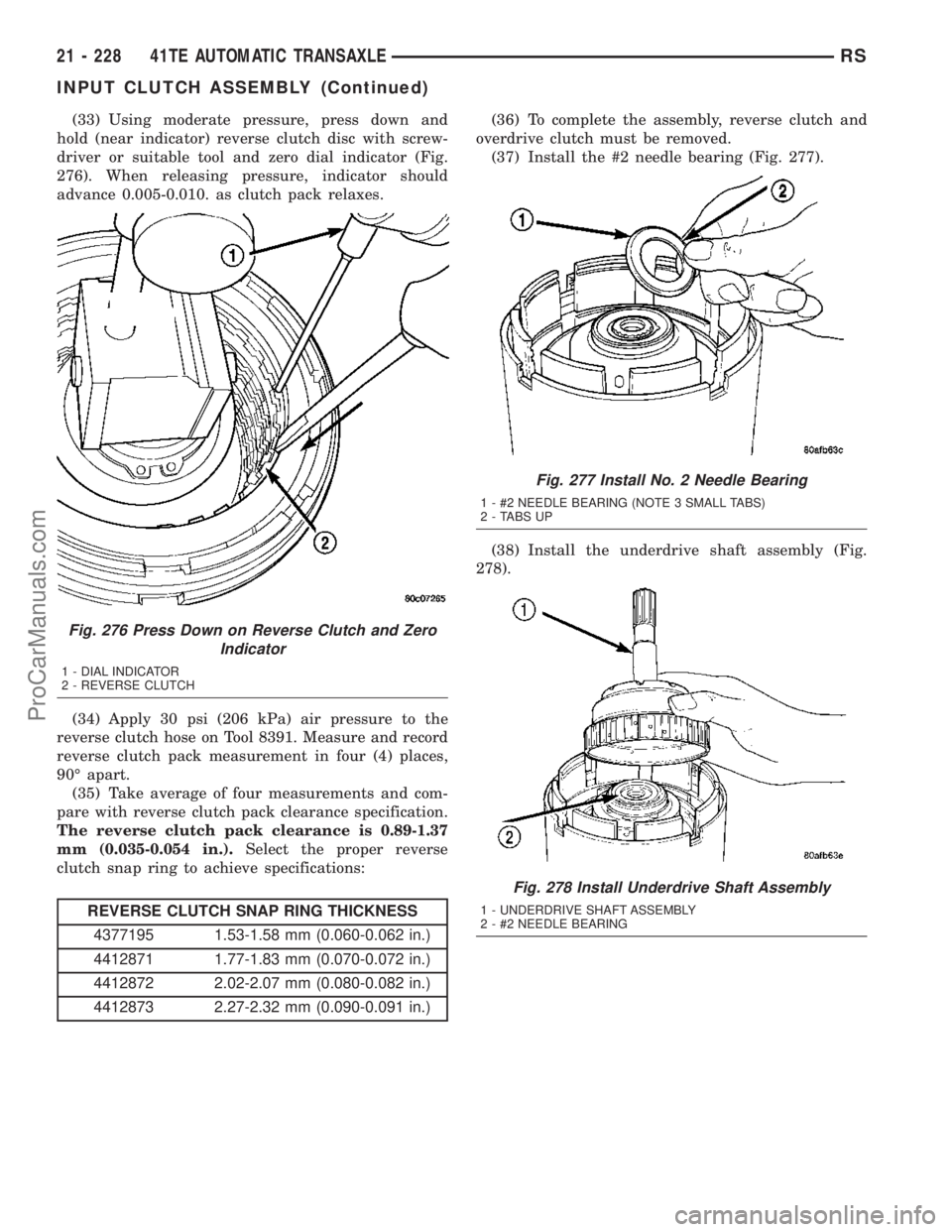

(33) Using moderate pressure, press down and

hold (near indicator) reverse clutch disc with screw-

driver or suitable tool and zero dial indicator (Fig.

276). When releasing pressure, indicator should

advance 0.005-0.010. as clutch pack relaxes.

(34) Apply 30 psi (206 kPa) air pressure to the

reverse clutch hose on Tool 8391. Measure and record

reverse clutch pack measurement in four (4) places,

90É apart.

(35) Take average of four measurements and com-

pare with reverse clutch pack clearance specification.

The reverse clutch pack clearance is 0.89-1.37

mm (0.035-0.054 in.).Select the proper reverse

clutch snap ring to achieve specifications:

REVERSE CLUTCH SNAP RING THICKNESS

4377195 1.53-1.58 mm (0.060-0.062 in.)

4412871 1.77-1.83 mm (0.070-0.072 in.)

4412872 2.02-2.07 mm (0.080-0.082 in.)

4412873 2.27-2.32 mm (0.090-0.091 in.)(36) To complete the assembly, reverse clutch and

overdrive clutch must be removed.

(37) Install the #2 needle bearing (Fig. 277).

(38) Install the underdrive shaft assembly (Fig.

278).

