ABS CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1719 of 2177

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

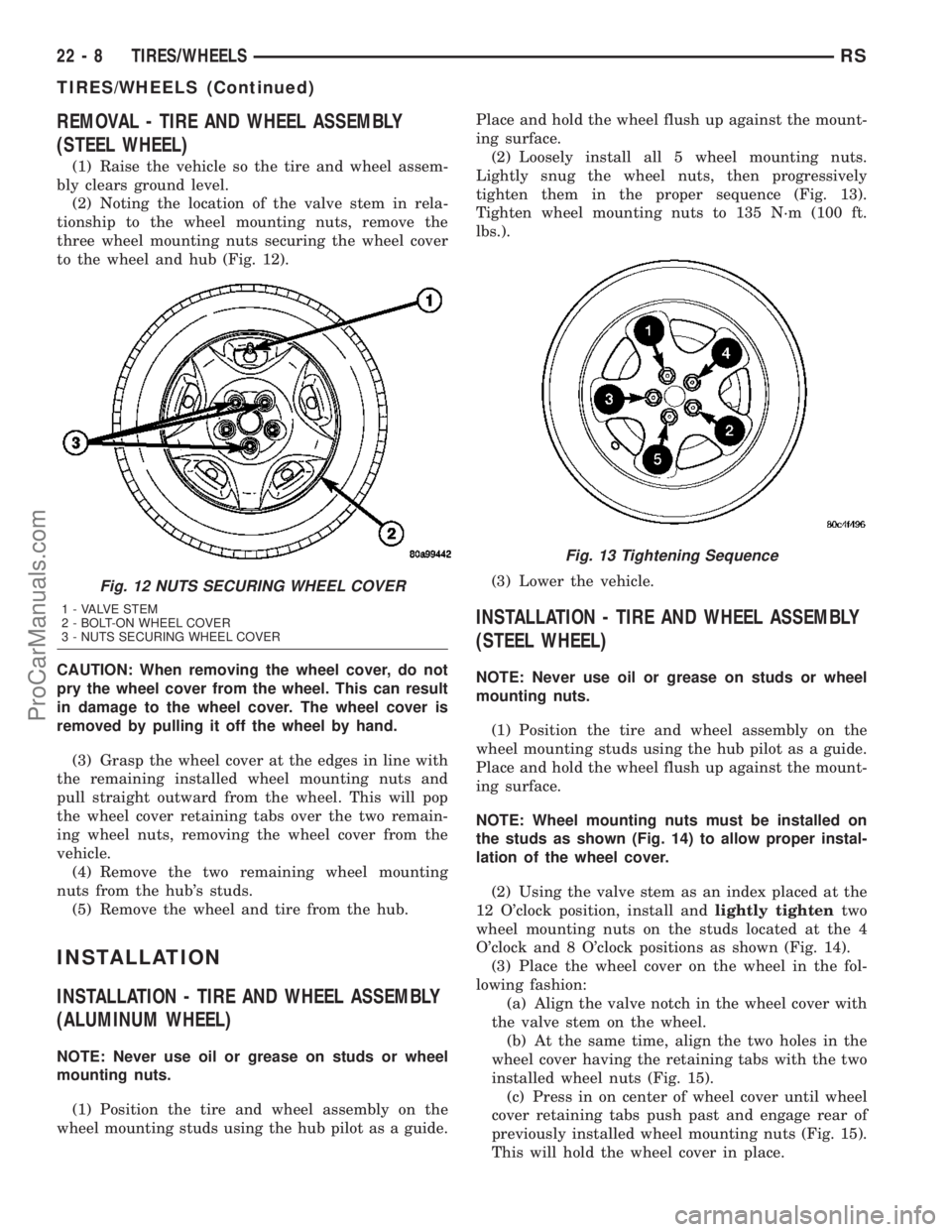

(2) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 12).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(3) Grasp the wheel cover at the edges in line with

the remaining installed wheel mounting nuts and

pull straight outward from the wheel. This will pop

the wheel cover retaining tabs over the two remain-

ing wheel nuts, removing the wheel cover from the

vehicle.

(4) Remove the two remaining wheel mounting

nuts from the hub's studs.

(5) Remove the wheel and tire from the hub.

INSTALLATION

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.Place and hold the wheel flush up against the mount-

ing surface.

