window CHRYSLER CARAVAN 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 407 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic prob-

lems. Prior to any test, perform the Self-Diagnostic

Test. The self diagnostic system displays instrument

cluster stored fault codes in the odometer display,

sweeps the gauges to the calibration points, and bulb

checks the warning indicators. When the key is in the

ON position with the engine not running, the MIL will

remain illuminated for regulatory purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS

CONDITIONS

Refer to the following tables for possible problems,

causes, and corrections.

²INSTRUMENT CLUSTER DIAGNOSIS

²SPEEDOMETER DIAGNOSIS

²TACHOMETER DIAGNOSIS

²FUEL GAUGE DIAGNOSIS

²TEMPERATURE GAUGE DIAGNOSIS

²ODOMETER DIAGNOSIS

²ELECTRONIC GEAR INDICATOR DISPLAY

DIAGNOSIS

NOTE: Always check the functionality of the cluster

by running the self test prior to troubleshooting.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 421 of 2177

(b) Install the switch in its bracket by aligning

the index tab on the switch with the slot in the

mounting bracket.

(c) When the switch is fully seated in its

bracket, rotate the switch clockwise approximately

30É to lock the switch into place.

(d) With the brake pedal in the fully released

position, move the lever on the back of the brake

lamp switch from the angled non-adjusted position

to the full vertical position as shown (Fig. 4). This

will adjust the brake lamp switch to the vehicle.(2) Install silencer panel below steering column

knee blocker.

(3) Reconnect the battery negative terminal.

(4) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

(5) Road test the vehicle to ensure proper opera-

tion of the brakes including ABS and speed control (if

equipped).

CENTER HIGH MOUNTED

STOP LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two retaining screws (Fig. 5).

(3) Twist socket counter-clockwise and remove

from lamp.

(4) Pull bulb from socket (Fig. 7).

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into the lamp unit.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two retaining screws (Fig. 5).