Fig. 276 Press Down on Reverse Clutch and Zero

Indicator

1 - DIAL INDICATOR

2 - REVERSE CLUTCH

Fig. 277 Install No. 2 Needle Bearing

1 - #2 NEEDLE BEARING (NOTE 3 SMALL TABS)

2 - TABS UP

Fig. 278 Install Underdrive Shaft Assembly

1 - UNDERDRIVE SHAFT ASSEMBLY

2 - #2 NEEDLE BEARING

21 - 228 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1676 of 2177

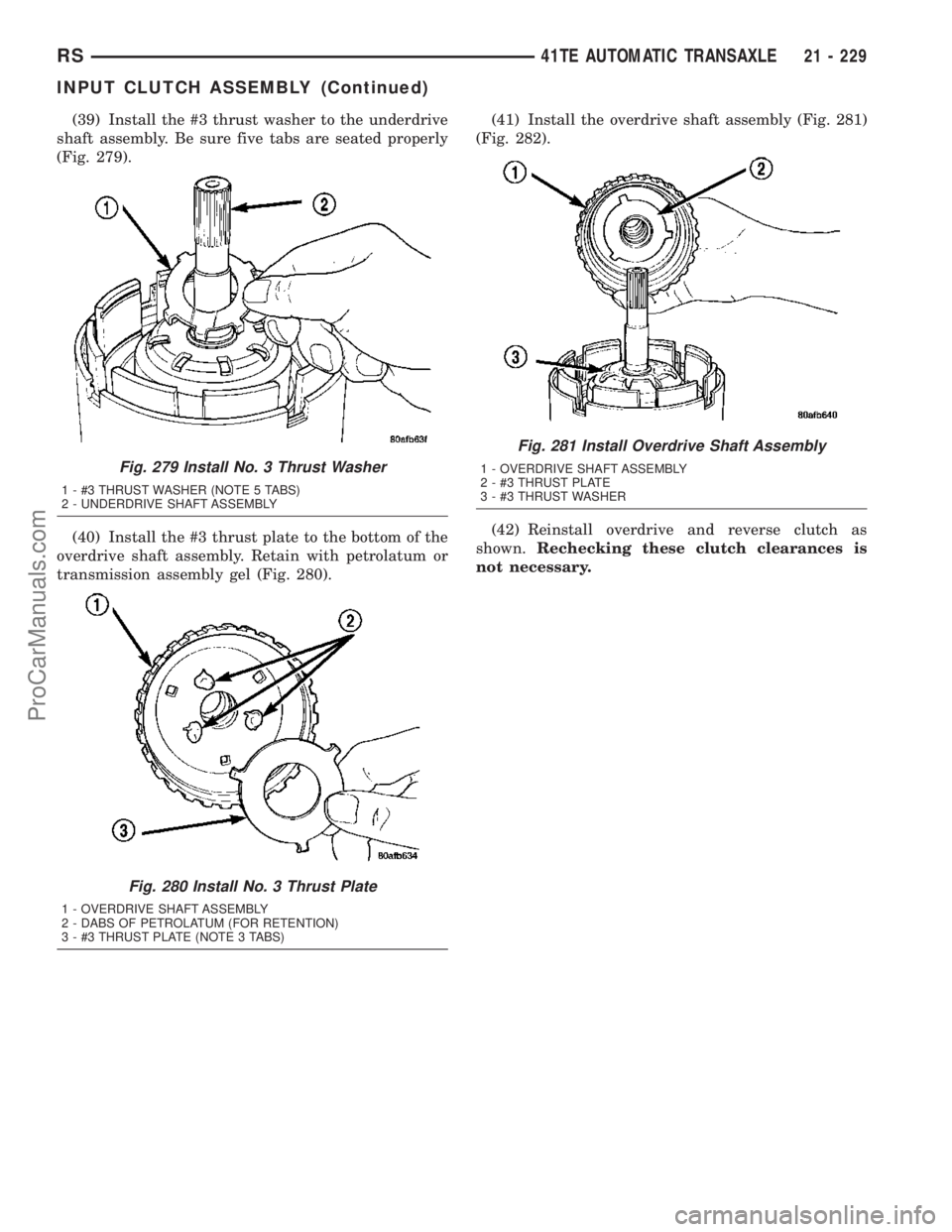

(39) Install the #3 thrust washer to the underdrive

shaft assembly. Be sure five tabs are seated properly

(Fig. 279).