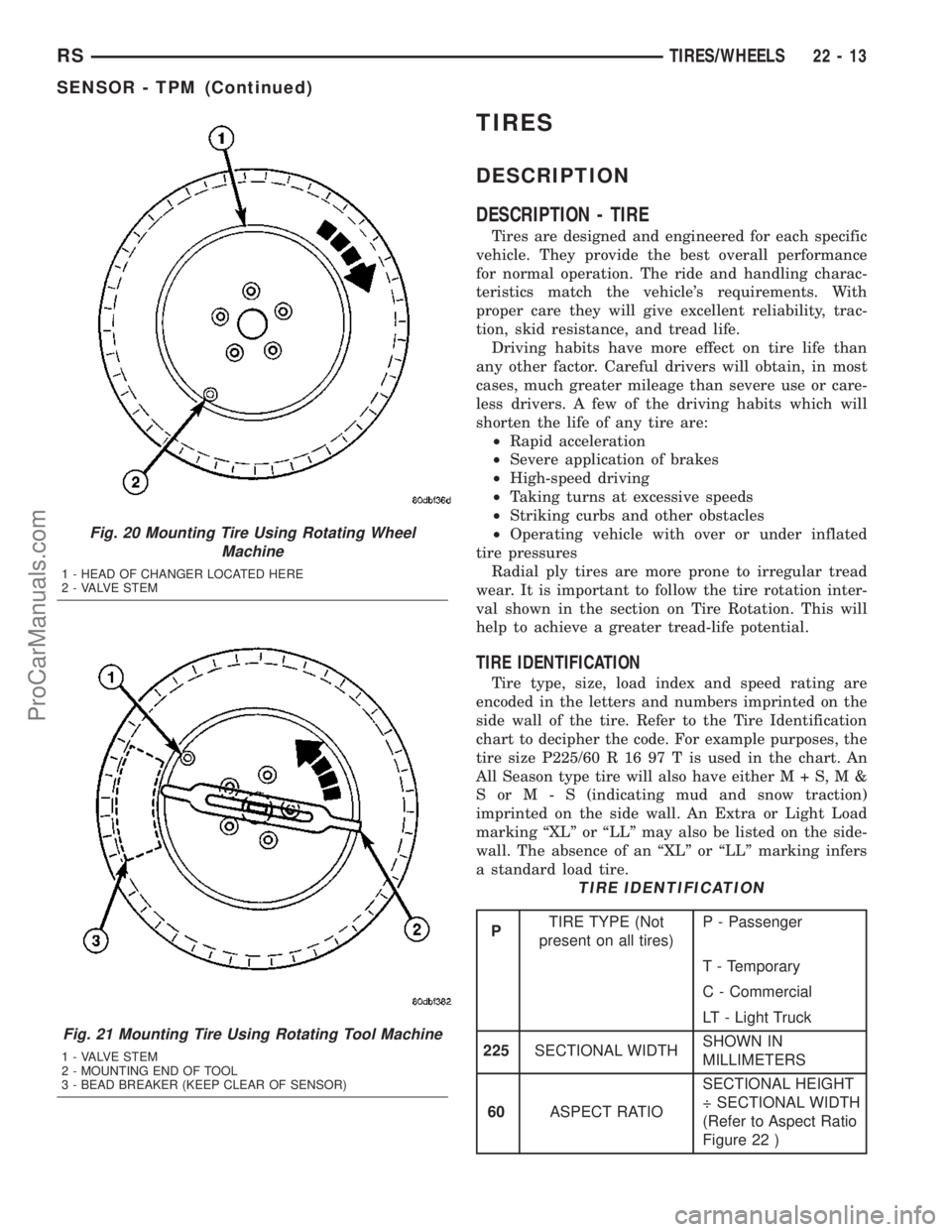

(2) Loosely install all 5 wheel mounting nuts.

Lightly snug the wheel nuts, then progressively

tighten them in the proper sequence (Fig. 13).

Tighten wheel mounting nuts to 135 N´m (100 ft.

lbs.).

(3) Lower the vehicle.

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

NOTE: Wheel mounting nuts must be installed on

the studs as shown (Fig. 14) to allow proper instal-

lation of the wheel cover.

(2) Using the valve stem as an index placed at the

12 O'clock position, install andlightly tightentwo

wheel mounting nuts on the studs located at the 4

O'clock and 8 O'clock positions as shown (Fig. 14).

(3) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

This will hold the wheel cover in place.

Fig. 12 NUTS SECURING WHEEL COVER

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 13 Tightening Sequence

22 - 8 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1720 of 2177

(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires (excludes spare).

Pressure in the spare tire is not monitored.

There is a sensor (transmitter) in each of the vehi-

cle's four road wheels. The system alerts the driver

when tire pressure falls outside predetermined

thresholds (pressure too low or too high). A message

is then displayed on the Electronic Vehicle Informa-

tion Center (EVIC) located in the overhead console.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit tire pressure read-

ings to a receiver located in the overhead console.

These transmissions occur once every minute at

speeds over 20 mph (32 km/h). The Tire Pressure

Monitoring system remains active even if no tire

pressure related message is displayed in the EVIC.

If any road tire pressure has exceeded the low or

high pressure threshold (refer to chart below), the

TPM system will display a message in the EVIC and

sound a chime. This message will be displayed for

the rest of the ignition cycle, or until either the Low/

High Tire pressure condition has been corrected. If

the C/T, MENU, STEP or RESET button is pressed,

the message is replaced by the new message

requested; however, if the Low/High Tire condition

has not been corrected, the Low/High Tire pressure

message will again be displayed.

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1724 of 2177

TIRES

DESCRIPTION

DESCRIPTION - TIRE

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

²Operating vehicle with over or under inflated

tire pressures

Radial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

TIRE IDENTIFICATION

Tire type, size, load index and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the Tire Identification

chart to decipher the code. For example purposes, the

tire size P225/60 R 16 97 T is used in the chart. An

All Season type tire will also have eitherM+S,M&

SorM-S(indicating mud and snow traction)

imprinted on the side wall. An Extra or Light Load

marking ªXLº or ªLLº may also be listed on the side-

wall. The absence of an ªXLº or ªLLº marking infers

a standard load tire.