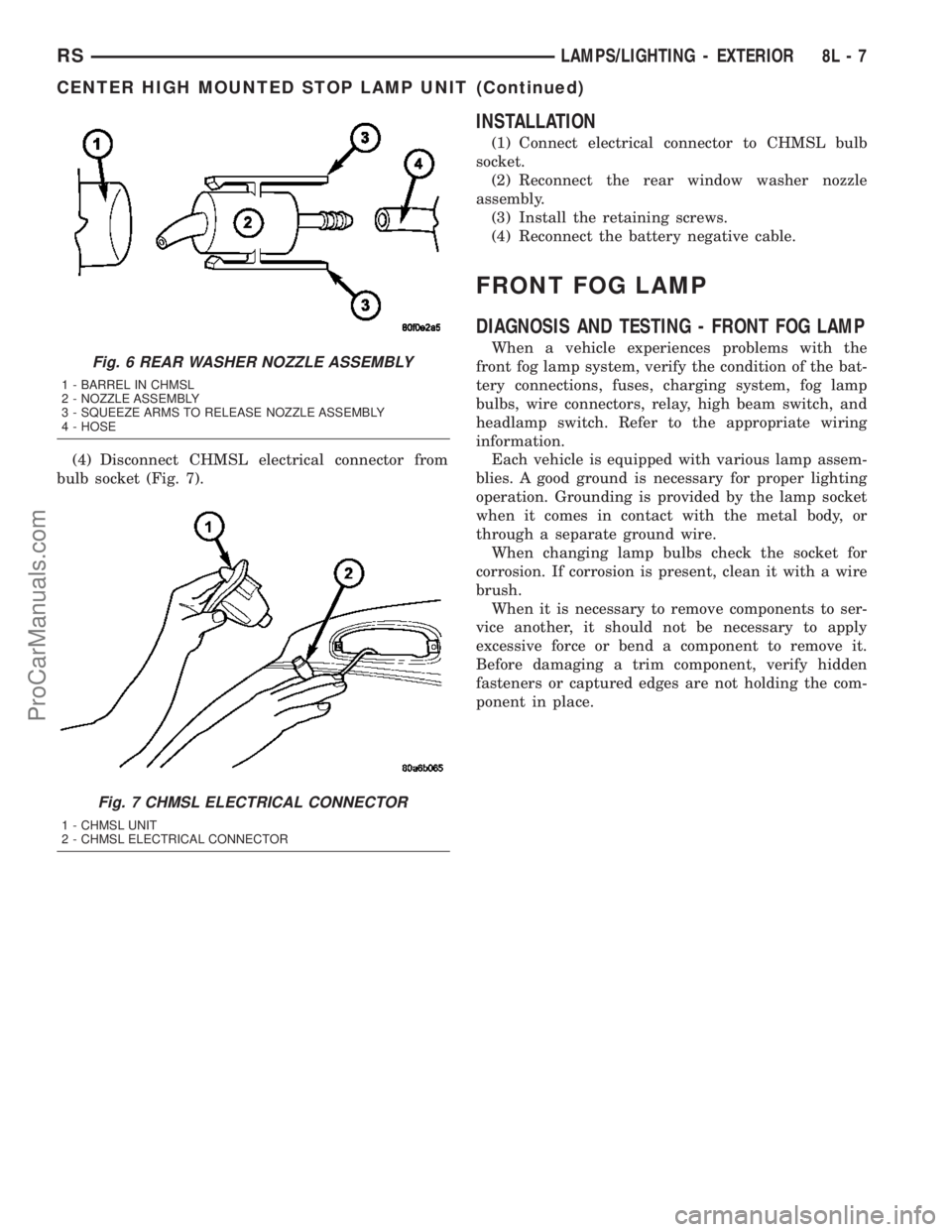

(3) Disconnect the rear window washer nozzle

assembly (Fig. 6).

Fig. 3 Brake Lamp Switch And Pedal With Bracket

1 - BRAKE LAMP SWITCH

2 - WIRING CONNECTOR

3 - PEDAL AND BRACKET

Fig. 4 Adjustment Lever Movement

Fig. 5 CHMSL UNIT

1 - CHMSL UNIT

2 - LIFTGATE

8L - 6 LAMPS/LIGHTING - EXTERIORRS

BRAKE LAMP SWITCH (Continued)

ProCarManuals.com

Page 422 of 2177

(4) Disconnect CHMSL electrical connector from

bulb socket (Fig. 7).

INSTALLATION

(1) Connect electrical connector to CHMSL bulb

socket.

(2) Reconnect the rear window washer nozzle

assembly.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

FRONT FOG LAMP

DIAGNOSIS AND TESTING - FRONT FOG LAMP

When a vehicle experiences problems with the

front fog lamp system, verify the condition of the bat-

tery connections, fuses, charging system, fog lamp

bulbs, wire connectors, relay, high beam switch, and

headlamp switch. Refer to the appropriate wiring

information.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.Fig. 6 REAR WASHER NOZZLE ASSEMBLY

1 - BARREL IN CHMSL

2 - NOZZLE ASSEMBLY

3 - SQUEEZE ARMS TO RELEASE NOZZLE ASSEMBLY

4 - HOSE

Fig. 7 CHMSL ELECTRICAL CONNECTOR

1 - CHMSL UNIT

2 - CHMSL ELECTRICAL CONNECTOR

RSLAMPS/LIGHTING - EXTERIOR8L-7

CENTER HIGH MOUNTED STOP LAMP UNIT (Continued)

ProCarManuals.com

Page 456 of 2177

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM.................. 1

POWER SLIDING DOOR SYSTEM............ 19

POWER LOCKS........................... 38POWER MIRRORS........................ 45

POWER SEAT SYSTEM..................... 50

POWER WINDOWS........................ 62

POWER LIFTGATE SYSTEM

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - POWER

LIFTGATE SYSTEM.....................4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIFTGATE

ADJUSTMENT.........................9

STANDARD PROCEDURE - POWER

LIFTGATE LEARN CYCLE................9

SPECIFICATIONS

SPECIFICATIONS TABLE................9

CHIME/THERMISTOR

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................10

ENGAGE ACTUATOR

DESCRIPTION.........................10

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

EXTERIOR HANDLE SWITCH

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................12

FULL OPEN SWITCH

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................13INSTALLATION.........................13

LATCH

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................14

LATCH ACTUATOR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

LIFTGATE MOTOR

DESCRIPTION.........................15

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

LIFT GEAR & LINK ROD

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

PINCH SENSOR

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

TRANSVERSE BRACKET

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................18

INSTALLATION.........................18

RSPOWER SYSTEMS8N-1

ProCarManuals.com

Page 471 of 2177

(2) Install the three motor assembly retaining

bolts. Torque the two rear most bolts first to 9.5 N´m

(85 in. lbs.). Torque the remaining bolt next to the

window actuator to 9.5 N´m (85 in. lbs.).