(40) Install the #3 thrust plate to the bottom of the

overdrive shaft assembly. Retain with petrolatum or

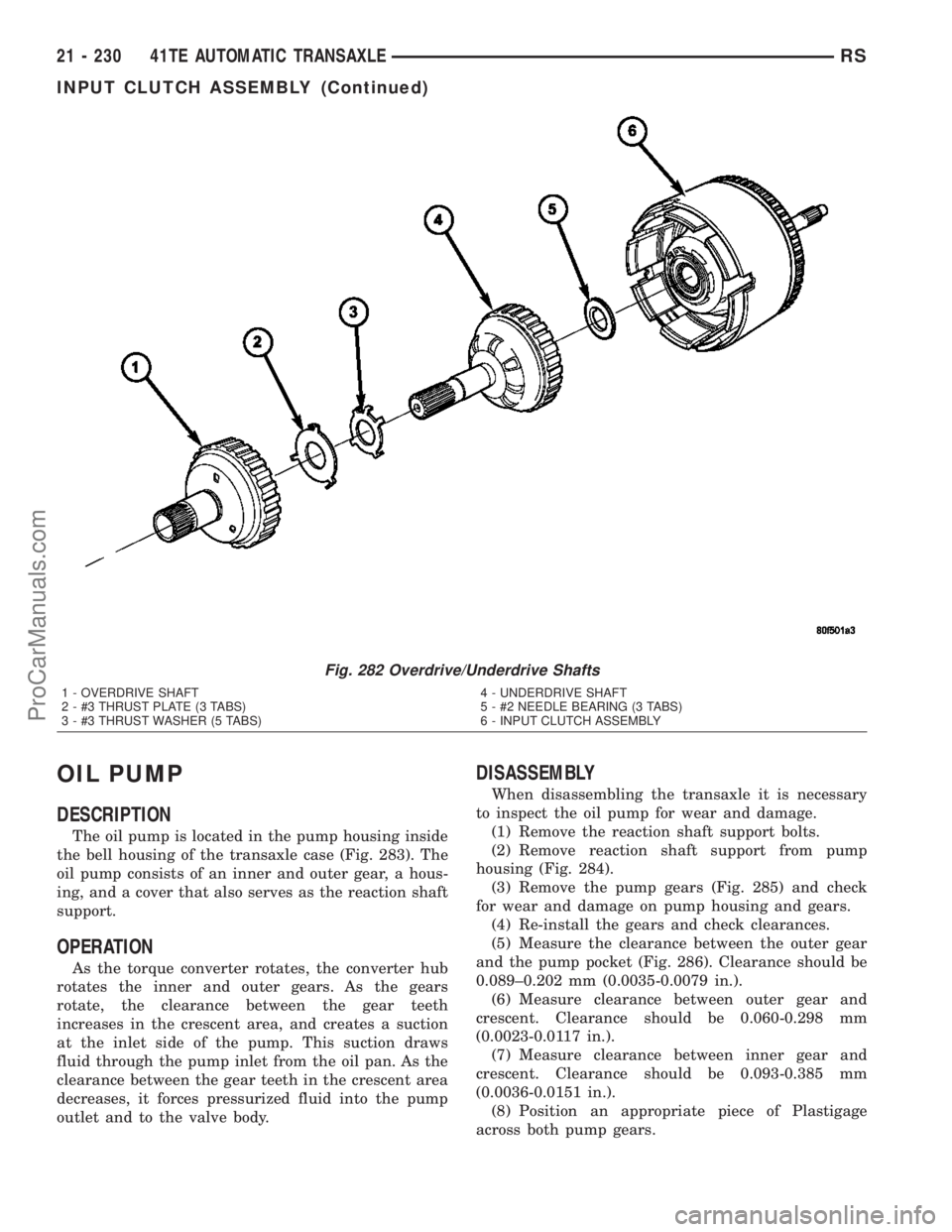

transmission assembly gel (Fig. 280).(41) Install the overdrive shaft assembly (Fig. 281)

(Fig. 282).

(42) Reinstall overdrive and reverse clutch as

shown.Rechecking these clutch clearances is

not necessary.

Fig. 279 Install No. 3 Thrust Washer

1 - #3 THRUST WASHER (NOTE 5 TABS)

2 - UNDERDRIVE SHAFT ASSEMBLY

Fig. 280 Install No. 3 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - DABS OF PETROLATUM (FOR RETENTION)

3 - #3 THRUST PLATE (NOTE 3 TABS)

Fig. 281 Install Overdrive Shaft Assembly

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #3 THRUST PLATE

3 - #3 THRUST WASHER

RS41TE AUTOMATIC TRANSAXLE21 - 229

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1677 of 2177

OIL PUMP

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transaxle case (Fig. 283). The

oil pump consists of an inner and outer gear, a hous-

ing, and a cover that also serves as the reaction shaft

support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

DISASSEMBLY

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage.

(1) Remove the reaction shaft support bolts.

(2) Remove reaction shaft support from pump

housing (Fig. 284).

(3) Remove the pump gears (Fig. 285) and check

for wear and damage on pump housing and gears.

(4) Re-install the gears and check clearances.

(5) Measure the clearance between the outer gear

and the pump pocket (Fig. 286). Clearance should be

0.089±0.202 mm (0.0035-0.0079 in.).

(6) Measure clearance between outer gear and

crescent. Clearance should be 0.060-0.298 mm

(0.0023-0.0117 in.).

(7) Measure clearance between inner gear and

crescent. Clearance should be 0.093-0.385 mm

(0.0036-0.0151 in.).

(8) Position an appropriate piece of Plastigage

across both pump gears.

Fig. 282 Overdrive/Underdrive Shafts

1 - OVERDRIVE SHAFT

2 - #3 THRUST PLATE (3 TABS)

3 - #3 THRUST WASHER (5 TABS)4 - UNDERDRIVE SHAFT

5 - #2 NEEDLE BEARING (3 TABS)

6 - INPUT CLUTCH ASSEMBLY

21 - 230 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com