TIRE IDENTIFICATION

PTIRE TYPE (Not

present on all tires)P - Passenger

T - Temporary

C - Commercial

LT - Light Truck

225SECTIONAL WIDTHSHOWN IN

MILLIMETERS

60ASPECT RATIOSECTIONAL HEIGHT

÷ SECTIONAL WIDTH

(Refer to Aspect Ratio

Figure 22 )

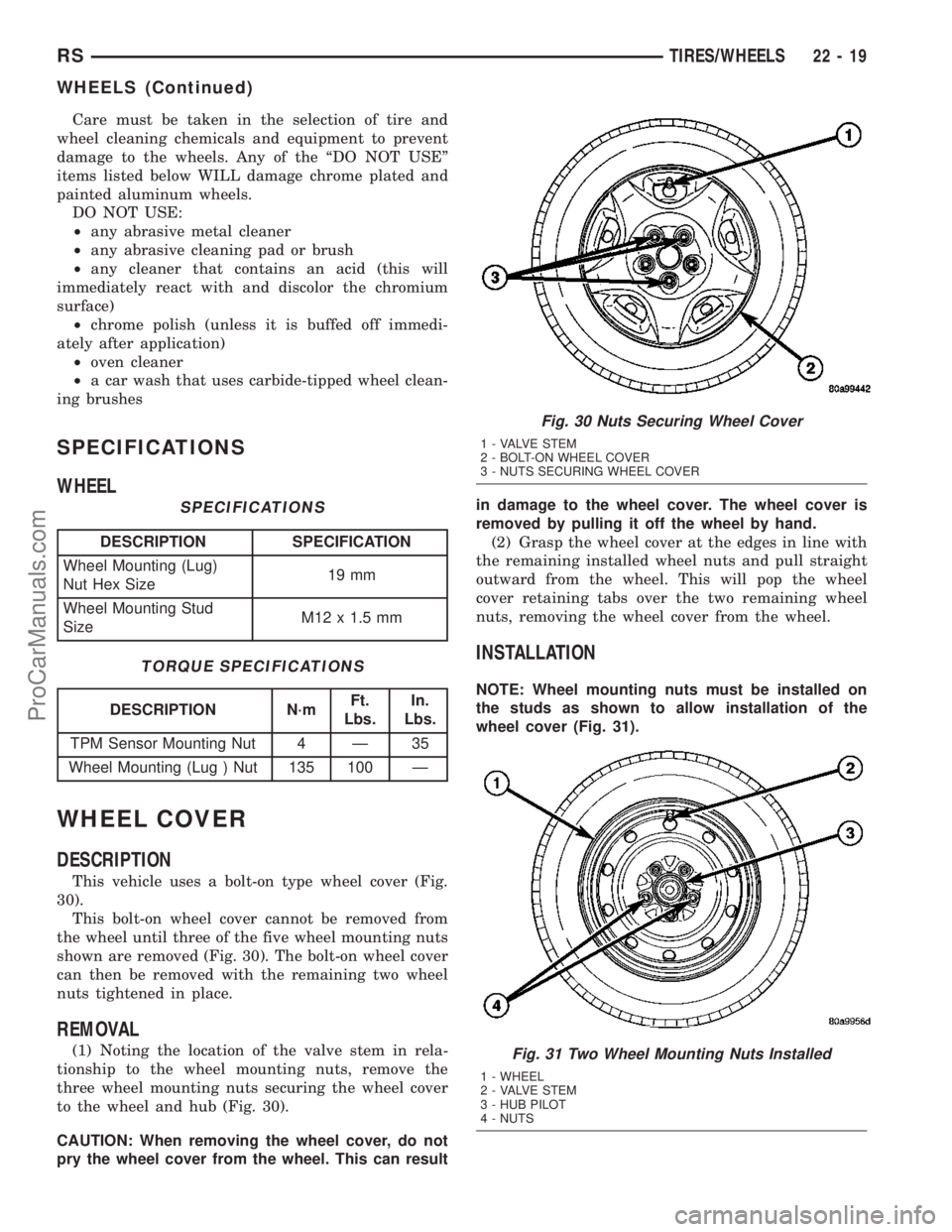

Fig. 20 Mounting Tire Using Rotating Wheel

Machine

1 - HEAD OF CHANGER LOCATED HERE

2 - VALVE STEM

Fig. 21 Mounting Tire Using Rotating Tool Machine

1 - VALVE STEM

2 - MOUNTING END OF TOOL

3 - BEAD BREAKER (KEEP CLEAR OF SENSOR)

RSTIRES/WHEELS22-13

SENSOR - TPM (Continued)

ProCarManuals.com

Page 1730 of 2177

Care must be taken in the selection of tire and

wheel cleaning chemicals and equipment to prevent

damage to the wheels. Any of the ªDO NOT USEº

items listed below WILL damage chrome plated and

painted aluminum wheels.

DO NOT USE:

²any abrasive metal cleaner

²any abrasive cleaning pad or brush

²any cleaner that contains an acid (this will

immediately react with and discolor the chromium

surface)

²chrome polish (unless it is buffed off immedi-

ately after application)

²oven cleaner

²a car wash that uses carbide-tipped wheel clean-

ing brushes

SPECIFICATIONS

WHEEL

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Wheel Mounting (Lug)