(3) Connect the liftgate motor assembly electrical

connector.

(4) Install the D-pillar trim panel on the vehicle.

Refer to Body for the procedure.

(5) Connect the negative battery cable.

(6) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes related to the door motor assembly.

(7) Verify power liftgate system operation. Cycle

the power liftgate through one complete open and

close cycle, this will allow the power liftgate control

module to relearn its cycle with the new components.

LIFT GEAR & LINK ROD

DESCRIPTION

Vehicles equipped with a power liftgate utilize a

lift gear and rod assembly. This lift gear and rod

assembly are located in the left rear of the vehicle

and are visible without removing the D-pillar trim

(Fig. 12). The lift gear provides the leverage to move

the liftgate from the closed to the open position. The

lift gear attaches to a bearing on the gear motor

assembly with four bolts. On the outboard side of thelift gear are riveted on teeth, which mesh with the

gear motor assembly drive gears during a open or

close operation. The rod assembly is a steel shaft,

equipped with two spherical rod ends which attaches

the lift gear to the liftgate.

The lift gear and rod assembly are serviceable com-

ponents. Consult your MoparŸ parts catalog for a

part number.

OPERATION

One end of the rod assembly is attached to the lift-

gate, the other attached to the lift gear. When the lift

gear is driven by the gear motor assembly the lift-

gate is moved to the open or closed position.

REMOVAL

(1) Remove the left rear D-pillar trim from the

vehicle. Refer to Body for the procedure.

(2) Remove the lift gear retaining bolts (Fig. 13).

(3) Remove the lift gear and rod from the vehicle.

INSTALLATION

(1)Position the lift gear assembly and install the

retaining bolts. Torque the bolts to 8 N´m (71 in. lbs.).

(2) Install the left rear D-pillar trim on the vehi-

cle. Refer to Body for the procedure.

CAUTION: Torque link rod to liftgate attachment

bolt to 250 in. lbs. Care must be taken not to over-

torque link rod bolt.

Fig. 12 LIFTGATE GEAR/MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

Fig. 13 LIFTGATE GEAR MOTOR ASSEMBLY

1 - ENGAGE ACTUATOR RETAINING SCREWS

2 - LIFT GEAR RETAINING BOLTS

8N - 16 POWER LIFTGATE SYSTEMRS

LIFTGATE MOTOR (Continued)

ProCarManuals.com

Page 473 of 2177

TRANSVERSE BRACKET

DESCRIPTION

Vehicles equipped with a power liftgate utilize a

transverse bracket (Fig. 15) to support and secure

the power liftgate gear/motor assembly to the left

rear body D-pillar.

The transverse bracket is a serviceable power lift-

gate component. Consult your MoparŸ parts catalog

for a specific part number.

OPERATION

The power liftgate transverse bracket supports the

gear motor assembly by supplying an additional

attachment point. Located on the leading edge of the

gear motor assembly, one end of the transverse

bracket attaches to the motor assembly the other to

the leading edge of the vehicles D-pillar.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the left D-pillar trim from the vehicle.

Refer to Body for the procedure.

(3) Disconnect the gear motor assembly electrical

connector and disengage retaining pushpin.

(4) Loosen the gear motor assembly retaining bolts

to allow room for transverse bracket to be removed.

(5) Remove the transverse bracket retaining bolts

(Fig. 12).

(6) Remove the transverse bracket from the vehi-

cle.

INSTALLATION

(1) Position the transverse bracket in the vehicle.

Be certain the transverse bracket is properly posi-

tioned. The bracket should just touch the engage

actuator arm and be positioned between the actuator

arm and the motor housing.

(2) Torque the transverse bracket retaining bolts

to the gear motor assembly to 9.5 N´m (85 in. lbs.).

Do not tighten the transverse bracket retaining bolt,

located under the window actuator at this time.

(3) Torque the gear motor assembly retaining bolts

to 9.5 N´m (85 in. lbs.).

(4) Torque the final transverse bracket retaining

bolt to 9.5 N´m (85 in. lbs.).

(5) Connect the gear motor assembly electrical con-

nector and engage retaining pushpin.

(6) Install the appropriate D-pillar trim from the

vehicle. Refer to Body for the procedure.

Fig. 15 LIFTGATE GEAR/MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

8N - 18 POWER LIFTGATE SYSTEMRS

ProCarManuals.com

Page 476 of 2177

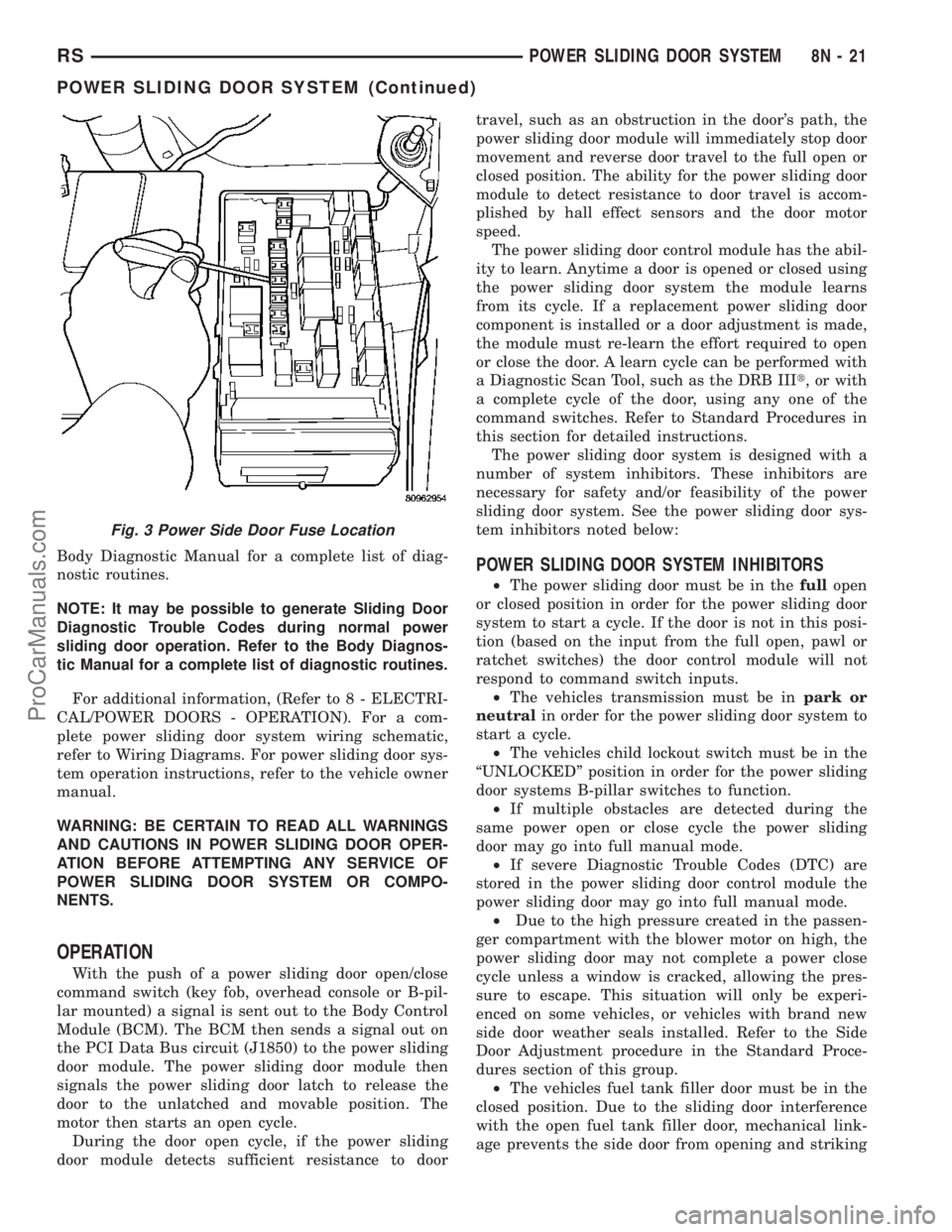

Body Diagnostic Manual for a complete list of diag-

nostic routines.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). For a com-