Nut Hex Size19 mm

Wheel Mounting Stud

SizeM12 x 1.5 mm

TORQUE SPECIFICATIONS

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

TPM Sensor Mounting Nut 4 Ð 35

Wheel Mounting (Lug ) Nut 135 100 Ð

WHEEL COVER

DESCRIPTION

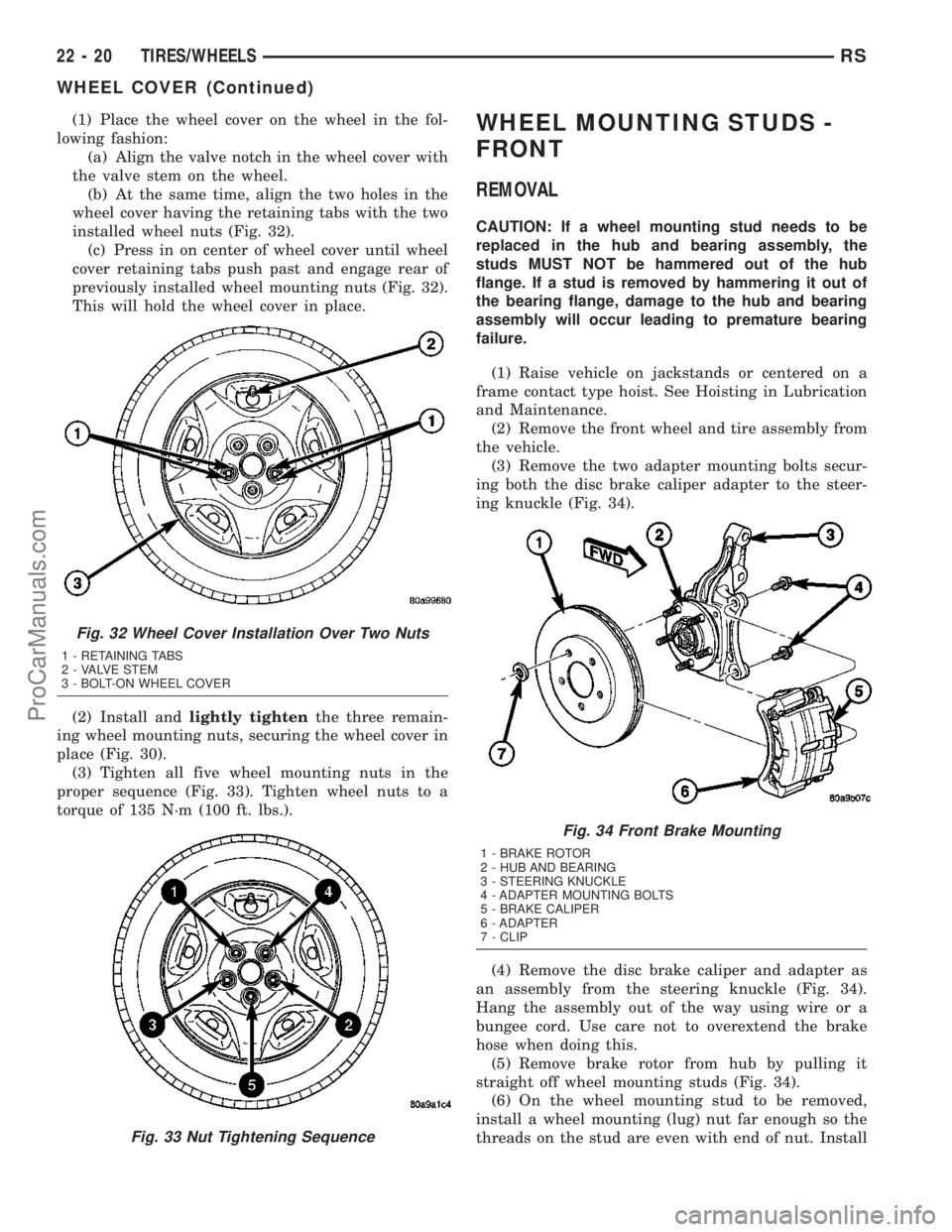

This vehicle uses a bolt-on type wheel cover (Fig.

30).

This bolt-on wheel cover cannot be removed from

the wheel until three of the five wheel mounting nuts

shown are removed (Fig. 30). The bolt-on wheel cover

can then be removed with the remaining two wheel

nuts tightened in place.

REMOVAL

(1) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 30).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can resultin damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

INSTALLATION

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 31).

Fig. 30 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 31 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

RSTIRES/WHEELS22-19

WHEELS (Continued)

ProCarManuals.com

Page 1731 of 2177

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 32).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 32).

This will hold the wheel cover in place.

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 30).

(3) Tighten all five wheel mounting nuts in the

proper sequence (Fig. 33). Tighten wheel nuts to a

torque of 135 N´m (100 ft. lbs.).WHEEL MOUNTING STUDS -

FRONT

REMOVAL

CAUTION: If a wheel mounting stud needs to be

replaced in the hub and bearing assembly, the

studs MUST NOT be hammered out of the hub

flange. If a stud is removed by hammering it out of

the bearing flange, damage to the hub and bearing

assembly will occur leading to premature bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the front wheel and tire assembly from

the vehicle.

(3) Remove the two adapter mounting bolts secur-

ing both the disc brake caliper adapter to the steer-

ing knuckle (Fig. 34).

(4) Remove the disc brake caliper and adapter as

an assembly from the steering knuckle (Fig. 34).

Hang the assembly out of the way using wire or a

bungee cord. Use care not to overextend the brake

hose when doing this.

(5) Remove brake rotor from hub by pulling it

straight off wheel mounting studs (Fig. 34).

(6) On the wheel mounting stud to be removed,

install a wheel mounting (lug) nut far enough so the

threads on the stud are even with end of nut. Install

Fig. 32 Wheel Cover Installation Over Two Nuts

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 33 Nut Tightening Sequence

Fig. 34 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

22 - 20 TIRES/WHEELSRS

WHEEL COVER (Continued)

ProCarManuals.com

Page 1736 of 2177

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR

There are many different types of plastics used in

today's automotive environment. We group plastics in

three different categories: Rigid, Semi-Rigid, and

Flexible. Any of these plastics may require the use of

an adhesion promoter for repair. These types of plas-

tic are used extensively on DaimlerChrysler Motors

vehicles. Always follow repair material manufactur-

er's plastic identification and repair procedures.