plete power sliding door system wiring schematic,

refer to Wiring Diagrams. For power sliding door sys-

tem operation instructions, refer to the vehicle owner

manual.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the PCI Data Bus circuit (J1850) to the power sliding

door module. The power sliding door module then

signals the power sliding door latch to release the

door to the unlatched and movable position. The

motor then starts an open cycle.

During the door open cycle, if the power sliding

door module detects sufficient resistance to doortravel, such as an obstruction in the door's path, the

power sliding door module will immediately stop door

movement and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors and the door motor

speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a Diagnostic Scan Tool, such as the DRB IIIt, or with

a complete cycle of the door, using any one of the

command switches. Refer to Standard Procedures in

this section for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. See the power sliding door sys-

tem inhibitors noted below:

POWER SLIDING DOOR SYSTEM INHIBITORS

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The vehicles transmission must be inpark or

neutralin order for the power sliding door system to

start a cycle.

²The vehicles child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed. Refer to the Side

Door Adjustment procedure in the Standard Proce-

dures section of this group.

²The vehicles fuel tank filler door must be in the

closed position. Due to the sliding door interference

with the open fuel tank filler door, mechanical link-

age prevents the side door from opening and striking

Fig. 3 Power Side Door Fuse Location

RSPOWER SLIDING DOOR SYSTEM8N-21

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 496 of 2177

CAUTION: Do not disconnect the switch from the

rear of the door key cylinder. This switch is a one

time use switch. Once it is removed from the rear of

the switch, it is not reusable and must be replaced.

Test the switch at the harness connector.

DOOR CYLINDER LOCK SWITCH RESISTANCE

SWITCH POSITION RESISTANCE VALUE

COUNTERCLOCKWISE 5.4K OHMS

NEUTRAL 18.4K OHMS

CLOCKWISE 2K OHMS

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel of the effected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - REMOVAL).

(3) Close the door window.

(4) Disconnect the door cylinder lock switch wire

connector from the door harness, and wiring clip

from the impact beam.

(5) Remove the outer door handle from the door.

(6) Remove the switch from the key cylinder in the

door handle and remove from vehicle.

INSTALLATION

(1) Install the switch on the key cylinder in the

door handle.

(2) Install the door handle.

(3) Connect the door cylinder lock switch wire con-

nector to the door harness, and the wiring clip to the

impact beam.

(4) Install the door trim panel of the affected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Verify system operation.

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR

Verify battery condition before testing door lock

motor(s) (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - DIAGNOSIS AND TESTING).

To determine which motor is faulty, check each

individual door for electrical lock and unlock or dis-

connect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem may be caused

by a shorted motor or a bad switch. Disconnecting

the defective motor will allow the others to work.To test an individual door lock motor, disconnect

the electrical connector from the motor. To lock the

door, connect a 12 volt power source to the positive

pin of the lock motor and a ground wire to the other

pin. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. To unlock the

door reverse the wire connections at the motor pin

terminals. If these results are NOT obtained, replace

the motor.