Rigid Plastics:

Examples of rigid plastic use: Fascias, Hoods,

Doors, and other Body Panels, which include SMC,

ABS, and Polycarbonates.

Semi-Rigid Plastics:

Examples of semi-rigid plastic use: Interior Panels,

Under Hood Panels, and other Body Trim Panels.

Flexible Plastics:

Examples of flexible plastic use: Fascias, Body

Moldings, and upper and lower Fascia Covers.

Repair Procedure:

The repair procedure for all three categories of

plastics is basically the same. The one difference is

the material used for the repair. The materials must

be specific for each substrate, rigid repair material

for rigid plastic repair, semi-rigid repair material for

semi-rigid plastic repair and flexible repair material

for flexible plastic repair.

Adhesion Promoter/Surface Modifier:

Adhesion Promoters/Surface Modifiers are required

for certain plastics. All three categories may have

plastics that require the use of adhesion promoter/

surface modifiers. Always follow repair material man-

ufacturer's plastic identification and repair

procedures.

SAFETY PRECAUTION AND WARNINGS

WARNING:

²EYE PROTECTION SHOULD BE USED WHEN

SERVICING COMPONENTS. PERSONAL INJURY

CAN RESULT.

²USE AN OSHA APPROVED BREATHING MASK

WHEN MIXING EPOXY, GRINDING, AND SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

RESIN, PETROLEUM, OR ALCOHOL BASED SOL-

VENTS. PERSONAL INJURY CAN RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT PROPERLY SUPPORTED ON

SAFETY STANDS. PERSONAL INJURY CAN

RESULT.

NOTE:

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components

and electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds

on undamaged painted surfaces around repair

areas. Damage to finish can result.

RSBODY23-3

BODY (Continued)

ProCarManuals.com

Page 1737 of 2177

RIGID, SEMI-RIGID, AND FLEXIBLE PLASTIC PARTS TYPES

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

ASA ACRYLONITRILE STYRENE

ACRYLITELURAN S CONSOLES, GRILLES

ABS ACRYLONITRILE

BUTADIENE STYRENETERLURAN9A9PILLARS, CONSOLES,

GRILLES

ABS/PC ABS/PC ALLOY PULSE, PROLOY,

BAYBLENDDOORS, INSTRUMENT

PANELS

ABS/PVC ABS/PV ALLOY PROLOY, PULSE, LUSTRAN,

CYCLOVINDOOR PANELS, GRILLES,

TRIM

BMC BULK MOLDING

COMPOUNDBMC FENDER EXTENSIONS

EMA EHTYLENE METHYL

ACRYLATE/IONOMERSURLYN, EMA, IONOMER BUMPER GUARDS, PADS

METTON METTON METTON GRILLES, KICK PANELS,

RUNNING BOARDS

MPPO MODIFIED

POLYPHENYLENE OXIDEMPPO SPOILER ASSEMBLY

PA POLYAMID ZYTEL, VYDYNE, PA,

MINLONFENDERS, QUARTER PANELS

PET THERMOPLASTIC

POLYESTERRYNITE TRIM

PBT/PPO PBT/PPO ALLOY GERMAX CLADDINGS

PBTP POLYBUTYLENE

THEREPTHALATEPBT, PBTP, POCAN, VALOX WHEEL COVERS, FENDERS,

GRILLES

PBTP/EEBC POLYBUTYLENE

THEREPTHALATE/EEBC

ALLOYBEXLOY,9M9, PBTP/EEBC FASCIAS, ROCKER PANEL,

MOLDINGS

PC POLYCARBONATE LEXAN, MERLON, CALIBRE,

MAKROLON PCTAIL LIGHT LENSES, IP TRIM,

VALANCE PANELS

PC/ABS PC/ABS ALLOY GERMAX, BAY BLENDS,

PULSEDOORS, INSTRUMENT

PANELS

PPO POLYPHENYLENE OXIDE AZDEL, HOSTALEN,

MARLEX, PRFAX, NORYL,

GTX, PPOINTERIOR TRIM, DOOR

PANELS, SPLASH SHIELDS,

STEERING COLUMN SHROUD

PPO/PA POLYPHENYLENE/

POLYAMIDPPO/PA, GTX 910 FENDERS, QUARTER PANELS

PR/FV FIBERGLASS REINFORCED

PLASTICFIBERGLASS, FV, PR/FV BODY PANELS

PS POLYSTYRENE LUSTREX, STYRON, PS DOOR PANELS, DASH

PANELS

RTM RESIN TRANSFER

MOLDING COMPOUNDRTM BODY PANELS

SMC SHEET MOLDED

COMPOUNDSMC BODY PANELS

TMC TRANSFER MOLDING

COMPOUNDTMC GRILLES

23 - 4 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1787 of 2177

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 14). Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install radiator sight shield.

(10) Install hood prop rod.

(11) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(12) Install bolts attaching hood latch to cross-

member. Tighten bolts to 13.5 N´m (10 ft. lbs.)

torque.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

(2) Remove front wheel.

(3) Remove push pin fasteners attaching splash

shield to frame rail forward of suspension.

(4) Remove push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender and front bumper fascia.

(6) Remove splash shield from vehicle (Fig. 15).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

15).

(2) Install push pin fasteners attaching splash

shield to frame rail forward of suspension.

(3) Install push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install screws attaching wheelhouse splash

shield to front fender.

(5) Install front wheel.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail

(Fig. 16).

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 17).

Fig. 15 FRONT WHEELHOUSE SPLASH SHIELD

1 - FRONT FENDER WHEELHOUSE SPLASH SHIELD

2 - PUSH PIN FASTENERS

3 - ACCESSORY DRIVE SPLASH SHIELD

4 - SCREWS

Fig. 16 LUGGAGE RACK RISER COVER

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

23 - 54 EXTERIORRS

GRILLE OPENING REINFORCEMENT (Continued)

ProCarManuals.com

Page 1793 of 2177

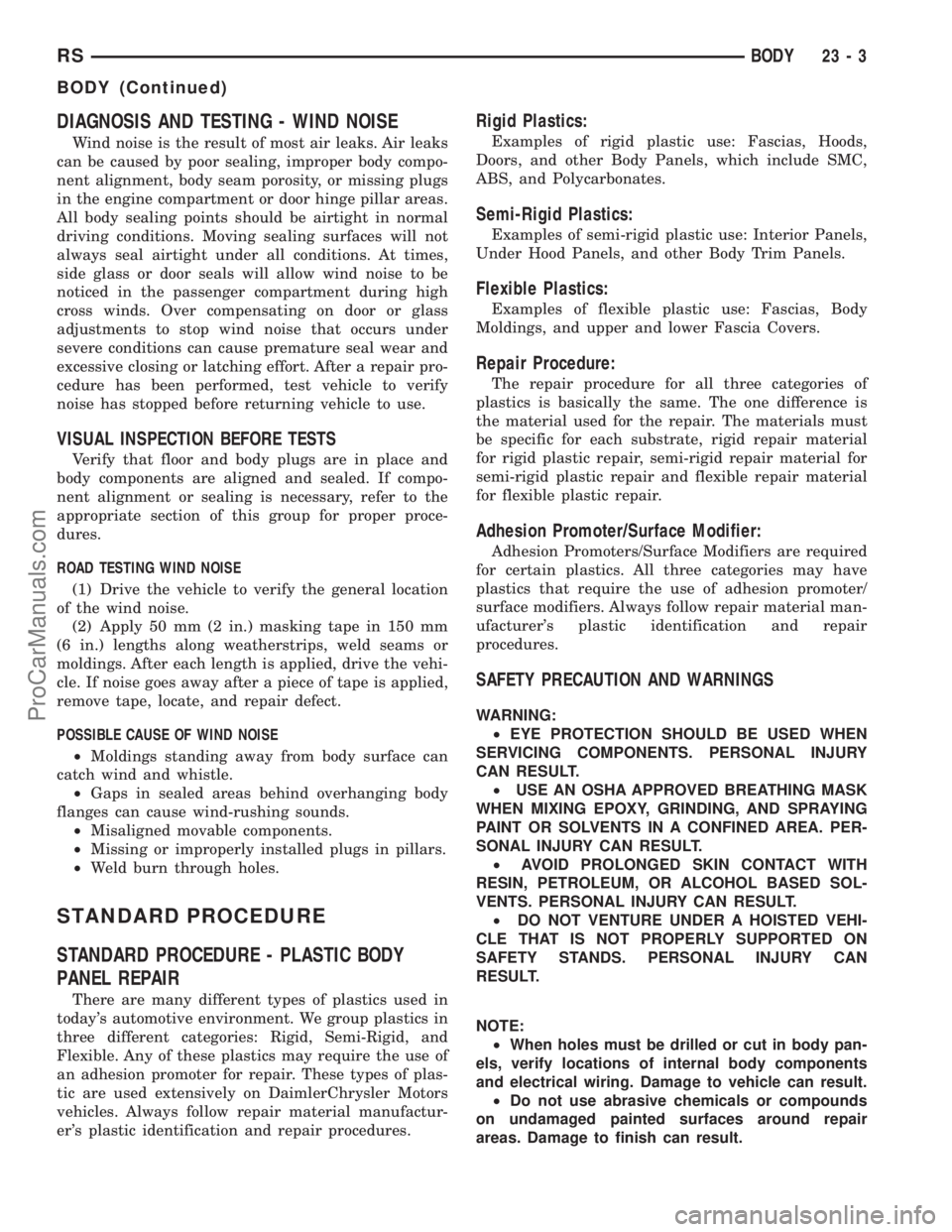

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts attaching

hood to hinge finger tight.

(2) Install top bolts attaching hood to hinge finger

tight.

(3) Position bolts at marks and tighten. Tighten

bolts to 13.5 N´m (120 in. lbs.) torque. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(4) Verify hood operation and alignment.