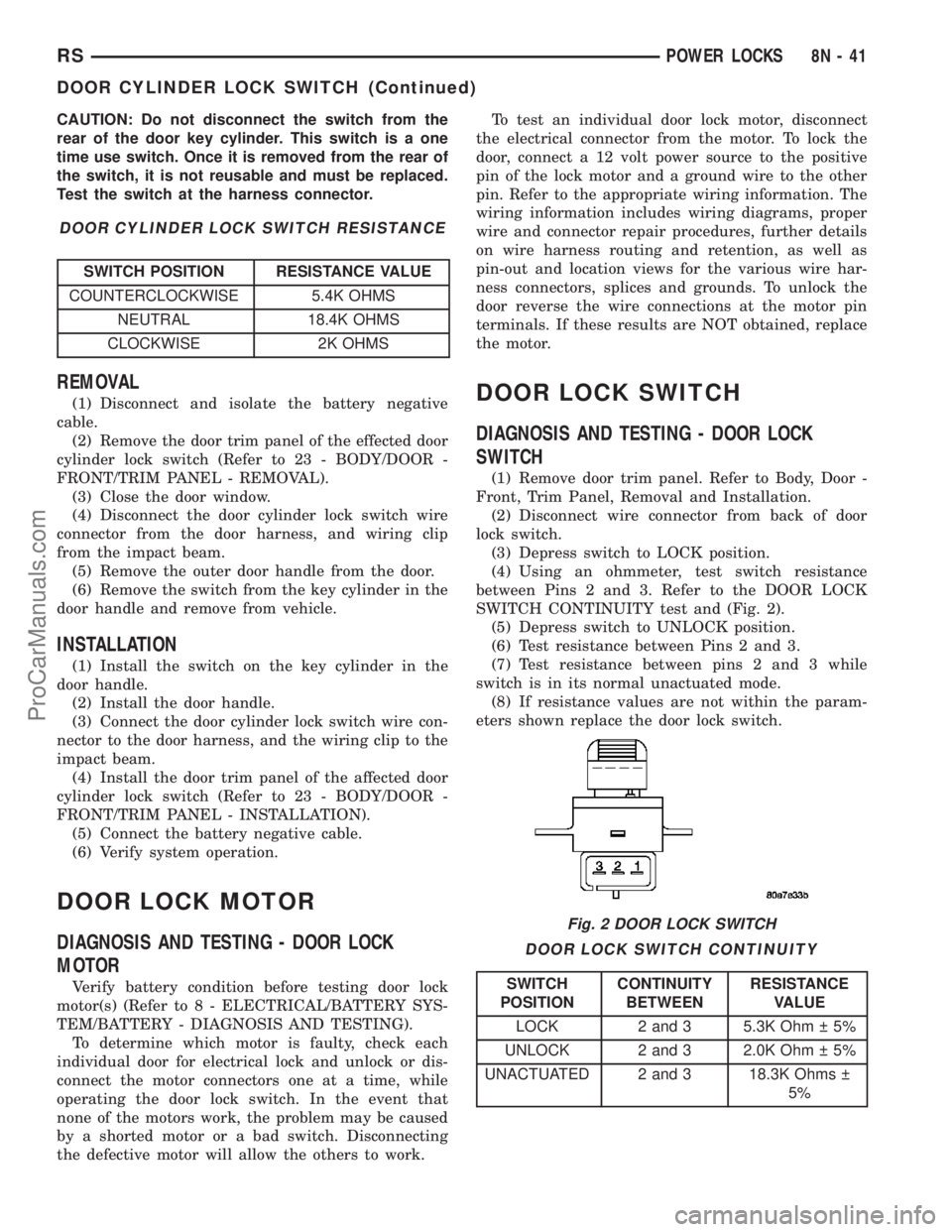

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK

SWITCH

(1) Remove door trim panel. Refer to Body, Door -

Front, Trim Panel, Removal and Installation.

(2) Disconnect wire connector from back of door

lock switch.

(3) Depress switch to LOCK position.

(4) Using an ohmmeter, test switch resistance

between Pins 2 and 3. Refer to the DOOR LOCK

SWITCH CONTINUITY test and (Fig. 2).

(5) Depress switch to UNLOCK position.

(6) Test resistance between Pins 2 and 3.

(7) Test resistance between pins 2 and 3 while

switch is in its normal unactuated mode.

(8) If resistance values are not within the param-

eters shown replace the door lock switch.

DOOR LOCK SWITCH CONTINUITY

SWITCH

POSITIONCONTINUITY

BETWEENRESISTANCE

VALUE

LOCK 2 and 3 5.3K Ohm 5%

UNLOCK 2 and 3 2.0K Ohm 5%

UNACTUATED 2 and 3 18.3K Ohms

5%

Fig. 2 DOOR LOCK SWITCH

RSPOWER LOCKS8N-41

DOOR CYLINDER LOCK SWITCH (Continued)

ProCarManuals.com

Page 502 of 2177

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

An automatic dimming inside day/night rear view

mirror and an automatic dimming driver side outside

rear view mirror are available factory-installed

options on this model. Following is a general descrip-

tion of this optional equipment.