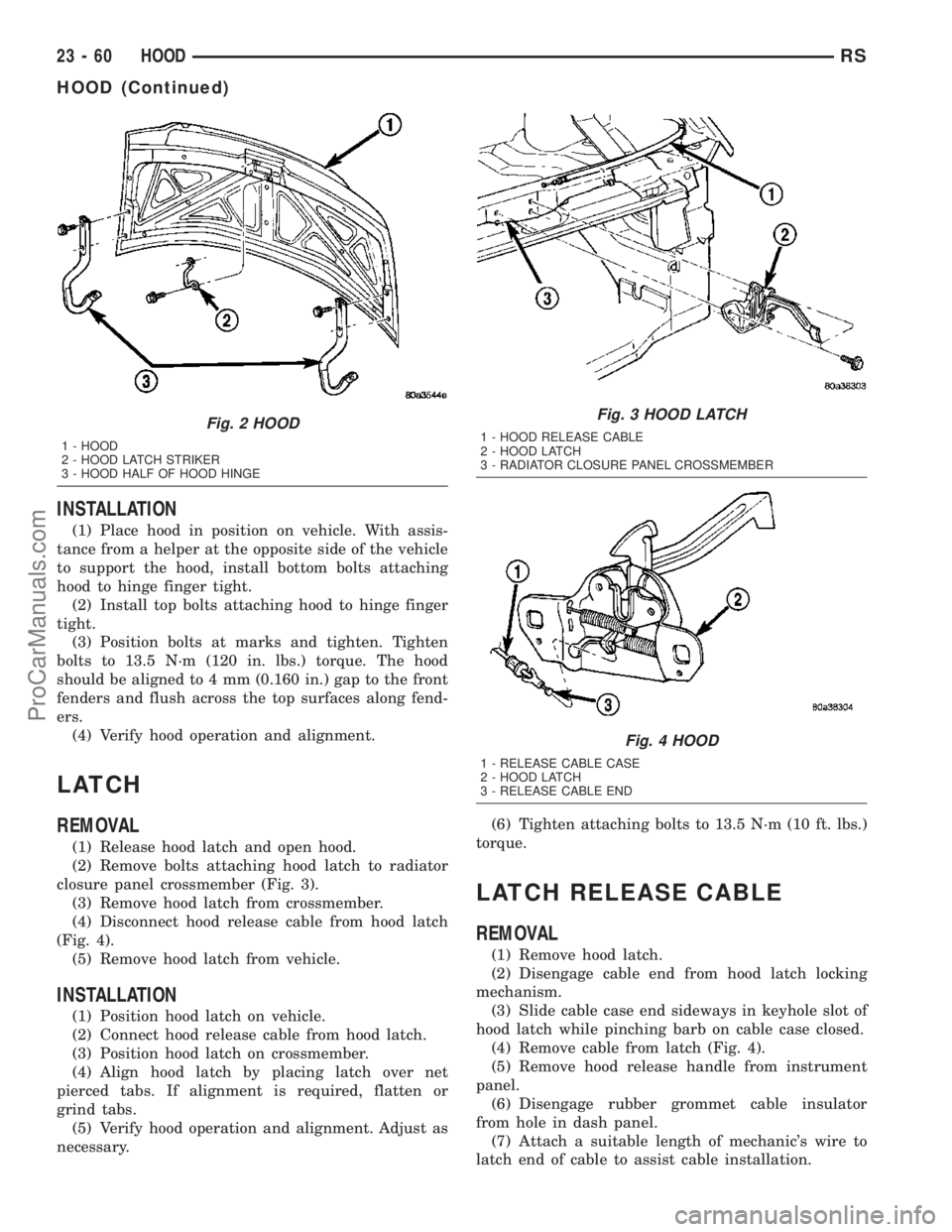

LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to radiator

closure panel crossmember (Fig. 3).

(3) Remove hood latch from crossmember.

(4) Disconnect hood release cable from hood latch

(Fig. 4).

(5) Remove hood latch from vehicle.

INSTALLATION

(1) Position hood latch on vehicle.

(2) Connect hood release cable from hood latch.

(3) Position hood latch on crossmember.

(4) Align hood latch by placing latch over net

pierced tabs. If alignment is required, flatten or

grind tabs.

(5) Verify hood operation and alignment. Adjust as

necessary.(6) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.

LATCH RELEASE CABLE

REMOVAL

(1) Remove hood latch.

(2) Disengage cable end from hood latch locking

mechanism.

(3) Slide cable case end sideways in keyhole slot of

hood latch while pinching barb on cable case closed.

(4) Remove cable from latch (Fig. 4).

(5) Remove hood release handle from instrument

panel.

(6) Disengage rubber grommet cable insulator

from hole in dash panel.

(7) Attach a suitable length of mechanic's wire to

latch end of cable to assist cable installation.

Fig. 2 HOOD

1 - HOOD

2 - HOOD LATCH STRIKER

3 - HOOD HALF OF HOOD HINGE

Fig. 3 HOOD LATCH

1 - HOOD RELEASE CABLE

2 - HOOD LATCH

3 - RADIATOR CLOSURE PANEL CROSSMEMBER

Fig. 4 HOOD

1 - RELEASE CABLE CASE

2 - HOOD LATCH

3 - RELEASE CABLE END

23 - 60 HOODRS

HOOD (Continued)

ProCarManuals.com

Page 1809 of 2177

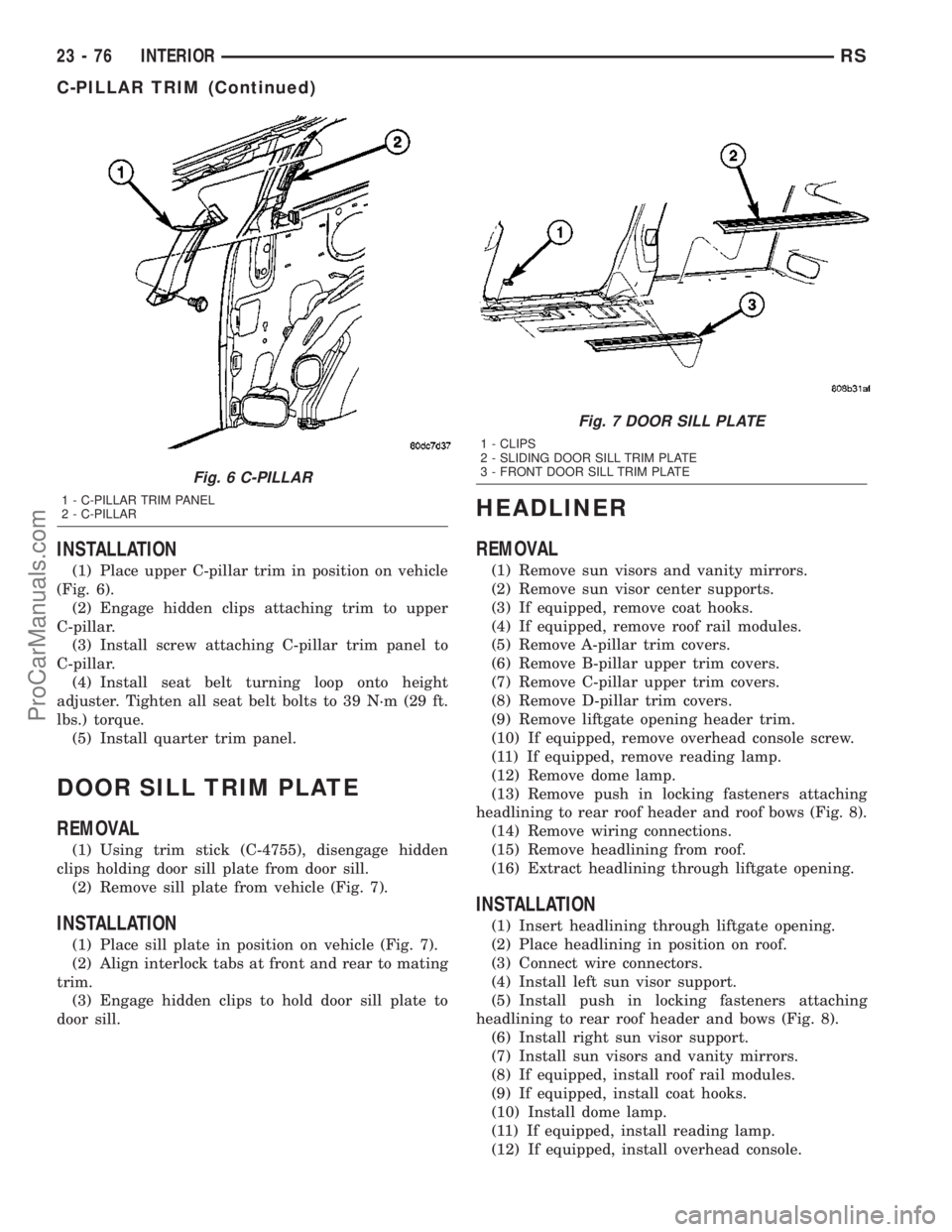

INSTALLATION

(1) Place upper C-pillar trim in position on vehicle

(Fig. 6).

(2) Engage hidden clips attaching trim to upper

C-pillar.

(3) Install screw attaching C-pillar trim panel to

C-pillar.

(4) Install seat belt turning loop onto height

adjuster. Tighten all seat belt bolts to 39 N´m (29 ft.

lbs.) torque.

(5) Install quarter trim panel.

DOOR SILL TRIM PLATE

REMOVAL

(1) Using trim stick (C-4755), disengage hidden

clips holding door sill plate from door sill.

(2) Remove sill plate from vehicle (Fig. 7).

INSTALLATION

(1) Place sill plate in position on vehicle (Fig. 7).

(2) Align interlock tabs at front and rear to mating

trim.

(3) Engage hidden clips to hold door sill plate to

door sill.

HEADLINER

REMOVAL

(1) Remove sun visors and vanity mirrors.

(2) Remove sun visor center supports.

(3) If equipped, remove coat hooks.

(4) If equipped, remove roof rail modules.

(5) Remove A-pillar trim covers.

(6) Remove B-pillar upper trim covers.

(7) Remove C-pillar upper trim covers.

(8) Remove D-pillar trim covers.

(9) Remove liftgate opening header trim.

(10) If equipped, remove overhead console screw.

(11) If equipped, remove reading lamp.

(12) Remove dome lamp.

(13) Remove push in locking fasteners attaching

headlining to rear roof header and roof bows (Fig. 8).

(14) Remove wiring connections.

(15) Remove headlining from roof.

(16) Extract headlining through liftgate opening.

INSTALLATION

(1) Insert headlining through liftgate opening.

(2) Place headlining in position on roof.

(3) Connect wire connectors.

(4) Install left sun visor support.

(5) Install push in locking fasteners attaching

headlining to rear roof header and bows (Fig. 8).

(6) Install right sun visor support.

(7) Install sun visors and vanity mirrors.

(8) If equipped, install roof rail modules.

(9) If equipped, install coat hooks.

(10) Install dome lamp.

(11) If equipped, install reading lamp.

(12) If equipped, install overhead console.

Fig. 6 C-PILLAR

1 - C-PILLAR TRIM PANEL

2 - C-PILLAR

Fig. 7 DOOR SILL PLATE

1 - CLIPS

2 - SLIDING DOOR SILL TRIM PLATE

3 - FRONT DOOR SILL TRIM PLATE

23 - 76 INTERIORRS

C-PILLAR TRIM (Continued)

ProCarManuals.com