The automatic day/night mirror is able to automat-

ically change its reflectance. A thin layer of electro-

chromic material between two pieces of conductive

glass make up the face of the mirror. Two photocell

sensors are used to monitor light levels and adjust

the reflectance of the mirror to reduce the glare of

headlamps approaching the vehicle from the rear.

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

OPERATION

The ambient photocell sensor faces forward, to

detect the outside light levels. A second sensor faces

rearward to detect the light level received through

the vehicles back window. When the difference

between the two light levels becomes too great (the

light level received at the rear of the mirror is much

higher than that at the front of the mirror), the mir-

ror begins to darken.

The mirror switch allows the driver a manual con-

trol of whether the automatic dimming feature is

operational. When AUTO is selected a small Light-

Emitting Diode (LED), to the right of the mirror

switch, is illuminated. The automatic dimming fea-

ture will only operate when the ignition switch is in

the On position. The mirror also senses the backup

lamp circuit, and will automatically disable its self-

dimming feature whenever the transmission gear

selector is in the Reverse position.

NOTE: The mirror always defaults to an ON state

upon ignition.

The driver side automatic dimming mirror is stan-

dard with the automatic dimming inside mirror. The

signal to control the dimming of that mirror is gen-

erated by the automatic day/night inside rear view

mirror circuitry. That signal is then delivered to the

driver side outside rear view mirror on a hard wired

circuit.

The automatic day/night mirror cannot be

repaired. If faulty or damaged, the entire inside rear

view mirror assembly must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC DAY /

NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the intelligent power module.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the intelli-

gent power module. If OK, go to Step 3. If not OK,

repair the open circuit to the ignition switch as

required.

(3) Unplug the wire harness connector from the

automatic day/night mirror. Check for battery voltage

at the fused ignition switch output circuit cavity of

the automatic day/night mirror wire harness connec-

tor. If OK, go to Step 4. If not OK, repair the open

circuit to the junction block as required.

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Turn the ignition switch to the On position. Set

the parking brake. Place the transmission gear selec-

tor lever in the Reverse position. Check for battery

voltage at the backup lamp switch output circuit cav-

ity of the automatic day/night mirror wire harness

connector. If voltage is present, reinstall the auto-

matic day/night mirror wire harness connector and

go to Step 6. If not OK, repair the open circuit as

required.

(6) Place the transmission gear selector lever in

the Neutral position. Place the automatic day/night

mirror switch in the On (LED in the switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7)

Shine a light into the rearward facing headlamp

photocell sensor. The automatic day/night mirror

should darken. The automatic day/night mirror should

darken within 2 minutes if testing for the first time.

For immediate response, turn the vehicle OFF and

back ON with the forward-facing light sensor still cov-

RSPOWER MIRRORS8N-47

ProCarManuals.com

Page 517 of 2177

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................62

OPERATION...........................62

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................62

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING - VENT WINDOW

MOTOR .............................63

REMOVAL.............................63INSTALLATION.........................64

WINDOW MOTOR

REMOVAL.............................64

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................64

REMOVAL.............................65

INSTALLATION.........................65

POWER WINDOWS

DESCRIPTION

The Power Window System is activated through

switches mounted on the driver and passenger door

panels.

OPERATION

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor ter-

minal pins will cause the motor to rotate in one direc-

tion. Reversing current through the motor terminals

will cause the motor to rotate in the opposite direction.

The power window motors ground through the

master switch in the driver door by a black wire

attached to the left cowl panel. Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

The power rear vent windows, if equipped, are

operated by switches mounted in the driver door

switch bezel. A separate switch is used for each win-

dow. Permanent magnet type motors connected to a

crank system are used to open and close the rear

vent windows. A battery positive and negative con-

nection to either of the two motor terminals will

cause the motor to rotate in one direction. Reversing

current through these same two connections will

cause the motor to rotate in the opposite direction.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - POWER

WINDOWS

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove front door trim panel and sound pad as

necessary to gain access to power window motor wire

connector, (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

8N - 62 POWER WINDOWSRS

ProCarManuals.com